Page 1

IntelliDoX™

| Gas Detection

Docking Module

User Manual

50104991-168 EN-C5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

INTELLIDOX DOCKING MODULE USER MANUAL || ABOUT THIS PUBLICATION

Table of Contents

Table of Contents .............................................................................................................................. 1

About this Publication ................................................................................................................................... 3

Important Safety Information: Read First .................................................................................................... 4

Getting Started ............................................................................................................................................... 5

About the IntelliDoX Docking Module ................................................................................................ 6

What’s in the Box ............................................................................................................................... 7

IntelliDoX at a Glance ........................................................................................................................ 8

Inlet Keys ........................................................................................................................................... 9

LCD Screen ..................................................................................................................................... 11

Keypad ............................................................................................................................................. 12

Assemble Modules ....................................................................................................................................... 13

Work Plan: Assemble Individual Modules ........................................................................................ 14

Work Plan: Assemble Gangs of up to Five Connected Modules ...................................................... 15

Assemble the Stand ......................................................................................................................... 16

Connect Modules ............................................................................................................................. 17

Mount on a Wall ............................................................................................................................... 18

Mount on Parallel DIN Rails ............................................................................................................. 22

Prepare Modules for Use ............................................................................................................................. 25

Attach the End Plate ........................................................................................................................ 26

Connect the Exhaust Tubing ............................................................................................................ 27

Connect the Inlet filter ...................................................................................................................... 28

Insert the Inlet Plugs ........................................................................................................................ 29

Connect the Power .......................................................................................................................... 30

Connect the Module to a Network .................................................................................................... 31

Connect a Calibration Gas Cylinder ................................................................................................. 35

Dock Station Settings Menu ........................................................................................................................ 37

Display the Adjust Dock Station Settings Menu ............................................................................... 38

Adjust the LCD Brightness ............................................................................................................... 39

Adjust Date and Time Settings ........................................................................................................ 40

Configure Gas Inlets ........................................................................................................................ 41

Display the Select Language Menu ................................................................................................. 43

Display the About Summary Screen ................................................................................................ 44

Detector Operations ..................................................................................................................................... 45

Insert a Detector .............................................................................................................................. 46

Detector Operations Menu ............................................................................................................... 47

Bump Test ....................................................................................................................................... 48

FastBump ........................................................................................................................................ 50

Calibration ........................................................................................................................................ 52

Transfer Datalogs from a Detector ................................................................................................... 55

Display the Adjust Dock Station Settings Menu ............................................................................... 56

Charge a Detector ........................................................................................................................... 57

Configure Settings via Fleet Manager II Software ..................................................................................... 58

Protect Module Operations with a Passcode ................................................................................... 59

Configure Module and Detector Settings ......................................................................................... 60

Adjust Time and Date Settings via Fleet Manager II Software ......................................................... 64

Hibernation ................................................................................................................................................... 67

Configure Hibernation ...................................................................................................................... 68

Transfer Data Files ....................................................................................................................................... 73

Transfer Data Files from the Module ............................................................................................... 74

HONEYWELL PAGE 1 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

INTELLIDOX DOCKING MODULE USER MANUAL || ABOUT THIS PUBLICATION

Update Firmware .......................................................................................................................................... 76

Update Module Firmware ................................................................................................................. 77

Update Detector Firmware ............................................................................................................... 80

Replace Detector Cradle and Calibration Insert ........................................................................................ 83

Replace the Detector Cradle ............................................................................................................ 85

Replace the Calibration Insert .......................................................................................................... 87

Maintenance ................................................................................................................................................. 89

Clean and Maintain the Module ....................................................................................................... 90

Calibration Equipment and Gases ................................................................................................... 91

Technical Specification and Warranty ....................................................................................................... 92

Technical Specification .................................................................................................................... 93

Limited Warranty and Limitation Liability .......................................................................................... 95

Troubleshooting ........................................................................................................................................... 96

Compliance Tests ............................................................................................................................ 97

Detectors ......................................................................................................................................... 99

Modules ......................................................................................................................................... 100

Network Connections ..................................................................................................................... 103

Calibration of PID Sensor .............................................................................................................. 104

Safety Suite Device Configurator Software ............................................................................................. 105

Connect an IntelliDoX to the Safety Suite Device Configurator ..................................................... 106

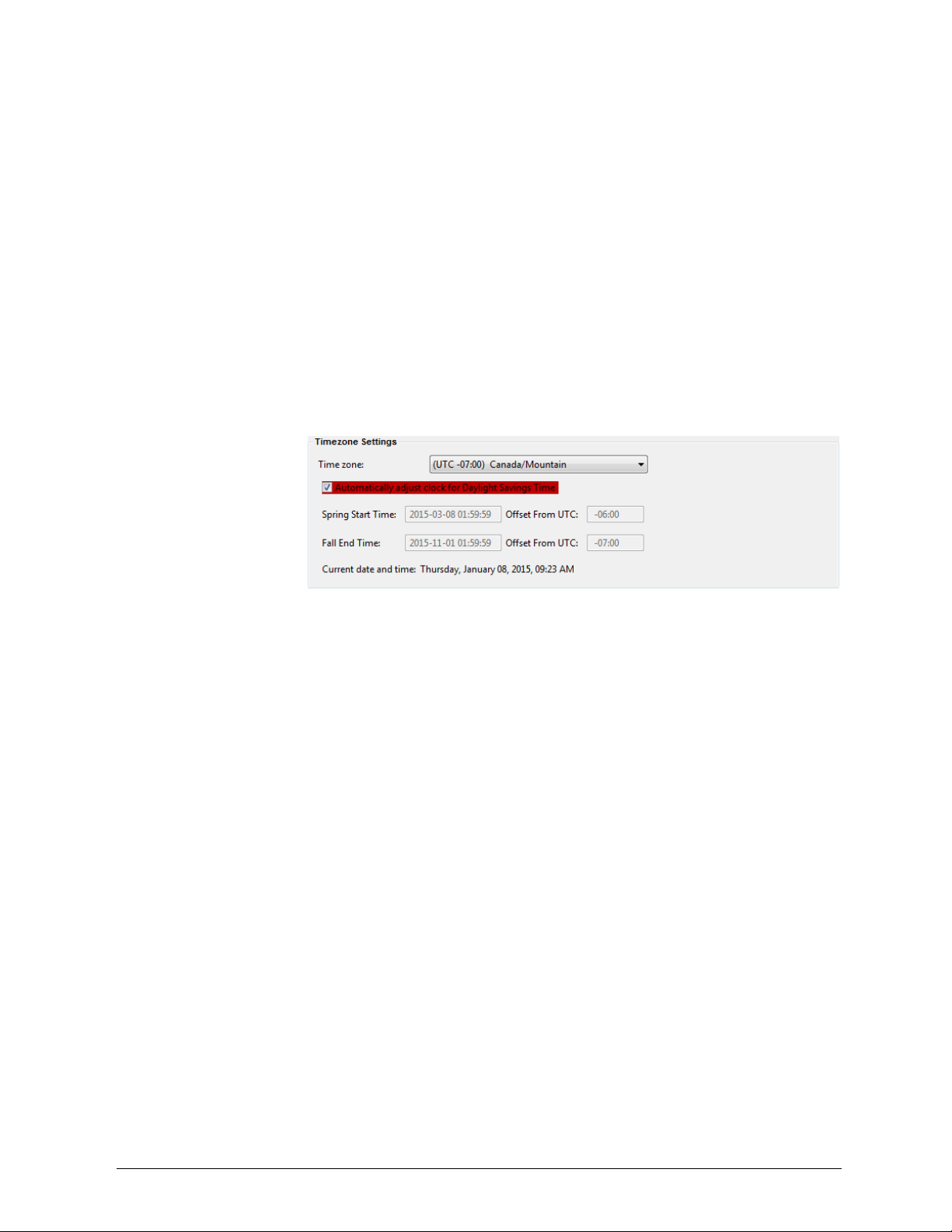

Adjust the Time and Date .............................................................................................................. 107

Set the Time Zone ......................................................................................................................... 108

Transfer data files .......................................................................................................................... 109

Download data from a file .............................................................................................................. 110

Update the Firmware ..................................................................................................................... 111

Glossary ...................................................................................................................................................... 114

Contact us .................................................................................................................................................. 117

HONEYWELL PAGE 2 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

INTELLIDOX DOCKING MODULE USER MANUAL || ABOUT THIS PUBLICATION

About this Publication

IntelliDoX® Docking ModuleOperator Manual

50104991-168 || OM-EN-FMSU-C1

© 2015-2018 Honeywell. All rights reserved.

