Page 1

808

$10.00

50066586

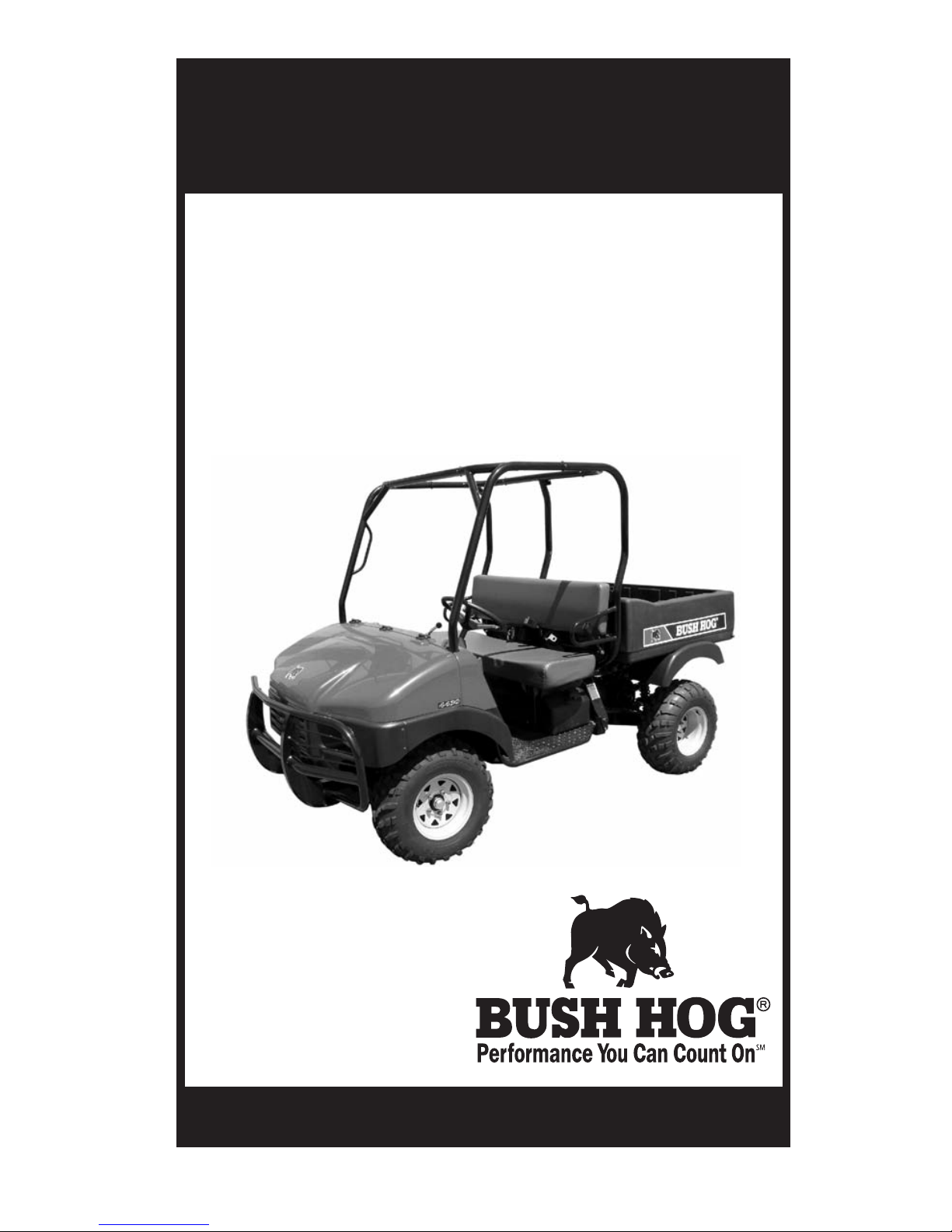

MODEL

4430

OFF ROAD UTILITY VEHICLE

Operator’s Manual

ASSEMBLY • OPERATION • MAINTENANCE

BUSH HOG

®

Page 2

CONGRATULATIONS!

You have invested in the best vehicle of its type on the market today.

The care you give your Bush Hog vehicle will greatly determine your

satisfaction with its performance and its service life. We urge a careful study of this manual to provide you with a thorough understanding

of your new vehicle before operating, as well as suggestions for operation and maintenance.

If your manualshould become lost or destroyed,Bush Hog will be glad

to provideyouwith a new copy. Order fromBushHog,P.O.Box1039,

Selma, Alabama 36702-1039.Mostof our manuals can also be downloaded from our website at www.bushhog.com.

As an authorized Bush Hog dealer, we stock genuine Bush Hog parts

which are manufactured with the same precision and skill as our original equipment. Our trained service personnel are well informed on

methods required to service Bush Hog equipment, and are ready and

able to help you.

Should you require additional information or assistance, please contact us.

YOUR AUTHORIZED BUSH HOG DEALER

BECAUSE BUSH HOG MAINTAINS AN ONGOING PROGRAM OF

PRODUCTIMPROVEMENT,WE RESERVETHERIGHT TO MAKE

IMPROVEMENTS IN DESIGNORCHANGES IN SPECIFICATIONS

WITHOUT INCURRINGANYOBLIGATIONTOINSTALLTHEMON

UNITS PREVIOUSLY SOLD.

BECAUSE OF THE POSSIBILITY THAT SOME PHOTOGRAPHS

IN THIS MANUAL WERE TAKEN OF PROTOTYPE MODELS,

PRODUCTION MODELS MAY VARY IN SOME DETAIL. IN ADDITION, SOME PHOTOGRAPHS MAY SHOW SHIELDS REMOVED

FOR PURPOSES OF CLARITY. NEVER OPERATE THIS IMPLEMENT WITHOUT ALL SHIELDS IN PLACE.

Page 3

BUSH HOG

®

4430 Utility Vehicle

TABLE OF CONTENTS

SECTION PAGE

Retail Customer’s Responsibility 2

Warranty 3

Dealer Preparation Check List 5

Safety Alert Symbols 6

Safety Precautions 7

I INTRODUCTIONANDDESCRIPTION 20

Introduction 20

Description 20

Specifications 27

II OPERATION 29

General Safety 29

Pre-Operation Checklist 29

Vehicle Break-In Period 29

Starting The Engine 30

Driving The Vehicle 30

Braking 31

Stopping The Engine 31

Using The Cargo Box 32

Load Distribution 33

Driving Safely 34

Driving On Slippery Surfaces 34

Driving Uphill 35

Sidehilling 36

Driving Downhill 36

Driving Through Water 36

Driving Over Obstacles 38

Driving In Reverse 39

Parking On An Incline 40

Hauling Cargo 41

Emptying The Cargo Box 42

Towing Loads 43

Parking The Vehicle 43

4-Wheel Drive 44

Disengaging 4-Wheel Drive 44

Noise Emission Control System 45

Spark Arrestor 46

SECTION PAGE

III MAINTENANCE 46

Periodic Maintenance Schedule 47

Lubrication Recommendations 50

Engine Oil 51

Engine Oil Filter Change 52

Transaxle 52

Front Differential 53

Right Angle Drive 54

Constantly Variable Transmission 55

Vehicle Immersion 56

Engine Air Filter 57

CVT Enclosure Air Filter 57

Fuel filter 58

Spark Plugs 58

Spark Arrestor 59

Throttle System 60

Brake Inspection 61

Parking Brake Adjustment 62

Steering Wheel Inspection 63

Seat Belts 63

Tires 64

Wheel Lug Nuts 64

Wheel Installation 65

Lights 65

Cleaning Your Vehicle 66

Storage 67

Removal From Storage 67

Battery 67

Replenishing Battery Fluid 68

Battery Removal 68

Battery Installation 69

Battery Storage 69

IVASSEMBLY 70

Attaching Occupant Protection

Structure 70, 71

Optional Equipment 70

Items To Check 70

Seat Belt Installation 71

Rubber Bumper Pad Adjustment 72

Troubleshooting CheckList 73

Safety Decals 74

Torque Specifications 76

1

Page 4

RETAIL CUSTOMER’S

RESPONSIBILITY

UNDER THE

BUSH HOG WARRANTY

It is the Retail Customer and/or Operator’s responsibility

to read the Operator’s Manual, to operate, lubricate, maintain and store the product in accordance with all instructionsand safetyprocedures. Failureof the operatorto read

the Operator’s Manual is a misuse of this equipment.

It is the Retail Customer and/or Operator’s responsibility

to inspect the product and to have any part(s) repaired or

replaced when continued operation would cause damage

or excessive wear to other parts or cause a safety hazard.

It is the Retail Customer’sresponsibility to deliver the product to the authorized Bush Hog Dealer, from whom he purchased it, for service or replacement of defective parts

which are covered by warranty. Repairs to be submitted

for warranty consideration must be made within thirty (30)

days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or hauling of the product for the purpose of performing a warranty obligation or

inspection.

2

Page 5

LIMITED WARRANTY

OOOOOOOOOOOOOOOOOOOO

OOOOOOOOOOO

Bush Hog warrants to the original purchaser of any new Bush

Hog equipment, purchased from an authorized Bush Hog dealer, that

the equipment be free from defects in material and workmanship for

a period of one (1) year for non-commercial, state, and municipalities’

use and ninety (90) days for commercial use from date of retail sale.

