Page 1

Operator’s Manual

Single Gas Detector

Page 2

Page 3

ConneX1 Operator’s Manual i

Limited Warranty and Limitation Liability

BW Technologies by Honeywell LP (BW) warrants the product to be free from defects in material and workmanship under nor mal use and service for a period of

two years, beginning on the date of shipment to the buyer. This warranty extends only to the sale of new and unused products to the original buyer. BW’s warranty

obligation is limited, at BW’s option, to refund of the purchase price, repair or replacement of a defective product that is returned to a BW authorized service center

within the warranty period. In no event shall BW’s liability hereunder exceed the purchase price actually paid by the buyer for the Product.

This warranty does not include:

a. fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the product arising from use;

b. any product which in BW’s opinion, has been misused, altered, neglected or damaged, b y accident or abnormal conditions of operation, handling or use; or

c. any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation of unapproved parts on the

product.

The obligations set forth in this warranty are conditional on:

a. proper storage, installation, calibration, use , maintenance and compliance with the product manual instructions and an y other applicable recommendations

of BW;

b. the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No goods shall be returned to BW

until receipt by the buyer of shipping instructions from BW; and

c. the right of BW to require that the buyer provide proof of purchase such as the original invoice, bill of sale or packing slip to establish that the product is

within the warranty period.

The buyer agrees that this warranty is the buyer’s sole and exclusive remedy and is in lieu of all other warranties, express or implied, including but not limited to any

implied warranty of merchantability or fitness for a particular purpose. BW shall not be liable f or an y special, indirect, incidental, lost profits, or consequential damages

or losses, including loss of data, whether arising from breach of warranty or based on contract, tort or reliance or any other theory.

Since some countries or states do not allow limitation of the term of an implied warranty , or exclusion or limitation of incidental or consequential damages , the limitations

and exclusions of this warranty ma y not apply to ev ery buyer . If any provision of this warranty is held invalid or unenf orceable b y a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

Page 4

ConneX1 Operator’s Manualii

Contacting BW Technologies by Honeywell

Corporate Headquarters

BW Technologies by Honeywell

2840 2nd Ave. SE

Calgary, AB

Canada T2A 7X9

+1.403.248.9226 / 1.800.663.4164

+1.403.573.3708

United States

BW Technologies by Honeywell

405 Barclay Blvd.

Lincolnshire, IL

USA 60069

+1.847.955.8200 / 1.800.538.0363

+1.847.955.8210

Europe

BW Technologies by Honeywell

4 Stinsford Road

Nuffield Industrial Estate

Poole, Dorset BH17 0RZ

+44 (0) 1295.700.300

+44 (0) 1295.700.301

info@gasmonitors.com

www.gasmonitors.com

Page 5

ConneX1 Operator’s Manual iii

Table of Contents

1. Introduction ....................................................................................1

1.1 Intended Use

...........................................................................1

1.2 Product Overview

....................................................................2

1.2.1 Parts of the ConneX1

..................................................2

1.2.2 Display Elements .........................................................3

1.2.3 Buttons .........................................................................4

1.3 Sensor Poisons and Contaminants .........................................5

2. Getting Started

...............................................................................6

2.1 Activating/Deactivating the Detector

.......................................6

3. Installing Fleet Manager II

...........................................................11

3.1 Using Fleet Manager II to Configure the Detector

.................11

4. User Options

................................................................................13

4.1 General User Options

...........................................................13

4.1.1 Message Configuration

..............................................15

4.1.2 Mandown Configuration .............................................15

4.1.3 Password Configuration ............................................15

4.2 Sensor and Profile Configuration ..........................................16

4.2.1 Profile Options

...........................................................16

4.2.2 Sensor Options ..........................................................16

4.3 Network Information Options ................................................19

5. Mandown Alarm

...........................................................................20

5.1 Break Mode

...........................................................................20

6. Panic Alarm

..................................................................................21

7. Alarms...........................................................................................21

7.1 Alarm Setpoints

.....................................................................24

7.2 Stopping a Gas Alarm

...........................................................24

7.2.1 Low and High Alarms.................................................24

7.2.2 TWA and STEL Alarms

..............................................24

7.2.3 Acknowledging Latching Alarms ................................24

8. Modes ...........................................................................................25

8.1 Standard Operation

...............................................................25

8.2 Stealth Mode

.........................................................................25

8.3 Safe Mode

.............................................................................25

8.4 Review Mode

........................................................................25

8.4.1 Gas Exposure

............................................................25

8.4.2 Sensor Details ...........................................................26

8.4.3 Detector Details .........................................................26

8.4.4 Messages ..................................................................26

9. Calibration ....................................................................................26

9.1 Calibration Using the IntelliDoX

............................................26

9.2 Calibration Guidelines

...........................................................26

9.3 Installing the Calibration Cap

................................................27

9.3.1 Gas Cylinder Connection

...........................................27

9.3.2 Calibration Gas Concentration ...................................27

9.4 Manual Calibration Procedure ...............................................28

Page 6

ConneX1 Operator’s Manualiv

10. Bump Test ...................................................................................30

10.1 Bump Test Using the IntelliDoX

...........................................30

10.2 Performing a Manual Bump Test

.........................................30

11. Datalogs......................................................................................32

12. Event Logs

.................................................................................32

13. Messaging

..................................................................................32

13.1 Receiving Messages

...........................................................32

13.2 Reading Messages

.............................................................33

13.2.1 Sending Messages

..................................................33

13.3 Panic Alarm Messages .......................................................33

14. LocaXion Manager

.....................................................................34

15. Fleet Manager II..........................................................................34

15.1 Downloading Data To Fleet Manager II

...............................34

15.2 Upgrading the Firmware

......................................................34

15.3 Generating Calibration Certificates

.....................................34

16. Maintenance

...............................................................................34

16.1 Charging the Rechargeable Battery

....................................35

16.1.1 Optimum Battery Operation

.....................................36

16.1.2 Rechargeable Battery Capacity ...............................36

16.2 Replacing the Sensor and Sensor Filter .............................36

16.2.1 Replacing the Sensor

..............................................38

16.2.2 Replacing the Sensor Filter .....................................38

17. WEEE Directive and Battery Directive

.....................................39

17.1 Removal and Disposal of the Rechargeable Battery.

.........39

18. T roubleshooting

.........................................................................41

19. Replacement Parts and Accessories

.......................................53

20. Specifications

............................................................................54

Appendix A Regional Setpoints

.....................................................56

A.1 North America

......................................................................56

Appendix B Configuration Menu Structure

...................................57

Appendix C Review Mode Menu Structure....................................58

Appendix D Datalog Information

....................................................59

Appendix E Event Log Information

................................................59

Page 7

ConneX1 Operator’s Manual v

a Cautions

• Warning: Substitution of components may impair Intrinsic Safety

• Before using the detector, refer to Sensor Poisons and Contaminants.

• Caution: For safety reasons, this equipment m ust be operated and serviced

by qualified personnel only. Read and understand the operator’s manual

completely before operating or servicing.

• Charge the detector before first-time use. BW Technologies by Honeywell

recommends the detector be charged after every workday.

• Calibrate the detector before first-time use and then on a regular schedule,

depending on use and sensor exposure to poisons and contaminants. BW

T echnologies by Honeyw ell recommends that the sensor should be calibrated

regularly and at least once every 180 days (6 months).

• Calibrate only in a safe area that is free of hazardous gas in an atmosphere

of 20.9% oxygen.

• BW Technologies by Honeywell recommends to bump test the sensor bef ore

each day’s use to confirm its ability to respond to gas by exposing the

detector to a gas concentration that exceeds the alarm setpoints. Manually

verify that the audible, visual, and vibrator alarms are activated. Calibrate

if the readings are not within the specified limits.

• Any rapid upscaling reading followed by a declining or erratic reading

may indicate a gas concentration beyond upper scale limit, which can be

hazardous.

• For use only in potentially explosive atmospheres where oxygen

concentrations do not exceed 20.9% (v/v).

• Extended exposure of the detector to certain concentrations of combustible

gases and air may stress an detector element that can seriously affect its

performance. If an alarm occurs due to high concentration of combustible

gases, calibrate the detector. If necessary, replace the sensor.

• Warning: The lithium batter y may present a risk of fire or chemical burn

hazard if misused. Do not disassemble, heat above 212°F (100°C), or

incinerate.

• Warning: Lithium polymer cells exposed to heat at 266°F (130°C) for 10

minutes can cause fire and/or explosion.

• e Warning: This detector contains a lithium polymer battery. Dispose of

used lithium cells immediately . Do not disassemble. Do not dispose of in fire.

Do not mix with the solid waste stream. Spent batteries must be disposed

of by a qualified recycler or hazardous materials handler.

• Keep lithium cells away from children.

• Deactivating the detector by removing the battery pack may cause improper

operation and harm the detector.

• e Warning: At the end of their working lives , sensors must be disposed

of in an environmentally safe manner, in accordance with local waste

management requirements and environmental legislation. Do NO T incinerate

sensors as they may emit toxic fumes.

Page 8

Page 9

ConneX1 Operator’s Manual 1

Introduction

1. Introduction

The ConneX1 is a compact, portable gas detector designed to be carried or worn

without hindering the user. Its purpose is to continuously monitor the atmosphere

continuously for hazardous levels. Audible, visual, and vibratory alarms alert the

user to danger when hazardous conditions are detected.

1.1 Intended Use

The ConneX1 has been designed to alert the user to potentially hazardous

atmospheres while carrying out his/her normal duties. Therefore, the detector

must be kept switched on and worn as close to the breathing area as possible,

and several accessories are provided to allow the detector to be w orn in a number

of different ways:

a. On the chest

b. On a belt

The detector is provided with various methods to enable the user to comply safely

and easily with confined space regulations.

CAUTION

BW recommends that the detector be calibrated at least every 6

months or in accordance with customer site procedures, whichever

is sooner. Correct operation of the detector should be conrmed with

test gas of known concentration before each use.

The use of the IntelliDoX accessory is strongly recommended as it

enables a calibration to be performed quickly and easily.

WARNING

A sensor which cannot be calibrated or which is found to be out of

tolerance should be replaced immediately.

