Page 1

Single Gas Detector

User Manual

Page 2

Limited Warranty and Limitation Liability

BW Technologies LP (BW) warrants the product to be free from defects in material and workmanship under normal use and service for a period of two years, beginning on the date of

shipment to the buyer. This warranty extends only to the sale of new and unused products to the original buyer. BW’s warranty obligation is limited, at BW’s option, to refund of the purchase

price, repair or replacement of a defective product that is returned to a BW authorized service center within the warranty period. In no event shall BW’s liability hereunder exceed the

purchase price actually paid by the buyer for the Product.

This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the product arising from use;

b) any product which in BW’s opinion, has been misused, altered, neglected or damaged, by accident or abnormal conditions of operation, handling or use;

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation of unapproved parts on the product; or

The obligations set forth in this warranty are conditional on:

a) proper storage, installation, calibration, use, maintenance and compliance with the product manual instructions and any other applicable recommendations of BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No goods shall be returned to BW until receipt by the buyer of

shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as the original invoice, bill of sale or packing slip to establish that the product is within the warranty period.

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PAR TIC ULA R PURPOSE. BW SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR BASED ON CONTRACT, TORT OR RELIANCE

OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of

this warranty may not apply to every buyer. If any provision of this warranty is held invalid or unenforceable by a court of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Warranty Registration

http://www.honeywellanalytics.com/support/product-registration

Contacting BW Technologies by Honeywell

USA & Canada: 1-888-749-8878

Europe: 00800-333-222-44 Other countries: 1-403-248-9226

BW Technologies by Honeywell

Corporate Headquarters Suite 110

4411-6 Street SE Calgary, Alberta

Canada, T2G 4E8

Bwa.customerservice@honeywell.com

www.honeywellanalytics.com

BW Technologies by Honeywell BW Technologies by Honeywell

America Europe

405 Barclay Blvd. Javastrasse 2

Lincolnshire, IL 8604 Hegnau

USA 60069 Switzerland

Page 3

Table of Contents

Page

Introduction ......................................................................................................................................................................... 1

Contacting BW Technologies by Honeywell .................................................................................................................... 2

Safety Information - Read First.......................................................................................................................................... 2

Getting Started .................................................................................................................................................................... 7

Activating the Detector..................................................................................................................................................... 11

Self-Test ........................................................................................................................................................................ 11

Self-Test Pass ............................................................................................................................................................... 14

Self-Test Fail.................................................................................................................................................................. 14

Deactivating the Detector................................................................................................................................................. 15

Confidence Beep............................................................................................................................................................... 15

User Options Menu ........................................................................................................................................................... 16

Exit ................................................................................................................................................................................ 17

Clock Option .................................................................................................................................................................. 17

Passcode Protection Option .......................................................................................................................................... 18

Enable Passcode Protection .................................................................................................................................... 18

Disable Passcode Protection.................................................................................................................................... 19

Deactivation Passcode Protection ............................................................................................................................ 19

Stealth Mode Option ...................................................................................................................................................... 20

Automatic Backlight Option............................................................................................................................................ 21

Latching Alarm Option ................................................................................................................................................... 21

Automatic Oxygen (O

Calibration Past Due Option .......................................................................................................................................... 23

Languages ..................................................................................................................................................................... 23

) Calibration Option.................................................................................................................... 22

2

i

Page 4

GasAlert Extreme

User Manual

Title Page

Portuguese Option.................................................................................................................................................... 23

Spanish Option ......................................................................................................................................................... 24

German Option ......................................................................................................................................................... 24

French Option ........................................................................................................................................................... 24

English Option .......................................................................................................................................................... 25

Datalogger Sampling Rate Option ................................................................................................................................. 25

Data Transfer Option ..................................................................................................................................................... 26

LAST and ALL Transfers .......................................................................................................................................... 27

EVNT Transfer .......................................................................................................................................................... 27

Unsuccessful Transfer .............................................................................................................................................. 27

Alarms ................................................................................................................................................................................ 28

Computed Gas Exposures ............................................................................................................................................. 30

Viewing Gas Exposures ................................................................................................................................................. 30

Toxic Gases.............................................................................................................................................................. 30

Oxygen ..................................................................................................................................................................... 30

Gas Alarm Setpoints ...................................................................................................................................................... 31

Stopping a Gas Alarm .................................................................................................................................................... 31

Clearing Gas Exposures ................................................................................................................................................ 32

Resetting Gas Alarm Setpoints ...................................................................................................................................... 32

Sensor Alarm ................................................................................................................................................................. 32

Low Battery Alarm.......................................................................................................................................................... 33

Automatic Shutdown Alarm............................................................................................................................................ 33

Calibration and Setting Alarm Setpoints ........................................................................................................................ 34

Guidelines ...................................................................................................................................................................... 34

Test Cap ........................................................................................................................................................................ 35

Calibration...................................................................................................................................................................... 36

Start Calibration ........................................................................................................................................................ 36

ii

Page 5

GasAlert Extreme

User Manual

Title Page

Auto Zero .................................................................................................................................................................. 36

Auto Zero Fail ........................................................................................................................................................... 36

Passcode Protected.................................................................................................................................................. 37

Set Span ................................................................................................................................................................... 37

Span ......................................................................................................................................................................... 38

Setting the Calibration Due Date ................................................................................................................................... 39

Setting the TWA Alarm Setpoint ............................................................................................................................... 39

Setting the STEL Alarm Setpoint .............................................................................................................................. 40

Setting the Low Alarm Setpoint ................................................................................................................................ 40

Setting the High Alarm Setpoint................................................................................................................................ 41

Verification ..................................................................................................................................................................... 41

Datalog and Event Log ..................................................................................................................................................... 42

Datalog........................................................................................................................................................................... 42

Event Log....................................................................................................................................................................... 42

Maintenance ...................................................................................................................................................................... 43

Replacing the Battery or Sensor .................................................................................................................................... 45

Replacing the Battery ............................................................................................................................................... 45

Replacing the Sensor ............................................................................................................................................... 45

Cleaning a Sensor Screen ............................................................................................................................................. 46

Clearing a Sensor .......................................................................................................................................................... 47

WEEE Directive and Battery Directive ............................................................................................................................ 47

Removal and Disposal of the Battery............................................................................................................................. 47

Troubleshooting................................................................................................................................................................ 48

Replacement Parts and Accessories .............................................................................................................................. 51

Specifications.................................................................................................................................................................... 52

General Specifications for Datalogger Units.................................................................................................................. 53

iii

Page 6

List of Figures

Title Figure Page

1. GasAlert Extreme Detector .................................................................................................................................. 8

2. Display Elements.................................................................................................................................................. 9

3. Test Cap ............................................................................................................................................................. 35

4. Replacing the Battery or Sensor ........................................................................................................................ 43

5. Rear Shell Seal .................................................................................................................................................. 44

6. Front Shell Seal .................................................................................................................................................. 44

v

Page 7

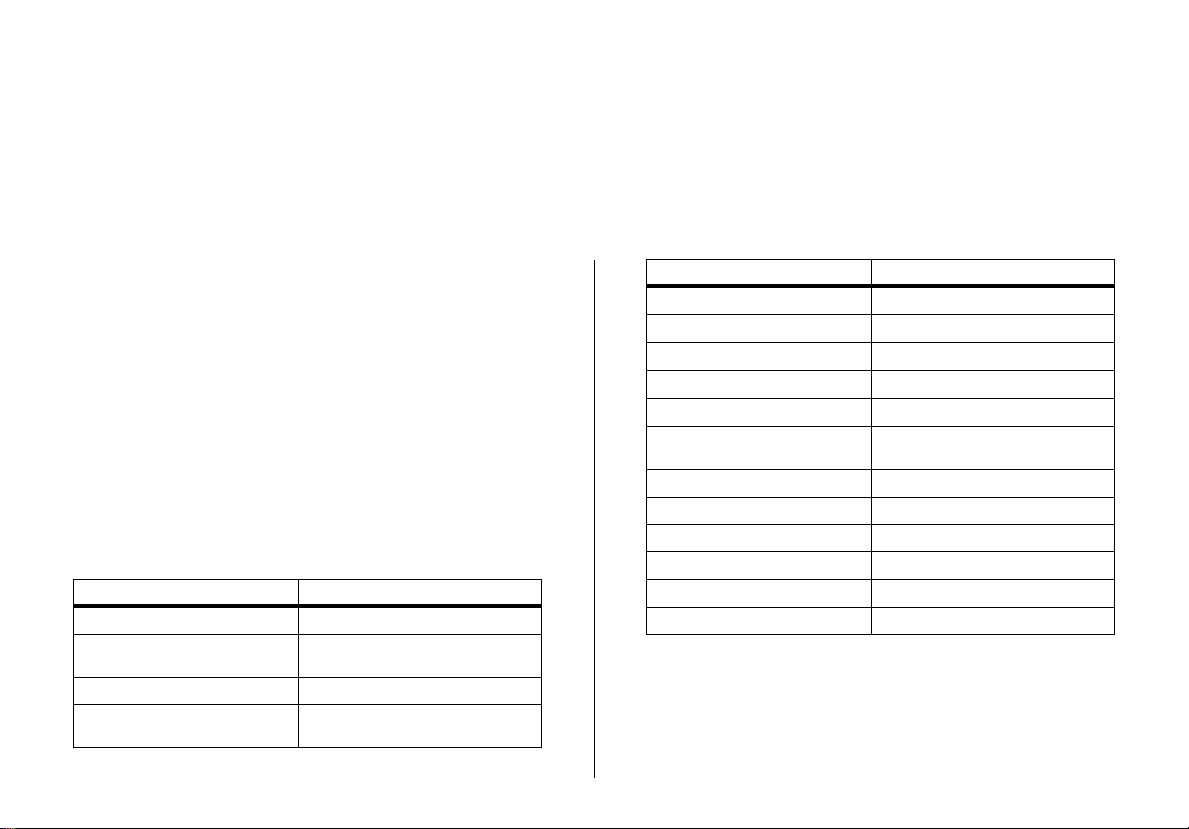

List of Tables

Table Title Page

1. GasAlert Extreme Models .................................................................................................................................... 1

