BVA Hydraulics PEW0501, PEW1002, PEW1503, PEW3005 User Manual

Electric Pumps

Instruction Manual

INCLUDES MODEL NUMBERS:

PE0501, PE1002, PE1503, PE3005,

PEW0501, PEW1002, PEW1503 & PEW3005

SFA Companies 10939 N. Pomona Ave. Kansas City, MO 64153

Tel: 888-332-6419 * Fax: 816-891-6599

E-mail: sales@bvahydraulics.com Website: www.bvahydraulics.com

PE0501-M0

Ver. 4.0 © 2006

Model No. PE0501

Model No. PE1002, PE1503 & PE3005

Model No.PEW0501

Model No. PEW1002, PEW1503 & PEW3005

Printed in Taiwan

Save these instructions. For your safety, read and understand the information contained within. The owner and

Drawn

operator shall have an understanding of this product and safe operating procedures before attempting to use this

product. Make certain that the operator thoroughly understands the inherent dangers associated with the use and

misuse of the product. If any doubt exists as to the safe and proper use of this product as outlined in this factory

authorized manual, remove from service immediately.

Inspect before each use. It is recommended that, prior to each use, an inspection be done by qualified personnel

and that any missing or damaged parts, decals, warning / safety labels or signs be replaced with factory authorized

replacement parts only. Any pump that appears to be damaged in any way, is worn, leaking or operates abnormally

shall be removed from service immediately until such time as repairs can be made. Any pump that has been or

suspected to have been subject to a shock load (a load dropped suddenly, causing the system pressure to exceed

10,000 PSI), shall be removed from service immediately until checked by qualified personnel. Owners and operators

of this equipment shall be aware that the use and subsequent repair of this equipment may require special training and

knowledge. Labels and owners manuals are available from the manufacturer (see Service Parts pages 8 thru 11).

PRODUCT DESCRIPTION

BVA Hydraulics Electric Pumps are engineered to meet or exceed ANSI B30.1 Standards for Performance and Safety.

Its unique hydraulic circuit allows quick displacement of hydraulic fluid under no load conditions and easy pumping in

loaded conditions. These electric hydraulic pumps supply compressed hydraulic fluid to compatible applications i.e.

rams, presses, spreaders, compactors and crimping machines, anywhere that 10,000 PSI of fluid pressure is needed.

Special skill, knowledge and training may be required for a specific task and the product may not be suitable for all the

jobs described above. Unsuitable applications would include applications that call for a device to move, level or support

persons, animals, hazardous materials, mobile homes/ dwellings in general, mirrors and/or plate glass, and/or to

connect/secure hatches, components, etc. between bulkheads. The user must make the decision regarding suitability

of the product for any given task and assume the responsibility of safety for himself and others in the work area.

Note: Always check connections before using. Alteration of these products is strictly prohibited. Use only those

adapters and attachments provided and approved by the manufacturer.

SPECIFICATIONS

Model

(PE

series)

PE0501 PEW0501 1 305 18 0.5 8

PE1002 PEW1002 2 458 37 1 15

PE1503 PEW1503 3 610 61 1.5 17

PE3005 PEW3005 5 793 110 3 230 15

Model

(PEW

series)

Usable

Oil

Capacity

(gal)

Rated Pressure

(psi)

