Page 1

BW TECHNOLOGIES

BY HONEYWELL

GasAlertClip Extreme

2 or 3 Year Gas Detector

Instruction Sheet

Introduction

The GasAlertClip Extreme gas detector (“the detector”) is a personal safety

device that warns when hazardous gas exceeds factory set alarm setpoints.

The detector stores and transmits gas alarm event data. It is your

responsibility to respond properly to the alarms.

Gas Detected Unit of Measure

Oxygen (O2) Percent by volume (%)

Carbon monoxide (CO) Parts per million (ppm)

Hydrogen sulfide (H2S) Parts per million (ppm)

Sulfur dioxide (SO2) Parts per million (ppm)

a Safety Information - Read First

Warning: Substitution of components may impair Intrinsic Safety.

Warning: Bump test the O2 detector before each day’s use to confirm its

ability to respond to gas by exposing the detector to a gas

concentration that exceeds the alarm setpoints. Manually verify

that the audible and visual alarms are activated.

Warning: To prevent ignition of flammable or combustible atmospheres,

disconnect power before servicing.

⇒ Do not activate the detector after the date on the package.

⇒ This product is a gas detector, not a measurement device.

⇒ Perform a self-test each day prior to use.

⇒ Ensure the sensor grill is free of dirt, debris, and is not obstructed.

⇒ Calibrate and bump test the detector in an ordinary location.

D2139/7 [English]

iERP: 124661

© BW Technologies 2006, all rights reserved.

a Safety Information - Read First

⇒ Periodically test the response of the sensor to gas by exposing the

detector to a target gas concentration that exceeds the low alarm setpoint.

Manually verify that the audible and visu al alarms are activated.

⇒ Periodically calibrate the GasAlertClip Extreme O

.

2

ec Note:

This instrument contains a lithium battery. Do not mix with the solid

waste stream. Spent batteries should be disposed of by a qualified

recycler or hazardous materials handler.