The IntelliDoX Docking Module is designed to support multiple detectors manufactured by

Honeywell. As a result, certain procedures, features and options described in this manual

may not be supported by most of the compatible detector models. To understand which

procedures, features and options are supported, refer to the appropriate detector operator

manual.

Ensure that you are familiar with the use of personal gas detection devices and

accessories, and take appropriate action in the event of an alarm condition.

While this information is presented in good faith and believed to be accurate, Honeywell

disclaims the implied warranties of merchantability and fitness for a particular purpose and

makes no express warranties except as may be expressly stated in its written agreement

with and for its customers. In no event is Honeywell liable to anyone for any indirect,

special or consequential damages. The information and specifications in this document

are subject to change without notice.

Trademarks

Brand or product names are trademarks of their respective owners. The following brand or

product names are trademarks of Honeywell:

• Fleet Manager II

• IntelliDoX

Signal Words

This manual uses the following signal words, as defined by ANSI Z535.4-1998:

Hazardous situation which, if not avoided, will result in death or serious injury. This

symbol identifies the most extreme hazardous situations.

Hazardous situation which, if not avoided, could result in death or serious injury.

Hazardous situation which, if not avoided, may result in moderate or minor injury.

Situations which, if not avoided, may result in property damage.

HONEYWELL PAGE 3 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

INTELLIDOX DOCKING MODULE USER MANUAL || IMPORTANT SAFETY INFORMATION: READ FIRST

Important Safety Information: Read First

To ensure personal safety, read all Safety

Information and Warnings before using this

equipment.

Use this equipment only as specified by the

manufacturer. Failure to do so may impair

protection provided by the equipment.

The safety and security of any system or network

incorporating this equipment and its accessory

components is the responsibility of the assembler

of the system.

Follow all required National Electric Codes (NEC)

and safety standards.

This IntelliDoX module is intended for use as a

stand-alone docking module, or as a component

in a connected gang of up to five IntelliDoX

modules.

If the equipment is damaged or parts are missing,

contact Honeywell immediately.

Substitution of components may impair the safety

of the equipment.

Do not attempt to disassemble, adjust, or service

the equipment unless instructions are provided to

perform a procedure, or a component is listed as

a user-replaceable component in the user

manual. Use only Honeywell replacement

components.

To eliminate the risk of electrical shock,

disconnect the equipment when cleaning or

performing maintenance.

This equipment uses potentially harmful gas for

calibrations. The equipment must be attached to

a venting system or be used in a well-ventilated

area.

To prevent gas leaks, the end plate must be

attached and locked with the latch arm lock

before connecting power supply and/or

connecting gas cylinders. The end plate must

remain securely latched at all times during

operation.

Perform calibrations and bump tests only in a

normal atmosphere (20.9% v/v O

hazardous gas.

) that is free of

2

The maximum recommended calibration tubing

length is 10 meters (33 feet). Use of tubing that is

longer than the recommended length may result

in inaccurate or failed compliance tests or

calibrations.

The maximum recommended exhaust tubing

length is 15 meters (49.5 feet).

Ensure that the inlet filter is clean.

The use of calibration gas cylinders other than

those specified by Honeywell may result in

unsafe calibration or possible non-recoverable

failure of the equipment, and will invalidate the

warranty.

Do not use calibration gas cylinders past their

expiration date.

Ensure that all calibration gas cylinders are in

good condition.

Ensure that all calibration gas cylinders contain

enough gas.

Ensure the exhaust line is not connected to a

negative pressure system.

A demand flow regulator must be used with all

calibration gas cylinder connections. The module

inlet should not be pressurized.

Failed tests can result if inlets are not set up

correctly.

Do not expose the equipment to electrical shock

or severe and/or continuous mechanical shock.

Do not immerse the equipment in liquids.

Products may contain materials that are

regulated for transportation under domestic and

international dangerous goods regulations.

Return product in compliance with appropriate

dangerous goods regulations. Contact freight

carrier for further instructions.

To prevent the corruption or loss of data and/or

software and/or firmware, do not deactivate the

equipment while performing datalog transfers,

bump tests, calibrations or other operations.

HONEYWELL PAGE 4 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

Getting Started

This section contains information and illustrations related to the module and its

components. It also includes an overview of the module settings menu and general

instructions for inserting a detector and using the detector operations menu on the

module.

HONEYWELL PAGE 5 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

About the IntelliDoX Docking Module

The IntelliDoX Docking Module (‘the module’) is an automatic test and calibration station

for use with portable gas detectors manufactured by Honeywell. The module automatically

performs essential procedures including sensor identification, bump tests, calibrations,

alarm tests and data transfers. It also retains a cumulative record of detector datalogs and

event logs that are transferred to and stored in onboard memory.

Modules may be used as individual, stand-alone docking stations. They may also be

connected to form gangs of up to 5 modules that function independently. Connected

modules share power, network and gas connections.

Modules may be connected to a network via an Ethernet cable for enhanced access to

and control of administrative and maintenance tasks. Modules are compatible with Fleet

Manager II software, version 4.0 or higher.

Normal Operating Conditions

The module is designed to be safe in the following conditions:

Indoor use only;

Normal atmosphere (20.9% v/v O

Temperature range of +50°F to +95°F (+10°C to +35°C) ; and

Relative humidity of 10% to 90% non-condensing.

If the intended operating environment does not match these criteria, Honeywell

recommends that you consult a qualified professional specialist prior to installing and

using any modules.

This equipment uses potentially harmful gas for calibrations. The module must be

attached to a venting system or be used in a well-ventilated area.

) that is free of hazardous gas;

2

Parts and Accessories

Replaceable parts are sold separately. To receive a complete list of replaceable parts

approved for use with this product, contact Honeywell or an authorized distributor, or visit

Gas detectors, calibration and purge gas cylinders, and other accessories are sold

separately. To receive a complete list of calibration gases and accessories approved for

use with this product, contact Honeywell or an authorized distributor, or visit the product

HONEYWELL PAGE 6 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

What’s in the Box

IntelliDoX Docking Module

Each IntelliDoX Docking Module package contains:

1. One module with a factory-installed nest for a compatible portable gas detector, a

single-inlet key, and an attached end plate;

NOTE: If the end plate is not attached to the IntelliDoX docking module or is

missing, contact Honeywell or an authorized distributor immediately.

One printed Quick Reference Guide;

One CD containing the module Operator Manual and Quick Reference Guide in PDF

format; and

One CD containing Fleet Manager II software, v4.0 or higher.

The power supply and power cord, Ethernet cable, tubing, inlet filters and plugs, quick

connect fittings, and miscellaneous other fittings are packaged separately as the

IntelliDoX Enabler Kit. One Enabler Kit is required for each individual module or gang of

up to 5 connected modules.

If the module is damaged or if parts are missing, contact Honeywell or an authorized

distributor immediately.

IntelliDoX Enabler Kit

You need one IntelliDoX Enabler Kit for each stand-alone IntelliDoX module or gang of up

to 5 connected modules. Each Enabler Kit contains:

1. One power supply and AC power cord appropriate to shipping destination;

One ethernet cable;

Gas tubing, 1/8 inch I.D., 4.6 meters (15 feet);

Quick connect fittings;

Inlet filters and plugs;

Connectors with attached 3/16 inch I.D. tubing for use with demand flow regulators;

Miscellaneous connectors;

One CD containing the IntelliDoX operator manual and the quick reference guide in

PDF format; and

One CD containing Fleet Manager II software, v4.0 or higher.

