Page 1

145

©2005 Cooper Bussmann

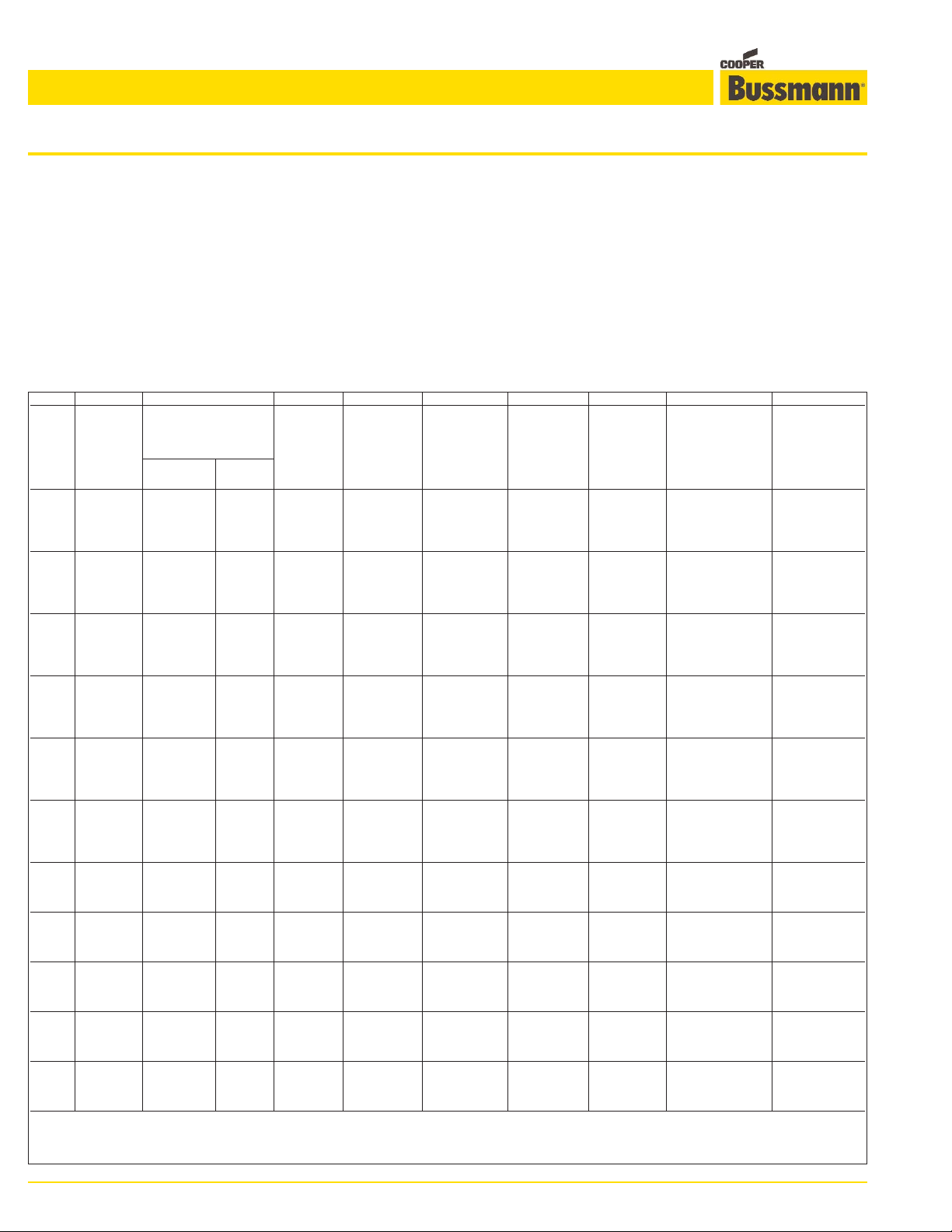

Columns 1 & 2

Motor horsepower ratings are listed in Column 1. Full load amps from Tables

430.247 through 430.250 are provided in Column 2.

Column 3

Various fuse types are listed in Column 3. The LPJ_SP is a 600Vac, 0 - 600 amp,

time-delay, Class J, “Low-Peak fuse, with a 300,000 amp interrupting rating. The

TCF is a 600Vac, 1 - 100 amp dual-element, time-delay, IP-20 finger-safe fuse with

Class J performance. The LP-CC is a 600Vac, 0 - 30 amp, time-delay, Class CC,

Low-Peak fuse with a 200,000 amp interrupting rating. The LPS-RK_SP and LPNRK_SP are 600 and 250Vac, 0 - 600 amp, time-delay, Class RK1, Low-Peak fuses

with interrupting ratings of 300,000 amps. FRS-R and FRN-R are 600 and 250Vac,

0 - 600 amp, time-delay, Class RK5, Fusetron Dual-Element fuses with interrupting

ratings of 200,000 amps. The KRP-C_SP is a 600Vac, 601 - 6000 amp, time-delay,

Class L, Low-Peak fuse, with a 300,000 amp AC interrupting rating. The DC listed

ratings for these fuses are:

LPJ 1 to 600SP 300Vdc LPN-RK 0 to 60SP 125Vdc

TCF 1 to 100 300Vdc LPN-RK 70 to 600SP 250Vdc

LP-CC

1

⁄2 to 2 8⁄10 300Vdc LPS-RK 0 to 600SP 300Vdc

LP-CC 3 to 15 150Vdc FRN-R 0 to 600 125Vdc

LP-CC 20 to 30 300Vdc FRS-R 0 to 600 300Vdc

Column 4 - Optimal Branch Circuit Protection

There are two distinct levels of protection philosophy provided in this Column. LPSRK_SP, LPN-RK_SP, FRS-R and FRN-R fuses are sized for motor running

“back-up” protection and provide superb short circuit protection at the same time.

LPJ_SP, TCF, and LP-CC fuses are sized a little larger but are even more current

limiting, providing an even greater degree of short circuit protection for the motor

circuit.

All the fuses selected from this column provide short circuit and ground-fault protection for motor branch circuits (430.52), but typically are not the maximum

allowed. Fuses sized in accordance with Column 4 must be used in conjunction

with properly sized motor overload protection such as overload relays or solid state

motor controllers (430.32). This fuse sizing is normally large enough to allow the

overload protective device to operate on overloads without opening the fuse. Yet

for many cases, this fuse amp rating selection is smaller than the maximums

allowed per Columns 5 or 6 (430.52). In some cases, this smaller amp rating

selection may provide the benefits of a smaller size disconnect and better short circuit protection. If a motor has a long starting time, high starting current profile or is

cycled frequently, it may be necessary to use Column 5 or 6.

The LPS-RK_SP, LPN-RK_SP, FRS-R and FRN-R fuses sized per this column provide short circuit and ground-fault protection for motor branch circuits (430.52) as

discussed in the previous paragraph. In addition, these dual-element fuses exhibit

longer time-delay characteristics and can therefore be sized to provide back-up

motor overload protection. The fuse sizing in Column 4 for LPS-RK_SP, LPNRK_SP, FRS-R and FRN-R fuses provides a degree of motor and circuit overload

protection to back-up the normal motor overload protective device. Note: This level

of protection requires a well-designed, true dual-element fuse. The Fusetron

Fuses, FRS-R and FRN-R, and Low-Peak Fuses, LPS-RK_SP and LPN-RK_SP,

are the industry leading dual-element fuses with excellent over-load time-delay

characteristics and current-limiting short circuit ability. The Low-Peak Dual-Element

Fuses have better current-limiting ability than Fusetron Dual-Element Fuses.

The amp ratings in Column 4 are determined by using Column 2 motor ampacity

values and the following:

LPJ_SP & TCF: 150% or the next larger Cooper Bussmann amp rating if 150% does

not correspond to a Cooper Bussmann fuse amp rating.

LP-CC 1⁄2 to 15A: 200% (150% for DC) or the next larger Cooper Bussmann size if

200% (150% for DC) does not correspond to a Cooper Bussmann fuse amp

rating.

LP-CC 20 to 30A: 300% (150% for DC) or the next larger Cooper Bussmann size if

300% (150% for DC) does not correspond to a Cooper Bussmann fuse amp

rating.

LPS-RK_SP and LPN-RK_SP: 130% or the next larger Cooper Bussmann amp rat-

ing if 130% does not correspond to a Cooper Bussmann fuse amp rating.

FRS-R and FRN-R: 125% or the next larger Cooper Bussmann amp rating if 125%

does not correspond to a Cooper Bussmann fuse amp rating.

Column 5 - Branch Circuit Protection, Max. General

Applications

Fuses selected from this column are intended to provide short circuit and groundfault protection for motor branch circuits. Fuses sized in accordance with Column 5

must be used in conjunction with properly sized motor overload protection such as

overload relays or solid state motor controllers (430.32). Column 5 fuse sizing

provides the maximum NEC®Table 430.52 amp ratings for general purpose

applications. It takes into account 430.52(C)(1) Exception No. 1, which allows the

next standard amp rating fuse (per standard fuse amp ratings in 240.6) to be used

if the maximum percentage in Table 430.52 does not correspond to a standard fuse

amp rating. If this Column 5 fuse sizing does not allow the motor to start, then

Column 6 may provide a larger amp rating.

The amp ratings in Column 5 are deter-mined by using Column 2 motor ampacity

values and the following:

LPJ_SP, TCF, LPS-RK_SP, LPN-RK_SP, FRS-R, FRN-R and KRP-C_SP: 175%

(150% for DC motors) or the next larger 240.6 standard fuse amp rating if 175%

(150% for DC motors) does not correspond to a standard fuse amp rating.