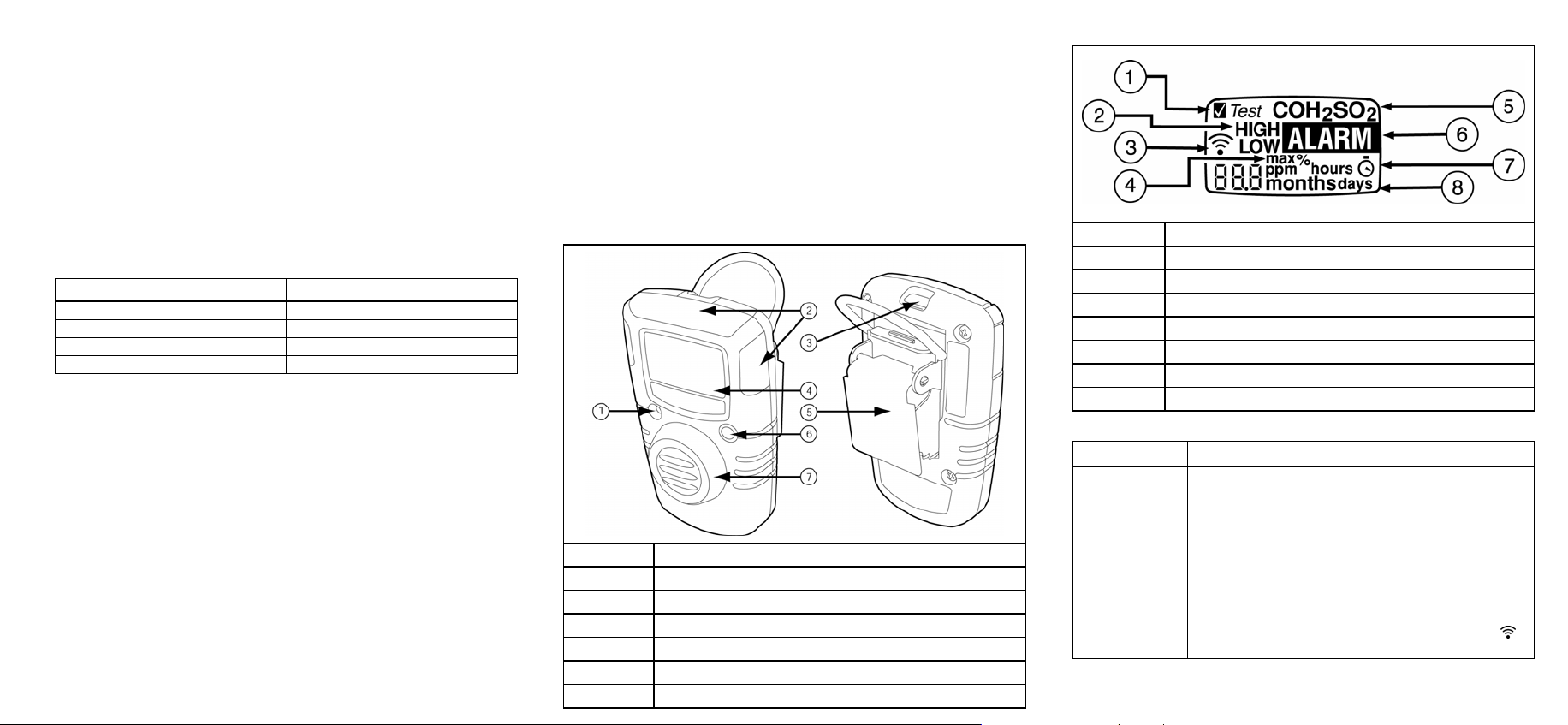

Parts of the GasAlertClip Extreme

1 Audible alarm

2 Visual alarm

3 Infrared download port

4 Liquid crystal display (LCD)

5 Alligator clip

6 Start/test button

7 Sensor and sensor grill

Display Elements

1 Self-test status

2 High and low alarm setpoints

3 Data transmission

4 Maximum exposure in alarm

5 Gas type

2 / 6 Alarm condition

7 / 8 Detector life-remaining indicators

4 / 8 Months/hours/days since last maximum exposure

Pushbutton

Pushbutton Description

• To activate the detector, press and hold C for

5 seconds.

• Press C within 24 hours of a gas alarm to view

C

the maximum gas exposure.

• When Test displays, press and hold

approximately 1 second to activate the self-test.

• To calibrate the O

for approximately 3 seconds.

• To display the gas alarm setpoints, press C.

• To transmit the data, press C when Prn and

display.