Page 10

ConneX1 Operator’s Manual2

Introduction

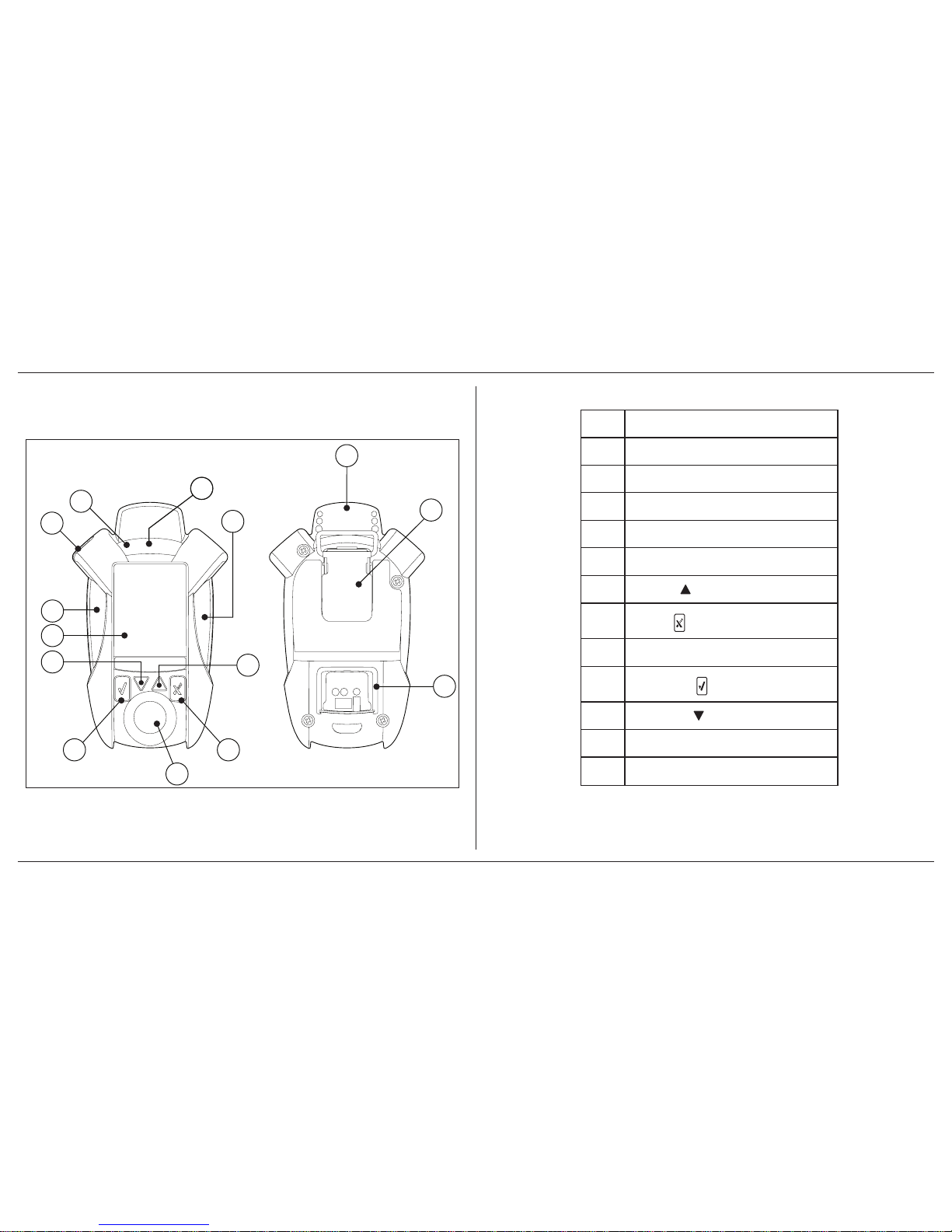

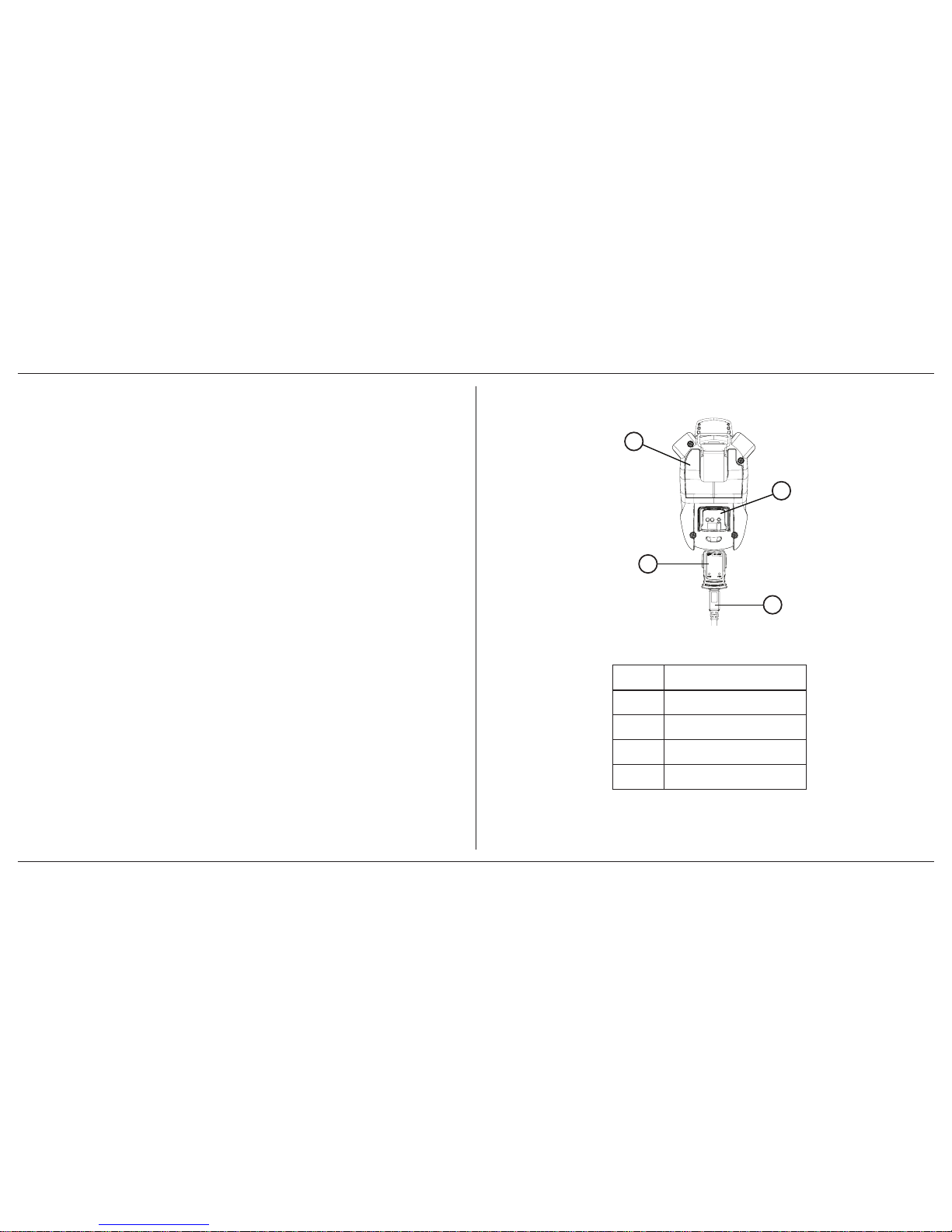

1.2 Product Overview

1.2.1 Parts of the ConneX1

3

4

5

2

6

7

8

9

10

11

2

12

2

11

Figure 1. Parts of ConneX1

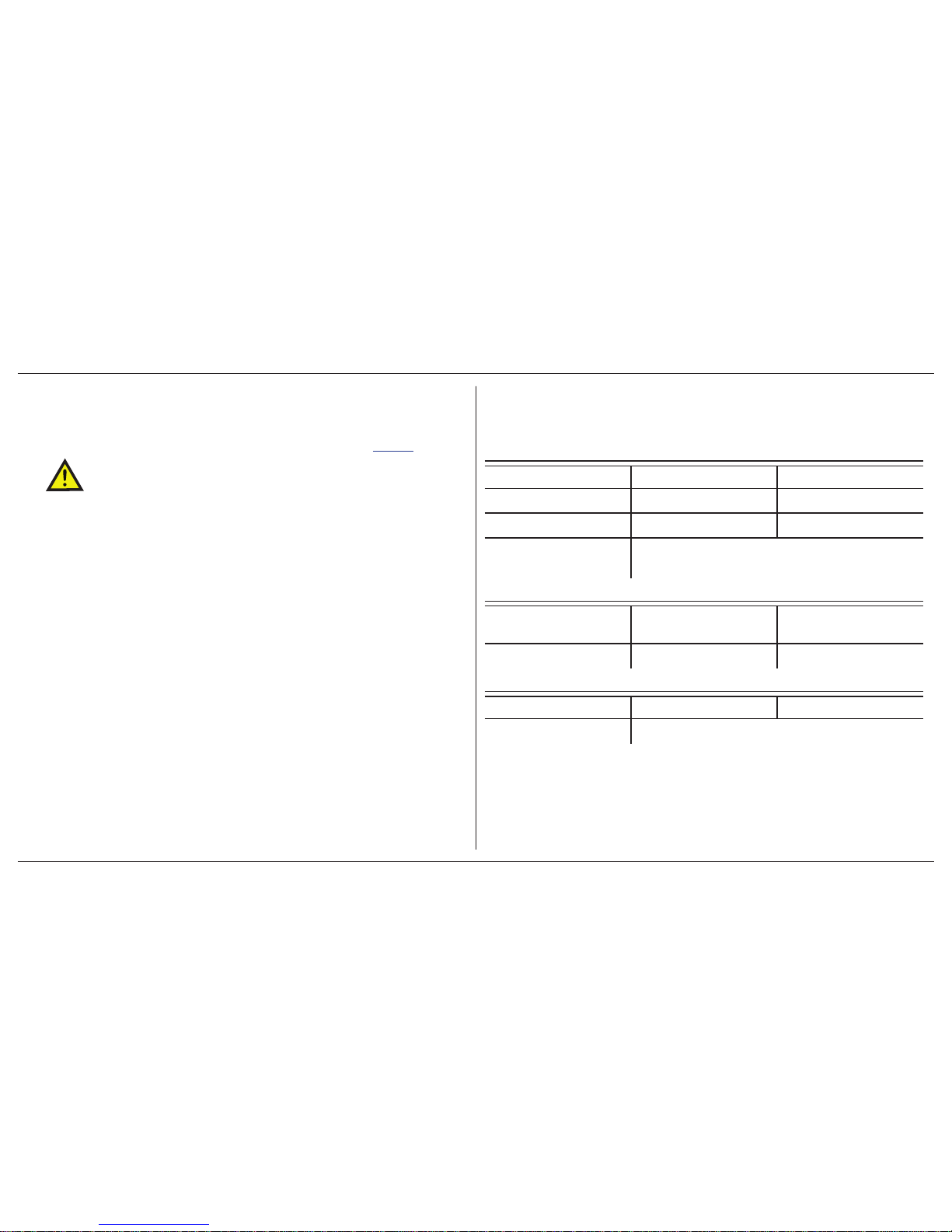

Table 1. Parts of ConneX1

Item Description

1 Condence ash

2 Alarm LED

3 Antenna

4 Belt clip

5 Charge connection/IR Link inferface

6

Up button

7

X button

8

Sensor

9

Check button

10

Down button

11

LCD

12 Beeper

Page 11

ConneX1 Operator’s Manual 3

Introduction

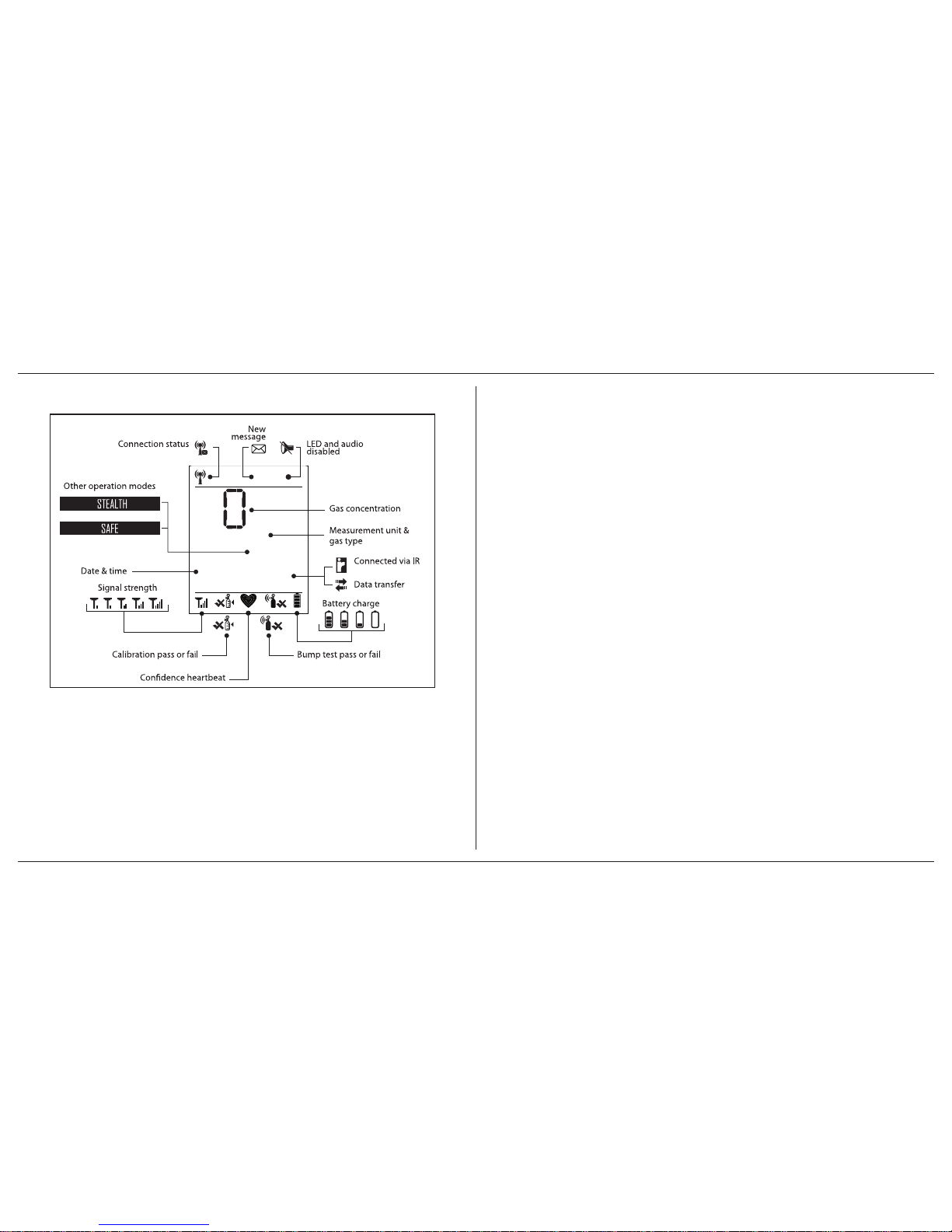

1.2.2 Display Elements

10/13/12

11:21 am

ppm - H2S

Page 12

ConneX1 Operator’s Manual4

Introduction

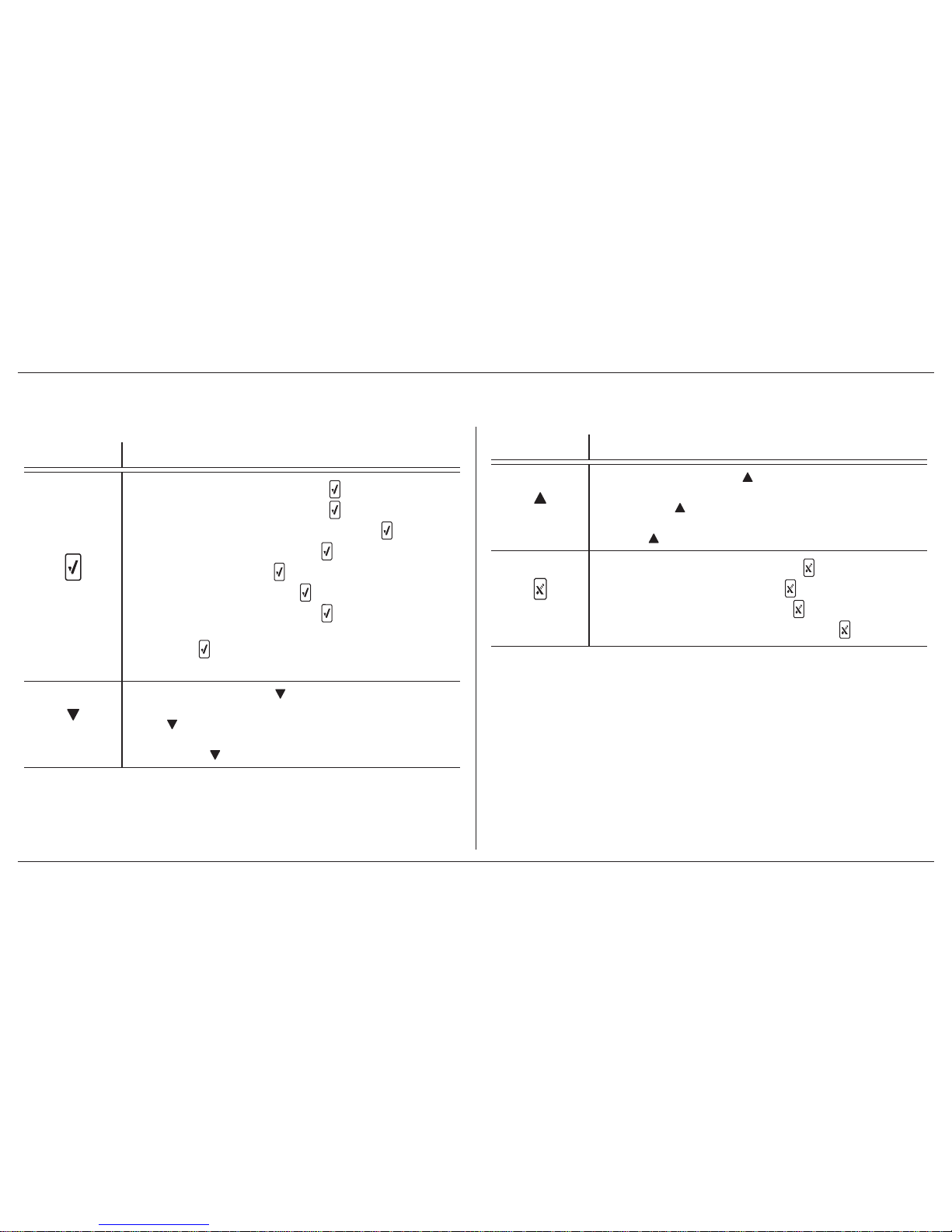

1.2.3 Buttons

Table 2. Pushbuttons

Button Description

Check

• To power on the detector, press and hold for 3 seconds

• To power off the detector, press and hold for 5 seconds

• To read a message when the pop up displays, press

• To enter the Conguration menu, press

• To select a menu item, press

• To select a menu command, press

• To acknowledge a latched alarm, press

• To acknowledge a low alarm and temporarily disable the audible

alarm, press

. The Low Alarm Acknowledgement option must be

enabled in Fleet Manager II

Down

• To enter Quick Review, press

• To decrement the displayed value, scroll down, scroll through digits,

press

• To scroll down an entire screen in Operator and Location menus,

press and hold

Table 2. Pushbuttons

Button Description

Up

• To enter Review Mode, press

• To increment the displayed value, scroll up, or move the cursor to

the right press

• To scroll up an entire screen in Operator and Location menus, press

and hold

X

• To generate a panic alarm, press and hold for 4 seconds