LP-CC: 300% (150% for DC motors) or the next larger 240.6 standard fuse amp

rating if 300% (150% for DC motors) does not correspond to a standard fuse amp

rating.

Sizes shown for the LP-CC can also be used for non-time delay fuses such as JKS,

KTN-R, KTS-R, JJN, JJS, and KTK-R.

Column 6 - Branch Circuit Protection, Max. Heavy Start

When the amp rating shown in Column 5 is not sufficient to start a motor, a larger

amp rating is often available by utilizing 430.52(C)(1) Exception No. 2. The amp

ratings in Column 6 are the larger of the amp rating allowed by 430.52(C)(1)

Exception No. 1, or 430.52(C)(1) Exception No. 2. These amp ratings will often be

required when acceleration times are greater than 5 seconds, when plugging or

jogging applications exist, or where there are high inrush currents (such as Design

E or energy efficient Design B motors). (In a few cases, the amp rating in Column 6

may be smaller than the maximum permitted due to the limitation of the fuse type,

such as LP-CC, Class CC fuses that are only available in ratings up to 30 amps. In

these cases, if the amp rating shown is not sufficient to start the motor, select a different family of fuses that meet the requirements.) The amp ratings in Column 6

are determined by using Column 2 motor ampacity values and the following:

LPJ_SP, TCF, LPS-RK_SP, LPN-RK_SP, FRS-R, and FRN-R: 225% or the next

smaller Cooper Bussmann amp rating if 225% does not correspond to a Cooper

Bussmann fuse amp rating.

LP-CC: 400% or the next smaller Cooper Bussmann amp rating if 400% does not cor-

respond to a Cooper Bussmann fuse amp rating.

KRP-C_SP: 300% or the next smaller Cooper Bussmann amp rating, if 300% does

not correspond to a Cooper Bussmann amp rating.

Sizes shown for the LP-CC can also be used for non-time delay fuses such as

JKS, KTN-R, KTS-R, JJN, JJS, AND KTK-R.

Column 7

Horsepower-rated switch sizes given in Column 7 are based on 115% (430.110) of

Column 2. Switch sizes need to be increased when, because of starting requirements, the fuses are sized above the rating of the switch shown in this column.

Column 8

Sizes listed are for general-purpose magnetic controllers (single speed, fullvolt-age for limited plugging and jogging-duty) as shown in NEMA Standards

Publication ICS-2-2000.

Motor Circuit Protection Tables

NEC®Article 430 and Tables Explanation

Page 2

146

©2005 Cooper Bussmann

Column 9

Copper wire sizes are based upon 125% (430.22) of values shown in Column 2

and ampacities listed in Table 310.16 for 75°C terminals. Although the NEC

®

allows 60°C terminations for equipment rated 100 amp or less, most

equipment terminations have been rated for 75°C conductors. If equipment terminations are rated for 60°C conductors only, the 60°C ampacities must be utilized

and therefore larger conductor sizes may be required than those shown in this column. See 110.14(C) (1)(a)(4).

Column 10

These rigid metallic conduit sizes are based upon copper conductors with THWN

or THHN insulation, Table C8 of Annex C, and 75°C equipment terminals.

Conduit sizes are for three conductors per circuit for three phase motors and two

conductors per circuit for single phase and DC motors. Conduit sizes may need to

be increased if equipment grounding conductors or neutrals are also installed in

the conduit.

If equipment terminations are rated for 60°C conductors only, the 60°C ampacities

must be utilized and therefore larger conductor sizes and conduit sizes may be

required.

Conductors operated in a high ambient temperature may need to be derated.

(See correction factor table at the bottom of Table 310.16.)

Motor Circuit Protection Tables

200Vac Three-Phase Motors & Circuits

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size Size Inches

LPJ_SP J 4 6 6

TCF J

ƒ

66 6

1

⁄2 2.5 LP-CC CC 5 10 10 30 00 14

1

⁄2

LPN-RK_SP RK1 3 1⁄2 66

FRN-R RK5 3 2⁄10 66

LPJ_SP J 5

6

⁄10 10 10

TCF J

ƒ

610 10

3

⁄4 3.7 LP-CC CC 7 1⁄2 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 5 10 10

FRN-R RK5 5 10 10

LPJ_SP J 8 10 10

TCF J

ƒ

10 10 10

1 4.8 LP-CC CC 10 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 6 1⁄4 10 10

FRN-R RK5 6 10 10

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

1

1

⁄2 6.9 LP-CC CC 15 25 25 30 00 14

1

⁄2

LPN-RK_SP RK1 9 15 15

FRN-R RK5 9 15 15

LPJ_SP J 12 15 17

1

⁄2

TCF J

ƒ

15 15 17 1⁄2

2 7.8 LP-CC CC 25 25 30 30 0 14

1

⁄2

LPN-RK_SP RK1 12 15 17 1⁄2

FRN-R RK5 10 15 17 1⁄2

LPJ_SP J 17 1⁄2 20 20

TCF J

ƒ

17 1⁄2 20 20

3 11 LP-CC CC 25 – – 30 0 14

1

⁄2

LPN-RK_SP RK1 15 20 20

FRN-R RK5 15 20 20

LPJ_SP J 30 35 35

5 17.5 TCF J

ƒ

30 35 35 30* 1 12

1

⁄2

LPN-RK_SP RK1 25 35 35

FRN-R RK5 25 35 35

LPJ_SP J 40 45 50

7

1

⁄2 25.3 TCF J

ƒ

40 45 50 60 1 10**

1

⁄2**

LPN-RK_SP RK1 35 45 50

FRN-R RK5 35 45 50

LPJ_SP J 50 60 70

10 32.2 TCF J

ƒ

50 60 – 60* 2 8** 1⁄2**

LPN-RK_SP RK1 45 60 70

FRN-R RK5 45 60 70

LPJ_SP J 80 90 100

15 48.3 TCF J

ƒ

80 90 100 100 3 6**

3

⁄4**

LPN-RK_SP RK1 70 90 100

FRN-R RK5 70 90 100

LPJ_SP J 100 110 125

20 62.1 TCF J

ƒ

100 – – 100* 3 4** 1

LPN-RK_SP RK1 90 110 125

FRN-R RK5 80 110 125

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

ƒ

Class J performance, special finger-safe dimensions.

NEC®Article 430 and Tables Explanation

Page 3

147

©2005 Cooper Bussmann

Motor Circuit Protection Tables

200Vac Three-Phase Motors & Circuits continued

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size Size Inches

LPJ_SP J 125 150 175

25 78.2 LPN-RK_SP RK1 110 150 175 100* 3 3** 1**

FRN-R RK5 100 150 175

LPJ_SP J 150 175 200

30 92 LPN-RK_SP RK1 125 175 200 200 4 2** 1**

FRN-R RK5 125 175 200

LPJ_SP J 200 225 250

40 120 LPN-RK_SP RK1 175 225 250 200* 4 1/0 1

1

⁄4

FRN-R RK5 150 225 250

LPJ_SP J 225 300 300

50 150 LPN-RK_SP RK1 200 300 300 200* 5 3/0 1

1

⁄2

FRN-R RK5 200 300 300

LPJ_SP J 300 350 350

60 177 LPN-RK_SP RK1 250 350 350 400 5 4/0 2

FRN-R RK5 225 350 350

LPJ_SP J 350 400 450

75 221 LPN-RK_SP RK1 300 400 450 400* 5 300 2

FRN-R RK5 300 400 450

KRP-C_SP L – – 650

LPJ_SP J 450 500 600

100 285 LPN-RK_SP RK1 400 500 600 400* 6 500 3

FRN-R RK5 400 500 600

KRP-C_SP L – – 800

LPJ_SP J 600 – –

125 359 LPN-RK_SP RK1 500 – – 600* 6 4/0 2/PHASE (2)2

FRN-R RK5 450 – –

KRP-C_SP L – 700 1000

LPN-RK_SP RK1 600 – –

150 414 FRN-R RK5 600 – – 600* 6 300 2/PHASE (2)2

KRP-C_SP L – 800 1200

200 552 KRP-C_SP L – 1000 1600 1200 72 500 2/PHASE (2)3

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

208Vac Three-Phase Motors & Circuits

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size2 Size Inches

LPJ_SP J 4 6 6

TCF J

ƒ

66 6

1

⁄2 2.4 LP-CC CC 5 10 10 30 00 14

1

⁄2

LPN-RK_SP RK1 3 1⁄2 66

FRN-R RK5 3 6 6

LPJ_SP J 5

6

⁄10 10 10

TCF J

ƒ

610 10

3

⁄4 3.5 LP-CC CC 7 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 5 10 10

FRN-R RK5 4 1⁄2 10 10

LPJ_SP J 7 10 10

TCF J

ƒ

10 10 10

1 4.6 LP-CC CC 10 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 6 10 10

FRN-R RK5 6 10 10

LPJ_SP J 10 15 15

TCF J

ƒ

10 15 15

1

1

⁄2 6.6 LP-CC CC 15 20 25 30 00 14

1

⁄2

LPN-RK_SP RK1 9 15 15

FRN-R RK5 9 15 15

*Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

**If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

ƒ

Class J performance, special finger-safe dimensions.