detector, press and hold C

2

C for

Page 2

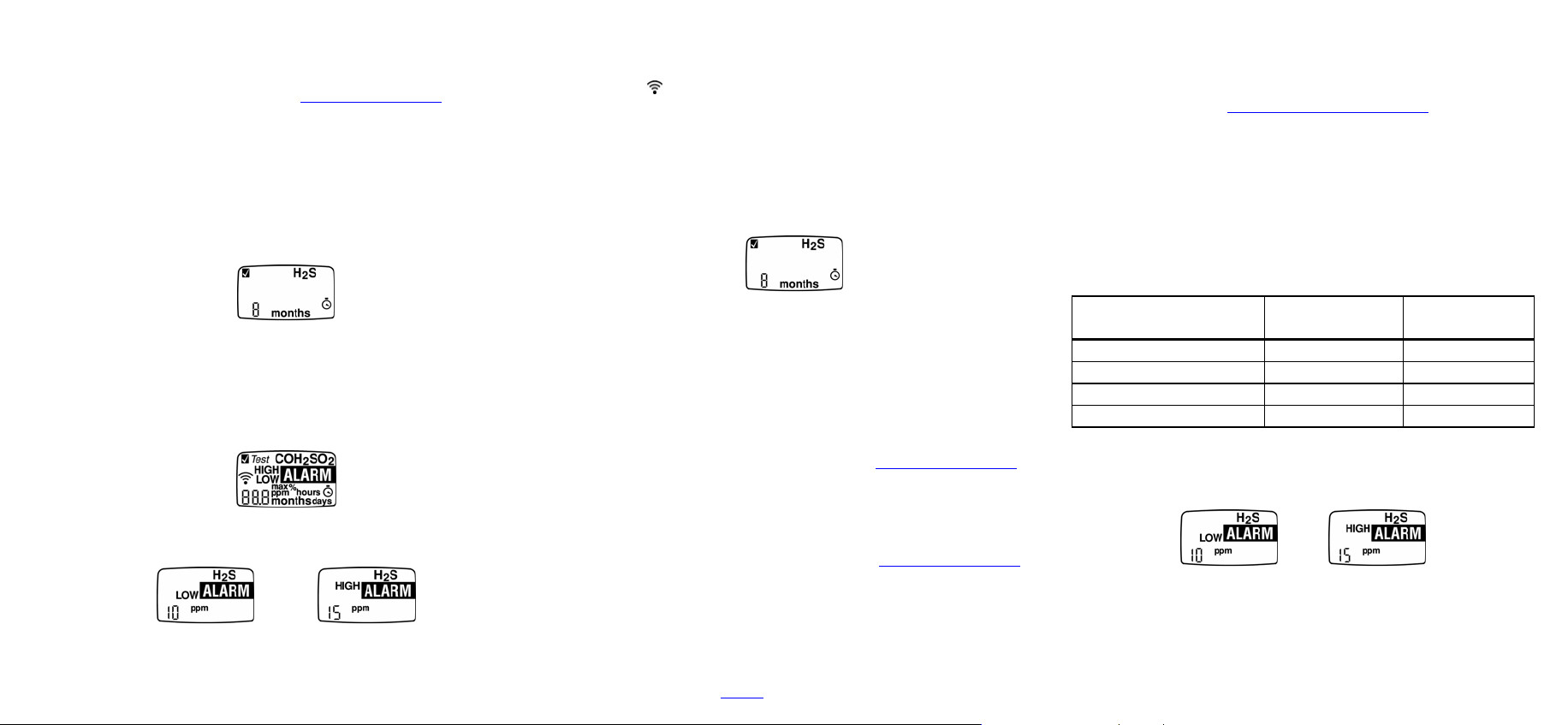

Activating the Detector

Press and hold C for 5 seconds.

Note: Once activated the detector cannot be deactivated, except after a

battery life-ending alarm. Refer to

Safety Shutdown Mode.

Performing a Self Test

Note: The self-test must be performed in an atmosphere that is free of

hazardous gas.

After a self-test is performed, wait 30 seconds before using to ensure

the detector accurately detects gas.

The self-test is activated prior to any other function. Prior to each day’s use,

a self-test of the detector must be performed.

When Test displays on the LCD, a self-test is required.

When the self-test is performed and passes,

are successful.

To perform a self-test, press and hold C for approximately 1 second. to

initiate the self-test. Confirm that the following tests are performed:

1. The detector emits one beep, one flash, and one vibration.

2. All LCD elements display.

3. Test flashes while the sensor integrity and battery life are tested.

4. The low and high alarm setpoints display.

displays to confirm the tests

u

5. If an alarm has occurred in the last 24 hours, the LCD displays the

maximum gas exposure value and the hours that have lapsed since

the exposure.

6. Prn and

Note: If a self-test is activated without Test being displayed, steps #1-3 are

bypassed.

flash.

Self-Test Pass

When the self-test is successful, the detector emits a short beep and a

single vibration.

u then displays to verify that the detector passed the self-test.

Twenty hours after performing the self-test, Test displays again to indicate

that a self-test is required.

Self-Test Fail

If the self-test fails, the detector emits five short beeps and flashes before

displaying a blank screen. The LCD then returns to the normal operating

screen and again displays Test.

Repeat the self-test.

Note: If the self-test fails three consecutive times, the LCD displays a blank

screen and the detector deactivates. Refer to

Automatic Battery Test

The battery is automatically tested every 2 hours. If the battery test fails,

another automatic test is initiated 30 minutes later.

Note: After five consecutive battery test failures, the LCD displays a blank

screen and the detector deactivates. Refer to

Detector Life-Remaining Clock

The detector life-remaining clock indicates how much longer the detector

will operate. The LCD displays the countdown value of the remaining

months, days, and then hours.

The detector continues to operate for a maximum of 8 hours after the

detector life-ending alarm initiates. Press C to deactivate the detector. For

more information, refer to

Alarms.

Safety Shutdown Mode.

Safety Shutdown Mode.

Safety Shutdown Mode

The LCD displays a blank screen when initiating safety shutdown mode.

The detector beeps, flashes, and vibrates rapidly (twice per second) until

the battery loses power. To deactivate the detector before the battery loses

power, press C. Contact

The detector initiates safety shutdown mode if the

• self-test fails three consecutive times,

• automatic battery test fails five consecutive times, or

• detector has not been manually deactivated within 8 hours of initiating

the detector life-ending alarm.

BW Technologies by Honeywell.

Gas Alarm Setpoints

The following is a list of the factory alarm setpoints.

Model

GasAlertClip Extreme O

GasAlertClip Extreme CO 35 ppm 200 ppm

GasAlertClip Extreme H2S 10 ppm 15 ppm

GasAlertClip Extreme SO

Note: Detector may be configured with customer specified alarm setpoints.

2

2

Displaying the Gas Alarm Setpoints

Press C to display the alarm setpoints.

