Save This Manual for Future Reference

Original Instruction

Log Splitter

Operator’s Manual

MODEL NUMBER :

SERIAL NUMBER :

Both model number and serial number may be found on the main

label. You should record both of them in a safe place for future use.

FOR YOUR SAFETY

READ AND UNDERSTAND THE ENTIRE MANUAL BEFORE

OPERATING MACHINE

8

30 TON

LOG SPLITTER

2

LOG SPLITTER

TABLE OF CONTENTS INTRODUCTION

ite ia ll it e

e ate an t p

u

Carefully read through this entire

operator' s m anual b efore usin g

your new unit. Pay attention to all

cautions and warnings.

This unit is a

engine driven hydraulic

log splitter. It is designed to split wood logs

for use as firewood for a stove or fireplace.

This log splitter will only split logs lengthwise

with the grain.

Engine Manual

The Engine Manufacturer is responsible for

all engine-related issues with regards to

performance, power rating, specifications,

warranty and service. Please refer to the

Eng ine Manufacturer ’ s owner/ o perato r’s

manual, packed separately with your unit,

or

more information.

Introduction 2

Specifications 3

Symbols 4

Safety 5

Contents Supplied 9

Assembly 10

Know Your Machine 14

Operation 16

Transporting 19

Maintenance 20

Storage 21

Warranty 21

Troubleshooting 22

Parts Diagram 23

Notes 26

3

LOG SPLITTER

*Splitting force and cycle times may vary depending on mechanical and environmental conditions.

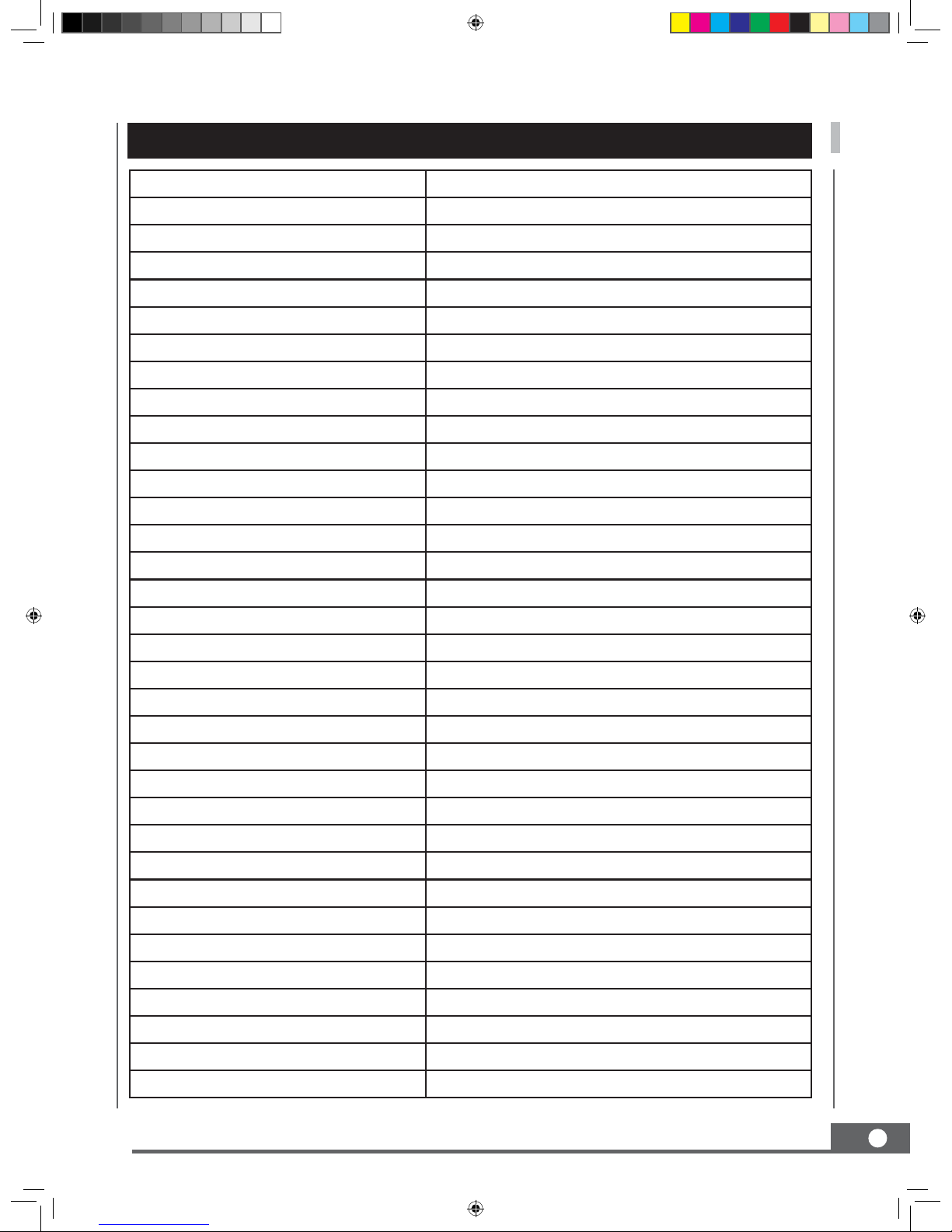

Specifications

Model # LS301

Splitting Force* 30 ton

Log Capacity 655 mm

Engine Kohler Command Pro CH395

Displacement 277 cc

Gross Torque @ 2600rpm 20 ONM

Fuel Capacity 7 L

Engine Oil Capacity 1.3 L

Starting System Recoil

Control Valve Auto Return with Adjustable Detent

Pump Size 17 GPM

Hydraulic Cylinder Bore

115 mm

Hydraulic Cylinder Stroke 610 mm

Hydraulic Rod Diameter 45 mm

Cylinder Cycle Time* 10.9 seconds

Hydraulic Capacity 22.5 L

Hydraulic Oil Included Pre-filled with premium hydraulic fluid

Replacement Filters Built-in, Sealed, Return Filter, Suction Screen

Hoses High pressure w/wire braid; Coil-wrapped

Beam Heavy duty U-shape formed construction

Wedge Size 190mm

Wedge Style 2-way

4-Way Wedge Optional

Rear Wheels 4.80-8, DOT Approved 16” O.D. Road Tyres

Hitch Coupler 2” Ball with Safety Chains

Safety Chains Standard

Max Towing Speed 50 kmh

Hitch Handle Standard

Horizontal/Vertical Splitting Standard

Open Operating Zone Standard

Log Cradle Standard

Log Table Optional

Weight 278 kgs

Dimensions (LxWxH) 232x121x94cm

4

ENVIRONMENTAL

SYMBOLS

The rating plate on your machine may

show symbols. These represent important

information about the product or instructions

on its use.

Recycle unwanted materials instead

of disposing of them as waste. All

tools, hoses, and packaging should

be resorted, taken to t he local

recycling center and disposed of in

an environmentally safe way.

Read these instr u c tions

carefully.

Wear eye protection.

Wear hearing protection.

Wear protective gloves.

Wear safety footwear.

Do not remove or tamper

with the protection and safety

devices.