2. International Symbols ........................................................................................................................................... 6

3. GasAlert Extreme Detector .................................................................................................................................. 8

4. Display Elements.................................................................................................................................................. 9

5. Pushbuttons ....................................................................................................................................................... 10

6. Alarms ................................................................................................................................................................ 28

7. Computed Gas Exposures ................................................................................................................................. 30

8. Gas Alarm Setpoints .......................................................................................................................................... 31

9. Factory Alarm Setpoints ..................................................................................................................................... 32

10. Test Cap ............................................................................................................................................................. 35

11. Replacing the Battery or Sensor ........................................................................................................................ 43

12. Rear Shell Seal .................................................................................................................................................. 44

13. Front Shell Seal.................................................................................................................................................. 44

14. Troubleshooting Tips.......................................................................................................................................... 48

15. Replacement Parts and Accessories ................................................................................................................. 51

vii

Page 8

GasAlert Extreme

Introduction

a Warning

To ensure your personal safety, read “Safety Information” before

using the detector.

The GasAlert Extreme gas detector (“the detector”) warns of hazardous

gas at levels above a factory set alarm setpoint. This product is a gas

detector, not a measurement device.

The detector is a personal safety device. It is your responsibility to

respond properly to the alarms.

Table 1 lists the GasAlert Extreme models and the gases monitored. This

manual includes examples from each model.

Table 1. GasAlert Extreme Models

Model Gas Monitored

GasAlert Extreme O

2

GasAlert Extreme CO

GasAlert Extreme CO Carbon monoxide (ppm)

GasAlert Extreme H

S

2

Oxygen (% by volume)

Carbon monoxide (ppm)

Low H2 sensitivity

Hydrogen sulfide (ppm)

High range

Model Gas Monitored

GasAlert Extreme H2S

GasAlert Extreme PH

GasAlert Extreme SO

GasAlert Extreme Cl

GasAlert Extreme NH

GasAlert Extreme NH

GasAlert Extreme NO

3

2

2

3

3

2

Hydrogen sulfide (ppm)

Phosphine (ppm)

Sulfur dioxide (ppm)

Chlorine (ppm)

Ammonia (ppm)

Ammonia (ppm)

High range

Nitrogen dioxide (ppm)

GasAlert Extreme HCN Hydrogen cyanide (ppm)

GasAlert Extreme ETO Ethylene oxide (ppm)

GasAlert Extreme ClO

GasAlert Extreme O

3

Chlorine dioxide (ppm)

2

Ozone (ppm)

GasAlert Extreme NO Nitric oxide (ppm)

1

Page 9

GasAlert Extreme

User Manual

Contacting BW Technologies by Honeywell

To contact BW Technologies by Honeywell, call:

USA & Canada: 1-888-749-8878

Europe: 00800-333-222-44

Other countries: 1-403-248-9226

Address correspondence to:

BW Technologies by Honeywell

Suite 110 4411-6 Street SE.

Calgary, Alberta

Canada, T2G 4E8

Email us at: Bwa.customerservice@honeywell.com

Visit BW Technologies by Honeywell’s website at:

www.honeywellanalytics.com

ISO 9001

Safety Information - Read First

Use the detector only as specified in this manual, otherwise the protection provided by the detector may be impaired.

International symbols used on the detector and in this manual are

explained in Table 2.

Read the Warnings and Cautions on the following pages before using

the detector.

c Note

This instrument contains a lithium battery. Do not mix with

the solid waste stream. Spent batteries should be disposed of by a qualified recycler or hazardous materials

handler.

2

Page 10

GasAlert Extreme

User Manual

To avoid possible personal injury, adhere to the following:

• Warning: Substitution of components may impair Intrinsic Safety.

• Warning: To prevent ignition of flammable or combustible atmospheres, disconnect power before servicing.

• Do not use the detector if it is damaged. Before using the detector, inspect the case. Look for cracks and missing

parts.

• Use only a sensor specifically designed for the GasAlert Extreme model. Refer to Replacement Parts and Accesso-

ries.

• Do not deactivate the detector during a work shift. Deactivating the detector resets the time-weighted average (TWA),

short-term exposure limit (STEL), and maximum gas exposure values to 0. Refer to Alarms

• Ensure the sensor screen is not blocked.

• If the detector is damaged or parts are missing, contact BW Technologies by Honeywell

• If the detector has been disassembled, ensure the front and rear shells are properly aligned and fastened before activating the detector. Refer to Maintenance

• BW recommends to bump test the sensor, before each day’s use, to confirm their ability to respond to gas by exposing the detector to a gas concentration that exceeds the alarm setpoints. Manually verify that the audible and visual

alarms are activated. For detectors with the calibration feature, calibrate the sensor if the reading is not within the

specified limits.

• Calibrate the detector before first-time use, and then at least once every 180 days. For HCN detectors, calibrate once

every 30 days.

• Use only the Panasonic CR-2PE/BN battery. Refer to Replacing the Battery or Sensor

• To reduce the risk of ignition of a flammable atmosphere, batteries must only be changed in a safe area free of hazardous gas.

a

Caution

.

immediately.

.

.

3

Page 11

GasAlert Extreme

User Manual

To avoid possible damage to the detector, adhere to the following:

• Do not expose the detector to electrical shock and/or severe continuous mechanical shock.

• The oxygen GasAlert Extreme detector is classified by Underwriters Laboratories Inc. up to an atmosphere of 21%

oxygen.

• Do not attempt to disassemble, adjust, or service the detector unless instructions for that procedure are contained in

the user manual, and/or that part is listed as a replacement part. Use only BW Technologies by Honeywell replacement

parts. Refer to Replacement Parts and Accessories

• The detector warranty will be voided if customer personnel or third parties damage the detector during repair

attempts. Non-BW Technologies by Honeywell repair/service attempts void this warranty.

Pour éviter toute blessure possible, respectez ce qui suit:

• • Avertissement : Le remplacement d'un composant de l'appareil peut altérer sa sécurité intrinsèque.

• • Avertissement : Pour éviter l'inflammation d'atmosphères inflammables ou combustibles, coupez l'alimentation électrique avant

• tout entretien.

• • N'utilisez pas le détecteur s'il est endommagé. Avant d'utiliser le détecteur, inspectez le boîtier. Assurez-vous

qu'aucune pièce ne

• manque et vérifiez l'absence de fissures.

• • Utilisez uniquement un capteur spécialement conçu pour le modèle GasAlert Extreme. Reportez-vous à la section

Replacement Parts and Accessories

• Ne désactivez pas le détecteur pendant un quart de travail. Si vous désactivez le détecteur, les valeurs de la moyenne

pondérée dans le temps (MPT), de la limite d'exposition (LECT) à court terme et d'exposition maximale aux gaz sont

réinitialisées à 0. Reportez-vous à la section Alarms.

• Assurez-vous que l'écran du capteur est verrouillé.

• Si le détecteur est endommagé ou que des pièces sont manquantes, contactez immédiatement BW Technologies by

Honeywell.

a

Caution

.

a Attention

.

4

Page 12

GasAlert Extreme

User Manual

• Si le détecteur a été démonté, assurez-vous que les coques avant et arrière sont correctement alignées et serrées

avant d'activer le détecteur. Reportez-vous à la section Maintenance

• • Avant chaque utilisation quotidienne, BW recommande d'effectuer un test fonctionnel du capteur afin de vérifier qu'il

réagit bien aux gaz présents, en exposant le détecteur à une concentration de gaz supérieure aux seuils d'alarme.

Vérifiez manuellement que les alarmes sonore et visuelle sont activées. Pour les détecteurs dotés de la fonction

d'étalonnage, étalonnez le capteur si la valeur ne se trouve pas dans les limites spécifiées.

• Étalonnez le détecteur lors de la première utilisation, puis une fois tous les 180 jours. Pour les détecteurs HCN, étalonnez-les tous les 30 jours.

• Utilisez uniquement la batterie Panasonic CR-2PE/BN. Reportez-vous à la section Replacing the Battery or Sensor

• Afin de réduire le risque d'inflammation d'une atmosphère inflammable, les batteries doivent être changées dans un

lieu sûr exempt de gaz dangereux.

• Ne soumettez pas le détecteur à des chocs électriques et/ou à d'importants chocs mécaniques continus.

• Le détecteur d'oxygène GasAlert Extreme est classifié conforme par Underwriters Laboratories Inc. jusqu'à une atmosphère contenant 21% d'oxygène.