If Enabler Kit parts are damaged or missing, or if additional Enabler Kits are required,

contact Honeywell or an authorized distributor immediately.

Fleet Manager II Software

Fleet Manager II is proprietary instrument management software developed by Honeywell.

You can use Fleet Manager II to:

• Configure and manage compatible docking modules and detectors;

• Update firmware for compatible docking modules and detectors;

• Configure and manage compliance tests;

• Import, manage and analyze datalogs, event logs and compliance test results; and

• Automate certain procedures and processes for compatible docking modules and

detectors.

To learn more about instrument management via Fleet Manager II software, refer to the

Fleet Manager II Operator Manual or visit the product website at

HONEYWELL PAGE 7 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

IntelliDoX at a Glance

HONEYWELL PAGE 8 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

Single-inlet key: IntelliDoX

activates gas inlet 1 and

Inlet Keys

By default, IntelliDoX is configured to connect one calibration gas cylinder to gas inlet 1.

In this configuration,

calibration gas cylinder to IntelliDoX, you must insert a multi-inlet key to activate

inlets 1, 2

Single-inlet Key

, 3, and 4.

gas inlets 2, 3, and 4 are inactive. To connect more than one

gas

Insert the single-inlet key when only one gas inlet is required to support compliance test

operations performed on the module.

When the single-inlet key is inserted into a module, gas inlet 1 is active and gas inlets 2, 3

and 4 are inactive.

Gas Cylinder with a Single-Inlet Key

When you connect a gas cylinder to IntelliDoX with a single-inlet key, you will see one

connected gas type on the LCD screen:

HONEYWELL PAGE 9 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

Multi-inlet key: IntelliDoX

Multi-inlet key: IntelliDoX

activates gas inlets 1, 2, 3,

Multi-inlet Key

Insert the multi-inlet key when more than one gas inlet is required to support compliance

test operations performed on the module.

When a multi-inlet key is inserted into a module, gas inlets 1, 2 3 and 4 are active.

Connected Gas Cylinders with a Multi-Inlet Key

When you connect multiple gas cylinders to IntelliDoX with a multi-inlet key, you will see

multiple connected gas types on the LCD screen:

Change an Inlet Key

To remove the inlet key, pinch the release tabs together, and then pull the inlet key out.

To insert the inlet key, align the inlet key with the opening and push firmly.

an inlet key.

1. Disconnect the power cord from the IntelliDoX.

On the inserted inlet key, press the release tabs and pull to remove the inlet key.

Insert the new inlet key into the IntelliDoX.

Connect the power cord to the IntelliDoX.

activates gas inlets 1, 2,

Always disconnect the power cord from the IntelliDoX before you change

Find Quality Products Online at: sales@GlobalTestSupply.com

HONEYWELL PAGE 10 OF 117

www.GlobalTestSupply.com

Page 12

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

LCD Screen

Screen Color

HONEYWELL PAGE 11 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

INTELLIDOX DOCKING MODULE USER MANUAL || GETTING STARTED

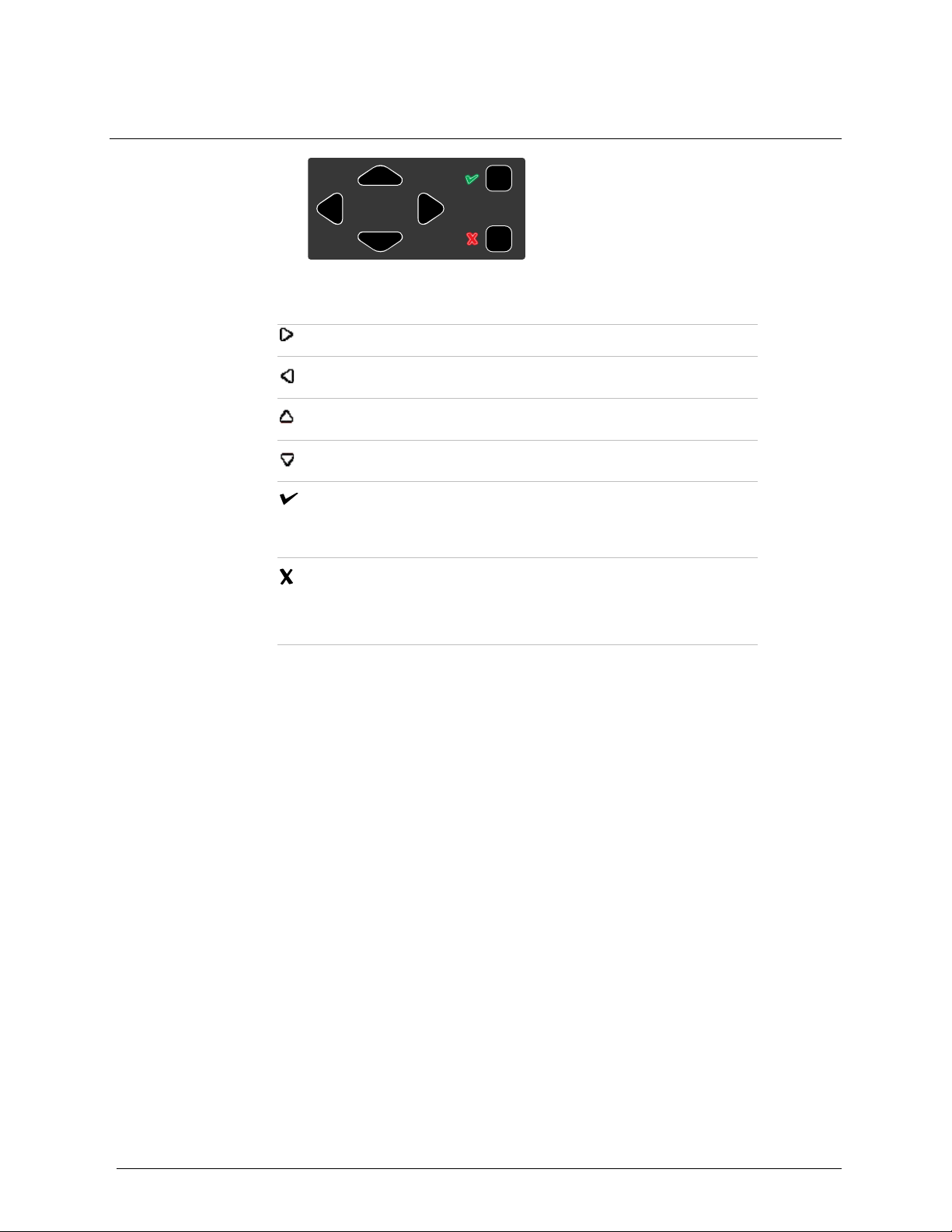

Keypad

Keypad Buttons

Scroll right

Scroll left

Scroll up

Scroll down

Press and hold until the module settings menu is displayed.

Press and release to select a menu item or save changes.

Press and hold until an operation is cancelled.

Press and release to close a menu item or return to a previous

screen or cancel changes.

HONEYWELL PAGE 12 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Assemble Modules

This section contains work plans and instructions for assembling and installing

individual modules and gangs of up to five modules.

HONEYWELL PAGE 13 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Work Plan: Assemble Individual Modules

Follow these steps to assemble and prepare an individual module for first-time use:

1. Place the module and component parts on a clean, dry work surface.

Verify that the appropriate inlet key is inserted. Replace the inlet key if necessary. For

more information, see Inlet Keys on page 9.

Assemble the stand, or mount the module on a wall or DIN rail. For more information see:

a. Assemble the Stand on page 16

b. Mount on a Wall on page 18.

c. Mount on Parallel DIN Rails on page 22.