Model 4430 also carries a three (3) year limited drive train warranty.

This three (3) year limited drive train warranty covers the CVT

clutches, transaxle, driveline, front differential, and all four CV shaft

assemblies.The obligation of Bush Hog to the purchaser under this

warranty is limited to the repair or replacement of defective parts.

Replacement or repair parts installed in the equipment covered by this limited warranty are warranted for ninety (90) days from

the date of purchase of such part or to the expiration of the applicable

new equipment warranty period, whichever occurs later. Warranted

parts shall be provided at no cost to the user at an authorized Bush

Hog dealer during regular working hours. Bush Hog reserves the right

to inspect any equipment or parts which are claimed to have been defective in material or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CON-

SEQUENTIAL DAMAGES

Bush Hog’s obligation under this limited warranty, to the extent allowed by law, is in lieu of all warranties, implied or expressed,

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE and any liability for inci-

dental and consequential damages with respect to the sale or use of

the items warranted. Such incidental and consequential damages

shall include but not be limited to: transportation charges other than

normalfreight charges;costofinstallationotherthan cost approvedby

Bush Hog; duty; taxes; charges for normal service or adjustment; loss

of crops or any other loss of income; rental of substitute equipment,

expenses due to loss, damage, detention or delay in the delivery of

equipment or parts resulting from acts beyond the control of Bush

Hog.

CONTINUED

3

Page 6

CONTINUED

THIS LIMITED WARRANTY SHALL NOT APPLY:

1. To vendor itemswhichcarry theirownwarranties,suchasengines,

tires, and tubes.

2. If the vehicle has been subjected to misapplication,abuse, misuse,

negligence, racing, fire or other accident.

3. If parts not made or supplied by Bush Hog have been used in connection with the vehicle, if, in the sole judgement of Bush Hog such

use affects its performance, stability or reliability.

4. If the vehicle has been altered or repaired outside of an authorized

Bush Hog dealership in a manner which, in the sole judgement of

Bush Hog, affects its performance, stability or reliability.

5. To normal maintenance service and normal replacement items to

include, but not limited to gearbox lubricant, engine oil, all filters, and

spark plugs, or to normal deterioration of such things as belts and

exterior finish due to use or exposure.

6. To expendable or wear items to include, but not limited to teeth,

chains, sprockets, belts, brake pads, springs and any other items that

in the company’s sole judgement is a wear item.

7. To CV boots nor damageto the shaft assembliesfromrunning with

damaged or missing boots.

NO EMPLOYEE OR REPRESENTATIVE OF BUSH HOG IS

AUTHORIZED TO CHANGE THIS LIMITED WARRANTY IN ANY

WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH

CHANGE IS MADE IN WRITING AND SIGNED BY BUSH HOG’S

SERVICE MANAGER, POST OFFICE BOX 1039, SELMA,

ALABAMA 36702-1039.

OOOOOOOOOOOOOOOOOOOO

Recordthe model number,serial numberanddatepurchased.This information will be helpful to your dealer if parts or service are required.

MODEL NUMBER

SERIALNUMBER

DATE OF RETAIL SALE

4

Page 7

DEALER PREPARATION CHECK

LIST

UTILITY VEHICLE

BEFORE DELIVERING MACHINE — The following

check list should be completed. Use the Operator’s

Manual as a guide.

r 1. Engine has been serviced.

r 2. Battery fluid level is checked.

r 3. All warning lights checked for operation.(Engine oil, park

brake, & neutral light)

r 4. Assembly completed

r 5. All fittings lubricated.

r 6. All shields in place and in good condition.

r 7. All fasteners torqued to specifications given in

Torque Chart.

r 8. All decals in place and readable. (See decal page.)

r 9. Overall condition good (i.e. paint, welds)

r 10.Parking brake checked and adjusted, if necessary.

r 11.Steering checked and adjusted, if necessary.

r 12.Check tire pressure.

r 13.Operators manual has been delivered to owner and

he has been instructed on the safe and proper use

of the utility vehicle.

Dealer’s Signature

Purchaser’s Signature

THIS CHECKLIST TO REMAIN IN

OWNER’S MANUAL

It is the responsibility of the dealer to complete the procedures listed above before delivery of this vehicle to the

customer.

5

Page 8

Safety Alert Symbol

Safety Signs Signal Words

The signal words DANGER, WARNING, AND CAUTION are used on

the equipment safety signs. These words are intended to alert the

viewer to the existence and the degree of hazard seriousness.

This signal word indicates a potentially hazardous situation which, if

not avoided, will result in death or

serious injury.

This signal word indicates a potentially hazardous situation which, if

not avoided, could result in death

or serious injury

This signal word indicates a potentially hazardous situation exist

which, if not avoided, may result in

minor or moderate injury. It may

alsobeused to alertagainst unsafe

practices.

6

This Safety Alert Symbol means:

“ATTENTION!BECOMEALERT! YOURSAFETY IS

INVOLVED!”

This symbol is used to call attention to safety pre-

cautions thatshould be followedbytheoperatorto

avoid accidents. When you see this symbol, carefullyreadthe message thatfollowsand heed itsadvice. Failure to comply with safety precautions

could result in death or serious bodily injury.

Page 9

IMPORTANT SAFETYPRECAUTIONS

In addition to the design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel in the operation,

transport, maintenance and storage of equipment. Lack of attention

to safety can result in accident, personal injury, reduction of efficiency

and worst of all—loss of life. Watch for safety hazards and correct deficiencies promptly. Use the following safety precautions as a general

guide to safe operations when using this machine. Additional safety

precautions are used throughout this manual for specific operating

and maintenance procedures.Read this manual and review the safety

precautions often until you know the limitations.

IMPORTANT OPERATOR SAFETY PRACTICES:

BEFORE OFF-ROAD UTILITY VEHICLE USE:

• Read, understand and follow all the Operator’s Manual instruc-

tions.

• Explain all instructions to operators who cannot read or under-

stand the instructions.

• Only allow vehicles to be operated by trained persons.

• Allow no persons younger than 16 years old to operate.

• Do not operate under the influence of alcohol or drugs.

• Inspect vehicle for safe operating condition.

DURING OFF-ROAD UTILITY USE:

• Fasten seat belt.

• Use vehicle only for off-road operations.

• Avoid sudden starts, stops, turns, or direction reversals to prevent

load shifts, endanger passengers, or losing vehicle control.

• Use speeds to allow vehicle to stop safely and be under control

in all travel conditions.

• Reduce speeds for wet, slippery, loose surfaces, steep grades

and unfamiliar terrain.

• Never operate vehicle on hills steeper than 15 degree slope.

• Use proper loading and securing material for loads in cargo box

and trailers.

• Use proper towing practices.

7

This symbol is used to call attention

to safety precautions that should be

followed by the operator to avoid accidents. When you see this symbol,

carefully read the message that follows and heed its advice. Failure to

comply with safety precautions

could result in serious bodily injury.

Page 10

• Do not tow heavy loads on hills steeper than 5 degree slope.

• Avoid driving through water exceeding floorboard height.

• Before leaving, servicing, or adjusting the vehicle, stop engine,

set parking brake, remove key, wait for engine and all moving

parts to stop.

AVOIDVEHICLERUNOVERANDRIDEROROPERATORFALLOFF:

• Only allow persons to ride in seats equipped with seat belts.

• All persons fasten seat belts when riding.

• Allow no riders in cargo box or on vehicle.

• Keep all persons clear of operating vehicle.

• Keep alert forstumps, holes,ruts,wet,slippery and uneven terrain.

• Before backing up or turning, look behind and around vehicle for

persons.

AVOID VEHICLE UPSETS AND ROLLOVER:

• Avoid sudden starts, stops, or turns.

• Use very slow speed when turning.

• Always use brakes when going down slope.

• Reduce speed and load on rough or hilly terrain.

• Avoid overloading vehicle and shifting loads.

• Keepalertforstumps,holes, ruts, wet,slipperyand uneven terrain.

AVOID FUEL FIRE AND EXPLOSIONS:

• Stop engine and allow to cool before refueling.

• Do not smoke while refueling.

• Never fill fuel tank indoors.

• Clean up spilled fuel before starting engine.

• Only use approved Underwriter’s Laboratory (U.L.) or American

Society for Testing & Material (ASTM) non-metal portable fuel

containers.

• Remove fuel containers from vehicle beds or trunks and placing

on the ground before filling.

• Keep nozzle in contact with fuel container opening while filling.

• Remove utility vehicle and equipment from truck beds or trailers

and re-fuel on the ground.

CARGO BOX LOAD OPERATIONS:

LOADING:

• Do not exceedvehicle’s Gross Vehicle Weight(GVW) rating. This

includes vehicle operating weight, material load (cargo box load),

personnel weight, options weight, accessories weight, and

attachments weight (towing loads).

• Do not exceed cargo box load rating.

• Confine loads to cargo box physical dimensions.

• Spread load evenly and securely anchor all loads in cargo box.

Shifting and uneven loads will effect vehicle controland stability.

• Avoid sudden starts, stops, and turns which could cause load

shifts.

8

Page 11

• Reduce loads and speed when operating over rough or hilly terrain.

• Use low vehicle speeds when operating with cargo box loads.