Page 4

148

©2005 Cooper Bussmann

Motor Circuit Protection Tables

208Vac Three-Phase Motors & Circuits continued

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

2 7.5 LP-CC CC 15 25 30 30 0 14

1

⁄2

LPN-RK_SP RK1 10 15 15

FRN-R RK5 10 15 15

LPJ_SP J 17

1

⁄2 20 20

3 10.6 TCF J

ƒ

17 1⁄2 20 20 30 0 14

1

⁄2

LPN-RK_SP RK1 15 20 20

FRN-R RK5 15 20 20

LPJ_SP J 30 30 35

5 16.7 TCF J

ƒ

30 30 35 30* 1 12

1

⁄2

LPN-RK_SP RK1 25 30 35

FRN-R RK5 25 30 35

LPJ_SP J 40 45 50

7

1

⁄2 24.2 TCF J

ƒ

40 45 50 60 1 10**

1

⁄2

LPN-RK_SP RK1 35 45 50

FRN-R RK5 35 45 50

LPJ_SP J 50 60 60

10 30.8 TCF J

ƒ

50 60 60 60 2 8

1

⁄2**

LPN-RK_SP RK1 45 60 60

FRN-R RK5 40 60 60

LPJ_SP J 70 90 100

15 46.2 TCF J

ƒ

70 90 100 60* 3 6**

3

⁄4**

LPN-RK_SP RK1 70 90 100

FRN-R RK5 60 90 100

LPJ_SP J 90 110 125

20 59.4 TCF J

ƒ

90 – – 100* 3 4** 1

LPN-RK_SP RK1 80 110 125

FRN-R RK5 80 110 125

LPJ_SP J 125 150 150

25 74.8 LPN-RK_SP RK1 100 150 150 100* 3 3** 1**

FRN-R RK5 100 150 150

LPJ_SP J 150 175 175

30 88 LPN-RK_SP RK1 125 175 175 200 4 2** 1**

FRN-R RK5 110 175 175

LPJ_SP J 175 200 250

40 114 LPN-RK_SP RK1 150 200 250 200* 4 1/0 1

1

⁄4

FRN-R RK5 150 200 250

LPJ_SP J 225 300 300

50 143 LPN-RK_SP RK1 200 300 300 200* 5 3/0 1

1

⁄2

FRN-R RK5 200 300 300

LPJ_SP J 300 300 350

60 169 LPN-RK_SP RK1 225 300 350 400 5 4/0 2

FRN-R RK5 225 300 350

LPJ_SP J 350 400 450

75 211 LPN-RK_SP RK1 300 400 450 400* 5 300 2

FRN-R RK5 300 400 450

KRP-C_SP L – – 601

LPJ_SP J 450 500 600

100 273 LPN-RK_SP RK1 400 500 600 400* 6 500 3

FRN-R RK5 350 500 600

KRP-C_SP L – – 800

LPJ_SP J 600 – –

125 343 LPN-RK_SP RK1 450 – – 600* 6 4/0 2/PHASE (2)2

FRN-R RK5 450 – –

KRP-C_SP L – 601 1000

LPJ_SP J 600 – –

150 396 LPN-RK_SP RK1 600 – – 600* 6 250 2/PHASE (2)2

FRN-R RK5 500 – –

KRP-C_SP L – 700 1100

200 528 KRP-C_SP L – 1000 1500 1200* 7 400 2/PHASE (2)2-2 1⁄2

*Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

**If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

ƒ

Class J performance, special finger-safe dimensions.

Page 5

149

©2005 Cooper Bussmann

Motor Circuit Protection Tables

230Vac Three-Phase Motors & Circuits (220-240Vac Systems)

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 3

1

⁄2 66

TCF J

ƒ

66 6

1

⁄2 2.2 LP-CC CC 4 1⁄2 10 10 30 00 14

1

⁄2

LPN-RK_SP RK1 3 6 6

FRN-R RK5 2 8/10 6 6

LPJ_SP J 5 6 7

TCF J

ƒ

66 6

3

⁄4 3.2 LP-CC CC 7 10 12 30 00 14

1

⁄2

LPN-RK_SP RK1 4 1⁄2 67

FRN-R RK5 4 6 7

LPJ_SP J 7 10 10

TCF J

ƒ

10 10 10

1 4.2 LP-CC CC 9 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 5 6⁄10 10 10

FRN-R RK5 5 8⁄10 10 10

LPJ_SP J 9 15 15

TCF J

ƒ

10 15 15

1

1

⁄2 6 LP-CC CC 12 20 20 30 00 14

1

⁄2

LPN-RK_SP RK1 8 15 15

FRN-R RK5 7 1⁄2 15 15

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

2 6.8 LP-CC CC 15 25 25 30 0 14

1

⁄2

LPN-RK_SP RK1 9 15 15

FRN-R RK5 9 15 15

LPJ_SP J 15 20 20

TCF J

ƒ

15 20 20

3 9.6 LP-CC CC 30 30 30 30 0 14

1

⁄2

LPN-RK_SP RK1 15 20 20

FRN-R RK5 12 20 20

LPJ_SP J 25 30 30

5 15.2 TCF J

ƒ

25 30 30 30 1 14

1

⁄2

LPN-RK_SP RK1 20 30 30

FRN-R RK5 20 30 30

LPJ_SP J 35 40 45

7

1

⁄2 22 TCF J

ƒ

34 40 45 30* 1 10

1

⁄2

LPN-RK_SP RK1 30 40 45

FRN-R RK5 30 40 45

LPJ_SP J 45 50 60

10 28 TCF J

ƒ

45 50 60 60 2 10**

1

⁄2

LPN-RK_SP RK1 40 50 60

FRN-R RK5 35 50 60

LPJ_SP J 70 80 90

15 42 TCF J

ƒ

70 80 90 60* 2 6

3

⁄4

LPN-RK_SP RK1 60 80 90

FRN-R RK5 60 80 90

LPJ_SP J 90 100 110

20 54 TCF J

ƒ

90 100 – 100* 3 4 1

LPN-RK_SP RK1 80 100 110

FRN-R RK5 70 100 110

LPJ_SP J 110 125 150

25 68 LPN-RK_SP RK1 90 125 150 100* 3 4** 1

FRN-R RK5 90 125 150

LPJ_SP J 125 150 175

30 80 LPN-RK_SP RK1 110 150 175 100* 3 3** 1**

FRN-R RK5 100 150 175

LPJ_SP J 175 200 225

40 104 LPN-RK_SP RK1 150 200 225 200* 4 1** 1

1

⁄4**

FRN-R RK5 150 200 225

LPJ_SP J 200 250 250

50 130 LPN-RK_SP RK1 175 250 250 200* 4 2/0 1

1

⁄2

FRN-R RK5 175 250 250

LPJ_SP J 250 300 300

60 154 LPN-RK_SP RK1 225 300 300 200* 5 3/0 1

1

⁄2

FRN-R RK5 200 300 300

*Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

**If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

ƒ

Class J performance, special finger-safe dimensions.

4 Limited by 600 amp being the largest amp rating for FRN-R and LPN-RK_SP.

Page 6

150

©2005 Cooper Bussmann

Motor Circuit Protection Tables

230Vac Three-Phase Motors & Circuits (220-240Vac Systems) continued

460Vac Three-Phase Motors & Circuits (440-480Vac Systems)

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 1

8

⁄10 33

TCF J

ƒ

33 3

1

⁄2 1.1 LP-CC CC 2 1⁄4 6 6 30 00 14

1

⁄2

LPS-RK_SP RK1 1 11⁄2 33

FRS-R RK5 1 4⁄10 33

LPJ_SP J 2

1

⁄2 33

1

⁄2

TCF J

ƒ

33 3

3

⁄4 1.6 LP-CC CC 3 2⁄10 66

1

⁄4 30 00 14

1

⁄2

LPS-RK_SP RK1 2 1⁄4 33

1

⁄2

FRS-R RK5 2 3 3 1⁄2

LPJ_SP J 3 2⁄10 66

TCF J

ƒ

66 6

1 2.1 LP-CC CC 4

1

⁄2 10 10 30 00 14

1

⁄2

LPS-RK_SP RK1 2 8⁄10 66

FRS-R RK5 2 8⁄10 66

LPJ_SP J 4

1

⁄2 66

TCF J

ƒ

66 6

1

1

⁄2 3 LP-CC CC 6 10 12 30 00 14

1

⁄2

LPS-RK_SP RK1 4 6 6 1⁄4

FRS-R RK5 4 6 6 1⁄4

LPJ_SP J 5 6⁄10 67

TCF J

ƒ

66 6

2 3.4 LP-CC CC 7 1 5 15 30 00 14

1

⁄2

LPS-RK_SP RK1 4 1⁄2 67

FRS-R RK5 4 1⁄2 67

1

⁄2

LPJ_SP J 8 10 10

TCF J

ƒ

10 10 10

3 4.8 LP-CC CC 10 15 15 30 0 14

1

⁄2

LPS-RK_SP RK1 6 1⁄4 10 10

FRS-R RK5 6 10 10

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

5 7.6 LP-CC CC 25 25 30 30 0 14

1

⁄2

LPS-RK_SP RK1 10 15 15

FRS-R RK5 10 15 15

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

ƒ

Class J performance, special finger-safe dimensions.

