Page 1

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

SECTION 7: STEERING SYSTEM

SECTION 7 – STEERING SYSTEM

SPECIFICATIONS........................................................................... 7-2

Type: Rack and Pinion............................................................. 7-2

TOOLS ........................................................................................... 7-3

SAFETY FIRST............................................................................... 7-3

DESCRIPTION ................................................................................ 7-4

Steering .................................................................................... 7-4

REPAIR........................................................................................... 7-5

INSPECTION ............................................................................ 7-5

REMOVAL ................................................................................ 7-5

RACK AND PINION REMOVAL......................................... 7-5

STEERING WHEEL REMOVAL ........................................ 7-8

STEERING SHAFT REMOVAL ......................................... 7-8

INSTALLATION ............................................................................... 7-9

RACK AND PINION INSTALLATION ................................. 7-9

STEERING SHAFT INSTALLATION .................................7-10

STEERING WHEEL INSTALLATION ................................7-10

ADJUSTMENT...................................................................7-11

7-1

Page 2

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

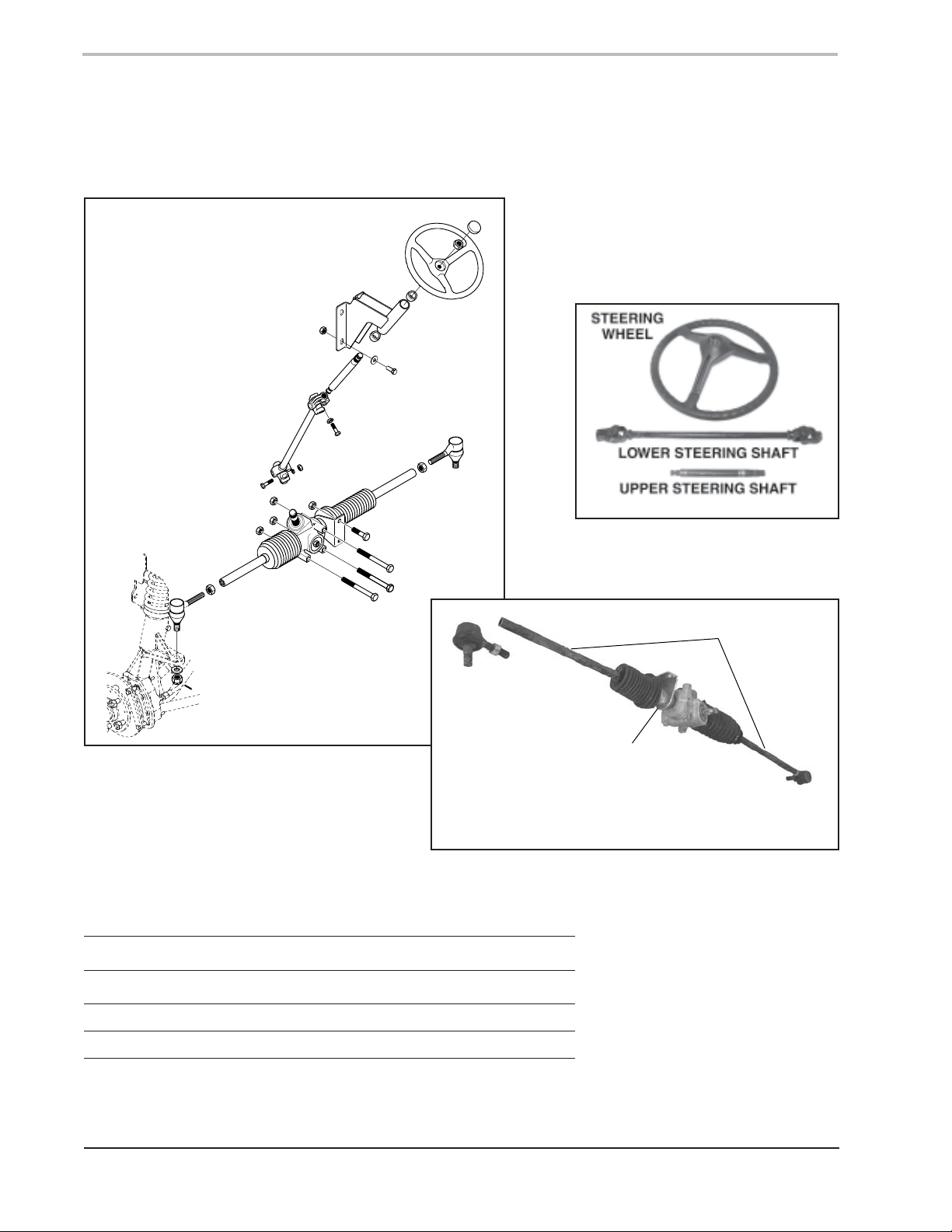

SPECIFICATIONS

TYPE: RACK AND PINION

STEERING

WHEEL

STEERING

SHAFT

BRACKET

STEERING

SHAFT

ASSEMBLY

TIE ROD

END

TIE ROD

END

Steering Assembly

TORQUE SPECIFICATIONS:

RACK & PINION

ASSEMBLY

TIE ROD

Steering Wheel and Shaft

RACK

LEFT

END

