Page 1

Technical Data 9000

Effective January 2019

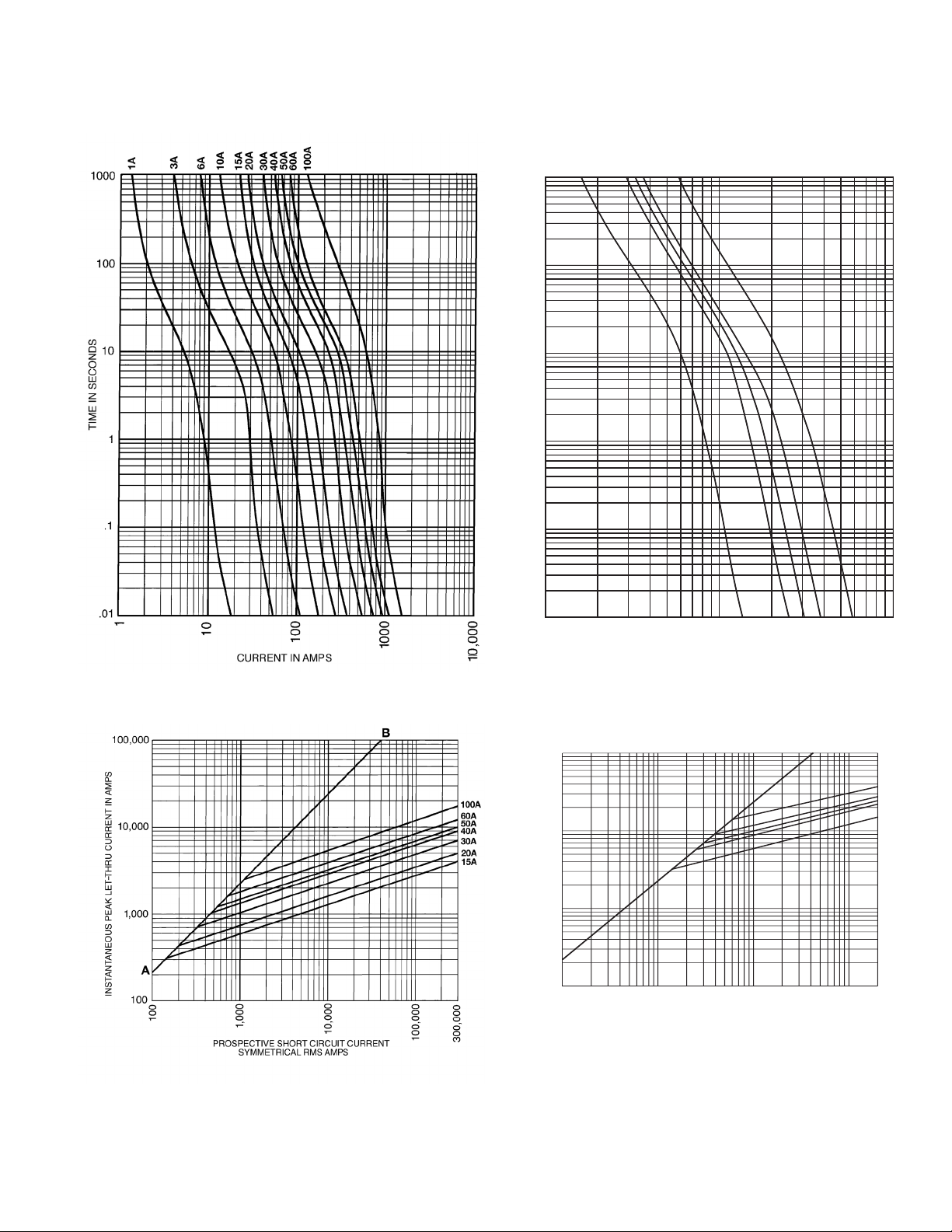

UL Class CF branch circuit time-delay CUBEFuse

0.01

0.1

1

10

100

1000

TIME IN SECONDS

CURRENT IN AMPS

110A

200A

250A

225A

400A

100

1,000

10,000

100

1,000,

10,000

100,000

B

A

250A

400A

225A

200A

110A

100

1,000

100,000

INSTANTANEOUS PEAK LET-THRU CURRENT IN AMPS

PROSPECTIVE SHORT CIRCUIT CURRENT

SYMMETRICAL RMS AMPS

10,000

Up to 100 A time-current characteristics — average melt

110 to 400 A time-current characteristics — average melt

Up to 100 A current let-through curves

110 to 400 A current let-through curves

3

Page 2

Technical Data 9000

Effective January 2019

UL Class CF branch circuit time-delay CUBEFuse

Motor sizing table (from NEC Tables 430.248 and 430.250)

Bussmann series TCF Low-Peak time-delay Class CF fuses

NEC

code max

(amps)

Voltage

Motor size

(Hp)

Motor FLA

(amps)

Min

(amps)