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 300 350 400

75 192 LPN-RK_SP RK1 250 350 400 400 5 250 2

FRN-R RK5 250 350 400

LPJ_SP J 400 450 500

100 248 LPN-RK_SP RK1 350 450 500 400* 5 350 2

1

⁄2

FRN-R RK5 350 450 500

KRP-C_SP L – – 700

LPJ_SP J 500 600 –

125 312 LPN-RK_SP RK1 450 600 – 400* 6 3/0 2/PHASE (2) 1

1

⁄2

FRN-R RK5 400 600 –

KRP-C_SP L – — 900

LPJ_SP J 600 – –

150 360 LPN-RK_SP RK1 500 6004 – 600* 6 4/0 2/PHASE (2) 2

FRN-R RK5 450 6004 –

KRP-C_SP L – 700 1000

200 480 FRN-R RK5 600 – – 600* 6 350 2/PHASE (2) 2-2

1

⁄2

KRP-C_SP L – 1000 1400

*Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

**If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

4 Limited by 600 amp being the largest amp rating for FRN-R and LPN-RK_SP.

Page 7

151

©2005 Cooper Bussmann

Motor Circuit Protection Tables

460Vac Three-Phase Motors & Circuits (440-480Vac Systems) continued

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 17

1

⁄2 20 20

7

1

⁄2 11 TCF J

ƒ

17 1⁄2 20 20 30 1 14

1

⁄2

LPS-RK_SP RK1 15 20 20

FRS-R RK5 15 20 20

LPJ_SP J 25 25 30

10 14 TCF J

ƒ

25 25 30 30 1 14

1

⁄2

LPS-RK_SP RK1 20 25 30

FRS-R RK5 17 1⁄2 25 30

LPJ_SP J 35 40 45

15 21 TCF J

ƒ

35 40 45 30* 2 10

1

⁄2

LPS-RK_SP RK1 30 40 45

FRS-R RK5 30 40 45

LPJ_SP J 45 50 60

20 27 TCF J

ƒ

45 50 60 60 2 10**

1

⁄2

LPS-RK_SP RK1 40 50 60

FRS-R RK5 35 50 60

LPJ_SP J 60 60 70

25 34 TCF J

ƒ

60 60 70 60* 2 8**

1

⁄2**

LPS-RK_SP RK1 45 60 70

FRS-R RK5 45 60 70

LPJ_SP J 60 70 90

30 40 TCF J

ƒ

60 70 90 60* 3 8**

1

⁄2**

LPS-RK_SP RK1 60 70 90

FRS-R RK5 50 70 90

LPJ_SP J 80 100 110

40 52 TCF J

ƒ

80 100 – 100* 3 6**

3

⁄4**

LPS-RK_SP RK1 70 100 110

FRS-R RK5 70 100 110

LPJ_SP J 100 125 125

50 65 TCF J

ƒ

100 – – 100* 3 4** 1

LPS-RK_SP RK1 90 125 125

FRS-R RK5 90 125 125

LPJ_SP J 125 150 150

60 77 LPS-RK_SP RK1 110 150 150 100* 4 3** 1**

FRS-R RK5 100 150 150

LPJ_SP J 150 175 200

75 96 LPS-RK_SP RK1 125 175 200 200 4 1** 1

1

⁄4**

FRS-R RK5 125 175 200

LPJ_SP J 200 225 250

100 124 LPS-RK_SP RK1 175 225 250 200* 4 2/0 1

1

⁄2

FRS-R RK5 175 225 250

LPJ_SP J 250 300 350

125 156 LPS-RK_SP RK1 225 300 350 200* 5 3/0 1

1

⁄2

FRS-R RK5 200 300 350

LPJ_SP J 300 350 400

150 180 LPS-RK_SP RK1 250 350 400 400 5 4/0 2

FRS-R RK5 225 350 400

LPJ_SP J 400 450 500

200 240 LPS-RK_SP RK1 350 450 500 400* 5 350 2

1

⁄2

FRS-R RK5 300 450 500

KRP-C_SP L – – 700

LPJ_SP J 500 600 –

250 302 LPS-RK_SP RK1 400 600 – 400* 6 3/0 2/PHASE (2) 1

1

⁄2

FRS-R RK5 400 600 –

KRP-C_SP L – – 900

LPJ_SP J 600 – –

300 361 LPS-RK_SP RK1 500 6004 – 600* 6 4/0 2/PHASE (2) 2

FRS-R RK5 500 6004 –

KRP-C_SP L – 700 1000

LPS-RK_SP RK1 600 – –

350 414 FRS-R RK5 600 – – 600* 6 300 2/PHASE (2) 2

KRP-C_SP L – 800 1200

400 477 KRP-C_SP L – 1000 1400 600* 6 350 2/PHASE (2 )2

1

⁄2

FRS-R RK5 600 – –

450 515 KRP-C_SP L – 1000 1500 1200* 7 400 2/PHASE (2) 2 1⁄2

500 590 KRP-C_SP L – 1200 1600 1200* 7 500 2/PHASE (2) 3

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

4 Limited by 600 amp being the largest amp rating for FRS-R and LPS-RK_SP.

ƒ

Class J performance, special finger-safe dimensions.

Page 8

152

©2005 Cooper Bussmann

Motor Circuit Protection Tables

575Vac Three-Phase Motors & Circuits (550-600Vac Systems)

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 1

4

⁄10 33

TCF J

ƒ

33 3

1

⁄2 0.9 LP-CC CC 1 8⁄10 33

1

⁄2 30 0 14

1

⁄2

LPS-RK_SP RK1 1 1⁄4 33

FRS-R RK5 1 1⁄8 33

LPJ_SP J 2 3 3

TCF J

ƒ

33 3

3

⁄4 1.3 LP-CC CC 2 8⁄10 6 6 30 0 14

1

⁄2

LPS-RK_SP RK1 1 8⁄10 33

FRS-R RK5 1 8⁄10 33

LPJ_SP J 2

8

⁄10 33

1

⁄2

TCF J

ƒ

33 3

1 1.7 LP-CC CC 3

1

⁄2 66

1

⁄4 30 0 14

1

⁄2

LPS-RK_SP RK1 2 1⁄4 33

1

⁄2

FRS-R RK5 2 1⁄4 33

1

⁄2

LPJ_SP J 4 6 6

TCF J

ƒ

66 6

1

1

⁄2 2.4 LP-CC CC 5 10 10 30 0 14

1

⁄2

LPS-RK_SP RK1 3 2⁄10 66

FRS-R RK5 3 6 6

LPJ_SP J 4

1

⁄2 66

TCF J

ƒ

66 6

2 2.7 LP-CC CC 5

6

⁄10 10 10 30 0 14

1

⁄2

LPS-RK_SP RK1 4 6 6

FRS-R RK5 3 1⁄2 66

LPJ_SP J 6 10 10

TCF J

ƒ

610 10

3 3.9 LP-CC CC 5 15 15 30 0 14

1

⁄2

LPS-RK_SP RK1 5 6⁄10 10 10

FRS-R RK5 5 10 10

LPJ_SP J 10 15 15

TCF J

ƒ

10 15 15

5 6.1 LP-CC CC 15 20 20 30 0 14

1

⁄2

LPS-RK_SP RK1 8 15 15

FRS-R RK5 8 15 15

LPJ_SP J 15 20 20

TCF J

ƒ

15 20 20

7

1

⁄2 9 LP-CC CC 30 30 30 30 1 14

1

⁄2

LPS-RK_SP RK1 12 20 20

FRS-R RK5 12 20 20

LPJ_SP J 17

1

⁄2 20 20

10 11 TCF J

ƒ

17 1⁄2 20 20 30 1 14

1

⁄2

LPS-RK_SP RK1 15 20 20

FRS-R RK5 15 20 20

LPJ_SP J 30 30 35

15 17 TCF J

ƒ

30 30 35 30* 2 12

1

⁄2

LPS-RK_SP RK1 25 30 35

FRS-R RK5 25 30 35

LPJ_SP J 35 40 45

20 22 TCF J

ƒ

35 40 45 30* 2 10

1

⁄2

LPS-RK_SP RK1 30 40 45

FRS-R RK5 30 40 45

LPJ_SP J 45 50 60

25 27 TCF J

ƒ

45 50 60 60 2 10**

1

⁄2**

LPS-RK_SP RK1 40 50 60

FRS-R RK5 35 50 60

LPJ_SP J 50 60 70

30 32 TCF J

ƒ

50 60 70 60* 3 8

1

⁄2

LPS-RK_SP RK1 45 60 70

FRS-R RK5 40 60 70

LPJ_SP J 70 80 90

40 41 TCF J

ƒ

70 80 90 60* 3 6

3

⁄4

LPS-RK_SP RK1 60 80 90

FRS-R RK5 60 80 90

LPJ_SP J 80 100 110

50 52 TCF J

ƒ

80 100 – 100* 3 6**

3

⁄4**

LPS-RK_SP RK1 70 100 110

FRS-R RK5 70 100 110

*Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

**If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

ƒ

Class J performance, special finger-safe dimensions.