RIGHT

SIDE

BRACKET

RIGHT

TIE ROD

END

Rack, Pinion and Tie Rod Ends

COMPONENT TORQUE

Tie Rod End Slotted Nut 30 lbs. ft. (41 Nm)

Lug Nuts 50 lbs. ft. (68 Nm)

7-2

Page 3

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

TOOLS

Common hand and shop tools can be used to remove and install

steering system components serviced in the section. All special

tools are listed below.

Ball Joint Removal Tool (1.0-1.5” (25.4-38.1mm): Needed for

removal of tie rod ends from the strut casting steering arm. Ball joint

removal tools are commercially available in various sizes.

SAFETY FIRST

CAUTION

Never work underneath a raised vehicle without adequate support. Use jack stands

to prevent the vehicle from falling. A falling vehicle can cause severe personal

injury or death.

CAUTION

When lifting a vehicle chock the wheels left on the ground to prevent the vehicle

from rolling or sliding backward.

7-3

Page 4

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

DESCRIPTION

STEERING

The UTV rack and pinion steering (Figure 1) is common in many

automotive systems. The rack is a flat gear that extends outward

from both ends of the assembly. A tie rod end connects the rack to

the suspension strut assembly.

NOTICE: The suspension struts are described in the Suspension

Section of this manual.

The pinion is a rotary gear attached to the steering shaft assembly.

When the operator rotates the steering wheel the steering shaft turns

the pinion gear which drives the rack in a back and forth movement.

The rack and pinion gear set converts rotary steering wheel motion

into linear motion needed to turn the wheels. The rack and pinion

also provides gear reduction making it easier to steer the machine.

The tie rods connect to a steering arm on the struts used for turning

the strut. The wheels and hubs are mounted to the strut. See the

section entitled Suspension for a description of the strut assemblies.