Heavy loads will affect steering, braking, stability, and overall

handling of the vehicle. Limit loads to those that can be safely

controlled.

• Allow for increased braking distance.

UNLOADING:

• Stop vehicle on level ground, set parking brake before raising

cargo box.

• Avoid unloading or dumping on slopes, hills or inclines.

MANUALLY RAISED CARGO BOX UNITS:

• Unload manual lift cargo box before raising cargo box by

hand.

• Securely lock manual support lift rod before working beneath

raised cargo box.

• Fully lower cargo box and securely re-latch lift rod before operating vehicle.

OPTIONAL ELECTRIC POWER LIFT CARGO BOX UNITS:

• Operate switch while seated in operator seat.

• Keep body parts away from cargo box and all bystanders away

from vehicle.

• Do not dump or unload vehicle parked on an incline, slopes, hills,

or with rear wheels at an edge of a drop-off. The cargo box

weight may shift and cause the vehicle to tip or rollover.

• Fully lower cargo box before operating vehicle.

TOWING OPERATIONS:

• Do not exceed vehicle’s Gross Vehicle Weight (GVW) rating. This

includes vehicle operating weight, material load (cargo box load),

personnel weight, options weight, accessories weight, and attachmentweight(towingloads).

• Always use approved rear hitch point.

• Do not tow a load weight (trailer weight and cargo weight) that

exceeds towing weight rating.

• Do not exceed the tongue weight rating.

• Never exceed 16 km/h (10 mph)when towing loads. Use slow

speeds to maintain control of vehicle and towing load.

• Allow for increased braking distance from towed load weight.

• Do not tow heavy loads on slopes greater than 5 degree incline.

• Heavy towed equipment may jackknife and cause utility vehicle

to overturn when going downhill or turning.

9

Page 12

CONTROLLING PARTY INFORMATION

(Reference: SAE J2258-DEC 2003-Light-Utility Vehicle, APPENDIX B,

PART II - For the Controlling Party.) The Controlling Party is the person(s) or organization(s) responsible for the operation and maintenance of a vehicle.

MAINTENANCE AND OPERATIONS:

The Controlling Party should perform the following:

• Properly use and maintain utility vehicle to avoid serious injury or

death.

• Follow additional specific safety practices as may reasonably be

required for safe operations.

• Perform periodic safety survey of vehicle operating areas.

• Identify operating area hazards.

• Identify areas where vehicle should not be operated.

SAFETY SURVEY:

The Controlling Party should conduct an operating area safety survey

to identify possible hazards:

• Steep Grade Hazards:

• Restrict vehicle operations to designated pathways in steep

grade areas.

• Erect steep grade warning signs.

• State: “Warning, steep grade, descend slowly” on signs.

• Loose Terrain Hazards:

• Keep vehicle traction, steering, stability and braking under

control by avoiding loose terrain areas.

• Wet area Hazards:

• Keep vehicle traction, steering, stability and braking under

control by avoiding wet areas.

• Sharp Turns, Blind Corners, Bridge Approaches Hazards:

• Erect warning signs,

• State precautions to avoid the hazards on signs.

• Pedestrian and Utility Vehicle Traffic Hazards:

• Erect warning signs.

• State warnings of traffic conditions and use caution on signs.

• Reroute vehicle or pedestrian traffic to avoid interference.

10

Page 13

OPERATOR TRAINING:

The controllingParty shoulddevelop, conductan operator-trainingprogram and permit only properly trained persons to operate the utility vehicle.

OPERATOR-TRAINING PROGRAM:

The program should include, as a minimum, the following:

Review:

• Vehicle operator’s manual instructions.

• Vehicle’s safety decals.

• Safe loading practices.

• Proper use of vehicle’s controls and consequences of

improper use.

• Controlling Party’s safety practices developed from operating

area safety survey.

Review conditions that affect vehicle’s stability and may cause

its instability:

• Operator’s failure to follow safety practices.

• Operator’s exercise of judgement.

• Operating area slopes, grades, and terrain conditions.

• Vehicle’s speed, turning, braking, loadings, towing and

dynamic forces.

• Attachments and improper loading.

TheControlling Party should trainand evaluatevehicleoperator’s competency to comply with these practices.

MAINTENANCE AND INSPECTION PROCEDURES:

• Review and perform vehicle manufacturer’s recommended

procedures.

• Use a scheduled preventive maintenance, lubrication, and

inspection program.

• Use trained and authorized personnel to maintain, repair,

adjust, and inspect vehicles

• Conduct recommended procedures in a properly ventilated

work area.

• Use original vehicle manufacturer’s replacement parts.

• Use recommended procedures for returning vehicle to service.

• Use recommended procedures for returning vehicle to service.

• Conduct vehicle performance checks in an area free of vehicular and pedestrian traffic.

• Use vehicle manufacturer’s engine shut down and vehicle

immobilization recommended procedures before undertaking

maintenance or repairs.

• Chock wheels and block chassis before working underneath

vehicle.

• Do not use open flames to check level or leakage of fuel,

battery electrolyte, or coolant.

• Equip work area with fire extinguisher equipment.

• Follow vehicle manufacturer’s recommended inspection and

maintenance procedures.

11

Page 14

FUEL SYSTEM:

• Check for leaks and condition of parts.

• Before disconnection fuel system parts and making repairs:

• Allow engine to run until fuel system is depleted.

• Allow engine to stop.

• Allow engine to cool.

• Disconnect battery.

CONDUCTPERIODIC INSPECTIONONTHEFOLLOWINGSYSTEMS:

• Brake system.

• Steering system.

• Electrical system.

• Transmission system.

• Exhaust system.

• Warning system.

• Switches and devices.

• Follow vehicle manufacturer’s recommended inspection maintenance procedures.

• Keep vehicle clean to reduce fire hazards and allow ease of

vehicle inspection.

VEHICLE INSTRUCTION AND SAFETY DECALS:

• Keep clean and legible.

• Replace illegible decals.

VEHICLE MODIFICATION AND ADDITIONS:

• Contact vehicle manufacturer before making modifications

that affect vehicle capacity and safe vehicle operations.

12

Page 15

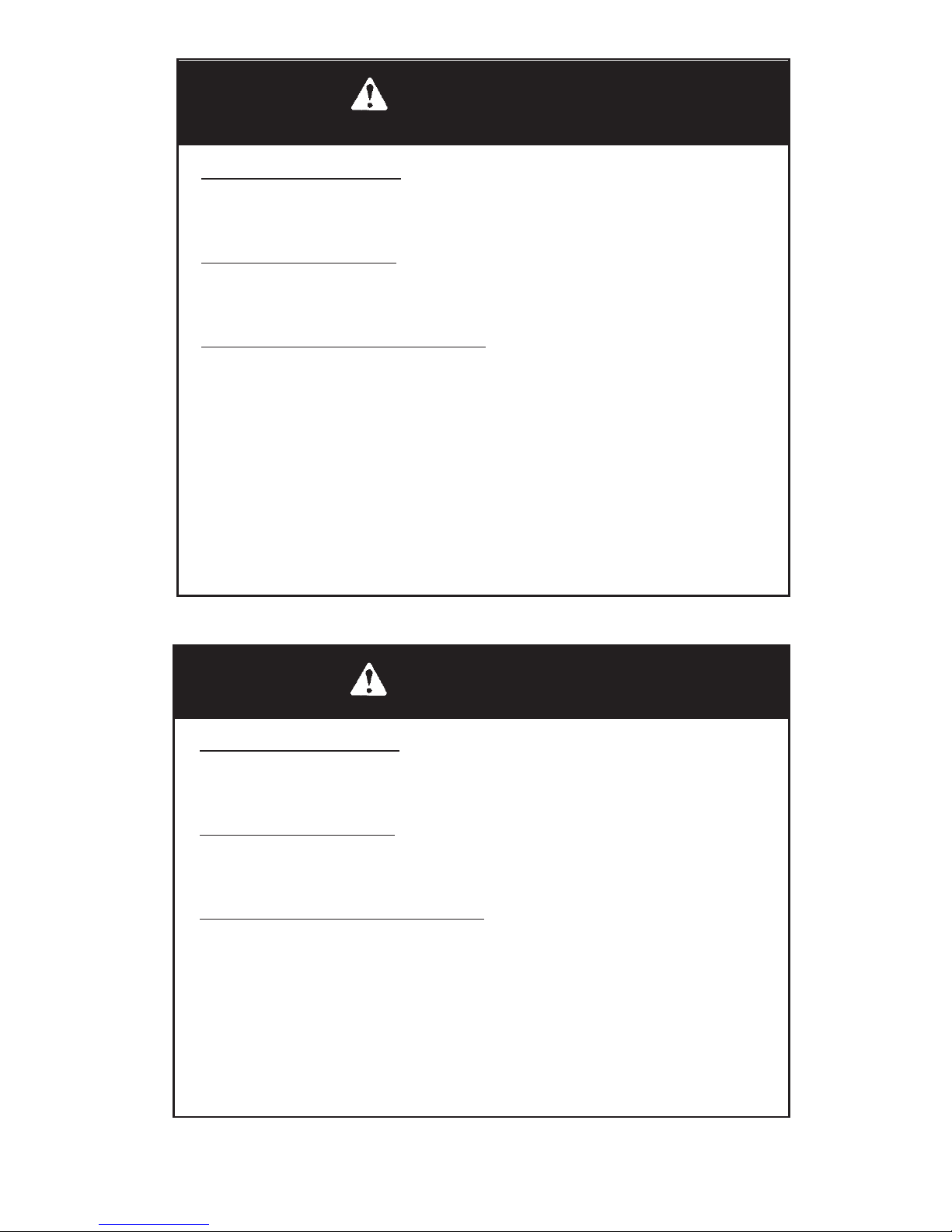

WARNING

13

POTENTIAL HAZARD

Stalling, rolling backwards while climbing a hill

WHAT CAN HAPPEN

Vehicle overturn

HOW TO AVOID THE HAZARD

Maintain a steady speed when climbing a hill

If you lose forward speed:

Apply the brakes.