• N'essayez pas de démonter, d'ajuster ou d'entretenir le détecteur, sauf si les instructions pour cette procédure vous

sont fournies dans le manuel d'utilisation et/ou si la pièce concernée est répertoriée comme pièce de rechange. Utilisez uniquement des pièces de rechange de BW Technologies by Honeywell. Reportez-vous à la section Replacement

Parts and Accessories.

• La garantie du détecteur sera annulée si le personnel du client ou des tiers ont endommagé le détecteur pendant des

tentatives de réparation. Les tentatives de réparation/d'entretien effectuées par des parties autres que BW Technologies by Honeywell entraîneront l'annulation de cette garantie.

a Attention

.

.

5

Page 13

GasAlert Extreme

User Manual

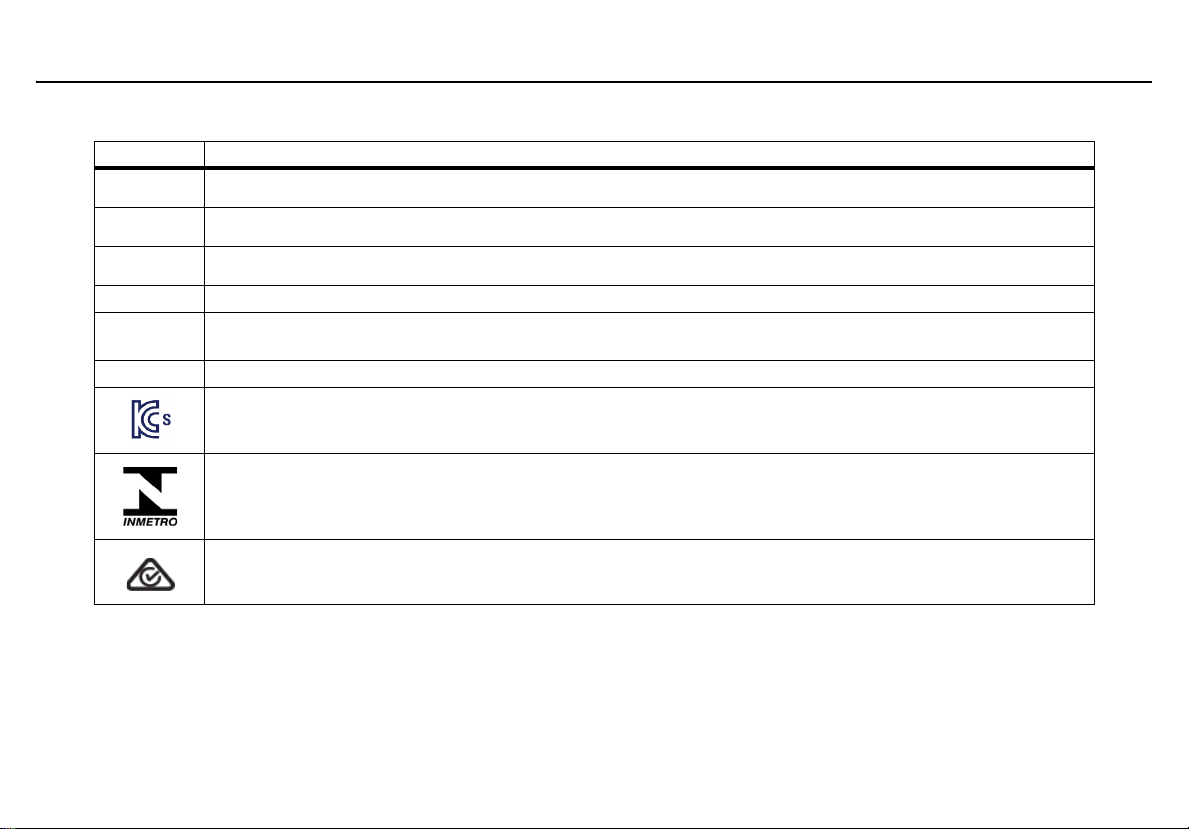

Table 2. International Symbols

Symbol Meaning

h

Classified to both U.S. and Canadian Safety standards by Underwriter’s Laboratories, Inc.

X

g

ATEX Conforms to European ATEX Directives

IECEx

EAC Ex Conforms to Russian Custom Union Certification and Declaration

6

Conforms to European Union Directives

European Explosives Protection

International Electrotechnical Commission Scheme for Certification to Standards for Electrical Equipment for Explosive Atmospheres

Conforms to Korea Testing Laboratory (KTL) Certification

Conforms to Brazilian InMetro Certification

Australian Regulatory Compliance Mark

Page 14

GasAlert Extreme

User Manual

Getting Started

The items listed below are included with the detector. If the detector is

damaged or parts are missing, contact the place of purchase immediately.

• 3 V lithium Panasonic CR-2PE/BN battery

• GasAlert Extreme O

GasAlert Extreme CO model: CO sensor

(low H2 sensitivity);

GasAlert Extreme CO model: CO sensor;

GasAlert Extreme H

GasAlert Extreme H

GasAlert Extreme PH

GasAlert Extreme SO

GasAlert Extreme Cl

GasAlert Extreme NH

GasAlert Extreme NH

GasAlert Extreme NO

GasAlert Extreme HCN model: HCN sensor;

GasAlert Extreme ETO model: ETO sensor;

GasAlert Extreme ClO

GasAlert Extreme O

GasAlert Extreme NO model: NO sensor.

• Test cap and hose

model: O2 sensor;

2

S model: H2S sensor (high range);

2

S model: H2S sensor;

2

model: PH3 sensor;

3

model: SO2 sensor;

2

model: Cl2 sensor;

2

model: NH3 sensor;

3

model: NH3 sensor (high range);

3

model: NO2 sensor;

2

model: ClO2 sensor;

2

model: O3 sensor;

3

The detector is shipped with the battery and sensor installed. To o r de r

replacement sensors and accessories, refer to Replacement Parts and

Accessories.

To become familiar with the features and functions of the detector, study

the following figures and tables:

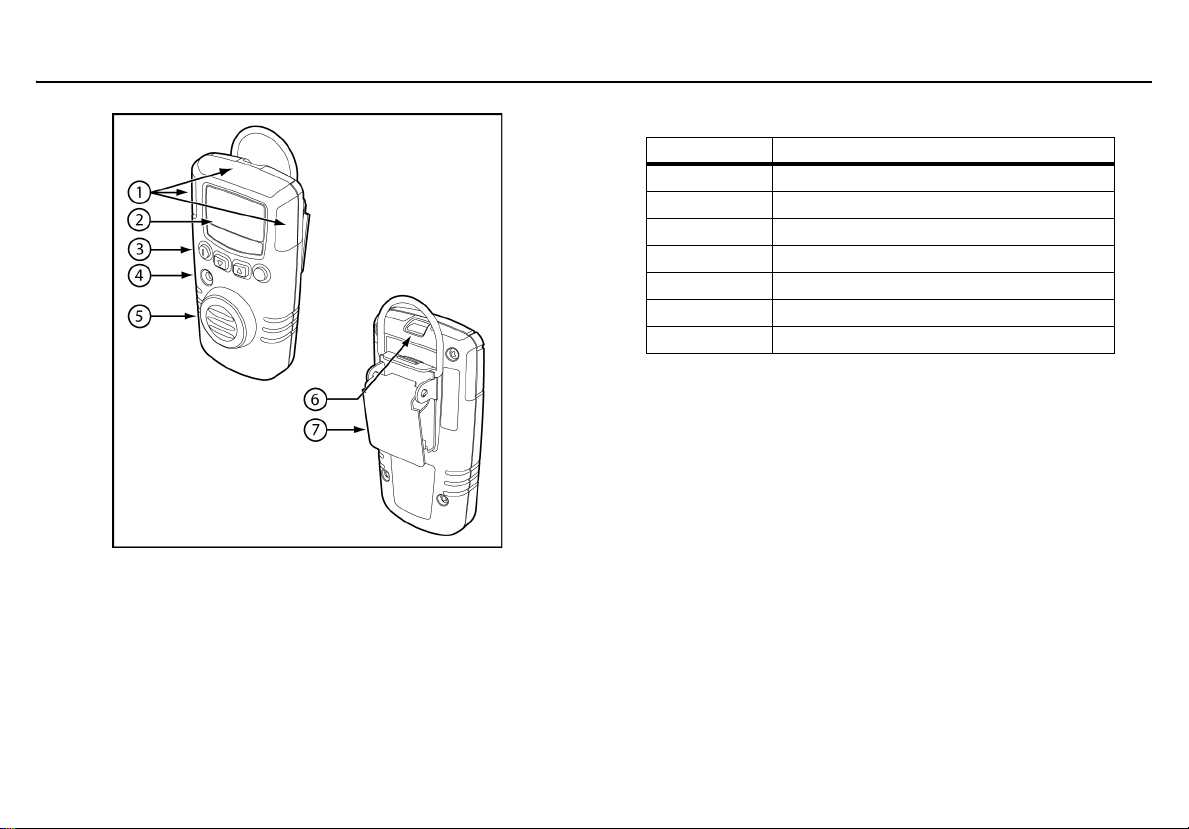

• Figure 1 and Table 3: GasAlert Extreme Detector

(describes the detector’s components).

