BVA Hydraulics J72101 User Manual

Low Prole Cylinder Kit

Instruction Manual

MODEL: J72101 - 10 Ton Capacity

SFA Companies 10939 N. Pomona Ave. Kansas City, MO 64153

Tel: 888-332-6419 * Fax: 816-891-6599

E-mail: sales@bvahydraulics.com Website: www.bvahydraulics.com

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!

J72101-M0

! ADVERTENCIA

• Leer, comprender, y seguir las instrucciónes antes de utilizar el aparato.

• El manual de instrucciónes y la información de seguridad deben estar comunicado en lengua del operador

antes del uso.

• No seguir estas indicaciónes puede causar daños personales o materiales.

Printed in Taiwan

SAFETY and GENERAL INFORMATION

Save these instructions. For your safety, read, understand, and follow the information provided with and on this

cylinder before using. The owner and operator of this equipment shall have an understanding of this cylinder and

safe operating procedures before attempting to use. The owner and operator shall be aware that use and repair of

this product may require special skills and knowledge. Instructions and safety information shall be conveyed in the

operator's native language before use of this cylinder is authorized. If any doubt exists as to the safe and proper use

of this cylinder, remove from service immediately.

Inspect before each use. Do not use if broken, bent, cracked or damaged parts are noted. Any cylinder that appears

damaged in any way, or operates abnormally shall be removed from service immediately. If the cylinder has been

or suspected to have been subjected to a shock load (a load dropped suddenly, unexpectedly upon it), immediately

discontinue use until cylinder has been checked by a factory authorized service center (contact distributor or

manufacturer for list of authorized service centers). It is recommended that an annual inspection be done by qualied

personnel. Labels and Operator's Manuals are available from manufacturer.

PRODUCT DESCRIPTION

BVA Hydraulics Single Acting Low Prole Cylinder is designed for rated capacity pushing, spreading and pressing

jobs. A wide variety of applications exist for this category of product. Special skill, knowledge and training may be

required for a specic task and the product may not be suitable for all the jobs described above. Unsuitable applications

would include applications that call for a device to move, level or support persons, animals, hazardous materials,

mobile homes/dwellings in general, mirrors and/or plate glass, and/or to connect/secure hatches, components, etc.

between bulkheads. The user ultimately must make the decision regarding suitability of the product for any given

task and therefore accept responsibility for that decision. Immediately after lifting, loads must be supported by

appropriate mechanical means.

NEVER use hydraulic cylinder as a support device.

!

Always check connections before using. Alteration of these products is strictly prohibited. Use only those

!

adapters and attachments provided and approved by the manufacturer.

WARNING: To reduce the risk of personal injury and/or property damage, ensure that the rated working

!

pressure of each pressurized attachment be equal to or greater than the rated working pressure developed

by the hydraulic pump.

SPECIFICATIONS

Model

Number

J72101 10 1.50 2.35 3.53 3.48 4.98 8,511 2.75 1.50

Cylinder

Capacity

(ton)

Stroke

(in)

Cylinder

Effective

Area

(in2)

Oil

Capacity

(in3)

Collapsed

Height

(in)

Extended

Height

(in)

Internal

Pressure

at

Capacity

(psi)

Cylinder

Housing

Dia.

(in)

Ram

Plunger

Dia.

(in)

2

INSTALLATION

IMPORTANT! Use an approved, high-grade pipe sealant to seal all hydraulic connections.

1.

Remove the dust cover and rubber plug from coupler

2. Inspect all threads and ttings for signs of wear or damage, and replace as needed.

3. Clean all threads and ttings.

4. Connect hydraulic hose from hydraulic pump to the cylinder coupler. Ensure that there are no uid leaks.

5. Install in-line pressure gauge.

6. Check for leaks in system and have repaired by qualied personnel.

Note: The use of cylinder attachments or extensions reduces the cylinder capacity by at least 50% per attachment/

extension.

Before operating the pump, tighten all hose connections with proper tools. Do not overtighten.

!

Connections should only be tightened securely and leak-free. Overtightening can cause premature thread

failure or high pressure ttings to burst.

!

Before repairs are made, depressurize cylinder.

Tips for hydraulic hoses & uid transmission lines:

• Avoid short runs of straight line tubing. Straight line runs do not provide for expansion and contraction due to

pressure and/or temperature changes.

• Reduce stress in tube lines. Long tubing runs should be supported by brackets or clips.

.

BEFORE USE

1. Before using this product, read the owner's manual completely and familiarize yourself thoroughly with the product,

its components and recognize the hazards associated with its use.

2.