Lock the parking brake after fully stopped.

If you begin rolling backwards:

Never apply engine power.

Apply the service brake gradually.

When fully stopped, lock parking brake.

In the event of an accident, have a qualified service dealer

check the complete vehicle for possible damage, including (but

not limited to) brakes, throttle and steering.

Page 16

WARNING

WARNING

POTENTIAL HAZARD

Operating this vehicle on paved surfaces

WHAT CAN HAPPEN

Loss of control

HOW TO AVOID THE HAZARD

This vehicle’s tires are designed for off-road use only, not for

use on pavement. Paved surfaces may seriously affect handling and control of the vehicle, and may cause the vehicle to

go out of control.

Avoid operating the vehicle on pavement. If you must operate

on a paved surface, travel slowly and do not make sudden

turns or stops.

POTENTIAL HAZARD

Operating this vehicle without proper instruction

WHAT CAN HAPPEN

Loss of control, accident

HOW TO AVOID THE HAZARD

The risk of an accident is greatly increased if the operator does

not know how to operate the vehicle properly in different situations and on different types of terrain.

Allopertorsmust read andunderstand the Operator’smanual and

allwarning andinstruction labelsbefore operating the vehicle.

14

Page 17

WARNING

WARNING

POTENTIAL HAZARD

Operating this vehicle on public streets, roads or highways

WHAT CAN HAPPEN

Collision with another vehicle

HOW TO AVOID THE HAZARD

Never operate this vehicle on any public street, road or highway, including dirt or gravel.

In many states it’s illegal to operate vehicles of this type on

public streets, roads and highways.

POTENTIAL HAZARD

Operating this vehicle after consuming alcohol or drugs

WHAT CAN HAPPEN

Could seriously affect your judgment.

Could cause you to react more slowly.

Could affect your balance and perception.

Could result in an accident.

HOW TO AVOID THE HAZARD

Driving this vehicle requires your full attention. DO NOT drink

alcohol or use drugsor medications beforeor while driving. They

willreduceyour alertness and slowyour reaction time.In most

states and provinces,it’s prohibited by law to drivewhile intoxicated or under the influence of drugs.

15

Page 18

WARNING

WARNING

POTENTIAL HAZARD

Operating this vehicle at excessive speeds

WHAT CAN HAPPEN

Loss of control, accident

HOW TO AVOID THE HAZARD

Always travel at a speed proper for the terrain, visibility and operating conditions, and your experience.

POTENTIAL HAZARD

Attempting jumps and other stunts

WHAT CAN HAPPEN

Loss of control, accident and/or vehicle overturn

HOW TO AVOID THE HAZARD

Never attempt jumps and other stunts. Avoid exhibition driving.

WARNING

POTENTIAL HAZARD

Operating on frozen bodies of water.

WHAT CAN HAPPEN

Severe injury or death can result if the vehicle and/or the operator fall through the ice.

HOW TO AVOID THE HAZARD

Never operate the vehicle on a frozen body of water.

16

Page 19

WARNING

WARNING

POTENTIAL HAZARD

Failure to inspect the vehicle before operating

Failure to properly maintain the vehicle

WHAT CAN HAPPEN

Accident, equipment damage

HOW TO AVOID THE HAZARD

Always inspect your vehicle before each use to make sure it’s

in safe operating condition.

Always follow the inspection and maintenance procedures and

schedules described in the Operator’s Manual.

POTENTIAL HAZARD

Failure to use extra caution when operating this vehicle on unfamiliar terrain

WHAT CAN HAPPEN

Loss of control, vehicle overturn

HOW TO AVOID THE HAZARD

Travel slowly and use extra caution when operating on unfamiliar terrain.

always be alert to changing terrain conditions when operating

the vehicle. May come upon hidden conditions when operating

the vehicle. You may come upon hidden rocks, bumps, or

holes suddenly, without enough time to react.

17

Page 20

WARNING

WARNING

POTENTIAL HAZARD

Failure to follow the minimum age recommendations for this vehicle.

WHAT CAN HAPPEN

Serious injury or death (the child or others)

HOW TO AVOID THE HAZARD

Only persons with a valid driver’s license should operate this

vehicle.

Even though a child may be within the age group for which

some vehicles are recommended, he or she may not have the

skills, abilities, or judgement needed to operate the vehicle

safely and may be involved in a serious accident.

POTENTIAL HAZARD

Operating this vehicle with improper tires or with improper or

uneven tire pressure

WHAT CAN HAPPEN

Loss of control, accident and/or overturn

HOW TO AVOID THE HAZARD

Always use the size and type of tires specified in the Operator’s

Manual for this vehicle.

always maintain proper tire pressure as described on the decal

and in the Operator’s Manual.

18

Page 21

19

WARNING

Leaving the keys in the ignition can lead to unauthorized use of

the vehicle resulting in serious injury or death. Always remove

the ignition key when the vehicle is not in use.

WARNING

After any overturn or accident, have a qualified service dealer inspect the entire vehicle for possible damage, including (but not

limited to) brakes, throttle and steering systems.

WARNING

Always keep combustible materials away from the exhaust system. Exposure to the hot components could result in a fire.

WARNING

Gasoline is highly flammable and is explosive under certain conditions. Always exercise extreme caution whenever handling

gasoline.

Always stop the engine when refueling.

Always refuel outdoors or in a well ventilated area.

Do not smoke or allow open flames or sparks in or near the refueling area or where gasoline is stored.

Do not over fill the tank. Do not fill the tank neck.

If gasoline spills on your skin or clothing, immediately wash it off

with soap and water and change clothing.

Never start the engine or let it run in an enclosed area. Gasoline

powered engine exhaust fumes are poisonous and can cause

loss of consciousness and death in a short time.

Page 22

SECTION I

INTRODUCTION AND DESCRIPTION

INTRODUCTION

We are pleased to have you as a Bush Hog customer. Your Bush Hog

Trail Series utility vehicle has been carefully designed to give maximum service with minimumdown time. This manual is provided to give

you the necessary operatingand maintenanceinstructions for keeping

your vehicle in top operating condition. Please read this manual thoroughly.Understand what eachcontrolis for and how to useit. Observe

all safety precautions decaled on the machine and noted throughout

the manual for safe operation of the vehicle. If any assistance or additionalinformationis needed, contactyour authorizedBush Hog dealer.