• To clear a panic alarm, press and hold for 4 seconds

• To move to a previous menu level, press

• To abort a menu command while in a menu, press

Page 13

ConneX1 Operator’s Manual 5

Introduction

1.3 Sensor Poisons and Contaminants

Several cleaners, solvents, and lubricants can contaminate and cause permanent

damage to the sensor. Before using cleaners, solvents, and lubricants in close

proximity to the sensor, read the following cautions and refer to Table 3.

CAUTION

Use only the following BW Technologies by Honeywell recommended

products and procedures:

• Use water-based cleaners.

• Use non-alcohol based cleaners.

• Clean the exterior of the detector with a soft, damp cloth

• Do not use soaps, polishes, or solvents

The following table lists common products to avoid using around sensor.

Table 3. Sensor Poisons and Contaminants

Cleaners and Lubricants

Brake cleaners Lubricants Rust inhibitors

Window and glass cleaner Dishsoaps Citrus-based cleaners

Alcohol-based cleaners Hand sanitizers Anionic detergents

Methanol (fuels and

antifreezes)

Silicones

Silicone cleaners and

protectants

Silicon based adhesives,

sealants, and gels

Hand/body and medicinal

creams that contain silicone

Tissues containing silicone Mold releasing agents Polishes

Aerosols

Bug repellents and sprays Lubricants Rust inhibitors

Window and glass cleaners

Page 14

ConneX1 Operator’s Manual6

Getting Started

2. Getting Started

2.1 Activating/Deactivating the Detector

CAUTION

Only activate the detector in a fresh air environment.

Activate: Press and hold for 3 second

Deactivate: Press and hold for 5 seconds.

1. The Segment Testing screen displays.

2. The Splash screen displays.

At this time the detector is running a self-test and auto zero on the sensor.