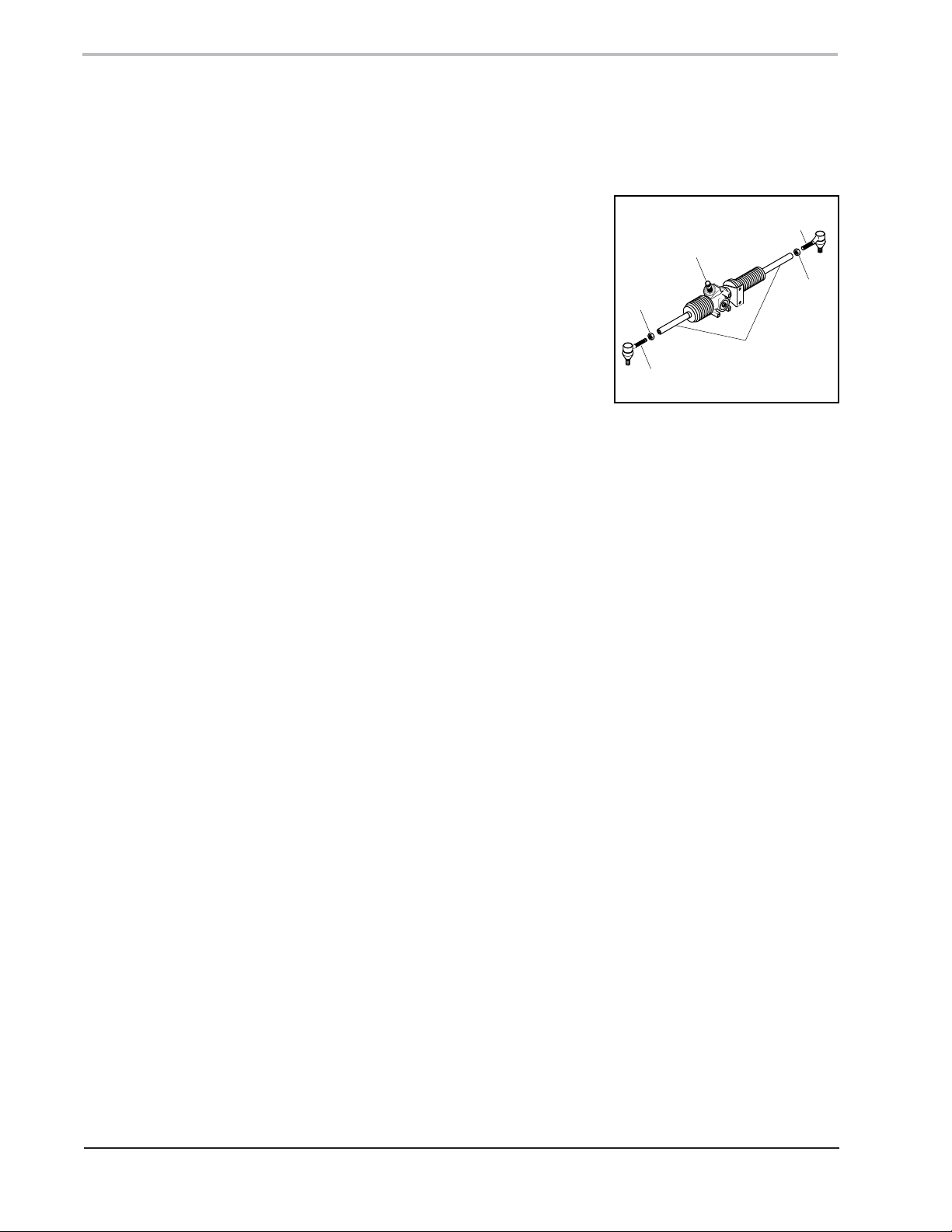

TIE ROD

END

LOCK

NUT

LOCK

NUT

TIE ROD

END

PINION

GEAR

DRIVE

RACK

Figure 1

Rack and Pinion Assembly

7-4

Page 5

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

REPAIR

INSPECTION

See the operator’s manual for recommendations on inspecting the steering system.

Complaints of steering wheel hard to turn, hard steering, or loose steering can be a result of a bad

pinion gear, bad rack, or bad tie rod ends.

Use the recommendations in the operator’s manual for initial testing. Inspect the rack and pinion and

tie rods for worn, loose, or damaged parts.

Check for excessive wear in the steering bracket and upper steering shaft. Inspect the upper and lower

steering shaft U-joints for excessive wear and damage. Replace the steering bracket bushings, steering

bracket, upper and lower steering shafts as needed.

REMOVAL

CAUTION

When working underneath a raised vehicle, always support the vehicle with jack

stands to prevent the vehicle from falling. A falling vehicle can cause severe

personal injury or death.

RACK AND PINION REMOVAL

1. Using a floor jack, lift the machine and support with jack stands.

TIE ROD END

2. Turn the steering tires all the way right.

3. Remove the cotter pin from both tie rod end slotted hex nuts.

Discard cotter pins.