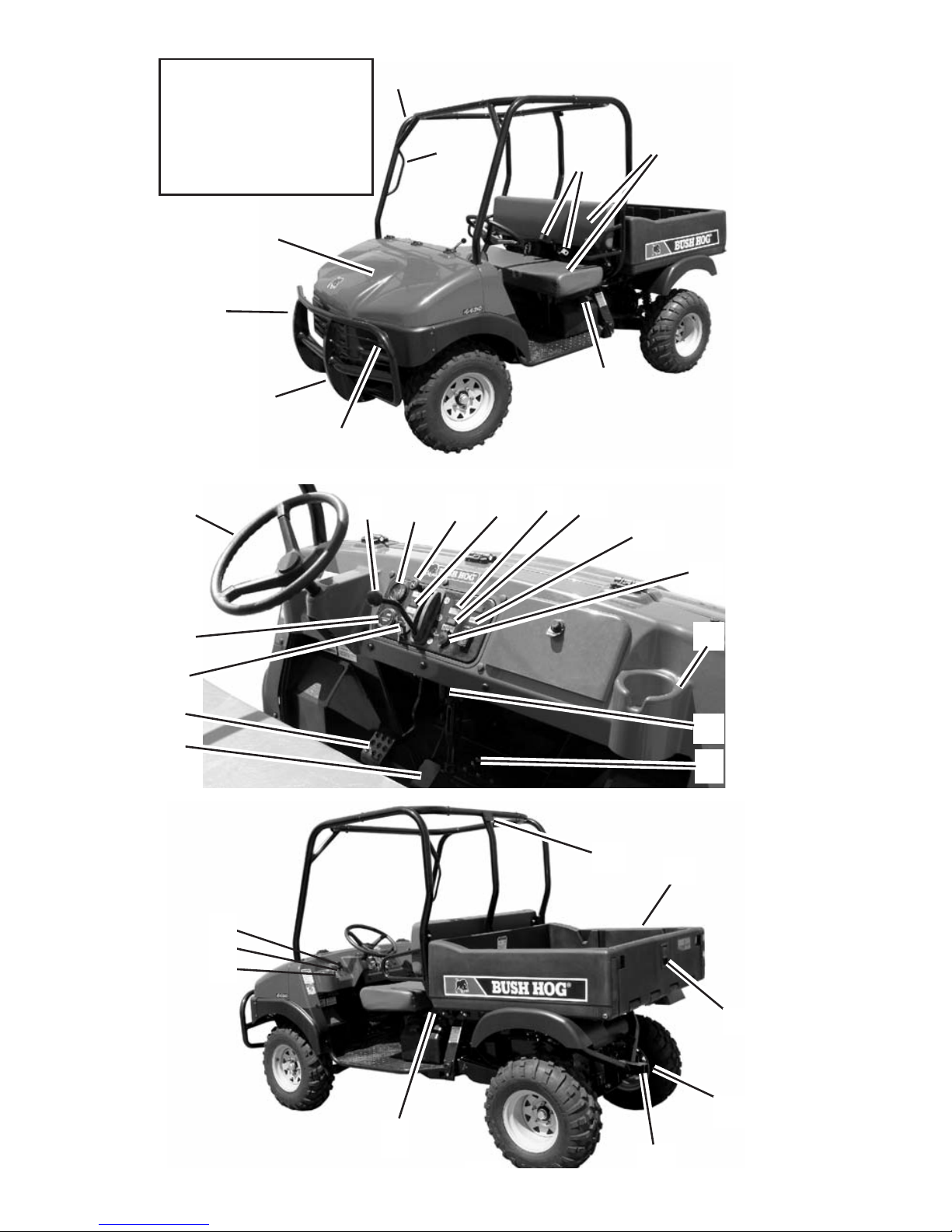

DESCRIPTION (Model 4430 shown on next page)

1. Occupant Protection

Structure (O.P.S.)

2. Hand hold

3. Gear Selector

4. Steering wheel

5. Seat

6. Seat Belt

7. Fuel Tank Cap

8. Battery (Under Hood)

9. Headlights

10.Front Bumper/

Brush Guard

11.PowerWinch

(Optional-NotShown)

12.CargoLight

(Optional- Not Shown)

13.Cargo Box

14.Hitch Receiver

15.Winch Wiring Pigtail

16.Cup Holder

17.Ignition Key

20

18.Fuel Gauge

19.Hour Meter

20.Choke Knob

21.

Power Bed Lift Switch

(Optional)

22.Neutral Light

23.4-Wheel Drive Switch

and Light

24.WinchSwitch

(Optional- Not Shown)

25.Driving Light Switch

26.Cargo Bed Light Switch

27.Parking Brake Light

28.Oil Pressure Light

29.DC Power Outlet

30.Parking Brake

31.Brake Pedal

32.Throttle Pedal

33.Tailgate Latch

34.CargoBoxReleaseHandle

Page 23

1

8

10

11

9

2

6

5

7

24

18

17

19

29

4

3

30

31

32

16

34

14

13

12

NOTICE!

LOCATIONS OF CON-

TROLS AND FEATURES

MAYVARY SLIGHTLY ON

DIFFERENT MODELS.