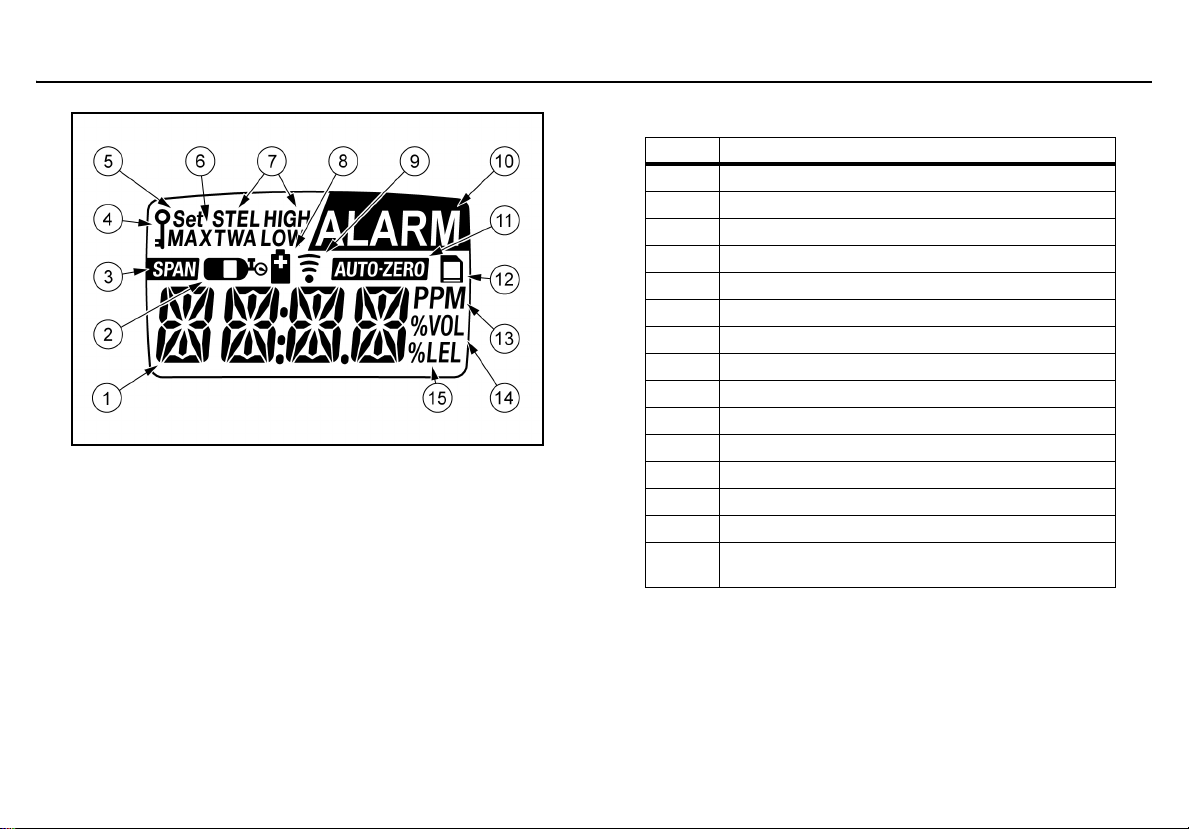

• Figure 2 and Table 4: Display Elements

(describes the LCD screen and icons).

• Table 5: Pushbuttons

(describes the buttons on the detector.

7

Page 15

GasAlert Extreme

User Manual

Figure 1. GasAlert Extreme Detector

Table 3. GasAlert Extreme Detector

Item Description

1 Visual alarm indicators (LEDs)

2 Liquid crystal display (LCD)

3 Pushbuttons

4 Audible alarm

5 Sensor and sensor screen

6 Infrared (IR) communication port

7 Alligator clip

8

Page 16

GasAlert Extreme

User Manual

Figure 2. Display Elements

Note

When enabled, the backlight option automatically activates for

3 seconds whenever there is insufficient light to view the LCD.

Press and hold (until the backlight activates) any button to activate the backlight for 6 seconds. The detector is shipped with

the backlight option enabled.

The backlight does not operate when stealth mode is enabled.

Table 4. Display Elements

Item Description

1 Numeric value

2 Gas cylinder

3 Automatically span sensor

4 Passcode lock

5 Set alarm setpoints and user options

6 Maximum gas exposure

7 Alarm conditions

8 Battery

9 Data transmission

10 Alarm or alarm setpoint

11 Automatically zero sensor

12 Optional datalogger indicator

13 Parts per million (ppm)

14 Percentage by volume (% vol.)

15

Percentage by lower explosive limit (% LEL)

(future use)

9

Page 17

GasAlert Extreme

User Manual

Button

A

E

D

C

Table 5. But

• To activate the detector, press A.

• To enable/disable the confidence beep, while the detector is deactivated press and hold

• To deactivate the detector, press

• To decrement the displayed value or to scroll down, press E.

• To enter the user options menu, press

• To initiate calibration and set alarm setpoints, press and hold

• To increment the displayed value, press D.

• To view the TWA, STEL and maximum (MAX) gas exposures, press

• To save a displayed value, press C.

• To clear TWA, STEL, and maximum (MAX) gas exposures, press and hold

• To acknowledge a latched alarm, press

tons

Description

C. While

holding

C, press A to enable or disable the confidence beep during start-up.

A and hold until OFF displays (5 seconds). If the detector is pass-

code protected to prevent deactivation, PAS S will display. A passcode must be entered to deactivate

the detector. For more information, refer to Deactivation Passcode Protection

.

E and D simultaneously and hold until OPTN and then EXIT

displays (5 seconds).

E and C simultaneously until CAL.

displays.

D and C simultaneously.

C for 6 seconds.

C.

10

Page 18

GasAlert Extreme

User Manual

Activating the Detector

To activate the detector, press A in a safe area, free of hazardous gas.

Self-Test

When the detector is activated, it performs several self-tests. Confirm the

following tests occur.

Note

The following tests are listed in the order they are automatically

performed on the detector.

1. Display Elements Test: The LCD displays all screen elements.

2. Alarm Function Test: The detector beeps, the LEDs flash, the

backlight activates briefly, and the detector vibrates.

3. Battery Test: The detector tests the batteries. If the battery volt-

age is too low to continue, the detector performs an automatic

shutdown. Refer to Automatic Shutdown Alarm

.

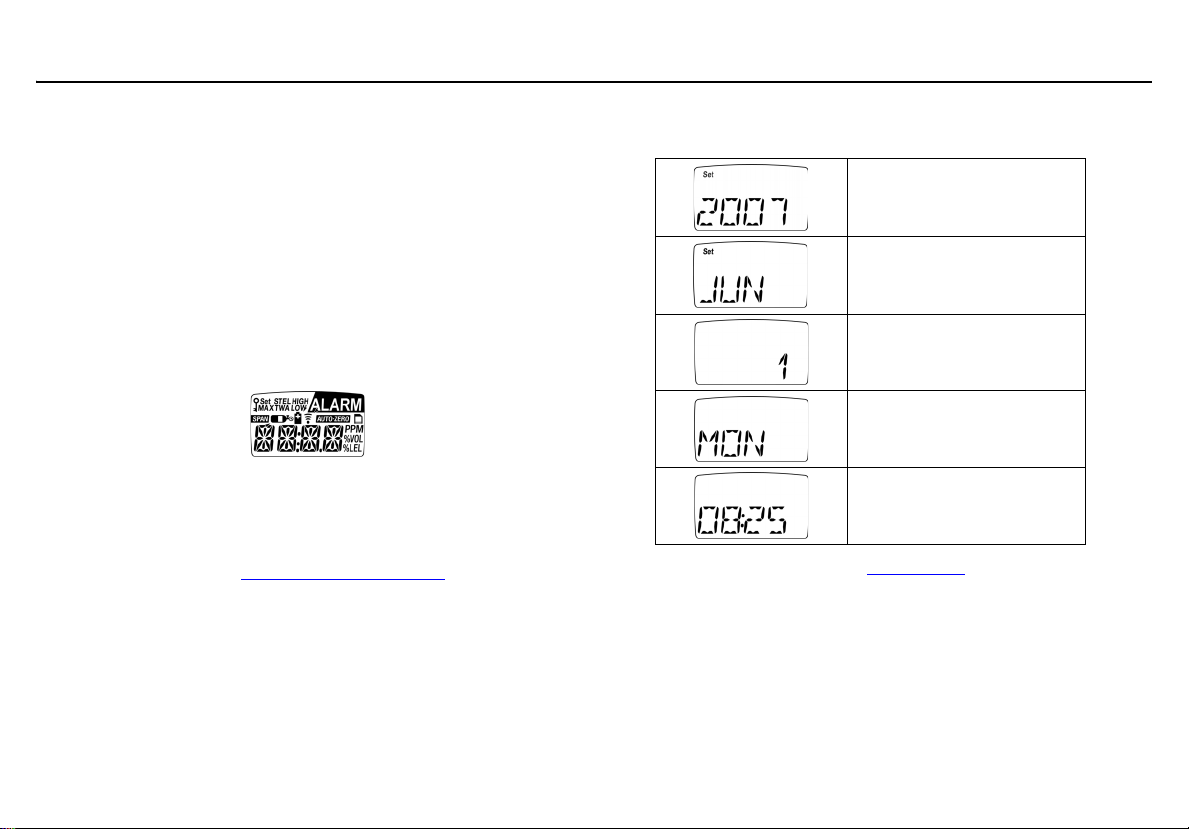

4. Date and Time: The LCD displays the date and time automatically in the following order.

Year: The LCD displays

the current year (20XX).

Month:

JAN, FEB, MAR, etc.