4. Remove both tie rod slotted hex nuts (Figure 2).

SLOTTED HEX NUT

Figure 2

Tie Rod End

7-5

Page 6

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

NOTICE: Place the ball joint tool between the tie rod end rubber

boot and the low side of the steering arm. Drive the tool into the joint

breaking the tie rod end loose from the steering arm.

5. Using a ball joint tool (Figure 3) remove tie rod ends from the struts.

6. Loosen the tie rod end lock nuts (Figure 4).

BALL JOINT TOOL

TIE ROD END

Figure 3

Ball Joint Removal Tool

TIE ROD

END

7. Unscrew the tie rod ends (Figure 5) while counting each

revolution of the tie rod end. Note the total number of revolutions

required to remove the tie rod end from the rack.

8. Remove the hex head capscrew (Figure 5), nut, and lock

washer securing the lower steering shaft U-joint to the rack

and pinion assembly.

LOCK

NUT

Figure 4

Tie Rod End Removal

LOWER U-JOINT CAPSCREW

PINION INPUT

SHAFT

LOWER U-JOINT

CLAMP

Figure 5

Rack and Pinion Assembly

7-6

Page 7

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

9. Remove three capscrews and hex nuts securing the rack and

pinion assembly (Figure 6) to the frame support.

10. Remove two capscrews and lock nuts securing the right side

rack bracket (Figure 6) to the machine frame.

11. Disconnect the shifting cable from the shifting arm (Figure 7).

BRACKET & CAPSCREWS

CAPSCREWS

Figure 6

Rack and Pinion Assembly

SHIFTING ARM

12. Loosen the shifting cable housing lock nuts just enough to

remove the housing from the bracket (Figure 8).

13. Carefully remove the rack and pinion from machine.

14. Place the rack and pinion assembly on a work bench.

SHIFTING CABLE

Figure 7

Shifting Cable Linkage

SHIFTING CABLE

SHIFTING CABLE HOUSING

Figure 8

Shifting Cable Housing

7-7

Page 8

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

STEERING WHEEL REMOVAL

1. Turn the steering wheel for access to the upper steering shaft Ujoint capscrew (Figure 9).

2. Remove capscrew and lock washer from the upper U-joint clamp.

3. Pull the steering wheel and upper steering shaft out from the top.

4. Remove the hub from the center of the steering wheel.

5. Remove the hex nut securing the steering wheel to the upper shaft.

6. Using a press with a brass insert, press the upper shaft free from

the steering wheel.

STEERING SHAFT REMOVAL

1. Turn the steering shaft for access to the upper steering shaft

U-joint (Figure 10).

2. Using the section entitled Removal – Steering Wheel, remove the

steering wheel.

CAPSCREW

Figure 9

Upper Steering Shaft

U-joint

3. Remove two capscrews and lock nuts securing the steering joint

cover to the firewall (Figure 11).

4. Remove the steering joint cover.

5. Remove the capscrew, lock washer, and nut securing the lower

steering shaft U-joint to the rack and pinion assembly.

6. Remove the lower steering shaft from the rack and pinion assembly.

Figure 10

Upper Steering Shaft

U-joint

LOWER STEERING JOINT

STEERING JOINT COVER

Figure 11

Steering Joint Cover

7-8

Page 9

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

TIE ROD

END

LOCK

NUT

INSTALLATION

CAUTION

When working underneath a raised vehicle, always support the vehicle with jack

stands to prevent the vehicle from falling. A falling vehicle can cause severe

personal injury or death.

RACK AND PINION INSTALLATION

1. Position the rack and pinion assembly against the firewall for

installation.

2. Using the note indicating the number of turns required to unscrew

the tie rod ends; install the tie rod ends the same number of

revolutions (Figure 12).

3. Securely tighten the tie rod end lock nuts.

4. Position the rack and pinion assembly with the tie rod ends

resting in the strut steering arms.