Page 9

153

©2005 Cooper Bussmann

Motor Circuit Protection Tables

575Vac Three-Phase Motors & Circuits (550-600Vac Systems) continued

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.250 430.250 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 100 110 125

60 62 LPS-RK_SP RK1 90 110 125 100* 4 4** 1

FRS-R RK5 80 110 125

LPJ_SP J 125 150 150

75 77 LPS-RK_SP RK1 110 150 150 100* 4 3** 1**

FRS-R RK5 100 150 150

LPJ_SP J 150 175 200

100 99 LPS-RK_SP RK1 150 175 200 200 4 1** 1

1

⁄4**

FRS-R RK5 125 175 200

LPJ_SP J 200 225 250

125 125 LPS-RK_SP RK1 175 225 250 200* 5 2/0 1

1

⁄2

FRS-R RK5 175 225 250

LPJ_SP J 225 300 300

150 144 LPS-RK_SP RK1 200 300 300 200* 5 3/0 1

1

⁄2

FRS-R RK5 200 300 300

LPJ_SP J 300 350 400

200 192 LPS-RK_SP RK1 250 350 400 400 5 250 2

FRS-R RK5 250 350 400

LPJ_SP J 400 450 500

250 242 LPS-RK_SP RK1 350 450 500 400* 6 350 2

1

⁄2

FRS-R RK5 350 450 500

KRP-C_SP L – – 700

LPJ_SP J 450 600 600

300 289 LPS-RK_SP RK1 400 600 600 400* 6 500 3

FRS-R RK5 400 600 600

KRP-C_SP L – – 800

LPJ_SP J 600 600 –

350 336 LPS-RK_SP RK1 450 600 – 600* 6 4/0 2/PHASE (2) 2

FRS-R RK5 450 600 –

KRP-C_SP L – 601 1000

LPJ_SP J 600 – –

400 382 LPS-RK_SP RK1 500 – – 600* 6 250 2/PHASE (2) 2

FRS-R RK5 500 – –

KRP-C_SP L – 700 1100

LPS-RK_SP RK1 600 – –

450 412 FRS-R RK5 600 – – 600* 7 300 2/PHASE (2) 2

KRP-C_SP L – 800 1200

500 472 FRS-R RK5 600 – – 600* 7 350 2/PHASE (2) 2

1

⁄2

KRP-C_SP L – 1000 1400

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

Page 10

154

©2005 Cooper Bussmann

Motor Circuit Protection Tables

115Vac Single-Phase Motors & Circuits (110-120Vac Systems)

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.248 430.248 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 8 10 10

TCF J

ƒ

10 10 10

1

⁄6 4.4 LP-CC CC 9 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 6 10 10

FRN-R RK5 5 6/10 10 10

LPJ_SP J 9 15 15

TCF J

ƒ

10 15 15

1

⁄4 5.8 LP-CC CC 12 20 20 30 00 14

1

⁄2

LPN-RK_SP RK1 8 15 15

FRN-R RK5 7 1⁄2 15 15

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

1

⁄3 7.2 LP-CC CC 15 25 25 30 00 14

1

⁄2

LPN-RK_SP RK1 10 15 15

FRN-R RK5 9 15 15

LPJ_SP J 15 20 20

TCF J

ƒ

15 20 20

1

⁄2 9.8 LP-CC CC 30 30 30 30 0 14

1

⁄2

LPN-RK_SP RK1 15 20 20

FRN-R RK5 15 20 20

LPJ_SP J 25 25 30

3

⁄4 13.8 TCF J

ƒ

25 25 30 30 0 14

1

⁄2

LPN-RK_SP RK1 20 25 30

FRN-R RK5 17 1⁄2 25 30

LPJ_SP J 25 30 35

1 16 TCF J

ƒ

25 30 35 30* 0 14

1

⁄2

LPN-RK_SP RK1 25 30 35

FRN-R RK5 20 30 35

LPJ_SP J 30 35 45

1

1

⁄2 20 TCF J

ƒ

30 35 45 30* 1 12

1

⁄2

LPN-RK_SP RK1 30 35 45

FRN-R RK5 25 35 45

LPJ_SP J 40 45 50

2 24 TCF J

ƒ

40 45 50 30* 1 10

1

⁄2

LPN-RK_SP RK1 35 45 50

FRN-R RK5 30 45 50

LPJ_SP J 60 60 70

3 34 TCF J

ƒ

60 60 70 60* 2 8**

1

⁄2**

LPN-RK_SP RK1 45 60 70

FRN-R RK5 45 60 70

LPJ_SP J 90 100 125

5 56 TCF J

ƒ

90 100 – 100* 3 4

3

⁄4**

LPN-RK_SP RK1 80 100 125

FRN-R RK5 70 100 125

LPJ_SP J 125 150 175

7

1

⁄2 80 LPN-RK_SP RK1 110 150 175 100* 3 3** 1**

FRN-R RK5 100 150 175

LPJ_SP J 150 175 225

10 100 LPN-RK_SP RK1 150 175 225 200* 42 1 1

1

⁄4

FRN-R RK5 125 175 225

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

ƒ

Class J performance, special finger-safe dimensions.

Page 11

155

©2005 Cooper Bussmann

Motor Circuit Protection Tables

230Vac Single-Phase Motors & Circuits (220-240Vac Systems)

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.248 430.248 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 3

1

⁄2 66

TCF J

ƒ

66 6

1

⁄6 2.2 LP-CC CC 4 1⁄2 10 10 30 00 14

1

⁄2

LPN-RK_SP RK1 3 6 6

FRN-R RK5 2 8⁄10 66

LPJ_SP J 4

1

⁄2 66

TCF J

ƒ

66 6

1

⁄4 2.9 LP-CC CC 6 10 10 30 00 14

1

⁄2

LPN-RK_SP RK1 4 6 6 1⁄4

FRN-R RK5 4 6 6 1⁄4

LPJ_SP J 5 6⁄10 10 10

TCF J

ƒ

610 10

1

⁄3 3.6 LP-CC CC 7 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 5 10 10

FRN-R RK5 4 1⁄2 10 10

LPJ_SP J 8 10 10

TCF J

ƒ

10 10 10

1

⁄2 4.9 LP-CC CC 10 15 15 30 00 14

1

⁄2

LPN-RK_SP RK1 8 10 10

FRN-R RK5 6 1⁄4 10 10

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

3

⁄4 6.9 LP-CC CC 15 25 25 30 00 14

1

⁄2

LPN-RK_SP RK1 9 15 15

FRN-R RK5 9 15 15

LPJ_SP J 12 15 17

1

⁄2

TCF J

ƒ

15 15 17 1⁄2

1 8 LP-CC CC 25 25 30 30 00 14

1

⁄2

LPN-RK_SP RK1 12 15 17 1⁄2

FRN-R RK5 10 15 17 1⁄2

LPJ_SP J 15 20 20

TCF J

ƒ

15 20 20

1

1

⁄2 10 LP-CC CC 30 30 30 30 0 14

1

⁄2

LPN-RK_SP RK1 15 20 20

FRN-R RK5 15 20 20

LPJ_SP J 20 25 25

TCF J

ƒ

20 25 25

2 12 LP-CC CC 25 – – 30 0 14

1

⁄2

LPN-RK_SP RK1 17 1⁄2 25 25

FRN-R RK5 15 25 25

LPJ_SP J 30 30 35

3 17 TCF J

ƒ

30 30 35 30* 1 12

1

⁄2

LPN-RK_SP RK1 25 30 35

FRN-R RK5 25 30 35

LPJ_SP J 45 50 60

5 28 TCF J

ƒ

45 50 60 60 2 10**

1

⁄2

LPN-RK_SP RK1 40 50 60

FRN-R RK5 35 50 60

LPJ_SP J 60 70 90

7

1

⁄2 40 TCF J

ƒ

60 70 90 60* 2 8**

1

⁄2**

LPN-RK_SP RK1 60 70 90

FRN-R RK5 50 70 90

LPJ_SP J 80 90 110

10 50 TCF J

ƒ

80 90 – 100* 3 6**

1

⁄2**

LPN-RK_SP RK1 70 90 110

FRN-R RK5 70 90 110

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

ƒ

Class J performance, special finger-safe dimensions.

Page 12

156

©2005 Cooper Bussmann

Motor Circuit Protection Tables

90Vdc3Motors & Circuits

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.257 430.257 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 6 6 6

TCF J

ƒ

66 6

1

⁄4 4.0 LPC_CC CC 6 6 15 30 1 14

1

⁄2

LPN-RK_SP RK1 6 6 9

FRN-R RK5 5 6 9

LPJ_SP J 8 10 10

TCF J

ƒ

10 10 10

1

⁄3 5.2 LP-CC CC 10 10 20 30 1 14

1

⁄2

LPN-RK_SP RK1 8 10 10

FRN-R RK5 7 10 10

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

1

⁄2 6.8 LP-CC CC 15 15 25 30 1 14

1

⁄2

LPN-RK_SP RK1 9 15 15

FRN-R RK5 9 15 15

LPJ_SP J 15 15 20

TCF J

ƒ

15 15 20

3

⁄4 9.6 LP-CC CC 15 15 30 30 1 14

1

⁄2

LPN-RK_SP RK1 15 15 20

FRN-R RK5 12 15 20

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

3 All equipment manufacturers should be consulted about DC voltage ratings of their equipment.

ƒ

Class J performance, special finger-safe dimensions.