Day of the month:

(1 to 31)

Day of the week:

MON, TUE, WED, etc.

Hour/Minute:

00:00 hours to 23:59

hours

To adjust the date or time, refer to Clock Option

.

11

Page 19

GasAlert Extreme

User Manual

5. Sensor Test: The detector tests the sensor. If the sensor test

fails, the detector beeps slowly, the LEDs flash slowly, and

ALARM flashes.

If the sensor test passes, the self-test continues.

6. Gas Type: The LCD displays the type of gas the detector is man-

ufactured to monitor.

Refer to Table 1 for the type of gases monitored.

If the battery is low, the LCD displays the low battery icon and the

self-test continues.

7. TWA Alarm Setpoint: The LCD displays the TWA alarm set-

point.

Note

The TWA alarm setpoint screen does not apply to O

detectors.

2

8. STEL Alarm Setpoint: The LCD displays the STEL alarm setpoint.

Note

The STEL alarm setpoint screen does not apply to O

detec-

2

tors.

12

Page 20

GasAlert Extreme

User Manual

9. Low Alarm Setpoint: The LCD displays the low alarm setpoint.

10. High Alarm Setpoint: The LCD displays the high alarm setpoint.

11. Calibration Due Test: The LCD displays the calibration due

date.

The LCD displays the number of days remaining before the

detector must be calibrated. For more information, refer to Cali-

bration.

If calibration is past due, CAL. PAST displays.

Press C to acknowledge the warning message.

If the calibration past due option is enabled or disabled, one of

the following two events will occur.

• Calibration Past Due Disabled: If the detector is not pass-

code protected and after the CAL. PAST message is acknowl-

edged, the detector continues the self-test and then enters

normal operation.

• Calibration Past Due Enabled: If the detector is passcode

protected and when CAL. PAST displays, press C to

acknowledge the message and to access the PAS S screen. If

required, refer to Passcode Protection Option

Press

D or E to scroll to the required passcode, and press

.

C within 10 seconds to confirm the selection. The detector

enters normal operation.

Note

Calibrate the detector before continuing operation.

If the passcode is not confirmed within 10 seconds or the passcode is incorrect, the detector beeps eight times, the LEDs

flash 8 times, and the LCD displays the following screen.

13

Page 21

GasAlert Extreme

User Manual

The detector then automatically deactivates.

12. Bump Test Fail: If a previous bump test failed, the detector beeps, vibrates, and BUMP FAIL displays:.

Press

C to acknowledge the alarm.

Note

Bump test the detector before continuing operation.

For information regarding bump tests, refer to the MicroDock ll

User Manual.

Self-Test Pass

If the detector passes the self-test, it enters normal operation. The LCD

displays the ambient gas reading.

The detector begins recording immediately. It records the

• maximum (MAX) gas exposure,

• the short-term exposure levels (STEL), and

• calculates the time-weighted average (TWA).

Self-Test Fail

If the detector fails the self-test, refer to Troubleshooting.

14

Page 22

GasAlert Extreme

User Manual

Deactivating the Detector

Note

If Deactivation Passcode Protection is enabled, the detector

cannot be disabled without entering a passcode first. PASS

displays immediately after OFF, refer to Deactivation Passcode

Protection. This option can only be enabled at the factory and

cannot be disabled by the customer.

To deactivate the detector, complete the following:

1. Press and hold

2. The detector beeps and vibrates four times, the LEDs flash four times, and then the detector deactivates.

A is not held down until OFF displays, the detector will

If

remain activated.

A until OFF displays (approximately 5 seconds).

Note

Confidence Beep

The confidence beep provides continuous confirmation that the detector

is operating properly. When the confidence beep is enabled, the detector

beeps every 5 seconds.

The confidence beep can be enabled or disabled during start-up.

Note

The detector is shipped with the confidence beep disabled.

Enabling the confidence beep decreases battery life.

To enable/disable the confidence beep, complete the following:

1. Ensure the detector is deactivated.

2. Press and hold

When the confidence beep option is enabled, the detector automatically begins beeping when activated.

When the confidence beep option is enabled in stealth mode, the

detector vibrates one time every 60 seconds. For more information refer to Stealth Mode Option

If confidence beep is enabled and a low battery alarm occurs,

the confidence beep deactivates.

C. While holding C, press A.

and Alarms.

Note

15

Page 23

GasAlert Extreme

User Manual

User Options Menu

Note

When selecting a user option, Set flashes and the LCD displays the opposite of what is currently enabled.

To access the user options menu, complete the following:

1. Press and hold

and then release the buttons.

The detector beeps and vibrates four times and the LEDs flash

four times while accessing the user options menu.

If the passcode protection is not enabled, the EXIT screen automatically displays.

If the detector is passcode protected, the following screen displays.

D and E simultaneously until OPTN displays

2. Press

If the passcode is not confirmed within 10 seconds, NO dis-

plays and the detector returns to normal operation.

3. From the EXIT screen, press

4. Press

As a safety precaution, if an option is not selected within

20 seconds the detector automatically returns to normal operation.

5. Press

D or E to scroll to the required passcode. Press C to

confirm the selection and access the EXIT screen.

Note

D or E to scroll through the user

options.

C to select a displayed option.

Note

When the required activities have been performed for a selected

option, the EXIT screen automatically displays.

D or E to select another option or press C to exit the

user options menu and return to normal operation.

16

Page 24

GasAlert Extreme

User Manual

Exit

When entering user options, the EXIT screen displays immediately following the options (OPTN) screen. The LCD automatically returns to the

EXIT screen after a user option has been accessed.

From the EXIT screen, use

Or

C to exit user options and return to normal operation.

Press

D or E to scroll to additional user options.

Clock Option

The clock (CLCK) option sets the date (year/month/day/day of the week)

and time (hour/minute) of the detector. To set the time or date, complete

the following:

1. From the EXIT screen, press

option.

2. Press

3. Press

4. Repeat step #3 for the remaining date/time changes.

C to select the option and access the first date/time

option, the year. Set and the last two digits of the year continually

flash.

D or E to scroll to the required year and press C to

confirm the selection.

Or

To bypass the year, press

automatically proceed to the month screen.

D or E to scroll to the CLCK

C to retain the current value and

5. Press

D or E to select another option or press C to exit the

user options menu and return to normal operation.

Note

The time and date values can only be changed in the

order they are presented in this table. To bypass any

setting, press

the current value and proceeds to the next date/time

option.

C. The detector automatically retains

Year: Requires only the last two

numerals of the year (00-99).

Month: Scroll to select the

required month (JAN, FEB, MAR,

etc.).

Day: Scroll to select the required

day (1-31). For months with 30

days (1-30) is available. For February, (1-28 & 29) is available.

Day of the week: Scroll to select

the required day (MON, TUE,

WED, etc.).

Time: The hour value flashes first.

Scroll to select (0:00 hours. to

23:59 hours).

17

Page 25

GasAlert Extreme

User Manual

Note

If a value is not bypassed by pressing

the detector automatically proceeds to the next date/time

option. If the Time Minute value was not bypassed, the detector automatically proceeds to the Exit screen.

If a new value is selected but not confirmed by pressing

within 10 seconds, NO displays and the detector proceeds to

the next date/time option. If a new Time Minute value was

selected but not confirmed, the detector automatically proceeds to the Exit screen.

C within 10 seconds,

C

Passcode Protection Option

The passcode protection option (PASS) prevents unauthorized access to

the user options and the calibration/set alarm setpoint functions.

The passcode protection option can be enabled or disabled.

Note

The detector is shipped with the passcode protection option

disabled.

Enable Passcode Protection

To enable passcode protection, complete the following:

Note

The passcode is provided on a separate card inside the shipping container.

18

1. From the EXIT screen of the user options menu, press

to scroll to the PASS option.

2. Press

3. Set and PAS S continually flash. Press

4. The ON screen displays and flashes continually. Press

5. Press

If an incorrect passcode is selected or a correct passcode is

not confirmed within 10 seconds, NO displays and the LCD

returns to the EXIT screen.

C to select the option.

D or E to scroll to the

required passcode, and press

confirm. The LCD then returns to the EXIT screen.

C to confirm the selection.

D or E to select another user option, or press C to exit

the user options and return to normal operation.

Note

D or E

C to

Page 26

GasAlert Extreme

User Manual

Disable Passcode Protection

When the detector is passcode protected, the key icon displays continually. To disable the passcode protection option, complete the following:

1. Press and hold

options menu.

The OPTN screen displays briefly before the flashing passcode

screen displays.

2. Press

3. Press

4. The LCD displays a flashing OFF screen. Press

D or E to scroll to the required passcode and press C

to confirm. The following EXIT screen displays.

The key icon indicates that the passcode protection is currently

enabled.

D or E to scroll to the PASS option, and press C to

select the option.

the disabling option.

D and E simultaneously to access the user

C to confirm

Note

To ensure if the passcode protection option is enabled/disabled, use

options. Display the desired option and press

selection.

The LCD returns to the EXIT screen.

5. Press

the user options and return to normal operation.

If a passcode value is not selected or confirmed by pressing

D and E to toggle between the ON and OFF

C to confirm the

D or E to select another user option, or press C to exit

Note

C within 10 seconds, NO displays and the LCD returns to the

EXIT screen.

Deactivation Passcode Protection

As a backup safety precaution, the deactivation passcode protection

option can be enabled prevent unauthorized deactivation. A separate

security passcode is required for this option and will be available to limited personnel only.