Alarm setpoints are factory configured and cannot be modified.

Low Alarm

Setpoint

19.5% 23.5%

5 ppm 10 ppm

High Alarm

Setpoint

Page 3

Alarms

Display Audible

Alarm

Low Gas Alarm

High Gas Alarm

Life-Ending Alarm

One slow

beep every

second

Two fast

beeps every

second

Eight slow

beeps per

minute

Note: When the gas level returns to the acceptable range, the gas alarm

stops.

The life of the battery decreases rapidly when in alarm conditions.

The battery life-ending alarm occurs when the battery life-remaining

clock displays 0 hours. The detector will continue to operate for

8 hours before automatically deactivating.

Visual

Alarm

One slow

flash every

second

Two fast

flashes every

second

Eight slow

flashes per

minute

Vibration

Alarm

One slow

vibration

every second

Two fast

vibrations

every second

Eight slow

vibrations

per minute

Maximum Gas Exposure

The detector records the maximum gas exposure that triggers an alarm

condition and begins calculating the number of hours from when the

maximum exposure occurred.

For each new exposure greater than the current maximum exposure, the

detector resets the maximum gas exposure to the new level and resets the

hours to 0. After 24 hours of gas readings in the acceptable range, the

detector resets both values to 0.

Viewing the Maximum Gas Exposure

Press C within 24 hours of receiving a gas alarm. The LCD displays the

following:

The low and high alarm setpoints.

If a maximum gas exposure has occurred within the last 24 hours, the

maximum gas exposure screens display.

For exposures beyond the detection range, over limit (OL) displays.

Calibrating the Oxygen (O2) Detector

a Warning

Bump test the O

its ability to respond to gas by exposing the detector to a gas

concentration that exceeds the alarm setpoints. Manually

verify that the audible and visual alarms are activated.

Every 30 days when the O

CAL and the detector life-remaining value to indicate that calibration is due.

To calibrate the O2 detector, complete the following:

1. Calibrate the detector only in a normal atmosphere (20.9% O2) that is

free of hazardous gas.

2. Press and hold C for approximately 3 seconds.

3. The detector emits one beep, one flash, and displays the following

screen:

Successful Calibration: The detector emits one vibration and one

extended beep to indicate that calibration is successful.

Unsuccessful Calibration: If the detector does not beep or vibrate after a

calibration, repeat steps 1 and 2 again. If the second attempt is

unsuccessful, contact

detector before each day’s use, to confirm

2

detector is due for calibration, the LCD flashes

2

BW Technologies by Honeywell.

Page 4

Gas Event Data Transmission Transferring Data to a Printer Safety Specifications

The detector stores the last ten alarm events. The recorded data includes the To transfer data using the handheld IR printer, complete the following:

• serial number,

• detector life-remaining value (months/days/hours),

• number of self-tests that have been performed,

• total number of events that have occurred,

• event type,

• duration of all events encountered,

• gas type,

• alarm level(s) (ppm or %),

• time elapsed since the alarm occurred (days/hours/minutes), and

• duration of the alarm (minutes/seconds).

Two options are provided to transmit the gas event data: 1) Transfer data to

a PC using an IR DataLink or 2) Print the data using the handheld IR printer.

Transfer Data

Transferring Data to a PC

To transfer the data to a PC, complete the following:

1. Connect the IR DataLink to the PC. Activate the IR DataLink

2. Position the detector and the device 2 in. (5 cm) apart.

3. From the detector, press C to access the transmission screen.

4. Prn and

flash on the detector LCD. Within 5 seconds, press C to

begin the transmission.

5. While data is being transmitted,

Y displays and flashes. A

countdown timer displays as a percentage value (70%) and indicates

how much data remains to be transmitted.

Using the handheld IR printer, complete steps 2-5 as listed for

Data to a PC.

General Specifications

Shelf life

Weight

Instrument

dimensions

Operating

temperature

Operating humidity 5% to 95% relative humidity

Audible alarm ≈ 95 dB at 30 cm (1 ft.)

Visual alarm Flashing, wide-angled alarm lens with quad red

Display Liquid crystal display (LCD)

Sensor type Electrochemical cells

Detection technique Instantaneous alarm

Battery Lithium, non-replaceable

Ratings and

certifications

Ingress protection

EMI/RFI

1 year before activation

76 g (2.7 oz.)

28 x 50 x 81 mm (1.1 x 2.0 x 3.2 in.)