Prepare the module for use. For more information, see Prepare Modules for Use on

page 25.

a. Attach the end plate. For more information, see Attach the End Plate on

page 26.

b. Connect an inlet filter to the purge inlet. For more information, see Connect

the Inlet filter on page 28.

c. Insert an inlet plug into each unused inlet. For more information, see Insert

the Inlet Plugs on page 29.

d. Connect the exhaust tubing. For more information, see Connect the

Exhaust Tubing on page 27.

e. Connect the power. For more information, see Connect the Power on page

30.

f. Connect to a network. See Connect the Module to a Network on page 31.

Connect the calibration gas cylinder or cylinders, and then configure the gas inlets. For

more information, see Configure Gas Inlets on page 41.

HONEYWELL PAGE 14 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

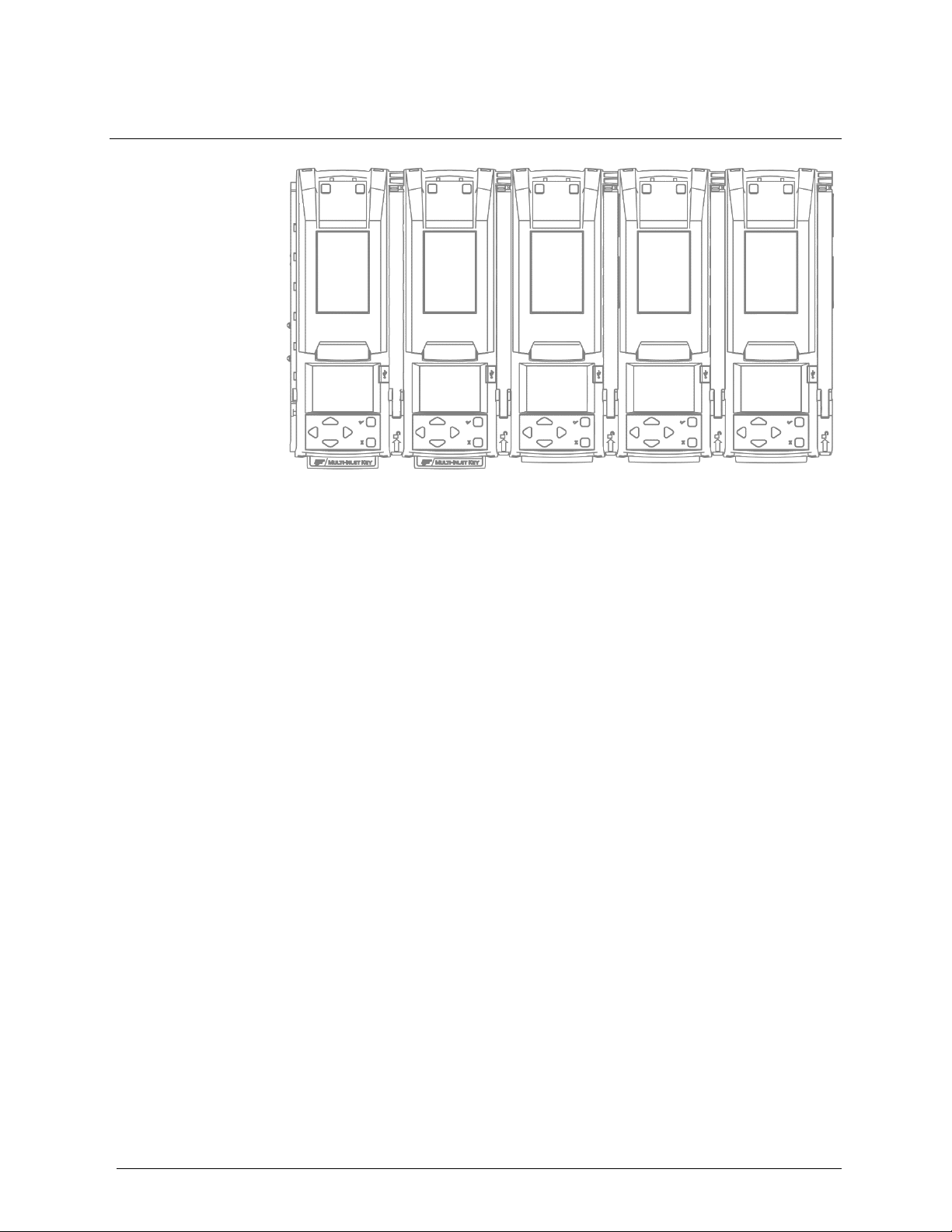

Work Plan: Assemble Gangs of up to Five Connected Modules

Up to five modules may be connected to form a gang. Connected modules share the

power supply, exhaust tubing, inlet filter, connected test gas cylinders and network

connection. Follow these steps to assemble and prepare gangs of up to five connected

modules for first use:

1. Place the modules and component parts on a clean, dry work surface.

Verify that the appropriate inlet keys are inserted. Replace the inlet keys if necessary. For

more information, see Inlet Keys on page 9.

Assemble the stand or mount the module on a wall or DIN rail if necessary. For more

information, see:

• Assemble the Stand on page 16.

• Mount on a Wall on page 18.

• Mount on Parallel DIN Rails on page 22.

Connect up to 5 modules. For more information, see:

• Connecting Modules on page 17.

• Mounting Connected Modules on a Wall on page 20.

Prepare the connected modules for use. For more information, see Prepare Modules for

Use on page 25.

a. Attach the end plate to the last module in the gang. See Attach the End Plate on

page 26.

b. Connect an inlet filter to the purge inlet on the first module in the gang. For more

information, see Connect the Inlet filter on page 28.

c. Insert an inlet plug into each unused inlet on the first module in the gang. For

more information, see Insert the Inlet Plugs on page 29.

d. Connect the exhaust tubing to the first module in the gang. For more information,

see Connect the Exhaust Tubing on page 27.

e. Connect the power to the first module in the gang.

f. Connect to a network. See Connect the Module to a Network on page 31.

Connect the calibration gas cylinder or cylinders, and then configure the gas inlets. For

more information, see Connect a Calibration Gas Cylinder on page 35 and Configure

Gas Inlets on page 41.

HONEYWELL PAGE 15 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Assemble the Stand

The back panel of the module can be used as a stand to support an individual module or

gang of up to five connected modules at an angle that is suitable for normal use.

Do not use the stand if parts are missing or damaged. Do not attempt to repair or

replace any parts of the stand. If the plate is damaged or missing, contact Honeywell

or an authorized distributor.

The equipment must be used only in a normal atmosphere (20.9% v/v O2) that is free

of hazardous gas. Do not use the equipment in a hazardous area. Failure to adhere

to this caution can lead to fire and/or explosion.

Do not install near heat sources or on vibrating surfaces.

The equipment is intended for indoor use only.

Assembling the Stand

1. Disconnect the power cord, network cable, tubing and inlet filter assemblies.

Detach the back panel.

a. Hold the module with the back panel facing toward you.

b. Find the panel latch at the top left side of the module, near the panel hinge.

c. Press down firmly on the panel latch, and then continue to press down while

Pinch the arms of the metal brace together to release the ends. If the metal brace is

damaged or missing, contact Honeywell or an authorized distributor.

Attach the back panel at the hinged joint. Align the hinges on the module with the hinge

pins on the back panel. Firmly push the back panel to the left to lock the hinge pins into

place.

Pinch the arms of the metal brace together and insert into the brace receptacle on the

back of the module.

Prepare the module for use.

a. Attach the end plate. Verify that the latch arm is lowered and locked.

b. Connect the inlet filters, tubing, network connection and power cord.

you slide the panel to the right until the hinge pins are detached.

HONEYWELL PAGE 16 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Connect Modules

Up to 5 modules may be connected to form a gang. Connected modules share a power

supply, network connection, exhaust tubing, inlet filter assemblies, and connected

calibration gas cylinders.