21

20

28

27

22

23

25

26

21

33

15

Page 24

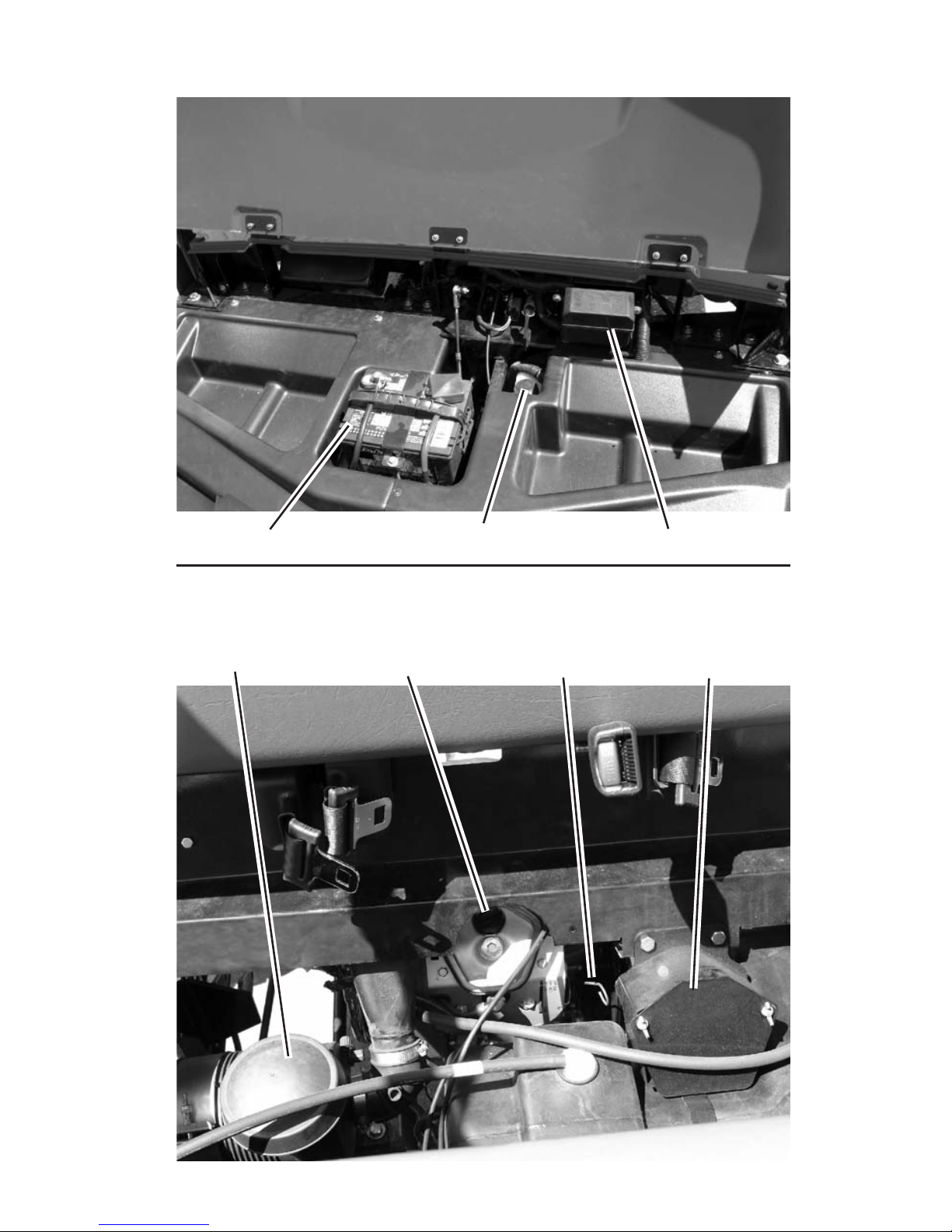

UNDER HOOD AREA

UNDER SEAT AREA

Battery Brake Fluid Reservoir Fuses and Relays

Engine Air

Intake

Engine Oil

Filler Cap

Engine Oil

Dipstick

CVT Enclosure

Air Cleaner

22

Page 25

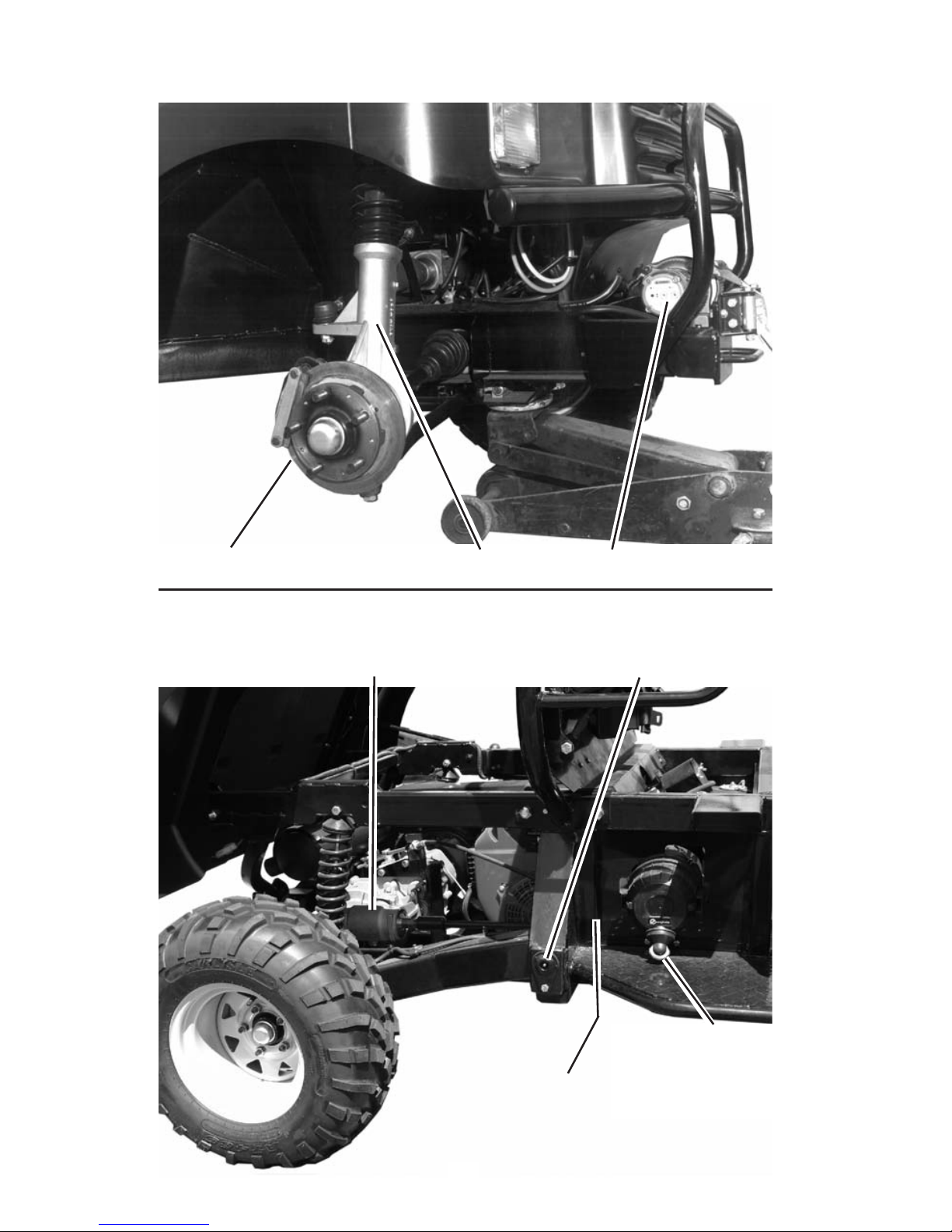

RIGHT FRONT WHEEL REMOVED

Disc Brake Assembly Front Strut Assembly Winch (Optional)

CARGO BED RAISED (SHOWING ENGINE COMPARTMENT)

Engine Air

Cleaner Housing

with

Evacuator Valve

Transfer Gearbox Trailing Arm Pivot Grease Fitting

Grease Fitting

For Pillow Block

Hidden From View

23

Page 26

FEATURES

DC Power Outlet

The 12 volt accessory port is provided to power auxiliary lights or

other accessories.

Indicator Lights

Lights on the dash indicate when the transmission is in neutral. Four

wheel drive models have a light that indicates when 4- wheel drive is

engaged. An oil pressure light indicates when oil pressure is lower

than normal and oil level needs to be checked.

Trailer Hitch Receiver

This vehicle is equipped with receiver hitch brackets at the front and

rear for use with trailer hitches or the optional winch kit. Trailer towing equipment if not supplied with this vehicle.

To avoid injury and property damage, observe the precautions on

page 43.

Seat Belts

The Bush Hog 4300 UTV is equipped with lap-style seat belts for the

operator and passengers.

24

WARNING

Falling from a moving vehicle could result in serious injury or

death. Always fasten your seatbelt securely before operating or

riding in the vehicle.

Passengers under five years of age require special restraints,

which are not available on this vehicle. No person under the age

of five years may ride in the Bush Hog utility vehicle.

To wear the seat belt properly, follow this procedure:

1. Place the belt acrossyour lap as low on your hips as possible,

takingcare that the belt is not twisted.

2. Push the latch plate into the buckle until it clicks.

3. Release the strap, it will self tighten.

To unfasten, press the red button on the side of the buckle.

Page 27

CONTROLS

Switches

Ignition Switch

The ignition switch is a three position, key-operated switch. The key

can be removed from the switch when it is in the OFF position.

OFF Engine off. All electrical circuits are off

except ACC. 12V.

ON Electrical circuits are on. Electrical equipment

can be used

START Electric starter is engaged by holding ignition

switch key in this position. Upon release,

the key will return to the ON position.

WARNING

LEAVING THE KEYS IN THE IGNITION CAN LEAD TO

UNAUTHORIZED USE OF THE VEHICLE RESULTING IN

SERIOUS INJURY OR DEATH. ALWAYS REMOVE THE IGNITION KEY WHEN THE VEHICLE IS NOT IN USE.

Light Switch

Turn the headlights and tailights on by flipping the rocker switch up

(the ignition switch must be in the ON position). Flip the switch down

to turn the lights off.

Cargo Bed Light Switch (Optional)

Flip the rocker switch up to turn on and down to turn off.

Power Bed Lift Switch (Optional)

Push and hold the spring loaded rocker switch up to raise the bed or

down to lower the bed.

4-Wheel Drive Switch (On 4-wheel drive models only)

Flip the rocker switch up to engage 4-wheel drive at any time and

down to disengage 4-wheel drive.

Winch Switch (Optional)

Push and hold the spring loaded rocker switch to the left to unwind

the cable or push and hold to the right to wind in the cable.

25

Page 28

CAUTION

DO NOT ATTEMPT TO SHIFT THE TRANSMISSION

WHILE THE VEHICLE IS MOVING OR DAMAGE TO THE

TRANSMISSION COULD RESULT.

ALWAYSPLACETHETRANSMISSIONINGEARWITHTHE

PARKINGBRAKEAPPLIEDANDTURNTHEVEHICLEOFF

WHENEVER THEVEHICLEISLEFT UNATTENDED.

Brake Pedal

The brake pedal is the left pedal on the floor board. Depressthe brake

pedal to slow or stop the vehicle.

Throttle Pedal

The throttle pedal is the right pedal on the floor board. Push the pedal

down to increase engine speed. Spring pressure returns the pedal to

the rest position when released. Always check to make sure that the

pedal returns normally before starting the engine.

Parking Brake Lever

The parking brake lever is located under the dash and is rotated back

and upward to engage and pushed down and forward to release. .

Make sure the parking brake is working properly before each operation. Always depress service brake pedal before engagingpark brake.

Gear Selector

The transmission gear selector is located on the console to the right

of the steering wheel. It has four positions: high, low, neutral, and reverse.

NOTE: Low gear is the primary driving range on this vehicle. High is

intended for use in hard packed surfaces with light loads

To changegears, stop the vehicleand with the engineidling, move the

gear lever to the desired gear. Do not attempt to shift gears with the

engine speed above idle or while the vehicle is moving.

Always place the transmission in gear with the parking brake locked

whenever the vehicle is left unattended.

Maintaining shift linkage adjustment is important to assure proper

transmission function. See your dealer if you experience any shifting

problems.

26

Page 29

SPECIFICATIONS

Bush Hog

4430 UTV

ENGINE

Type 4-cycle, OHV V-twin, air-cooled gas

Make Honda

HP / (cc) 24 hp (670cc)

Lubrication Full Pressure with automotive style spin-on canister

Air Cleaner Remote,2-stagecyclonetypewithreplacementdualelements

Electrical Systems 12 volt DC with 20-amp alternator

CHASSIS

Suspension, Front MacPherson strut, single A-Arm

Suspension, Rear Independent trailing arm, coil-over-shock

Wheel travel, Frt/Rr 5.7 inches / 6.0 inches

Steering Rack and Pinion

Turning Radius 13 ft

Front Tires AT 25 x 10.0 - 12 NHS

Rear Tire AT 25 x 11.0 - 12 NHS

Brakes 4-wheel hydraulic disc brakes; self-adjusting with

tandem master cylinder

Park Brake Rear mechanical disc

GroundClearance 9-inches

27

Page 30

DRIVE TRAIN

Transmission Continuously Variable Transmission (CVT)

CVT Protection Fully enclosedpressurized withfiltered airintake.

Final Drive

BushHogDual-Rangetransaxlewith High, Low,Neutral andReverse

Differential Lock Truck-Style, automatic positive lockingdifferential;

featuringDetroit Gearless Locker

TM

Ground Speed 0 - 25mph

4WD True On-Demand 4-wheel drive; switch engage

(4wd models only)

DIMENSIONS

Dry Weight 1,500 lbs.

Wheel Base 76 inches

Vehicle 1,500 lbs.

Load Capacity

Cargo Box 1,000 lbs.

Load Capacity

Towing Capacity 1,500 lbs.

Fuel Capacity 7 gallons

Seating Capacity 3

Lights

Dual 37-watt halogen headlights, tail lights and brake lights

Colors Classic Bush Hog Red. Deep Forest Green and

Mossy Oak’s Obsession™ camouflage

WARRANTY •One-year limited.

•Two-year engine limited warranty administered

through engine manufacturers.

•Three-year limited drivetrain warranty.

•See dealer for complete details.

28

SPECIFICATIONS

Bush Hog

4430 UTV

Page 31

SECTION II

OPERATION

GENERAL SAFETY

Only qualified people familiar with this operator’s manual should operate this machine.

PRE-OPERATION CHECKLIST

1. Fill the fuel tank with unleaded regular gasolIne.

2. Make sure dirt and foreign matter are kept out of fuel tank. Use

a clean funnel and fuel can.

3. Do not mix oil with gasoline.

4. Do not use white, high test or premium gasoline. Do not use

de-icers, carburetor cleaners or other such additives.

5. Check the crankcase oil level. Make sure the engine is off. The

vehicle should be parked on a level area. Do not overfill. (See

your engine manual for more detailed instructions.)

6. Check battery fluid level.

7. Checktirepressure:12psi inall fourtires.

8. Clean the air intake screen on the engine if necessary.

9. Perform any other maintenance as it becomes necessary. (See

“Maintenance” section)

VEHICLE BREAK-IN PERIOD

The break-in period for your new Bush Hog Utility Vehicle is defined

as the first24 hours of operation,or the time it takes to use the firsttwo

tanks full of fuel. A proper break-in procedure will result in more efficient performance and longer life for the engine. Carefully perform the

following procedures.