0.167 4.4 10 10 10

0.25 5.8 10 15 15

0.333 7. 2 15 15 15

0.5 9.8 15 20 20

0.75 13.8 25 25 30

115 Vac,

1-phase

1 16 25 30 35

1. 5 20 30 35 45

2 24 40 45 50

3 34 50 60 70

5** 56 90 100 125

7. 5 80 125 15 0 175

10 100 150 175 225

0.167 2.2 6 6 6

0.25 2.9 6 6 6

0.333 3.6 6 10 10

0.5 4.9 10 10 10

0.75 6.9 15 15 15

230 Vac,

1-phase

1 8 15 15 1 7. 5

1. 5 10 15 20 20

2 12 20 25 25

3 17 25 30 35

5 28 45 50 60

7. 5 40 60 70 90

10** 50

80 90 110

0.5 2.5 6 6 6

0.75 3.7 6 10 10

1 4.8 10 10 10

1. 5 6.9 15 15 15

2 7. 8 15 15 1 7. 5

3 11 1 7. 5 20 20

200 Vac,

3-phase

5 17. 5 30 35 35

7. 5 25.3 40 45 50

20** 62.1 10 0 110 125

25 78.2 125 15 0 175

30 92 150 175 200

40 120 200 225 250

50 150 225 300 300

60 177 300 350 350

Note: Use NEC code max column for low to moderate reverse/jog/

plug applications.

* Heavy Start permitted only if NEC code max does not allow motor start-up.

** If equipment terminations are rated for 60°C conductors only, the 60°C

conductor ampacities must be utilized and therefore larger conductor sizes or

conduit sizes may be required.

Heavy

start*

(amps)

Voltage

Motor size

(Hp)

Motor FLA

(amps)

Min

(amps)

NEC

code max

(amps)

Heavy

start*

(amps)

0.5 2.4 6 6 6

0.75 3.5 6 10 10

1 4.6 10 10 10

1. 5 6.6 10 15 15

2 7. 5 15 15 15

3 10.6 1 7. 5 20 20

208 Vac,

3-phase

5 16.7 25 30 35

7. 5 24.2 40 45 50

20** 59.4 90 110 12 5

25 74.8 125 150 150

30 88 150 175 175

40 11 4 175 200 250

50 143 225 300 300

60 169 300 300 350

0.5 2.2 6 6 6

0.75 3.2 6 6 6

1 4.2 10 10 10

1. 5 6 10 15 15

2 6.8 15 15 15

3 9.6 15 20 20

230 Vac,

3-phase

5 15.2 25 30 30

7. 5 22 35 40 45

20** 54 90 100 110

25 68

110 125 150

30 80 125 150 175

40 104 175 200 225

50 130 200 250 250

60 154 250 300 300

75 192 300 350 400

0.5 1. 1 3 3 3

0.75 1. 6 3 3 3

1 2.1 6 6 6

1. 5 3 6 6 6

2 3.4 6 6 6

3 4.8 10 10 10

5 7. 6 15 15 15

460 Vac,

3-phase

7. 5 11 1 7. 5 20 20

10 14 25 25 30

15 21 35 40 45

20 27 40 50 60

50** 65 10 0 125 125

60 77 125 150 150

75 96 150 175 200

100 124 200 225 250

125 156 250 300 350

150 180 300 350 400

Note: Use NEC code max column for low to moderate reverse/jog/

plug applications.

* Heavy Start permitted only if NEC code max does not allow motor start-up.

** If equipment terminations are rated for 60°C conductors only, the 60°C

conductor ampacities must be utilized and therefore larger conductor sizes or

conduit sizes may be required.

4

Page 3

Technical Data 9000

Effective January 2019

UL Class CF branch circuit time-delay CUBEFuse

Motor sizing table (from NEC Tables 430.248 and 430.250)

Bussmann series TCF Low-Peak time-delay Class CF fuses

NEC

code max

(amps)

Voltage

Motor size

(Hp)

Motor FLA

(amps)

Min

(amps)

0.5 0.9 3 3 3

0.75 1. 3 3 3 3

1 1. 7 3 3 3

1. 5 2.4 6 6 6

2 2.7 6 6 6

3 3.9 6 10 10

5 6.1 10 15 15

575 Vac,

3-phase

7. 5 9 15 20 20

10 11

40** 41 70 80 80

1 7. 5 20 20

50 52 80 100 110

60 62 100 110 125

75 77 125 150 150

100 99 150 175 200

125 125 200 225 250

150 144 225 300 300

200 192 300 350 400

Note: Use NEC code max column for low to moderate reverse/jog/

plug applications.

* Heavy Start permitted only if NEC code max does not allow motor start-up.

** If equipment terminations are rated for 60°C conductors only, the 60°C

conductor ampacities must be utilized and therefore larger conductor sizes or

conduit sizes may be required.

Heavy

start*

(amps)

5

Loading...

Loading...