Don’t stand or sit on the log

splitter.

Opera te the l og splitter on

level surfaces. Stay off slopes

and slippery surfaces.

Do not touch parts that are

hot from operation. Serious

burns may result.

No smoking, sparks, or flames.

Properly dispose of waste oil!

HYDRAULIC

OIL

FILLING

MAX.

MIN.

REVERSE

FORWARD

N

Keep children and bystanders

o and away from the log

splitter.

Be sure the engine's switch is

o before transporting the

machine or performing any

maintenance.

Keep hands and fingers away

from all pinch points.

Never remove partially split

wood from the wedge with

your hands. Fingers may

become trapped between the

split wood.

Keep hands away from

moving parts. Moving parts

can crush or cut.

Keep feet away from moving

parts. Moving parts can crush

or cut.

Always keep body and hands

away from pin holes or nozzles

that eject hydraulic fluid under

pressure. Escaping hydraulic

fluid can puncture skin and

cause blood poisoning.

Thrown objects.

Check and fill hydraulic oil.

Follow the direction indicated

to use the control lever.

For logs that are not cut

square, the longest portion of

the log should be rotated

down and the most square

end placed toward the end

plate.

LOG SPLITTER

LOG SPLITTER

5

a responsible adult.

Do not operate the machine while under the

influence of drugs, alcohol, or any medication

that could affect your ability to use it properly

.

Dress properly. Wear heavy long pants, boots,

and gloves. Do not wear loose clothing, short

pants, or jewellery of any kind. Secure long

hair so it is above shoulder level. Keep your

hair, clothing, and gloves away from moving

parts. Loose clothes, jewellery, or long hair

can be caught in moving parts.

Protect eyes, face, and head from objects that

may be thrown from the unit. Always wear

safety goggles or safety glasses with side

shields when operating.

Wear appropriate hearing protection.

Always keep hands and feet away from

all moving parts during operation. Moving

parts can cut or crush body parts.

Always keep hands and feet away from all

pinch points.

Do not to uch parts that might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust, or service.

Stay alert, watch what you are doing, and use

common sense when operating the machine.

Do not overreach. Do not operate the

machine whil

e barefoot or when wearing

sandals or similar lightweight footwear.

Wear protective footw ear that will

protect you r feet an d improve your

footing on slippery surfaces. Keep proper

footing and balance at all times. This enables

better control of the machine in unexpected

situations.

Inspect your Machine

Check your machine before starting it. Keep

guards in place and in working order. Make

sure all nuts, bolts, etc are securely tightened.

Never operate the machine when it is in need

of repair or is in poor mechanical condition.

Replace damaged, missing, or failed parts

before using it. Check for fuel leaks. Keep the

machine in safe working condition.

Do not

use the machine if the engine’s switch

does not turn it on or off. Any p etrol

powered machine that can’t be controlled with

the engine switch is dangerous and must be

replaced.

SAFETY

General Safety Rules

Understand your Machine

Read this manual and labels affixed to the

machine to understand its limitations and

potential hazards.

Be thoroughly familiar with the controls and

their proper operation. Know how to stop the

machine and disengage the controls quickly.

Make sure to read and understand all the

instructions and safety precautions as outlined

in the Engine Manufacturer’s manual

packed separately with your unit. Do not

attempt to operate the machine until you

fully understand how to properly operate

and maintain the engine and how to avoid

accidental injuries and/or property damage.

If the unit is to be used by someone other than

original purchaser or loaned, rented, or sold,

always provide this manual and any needed

safety training before operation. The user can

prevent and is responsible for accidents or

injuries that may occur to themselves, other

people, and property.

Do not force the machine. Use the correct

machine for your application. The correct

machine will do the job more efficiently and

safer at the rate it was designed.

Personal safety

Do not permit children to operate this machine

at any time.

Keep children, pets, and other people not

using the unit away from the work area. Be

alert and shut off unit if anyone enters work

area. Keep children under the watchful care of

MAX. 50 KPH

Do not transport with objects on the machine.

Maximum towing speed of

ph.

6

tank indoors.

Keep grounded conductive objects, such as

tools, away from exposed, live electrical parts

and connections to avoid sparking or arcing.

These events could ignite fumes or vapors.

Always stop the engine and allow it to cool

before filling the fuel tank. Nev er remove

the cap of the fuel tank or add fuel while the

engine is running or when the engine is hot.

Do not operate the machine with known leaks

in the fuel system.

Loosen the fuel tank cap slowly to relieve any

pressure in the tank.

Never overfill the fuel tank. Fill the tank to no

more than 1/2” below the bottom of the filler

neck to provide space for expansion as the

heat of the engine can cause fuel to expand.

Replace all fuel tank and container caps

securely and wip e up spilled fu el. Never

operate the unit without the fuel cap securely

in place.

Avoid creating a source of ignition for spilled

fuel. If fu

el is spilled, do not attempt to start

the engine but move the machine away

from the area of spillage and avoid creating

any source of ignition until fuel vapors have

dissipated.

When fuel i s spilled on yourse lf or your

clothes, wash your skin and change clothes

immediately.

Store fuel in containers specifically designed

and approved for this purpose.

Store fuel in a cool, well-ventilated area, safely

aw ay from s parks, op en flames, or other

sources of ignition.

Never store fuel or a machine with fuel in the

tank inside a building where fumes may reach

a spark, open flame, or any other source of

ignition, such as a water heater, furnace, or

clothes dryer. Allow the engine to cool before

storing in any enclosure.

Hydraulic system safety

The hydraulic system of the machine requires

careful inspection along with the mechanical

parts. Be sure to replace frayed, kinked,

cracked, or otherwise

damaged hydraulic

hoses or hydraulic components.

Hydraulic fluid can result in severe burns. Fluid

Regularly check to see that keys and adjusting

wrenches are removed from the machine area

before starting it. A wrench or a key that is left

attached to a rotating part of the machine may

result in personal injury.

Avoid accidental starting. Be sure the engine’s

switch is off before transporting the machine or

performing any maintenance or service on the

unit. Transporting or performing maintenance

or service on a machine with its switch on

invites accidents.

If the machin e should start to v i brat e

abnormally , stop the engi ne (motor) and

check immediately for the cause. Vibration is

general

ly a warning sign of trouble.

Engine safety

This machine is equipped with an internal

combustion engine. Do not use on or near any

unimproved, forest covered, or brush covered

land unless the exhaust system is equipped

with a spark arrester meeting applicable local,

state, or federal laws.

Under Australian Law, a spark arrester is to

be fitted to the engine. A spark arrester, if

used, must be maintained in effective

working order by the operator.

Never start or run the engine inside a closed

are a. The e xhaust f umes a re

dan gerous , containing carbon monoxide, an

odorless and deadly . Operate this unit

only in a well-ventilated outdoor area.

Do not tamper with the engine to run it

at excessive speeds. The maximum engine

speed is preset by the manufacturer and is

within safety limits. See engine manual.

Keep a Class B fire extinguisher on hand when

operating this log splitter in dry areas as a

precautionary measure.

Fuel safety

Fu

el is highly flammable, and its vapors can

explode if ignited. Take precautions when

using to reduce the chance of serious personal

injury.