WARNING

IF A PROPER INSPECTION IS NOT DONE BEFORE EACH

USE, SEVERE INJURY OR DEATH COULD RESULT. ALWAYS INSPECT THE VEHICLE BEFORE EACH USE TO

ENSURE IT’S IN PROPER OPERATING CONDITION.

29

Page 32

Starting The Engine

1. Sit in the driver’s seat and fasten the seat belt.

2. Lock the parking brake

3. Place the transmission in neutral.

4. Pull the choke control all the way out.

5. Turntheignitionkeyto STARTandcrankfor10secondsmaximum.

6. If engine does not start, release ignition switch and wait five seconds; then turn the ignition switch for another five seconds.

Repeat this procedure until engine starts. NOTE: do not

press the accelerator pedal while starting the engine.

7. If the engine slows or stops, push the choke knob in half way.

8. Vary the engine RPM slightly with the throttle to aid in warm up

until engine idles smoothly. Then push the choke all the way in.

Starting A Warm Engine

Warm engines do not normally require the use of the choke. Overuse

of the choke can cause the spark plugs to become fouled.

1. Place the transmission in neutral and lock the parking brake.

2. Sit in the driver’s seat with the seat belt fastened.

3. Turn the ignition key to START.

4. If the engine has cooled and does not readily start, intermittent

use of the choke knob (pulled half way out) may be necessary.

5. If the engine is over-choked when warm, depress the throttle

pedal fully while cranking to aid in starting.

6. Release the throttle pedal immediately after the engine starts.

NOTE: If the engine does not start and all conditions are favorable,

change the spark plugs.

Driving The Vehicle

1. Check the surrounding area and determine your path of travel.

Select an area which is open and will give you room to familiarize yourself with the operation and handling of the vehicle.

2. With foot on brake pedal, release parking brake and shift transmission into low gear.

ENGINE EXHAUST GASES CONTAIN

POISONOUS CARBON MONOXIDE.

ll

NEVER RUN ENGINE IN A CLOSED BUILDING OR CONFINED AREA.

ll

AVOID INHALING EXHAUST GASES.

WARNING

30

Page 33

3. With both hands on the steering wheel, release pressure on

brake pedal and carefully apply pressure to throttle pedal.

Vehicle speed is controlled by the amount of pressure on the

throttle pedal. The CVT shifting is done automatically.

4.

Drive slowly at first, practicing maneuvering and using the throttle

and brakes on level surfaces .

5. Vary the throttle pedal position. Do not operate at sustained idle.

6. You may switch to 4-wheel drive at any time. It will only engage when

the rear wheels begin to lose traction.

7. Do not exceed recommended towing capacity.

8. Perform regular checks on fluid levels, and all important areas on

the vehicle as outlined on the pre-operation check list.

IMPORTANT

Braking

Practice starting and stopping (using the brakes) until you are familiar with

the controls. NOTE: When the accelerator is released completely and the

engine speed drops to near idle, the vehicle has no engine braking.

1. Release the throttle pedal completely.

2. Press on the brake pedal evenly and firmly.

Stopping The Engine

1. Release the throttle pedal completely

2. Place the transmission selector lever in neutral.

3. Apply the parking brake to help prevent the vehicle from rolling.

4. Turn the ignition key to the off position and remove the key.

LOW GEAR IS THE PRIMARY GEAR FOR OPERATING THIS VEHICLE. HIGH IS INTENDED FOR USE ON HARD PACKED SURFACES WITH LIGHT LOADS. PREMATURE BELT WEAR IS THE

RESULT OF OPERATING IN A GEAR THAT IS UNSUITABLE FOR

THE TERRAIN.

TO CHANGE GEARS, STOP THE VEHICLE AND WITH THE ENGINE IDLING, MOVE THE LEVER TO THE DESIRED GEAR. DO

NOT ATTEMPT TO SHIFT GEARS WITH THE ENGINE ABOVE IDLE

OR WHILE MOVING.

WHEN CARRYING CARGO OR TOWING A TRAILER, REMEMBER

THAT LOAD WEIGHT WILL INCREASE BRAKING DISTANCES.

FAILURE TO ALLOW FOR INCREASED BRAKING DISTANCES

MAY RESULT IN ACCIDENT AND INJURY.

WARNING

31

WHEN VEHICLE IS IN MOTION, DRIVER AND PASSANGERS

SHOULD ALWAYS KEEP ALL BODY PARTS INSIDE THE VEHICLE. FAILURE TO DO SO CAN RESULT IN INJURY OR DEATH.

WARNING

Page 34

ALWAYS APPLY THE PARKING BRAKE BEFORE LEAVING

THE VEHICLE. THE ENGINE/TRANSMISSION PROVIDES NO

BRAKING EFFORT WHEN THE ENGINE IS NOT RUNNING. IF

THE VEHICLE MOVES, IT MIGHT BE DAMAGED OR CAUSE

INJURY.

WARNING

CAUTION

EXHAUST SYSTEM COMPONENTS ARE VERY HOT DURING

AND AFTER USE OF THE VEHICLE AND WILL CAUSE

BURNS IF THEY COME IN CONTACT WITH SKIN.

Using The Cargo Box

The tailgate of the cargo box can be opened by pulling up on the handle

at the rear center of the tailgate.

The cargo box can be raised for dumping material or gaining access to

the engine area. Models with the electric power lift feature only require

pushing the rocker switch on the dash. Manual models require pulling

the release handle (located under the front left corner of the cargo box)

upward. (Refer to photograph on next page)

CAUTION

NEVER EXCEED THE LOAD CAPACITY LISTED IN THE SPECIFICATIONS CHART FOR YOUR PARTICULAR VEHICLE. AN

OVERLOADED CARGO BOX CAN CAUSE INSTABILITY DURING OPERATION OF THE VEHICLE.

WARNING

FAILURE TO ALLOW FOR INCREASED BRAKING DISTANCE WHEN HAULING CARGO OR TOWING A

TRAILER MAY RESULT IN ACCIDENT AND INJURY. ALWAYS SLOW DOWN AND ALLOW ADDITIONAL BRAKING DISTANCE WHEN TOWING OR HAULING CARGO.

CAUTION

ON MODELS WITHOUT THE ELECTRIC POWER LIFT FEATURE, THE CARGO BOX SHOULD BE EMPTIED BEFORE ATTEMPTING TO LIFT THE BOX.

32

Page 35

Load Distribution

1. Always load the cargo box placing the load as far forward as

possible.

2. Always operate the vehicle with extreme care whenever hauling

or towing loads.

3. Drive slowly with the transmission in low range.

4. Insure that the cargo box latch (on manual lift models) is securely latched before loading and operating. Unintentional box tilting

may result if weight is place in the rear of the box and the

latch is not secured.

WARNING

Manual Cargo Box

Release Handle

Electric Cargo Box

Power Lift Actuator

33

NEVER OPERATE THIS VEHICLE WITH THE CARGO BOX IN

THE RAISED POSITION. THE CARGO BOX COULD CLOSE

UNEXPECTEDLY WHILE DRIVING, SEVERELY INJURING

THE DRIVER.

Page 36

Driving Safely

Driving Procedures

1. Sit in the driver’s seat with the seat belt fastened.

2. After starting the engine and allowing it to warm up, shift the

transmission into gear.

3. Check your surroundings and determine your path of travel.

4. Release the parking brake.

5. Keeping both hands on the steering wheel, slowly depress the

throttle with your right foot and begin driving. Vehicle speed is

controlled by the amount of throttle opening and the CVT transmission shifting is automatic.

6. Drive slowly. Practice maneuvering and using the throttle and

brakes on level surfaces.

NOTE: Low is the primary gear for operating this vehicle. High gear is

intended for use on hard-packed surfaces with light loads.

Driving on Slippery Surfaces

When driving on slippery surfaces such as wet trails, loose gravel, or

ice, be alert for the possibility of skidding and sliding. Under these conditions, follow these precautions:

1. Slow down when entering slippery areas.

2. Maintain a high level of alertness, reading the trail and avoiding

quick, sharp turns, which can cause skids.

3. Correct a skid by turning the steering wheel in the direction of the skid.

4. Drive with 4-wheel drive engaged to assist in controlling the vehicle.

WARNING

FAILURE TO EXERCISE CARE WHEN OPERATING ON

SLIPPERY SURFACES CAN RESULT IN LOSS OF TIRE

TRACTION AND CAUSE LOSS OF CONTROL, ACCIDENT,

AND SERIOUS INJURY OR DEATH.

NEVER APPLY THE BRAKES DURING A SKID.

DO NOT OPERATE ON EXCESSIVELY SLIPPERY SUR-

FACES.

ALWAYS REDUCE SPEED AND USE ADDITIONAL CAU-

TION WHEN OPERATING ON SLIPPERY SURFACES.

34

Page 37

Driving Uphill

Whenever traveling uphill, follow these precautions:

1. Always travel straight uphill.

2. Avoid steep hills (15° maximum).

3. Proceed at a steady rate of speed and throttle opening.

WARNING

CLIMBING HILLS IMPROPERLY CAN CAUSE LOSS OF

CONTROL OR VEHICLE OVERTURN. ALWAYS CHECK

THE TERRAIN CAREFULLY BEFORE CLIMBING A HILL.