3. The firmware version, hardware version, and serial number displays.

Page 15

ConneX1 Operator’s Manual 7

Getting Started

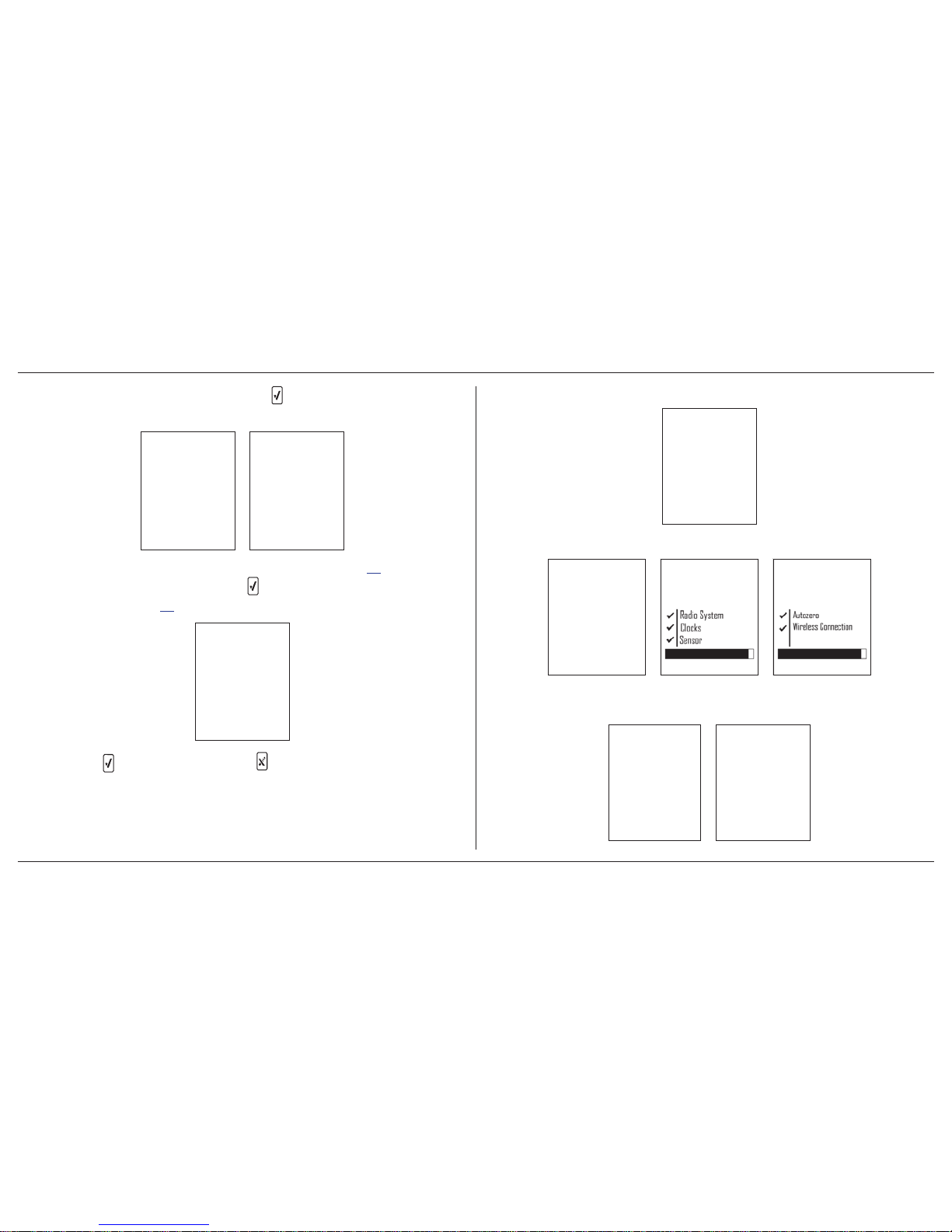

4. If a startup message is enabled in Fleet Manager, the text displays.

5. The current profile, operation mode, and Wi-Fi mode display. For more

information on profiles, refer to 4.2 Sensor and Profile Configuration on

page 16.

6. The detector presents the opportunity to select a different operator. To

confirm the selection, press

or and then to select a different operator .

7. The detector presents the opportunity to select a new location. To confirm

the selection, press

or and then to select a different location.

Page 16

ConneX1 Operator’s Manual8

Getting Started

8. The screen then displays the measuring range, TW A Alarm, STEL Alarm,

Low Alarm, and High Alarm.

9. The detector then completes the sensor self-test.

10. If Auto Zero is enabled, the sensor begins to auto zero.

Page 17

ConneX1 Operator’s Manual 9

Getting Started

11. If the last calibration failed, press to acknowledge. If the failure is not

acknowledged, the detector powers off.

12. If the calibration is overdue, press to acknowledge. If calibration is not

overdue, proceed to step #13.

(Note: “ To start” alternates with “ To continue” every 4 seconds.)

If Force Calibration is enabled, a calibration must be completed before entering

normal operation. If a calibration is not perfor med, the detector automatically

powers off.

13. If Cal Reminder is enabled, the screen displays the number of da ys before

a calibration should be performed.

If Cal Reminder is not enabled, the Calibration Interval displays. Proceed

to step #15.

Page 18

ConneX1 Operator’s Manual10

Getting Started

14. If the last bump test failed, press to accept. If the failure is not

acknowledged, the detector powers off.

If the last bump test was successful, proceed to step #16.

15. If the bump test is overdue, press to accept. If bump test is not ov erdue,

proceed to step #16.

(Note: “ To start” alternates with “ To continue” every 4 seconds.)

If Force Bump Test is enabled, a bump test must be completed before

entering normal operation. If a bump test is not performed, the detector

automatically powers off.

16. The screen displays the number of days until the next bump test.

17. The detector displays a startup summary.

18. If the startup summary is error-free, the screen displays that the startup

sequence is finished. The detector then enters normal operation.

Page 19

ConneX1 Operator’s Manual 11

Installing Fleet Manager II

3. Installing Fleet Manager II

Fleet Manager II is required to configure the detector. To install Fleet Manager II,

refer to the Fleet Manager II CD-ROM that includes the

• installation wizard, and

• Fleet Manager II Operator’s Manual (located under Help)

3.1 Using Fleet Manager II to Configure the

Detector

1. Activate the detector and wait for the startup sequence to complete.

2. Connect the USB cable to the USB port of the computer.

NOTE Plug the USB into the same USB port where the USB drivers

were installed.

3. Connect the USB cable to the IR Link.

4. Insert the IR Link into the IR interface on the back of the detector.

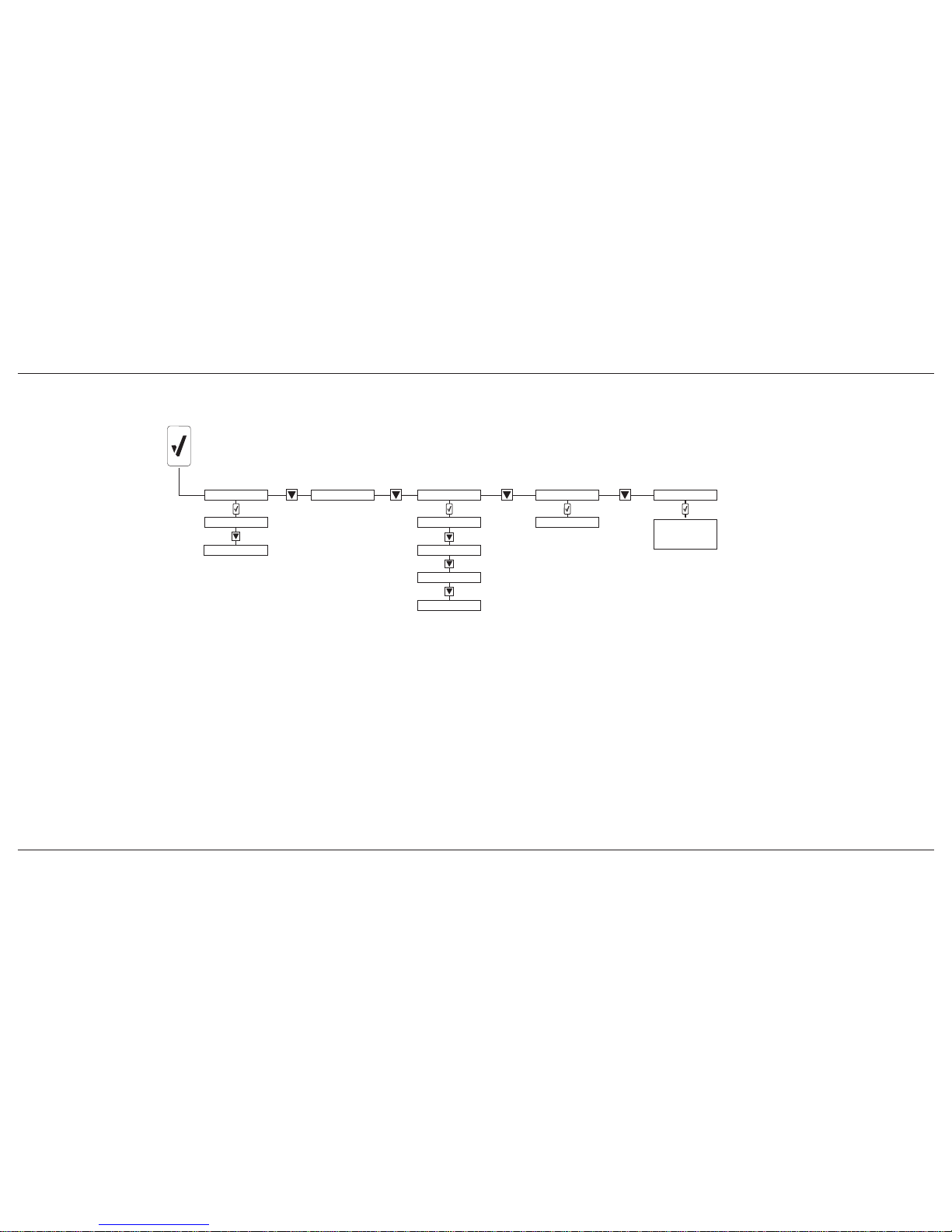

Figure 2. Connecting the IR Link

1

2

3

4

Table 4. Connecting the IR Link

Item Description

1 Detector

2 IR Link interface

3 IR Link

4 USB cable

Page 20

ConneX1 Operator’s Manual12

Installing Fleet Manager II

5. From the PC, open Fleet Manager II.

The following screen displays when the IR Link is connected to the detector .

6. Click Administration.

7. From the Administration toolbar, click Login / Logout to access the

Enter Password dialog box. Enter Admin and click OK (password is

case sensitive).

8. From the Devices toolbar, click Configure Device via IR Link.

9. The Device selection popup displays. Select ConneX1 and click OK.

10. From the configuration window, click Retrieve from Device at the bottom

of the window. The fields automatically populate with the detector’ s current

configuration settings.

11. Refer to 4. User Options on page 13 for descriptions about how to enter

data, enable/disable, and define settings.

12. When all settings are defined, click Save to Device at the bottom of the

window. The detector is now updated with the new settings.

Page 21

ConneX1 Operator’s Manual 13

User Options

4. User Options

User options can be configured using Fleet Manager II.

4.1 General User Options

Backlight timeout (seconds): Define how long (0-30 seconds) the bac klight will

stay lit after pressing a button. The default value is 10 seconds. This does not

affect the backlight behaviour during alarms, startup sequence, critical system

faults, and powering off. Default is XX seconds.

Enable Calibration Lock: If enabled, the sensor can only be calibrated when

calibration is initiated from Fleet Manager II or with the IntelliDoX.

Confidence Beep/Flash Interval (seconds): The field defines how often the

confidence beep (5-255 seconds) and confidence flash (1-120 seconds) occur

(The default confidence beep interval is 10 seconds. The default flash interval is

1 second). Enter the desired value.

Date Format: Choose how the date will display, either day/month/year or month/

day/year. Select dd/mm/yyyy or mm/dd/yyyy. Default is mm/dd/yyyy.

Distributor Contact Information: Contact information (phone number or email)

of the distributor.

Distributor Name: Name of the distributor company.

Enable Force Bump: If Force Bump is enabled and the sensor is past due for a

bump test, the following screen displays during the startup self-tests.

(Note: “ To start” alternates with the progress bar every 4 seconds.)

The sensor must be bump tested to continue and enter normal operation. Press

, and refer to 10.2 Performing a Manual Bump Test on page 30.