When refilling or draining the fuel tank, use

an approved fuel storage container while in

a clean, well-ventilated outdoor area. Do not

smoke, or allow sparks, open flames, or other

sources of ignition near the area while adding

fuel or operating the unit. Never fill the fuel

LOG SPLITTER

LOG SPLITTER

7

in the hydraulic system can penetrate skin

and result in serious injury or death. Be sure to

stop the engine and relieve hydraulic pressure

before doing any work on hydraulic parts.

Keep body and hands away from pin holes or

nozzles that expel hydraulic fluid when under

pressure. Use paper or cardboard, not hands,

to search for leaks.

Ensure all hydraulic fluid connections are tight

and all hydraulic hoses and lines are in good

condition before applying pressure to the

system.

Do not remove the cap from the hydraulic

tank or reservoir while the machine is running.

The tank could contain hot oil under pressure,

which could result in serious injury.

Do not adjust the pressure setting on the

hydraulic pump or valve.

If injured by escaping fluid, no matter how

small the wound is, see a doctor at once.

A typical injection injury may be a small

wound that does not look serious. However,

severe in

fection or reaction can result if

proper medical treatment is not administered

immediately by a doctor who is familiar with

injection injuries.

Specific Safety Rules

Preparation of the log

Both ends of the log should be cut as square

as possible to prevent the log from rotating

out of the splitter during operation.

Never split logs greater than the specified log

capacity.

Do not operate the log splitter on icy, wet,

muddy, or slippery ground. Only operate your

log splitter on level ground.

Operating on a slope could cause

the log splitter to roll over or logs

to fal l o the equipment, which

could result in injury.

Do not move the log splitter ov er hilly or

uneven terrai n wi thout a t ow v ehicle or

adequate help.

Keep the work area free of clutter. Remove

spl i t wood from a r ound the log splitt e r

immediately after each use to avoid potential

tripping.

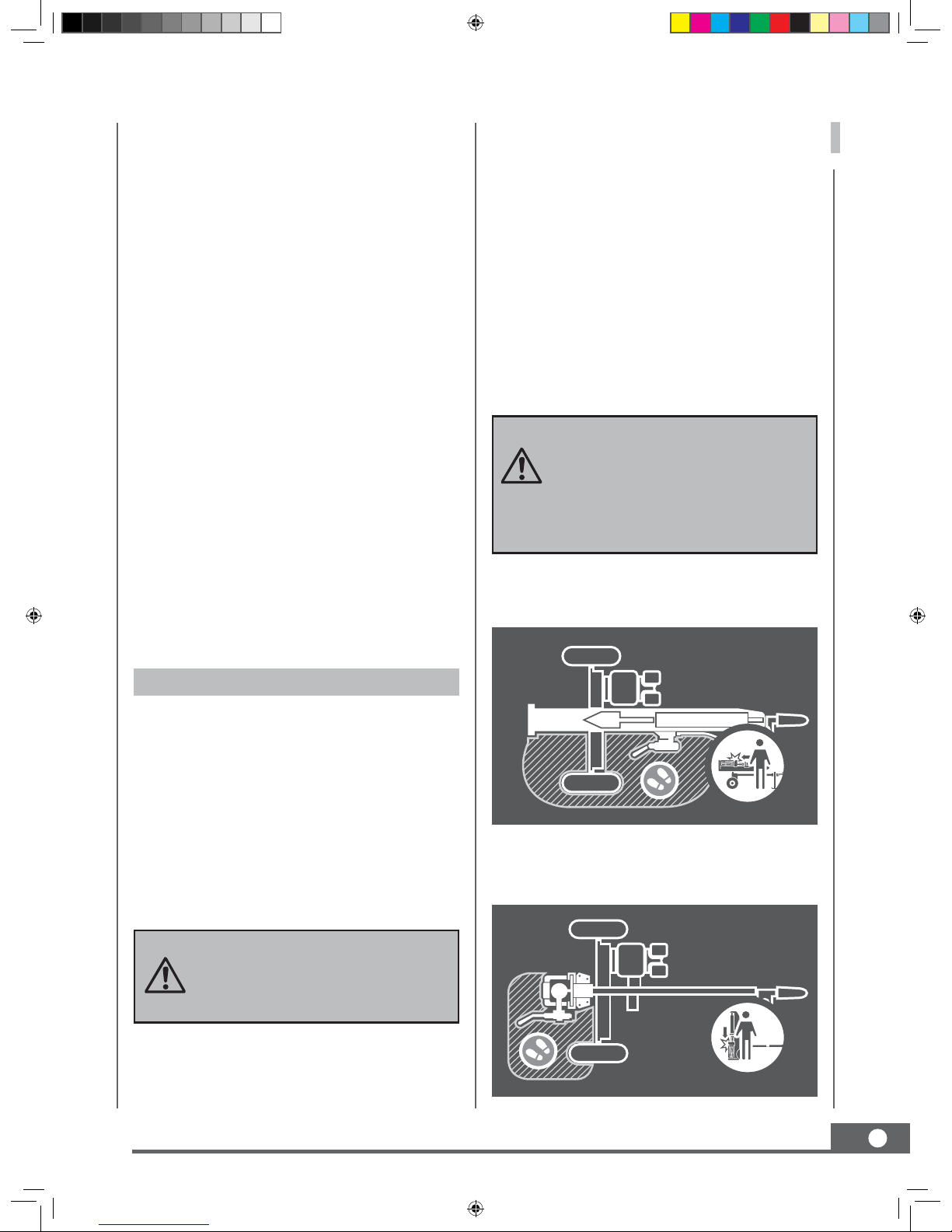

Operator zone

This unit is designed to be operated by one

person located in the operator zone as shown

in the following diagrams.

Operate the unit only when standing in the

operator zone.

Always stop the unit and allow moving parts

to stop before leaving operation zone. Do not

leave a running unit unattended.

Many accidents occur when more

than one person operates the log

splitter.

The adult who loads and stabilises

the log must be the person who

operates the control handle.

Horizontal operating position

Vertical operating position

8

Machine use and care

Never operate the machine without good

visibility or light.

Never attempt to split wood across the grain.

The log splitter was not designed for crossgrain splitting.

Al ways block the front and back of both

wheels to prevent unintended movement.

Hold the bark side of the logs when loading or

positioning, never the ends. Never place your

hands or any part of your body between a log

and any part of the log splitter.

Do not straddle or step over the log splitter

during operation.

Do not reach or bend over the log splitter to

pick up a log.

When stabilizing a log wi th the le ft hand,

remove your hand when the wedge contacts

the log or serious injury may occur.

Never attempt to split more than one log at a

time.

Do not attempt to load your log splitter when

the ram or wedge is in motion.

Use your hand to operate the control lever on

the valve. Do not use your foot, a rope, or any

extension device.

Do not move the log splitter while the engine

is running.

Towing safety

Check

all local and state regulations regarding

towing, licensing, and lights before towing

your log splitter.

Before towing the log splitter, check t

res

for excessive wear, cuts, or damage. Check

for proper t

re inflation. Add air as

required. Do not over inflate t

res. Serious

injury can result if t res explode.