Page 13

157

©2005 Cooper Bussmann

Motor Circuit Protection Tables

120Vdc3Motors & Circuits

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.257 430.257 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 5 6 6

TCF J

ƒ

66 6

1

⁄4 3.1 LP-CC CC 6 6 12 30 1 14

1

⁄2

LPN-RK_SP RK1 4 1⁄2 66

1

⁄4

FRN-R RK5 4 6 6 1⁄4

LPJ_SP J 7 10 10

TCF J

ƒ

10 10 10

1

⁄3 4.1 LP-CC CC 9 10 15 30 1 14

1

⁄2

LPN-RK_SP RK1 5 6⁄10 10 10

FRN-R RK5 5 6⁄10 10 10

LPJ_SP J 9 10 12

TCF J

ƒ

10 10 10

1

⁄2 5.4 LP-CC CC 10 10 20 30 1 14

1

⁄2

LPN-RK_SP RK1 7 1⁄2 10 12

FRN-R RK5 7 10 12

LPJ_SP J 12 15 15

TCF J

ƒ

15 15 15

3

⁄4 7.6 LP-CC CC 15 15 30 30 1 14

1

⁄2

LPN-RK_SP RK1 10 15 15

FRN-R RK5 10 15 15

LPJ_SP J 15 15 20

TCF J

ƒ

15 15 20

1 9.5 LP-CC CC 15 15 30

5

30 1 14

1

⁄2

LPN-RK_SP RK1 15 15 20

FRN-R RK5 12 15 20

LPJ_SP J 20 20 25

TCF J

ƒ

20 20 25

1

1

⁄2 13.2 LP-CC CC 20 20 30

5

30 1 14

1

⁄2

LPN-RK_SP RK1 17 1⁄2 20 25

FRN-R RK5 17 1⁄2 20 25

LPJ_SP J 30 30 35

TCF J

ƒ

30 30 35

2 17 LP-CC CC 30 30 30

5

30* 1 12

1

⁄2

LPN-RK_SP RK1 25 30 35

FRN-R RK5 25 30 35

LPJ_SP J 40 40 50

3 25 TCF J

ƒ

40 40 50 60 1 10**

1

⁄2

LPN-RK_SP RK1 35 40 50

FRN-R RK5 35 40 35

LPJ_SP J 60 60 90

5 40 TCF J

ƒ

60 60 60 60* 2 8**

1

⁄2**

LPN-RK_SP RK1 60 60 90

FRN-R RK5 50 60 90

LPJ_SP J 90 90 125

7

1

⁄2 58 TCF J

ƒ

90 90 – 100* 3 4**

3

⁄4**

LPN-RK_SP RK1 80 90 125

FRN-R RK5 80 90 125

LPJ_SP J 125 125 150

10 76 LPN-RK_SP RK1 100 125 150 100* 3 3** 1

FRN-R RK5 100 125 150

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 Reduced voltage magnetic controller ratings

3 All equipment manufacturers should be consulted about DC voltage ratings of their equipment.

5 Largest LP-CC Fuse 30 amp. With other type fuse, could use larger amp rating in this application.

ƒ

Class J performance, special finger-safe dimensions.

Page 14

158

©2005 Cooper Bussmann

Motor Circuit Protection Tables

180Vdc3Motors & Circuits

240Vdc3Motors & Circuits

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.257 430.257 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 3 3 4

1

⁄2

1

⁄4 2.0 TCF J

ƒ

33 3 30 1 141⁄2

LPS-RK_SP RK1 2 8⁄10 34

1

⁄2

FRS-R RK5 2 1⁄2 34

1

⁄2

LPJ_SP J 4 6 6

1

⁄3 2.6 TCF J

ƒ

66 6 30 1 141⁄2

LPS-RK_SP RK1 3 1⁄2 66

FRS-R RK5 3 1⁄2 66

LPJ_SP J 5

6

⁄10 66

1

⁄2 3.4 TCF J

ƒ

66 6 30 1 141⁄2

LPS-RK_SP RK1 4 1⁄2 66

1

⁄4

FRS-R RK5 4 1⁄2 67

1

⁄2

LPJ_SP J 8 10 10

3

⁄4 4.8 TCF J

ƒ

10 10 10 30 1 14

1

⁄2

LPS-RK_SP RK1 6 1⁄4 10 10

FRS-R RK5 6 10 10

LPJ_SP J 10 10 12

1 6.1 TCF J

ƒ

10 10 10 30 1 14

1

⁄2

LPS-RK_SP RK1 8 10 12

FRS-R RK5 8 10 12

LPJ_SP J 15 15 17

1

⁄2

TCF J

ƒ

15 15 15

1

1

⁄2 8.3 LP-CC CC – – 30 30 1 14

1

⁄2

LPS-RK_SP RK1 12 15 17 1⁄2

FRS-R RK5 12 15 17 1⁄2

LPJ_SP J 15 20 20

TCF J

ƒ

15 20 20

2 10.8 LP-CC CC 20 20 30 30 1 14

1

⁄2

LPS-RK_SP RK1 15 20 20

FRS-R RK5 15 20 20

LPJ_SP J 25 25 35

TCF J

ƒ

25 25 35

3 16 LP-CC CC 25 25 30 30* 1 14

1

⁄2

LPS-RK_SP RK1 20 25 35

FRS-R RK5 20 25 35

LPJ_SP J 40 45 60

5 27 TCF J

ƒ

40 45 60 60 2 10**

1

⁄2

LPS-RK_SP RK1 40 45 60

FRS-R RK5 35 45 60

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 These sizes are typical. They are not shown in NEMA ICS 2-2000.

3 All equipment manufacturers should be consulted about DC voltage ratings of their equipment.

ƒ

Class J performance, special finger-safe dimensions.

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.257 430.257 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 2

1

⁄2 33

1

⁄2

1

⁄4 1.6 TCF J

ƒ

33 3 30 1 141⁄2

LPN-RK_SP RK1 2 1⁄4 33

1

⁄2

FRS-R RK5 2 3 3 1⁄2

LPJ_SP J 3 3 4 1⁄2

1

⁄3 2.0 TCF J

ƒ

33 3 30 1 141⁄2

LPS-RK_SP RK1 2 8⁄10 34

1

⁄2

FRS-R RK5 2 1⁄2 34

1

⁄2

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 Reduced voltage magnetic DC controller ratings.

3 All equipment manufacturers should be consulted about DC voltage ratings of their equipment.

ƒ

Class J performance, special finger-safe dimensions.

Page 15

159

©2005 Cooper Bussmann

Motor Circuit Protection Tables

240Vdc3Motors & Circuits continued

12 3 456789 10

Motor Motor Fuse Optimal NEC

®

NEC®Max Minimum Minimum Minimum Minimum

Size FLA Branch Ckt Max for for Heavy Switch NEMA Copper Wire Rigid Metallic

Protection Gen. Applic Start Size Starter THWN or THHN AWG Conduit

Table Table 430.52(C)(1) 430.52(C)(1) 430.110 NEMA ICS 2- or KCMIL Annex C

430.257 430.257 Type Class Exc. No. 1 Exc. No. 2 2000 Table 310.16 Table C8

HP AMPS AMPS

1

AMPS

1

AMPS

1

AMPS Size

2

Size Inches

LPJ_SP J 4

1

⁄2 66

1

⁄2 2.7 TCF J

ƒ

66 6 30 1 141⁄2

LPS-RK_SP RK1 4 6 6

FRS-R RK5 3 1⁄2 66

LPJ_SP J 6 6 8

TCF J

ƒ

66 6

3

⁄4 3.8 LP-CC CC — — 15 30 1 14

1

⁄2

LPS-RK_SP RK1 5 6 8

FRS-R RK5 5 6 8

LPJ_SP J 8 10 10

1 4.7 TCF J

ƒ

10 10 10 30 1 14

1

⁄2

LPS-RK_SP RK1 6 1⁄4 10 10

FRS-R RK5 6 10 10

LPJ_SP J 10 10 12

1

1

⁄2 6.6 TCF J

ƒ

10 10 10 30 1 14

1

⁄2

LPS-RK_SP RK1 9 10 12

FRS-R RK5 9 10 12

LPJ_SP J 15 15 17

1

⁄2

2 8.5 TCF J

ƒ

15 15 15 30 1 14

1

⁄2

LPS-RK_SP RK1 12 15 17 1⁄2

FRS-R RK5 12 15 17 1⁄2

LPJ_SP J 20 20 25

TCF J

ƒ

20 20 25

3 12.2 LP-CC CC 20 20 30 30 1 14

1

⁄2

LPS-RK_SP RK1 17 1⁄2 20 25

FRS-R RK5 17 1⁄2 20 25

LPJ_SP J 30 30 45

TCF J

ƒ

30 30 45

5 20 LP-CC CC 30 30 30 30* 1 12

1

⁄2

LPS-RK_SP RK1 30 30 45

FRS-R RK5 25 30 45

LPJ_SP J 45 45 60

7

1

⁄2 29 TCF J

ƒ

45 45 60 60 2 8

1

⁄2

LPS-RK_SP RK1 40 45 60

FRS-R RK5 40 45 60

LPJ_SP J 60 60 80

10 38 TCF J

ƒ

60 60 60 60* 2 8**

1

⁄2**

LPS-RK_SP RK1 50 60 80

FRS-R RK5 50 60 80

LPJ_SP J 90 90 110

15 55 TCF J

ƒ

90 90 – 100* 3 4 3/4**

LPN-RK_SP RK1 80 90 110

FRS-R RK5 70 90 110

LPJ_SP J 110 110 150

20 72 LPN-RK_SP RK1 100 110 150 100* 3 3** 1

FRS-R RK5 90 110 150

LPJ_SP J 150 150 200

25 89 LPN-RK_SP RK1 125 150 200 200 3 2** 1**

FRS-R RK5 125 150 200

LPJ_SP J 175 175 225

30 106 LPN-RK_SP RK1 150 175 225 200* 4 1/0** 1

1

⁄4

FRS-R RK5 150 175 225

LPJ_SP J 225 225 300

40 140 LPN-RK_SP RK1 200 225 300 200* 4 2/0** 1

1

⁄4**

FRS-R RK5 175 225 300

LPJ_SP J 300 300 350

50 173 LPN-RK_SP RK1 225 300 350 400 5 4/0** 1

1

⁄2**

FRS-R RK5 225 300 350

LPJ_SP J 350 350 450

60 206 LPN-RK_SP RK1 300 350 450 400* 5 300** 2**

FRS-R RK5 300 350 450

LPJ_SP J 400 400 500

75 255 LPN-RK_SP RK1 350 400 500 400* 5 400** 2**

FRS-R RK5 350 400 500

LPJ_SP J 600 600 –

100 341 LPN-RK_SP RK1 450 600 – 600 6 4/0 2/PHASE (2) 1

1

⁄2**

FRS-R RK5 450 600 –

* Switch size must be increased if the amp rating of the fuse exceeds the amp rating of the switch.