1st Stage 2nd Stage 1st Stage 2nd Stage

10,000580

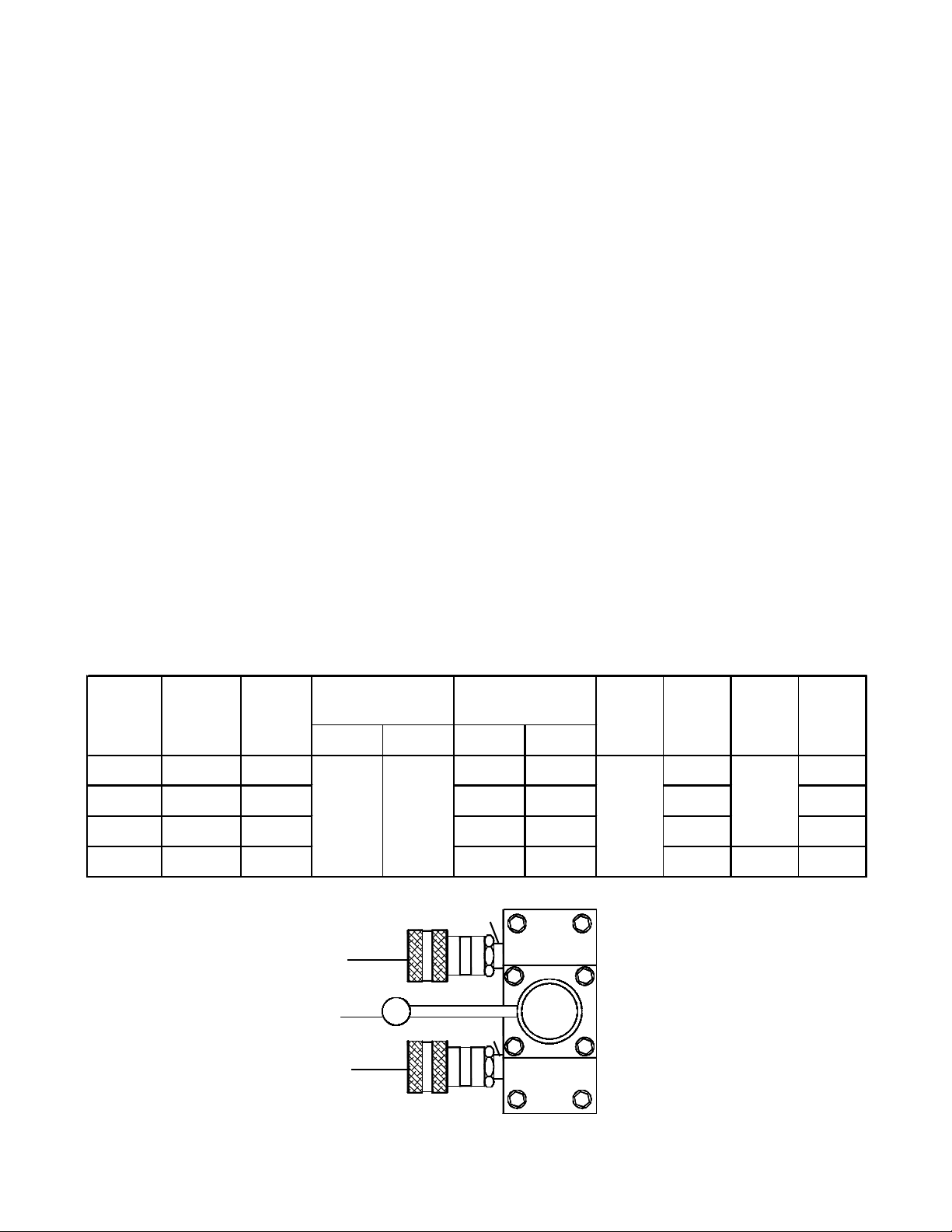

3/8"-18 NPTF

Coupler

(not included)

Control Valve Handle

3/8"-18 NPTF

Coupler

(not included)

Output Flow Rate

(in3/min)

Valve

Type

4-way, 3

position

Motor

(HP)

Motor

Voltage

(V)

110/115

Current

(A)

Figure 1 - Typical Control Valve with Couplers

2

Electric Motor

Control Box

Electric Motor

Control Valve

Control Valve

Lever

Oil Output

Ports

Carry Handle

Drain Plug

Figure 2 - Typical PE series Electric Pump Components

(PE1002 shown)

Electric Motor

ON/OFF Switch

Vent Cap

Power Cord

Reservoir

Control Valve

Control Valve

Lever

Oil Output

Ports

Carry Handle

Drain Plug

Figure 3 - Typical PEW series Electric Pump Components

(PEW1002 shown)

Power Cord

Reservoir

SAFETY INFORMATION

Read all the INSTRUCTIONS and WARNINGS in the manual provided within. Failure to heed these warnings may

result in personal injury as well as property damage.

WARNING

!

• Do not exceed the rated capacity of this device.

• Never attempt to lift a load weighing more than the

capacity of the cylinder.

• Burst hazard exists if hose or connection pressure

exceeds rated pressure.

• Use gauge or other load measuring instrument to

monitor load.

• Use of incorrect power source will damage the motor.

• Do not use an ungrounded (two-prong) extension cord.

• Do not install, remove or rewire the motor with power

applied. Have qualified technician to install, adjust

and service the motor.

• Do not operate this device in an extreme temperature,

explosive atmosphere or in the presence of conductive

liquids.

• Always inspect hoses and connections for damage

prior to use.

• Always tie up long hair, wear protective clothing and

eye protection when operating this equipment.

• Keep hand and feet away from cylinder and workpiece

during operation.

• Ensure the device is placed on a hard, level surfaces.

• Always ensure that the chosen application is stable

to work on and around.