Check before towing to make sure the log

splitter is correctly and securely attached to

the towing vehicle and the safety chains are

secured to the hitch or bumper of the vehicle

with enough slack to allow turning. Always use

a class I, 2" ball with this log splitter.

Make sure the coupler is tight before towing

and after towing 50

LOG SPLITTER

Never transport cargo on the log splitter.

Never allow anyone to ride or sit on the log

splitter.

Always stop the engine, lock the beam in the

horizontal position, and close the fuel shut-off

valve when transporting the unit.

Use extra care when towing the log splitter.

Do not exceed 50 kph. Towing the log splitter

at a speed greater than 50 kph could result

in loss of control, damage to the

equipment, serious injury, or death.

Avoid sharp turns and steep angles. Avoid

lar ge holes o r ditches when towing t h e

equipment. Always be careful when backing

up with your log splitter when to wing; it

could jackknife. Use caution when backing

up; a spotter outside the vehicle is highly

rec

ommended. Disconnect the log splitter

from the towing vehicle before operating it.

LOG SPLITTER

9

CONTENTS SUPPLIED

1. Beam with Cylinder

2. Reservoir with Engine

3. Beam Lock Bracket

4. Pivot Bracket

5.

Log Cradle (Left)

6.

Log Cradle (Right)

7.

Wheels

8.

Tow Bar

9. Manual Tube

10. Operator’s Manual and Engine Manual

11.

Tools for Spark plug Assembly

12.

Log Table (Optional)

13. Hardware Kit, Including:

3

4

7

9

8

OPTIONAL

12

11

10

2

1

6

5

13

Your log splitter comes partially assembled and contains the following:

OPTIONAL

M22 X 2

A

4 X 50

X 2

X 2

M12 X 90 X 2 B

M10 X 25 X 4 C

20 X 110 X 1

D

Bridge Pin X 1

M10 X 25 X 2 E

M8 X 20 X 2 F

M12 X 35 X 8 G

M10 X 25 X 4 H

LOG SPLITTER

10

This log splitter was partially assembled at the

factory. To assemble your machine follow the

below instructions.

WHEELS

ASSEMBLY

Remove the anti-dust sleeves from the two

wheels. Take the anti-dust washers and

roller bearings from the wheels and set

aside for later use.

1.

At least two people are needed to move

the reservoir outside of the pallet. Place

the engine at the end corner of the pallet.

Remove the two anti-dust sleeves from the

wheel axle.

2.

3.

Assistant holds the engine, while the other

person assembles the wheel opposite of

the engine first.

4.

Slide the anti-dust washer and one roller

bearing onto the axle. Use a soft-faced

hammer to tap the roller bearing lightly

to make sure the bearing is in the right

position.

Slide the wheel with the valve stem facing

out to the wheel axle and the other roller

bearing, then put the wheel washer against

the bearing. Use a 32mm socket to tighten

the axle nut completely.

Spin the wheel

clockwise or counterclock

wise to ensure proper bearing seating.

Loosen the axle nut until it is loose enough

to turn the wheel with your fingers.

Retighten the axle nut until "finger tight."

Insert the cotter pin through the hole in the

axle. Bend open and spread the prongs in

5.

7.

8.

9.

10.

6.

An-dust Washer (x2)

An-dust Sleeve (x4)

Roller Bearing (x4)

Figure 1a

Reservoir with Engine

45

o

Use the shipping crate boom

for balancing when installing

the wheel assembly.

Figure 1b

An-dust Sleeve (x2)

Wheel Sha

Figure 1c

Axle Nut (x1)

Coer Pin (x1)

Roller Bearing (x2)

An-dust Washer (x1)

Wheel Washer (x1)

Wheel

Cap

(x1)

32

mm

Figure 1d

M22 X 2

A

4 X 50

X 2

X 2

LOG SPLITTER

11

opposite directions so the axle nut will not

come off (make sure the tyre spins freely).

Use a soft-faced hammer to tap the antidust washer in the right position.

Align the wheel cap against the wheel hub.

Use a soft-faced hammer to tap the wheel

cap onto the wheel hub properly.

Follow the same procedure to assemble

the other wheel (follow steps 4 – 12 under

wheel assembly.)

11.

13.

12.

Install ation of the cotter p in is

important and required. Failure

to install the cotter pin can result

in loss of wheel retention. Always

assemble using a new cotter pin. Do

not reuse.

Hold and pull the beam until the log cradle

mount and the beam is against the wooden

block in-pallet.

Slowly lift the top of the beam and stand

the beam on the end plate in the vertical

position.

1.

2.

BEAM

Aft er the beam and cyl inder

assembly is in the vertical position, a

helper is needed to prevent the beam

from tipping over until it is secured

on the hydraulic tank assembly with

the hitch pin and R-clip.

The beam assembly is heavy and

has a small foot print. When in the

vertical position, the beam may fall,

causing damage to the machine and

could result in personal injury.

TOW BAR

Insert the tow bar into the tank pivot mount. Align

the holes in the tow bar with the holes in the tank

pivot mount. Connect and tighten the tow bar to

the tank by using the M12x90 bolts, flat washers,

spring washer, and nuts. (See

Figure 3)

Figure 2a

Wooden Block

Log Cradle Mount

Beam

Figure 2b

Beam

M12x90 (x2)

Tank Assembly

Tow Bar

Tank Pivot Mount

M12 (x2)

18

mm

19

mm

30

mm

X 2

Figure 3

M12 X 90 X 2 B

SUPPORT LEG

Lift the tow bar slightly. Pull out the lock lever

and put the support leg in the DOWN position,

then release the lever and make sure the leg is

secured. Remove the bottom pallet.

Support Leg

Support Leg Lock

Liing Handle

Figure 4

SPLITTER

12

PIVOT BRACKET

Align the holes in the pivot bracket with the

holes on the beam and insert and tighten

bolts, spring washers, and flat washers.

The beam can be very heavy and

dangerous if it tips over and

may cause personal injury.

BEAM TO RESERVOIR

Make sure a helper holds on to the beam

to keep it from falling. Reposition the

beam and reservoir so the back of the tank

is facing the vertical beam as shown in

Figure 6a.

1.

Ali gn the pivot brac ket on the beam

assembly to the pivot mount on the tank

weldment and insert the beam pivot pin

and washer. (See

Figure 6b

)

2.

Insert the bridge pin through the hole in

the beam pivot pin.

3.

M10x25 (x4)

Pivot Bracket

Beam

Parallel Lines

16

mm

19

mm

Figure 5

Figure 6a

Beam Pivot Pin (x1)

Tank Pivot Mount

Washer (x1)

Bridge Pin (x1)

Pivot Bracket

Figure 6b

BEAM LOCK BRACKET

When mounting the lock latch assembly,

make sure the latch rod side of the bracket

is on the same side as the engine. Install

the beam lock bracket to the beam by

using the beam lock M10x25 bolts, spring

washer, and flat washers. (See

Figure 7a)

1.