Or

Press and hold

to deactivate the detector.

A value must be entered in the Bump Interval (days) field in the Sensor

Configuration section before enabling Force Bump.

CAUTION

If 0 is entered in the Bump Interval (days) eld, the Force Bump

option is automatically disabled.

Page 22

ConneX1 Operator’s Manual14

User Options

NOTE BW Technologies by Honeywell recommends to bump test the

sensor before each day’s use to conrm its ability to respond

to gas by exposing the detector to a gas concentration that

exceeds the alarm setpoints. Verify that the audible and visual

alarms activate. Calibrate if the readings are not within the

specied limits.

For complete instructions to perform a bump test, refer to 10.2 P erforming a Manual

Bump Test on page 30.

The detector is shipped with the Force Bump option disabled.

Enable Force Calibration: If enabled and a sensor is past due for calibration or

the last calibraiton failed, the follo wing screen displays during the startup self-tests.

The sensor must be calibrated to continue and enter normal operation. Press ,

and refer to 9.4 Manual Calibration Procedure on page 28.

Or

Press and hold

to deactivate the detector.

A value must be entered in the Cal Interval (da ys) field in the Sensor Configuration

section before enabling Force Calibration.

CAUTION

If 0 (zero) is entered in the Cal Interval (days) eld, the Force

Calibration option is automatically disabled.

The detector is shipped with the Force Calibration option disabled.

Language: Choose the display language. All screens are displayed in that

language. Currently, only English is available . Later releases of firmware will hav e

other languages.

Locations: List of locations that can be assigned as the default location. Up to

20 locations can be customized.

Log Interval (seconds): This field defines how often the detector records a

datalog (1 to 600 seconds).

The total number of 8-hour days datalogs that can be recorded is assuming 90%

of the day has no gas concentrations.

Table 5. Datalog Storage Capacity

Datalog Interval Total Number of Days Datalogs Can Be Recorded

5 seconds up to 15 days

15 seconds up to 45 days

60 seconds up to 180 days

Page 23

ConneX1 Operator’s Manual 15

User Options

CAUTION

When the memory is full, the detector replaces the oldest datalogs

with the most recent datalogs.

The detector is shipped with the default setting of 5 seconds.

Operators Name: List of names that can be assigned as the default operator . Up

to 10 operator names can be customized.

Owner Name: Name of the detector owner. Field can be used to identify personnel

responsible for detector upkeep.

Profile Name/Default: Choosing a profile pre-selects user options appropriate to

the working condition. Ref er to Fleet Manager II Operator’s Manual to set up profiles .

Refer to Appendix A Regional Setpoints on page 56.

Serial Number: Displays the unique serial number of the detector. This is a read-

only field. Serial number is factory defined

Time Format: Select the 12-hour clock or 24-hour clock in time stamps. Select

from 12 (12-hour clock) or 24 (24-hour clock). Default is 12-hour clock.

Wireless Mode Selection: If enabled, the user can enable or disable WiFi. The

detector is shipped with Wireless Mode Selection enabled.

4.1.1 Message Configuration

Pre-Configured Message: Create messages to respond to received messages

sent from LocaXion Manager (20 characters maximum). These messages are

used to communicate with LocaXion Manager.

Enable Startup Message: When checked, a message will displa y on the detector

LCD during startup.

Startup Message: Enter text to display on the detector LCD during startup (25

characters maximum).

4.1.2 Mandown Configuration

For more information, refer to 5. Mandown Alarm on page 20.

Enable Mandown Feature: If enabled, the detector alarms if movement is not

detected after a certain time period. The time period is defined in Mandown Timeout.

Mandown Idle Time: Defines how long no motion must be detected before a

Mandown alarm (10 to 240 seconds). The default value is 10 seconds.

Mandown Sensitivity: Define the sensitivity of the detector accelerometer. 100

equals high sensitivity and 0 equals low sensitivity.

4.1.3 Password Configuration

Enable User Config Password: When enabled, a password must be entered

to to enter Configuration Menu on the detector. The detector is shipped with the

password disabled.

Enable Passwor d Protection for Device Shutdo wn: When enabled, a pass word

must be entered to deactivate the detector. The detector is shipped with the

password disabled.

Password: Set the 4-digit password.

Page 24

ConneX1 Operator’s Manual16

User Options

4.1.3.1 Entering a Password

To enter the password on the detector. Complete the following procedure.

1. Change the digit by pressing to increment the digit and to decrement

the digit. Mov e the cursor to the next digit by pressing . Move the cursor

to the previous digit by pressing .

2. When at the last digit and the correct number is selected, press to

enter the password.

4.2 Sensor and Profile Configuration

A profile is a set of configuration options which allows the user to quickly change

the configuration and behaviour of the instrument, depending on the situation.

4.2.1 Profile Options

Beep per key press: If enabled, ev ery time a button is pressed, the beeper sounds.

The detector is shipped with the beep per key press enabled. Beep per key press

is disabled if Stealth Mode is enabled.

Confidence Beep: If enabled, the Confidence Beep provides continuous audible

confirmation that the detector is operating correctly. Frequency of the beep is

defined with Confidence Beep/Flash Interval (seconds).

NOTE The condence beep automatically disables if the bump test is

overdue, low battery, calibration is overdue, watchdog timer,

self-test fail, any alarm condition, any warnings or faults.

The detector is shipped with confidence beep disabled.

IntelliFlash: If enabled, a green LED flashes to indicate the detector is operating

correctly . The Confidence Flash deactiv ates during a low battery alarm, calibration

fail, bump test fail, self-test fail, and during an alar m condition. Frequency of the

flash is defined with Confidence Beep/Flash Interval (seconds).

Latching Alarms: If enabled, during an alarm condition the Latching Alarms option

causes the low and high gas alarms (audio, visual, and vibrator) to persist until the

alarm is acknowledged and the alarm condition no longer exists. The LCD displa ys

the peak concentration until the alarm no longer exists. Local regulations in your

region may require the Latching Alarms option be enabled.

The detector is shipped with the Latching Alarms option disabled.

Default Operation Mode Selection: Defines the operation mode as Standard,

Stealth, or Safe. Refer to 8. Modes on page 25 for more information.

WiFi: Enable/disable WiFi. If WiFi is disabled,

and display on the LCD. The

detector is shipped with the WiFi enabled.

4.2.2 Sensor Options

4.2.2.1 Alarm Settings by Profile

NOTE The alarm setpoints are different between the two proles.

Low Alarm: Define the low alarm setpoints for each sensor . Refer to Appendix A

Regional Setpoints on page 56 for alarm setpoints.

Page 25

ConneX1 Operator’s Manual 17

User Options

High Alarm: Define the high alarm setpoints for each sensor. Refer to Appendix

A Regional Setpoints on page 56 for alarm setpoints.

STEL Alarm: The short-term exposure limit (STEL) is the maximum permissible

gas concentration a worker can be safely exposed to for short per iods of time

(5-15 minutes maximum). For toxic sensors only.

Refer to Appendix A Regional Setpoints on page 56 for alarm setpoints.

NOTE Standard factory alarm setpoints may vary by region. Refer to

Appendix A Regional Setpoints on page 56.

TWA Alarm: The time-weight a verage (TW A) is a safety measure used to ca lculate

accumulated averages of gases. Using the US Occupational Safety and Health

Administration (OSHA) method or the American Conference of Governmental

Hygienists (ACGIH) method, an average is calculated to ensure the detector

alarms when the TWA has accumulated. For toxic sensors only.

Refer to Appendix A Regional Setpoints on page 56 for alarm setpoints.

4.2.2.2 Sensor Configuration

NOTE The sensor conguration settings are the same between the

two proles.

20.8 based: When enabled, the detector assumes 20.8% O

2

as ambient air (factory

default is 20.9% O2). Applicable to the O2 sensor only.

The detector is shipped with the 20.8 based option disabled.

Auto Zero on Startup: When enabled, the sensor automatically zeros during

the startup sequence.

The detector is shipped with the Auto Zero on Startup option enabled.

Enable Low Alarm Acknowledgement: If enabled, the audible alarm can

be disabled during a low alarm. The LEDs and visual alar m indicators remain

active until the gas concentration changes or the detector deactivates. For toxic

sensors only.

Press

to acknowledge the low alarm and deactivate the audible alarm. If the

alarm escalates to a high, TWA, or STEL alarm, the audible alarm reactivates.

The detector is shipped with the Low Alarm Acknowledgement disabled.

STEL Period: The STEL Interval option pro vides protection for work ers from over

exposure to high concentrations of gas, and is based on user-defined 5-15 minute

intervals. When the maximum STEL is reached, the detector alarms to notify the

worker. For toxic sensors only.

CAUTION

Follow all safety procedures as dened by your employer.

Enter the interval (5-15 minutes) in the STEL Interval (minutes) field. The detector

is shipped with a default setting of 15 minutes.

TWA Method: The TWA Method defines the TW A calculating method. Select either

the US Occupational Safety and Health Administration (OSHA) or the American

Conference of Governmental Industrial Hygienists (ACGIH) TWA calculating

method. The detector is shipped with the default method of US OSHA. For toxic

sensors only.

• US OSHA Method: 8 hours moving average

The US OSHA method is defined as a moving average that accum ulates

over an 8-hour average. If the worker is in the field longer, the oldest

accumulated values (first hour) are replaced by the newest values

Page 26

ConneX1 Operator’s Manual18

User Options

(ninth hour). This continues for the duration of the work shift until the

detector is deactivated.

• ACGIH Method: Infinite accumulated average to 8 hours

The ACGIH method is defined as the infinite (total) accumulated

average, where it is 2 hours or 8 hours.

TWA P eriod: The TWA Period (hours) option calculates a time-weighted moving

average of accumulated gases o ver a period of 4-16 hours, to ensure the detector

alarms when the defined maximum average is accum ulated. F or toxic sensors only.

Example: The TWA Period option is set to 8 hours. Therefore, the moving a verage

accumulates over a 8-hour average. If the worker is in the field longer, the oldest

accumulated values (first hour) are replaced by the newest values (ninth hour).

This continues for the duration of the work shift until the detector is deactivated.

NOTE Regulations may vary depending upon region. Adhere to the

regulations dened for your area.

Enter the period (4-16 hours) in the TWA Period (hours) field. The detector is

shipped with a default setting of 8 hours.

4.2.2.3 Calibration and Bump Setup

NOTE The calibration and bump test settings are the same between

the two proles.

Bump Interval: Define how often the sensor should be calibrated.

1. Enter the value (0-365 days) for the sensor.

2. Enter 0 to disable the bump interval option. The detector is shipped with

the factory default setting of 0 days.

Bump Response Time (seconds): Define the maximum response time for the

detector to react to bump test gas.

Bump Threshold (%): Define the minimum bump test gas concentration that

must be registered by the detector to pass the bump test.

Cal Gas concentration (ppm):

WARNING

The gas concentration value entered in Fleet Manager II must match

the gas concentration value on the gas cylinder.

Enter the gas concentration value in the Calibration gas (ppm) field.

Cal Interval (days): Define how often the sensor should be calibrated.