Connecting Modules

1. Assemble the stand for each module you plan to connect. For more information, see

Assemble the Stand on page 16.

Connect two modules.

a. Unlock and raise the latch arm on the first module. If an end plate is

attached, remove it.

b. Align the connection port, outlets and stand on the first module with the

connection port, inlets and stand on the second module.

c. Push the modules firmly together to connect. Verify that the stands are

connected, and then lower and lock the latch arm on the first module.

2. Unlock and raise the latch arm on the last connected module, and then connect

another module. Repeat as necessary to connect up to a maximum of five modules in

one gang.

3. Prepare connected modules for use.

a. Verify that connected modules are firmly attached and latch arms are lowered

and locked.

b. Attach the end plate to the last module in the gang. Verify that the latch arm is

lowered and locked.

c. Connect the inlet filters, tubing, network connection and power cord.

d. Verify that each module in the gang is activated and a consecutive bay number is

displayed on the LCD. See LCD Screen on page 11.

Disconnecting Modules

1. Disconnect the power.

a. Unlock and raise the latch arm between two modules.

b. Holding one unit in each hand, gently pull the modules apart.

c. Repeat as necessary until all modules in the gang are disconnected.

HONEYWELL PAGE 17 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Mount on a Wall

You can use the back panel to mount the module securely to a wall. Because wall

materials vary, mounting hardware is not provided. Honeywell strongly recommends that

wall-mounting is performed by a qualified installation contractor. Sufficient expertise is

required to:

1. Determine the strength of the wall supporting the module; and

Select mounting hardware appropriate to the weight and normal use of the module.

Before you Begin

1. Select a suitable installation location. Each module or gang of connected modules

requires:

• Access to an appropriate power source.

• Access to a network connection, if using.

• Access to calibration gas sources.

• Adequate clearance for the power cord, cables and tubing.

• Adequate clearance for normal use, maintenance and cleaning.

Have ready appropriate mounting hardware. Each module requires sufficient hardware for

4 anchor points.

Have ready tools and accessories required to install the mounting hardware.

Incomplete or improper mounting may result in property damage and/or personal

injury.

Do not install near heat sources or on vibrating surfaces.

The wall and the mounting hardware must be strong enough to support the

equipment during normal use.

The equipment must be used only in a normal atmosphere (20.9% v/v O

of hazardous gas. Do not use the equipment in a hazardous area. Failure to adhere

to this caution can lead to fire and/or explosion.

The equipment is intended for indoor use only.

This equipment uses potentially harmful gas for calibrations. The equipment must be

attached to a venting system or be used in a well-ventilated area.

) that is free

2

HONEYWELL PAGE 18 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Mounting Individual Modules on a Wall

1. Prepare the modules for mounting.

a. Disconnect modules that are connected into gangs.

b. Disconnect the power cord, network cable, tubing and inlet filter

assemblies.

c. Remove the end plate.

2. Detach the back panel.

a. Hold the module with the back panel facing toward you.

b. Find the panel latch at the top left side of the module, near the panel hinge.

c. Press down firmly on the panel latch, and then continue to press down while

you slide the panel to the right until the hinge pins are detached.

3. Mark the position of the anchor points on the wall, and then drill the holes.

a. Hold the panel against the wall in the desired position.

b. Use a pencil or non-permanent marker to mark the center of the 4 anchor

points, and then set the back panel aside.

c. Drill through the center of each anchor point mark.

4. Secure the panel to the wall with the metal brace facing out. Use appropriate

hardware for each of the 4 anchor points. Do not overtighten.

Attach the module to the mounted back panel.

a. Align the hinges and hook receptacles on the module with the hinge pins

and hooks on the mounted panel.

b. When the module lies flat against the mounted panel, push it firmly to the

left to lock it onto the panel.

5. Prepare the module for use. For more information, see Prepare Modules for Use on

page 25.

a. Attach the end plate. Verify that the latch arm is lowered and locked.

b. Connect the inlet filters, tubing, network connection and power cord.

Removing an Individual Module from a Mounted Back Panel

1. Disconnect the power cord, network cable, tubing and inlet filter assemblies.

2. Find the panel latch at the top right side of the module, near the panel hinge.

3. Press down firmly on the panel latch, and then continue to press down while you push

the module to the right until the hinge pins and hooks are detached. Remove the

module.

HONEYWELL PAGE 19 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Mounting Connected Modules on a Wall

1. Prepare the modules for mounting.

c. Disconnect modules that are connected into gangs.

d. Disconnect the power cord, network cable, tubing and inlet filter

assemblies.

e. Remove the end plate.

2. Detach the back panel from the modules.

a. Hold the module with the back panel facing toward you.

b. Find the panel latch at the top left side of the module, near the panel hinge

c. Press down firmly on the panel latch, and then continue to press down while

you slide the panel to the right until the hinge pins are detached.

3. Mark the position of the anchor points, and drill holes for the first panel.

a. Hold the panel against the wall in the desired position.

b. Use a pencil or non-permanent marker to mark the center of the 4 anchor

points, and then set the back panel aside.

4. Drill through the center of each anchor point mark.

Secure the first panel to the wall with the metal brace facing out. Use appropriate

hardware for each of the 4 anchor points. Do not overtighten.

Clip the second panel to the first panel, and then secure it to the wall. Use

appropriate hardware for each of the 4 anchor points. Do not overtighten. Repeat

as necessary to mount up to 5 connected panels.

5. Attach a module to the first panel.

a. Align the hinges on the module with the hinge pins on the mounted panel.

Align the hooks on the mounted panel with the hook receptacles on the

module.

b. When the module lies flat against the mounted panel, firmly push to the left

to lock onto the panel. If this is difficult, loosen the mounting hardware

slightly and try again.

6. Attach a module to the second panel and connect it to the first module.

a. Unlock and raise the latch arm on the first module.

b. Align the hinges on the next module with the hinge pins on the next

mounted panel. Align the hooks on the next mounted panel with the hook

receptacles on the next module. Align the connections on the modules.

c. When the next module lies flat against the next mounted panel, firmly push

to the left to lock it onto the panel and ensure a full connection with the first

module.

d. Lower and lock the latch arm. Repeat as necessary to attach and connect

up to 5 modules.

7. Prepare connected modules for use.

f. Verify that connected modules are firmly attached and latch arms are

lowered and locked.

g. Attach the end plate to the last module in the gang. Verify that the latch

arm is lowered and locked.

h. Connect the inlet filters, tubing, network connection and power cord.

i. Verify that each module in the gang is activated and a consecutive bay

number is displayed on the LCD. See LCD Screen on page 11.

HONEYWELL PAGE 20 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Removing Connected Modules from Mounted Back Panels

1. Disconnect the power cord, network cable, tubing and inlet filter assemblies.

2. Unlock and lift the latch arm between the two modules at the end of the gang.

3. Find the panel latch at the top right side of the module at the end of the gang.

4. Press down firmly on the panel latch, and then continue to press down while you push

the module to the right until the hinge pins and hooks are detached. For best results,

Honeywell recommends that you hold the remainder of the gang firmly in position

while pushing to help protect the remaining modules in the gang from excessive

movement or falls.

5. Repeat steps 2, 3 and 4 until only one module remains.

6. Repeat steps 3 and 4 to remove the final module.

HONEYWELL PAGE 21 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Mount on Parallel DIN Rails

The module is designed for installation on two parallel top hat DIN rails that are 35

millimeters by 7.5 millimeters, as per EN Standard 50022. Honeywell strongly

recommends that mounting is performed by a qualified installation contractor. Sufficient

expertise is required to:

1. Determine the strength of the wall supporting the module; and

2. Select DIN rails and mounting hardware appropriate to the weight and normal use of

the total number of mounted modules.

What is a DIN Rail?