M10x25 (x2)

Beam Lock Bracket

Beam

Parallel Lines

16

mm

19

mm

Figure 7a

M10 X 25 X 4 C

M10 X 25 X 2 E

20 X 110 X 1

D

Bridge Pin X 1

LOG SPLITTER

13

Hold the lifting handle and slowly lower the

beam. It will lock automatically. Double

check to make sure the beam bracket is

locked onto the beam.

2.

Do not let the beam suddenly drop.

Keep hand s and fingers clear of

pinch or crush points at all times.

MANUAL TUBE

LOG CRADLES

Remove the cap from the manual tube.

Align the holes in the manual tube with

the holes in the tow bar. Insert and tighten

bolts and washers. (See Figure 8)

Reattach the cap.

1.

2.

M12x35 (x8)

Log Cradle (Right)

Outside Holes

Inside Holes

Figure 9

18

mm

19

mm

30

mm

19

mm

Beam Lock Bracket

Figure 7b

M8x20 (x2)

Manual Tube

Cap

16

mm

13

mm

18

mm

19

mm

30

mm

Figure 8

2. Follow step 1 to assemble the left log cradle.

(See Figure 9)

1. Align the holes on the right log cradle to the

inside and lower holes on the beam mounts.

Insert the M12x35 bolts, flat washers, and

nuts and securely tighten.

M12 X 35 X 8 G

M8 X 20 X 2 F

LOG TABLE (OPTIONAL)

Refer to Figures 9 and 10 to install the work

table. Remove the bolts, flat washers, and nuts

from the inside holes. Move the log cradle

from the incline position to the horizontal

position. Align the holes on the log cradle

with the outside holes on the beam mount.

Reinstall the bolts, flat washers, and nuts.

Place the work table over the holes in the log

cradle and align the 4 holes from the work

table plate and log cradle. Insert and tighten

the M10x25 bolts, spring washers, flat washers,

and nuts.

M10x25 (x4)

Work Table

Outside Holes

Log Cradle (Right)

Inside Holes

M10 X 25 X 4

8

16

mm

18

mm

19

mm

30

mm

Figure 10

SPLITTER

14

KNOW YOUR MACHINE

Features and Controls

Log Stripper

Split Control Handle

4-Way Wedge(Optional)

Log Spinner Foot Plate

2-Position Log Cradle

Cylinder

Lifting Handle

Manual Tube

Reservior

Safety Chains

Control Valve

Hydraulic Breather/Dipstick

Beam Lock Bracket

Support Leg

Beam Assembly

2” Ball Hitch Coupler

Hydraulic Pump

Log Table (Optional)

LOG SPLITTER

15

Engine On/O Switch

Recoil Starter Handle

Choke Control

Fuel Shut-O Valve

Throttle Control

LOG SPINNER FOOT PLATE

The foot plate holds the log in place while

the wedge splits the log.

The foot plate allows the operato r to

easily spin a log in prep for splitting and

allows the log to rotate when splitting

instead of causing unnecessary stress on

the beam.

It is easy to replace when the grip teeth

are damage d . No repair weldi ng is

required.

2-POSITION LOG CRADLE

The log cradles are designed to catch the log

after it is split.

2-position function – The first positon is

to center logs on the beam. The second

position provid es a fla t s urface and

worktable on which to put logs.

SPLIT CONTROL HANDLE

The c ont rol handle i s u s ed to mo ve

the wedge up and down to split logs.

The control handle has three positions:

Forward, Neutral, and Reverse. See th

e

“operation” section for instruction.

MANUAL TUBE

Keep manuals safely in the tube.

BEAM LOCK BRACKET

The beam lock bracket is used to secure

the beam in the horizontal position.

LIFTING HANDLE

The liftin g handle is inclu ded for easy

transition from horizontal to vertical.

2” BALL HITCH COUPLER

The coupler h itch is at the end of the

tow bar and attaches to a tow ball for

transportation purposes.

4-WAY WEDGE(OPTIONAL)

The 4-way wedge is used to split the log

into four pieces at one time.

LOG STRIPPER

The log stripper is designed to remove

any partially split wood from the wedge.

This may occur while splitt ing large

diameter wood or freshly cut wood.

BEAM ASSEMBLY

The U-beam s tru c tura l de sign i s

significantly stronger than a typical I-beam

design.

LOG TABLE (OPTIONAL)

A log table/platform can be mounted on

the log cradle directly.

ENGINE ON/OFF SWITCH

The engine switch has two positions.

OFF - engine will not start or run.

ON - engine will start and run.

LOG SPLITTER

16

RECOIL STARTER HANDLE

The handle is used to start the engine.

FUEL SHUT-OFF VALVE

The fuel shut – off has two p osition.

CLOSED (

) - use t h is position t o

service, transport, or store the unit.

OPEN (

) - use this position to run the

unit.

CHOKE CONTROL

The choke control is used to choke the

carburetor and assi st in starting th e

engine. The choke control slides between

the CHOKE CLOSED

and CHOKE

OPEN

positions.

THROTTLE CONTROL

The throttle control regulates the speed

of the engine and will shut off the engine

when it is moved to the STOP position.

The throttle control moves between FAST

, SLOW , and S

TOP positions.

OPERATION

3. Using a funnel, add oil up to the FULL mark

on the dipstick. (See engine manual for oil

capacity, oil recommendation, and location

of fill cap.)

The engine is shipped without oil.

Do not start the engine before

adding oil.

Pet rol is highly flam mable

and explosive. You can be

burne d o r seriously injured when

handling fuel. Us e extreme care

when handling petrol.

Fill the fuel tank outdoors, never

indoors. Petrol vapors can ignite if

they collect inside an enclosure.

Explosion can result.

IMPORTANT: DO NOT OVERFILL!

This equipment and/or its engin e

may include evaporative emissions

c o n tr ol syst e m c omponent s ,

required to meet EPA and/or CARB

regulations, that will only function

properly when the fuel tank has been

fi lled to th e r ecommen ded

l eve l.

Overfilling may c ause permanent

damage to evaporative emissions

control system components. Filling

to the recommended level ensures

a vapor gap required to allow for

fuel expansion. Pay close attention

while filling the fuel tank to ensure

th at the recommended fuel lev el

inside the tank is not exceeded. Use

a portable petrol container with an

appropriately sized dispensing spout

when filling the tank. Do not use a

funnel or other device that obstructs

the view of the tank filling process.

DO NOT OVERFILL. Check engine

oil level daily and add as needed.

1. The engine must be off and allowed to cool

at least two minutes before adding fuel.

2. Remove the fuel filler cap and fill the tank.

(See engine manual for fuel capacity, fuel

recommendation, and location of fuel cap.)

ADD PETROL TO ENGINE

Many accidents occur when more than

one person operates the log splitter.

If a helper is assisting in loading logs

to be split, never operate the controls

until the helper is clear of the area.

2. Remove the oil fill

c ap/ dipstick t o

add oil.

CLOSEDOPEN

ADD OIL TO ENGINE

1. Make sure the log splitter is on a flat, level

surface.

3. Reinstall the fuel cap and tighten. Always

clean up spilled fuel.

LOG SPLITTER

17

The splitter wedge is designed

to reach the full extension before

contacting the foot plate.