Verify that the product and the application are compatible. If in doubt,

3. Inspect before each use. Do not use if bent, broken, leaking or damaged components are noted.

4.

Replace worn or damaged parts and assemblies with BVA Hydraulics authorized replacement parts only. Lubricate

as instructed in Maintenance Section.

5. Ensure method of conrming load is accurate and working properly. Have gauge or load cell accuracy veried by

qualied personnel on a yearly basis.

6. Cylinders should be stored where protected from the elements, abrasive dust, and damage. These cylinders

should be stored in the upright position.

call BVA Technical Service (888) 332-6419.

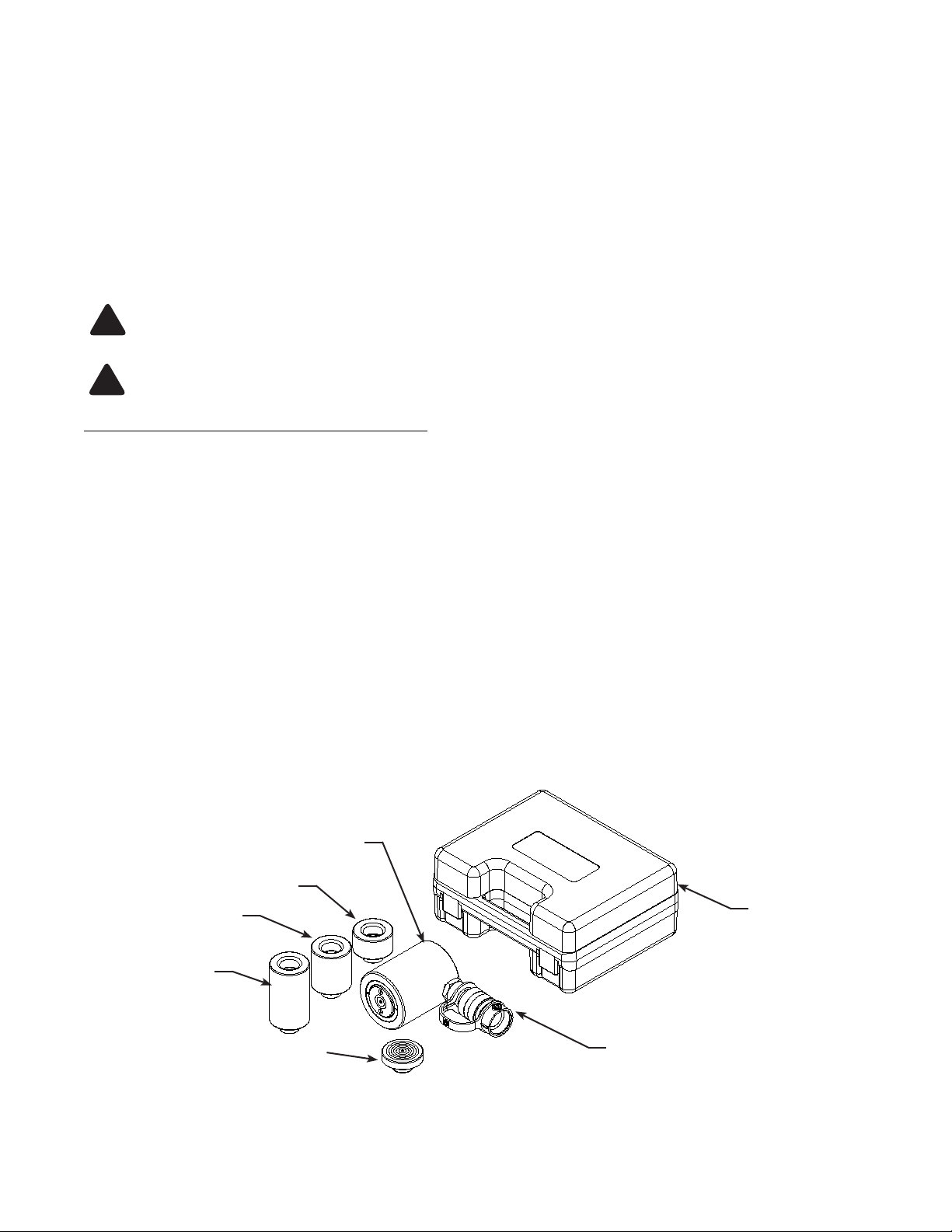

Extension II, 2”

Extension III, 3”

Extension I, 1”

Cylinder

Base

Figure 1 - Low Prole Cylinder Kit Components

3

Carrying

Case

Female Coupler

3/8” NPTF

Loading...

Loading...