A DIN rail is a metal strip that is used to mount industrial equipment. DIN rail can be cut to

suit specific applications. Multiple rows of DIN rail can be used. The module is designed

for installation on two parallel top hat DIN rails that are 35 millimeters by 7.5 millimeters,

as per EN Standard 50022.

Before You Begin

1. Select a suitable installation location. Each module or gang of connected modules

requires:

Install two parallel top hat DIN rails that are 35 millimeters by 7.5 millimeters. Use

DIN rails that are appropriate for the combined weight and normal use of the total number

of mounted modules. Space the DIN rails 15.2 centimeters (6 inches) apart on center.

Honeywell strongly recommends using a DIN rail end plate when mounting in a vehicle, or

when lateral motion is possible, or when attaching the first module in a ganged system. If

a DIN rail end plate is not available, use the anchor holes in the back panel to secure the

module to the wall.

Incomplete or improper mounting may result in property damage and/or personal

injury.

Do not install near heat sources or on vibrating surfaces.

The wall and the mounting hardware must be strong enough to support the

equipment during normal use.

The equipment must be used only in a normal atmosphere (20.9% v/v O

of hazardous gas. Do not use the equipment in a hazardous area. Failure to adhere

to this caution can lead to fire and/or explosion.

The equipment is intended for indoor use only.

• Access to an appropriate power source.

• Access to a network connection, if using.

• Access to calibration gas sources.

• Adequate clearance for the power cord, cables and tubing.

• Adequate clearance for normal use, maintenance and cleaning.

) that is free

2

HONEYWELL PAGE 22 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Mounting Modules on Parallel DIN Rails

1. Prepare the modules for mounting.

a. Disconnect modules that are connected into gangs.

b. Disconnect the power cord, network cable, tubing and inlet filter

assemblies.

c. Remove the end plate.

2. Attach a module to the DIN rails. Repeat as necessary until all modules attached.

a. Hold the module upright with the back panel toward the DIN rails. Place the

top DIN mount over the top of the upper DIN rail and then lower the module

toward the lower DIN rail until it snaps into place.

b. Verify that the module is firmly attached to both the upper DIN rail and the

lower DIN rail.

3. Connect the attached modules into gangs of up to 5, if using. Repeat as necessary

until all gangs are connected.

a. Snap the first module into position on the DIN rail, and then unlock and

raise the latch arm.

b. Snap the second module onto the DIN rail, and then slide it into position

beside the first module. Push the modules firmly together and then lower

and lock the latch arm.

c. Repeat as necessary until the gang is complete.

4. Prepare the module for use. For more information, see Prepare Modules for Use on

page 25.

a. Attach the end plate. Verify that the latch arm is lowered and locked.

b. Connect the inlet filters, tubing, network connection and power cord.

HONEYWELL PAGE 23 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

INTELLIDOX DOCKING MODULE USER MANUAL || ASSEMBLE MODULES

Removing an Individual Module from Parallel DIN Rails

1. Disconnect the power cord, network cable, tubing and inlet filter assemblies.

Remove the end plate.

Find the DIN mount lock on the lower right side of the module.

Hold the DIN mount lock down, and then tilt the module away from the lower DIN rail until

the lower DIN mount is released. Release the DIN mount lock and remove the module

from the upper DIN rail.

Removing Connected Modules from Parallel DIN Rails

1. Disconnect the power cord, network cable, tubing and inlet filter assemblies.

Remove the end plate.

Lift the latch arm between connected modules at the end of the gang.

Find the DIN mount lock on the lower right side of the last module. Hold the DIN mount

lock down, and then slide the module along the DIN rails until it is separated from the

gang.

Hold the DIN mount lock down, and then tilt the module away from the lower DIN rail until

the lower DIN mount is released. Release the DIN mount lock and remove the module

from the upper DIN rail.

Repeat steps 3, 4 and 5 until only one module remains.

Repeat steps 3 and 4 to remove the final module.

HONEYWELL PAGE 24 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Prepare Modules for Use

This section contains instructions and information related to preparing modules for use.

The following topics are included.

HONEYWELL PAGE 25 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Attach the End Plate

The end plate must be attached and locked with the latch arm before connecting power

supply or connecting gas cylinders. The end plate must remain securely latched at all

times during operation. If the end plate is detached during operation, disconnect power

and replace the end plate immediately. Abnormal performance may occur when the end

plate is detached or removed.

Failure to comply may result in incorrect or failed compliance tests or calibrations.

Attaching the End Plate

1. Unlock and raise the latch arm.

2. Attach the end plate. Verify that the end plate is firmly attached and set flush with the

edge of the module.

3. Lower and lock the latch arm.

Removing the End Plate

1. Unlock and raise the latch arm.

Remove the end plate.

HONEYWELL PAGE 26 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connect the Exhaust Tubing

Each IntelliDoX Enabler Kit includes tubing that may be cut to a length that is appropriate

for the exhaust inlet.

The maximum recommended exhaust tubing length is 15 meters (49.5 feet).

Ensure the exhaust line is not connected to a negative pressure system.

Connecting the Exhaust Tubing

1. Inspect the tubing to ensure that it is free of obstructions and defects.

Cut tubing to a length that is appropriate for exhaust, and then attach a male quick

connect fitting to one end.

Connect the exhaust tubing to the exhaust outlet using the quick connect fitting.

Verify that the exhaust tubing is not connected to a negative pressure system, or

obstructed in any way.

HONEYWELL PAGE 27 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connect the Inlet filter

Each IntelliDoX Enabler Kit contains inlet filters. Unless otherwise specified, the purge

inlet is configured to use ambient air in a fresh air environment with a normal atmosphere

of 20.9% v/v O

purge inlet and each unused gas inlet before using the module.

Once connected, the inlet filters help to protect the module from dust ingress. For best

results, replace the inlet filters periodically, or whenever the inlet filter is damaged or dirty.

You may connect an extension tubing to the inlet filter to draw ambient air from an

adjacent fresh air environment.

If an inlet filter is damaged, dirty, or missing, replace it immediately. For replacement

parts, contact Honeywell or an authorized distributor.

Failure to comply may result in damaged equipment.

Connecting the Inlet Filter

that is free of hazardous gas. Verify that an inlet filter is attached to the

2

1. Verify that each inlet filter is free of obstructions and defects.

Connect an inlet filter to the purge inlet.

If necessary, connect an extension tubing to each inlet filter to draw ambient air from an

adjacent fresh air environment.

HONEYWELL PAGE 28 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Insert the Inlet Plugs

Each IntelliDoX Enabler Kit contains inlet plugs. Verify that an inlet plug is inserted into

each unused gas inlet before using the module. Once inserted, the inlet plugs help to

protect the module from dust ingress.

If an inlet plug is damaged or missing, replace it immediately. If plugs are not available,

you may use inlet filters instead. For replacement parts, contact Honeywell or an

authorized distributor.

Failure to comply may result in damaged equipment.

HONEYWELL PAGE 29 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connect the Power

Each IntelliDoX Enabler Kit contains one power supply and AC power cord. Use only the

power supply provided in the Enabler Kit to connect the module to an appropriate

electrical power outlet. When the power is connected, the module activates and a self-test

is performed.

Connecting the Power

1. Verify that the power supply and power cord provided in the Enabler Kit are

compatible with the local power source. If the power supply is not compatible, do not

attempt to connect the module to a power source. Contact Honeywell or an

authorized distributor immediately.

Connect the AC power cord to the power supply.

Connect the power supply into the power connection on the module. Press firmly until you

hear a click. The click confirms that the plug is locked.

Plug the AC power cord into a suitable wall outlet.

When the power is connected, the LCD activates and a self-test is performed.

Disconnecting the Power

To deactivate a module or gang of modules, disconnect the power supply. The module or

gang of modules deactivates immediately and without warning.

1. Retract the plastic cover on the plug to unlock it.

While the cover is retracted, pull the plug out of the module.

To prevent the corruption or loss of data and/or software and/or firmware, do not

deactivate the equipment while performing datalog transfers, bump tests, calibrations

or other operations.