To extend the life of the hydraulic

cylinder, avoid “bottoming out”

the wedge plate to the foot piece.

Cracks in logs can close quickly

and pinch fingers. Keep fingers

away from any cracks that open in

partially split logs.

Keep hands and fingers away from

the splitter wedge and log stripper

during cylinder retraction.

Never operate through the relief

valve for more than 5 seconds.

Forward position – Move the lever in this

direction to extend the cylinder toward the

spinner foot plate. Keep pressure on the lever

until the log splits. The lever does not lock in

this position. Release as soon as the log is split

or the cylinder is fully extended. (See Figure

11a and Figure 11b).

SPLIT CONTROL HANDLE

Neutral position – In this position the cylinder

does not move even though the engine is

running.

Reverse position – Move the lever in this

position to retract the cylinder. Push the lever

fully in this direction to lock it return mode. The

lever will automatically return to the neutral

position once the cylinder fully retracts.

Sudden stopping at a high speed,

under a heavy load, is not

recommended.

Engine damage may result.

STOP ENGINE

Return the cylinder to fully retracted position

or home position. Move the Throttle lever to

SLOW (

). Move the engine switch to OFF.

Close the fuel shut-off valve ( ).

If the engine is

hot, closing the

choke is not

necessary.

Rapid retraction of the starter cord

(kickback) will pull your handand arm

toward the engine faster than you

can let go. Broken bones, fractures,

bruises, or sprains could result.

STARTING ENGINE

OPENCLOSED

SLOWFAST

ONOFF

ONOFF

Make sure the control lever is in the neutral

position.

Pu l l the r ecoil s t art e r until engine

compression has become difficult to pull.

Let the recoil return to the home position,

then pull quickly to start the engine. Repeat

steps as needed. Fully open the choke and

set the throttle to the FAST position, before

operating the unit.

Move the engine

switch to the ON

position.

Open the fuel shutoff valve.

M ove t h e c hoke

lever to the CLOSED

position.

Move the throttle

lever slightly to the

FAST speed.

1.

6.

2.

3.

4.

5.

LOG SPLITTER

18

Reverse

Posion

Neutral Posion

Forward

Posion

Reverse Posion

Neutral Posion

Forward Posion

Liing Handle

Horizontal Beam Lock

1 2

Vertical Position

Rotating Position

Horizontal Position

CONVERSION BETWEEN HORIZONTAL

SPLIT TING PO SITION AN D V E R T ICAL

SPLITTING POSITION

STUCK LOG PROCEDURE

If a log does not split completely and becomes

stuck on the wedge, never attempt to

remove it by modifying the splitter or adding

attachments to the splitter.

Move the control lever to the Reverse positon

and allow the cylinder to retract until the stuck

log contacts the stripper plates. Continue to

retract the cylinder until the log is dislodged

from the wedge.

Do not use the unit if the stripper

plates are bent or damaged. Bent

or damaged stripper plates must be

repaired or replaced before use.

Figure 11b

Figure 11a

LOG SPLITTER

19

Support Leg lock

Up Posion

Down Posion

Figure 12

TRANSPORTING

The log splitter is heavy. It can

crush and cause serious injury if it

rolls out of control or tips over.

Make sure the log splitter engine

is o. Never move the log splitter

with its engine running.

MOVING BY HANDS

Foll ow the instructions below for safely

moving the log splitter.

Make sure the log splitter is locked in the

horizontal position with latch rod before

moving.

Turn the fuel shut-off valve to the OFF

position. This prevents carburetor flooding

and reduces the chance of fuel leakage.

Refer to the engine manual for fuel valve

location.

Lock the support leg in the DOWN position

before you move the log splitter.

Move the log splitter by hand to desired

work site.

1.

2.

3.

4.

Do not move the log splitter up or

down hills by hand.

Never allow anyone to sit or ride

on the log splitter.

Never transport cargo or wood on

the log splitter.

2. Check the tyres to ensure they are fully

inflated to 30 PSI for proper functionality.

TOWING BY VEHICLE

ONOFF

Turn the fuel shutoff valve off. This

prevents fuel from

flooding the engine.

1.

Do not t res. Serious

injury can occur if t re explodes.

When seating a bead after repair,

do not exceed 30 PSI. Pressures

higher than 30 PSI can cause the

t re and wheel to ruptu re

and explode.

Make sure hitch is in good working order.

Check safety chains. Two safety chains

must be used while towing. Cross safety

chains under the coupler, allowing only

enough slack for vehicle turns.

Pull out the lock lever and put the support

leg in the UP position, then release the lever

and make sure the leg is secured.

3.

4.

5.

Never tow this log splitter over

50 kph. Faster speeds may result

in loss of control.

Be aware of the added length of

the splitter.

6. Tow the log splitter carefully to desired

work site.

Drive slowly and take extra caution

when traveling over rough terrain.

Turn o the towing vehicle before

leaving the splitter unattended.

If towing on a public road, make

sure to comply with all local, state,

and federal towing requirements.

It is the sole responsibility of the

purchaser to obtain licensing, trailer

lights, safety chains, or signage as

needed to comply.

20

Oil-drain plug

Figure 13

Never operate the log splitter while

it is attached to the vehicle.

Lock the support leg in the DOWN position

and disconnect from vehicle.

7.

MAINTENANCE

Inspect and maintain the log splitter before

each use. If the log splitter has been used

p rev iou sly, it must be inspe cted and

maintained before each subsequent use.

Always shut off the engine and relieve

system pressure before inspecting, cleaning,

adjusting, or repairing the splitter. Relieve

system pressure by moving the split control

lever back and forth several times.

Remove debris from the engine, muffler, and

moving parts. Debris on a hot engine can be

a fire hazard. Clean debris and chaff from

the engine cylinder head, cylinder head fins,

blower housing rotating screen, and muffler

areas.

Avoid contact with hot muer.

Debris on mo v i ng parts can

cause excess wear. Clear debris

from the slide beam, wedge, and

end plate.

OIL DRAINING

Use a drain pan to aid in the remova

l of all

used oil and particles.

Remove oil drain plug to drain oil from the

hydraulic transmission system. Examine oil

fo r metal chips as a precaution to future

problems.

After oil has been completely drained from

the machine, reinstall drain plug.

LOG SPLITTER

HYDRAULIC

OIL

FILLING

MAX.

MIN.

ADD HYDRAULIC OIL TO OIL TANK

Never remove the hydrau li c

oil dipstick when the engine is

running or hot. Hot oil can escape

causing severe burns. Allow the

log splitter t o cool completely

before removing the hydraulic oil

dipstick.

The recommended

hydraulic oil type:

22 Anti-Wear

10W AW32

ASLE H-150

ISO 32

Make sure the hydraulic oil level reaches

the upper line of the dipstick.

Make sure the log splitter is on a flat, level

surface.

Remove the oil dipstick from the oil tank.

3.

4.

1.

2.

Completely install t he dipstick

when checking oil level.

Start the engine and use the control valve

handle to extend and retract the wedge

five times to remove a ir f rom the high

pressure lines.

With the wedge retracted and engine off,

check the oil level again. Fill if necessary.