1. Enter the value (0-365 days) for the sensor.

2. Enter 0 to disable the calibration interval option. Entering 0 automatically

deactivates the Force Calibration option. The detector is shipped with

the factory default setting of 180 days.

CAUTION

BW Technologies by Honeywell recommends that the sensor be

calibrated at least once every 180 days (6 months).

Page 27

ConneX1 Operator’s Manual 19

User Options

Cal Reminder (days): A reminder for the next calibr ation will display a n umber of

days before the calibration is due . The reminder can appear anywhere from 0-365

days before the calibration due date.

Enter 0 automatically deactivates the Cal Reminder option. The detector is shipped

with a default setting of 10 days.

Bump Interval (days): Define how often a bump test should be perfor med for

each sensor in the Bump Interval (days) field. A different bump interval can be

defined for each sensor.

1. Enter the value (1-365 days) for each sensor.

2. Enter 0 to disable the bump interval option. Enter 0 automatically

deactivates the Force bump option.

The detector is shipped with the factory default setting of 0 days.

NOTE BW Technologies by Honeywell recommends to bump test the

sensor before each day’s use to conrm its ability to respond to

gas by exposing the detector a gas concentration that exceeds

the alarm setpoints. Verify that the audible and visual alarms

activate. Calibrate if the readings are not within the specied

limits.

4.3 Network Information Options

NOTE For best results, consult with your IT department for optimal

settings.

Use DHCP: When enabled, a dynamic IP address is assigned to the detector.

Use a Static IP Address: When enabled, a static IP address is assigned to the

detector.

• Static IP Address: Assign a static IP address to the detector

• Gateway: Enter the Gateway address

• Subnet Mask: Enter the Subnet Mask

Scan Channel List: Lists the channels the detector will scan for a signal. Click

Edit to add more channels to the list. Default is all channels.

Security Mode: Select the type of security. Choose from WEP, WPA-Personal,

WPA2-Personal, and WPA2-Mixed. Select disabled for no security.

Security Key: Enter the password to access the network.

SSID: Enter the name of the network.

LocaXion Manager IP Address: Enter the IP address of the computer running

LocaXion Manager.

LocaXion Manager UDP Port: Leave as default 50009.

Page 28

ConneX1 Operator’s Manual20

Mandown Alarm

5. Mandown Alarm

activated!

Mandown

activated!

To cancel

Mandown

PANIC ALARM

The Mandown feature allows sueprvisors to take action if no motion is detected.

If no motion is detected for a user-defined period, the Mandown notification screens

display for 10 seconds, alternating between “To cancel” and the countdown bar

every 2 seconds. If the alar m is not cancelled by pressing

, the Panic Alarm

activates and a Help message is sent to LocaXion Manager.

Mandown Alarm is temporarily disabled while the detector is in IntelliDoX,

communicating with Fleet Manager via IR Link, and charging.

For more information on Panic Alarm, refer to 6. Panic Alarm on page 21.

5.1 Break Mode

If the Mandown Alarm needs to be temporarily disabled, press and hold and .

The detector will flash, beep, and vibrate once to indicate Break Mode is active.

The LCD indicates that Break Mode is active.

Break Mode will deactivate after 30 minutes.

Page 29

ConneX1 Operator’s Manual 21

Panic Alarm

6. Panic Alarm

Starting

panic alarm...

3

PANIC ALARM

When Panic Alarm is activated, the detector activates the LEDs and audible

alarm to maximum volume to alert nearby personnel for help. The detector sends

a message to LocaXion Manager so the operator can send assistance. The

detector will continue to send a message to LocaXion Manager until the operator

acknowledges that the message has been received. LocaXion Manager cannot

be operated until the message has been acknowledged.

To activate the Panic Alarm, press and hold

for 2 seconds. This will prompt the

Panic Alarm warning. Continue to hold for 3 more seconds to activate the alarm.

Follow the same procedure to deactivate the alarm.

7. Alarms

Gas alarms are one of four cautionary notifications for the detector. See Table 7.

Recommended Calibration Gas Concentration on page 27 for infor mation on

severity of the cautionary notifications.

When an alarm occurs the heartbeat icon disappears, and if enabled, the

confidence beep and confidence beep discontinue.

Table 6. Alarms describes the detector alarm and corresponding behaviour.

Page 30

ConneX1 Operator’s Manual22

Alarms

Table 6. Alarms

Alarm Screen Alarm Screen

Low Alarm

• Slow siren (upward tone)

• Slow LED ash

• Vibrator alarm activates

• Backlight activates

High Alarm

• Fast siren (downward tone)

• Fast LED ash

• Vibrator alarm activates

• Backlight activates

TWA Alarm

• Fast siren (downward tone)

• Fast LED ash

• Vibrator alarm activates

• Backlight activates

STEL Alarm

• Fast siren (downward tone)

• Fast LED ash

• Vibrator alarm activates

• Backlight activates

Over Limit (OL) Alarm

• OL displays in gas channel;

• Fast siren (downward tone)

• Fast ash

• Vibrator alarm activates

• Backlight activates

• Note: LCD may also display an underlimit reading (-OL)

Low Battery Alarm

• Sequence of 10 rapid sirens and alternating ashes

with 7 seconds, lasting 15 minutes

• Empty battery icon ashes

• Vibrator alarm pulses

• Backlight activates

• After 15 minutes of the low battery alarm sequence,

the detector enters critical battery alarm (see Critical

Battery Alarm below)

Page 31

ConneX1 Operator’s Manual 23

Alarms

Alarm Screen Alarm Screen

Mandown

1. A sequence 10 consecutive beeps f

2. Alternating LED ashes and vibrator

3. Silence for 3 seconds then the cycle repeats.

Critical Battery Alarm

• 15 minutes after the low battery alarm activates, a

sequence of 10 rapid sirens and alternating ashes with

1 second of silence in between (sequence reactivates

seven times

• Vibrator alarm pulses

• Fast ash

• Backlight activates

Panic Alarm

• Maximum beeper volume

• Fast ash

• Vibrator pulses

• Backlight activates

PANIC ALARM

An alarm stops when the gas concentration is below the low alarm setpoint. If the alarms are set to latch, press to reset the alarms.

Page 32

ConneX1 Operator’s Manual24

Alarms

7.1 Alarm Setpoints

To change the alarm setpoints, refer to 4.2.2 Sensor Options on page 16.

To see the regional alarm setpoints, refer to Appendix A Regional Setpoints on

page 56.

7.2 Stopping a Gas Alarm

7.2.1 Low and High Alarms

The low and high gas alarms stop when the gas concentration is below the alarm

setpoints. If the Latching Alarm option is enabled in Fleet Manager II, ref er to 7.2.3

Acknowledging Latching Alarms on page 24.

7.2.2 TWA and STEL Alarms

WARNING

Follow all safety procedures as dened by your employer. Conrm

with your supervisor before clearing the TWA and STEL alarms.

TWA and STEL alarms can be stopped either by

• deactivating and then reactivating the detector, or

• clearing the TWA/STEL/peak exposure readings. Refer to 8.4 Review

Mode on page 25.

7.2.3 Acknowledging Latching Alarms

If the Latching Alarm option is enabled, during an alarm the low and high gas

alarms (audible, visual, and vibrator) persist until the alarm is acknowledged and

the gas concentration is below the low alarm setpoint.

Press

to acknowledge a latched alarm.

Local regulations in your region may require the Latching Alarms option be enabled.

Page 33

ConneX1 Operator’s Manual 25

Modes

8. Modes

Selecting one of five modes determines how the detector behaves during alarms

and during gas-free conditions.

8.1 Standard Operation

In standard operation is the default mode. It displays the gas channels and icons.

When an alarm occurs, the audible, visual and vibrator alarms activate.

8.2 Stealth Mode

In Stealth Mode, the audible and visual alarms are disabled. The icon display

on the LCD. When an alarm does occur, the vibrator alarm activates and the LCD

displays the alarm condition, and the audible and visual alarms do not activate.

8.3 Safe Mode

If there is no alarm, the LCD displays Safe instead of real time gas readings, gas

name, or measurement units. When an alarm occurs it will exit safe mode and

display the alarm icon and peak gas reading, The audible, visual, and vibrator

alarms activate normally.

8.4 Review Mode

In Review Mode, the user can view the

• 8.4.1 Gas Exposure on page 25

• 8.4.2 Sensor Details on page 26

• 8.4.3 Detector Details on page 26

• 8.4.4 Messages on page 26

Press

to enter Review Mode.

8.4.1 Gas Exposure

Viewing gas exposure readings for the sensor, shows the

• peak reading

• minimum reading

• STEL reading (only applicable for toxic sensor)

• TWA reading (only applicable for toxic sensor)

Press

or to scroll through the gas exposures.

To reset the peak gas exposures, press when prompted.

Page 34

ConneX1 Operator’s Manual26

Calibration

8.4.2 Sensor Details

The information can also be viewed/altered in Fleet Manager II.

• Measuring range

• Low Alarm setpoint

• High Alarm setpoint

• TWA alarm setpoint

• STEL Alarm setpoint

• Calibration due date

• Bump test due date

8.4.3 Detector Details

The following information details the detector settings.

The following information can also be viewed or changed in Fleet Manager.

• Current operator and location

• Current profile and operation mode

• Owner and WiFi status

• Software version, hardware revision, and serial number

• MAC address, IP address, and WiFi network name

• Distributor details

• Date format

• Time format

8.4.4 Messages

• Messages received from LocaXion Manager

• Messages sent to LocaXion Manager

9. Calibration

A calibration is performed to adjust the sensitivity levels of the sensor to ensure

accurate responses to gas.

9.1 Calibration Using the IntelliDoX

If Cal IR Lock is enab led, calibration must be completed with the IntelliDoX. Ref er

to on page 12 or the IntelliDoX Technical Reference Guide for more information.

9.2 Calibration Guidelines

• Calibrate only in a fresh air environment. Do not calibrate in a hazardous

area.

• The maximum hose length for calibration is 1 ft. (30 cm).

• To cancel the calibration or zero sensor, press .

• For calibration troubleshooting, refer to Table 13. Calibration Error

Screens on page 49

Page 35

ConneX1 Operator’s Manual 27

Calibration

9.3 Installing the Calibration Cap

9.3.1 Gas Cylinder Connection

Gas Cylinder Guidelines

• To ensure accurate calibration, use a premium-grade calibration

gas. Use gases approved by the National Institute of Standards and

Technology or equivalent.

• If a certified calibration is required, contact BW Technologies by

Honeywell.

• Do not use a gas cylinder past its expiration date .

Read the following steps prior to initiating a calibration or a bump test.

1. Verify the calibration gas being used matches the span concentration

value(s) that are set for the detector.

2. Connect the calibration hose to the 0.5 l/min regulator on the gas cylinder.

3. Connect the calibration hose to the intake inlet on the calibration cap.

Begin the calibration or bump test procedure. Do not attach the calibration

cap until instructed to apply gas.

4. When instructed, place the calibration cap on the detector

When calibration is complete, turn off the gas, and disconnect the hose from the

calibration cap and the regulator. Remove the calibration cap from the detector.