S: -40 to +50°C / -40 to +122°F

H

2

CO: -30 to +50

: -30 to +50°C / -22 to +122°F

SO

2

: -20 to +50°C / -4 to +122°F

O

2

Internal vibrating operates to: -15°C / +5°F

(non-condensing)

LEDs plus alarm LCD readout

Classified by UL to both U.S. and Canadian

Standards as intrinsically safe for Class I, Division

1, Group A, B, C, D and Class I, Zone 0, Group IIC

: CE 0539 g II 1 G EEx ia IIC T4

ATEX

DEMKO 03 ATEX 0321968

IECEx

CE: European Conformity

ABS Type Approved VA-348-169-X

IP 66/IP 67

Complies with EMC Directives 89/336/EEC

°C / -22 to +122°F

Transferring

Maximum operating

life

Detection range H

Alarm setpoints Instant low and instant high

Calibration H

Note: This product has been classified for use in atmospheres not more

than 21% v/v O

.

2

Event Logging Specifications

Number of stored

events

Data transmission

method

Information

transmitted

Data transmission

time

24 Month detector: 2 years after activation,

assuming 3-5 minutes of alarm time/day

36 Month detector: 3 years after activation,

assuming 1.5 minutes of alarm time/day

S: 0 to 100 ppm

2

CO: 0 to 300 ppm

O2: 0 to 30% by volume

SO2: 0 to 100 ppm

S, CO, SO2: Not required

2

O2: Self-calibrating

Up to ten events encountered. If more than ten, the

older events are replaced by the newer events.

Via infrared port to thermal printer or via IR

DataLink to PC (for ordinary locations only)

Serial number

Life remaining

Self-tests performed

Total number and duration of all events

encountered

Last ten events:

Maximum exposure, MicroDock II bump check, or

calibration

O

2

Data shown for maximum exposures and bump

checks:

Gas type and alarm level in ppm or %

Time elapsed since the alarm occurred in days,

hours, and minutes

Duration of alarm in minutes and seconds

45 seconds plus 10 seconds per record

Page 5

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC rules and ICES-003

Canadian EMI requirements. These limits are designed to provide

reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and the receiver.

-- Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

Contacting BW Technologies by Honeywell

To contact BW Technologies by Honeywell call:

USA: 1-888-749-8878

Canada: 1-800-663-4164

Europe: +44 (0) 1295 700300

Other countries: +1-403-248-9226

Address correspondence to:

BW Technologies by Honeywell

2840 – 2

Calgary, AB

T2A 7X9

CANADA

Email us at:

Visit BW Technologies by Honeywell’s web site at:

nd

Avenue S.E.

info@bwtnet.com

www.gasmonitors.com

BW Technologies by

Honeywell

Corporate Headquarters America Europe

2840 - 2 Ave. SE 3279 West Pioneer Parkway 5 Canada Close

Calgary, AB Arlington, TX Banbury, Oxfordshire

Canada T2A 7X9 USA 76013 United Kingdom OX16 2RT

BW Technologies by

Honeywell

BW Technologies by

Honeywell

Warranty

BW Technologies LP (BW) warrants this product to be free from defects in material and

workmanship under normal use and service for a period of two or three years

(depending upon detector), beginning on the date of activation. This Warranty is valid

only if the detector is activated by the date on the package. This warranty extends only

to the sale of new and unused products to the original buyer. BW’s warranty obligation

is limited, at BW’s option, to refund of the purchase price, repair, or replacement of a

defective product that is returned to a BW authorized service center within the warranty

period. In no event shall BW’s liability hereunder exceed the purchase price actually

paid by the buyer for the Product.

This warranty does not include:

The obligations set forth in this warranty are conditional on:

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE

REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. BW SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR

BASED ON CONTRACT, TORT OR RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied

warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this warranty is held invalid or unenforceable by a court of competent

jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

LIMITED WARRANTY & LIMITATION OF LIABILITY

a) fuses, disposable batteries or the routine replacement of parts due to the normal

wear and tear of the product arising from use;

b) any product which in BW’s opinion, has been misused, altered, neglected or

damaged by accident or abnormal conditions of operation, handling or use;

c) any damage or defects attributable to repair of the product by any person other

than an authorized dealer, or the installation of unapproved parts on the product;

or

a) proper storage, installation, calibration, use, maintenance and compliance with

the product manual instructions and any other applicable recommendations of

BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making

the product available for correction. No goods shall be returned to BW until

receipt by the buyer of shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as the

original invoice, bill of sale or packing slip to establish that the product is within

the warranty period.

Loading...

Loading...