Cy cle the c yli nder again until it has a

constant speed. This indicates that all air

has been expelled.

5.

6.

7.

LOG SPLITTER

21

STORAGE

WARRANTY

Never spray the engine or lo g

splitter with a pressure washer.

Water can contaminate the fuel

system and can enter the engine

and damage the engine.

Follow the instructions below for storing your

log splitter between uses.

Retract the wedge completely to keep the

rod protected from corrosion.

Allow the machine to cool 5 minutes before

storing.

Refer to the engine manual f or p roper

engine storage instructions.

Clear the debris from the beam, wedge,

and end plate. Use a damp cloth to clear

exterior surfaces of the engine and log

splitter. Use a soft bristle brush to remove

excess dirt and oil. Use an air compressor

(25 PSI) to clear dirt and small debris. Wipe

the beam, wedge, and all metal parts with

an oil rag to prevent corrosion.

1.

2.

4.

3.

can become stale when

stored over 30 days. Stale fuel

can cause acid and gum deposits

that form in the fuel system or on

carburetor parts. For engine fuel

that is stored less than 30 days,

add a fuel stabiliser to keep the

fuel fresh. Turn the fuel valve lever

to the o position. If fuel is stored

over 3 0 days, then drain t h e

fuel tank as stated in the engine

manual.

Always drain fuel from the tank in

an outdoor, well-ventilated area.

Stay away from sources of heat,

flame or sparks while handling

fuel.

Clean up fuel spills immediately.

Never store the log splitter inside

where there is a source of heat

or an open flame, spark, or pilot

light, such as a water heater,

sp ace heat er, f urnace, c lothe s

dryer, or o ther appl iance .

EVEN IF the log splitter's fuel tank

is empty, residual

vapors

could ignite.

Never store the log splitter near

fertiliser or any other corrosive

material.

vapors can ignite if they

collect inside an enclosure

and explosion can result.

Store petrol in a cool, dry place in a

tightly sealed container.

Store the log splitter in a location away

from corrosive materials, sources of heat,

open flames, sparks, or pilot lights.

6.

5.

3 years domestic warranty (excludes engine and

hydraulic components). 1 year hydraulic components.

Engine as per engine manufacturer’s warranty.

This warranty does not extend to:

• Replacement of parts due to fair wear and tear

over time.

• Damage caused by the purchaser such as failure to

maintain, operate, fuel or store the goods according

to the procedures specified in the owner`s manual

and abnormal use of the goods.

• Failure or damage caused by the modifications or

alterations to the goods which change their

intended use or adversely affect their performance,

safety, operation or durability.

To be entitled to claim on this warranty the purchaser

must report the fault of defect to an authorised

Bushranger

TM

dealer and provide proof of purchase

within the relevant warranty period specified.

AUSTRALIAN CONSUMER LAW (REG. 90):

The benefits to the consumer given by this warranty

are in addition to other rights and remedies of the

Consumer under a law in relation to the goods or

services to which this warranty relates.

Our goods come with guarantees that cannot be

excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure

and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to

be of acceptable quality and the failure does not

amount to a major failure.

The text above applies notwithstanding anything else

expressed or implied to the contrary in this warranty

document.

LOG SPLITTER

22

Problem Cause Remedy

Wedge movement is

slow or erratic

1.

Air in the hydraulic oil

system

2. Debris lodged in beam

guides

3. Low hydraulic oil

1. Purge air by extending and

retracting the wedge several times

until motion is smooth

2. Clear debris from beam

3. Check oil level and add as needed

Oil leak from cylinder

1. Faulty cylinder rod seal

2. Scored or bent cylinder rod

3. Loose hydraulic fitting

4. Faulty combination washer

seal on cylinder hydraulic

fitting

1. Contact customer service

2. Contact customer service

3. Tighten hydraulic fitting

4. Contact your Bushranger

TM

Dealer

Oil leak from hose

connection

Loose hose clamp or hydraulic

fitting

Tighten hose clamp or hydraulic fitting

Wedge will not

extend or retract

1. Faulty control valve

2. Faulty hydraulic pump

3. Low hydraulic oil

1. Contact your Bushranger

TM

Dealer

2. Contact your BushrangerTM Dealer

3. Check oil level and add as needed

Wedge does not

auto-return

1. Low hydraulic oil

2. Faulty control valve

1. Check oil level and add as needed

2. Contact your Bushranger

TM

Dealer

Excessive bouncing

while towing

Underinflated Inflate tyres to proper pressure

Control valve handle

does not return to

neutral when released

from forward position

1. Hydraulic oil too cold

2. Hydraulic oil too thick

3. Hydraulic oil contaminated

4. Faulty control valve

1. Warm up engine

2. Replace hydraulic fluid

3. Replace hydraulic fluid

4. Contact customer service

Engine will not start

1. Engine switch in OFF

position

2. Fuel shut-off valve in OFF

position

3. Fuel tank empty

4.