9.3.2 Calibration Gas Concentration

Refer to the table below for recommended gas concentrations for calibrations:

Table 7. Recommended Calibration Gas Concentration

Gas Type Allowable Range

Carbon monoxide 50 ppm to 500 ppm

Hydrogen sulde 15 ppm to 50 ppm

Oxygen 18% vol

Sulfur dioxide 5 ppm to 20 ppm

Page 36

ConneX1 Operator’s Manual28

Calibration

9.4 Manual Calibration Procedure

To cancel calibration at any time, press .

1. From normal operation, press to enter Configuration Mode. Press

to select Calibration.

2. In the Calibration menu, scroll down and select Calibration.

3. The detector zeroes the sensor before the calibration.

4. When the zero calibration is complete, attach the calibration cap and apply

the calibration gas at a flow rate of 0.25-0.50 L/min.

Gas concentration 25ppm

Apply gas now

waiting... 300

If Cal IR Lock is enabled, the f ollowing screen displays to i ndicate calibration

can only be performed using an IR device (IntelliDoX or IR Link Adapter).

5. Once the detector has detected a sufficient amount of gas, the detector

begins calibration of the sensor.

25ppm

Calibrating

ppm - H2S

Page 37

ConneX1 Operator’s Manual 29

Calibration

6. When the following screen displays, close the valve on the gas cylinder

and remove the calibration cap from the detector.

7. When calibration is complete, the following screen displays.

8. The calibration due date resets to the number of days defined in the Cal

Interval field in Fleet Manager II.

9. The detector now enters normal operation.

Page 38

ConneX1 Operator’s Manual30

Bump Test

10. Bump T est

A bump test is the process of applying a small amount of test gas to force the

detector into alarm. A bump test should be perf ormed daily to confirm the sensor is

responding correctly to gas, and that the audible, visual, and vibrator alarms activate

during an alarm condition. Calibrate if the readings are not within specified limits.

10.1 Bump Test Using the IntelliDoX

The IntelliDoX can peform bump tests. Refer to the IntelliDoX Technical Reference

Guide for more information.

10.2 Performing a Manual Bump Test

CAUTION

BW Technologies by Honeywell recommends to bump test the sensor

before each day’s use to conrm its ability to respond to gas by

exposing the sensor to a gas concentration that exceeds the alarm

setpoints.

Follow this procedure when Force Bump is enab led and a bump test is required

during startup. To perform a bump test with the IntelliDoX, refer to the IntelliDoX

Technical Reference Guide.

1. Connect the calibration hose to the 0.3 l/min regulator on the gas cylinder.

2. Connect the calibration hose to the intake inlet on the calibration cap. Ref er

to 9.3 Installing the Calibration Cap on page 27.

3. Press to enter Configuration Mode. Scroll do wn to Bump Test. Press .

4. When the following screen displays, attach the calibration cap and apply

bump test gas at a flow rate of 250-500 mL/min. Ref er to 9.3 Installing the

Calibration Cap on page 27.

Page 39

ConneX1 Operator’s Manual 31

Bump Test

5. When the sensor detects sufficient gas to enter an alarm state, all expected

alarm responses are tested. Test results are displayed on screen.

beeping...

ppm - H2S

flashing...

ppm - H2S

vibrating...

ppm - H2S

6. When the following screen displays, close the valve on the gas cylinder

and remove the calibration cap from the detector.

7. When bump test is complete, the following screen displays.

8. The LCD returns to the Bump Test Configuration Menu screen.

If the bump test failed, repeat the bump test again or refer to 18. T roubleshooting

on page 41

Page 40

ConneX1 Operator’s Manual32

Datalogs

11. Datalogs

The detector records datalog samples that can be compiled to create a report

using Fleet Manager II.

Using Fleet Manager II, define the logging interval from 1 to 600 seconds. Def ault

is 5 seconds.

The total number of 8-hour days of datalogs that can be recorded, assuming 90%

of the day has no gas concentrations.

Table 8. Datalog Storage Capacity

Datalog Interval

Total Number of 8-Hour Days

Datalogs Can Be Recorded

5 seconds up to 15 days

15 seconds up to 45 days

60 seconds up to 180 days

When the memory is full, the detector replaces the oldest datalogs with the most

recent datalogs.

The detector is shipped with the default setting of 5 seconds.

For more information on what is recorded in a datalog, ref er to Appendix D Datalog

Information on page 59.

12. Event Logs

An event log is recorded when the user changes the instrument status such as

activating/deactivating the detector, profile change, or activation of a gas alarm.

Event logs are downloaded via Fleet Manager II and can be viewed with the

program.

Up to 30 event logs can be recorded. When event log memory is full, the newer

event logs overwrites the oldest event logs.

Refer to Appendix E Event Log Information on page 59.

13. Messaging

13.1 Receiving Messages

When the detector receives a message, an env elope appears and a brief portion

of the message appears on the LCD. Press

to read the full message.

After 10 seconds, if the message is not read, appears in the at the top of

the screen. The detector will beep and vibrate to aler t the user that there is an

unread message.

Page 41

ConneX1 Operator’s Manual 33

Messaging

13.2 Reading Messages

When reading a message, press to scroll through the message and press to

scroll to the beginning of the message.

To exit from the message, press .

To reply to a message, press .

For more information, refer to 13.2.1 Sending Messages on page 33.

13.2.1 Sending Messages

A message can be sent as a reply or as a new message to a LocaXion Manager

operator. Refer to the following to send messages or reply to received messages.

1. If replying to a recieved message, press from the full message screen.

If sending a new message, press and scroll to Send message.

2. Select the pre-configured message and press to send the message.

3. When the message has been sent, the following screen displays.

4. The detector returns to normal operation.

13.3 Panic Alarm Messages

When Panic Alarm is activated, a message is automatically sent to LocaXion

Manager.

For more information, refer to 6. Panic Alarm on page 21.

Page 42

ConneX1 Operator’s Manual34

LocaXion Manager

14. LocaXion Manager

For more information, refer to the Network Settings section.

15. Fleet Manager II

Go to

www.gasmonitors.com

for information about Fleet Manager II.

15.1 Downloading Data To Fleet Manager II

The datalog and event log files can be downloaded to a PC using the IR Link or

IntelliDoX. Refer to either the

• Fleet Manager II Operator’s Manual

• IntelliDoX Technical Reference Manual

When downloading event logs and datalogs from the detector, the following

screen displays.

For more information on what is recorded in a datalog, ref er to Appendix D Datalog

Information on page 59.

15.2 Upgrading the Firmware

The detector firmware can be upgraded using the IR Link or IntelliDoX.

For more information, refer to the Fleet Manager II Operator’ s Manual or IntelliDoX

Technical Reference Manual.

15.3 Generating Calibration Certificates

A calibration certificate can be generated from any calibration done manually or

with the IntelliDoX. A certificate is generated using Fleet Manager II.

WARNING

This is not a certied calibration certicate. If a certied calibration is

required, contact BW Technologies by Honeywell.

16. Maintenance

To maintain the detector in good operating condition, perform the following basic

maintenance as required.

• Calibrate, bump test, and inspect the detector at regular intervals

• Maintain an operations log of all maintenance, bump tests, calibrations ,

and alarm event

• Clean the exterior with a soft damp cloth. Do not use solv ents, soaps, or

polishes. Refer to 1.3 Sensor Poisons and Contaminants on page 5.

Page 43

ConneX1 Operator’s Manual 35

Maintenance

16.1 Charging the Rechargeable Battery

WARNING

To avoid personal injury and/or property damage, adhere to the

following:

• Charge the battery immediately when the detector emits a low battery alarm.

• Charge the battery in a safe area that is free of hazardous gas in temperatures

ranging from 5°C to 40°C (41°F to 104°F).

• Charge the battery using BW Technologies by Honeywell charger adapters

designed for the ConneX1 only. Do not use any other charger adapters. Failure

to adhere to this caution can lead to re and/or explosion.

• The charging adapter is voltage specic to your region. Use of the charging

adapter outside your region will damage the charger and the detector.

• The ConneX1 uses a lithium battery that may present a risk of re or chemical

burn hazard if misused. Do not disassemble, heat above 100°C (212°F), or

incinerate.

• Lithium polymer cells exposed to heat at 130°C (266°F) for 10 minutes can

cause re and/or explosion.

• e Dispose of used lithium cells immediately. Do not disassemble and do

not dispose of in a re. Do not mix with the solid waste stream. Spent batteries

must be disposed of by a qualied recycler or hazardous materials handler.

• Keep lithium cells away from children.

CAUTION

• When charging, the detector will not detect gas.

• When charging, the detector will not communicate with LocaXion Manager.

WARNING

The battery must be charged in a safe area that is free of hazards and

in temperatures of 5°C to 40°C (41°F to 104°F).

If the battery is charged outside of the charging temperature

specications, a charging error will result.

To charge the battery, refer to Figure 1. Parts of ConneX1 on page 2 and the

following procedures.

1. Press and hold to deactivate the detector.

NOTE The time required to charge will increase if the detector is activated.

2. Plug the charger into an AC outlet.

CAUTION

The charging adapter is voltage specic to your region. Use of the

charging adapter outside your region will damage both the charger

and the detector.

Page 44

ConneX1 Operator’s Manual36

Maintenance

16.1.1 Optimum Battery Operation

To ensure maximum use of the battery, perform the following:

• To obtain full operating capacity, allow the battery to fully charge and

discharge.

• To achieve the maximum number of charges, ensure the battery is

charged between 5°C and 40°C (41°F and 104°F). Do not charge

the battery in temperatures above 40°C (104°F) or below 5°C (32°F).

If the battery is charged outside of the charging temperature

specifications, a charging error will result.

16.1.2 Rechargeable Battery Capacity

A rechargeable battery’s runtime decreases approximately 20% over a two-year

period of typical use.

To maximize the battery’s capacity over its lifetime, charge the battery at 20°C.

16.2 Replacing the Sensor and Sensor Filter

WARNING

To avoid personal injury and/or property damage, use only

sensors that are specically designed for the detector. Refer to 19.

Replacement Parts and Accessories on page 53.

CAUTION

• The sensor has a high degree of resistance to common vapours and gases.

To clear a sensor, move the detector to a clean environment and wait 10 to

30 minutes.

• To prevent accidental poisoning of the sensor, refer to 1.3 Sensor Poisons and

Contaminants on page 5.

1. Press and hold to deactivate the detector.

2. Remove the four machine screws from the rear shell.

Page 45

ConneX1 Operator’s Manual 37

Maintenance

3. Remove the rear shell.

4. Simultaneously push on the PCB release tab while lifting the PCB up

by the battery.

5. Gently remove the PCB by sliding out and then up. Place the PCB on a

clean surface.

To replace the sensor, refer to 16.2.1 Replacing the Sensor on page 38.

T o replace the sensor filter , ref er to 16.2.2 Replacing the Sensor Filter on page 38

Page 46

ConneX1 Operator’s Manual38

Maintenance

16.2.1 Replacing the Sensor

1. Remove the spent sensor from the PCB.

2. Insert the new sensor.

3. Reassemble the detector. Ensure the antenna is inserted first before

the PCB.

4. Press the PCB down until a click is heard.

5. Replace the rear shell. Ensure the front and rear shells hav e a tight, uniform

1 mm (1/16 in.) seal on all sides of the detector.