1 Per 430.52(C)(2), if the motor controller manufacturer’s overload relay tables state a maximum branch circuit protective device of a lower rating, that lower rating must be used in lieu of the sizes shown in Columns 4, 5, or 6.

** If equipment terminations are rated for 60°C conductors only, the 60°C conductor ampacities must be utilized and therefore larger conductor sizes or conduit sizes may be required.

2 Reduced voltage magnetic DC controller ratings.

3 All equipment manufacturers should be consulted about DC voltage ratings of their equipment.

ƒ

Class J performance, special finger-safe dimensions.

Page 16

Recommendations for Electrician and

Maintenance Crews

Often, for various reasons, motors are oversized for applications. For instance,

a 5Hp motor is installed when the load demand is only 3Hp. In these cases a

much higher degree of protection can be obtained by sizing the overload relay

elements and/or Fusetron and Low-Peak dual-element, time-delay fuses

based on the actual full-load current draw.

160

©2005 Cooper Bussmann

Motor Protection

Tips For Electricians & Maintenance Crews

Selection of Fusetron or Low-Peak Dual-Element

Fuses based upon Motor FLA for Optimum Motor

Circuit Protection*

Fusetron or

Low-Peak Motor Current

Dual- FRN-R LPN-RK_SP

Element FRS-R LPS-RK_SP LPJ_SP LP-CC

Fuse Size Class RK5 Class RK1 Class J Class CC

1

⁄10 0-0.08 0.0000-0.0769 — —

1

⁄8 0.09-0.10 0.0770-0.0961 — —

15

⁄100 0.11-0.12 0.0962-0.1153 — —

2

⁄10 0.13-0.16 0.1154-0.1538 — —

1

⁄4 0.17-0.20 0.1539-0.1923 — —

3

⁄10 0.21-0.24 0.1924-0.2307 — —

4

⁄10 0.25-0.32 0.2308-0.3076 — —

1

⁄2 0.33-0.40 0.3077-0.3846 — 0.0000-0.2500

6

⁄10 0.41-0.48 0.3847-0.4615 — 0.2501-0.3000

8

⁄10 0.49-0.64 0.4616-0.6153 — 0.3001-0.4000

1 0.65-0.80 0.6154-0.7692 0.0-0.6666 0.4001-0.5000

1 1⁄8 0.81-0.90 0.7693-0.8653 0.6667-0.7500 0.5001-0.5625

1 1⁄4 0.91-1.00 0.8654-0.9615 0.7501-0.8333 0.5626-0.6250

1 4⁄10 1.01-1.12 0.9616-1.076 0.8334-0.9333 0.6251-0.7000

1 1⁄2 1.13-1.20 1.077-1.153 0.9334-1.000 0.7001-0.7500

1 6⁄10 1.21-1.28 1.154-1.230 1.001-1.066 0.7501-0.8000

1 8⁄10 1.29-1.44 1.231-1.384 1.067-1.200 0.8001-0.9000

2 1.45-1.60 1.385-1.538 1.201-1.333 0.9001-1.000

2 1⁄4 1.61-1.80 1.539-1.730 1.334-1.500 1.001-1.125

2 1⁄2 1.81-2.00 1.731-1.923 1.501-1.666 1.126-1.250

2 8⁄10 2.01-2.24 1.924-2.153 1.667-1.866 1.251-1.400

3 2.25-2.40 2.154-2.307 1.867-2.000 1.401-1.500

3 2⁄10 2.41-2.56 2.308-2.461 2.001-2.133 1.501-1.600

3 1⁄2 2.57-2.80 2.462-2.692 2.134-2.333 1.601-1.750

4 3.81-3.20 2.693-3.076 2.334-2.666 1.751-2.000

4 1⁄2 3.21-3.60 3.077-3.461 2.667-3.000 2.001-2.250

5 3.61-4.00 3.462-3.846 3.001-3.333 2.251-2.500

5 6⁄10 4.01-4.48 3.847-4.307 3.334-3.733 2.501-2.800

6 4.49-4.80 4.308-4.615 3.734-4.000 2.801-3.000

6 1⁄4 4.81-5.00 4.616-4.807 — 3.001-3.125

7 5.01-5.60 4.808-5.384 4.001-4.666 3.126-3.500

7 1⁄2 5.61-6.00 — — 3.501-3.750

8 6.01-6.40 5.385-6.153 4.667-5.333 3.751-4.000

9 6.41-7.20 6.154-6.923 5.334-6.000 4.001-4.500

10 7.21-8.00 6.924-7.692 6.001-6.666 4.501-5.000

12 8.01-9.60 7.693-9.230 6.667-8.000 5.001-6.000

15 9.61-12.00 9.231-11.53 8.001-10.00 6.001-7.500

17 1⁄2 12.01-14.00 11.54-13.46 10.01-11.66 7.501-8.750

20 14.01-16.00 13.47-15.38 11.67-13.33 8.751-10.00

25 16.01-20.00 15.39-19.23 13.34-16.66 10.01-12.50

30 20.01-24.00 19.24-23.07 16.67-20.00 12.51-15.00

35 24.01-28.00 23.08-26.92 20.01-23.33 —

40 28.01-32.00 26.93-30.76 23.34-26.66 —

45 32.01-36.00 30.77-34.61 26.67-30.00 —

50 36.01-40.00 34.62-38.46 30.01-33.33 —

60 40.01-48.00 38.47-46.15 33.34-40.00 —

70 48.01-56.00 46.16-53.84 40.01-46.66 —

75 56.01-60.00 — — —

80 60.01-64.00 53.85-61.53 46.67-53.33 —

90 64.01-72.00 61.54-69.23 53.34-60.00 —

100 72.01-80.00 69.24-76.92 60.01-66.66 —

110 80.01-88.00 76.93-84.61 66.67-73.33 —

125 88.01-100.00 84.62-96.15 73.34-83.33 —

150 100.01-120.00 96.16-115.3 83.34-100.0 —

175 120.01-140.00 115.4-134.6 100.1-116.6 —

200 140.01-160.00 134.7-153.8 116.7-133.3 —

225 160.01-180.00 153.9-173.0 133.4-150.0 —

250 180.01-200.00 173.1-192.3 150.1-166.6 —

300 200.01-240.00 192.4-230.7 166.7-200.0 —

350 240.01-280.00 230.8-269.2 200.1-233.3 —

400 280.01-320.00 269.3-307.6 233.4-266.6 —

450 320.01-360.00 307.7-346.1 266.7-300.0 —

500 360.01-400.00 346.2-384.6 300.1-333.3 —

600 400.01-480.00 384.7-461.5 333.4-400.0 —

1. Preferable – With a clamp-on meter, determine running RMS current when the

motor is at normal full-load. (Be sure this current does not exceed nameplate

current rating.) The advantage of this method is realized when a lightly loaded

motor (especially those over 50 HP) experiences a single-phase condition. Even

though the relays and fuses may be sized correctly based on motor nameplate,

circulating currents within the motor may cause damage.

Alternate – if unable to meter the motor current, then take the current rating off

the nameplate.

2. Then size the overload relay elements and Fusetron FRS-R and FRN-R or LowPeak LPS-RK_SP and LPN-RK_SP dual-element fuses based on this current. For

optimum motor circuit protection offering a high degree of “back-up overload”

protection, use the table that follows to assist in sizing dual-element fuses. The

other fuses in the table LPJ_SP, TCF and LP-CC can provide excellent short circuit

protection when sized for Optimum Motor Circuit Protection. However, they typically

can not be sized close enough to provide motor back-up overload protection.

3. Use a labeling system to mark the type and amp rating of the fuse that should be

in the fuse clips, such as FRS-R 6 1/4. This simple step makes it easy to run spot

checks for proper fuse replacement. When installing the proper fuses in the switch

to give the desired level of protection, it often is advisable to leave spare fuses on

top of the disconnect, the starter enclosure or in a cabinet adjacent to the motor

control center. In this way, should the fuses open, the problem can be corrected

and proper size fuses easily reinstalled.

* Abnormal installations may require Fusetron or Low-Peak dual-element fuses of a larger size than shown provid-

ing only short circuit protection. These applications include:

(a) Fusetron or Low-Peak dual-element fuses in high ambient temperature environments.

(b) A motor started frequently or rapidly reversed.

(c) Motor is directly connected to a machine that cannot be brought up to full speed

quickly (large fans, centrifugal machines such as extractors and pulverizers, machines

having large fly wheels such as large punch presses.)