• Do not subject the pump and its components to shock

loads.

• Do not subject the hose to potential hazard such as

sharp objects, extreme heat or heavy impact.

• Do not connect to application which can return more

oil to the reservoir than the pump reservoir can hold.

• Do not handle pressurized hose. Escaping oil under

high pressure can penetrate the skin, causing

serious injury.

• The load must be centered on the ram, or equally

distributed on multiple rams.

• Never hold or stand directly in line with any hydraulic

connections while pressurizing.

• Do not work under a lifted load. This device is not

suitable for use as support device!

• Release all line pressure before disconnecting hoses.

• When loading a cylinder, always insure that coupler,

port, and adapter threads have not been damaged.

• Failure to heed these warnings may result in personal

injury as well as property damage.

• If oil leakage is detected, discontinue use of the pump

immediately and contact your nearest BVA Hydraulics Authorized Service Center.

WARNING

!

WARNING!

To avoid crushing and

related injuries:

Do not work on, under or

around a lifted load.

Vent Cap

Remote

Pendant

3

BEFORE USE

Read all instructions carefully before attempting to

assemble or operate these pumps. Most malfunctions

in new equipment are the result of improper operation

and/or improper set-up assembly.

Visually inspect all components for shipping damage.

Do not use if any damage is found.

Note: E-Pumps are shipped without hydraulic oil filled.

Add oil before starting motor and operation.

Familiarize yourself with the specification and illustrations

in this owner manual. Use service parts drawing on page

8 thru 11 as reference of location and assembly.

Electrical Connections:

1. Compare motor nameplate against power availability

to prevent motor burnout or dangerous electrical

overloading.

2. (a) Model PE0501/PEW0501 (0.5hp), PE1002/

PEW1002 (1hp) and PE1503/PEW1503 (1.5hp)

motors are wired for 110 volts unless otherwise

specified, and are supplied with a plug and cord.

(b) Model PE3005 & PEW3005 (3hp) have accessible

motor leads and should be connected only by a

qualified electrician to prevent improper connection and

possible damage to the motor.

3.Try to minimize the use of long extension cord and

make sure the wire size is adequate and with grounded

connections.

Hydraulic Connections:

1. Make sure to use correct type of hydraulic oil specified

by the manufacturer. Check and make sure the oil

level in reservoir is at about 2" from top of reservoir

plate, with cylinders retracted and motor off.

2. Use of pressure gauge is strongly recommended.

Attach a pressure gauge between the pump and

cylinder to monitor pressure on cylinder.

3. Make sure coupler, hose, valve, gauge are tighten

securely to prevent accidental removal of components

while in use. Hoses shall not be kinked or twisted.

OPERATION

1. Check oil level, add oil if necessary.

2. Make sure system fittings and connections are tight

and leak free.

3. Place control valve lever in the middle (Neutral/Hold)

position to prevent accidental lifting or moving of load.

4. To

start the motor:

(a) For PE series, turn the ON/OFF switch on the

control box to ON position.

(b) For PEW series, press and hold on the switch of

the remote pendant.

5. Let the pump idle for a few minutes before put into

operation.

Note. To ensure smooth operation, bleed air from the

system by fully advancing and retracting the cylinder

several times.

6. Use the control valve lever to control the direction of

fluid flow. These pumps are equipped with a 4-way 3position valve. Refer to figure 3(a) on page 5 for the

flow path.

7. Always monitor the pressure, load and position.

8. Shift the control valve, until desired pressure, load or

position is read.

Note: Do not continue to operate pump after cylinder

plunger is fully extended or retracted.

9. To turn off the motor:

(a) For PE series, turn the ON/OFF switch on the

switch box to OFF position.

(b) For PEW series, the motor will stop when the

switch is released.

10.Depressurize all connections before disconnect.

Note: Control valves on these pumps are 4-way, 3position, for use with double acting cylinders. If your

application require a 3-way setting shown in figure 3(b),

it can be changed by an authorized BVA Service Center.

If you have any doubt, please consult BVA Technical

Service 888-332-6419.

Note: Always secure threaded port connections with

non-hardening pipe thread compound. Take care not to

introduce compound into port orifices.

4. Do not exceed the rated capacity of the equipment

connected to the pump. Use larger capacity of

cylinders if necessary.

IMPORTANT: The pump's maximum working pressure

is 10,000 PSI. Make sure that all hydraulic equipment

such as cylinders, hoses, coupler and etc. used with

this pump are rated at 10,000 PSI operating pressure.

4

Loading...

Loading...