HONEYWELL PAGE 30 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connect the Module to a Network

Individual modules and gangs of up to 5 connected modules may be connected to a

computer network via an Ethernet cable. Gangs of up to 5 modules share one network

connection. Each individual or connected module requires a unique and separate

IP address.

You can manage network settings through an internet browser window or via

FleetManager II software. When modules are connected to a network, you may use Fleet

Manager II software to update firmware, reconfigure modules and detectors, manage

datalog transfers, and automate certain administrative functions.

To improve performance, Honeywell recommends that you assign a static IP

address to each networked module.

To improve security, Honeywell recommends that you change the password for

each networked module.

Before you Begin

1. Verify that you have access to one active network port for each module or gang of up

to 5 connected modules. Network ports are usually managed by a network

administrator. For more information, contact your network administrator or Help Desk.

Have ready one static IP address for each individual or connected module. Static

IP addresses are usually provided by a network administrator. For more information,

contact your network administrator or Help Desk.

Have ready one Ethernet cable for each module or gang of up to 5 connected modules.

Verify that the power supply is connected and the module is activated.

Verify that you have access to a networked computer that is part of the same network as

the module.

Network Passcode

To prevent product tampering on IntelliDoX there is now a Network Passcode menu.

To be granted access to this menu, the user needs to first enter the Module Passcode.

This UI password requirement is designed to stop unauthorized access to view or change

the Network Passcode.

The default password is “000000”. Once in the menu, the user will be prompted to set

a 6 digit numeric password.

An example of the menu and the change passcode screen are shown below:

HONEYWELL PAGE 31 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connecting the Module to a Network

Insert one end of the Ethernet cable into the Ethernet port on the module. Insert the free

end of the Ethernet cable into the network outlet. When the module is connected to the

network, the network symbol is displayed at the top right corner of the LCD.

If the network symbol is not displayed within several seconds, then follow these steps:

1. Verify that the module is activated.

Verify that one end of the Ethernet cable is fully inserted into the Ethernet port on the

module, and then verify that the free end is fully inserted into an active network outlet.

Press and hold until the Adjust docking station settings menu is displayed. Press

or to scroll to About, and then press to display the About screen. If the IP address

displays only zeroes, then the connection is not active.

If problems persist, contact your network administrator or Help Desk.

Connecting IntelliDoX to Fleet Manager

Fleet Manager’s versions older than FMSUMF_08_000 will not require a passcode to

access connect to IntelliDoX.

For newer Fleet Manager versions, Fleet Manager will require entering the Network

Passcode in order to add IntelliDoX. This will be a one time only process. Fleet Manager

will need to send the IntelliDoX the network passcode to verify the connection.

HONEYWELL PAGE 32 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Managing Network Settings through an Internet Browser

You can change network settings and the administrative password for networked modules

through an internet browser. To improve performance, Honeywell recommends that you

assign a static IP address to each networked module. To improve security, Honeywell

recommends that you change the password for each networked module.

Default User Name and Password for Internet Browser Access

The user name and password are case sensitive. Honeywell recommends that you

change the password for each networked module.

• The default user name is admin.

• The default password is admin.

Changing Network Settings and Password through an Internet Browser Window

1. When the module is successfully connected to a network, display the About

summary screen, and then record the IP address for the module. To display the

About summary screen, follow these steps:

a. Press and hold until the Adjust docking station settings menu is

displayed.

b. Press or to scroll to About, and then press to display the About

screen.

From a networked computer, open an internet browser window. In the address bar of the

internet browser window, type http:// followed by the IP address of the module. The

IntelliDoX Login webpage is displayed in the browser window.

HONEYWELL PAGE 33 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Type the user name and password in the text boxes provided, and then click Login. The

Enter Your Network Parameters webpage is displayed in the browser window.

Change the Select Network Type to Static IP, and then type a unique IP address.

Unique IP addresses are usually provided by a network administrator or Help Desk. For

more information, contact your network administrator or Help Desk.

To change the password, type the old password. Type a new password, and then type the

new password again. Click Save to save your settings and return to the IntelliDoX Login

webpage, or click Cancel Changes to abandon the changes and return to the IntelliDoX

Login webpage.

Close the browser window, or type a different IP address in the browser address bar to

change network settings for another module.

Managing Network Settings through Fleet Manager II Software

When you log in to Fleet Manager II software as an administrative user, you can change

network settings and the administrative password for networked modules. For more

information, refer to the Fleet Manager II operator manual.

HONEYWELL PAGE 34 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connect a Calibration Gas Cylinder

The IntelliDoX Enabler Kit includes tubing and quick connect fittings that are appropriate

for use with calibration gas cylinders that are approved for use with this product. For best

results, Honeywell recommends that the tubing is between 39 inches (1 meter) and 33

feet (10 meters) in length for calibration gas cylinders.

Before You Begin

1. Read and understand the warnings and cautions in this section.

Verify that you are in a normal atmosphere (20.9% v/v O2) that is free of hazardous gas.

Verify that the end plate is attached and the latch arm is lowered and locked.

Verify that the exhaust tubing is connected, and that it is free of defects and obstructions.

The maximum recommended calibration tubing length is 10 meters (33 feet). Use of

tubing that is longer than the recommended length may result in inaccurate or failed

compliance tests or calibrations.

A demand flow regulator must be used with all calibration gas cylinder connections.

The module inlet should not be pressurized.

The use of calibration gas cylinders other than those specified by Honeywell may

result in unsafe calibration or possible non-recoverable failure of the equipment, and

will invalidate the warranty.

Do not use calibration gas cylinders past their expiration date.

Ensure that all calibration gas cylinders are in good condition.

Ensure that all calibration gas cylinders contain enough gas.

This equipment uses potentially harmful gas for calibrations. The equipment must be

attached to a venting system or be used in a well-ventilated area.

HONEYWELL PAGE 35 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

INTELLIDOX DOCKING MODULE USER MANUAL || PREPARE MODULES FOR USE

Connecting a Calibration Gas Cylinder

1. Connect a demand flow regulator to the calibration gas cylinder, and then attached

the supplied connector with attached 3/16 inch (9.5 millimeter) I.D. tubing to the

demand flow regulator.

Cut 1/8 inch (3.2 millimeter) I.D. tubing to an appropriate length. Honeywell recommends

that the tubing is between 39 inches (1 meter) and 33 feet (10 meters) in length.

Attach one end of the 1/8 inch (3.2 millimeter) I.D. tubing to the demand flow regulator.

Insert a quick connect fitting into the free end of the tubing, and then connect it to Inlet 1

on the module.

If a multi-inlet key is inserted in an individual module or one or more connected modules in

a gang, then repeat steps 1, 2, 3 and 4 as necessary until up to 4 cylinders are attached.

Configure the gas inlets before using the module. See Configure Gas Inlets on page 41.

HONEYWELL PAGE 36 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Dock Station Settings Menu

This section contains information and instructions for using the Dock Station Settings

menu.

HONEYWELL PAGE 37 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Display the Adjust Dock Station Settings Menu

Display the Adjust dock station settings menu when you want to:

1. Adjust the brightness of the LCD screen;

2. Change date and time settings for the module;

3. Configure gas inlet settings for attached calibration gas cylinders; and

4. Display network and other information about the module.

Displaying the Adjust Dock Station Settings Menu

1. Press and hold on the keypad until the Adjust dock station settings menu is

displayed.

2. Press or on the keypad to select a settings option, and then press to

display the option menu.

HONEYWELL PAGE 38 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Adjust the LCD Brightness

When you adjust and save the settings for one module in a gang, the settings for all of the

modules in the gang are also changed.

Adjusting LCD Brightness

1. Press and hold on the keypad until the Adjust dock station settings menu is

displayed on the LCD.

Press or on the keypad to select Adjust dock station settings menu, and then

press to display the Adjust dock station settings menu.

Press or to adjust the brightness of the LCD screen.