6. Replace the four machine screws using 3-4 in. lbs of torque. Do not

overtighten the screws.

7. New sensor should be calibrated prior to use. Calibrate the new sensor

immediately. Refer to 9. Calibration on page 26.

16.2.2 Replacing the Sensor Filter

Replace the sensor filter as required. Environments with more airborne particulates

may require more frequent filter changes.

1. Gently remove the PCB by sliding out and then up.

2. Remove the sensor filter.

3. Insert the new filter. Ensure the black side of the filter f aces the sensor grill.

The white back of the sensor filter should face the sensor.

Page 47

ConneX1 Operator’s Manual 39

WEEE Directive and Battery Directive

4. Reassemble the detector. Ensure the antenna is inserted first before

the PCB.

5. Press the PCB down until a click is heard.

6. Replace the rear shell. Ensure the front and rear shells hav e a tight, uniform

1 mm (1/16 in.) seal on all sides of the detector.

7. Replace the four machine screws using 3-4 in. lbs of torque. Do not

overtighten the screws.

17. WEEE Directive and Battery Directive

e Warning: At the end of their working lives, sensors must be disposed of in

an environmentally safe manner, in accordance with local waste management

requirements and environmental legislation. Do NOT incinerate sensors as they

may emit toxic fumes. Failure to comply with the following battery removal and

disposal instructions may result in battery shorting, battery leakage, and/or other

damage. Ensure a qualified technician completes the following procedure.

e

Warning: This detector contains a lithium polymer battery. Dispose of used

lithium cells immediately . Do not disassemble. Do not dispose of in fire . Do not mix

with the solid waste stream. Spent batteries must be disposed of by a qualified

recycler or hazardous materials handler.

17.1 Removal and Disposal of the Rechargeable

Battery

1. Press and hold to deactivate the detector.

2. Remove the four machine screws from the rear shell.

3. Remove the rear shell.

4. Simultaneously push on the PCB release tab while lifting the PCB up

by the battery.

Page 48

ConneX1 Operator’s Manual40

WEEE Directive and Battery Directive

5. Gently remove the PCB by sliding out and then up.

6. Lift the battery straight up by its sides.

7. Disconnect the female connector of the battery.

8. Dispose of the battery in accordance with the local laws.

Page 49

ConneX1 Operator’s Manual 41

Troubleshooting

18. Troubleshooting

If a problem occurs, refer to the solutions provided in this section. Refer to Table 10. Detector Operation on page 42, Table 11. Charging Troubleshooting on page

44, and Table 12. Startup Error Screens on page 45. If the problem persists, contact BW Technologies by Honeywell.

Table 9. Startup Troubleshooting

Problem Possible Cause Solution

The detector does not

activate

Depleted battery

Recharge batteries. Refer to 16.1 Charging the Rechargeable Battery on page 35.

Damaged detector

Contact BW Technologies by Honeywell

Detector automatically

deactivates

Automatic deactivation due to critical

low battery.

Replace alkaline batteries. Refer to Charging the Rechargeable Battery.

Sensor requires calibration

Refer to 9. Calibration on page 26

The detector enters alarm

immediately when activated.

Sensor needs to stabilize

Used sensor: Wait 60 seconds

New sensor: Wait 5 minutes

Hazardous environment Leave the area immediately. Deactivate and reactivate the detector in safe area in a fresh air environment

Low battery or critical low battery alarm

Charge the rechargeable battery pack. Refer to 16.1 Charging the Rechargeable Battery on page 35

A new sensor has been inserted Calibrate the sensor

The activation startup selftest fails

General fault

Contact BW Technologies by Honeywell

Sensor error

Contact BW Technologies by Honeywell

Page 50

ConneX1 Operator’s Manual42

Troubleshooting

Table 10. Detector Operation

Problem Possible Cause Solution

Detector does not display normal gas

reading after startup sequence

Sensor not stabilized

Used sensor: Wait 60 seconds

New sensor: Wait 5 minutes

Sensor requires calibration

Refer to 9. Calibration on page 26

Target gas is present Detector is operating properly. Use caution in suspect areas.

Detector does not respond to pushbutton

Battery is in critical low battery state or is

completely depleted

Charge the rechargeable battery pack. Refer to 16.1 Charging the Rechargeable Battery on page 35

Detector is performing operations that do

not require user input

Pushbutton operation restores automatically when the operation ends

Detector does not accurately measure gas

Sensor requires calibration

Refer to 9. Calibration on page 26

Detector is colder/hotter than gas

temperature

Allow the detector to attain ambient temperature before use

Sensor lter is blocked

Refer to 16.2.2 Replacing the Sensor Filter on page 38

Detector does not enter alarm

Alarm setpoint(s) are set incorrectly

Refer to 7.1 Alarm Setpoints on page 24. The alarm setpoints are dened in Fleet Manager II

Alarm setpoint(s) set to zero

Refer to 7.1 Alarm Setpoints on page 24. The alarm setpoints are dened in Fleet Manager II

Detector is in calibration mode Complete calibration

Page 51

ConneX1 Operator’s Manual 43

Troubleshooting

Table 10. Detector Operation

Problem Possible Cause Solution

Detector intermittently enters alarm

without reason

Ambient gas levels are near alarm

setpoint or the sensor is exposed to a puff

of hazardous gas

Detector is operating normally. Use caution in suspect areas. Check peak gas exposure reading

Alarm setpoints are set incorrectly

Refer to 7.1 Alarm Setpoints on page 24. The alarm setpoints are dened in Fleet Manager II

Sensor requires calibration

Refer to Calibration on page 26

Missing or faulty sensor

Refer to Replacing the Sensor and Sensor Filter on page 36

Features and options are not operating

as expected

Changes in Fleet Manager II Verify that the settings in Fleet Manager II are correct

Page 52

ConneX1 Operator’s Manual44

Troubleshooting

Table 11. Charging Troubleshooting

Problem Possible Cause Solution

Battery has been charging for 6 hours.

Charging indicator on LCD shows the battery

is still charging

Battery is trickle charging Battery is fully charged and is ready for operation

Battery indicator does not display when

charging

Battery is depleted below normal levels

Charge the battery for 8 hours.

If the battery indicator does not light after charging, contact Honeywell Analytics

Battery does not charge

If the battery is not charged after charging for 8 hours, contact Honeywell Analytics

Page 53

ConneX1 Operator’s Manual 45

Troubleshooting

Table 12. Startup Error Screens

Error Screen Problem Solution

Critical Low Battery

Battery is in critical low battery state or is completely depleted

Charge the rechargeable battery pack. Refer to Charging the

Rechargeable Battery on page 35

Self-test Failed

Sensor failed the self-test during startup.

Replace the sensor. Refer to 16.2.1 Replacing the Sensor on

page 38.

Contact BW Technologies by Honeywell

Auto-zero Error

Sensor failed to auto-zero.

Calibrate the sensor.

Page 54

ConneX1 Operator’s Manual46

Troubleshooting

Table 12. Startup Error Screens

Error Screen Problem Solution

Force Calibration

If the Force Calibration option is enabled, the sensor must be

calibrated to enter normal operation.

Press and calibrate the sensor immediately. Refer to 9. Calibration

on page 26. If the Calibration Lock option is enabled, an IR device

(IR Link or IntelliDoX) must be used to calibrate.

Last Calibration Failed

Displays when the last calibration failed. If the Force Calibration

option is enabled, the sensor must be calibrated.

Press and calibrate the sensor immediately. Refer to 9. Calibration

on page 26. If the Calibration Lock option is enabled, an IR device

(IR Link or IntelliDoX) must be used to calibrate.

Calibration Overdue

Displays when calibration is overdue. If the Force Calibration

option is enabled, the sensor must be calibrated to enter normal

operation.

Press and calibrate the sensor immediately. Refer to 9. Calibration

on page 26. If the Calibration Lock option is enabled, an IR device

(IR Link or IntelliDoX) must be used to calibrate.

Page 55

ConneX1 Operator’s Manual 47

Troubleshooting

Table 12. Startup Error Screens

Error Screen Problem Solution

Calibration Due Today

Displays when calibration is due today. If the Force Calibration

option is enabled, the sensor must be calibrated to enter normal

operation.

Press and calibrate the sensor immediately. Refer to 9. Calibration

on page 26. If the Calibration Lock option is enabled, an IR device

(IR Link or IntelliDoX) must be used to calibrate.

Last Bump Test Failed

If the last bump test failed and the Force Bump option is enabled,

a bump test must be performed.

Press and and perform a bump test immediately. Refer to 10.

Bump Test on page 30.

Force Bump Test

If the Force Bump option is enabled, a bump test must be

performed to enter normal operation.

Press and and perform a bump test immediately or place the

detector into the IntelliDoX. Refer to 10. Bump Test on page 30.

Page 56

ConneX1 Operator’s Manual48

Troubleshooting

Table 12. Startup Error Screens

Error Screen Problem Solution

Bump Test Overdue

Screen displays when the sensor is over due for a bump test. If the

Force Bump option is enabled, a bump test must be performed to

enter normal operation.

Press and perform a bump test immediately. Refer to 10. Bump

Test on page 30.

Or

Press

and proceed to the next step in the start-up sequence.

Bump Test Due Today

Screen displays when the sensor is due for a bump test today.

If the Force Bump option is enabled, a bump test must be

performed to enter normal operation.

Press and perform a bump test immediately. Refer to 10. Bump

Test on page 30.

Or

Press

and proceed to the next step in the start-up sequence.

Page 57

ConneX1 Operator’s Manual 49

Troubleshooting

Table 13. Calibration Error Screens

Error Screen Problem Solution

Zeroing Error

Sensor failed to zero.

Zero the sensor in fresh air.

Force Calibration

If the Force Calibration option is enabled, the sensor must be

calibrated to enter normal operation.

Press and calibrate the sensor immediately. Refer to 9. Calibration

on page 26. If the Calibration Lock option is enabled, an IR device

(IR Link or IntelliDoX) must be used to calibrate.

Calibration Lock

IR Lock enabled screen displays

An IR Device must be used to perform a calibration (IR Link or

IntelliDoX). For manual calibration, refer to 9.1 Calibration Using

the IntelliDoX on page 26. For automated calibration, refer to the

IntelliDoX Technical Reference Guide.

Page 58

ConneX1 Operator’s Manual50

Troubleshooting

Table 13. Calibration Error Screens

Error Screen Problem Solution

Calibration Error

An error occured during calibration.

Contact BW Technologies by Honeywell

Calibration Gas Not Detected

Insufcient amount of gas detected.

Verify the span gas values on the gas cylinder match the span gas

values dened for the detector.

Ensure gas is applied at a ow rate of 0.25-0.50 L/min.

Ensure the gas cylinder is not empy nor expired. Replace immediately

if required.

Replace the regulator.

Calibration Error

An error occured during calibration

Retry calibration.

Contact BW Technologies by Honeywell

Page 59

ConneX1 Operator’s Manual 51

Troubleshooting

Table 14. Bump Test Error Screens

Error Screen Problem Solution

Bump Test Gas Not Detected

Insufcient amount of gas detected.