Spark plug disconnected

5. Faulty spark plug

6. Choke lever in wrong

position

7. Faulty engine

1. Move switch to ON position

2. Move valve to ON position

3. Fill fuel tank with fuel

4. Connect spark plug

5. Replace spark plug

6. Adjust choke lever position

7. Contact customer service

TROUBLESHOOTING

LOG SPLITTER

23

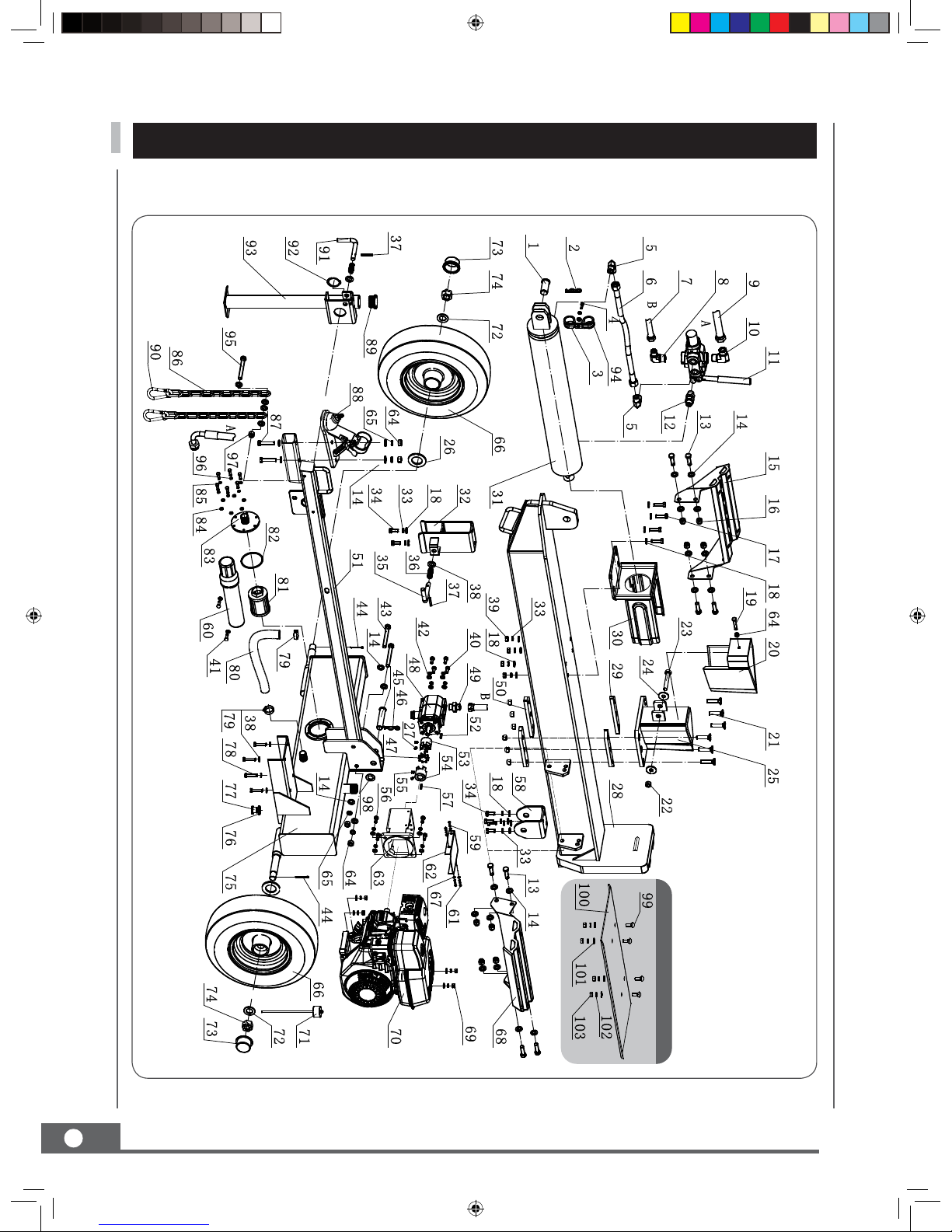

ILLUSTRATED PARTS LIST FOR LS301

30T LOG SPLITTER

LOG SPLITTER

24

* Parts List on page 26

PARTS DIAGRAM

LOG SPLITTER

25

PARTS LIST

No. Description

Qty

1 Pin 35

1

2 Bridge Pin

1

3 Hose Clamp 40

1

4

Hex Socket Head Cap

Screw M6x20

1

5 Right-Angle Fitting

2

6 Welded Hose

1

7 High Pressure Supply

Hose 1/2

1

8 Right-Angle Fitting 1

1

9 Low Pressure Return

Hose

1

10 Right-Angle Fitting 2

1

11 Control Valve

1

12 Straight Fitting

1

13 Bolt M12x35

8

14 Flat Washer 12

24

15 Log Cradle 1

1

16 Lock Nut M12

14

17 Bolt M10x35

4

18 Washer 10

18

19 Bolt M12x30

1

20 1-Way Wedge

1

21 Hexagon Recessed

Head Screw M12x55

6

22 Lock Nut M14

1

23 BOLT 14X90

1

24 Washer 14

4

25 Wedge

1

26 Anti-Dust Washer

2

27 Bolt M6x10

2

28 Beam Weldment

1

29 Guide Slide

2

30 Log Stripper Weldment

1

31 Cylinder

1

32 Beam Lock Bracket

1

33 Spring Washer 10

14

34 Bolt M10x25

6

35 Latch Rod

1

36 Pressure Spring

2

37 Pin 6X40

2

38 Washer 10

8

39 Nut M10

8

No. Description

Qty

40 Spring Washer 8

8

41 Bolt M8x20

6

42 Washer 8

10

43 Bolt M12x90

2

44 Cotter Pin 4x50

2

45 Beam Pivot Pin 20x110

1

46 Bridge Pin

1

47 Elastic Spider Block

1

48 Gear Pump

1

49 Outlet Connector of

Pump

1

50 Retainer Slide

2

51 Bracket Weldment

1

52 Key 3*25

1

53 Gear Pump Connector

Left

1

54 Gear Pump Connector

Right

1

55 Bolt M8x10

2

56 Bolt 5/16-24UNF

4

57 Key1/4*50

1

58 Pivot Bracket

1

59 Spring Washer 5

4

60 Manual Tube

1

61 Screw M5x10

4

62 Cover of Pump Bracket

1

63 Pump Bracket

1

64 Nut M12

5

65 Spring Washer 12

4

66 Wheel

2

67 Washer 5

4

68 Log Cradle 2

1

69 Nut M10

4

70 Engine

1

71 Dipstick

1

72 Wheel Washer 22

2

73 Dust Cap

2

74 Axle Nut M22

2

75 Tank Assembly

1

76 Washer 20

1

77 Oil Plug 20*1.5

1

78 Bolt M10x45

4

79 Clamp 25-38

2

Part Number

50001

50002

50003

50004

50005

50006

50007

50008

50009

50010

50011

50012

50013

50014

50015

50016

50017

50018

50019

50020

50021

50022

50023

50024

50025

50026

50027

50028

50029

50030

50031

50032

50033

50034

50035

50036

50037

50038

50039

Part Number

50040

50041

50042

50043

50044

50045

50046

50047

50048

50049

50050

50051

50052

50053

50054

50055

50056

50057

50058

50059

50060

50061

50062

50063

50064

50065

50066

50067

50068

50069

50070

50071

50072

50073

50074

50075

50076

50077

50078

50079

LOG SPLITTER

26

No. Description

Qty

80 Suction Hose

1

81 Return Oil Filter

1

82 O-Ring D81*3.1

1

83 Flange of Filter

1

84 Washer 6

7

85 Bolt M6x16

6

86 Safety Chain

2

87 Bolt M12x80

2

88 50mm Ball Hitch

1

89 Pipe Plug 48

1

90 Safety Clasp

1

91 Latch Rod

1

92 Circlip 34

1

93 Support Leg Weldment

1

94 Hose Clamp 45

1

95 Bolt M10x85

1

96 Washer 6

7

97 Nut M10

1

98 Flat Washer 20

1

Optional Work Table

99 Bolt M10x25

4

100 Log Table

1

101 Flat Washer 10

4

102 Spring Washer 10

4

103 Nut M10

4

Part Number

50080

50081

50082

50083

50084

50085

50086

50087

50088

50089

50090

50091

50092

50093

50094

50095

50096

50097

50098

50099

50100

50101

50102

50103

LOG SPLITTER

27

NOTES

LOG SPLITTER

28

or call 1300 363 027

for more information.

bushrangerpe.com.au

Visit

Bushranger™ is a trademark of Roy Gripske & Sons Pty Ltd. PLP shall not be liable for technical or editorial

errors or omissions contained herein, nor for incidental or consequential damages resulting from furnishing

this material. The information is provided “as is” without warranty of any kind and is subject to change

without notice. PLP also reserves the right to revise the content of this document at any time without prior

notice. No part of this document may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying, recording or storing in a retrieval system, or translated into any

language form without prior written permission of PLP.

Images are for illustrative purposes only. 866.

Copyright © 2018 Roy Gripske and Sons Pty. Ltd. All rights reserved

Loading...

Loading...