Note

The detector can be shipped with this option enabled permanently. This option can only be enabled at the factory and cannot be disabled by a customer.

The passcode must be entered every time the detector is deactivated.

19

Page 27

GasAlert Extreme

User Manual

To deactivate the detector, complete the following:

1. From normal operation, press and hold

detector.

If the detector is passcode protected to prevent deactivation,

OFF displays briefly and then PASS immediately displays.

2. Press

D or E to scroll to the required security passcode.

C to confirm the selection.

Press

The detector then deactivates.

A to deactivate the

Stealth Mode Option

The stealth (STLH) mode option ensures that the detector is undetected

in situations that require concealment. This option disables the

• audible alarms,

• visual alarms, and

• backlight.

Only the vibrator alarm remains enabled.

Note

The detector is shipped with stealth mode disabled.

To enable/disable the stealth mode, complete the following:

20

1. From the EXIT screen, press

option.

2. Press

3. Press

If stealth mode has been enabled, the screen displays STLH continually

unless

• functions are being performed,

• readings are not 0 ppm for toxics, or

• reading is not 20.9% vol for oxygen.

The vibrator alarm is disabled at -20°C.

4. Press

C to select the option. The LCD flashes either ON or

OFF.

Enabled Disabled

D or E to toggle between the ON/OFF options. Ensure

the desired option is displayed and press

selection.

The LCD returns to the EXIT screen.

D or E to scroll to a new user option or press C to exit

and return to normal operation.

D or E to scroll to the STLH

C to confirm the

Note

Page 28

GasAlert Extreme

User Manual

Note

If the option is not confirmed by pressing

the detector returns to normal operation.

C within 10 seconds,

Automatic Backlight Option

The automatic backlight (BKLT) option enables or disables the backlight

of the detector. When enabled, the backlight automatically activates for 3

seconds whenever there is insufficient light to view the LCD.

Press any button to activate the backlight for 6 seconds.

Note

The detector is shipped with the automatic backlight option

enabled. The backlight option is not available in the user

options menu when stealth mode is enabled.

To enable/disable the automatic backlight, complete the following:

1. From the EXIT screen, press

option.

2. Press

3. Press

C to select the option. The LCD flashes either ON or

OFF.

D or E to toggle between the ON/OFF options. Ensure

the desired option is displayed and press

selection.

The LCD returns to the EXIT screen.

D or E to scroll to the BKLT

C to confirm the

4. Press

If the option is not confirmed by pressing

the detector returns to normal operation.

D or E to scroll to a new user option or press C to exit

and return to normal operation.

Note

C within 10 seconds,

Latching Alarm Option

The latch alarm (LTCH) option ensures that an alarm persists until it is

acknowledged by the user.

If enabled, during an alarm condition the latched alarms (LTCH) option

causes the low and high gas alarms (audible, visual, and vibrator) to persist until the gas concentration is below the alarm setpoint and the

alarms have been acknowledged by pressing

The audible alarm can be temporarily deactivated (press

onds, but the LCD continues to display the peak concentration until the

alarm condition no longer exists.

In stealth mode, the detector continues to vibrate until the alarm is

acknowledged.

Note

The detector is shipped with the latching alarm option disabled.

C.

C) for 30 sec-

21

Page 29

GasAlert Extreme

User Manual

To enable/disable the latching alarm option, complete the following:

1. From the EXIT screen, press

option.

2. Press

3. Press

4. Press

If the option is not confirmed by pressing

the detector returns to normal operation.

C to select the option. The LCD flashes either ON or

OFF.

D or E to toggle between the ON/OFF options. Ensure

the desired option is displayed and press

selection.

The LCD returns to the EXIT screen.

D or E to scroll to a new user option or press C to exit

and return to normal operation.

D or E to scroll to the LTCH

C to confirm the

Note

C within 10 seconds,

Automatic Oxygen (O2) Calibration Option

Note

For oxygen detectors only.

If the automatic oxygen (O

ensure the detector is activated in safe area in normal (20.9%)

oxygen atmosphere.

) calibration option is enabled,

2

This option enables/disables the automatic oxygen (O

calibration begins automatically during start-up after the calibration

O

2

due screen displays.

Note

The detector is shipped with the automatic O

disabled.

To enable/disable the automatic O

lowing:

1. From the EXIT screen of the user options menu, press

to scroll to the ACAL option.

2. Press

3. Press

4. Press

If the option is not confirmed by pressing

the detector returns to normal operation.

C to select this option. The LCD flashes either ON or

OFF.

D or E to toggle between the ON/OFF options. Ensure

the desired option is displayed and press

selection.

The LCD returns to the EXIT screen.

D or E to scroll to a new user option or press C to exit

and return to normal operation.

calibration option, complete the fol-

2

Note

C within 10 seconds,

) calibration. The

2

calibration option

2

D or E

C to confirm the

22

Page 30

GasAlert Extreme

User Manual

Calibration Past Due Option

The calibration past due (PAST) option enables an automatic shutdown

during start-up if the detector is past due for calibration.

Note

The detector is shipped with the calibration past due shutdown

option disabled.

To calibrate a past due calibration detector, refer to Calibration Past Due

Enabled in Self-Test.

To enable/disable the calibration past due automatic shutdown option,

complete the following:

1. From the EXIT screen of the user options menu, press

to scroll to the PAST option.

2. Press

3. Press

4. Press

C to select the option. The LCD flashes either ON or

OFF.

D or E to toggle between the ON/OFF options. Ensure

the desired option is displayed and press

selection.

The LCD returns to the EXIT screen.

C to confirm the

D or E to scroll to a new user option or press C to exit

and return to normal operation.

23

D or E

Note

If the option is not confirmed by pressing

the detector returns to normal operation.

C within 10 seconds,

Languages

The LCD can display text in five different languages. Refer to the following language options.

Portuguese Option

The Portuguese (PORT) option enables the LCD to display text in Portuguese.

Note

If the multi-language option is included, the detector is shipped

with English selected as the default language.

1. From the EXIT screen of the user options menu, press

to scroll to the PORT option.

2. Press

3. Press

C to select the option. The LCD then displays the Portu-

guese exit screen.

D or E to scroll to another user option or press C to

exit and return to normal operation.

D or E

Page 31

GasAlert Extreme

User Manual

Spanish Option

The Spanish (ESPA) option enables the LCD to display text in Spanish.

Note

If the multi-language option is included, the detector is shipped

with English selected as the default language.

1. From the EXIT screen of the user options menu, press

to scroll to the ESPA option.

2. Press

3. Press

C to select the option. The LCD then displays the Span-

ish exit screen.

D or E to scroll to another user option or press C to

exit and return to normal operation.

D or E

German Option

The German (DEUT) option enables the LCD to display text in German.

Note

If the multi-language option is included, the detector is shipped

with English selected as the default language.

1. From the EXIT screen of the user options menu, press

to scroll to the DEUT option.

2. Press

3. Press

C to select the option. The LCD then displays the Ger-

man exit screen.

D or E to scroll to a new user option or press C to exit

and return to normal operation.

D or E

French Option

The French (FRAN) option enables the LCD to display text in French.

Note

If the multi-language option is included, the detector is shipped

with English selected as the default language.

1. From the EXIT screen of the user options menu, press

to scroll to the FRAN option.

D or E

24

Page 32

GasAlert Extreme

User Manual

2. Press C to select the option. The LCD then displays the French

exit screen.

3. Press

D or E to scroll to another user option or press C to

exit and return to normal operation.

English Option

The English (ENGL) option enables the LCD screens to display text in

English.

Note

If the multi-language option is included, the detector is shipped

with English selected as the default language.

1. From the EXIT screen of the user options menu, press

to scroll to the ENGL option.

2. Press

C to select the option. The LCD then displays the English

exit screen.

D or E

3. Press

D or E to scroll to another user option or press C to

exit and return to normal operation.

Datalogger Sampling Rate Option

The datalogger sampling rate (RATE) option defines how often the

detector records a datalog. The datalogger sampling rate ranges from

1 to 60 seconds.

Note

The detector is shipped with a datalogging sampling rate of

5 seconds.

To adjust the datalogger sampling rate, complete the following:

1. From the EXIT screen of the user options menu, press

D and

E to scroll to the RATE option.

2. Press

3. The sample rate screen displays the current selected rate. Press

C to select the option and display the sample rate screen.

D or E to scroll to a new rate and press C to save the new

value.

25

Page 33

GasAlert Extreme

User Manual

4. Press D or E to scroll to another user option or press C to exit and return to normal operation.

Note

If a datalogging sample rate value is not selected or confirmed

by pressing

displays the EXIT screen.

C within 10 seconds, NO displays and the LCD

Data Transfer Option

The data transfer (SEND) option transfers the datalog/event log information from the detector to a PC.

Note

An IR DataLink (or other BW accessory) is required to transfer

the data from the detector to a PC.

To transfer data, complete the following:

1. Connect the IR DataLink (or other BW accessory) to the detector and the PC.

Refer to the IR DataLink Instruction Sheet.

2. From the EXIT screen of the user options menu, press

to scroll to the SEND option.

D or E

3. Press

4. Select one of the following options to transfer data.

5. When the data transfer is complete, the detector beeps and

C to select the option and to access the data transfer

option screens.

Press D or E to scroll to the

event (EVNT) option. Press

automatically transfer all events.