Press to save settings and return to the Adjust dock station settings menu, or press

to return to prior settings.

HONEYWELL PAGE 39 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Adjust Date and Time Settings

Follow these instructions when you want to adjust the module time and date settings

manually via the Adjust dock station settings menu. When you adjust and save the

settings for one module in a gang, the settings for all of the modules in the gang are also

changed.

Adjusting Time and Date via the Module Settings Menu

1. Press and hold on the keypad until Adjust dock station settings is displayed on

the LCD.

Press or to select Adjust time and date and then press . If the procedure is

passcode-protected, then enter the passcode and press to continue.

The Adjust time and date menu is displayed and date settings are ready to edit. Edit the

date settings, or press to skip to the time settings.

a. To set the date, press or to select day, month or year, and then press

or to change the value.

b. To change the date format, press or until the date labels are selected,

and then press or to change the date display to year-month-day, daymonth-year, or month-day-year.

Press to save the date settings and continue, or press to cancel the date changes

and go to time settings. The time settings screen is displayed.

Edit the time settings, or press to skip the date settings and return to the Adjust dock

station settings menu.

a. To set the time, press or to select a hours or minutes, and then press

or to change the value.

b. To change the time format, press or until the time format is selected,

and then press or to change the clock format to 12-hour or 24-hour.

Press to save the changes and return to the Adjust dock station settings menu, or

press to cancel the time settings and return to the Adjust dock station settings menu.

HONEYWELL PAGE 40 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Configure Gas Inlets

For each attached calibration gas cylinder, you must configure the gas blend, and then

configure each gas type and concentration contained in the gas blend. You may also

record the lot number of the calibration gas cylinder.

If a single-inlet key is inserted in an individual module or all connected modules in a gang,

then you can attach one calibration gas cylinder. If a multi-inlet key is inserted in an

individual module or one or more connected modules in a gang, then, then you can attach

up to four calibration gas cylinders. For more information, see Inlet Keys on page 9.

If the module is part of a gang of up to 5 connected modules, then changes to the gas inlet

settings affect all of the modules in the gang. If the gang contains both single-inlet and

multi-inlet key modules, then changes to Inlet 1 affect all modules and changes to Inlets 2,

3 and 4 affect the multi-inlet key modules only.

Configuring Gas Inlets

1. Press and hold on the keypad until Adjust dock station settings is displayed on

the LCD.

Press or to select Configure gas inlets and then press . If the procedure is

passcode-protected, then enter the passcode and press to continue.

2. The Inlet overview for Inlet 1 is displayed. If a multi-inlet key is inserted in an

individual module or one or more connected modules in a gang, then four inlet tabs

are displayed. Press or to select and configure a different inlet.

Configure the gas blend for the selected inlet.

j. Press to display the Inlet edit menu. Gas blend is highlighted.

k. Press to select Gas blend, and then press or to select a single-

gas blend or a multi-gas blend of 2 or more gas types. If the inlet is not

connected to a gas cylinder, select No inlet.

l. Press to save the changes and return to the Inlet edit menu, or press

to abandon the changes and return to the Inlet edit menu.

HONEYWELL PAGE 41 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Configure the gas type for the blend.

m. To configure a gas type in a multi-gas blend, select Gas blend from the

Inlet edit menu, and then press or to select one of the gases

available in the blend.

n. Select gas type from the Inlet edit menu, and then press or to find

and select the type of gas. Verify that the gas type selected matches the

type of gas contained in the calibration cylinder.

o. Press to save the changes and return to the Inlet edit menu, or press

to abandon the changes and return to the Inlet edit menu.

Configure the gas concentration .

p. Verify that the gas concentration displayed on the screen matches the

gas concentration contained in the calibration gas cylinder. If the

concentration does not match, select Concentration: from the Inlet edit

menu, and then press to edit.

q. Press or to configure the gas concentration.

r. Press to save the changes and return to the Inlet edit menu, or press

to abandon the changes and return to the Inlet edit menu.

Record the lot number of the calibration gas cylinder.

s. Select the lot number setting from the Inlet edit menu.

t. Press to edit the lot number, and then press or to find and

select alphabetic, numeric and special characters. Press or to

move to the next character space. Up to 14 characters may be entered.

u. Press to save the changes and return to the Inlet edit menu, or press

to abandon the changes and return to the Inlet edit menu.

Repeat steps 3, 4, 5, and 7 until all of the gas inlets are configured.

Press to close the Inlet edit menu and return to the Inlet overview. Press again to

return to Adjust dock station settings.

HONEYWELL PAGE 42 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Display the Select Language Menu

Use the Select Language menu to change the docking station's display language. You

can select English, French, German, Spanish, or Portuguese.

1. Press and hold on the keypad until

on the LCD.

Press or on the keypad to select

the Select Language menu.

Press or to select a language.

Press to save settings and return to the Adjust Dock Station Settings menu, or press

to return to the prior settings.

Adjust dock station settings is displayed

Select Language, and then press to display

HONEYWELL PAGE 43 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

INTELLIDOX DOCKING MODULE USER MANUAL || DOCK STATION SETTINGS MENU

Display the About Summary Screen

The About information screen displays summary information about the module that may

be helpful when you install or configure modules, such as:

1. Module serial number;

2. Versions of firmware and hardware installed on the module;

3. IP address, and

4. MAC address.

Displaying the About Summary Screen

1. Press and hold on the keypad until Adjust dock station settings is displayed on

the LCD.

2. Press to return to the Adjust dock station settings menu.

HONEYWELL PAGE 44 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

INTELLIDOX DOCKING MODULE USER MANUAL || DETECTOR OPERATIONS

Detector Operations

This section contains information and instructions for inserting a detector and

performing certain operations.

HONEYWELL PAGE 45 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

INTELLIDOX DOCKING MODULE USER MANUAL || DETECTOR OPERATIONS

Insert a Detector

1. Verify that the detector is compatible with the module. The detector model must

match the model displayed on the module lid.

Activate the detector if necessary. If you plan to perform compliance tests, then activate

the detector and verify it is in normal operating mode prior to insertion. If you plan to

configure a compliant detector prior to activation or charge a rechargeable battery, then

activation may not be required. For more information, refer to the appropriate detector

operator manual.

Press the lid release button and lift the module lid. Insert the detector and then close the

lid. Detector identification is displayed.

When the detector is recognized, procedures specified to occur automatically on insertion

are performed. If the detector contains a rechargeable battery, battery charging begins.

Progress screens may be displayed while certain procedures are performed.

After the detector is recognized and automated procedures are completed, the detector

operations menu and What do you need to do? are displayed.

Press or on the keypad to select a menu item. Follow on-screen instructions to

perform the selected procedure.

After the procedures are completed, you may leave the detector in the module for

charging. If the detector is activated, the module will deactivate it after 10 minutes of

inactivity and continue charging the battery. When charging is complete, remove the

detector from the module.

HONEYWELL PAGE 46 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

INTELLIDOX DOCKING MODULE USER MANUAL || DETECTOR OPERATIONS

Detector Operations Menu

After the detector is recognized and automated procedures are completed, the detector

operations menu and What do you need to do? are displayed.

Press or on the module keypad to select a menu item, and then follow on-screen

instructions to perform the selected procedure.

HONEYWELL PAGE 47 OF 117

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

INTELLIDOX DOCKING MODULE USER MANUAL || DETECTOR OPERATIONS

Bump Test

For optimal performance, Honeywell recommends bump testing detectors before

each use. For more information, refer to the appropriate detector operator

manual.

A bump test is a procedure that confirms a detector’s ability to respond to target gases by

exposing the detector to a known gas concentration. The module supports two types of

bump test:

1. FastBump, an accelerated test that performs the bump procedure and event log

transfer only; and

2. Standard Bump Test, a test that performs the bump procedure and other procedures

specified to occur automatically on insertion, such as datalog transfers or firmware

updates.

Before You Begin