(d) Motor has a high Code Letter (or possibly no Code Letter) with full voltage start.

(e) WYE delta open transition start.

(f) Motor has a large inrush current, such as a Design B.

5 Amperes

READ NAMEPLATE

1

/

FRS-R 6

4

460V.

5 Amperes

460V.

460V.

Page 17

61

©2005 Cooper Bussmann

Transformers — 600V or Less

Equipment Protection

The requirements of 450.3 cover only transformer protection. In practice, other

components must be considered in applying circuit overcurrent protection. For

circuits with transformers, requirements for conductor protection per Articles

240 and 310 and for panelboards per Article 408, must be observed. Refer to

240.4(F), 240.21(B)(3), 240.21(C), 408.36(A) & (B).

Primary Fuse Protection Only [450.3(B)] (See Figure below) If secondary fuse

protection is not provided (as discussed in the next Section) then the primary

fuses must not be sized larger than as shown below.

Individual transformer primary fuses are not necessary where the primary

circuit fuse provides this protection.

Note: Section 450.3 requirements pertain only to transformer protection. Additional

circuit overcurrent protection for conductors or panelboards may be required per

Articles 240, 310, 408, 430.72.

* Primary Fuse (600V or less) and Secondary Fuse (600V or less). If

secondary (600V or less) fuses are sized not greater than 125% of transformer secondary current, individual transformer fuses are not required in the

primary (600V or less) provided the primary feeder fuses are not larger than

250% of the transformer rated primary current. [See Note 3 of Table 450.3(B)

for overcurrent protection requirements of thermally protected transformers].

Note: Transformer overload protection will be sacrificed by using overcurrent

protective devices sized much greater than the transformer F.L.A. The limits of

150%, 167%, 250% and 300% may not adequately protect transformers. It is

suggested that for the highest degree of transformer overload protection the

fuse size should be within 125% of the transformer full-load amps.

Normal magnetizing inrush currents for power transformers can range from 10

times to 12 times the transformer full load current, for up to 6 cycles, and as

high as 25 times transformer full load current at 0.01 seconds. Some

transformers may have inrush magnitudes substantially greater. Severe inrush

should be compared with melting times to assure that unnecessary opening of

the device does not occur.

There is a wide fuse amp rating range available to properly protect

transformers. Fusetron Class RK5 and Low-Peak Class RK1 dual-element

fuses can be sized on the transformer primary and/or secondary rated at

125% of the transformer F.L.A. These dual-element fuses have sufficient timedelay to withstand the high magnetizing inrush currents of transformers. There

is a wide amp rating selection in the 0 to 15A range for these dual-element

fuses to provide protection for even small control transformers.

The required secondary protection may be satisfied with multiple overcurrent

devices that protect feeders fed from the transformer secondary. The total amp

rating of these multiple devices may not exceed the allowed value of a single

secondary overcurrent device. If this method is chosen, dual-element, timedelay fuse protection offers much greater flexibility. Note the following

examples:

Design 1 utilizes a single secondary overcurrent device. It provides the

greatest degree of selective coordination, transformer

protection, secondary cable protection, and switchboard/

panelboard/load center protection. The transformer

cannot be overloaded to a significant degree if future loads

are added (improperly). With this arrangement the

transformer’s full capacity is utilized.

Primary Fuse Only

Primary Current Primary Fuse Rating

9 amps or more 125% or next higher standard rating if

2 amps to 9 amps 167% maximum

Less than 2 amps 300% maximum

TRANSFORMER No Secondary

Primary

600V

or Less

Fuse must not be larger than 125% of transformer primary F.L.A.

When no transformer secondary protection is provided

(exceptions as noted above).

125% does not correspond to a standard fuse

size.

Protection

Secondary

600V

or Less

Primary and Secondary Fuses

Secondary Current Primary Fuse Rating Secondary Fuse Rating

9 amps or more 250% max. 125% or next higher standard

Less than 9 amps 250% max. 167% max.

TRANSFORMER

Primary

600V

Or Less

Individual primary transformer fuse or primary feeder fuse

must not be larger than 250% of primary full-load current

when secondary fuses are provided at 125%, except

as noted above.

Secondary

600V

Or Less

rating if 125% does not correspond to a standard fuse size

Secondary Fuses at 125%

of secondary F.L.A. except

as noted above.

Page 18

62

©2005 Cooper Bussmann

Transformers — 600V or Less

Equipment Protection

Design 2 In this case the single secondary overcurrent device is

eliminated, much of the protection described in Design 1 will

be reduced. If dual-element fuses are utilized as branch circuit

protection, the transformer can continue to be loaded with the

five 83A motors because 5 x 110 = 550A, (less than the

maximum 600A). If additional loads are improperly added in

the future, overload protection will be lost because the primary

device can be sized at 250%.

Design 3 If the single secondary overcurrent device is eliminated and

MCPs are utilized as branch circuit protection, the transformer

will be seriously under-utilized because only one motor can be

connected. For one motor, 1 x 700% of 83 = 581 amps. For

two motors, 2 x 700% of 83 = 1162 amps. Since the sum of

the devices cannot exceed 600 amps, only one motor can be

connected when the motor circuit is protected by an MCP.

Design 4 Using the same procedure, if the single secondary main is

eliminated and thermal magnetic circuit breakers are utilized

as branch circuit protection per 430.52, only three of the

motors can be connected because the thermal magnetic

breakers will have been sized at approximately 250% of the

motor F.L.A. (83 x 250% = 207.5A.)

Note: If sized less than permitted by 430.52, nuisance tripping may result

since the new energy efficient motors have higher inrush currents.

Using a 200A circuit breaker would allow only three (600 ÷ 200) motors to be

connected. To add two additional motors of the same type as shown in Design

1 and Design 2 requires a larger transformer - one that would have a 1000A or

more secondary capability. A 300kVA 208V transformer has a 830A secondary

rating which is not sufficient. Therefore, the next standard size 3Ø transformer

is a 400kVA with a 1110A capacity to meet the new rule.

Page 19

63

©2005 Cooper Bussmann

Transformers — Over 600V

Equipment Protection

Primary and Secondary Protection

In unsupervised locations, with primary over 600V, the primary fuse can be

sized at a maximum of 300%. If the secondary is also over600V, the

secondary fuses can be sized at a maximum of 250% for transformers with

impedances not greater than 6% or 225% for transformers with impedances

greater than 6% and not more than 10%. If the secondary is 600V or below,

the secondary fuses can be sized at a maximum of 125%. Where these

ratings do not correspond to a standard fuse size, the next higher standard

size is permitted.

In supervised locations, the maximum ratings are as shown in the next

diagram. These are the same maximum settings as the unsupervised

locations except for secondary voltages of 600V or less, where the secondary

fuses can be sized at maximum of 250%.

Primary Protection Only

In supervised locations, the primary fuses can be sized at a maximum of

250%, or the next larger standard size if 250% does not correspond to a

standard fuse size.

Note: The use of “Primary Protection Only” does not remove the requirements

for compliance with Articles 240 & 408. See (FPN) in Section 450.3, which

references 240.4, 240.21, 240.100 and 240.101 for proper protection for

secondary conductors.

E-Rated Fuses for Medium Voltage

Potential & Small Power Transformers

Low amperage, E-Rated medium voltage fuses are general purpose currentlimiting fuses. A general purpose current-limiting fuse is capable of interrupting

all current from the rated interrupting current down to the current that causes

melting of the fusible element in 1 hour (ANSI C37.40). The E rating defines

the melting-time-current characteristic of the fuse and permits electrical

interchangeability of fuses with the same E Rating. For a general purpose fuse

to have an E Rating the following condition must be met:

The current responsive element shall melt in 300 seconds at an RMS current

within the range of 200% to 240% of the continuous current rating of the fuse,

fuse refill, or link (ANSI C37.46).

Cooper Bussmann low amperage, E-Rated fuses are designed to provide

primary protection for potential, small service, and control transformers. These

fuses offer a high level of fault current interruption in a self-contained nonventing package which can be mounted indoors or in an enclosure.

Application

As for all current-limiting fuses, the basic application rules found in the

fuseology section of this brochure should be adhered to. In addition, potential

transformer fuses must have sufficient inrush capacity to successfully pass

through the magnetizing inrush current of the transformer. If the fuse is not

sized properly, it will open before the load is energized. The maximum

magnetizing inrush currents to the transformer at system voltage, and the

duration of this inrush current varies with the transformer design. Magnetizing

inrush currents are usually denoted as a percentage of the transformer

full-load current, i.e., 10x, 12x, 15x, etc. The inrush current duration is usually

given in seconds. Where this information is available, an easy check can be

made on the appropriate Cooper Bussmann minimum melting curve to verify

proper fuse selection. In lieu of transformer inrush data, the rule of thumb is to

select a fuse size rated at 300% of the primary full-load current and round up

to the next larger standard size.

Example:

The transformer manufacturer states that an 800VA 2400V, single phase

potential transformer has a magnetizing inrush current of 12x lasting for 0.1

second.

A. IFL= 800VA/2400V = 0.333A

Inrush Current = 12 x 0.333 = 4A

Since the voltage is 2400 volts we can use either a JCW-1E or JCD-1 E.

B. Using the rule of thumb–300% of 0.333A is 0.999A.

Therefore we would choose a JCW-1E or JCD-1E.

PRIMARY

Over

600V

Max Fuse

=

300%

Over

600V

Max Fuse