D or E to scroll to the

Press

last (LAST) option. Press

automatically send all of the data-

logs since the last datalog download.

Press

D or E to scroll to the all

(ALL) option. Press

matically send all of the datalogs

that are saved on the detector.

vibrates, and the LEDs flash. The LCD displays the EXIT screen.

C to

C to

C to auto-

26

Page 34

GasAlert Extreme

User Options Menu

LAST and ALL Transfers

If the LAST or ALL option is selected, the LCD displays a countdown

and the data transmission icon to indicate that the detector is transferring

data.

Note

The number at the beginning of the countdown depends upon

the amount of data to transfer.

EVNT Transfer

If the EVNT option is selected, the event logs transfer immediately and

the LCD displays the EXIT screen.

Unsuccessful Transfer

If the connection between the detector and the IR DataLink is disconnected during a transfer, FAIL displays.

The LCD then displays the EXIT screen.

1. From the PC, save the previously transferred data to ensure that it will not be deleted.

2. Repeat steps #3-5 of the Data Transfer Option

3. From the detector, select LAST to automatically resume the transfer from where it stopped sending.

Or

Select ALL to transfer all of the data again.

.

27

Page 35

GasAlert Extreme

User Manual

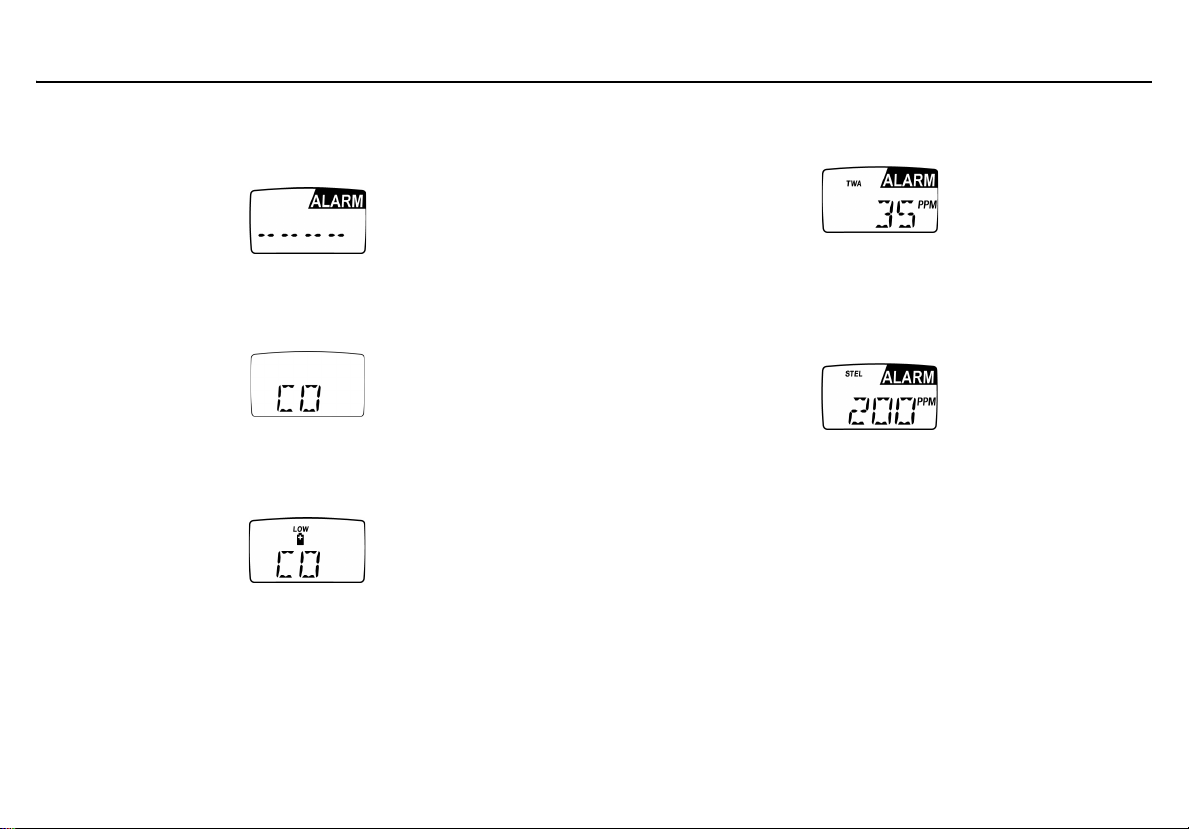

Alarms

Table 6 describes detector alarms and corresponding screen. During an

alarm condition, the detector activates the backlight and the LCD displays the current ambient gas reading.

Alarm Display Alarm Display

Low Alarm:

• Slow beep

•Slow flash

• ALARM flashes

• Slow vibrations

High Alarm:

• Fast beep

• Fast flash

• ALARM flashes

• Fast vibrations

Sensor Alarm:

• Slow beep

•Slow flash

• ALARM flashes

• Slow vibrations

To change the factory-set alarm setpoints, refer to Calibration and Set-

ting Alarm Setpoints.

Table 6. Alarms

TWA Alarm:

• Slow beep

•Slow flash

• ALARM flashes

• Slow vibrations

STEL Alarm:

• Fast beep

• Fast flash

• ALARM flashes

• Fast vibrations

Low Battery Alarm:

• One beep and one flash every

5 seconds, and one quick vibration

every minute (when confidence

beep is disabled).

• If confidence beep is enabled no

beeps, flashes, or vibrations

• LOW displays

28

Page 36

GasAlert Extreme

User Manual

Table 6. Alarms

Alarm Display Alarm Display

Automatic Shutdown Alarm:

(Low battery)

• Eight beeps, flashes, and vibrations

• LOW displays

Automatic Shutdown Alarm:

(After Automatic Shutdown Alarm)

• No beep

• No flash or vibrations

• displays for a short time

Note

The high alarm and STEL alarm have the same priority. A high

alarm and/or STEL alarm overrides a low alarm and/or TWA

alarm. To check STEL and TWA alarms specifically, press and

hold

C and D simultaneously.

The vibrator alarm is disabled at -20°C.

The high and low alarms deactivate when the gas concentration is lower than the low alarm setpoint. If the alarms are set to

latch, alarms persist until the gas concentration is below the

alarm setpoint and the alarms have been acknowledged by

pressing

ing the TWA and STEL peak exposure. Refer to Clearing Gas

Exposures.

C. The TWA and STEL alarms deactivate by clear-

Automatic Shutdown Alarm:

(Calibration past)

• Eight beeps, flashes, and vibrations

Confidence Beep:

• One beep every 5 seconds

• One quick vibration per minute

Note

If the detector enters low battery

alarm, the confidence beep deactivates.

29

Page 37

GasAlert Extreme

User Manual

Computed Gas Exposures

a Warning

To avoid possible personal injury, do not deactivate the detector

during a work shift. The detector automatically resets the TWA,

STEL, and MAX gas exposures during start-up. If the detector is

reactivated during a work shift, the new values will not reflect the

entire work shift.

Table 7. Computed Gas Exposures

Gas Exposure Description

TWA Time-weighted average based on an

8-hour workday.

Accumulated value.

STEL Short-term exposure limit (STEL) to

gas based on a 15-minute period.

Accumulated value.

MAX* Maximum (MAX) concentration

encountered during a work shift.

*For oxygen, it is the highest or the lowest value from

20.9% encountered.

Viewing Gas Exposures

Toxic Gases

1. Press C and D simultaneously. The LCD displays the TWA

gas exposure first.

2. Then the LCD displays the STEL gas exposure.

3. Then the LCD displays the MAX gas exposure.

Oxygen

For oxygen detectors, press C and D simultaneously to view both the

maximum low and maximum high levels of oxygen exposure.

30

Page 38

GasAlert Extreme

User Manual

Gas Alarm Setpoints

Table 8 describes the gas setpoints that trigger the gas alarms.

Table 8. Gas Alarm Setpoints

Alarm Condition

Low alarm Toxic gases: Ambient gas level

above low alarm setpoint.

O

: ambient gas level may be set

2

to above or below 20.9%.

High alarm Toxic gases: ambient gas level

above high alarm setpoint.

O

: ambient gas level may be set

2

to above or below 20.9%.

TWA alarm TWA above TWA alarm setpoint.

(O

: not applicable)

2

STEL alarm STEL above STEL alarm setpoint.

(O

: not applicable)

2

Stopping a Gas Alarm

The low and high alarms deactivate when the ambient gas level returns

to below the low alarm setpoint.

Note

If alarms are set to latch, the alarms deactivate after the gas

concentration is lower than the low alarm setpoint and the

alarms have been acknowledged by pressing

C.

The TWA and STEL alarms can be stopped either by

• Clearing the MAX, TWA, and STEL peak exposures. Refer to

Clearing Gas Exposures

.

or

• deactivating the detector and reactivating it again.

If the detector is passcode protected to prevent deactivation,

refer to Deactivation Passcode Protection

.

a Caution

Follow all safety procedures as defined by your employer. Confirm

with your supervisor before clearing TWA and STEL alarms.

31

Page 39

GasAlert Extreme

User Manual

Clearing Gas Exposures

The peak gas exposures automatically clear after deactivating the detector.

To clear the MAX, TWA, and STEL peak exposure readings immediately,

press and hold

C for 6 seconds. The detector beeps and vibrates two

times to confirm that the exposures have been cleared.

a Caution

Follow all safety procedures as defined by your employer. Confirm

with your supervisor before clearing TWA and STEL alarms.