NOTICE: The rack and pinion shaft can only be installed in one

position, one spline on the shaft is wider than the others and

must be aligned with the wider slot in the U-joint.

5. Install the pinion assembly into the lower steering shaft U-joint.

Secure the U-joint and pinion input shaft with a capscrew, lock

washer and hex nut. Tighten nut securely.

6. Install three capscrews and hex nuts securing the rack and

pinion assembly to the fire wall (Figure 13). Tighten securely.

7. Install two capscrews through the right side rack extension

bracket and frame support. Secure the bracket with two hex

nuts. Tighten securely.

8. Install a slotted nut on both tie rod ends. Tighten the nuts to 30

lbs. ft. (41 Nm) then back off to the first through slot.

9. Install and lock a new cotter pin in each slotted nut and tie rod end.

Figure 12

Tie Rod Installation

CAPSCREWS

Figure 13

Rack and Pinion

7-9

Page 10

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

10. Place the shifting cable housing on the mounting bracket with a

lock washer on each side of the bracket (Figure 14).

11. Tighten shifting cable housing nuts (Figure 14) securely.

12. Connect the shifting cable to the shifting arm. Tighten nut to

general torque specifications.

STEERING SHAFT INSTALLATION

NOTICE: The rack and pinion shaft can only be installed in one

position, one spline on the shaft is wider than the others and must

be aligned with the wider slot in the U-joint.

1. Position the lower steering shaft with the lower U-joint installed

on the pinion input shaft. Secure with a capscrew, lock washer

and hex nut. Tighten hex nut securely.

2. Install the steering joint cover over the bottom of the lower

steering shaft and align with mounting holes on the firewall.

Secure joint cover with two capscrews and lock nuts. Tighten

lock nuts securely.

LOCK WASHER

LOCK WASHER

Figure 14

Shifting Cable Housing

3. Using the section entitled Installation – Steering Wheel install

the steering wheel on the end of the upper steering shaft.

STEERING WHEEL INSTALLATION

1. Install the upper steering shaft through the steering bracket and

into the top of the upper steering shaft U-joint (Figure 15).

2. Install a capscrew and lock washer through the upper U-joint

clamp. Tighten securely.

3. Position the steering wheel on the end of the upper steering shaft

in the desired position. Secure steering wheel with hex nut.

Tighten hex nut securely.

4. Install hub in the center of the steering wheel.

Figure 15

Upper U-joint

7-10

Page 11

BUSH HOG® UTILITY VEHICLE WORKSHOP MANUAL – SECTION 7: STEERING SYSTEM

ADJUSTMENT

The UTV steering alignment can be checked for proper forward travel

by measuring (Figure 16) between the front center of the right

steering tire and left steering tire.

• Make note of the distance.

• Next measure between the rear center of the right steering tire

and the rear left steering tire. Make note of the distance.

• Compare the measurements of the center tire spread front and

rear. The measurement should be within 1/4".

CAUTION

When adjusting steering, compensation should not be

made for tire or rim deformities. Deformed tires or

wheels should be replaced to provide safe steering

and vehicle operation.

Adjustment can be made by removing the tie rod ends from the strut

steering arms.

FRONT

REAR

Figure 16

Steering Tire Alignment

1. Remove the tie rod ends slotted nut and cotter pin. Discard

cotter pin.

2. Use a ball joint removal tool to remove the tie rod end from the

strut. See the section entitled Removal – RACK AND PINION.

3. Loosen the tie rod end lock nuts.

4. Tighten or loosen the tie rod ends (Figure 17) in the rack to align the

steering tires. Secure the tie rod ends by tightening the lock nuts.

5. Position tie rod ends in the strut steering arms. Secure tie rod

ends with slotted nuts. Tighten nuts securely and back off to first

through hole in the nut and tie rod end. Install and lock new

cotter pins in each tie rod end.

6. Remove jack stands and lower vehicle. Perform steering

inspection as outlined in the operator’s manual.

Figure 17

Strut and Tie Rod End

7-11

Loading...

Loading...