Resetting Gas Alarm Setpoints

Note

Standard factory alarm setpoints vary by region.

Table 9 lists the factory alarm setpoints.

To change the factory alarm setpoints, refer to Calibration and Setting

Alarm Setpoints.

Note

To disable an alarm, set the alarm setpoint to 0.

The ETO sensor is extremely cross sensitive and it responds

strongly to CO.

Table 9. Factory Alarm Setpoints

Gas TWA STEL Low High

O

2

CO

(low H2)

N/A N/A 19.5% vol. 23.5% vol.

35 ppm 200 ppm 35 ppm 200 ppm

CO 35 ppm 200 ppm 35 ppm 200 ppm

H2S

(high range)

S 10 ppm 15 ppm 10 ppm 15 ppm

H

2

PH

3

SO

2

Cl

2

NH

3

NH

3

(high range)

NO

2

10 ppm 15 ppm 10 ppm 15 ppm

0.3 ppm 1.0 ppm 0.3 ppm 1.0 ppm

2.0 ppm 5.0 ppm 2.0 ppm 5.0 ppm

0.5 ppm 1.0 ppm 0.5 ppm 1.0 ppm

25 ppm 35 ppm 25 ppm 50 ppm

25 ppm 35 ppm 25 ppm 50 ppm

2.0 ppm 5.0 ppm 2.0 ppm 5.0 ppm

HCN 4.7 ppm 10.0 ppm 4.7 ppm 10.0 ppm

ETO 1.0 ppm 5.0 ppm 1.0 ppm 5.0 ppm

ClO

O

3

2

0.1 ppm 0.3 ppm 0.1 ppm 0.3 ppm

0.10 ppm

0.10 ppm 0.10 ppm 0.20 ppm

NO 25 ppm 25 ppm 25 ppm 25 ppm

Sensor Alarm

The detector tests for a missing or defective sensor during the activation

self-test. Refer to Troubleshooting

.

32

Page 40

GasAlert Extreme

User Manual

Low Battery Alarm

If a low battery alarm occurs, follow your company’s safety procedures.

The detector tests the battery upon activation and continuously thereafter. If the battery voltage is low, the detector activates the low battery

alarm.

The low battery alarm continues until the battery is replaced or the battery power is almost depleted. If the battery voltage drops too low, the

detector automatically deactivates.

Note

If the detector enters low battery alarm, the confidence beep

deactivates.

a Caution

Replace the battery in only a safe area, free of hazardous

gas.

Automatic Shutdown Alarm

There are two situations when an automatic shutdown alarm occurs.

1. If the battery voltage is in immediate danger of falling below the minimum operating voltage, the detector beeps and vibrates eight times, and the LEDs flashes eight times. After 3 seconds, the LCD deactivates and the detector deactivates.

The LCD periodically displays until the battery power is

depleted.

To replace the battery, refer to Replacing the Battery or Sensor

Note

The low battery alarm continues for approximately 30 minutes

before an automatic shutdown occurs.

2. If the calibration past due user option is enabled and the detector

is past the calibration due date, the detector automatically deactivates.

.

33

Page 41

GasAlert Extreme

User Manual

Calibration and Setting Alarm Setpoints

Guidelines

When calibrating the detector, adhere to the following guidelines.

• Recommended gas mixture:

O

: clean air, 20.9% vol.

2

CO (low H

CO: 50 to 500 ppm balance N2

H

S (high range): 10 to 100 ppm balance N

2

H2S: 10 to 100 ppm balance N

PH3: 1 to 5 ppm balance N

SO2: 10 to 50 ppm balance N

Cl2: 3 to 25 ppm balance N

NH3: 20 to 100 ppm balance N

NH3: (high range) 20 to 100 ppm balance N

NO2: 5 to 50 ppm balance N

HCN: 5 to 20 ppm balance N

ETO: 5 to 50 ppm balance N

ClO2: 0.1 to 1.0 ppm balance N

O3: 0.1 to 1.0 ppm balance N

NO: 10 to 250 ppm balance N

• Before operating an ETO detector, allow the detector to stabilize

at the temperature it will be operating in. After the detector has

stabilized, zero the detector.

• It is necessary to periodically re-zero the ETO detector.

• To ensure accurate calibration, BW recommends using a premium-grade calibration gas approved by the National Institute of

Standards and Technology (NIST).

• Do not use a gas cylinder beyond its expiration date.

sensitivity): 50 to 500 ppm balance N

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

• Before calibrating a new NO or ETO sensor, allow the sensor to

stabilize for 2 hours in a safe area that is free of hazardous gas.

• Calibrate a new sensor before use. Allow the sensor to stabilize

before starting calibration (used: 60 seconds; new: 5 minutes).

• Calibrate the detector at least once every 180 days (for HCN

detectors calibrate at least once every 90 days), depending upon

use and sensor exposure to poisons and contaminants.

• Calibrate the detector if the ambient gas display varies at

start-up.

• It is best to calibrate the sensor before changing the alarm setpoints.

• Calibrate only in a safe area that is free of hazardous gas.

• To disable an alarm, set the alarm setpoint to zero.

• If a certified calibration is required, contact

BW Technologies by Honeywell

.

Note

A generator must be used to calibrate O

and ClO2 GasAlert

3

Extreme sensors.

34

Page 42

GasAlert Extreme

User Manual

Test Cap

The calibration cap and hose are shipped with the detector for calibration.

Refer to Table 10 and Figure 3 for installation information.

Note

Only use the calibration cap during calibration.

Table 10. Test Cap

Item Description

1Test cap

2Hose

3 Regulator

4 Gas cylinder

35

Figure 3. Test Cap

Page 43

GasAlert Extreme

User Manual

Calibration

Calibration requires several steps, some of which can be bypassed. A

note is added to each option that can be bypassed.

Start Calibration

Note

To quit calibration at any point, press

any saved values and the detector beeps and vibrates four

times before returning to normal operation.

Calibrate O

1. To enter calibration, in a safe area free of hazardous gas, press

and hold

vibrates four times, and the LEDs flash four times.

After the CAL. screen displays, the detector beeps one time and

the auto zero screen displays.

in clean air only.

2

C and E simultaneously as the detector beeps and

A. The detector retains

Auto Zero

The auto zero function automatically zeroes the detector.

2. The LCD flashes while the detector automatically zeroes the sensor. When the auto zero is complete the detector beeps twice.

Note

Do not apply the calibration gas until the LCD displays the

flashing gas cylinder icon; otherwise, the detector auto zero will

fail.

Auto Zero Fail

If the sensor fails auto zero, the following screen displays.

The detector then bypasses the sensor span and automatically proceeds

to the alarm setpoints.

1. Press A to exit the alarm setpoint screens and to return to normal operation.

2. Restart the calibration procedures in a safe area that is free of hazardous gas. If auto zero fails a second time, deactivate and then reactivate the detector to test the sensors.

3. If the auto zero is successful and the passcode protection is disabled, the detector automatically proceeds to the auto span function.

36

Page 44

GasAlert Extreme

User Manual

Passcode Protected

After a successful auto zero, and if the passcode protected option is

enabled, PASS displays. The passcode is required to access the auto

span and alarm setpoint functions.

3. Press

D or E to scroll to the required passcode and press C

to confirm. For additional information, refer to Passcode Protec-

tion Option.

If the correct code is confirmed by pressing

onds, the detector beeps twice and automatically proceeds to the

set span screen.

If the passcode is not confirmed within 10 seconds or the passcode is incorrect, NO displays.

The detector then beeps four times and automatically returns to

normal operation.

C within 10 sec-

Set Span

Note

To bypass the set span function, press

ceed to the span screen.

The set span function inputs a new calibration gas concentration value.

4. Set SPAN flashes.

D or E to scroll to the required gas concentration. The

Press

detector value must match the concentration value on the gas

cylinder.

Note

If a new value is selected but not confirmed within 10 seconds

by pressing

plays. The detector beeps six times and retains the original

value. The detector automatically proceeds to the span screen.

5. Press

C, the detector rejects the new value and NO dis-

C to save the new value and proceed to the span screen.

C to automatically pro-

37

Page 45

GasAlert Extreme

User Manual

Span

Note

To bypass the span function, press

ceed to the alarm setpoint screens. If the span is bypassed, the

calibration due date cannot be changed.

Verify that the calibration gas being used matches the span

concentration values that are defined for the detector. For more

information, refer to Calibration Guidelines

6. The set span screen displays a flashing .

The flashing does not display for oxygen (O

7. Apply the calibration gas.

8. Apply gas to the sensor at a flow rate of 500 ml/min.

(for NH

, Cl2, and ETO: 1000 ml/min.)

3

The gas readings change as gas is applied to the sensor. When

the detector senses a sufficient concentration of gas (approximately 30 seconds), the detector beeps once.

9. The detector then begins spanning the sensor as follows:

•NH

•O

, Cl2, ClO2, O3, and ETO: 5 minutes to span

3

: 30 seconds to span

2

• other gases: 2 minutes (approximately) to span.

The detector beeps three times when the span is complete.

C to automatically pro-

.

Note

) detectors.

2

Successful Span

If the span is successful, the LCD automatically displays the calibration

due date screen.

Unsuccessful Span

If the detector fails to span a sensor successfully,

FAIL displays.