BRAKING AND HANDLING ARE GREATLY AFFECTED

WHEN OPERATING IN HILLY TERRAIN. IMPROPER PROCEDURE COULD CAUSE LOSS OF CONTROL OR OVERTURN AND RESULT IN SERIOUS INJURY OR DEATH.

AVOID CLIMBING STEEP HILLS (15° MAXIMUM)

USE EXTREME CAUTION WHEN OPERATING ON HILLS,

AND FOLLOW PROPER OPERATING PROCEDURES

OUTLINED IN THE OPERATOR’S MANUAL

NEVER CLIMB HILLS WITH EXCESSIVELY SLIPPERY OR

LOOSE SURFACES.

NEVER ACCELERATE SUDDENLY.

NEVER GO OVER THE CREST OF A HILL AT HIGH

SPEED. AN OBSTACLE, A SHARP DROP, OR ANOTHER

VEHICLE OR PERSON COULD BE ON THE OTHER SIDE

OF THE HILL.

15° Maximum

35

Page 38

Sidehilling

Driving Downhill

Whenever descending a hill, follow these precautions:

1. Proceed directly downhill.

2. Slow down.

3. Apply the brakes slightly to aid in slowing.

Driving Through Water

Your Bush Hog utility vehicle can operate through water up to a maximum recommended depth equal to the floorboards. Follow these procedures when operating through water:

WARNING

CROSSING DOWNHILL OR TURNING ON HILLS CAN RESULT IN LOSS OF CONTROL OR VEHICLE OVERTURN,

RESULTING IN SEVERE INJURY OR DEATH. AVOID

CROSSING THE SIDE OF A HILL WHEN POSSIBLE. WHEN

UNAVOIDABLE, EXERCISE EXTREME CAUTION. AVOID

OPERATING ON STEEP HILLS (15° MAXIMUM)

WARNING

TRAVELING DOWNHILL IMPROPERLY COULD CAUSE

LOSS OF CONTROL OR VEHICLE OVERTURN. ALWAYS

CHECK TERRAIN CAREFULLY BEFORE DESCENDING A

HILL

NEVER DESCEND A HILL AT HIGH SPEED. EXCESSIVE

SPEED MAY RESULT IN LOSS OF VEHICLE CONTROL

AND LEAD TO SERIOUS INJURY OR DEATH. ALWAYS

OPERATE SLOWLY WHEN TRAVELING DOWNHILL

AVOID DESCENDING A HILL AT AN ANGLE, WHICH

WOULD CAUSE THE VEHICLE TO LEAN SHARPLY TO

ONE SIDE. TRAVEL STRAIGHT DOWNHILL WHEN POSSIBLE.

WARNING

THE LARGE TIRES ON YOUR UTILITY VEHICLE MAY

CAUSE THE VEHICLE TO FLOAT IN DEEP OR FASTFLOWING WATER, WHICH COULD RESULT IN LOSS OF

CONTROL AND LEAD TO SERIOUS INJURY OR DEATH.

NEVER CROSS DEEP OR FAST FLOWING WATER WITH

YOUR BUSH HOG UTILITY VEHICLE.

36

Page 39

1. Always determine water depths and current before entering.

2. Choose a crossing where both banks have gradual inclines.

3. Proceed slowly, avoiding rocks and obstacles.

4. After leaving water, always dry the brakes by applying light pressure to the lever repeatedly until braking action is normal.

NOTE: After running your vehicle in water, it’s critical that you perform

the services outlined in the Maintenance section on page 47. Give special attention to engine oil, transmission oil, front and rear gearcases,

and all grease fittings.

CAUTION

IMMERSION CAN RESULT IN MAJOR DAMAGE IF THE

VEHICLE ISN’T SERVICED CORRECTLY AND

PROMPTLY. AFTER IMMERSION, ALWAYS TAKE THE

VEHICLE FOR YOUR DEALER TO SERVICE. DO NOT

START THE ENGINE!

IF IT IS NOT POSSIBLE TO TAKE THE VEHICLE TO

YOUR DEALER BEFORE STARTING THE ENGINE, PERFORM THE SERVICE OUTLINES IN PAGE 56, AND

TAKE THE VEHICLE TO YOUR DEALER AT THE FIRST

OPPORTUNITY.

37

Page 40

Driving Over Obstacles

Be alert! Look ahead and learn to read the terrain you’re traveling on.

Watch for hazards such as logs, rocks and low hanging branches.

WARNING

SEVERE INJURY OR DEATH CAN RESULT IF YOUR VEHICLE SUDDENLY COMES IN CONTACT WITH A HIDDEN OBSTACLE. NOT ALL OBSTACLES ARE

IMMEDIATELY VISIBLE. REDUCE SPEED AND TRAVEL

WITH CAUTION IN UNFAMILIAR TERRAIN

38

Page 41

Driving In Reverse

Follow these guidelines when operating in reverse:

1. Back slowly.

2. Apply the brakes lightly for stopping.

3. Avoid turning at sharp angles.

4. Always avoid backing downhill.

5. Never open the throttle suddenly while backing.

6. Always inspect left and right fields of vision before backing.

WARNING

39

FAILURE TO USE CAUTION WHEN OPERATING IN REVERSE CAN RESULT IN SERIOUS INJURY OR DEATH. BEFORE SHIFTING INTO

REVERSE, ALWAYS CHECK FOR OBSTACLES

OR PEOPLE BEHIND THE VEHICLE AND FOLLOW THE REVERSE OPERATION PROCEDURES OUTLINED IN THIS MANUAL. ALWAYS

BACK SLOWLY.

Page 42

Parking On An Incline

Avoid parking on an incline if possible. If it is unavoidable, follow these

precautions:

1. Place the transmission in low gear to help prevent rolling.

2. Set the parking brake after depressing service brake.

3. Block the rear wheels on the downhill side.

WARNING

40

A ROLLING VEHICLE CAN CAUSE PROPERTY

DAMAGE AND SERIOUS INJURY. ALWAYS

APPLY THE PARKING BRAKE AFTER STOPPING THE ENGINE. ALWAYS BLOCK THE

DOWNHILL SIDE OF THE WHEELS IF LEAVING

THE VEHICLE ON A HILL, OR PARK THE VEHICLE IN A SIDEHILL POSITION INSTEAD.

OPERATING THE VEHICLE WHILE THE PARKING BRAKE IS ENGAGED COULD CAUSE LOSS

OF CONTROL AND RESULT IN SERIOUS INJURY OR DEATH. ALWAYS DISENGAGE THE

PARKING BRAKE BEFORE OPERATING THE

VEHICLE.

Page 43

Hauling Cargo

Bush Hog utility vehicles have been designed to carry or tow specific

capacities. Always read and understand the load distribution warnings

listed on the warning decals.Never exceed the following capacities.

Model Max. Capacity Cargo Box Towing Capacity

4430 1,500 lbs. 1,000 lbs. 1,500 lbs.

WARNING

HAULING CARGO IMPROPERLY CAN ALTER VEHICLE

HANDLING AND MAY CAUSE LOSS OF CONTROL OR

BRAKE INSTABILITY, WHICH CAN RESULT IN SERIOUS

INJURY OR DEATH. ALWAYS FOLLOW THESE PRECAUTIONS WHEN HAULING CARGO:

ALWAYS LOAD THE CARGO BOX WITH THE LOAD AS

FAR FORWARD AS POSSIBLE.

ALWAYS OPERATE THE VEHICLE WITH EXTREME

CARE WHEN HAULING OR TOWING LOADS.

SLOW DOWN AND DRIVE IN LOW GEAR.

WARNING

41

DRIVING WITH PASSENGERS IN THE CARGO BOX CAN

RESULT IN SEVERE INJURY OR DEATH.

NEVER ALLOW PASSENGERS TO RIDE IN THE CARGO

BOX. PASSENGERS MUST ALWAYS RIDE IN THE CAB

WITH SEAT BELTS FASTENED SECURELY.

Page 44

Emptying The Cargo Box (Electric Lift Models)

1. Select a level site to empty the cargo box. Do not attempt to

unload the vehicle while parked on an incline.

2. Set the parking brake.

3. Dismount the vehicle.

4. Release the tailgate latch.

5. Operate the bed lift switch to raise the box.

6. Using the switch, lower the cargo box completely before moving

the vehicle.

WARNING

OPERTATING THE VEHICLE WHILE THE CARGO BOX IS

RAISED COULD RESULT IN SEVERE INJURY. THE BOX

COULD CLOSE UNEXPECTEDLY AND CAUSE INJURY TO

THE DRIVER OR PASSENGER. NEVER OPERATE THIS VEHICLE WITH THE CARGO BOX IN THE RAISED POSITION.

WARNING

Cargo Box

Release Lever

ON MANUAL LIFT MODELS:

IF THE WEIGHT DISTRIBUTION ON THE BOX IS LOCATED

TOWARD THE REAR OF THE BOX WHEN THE RELEASE

LEVER IS PULLED UPWARD, THE BOX MAY DUMP UNEXPECTEDLY AND CAUSE SERIOUS INJURY TO THE OPERATOR OR BYSTANDERS.

NEVER OPERATE THE DUMP LEVER WITHOUT ENSURING THAT THE BOX IS EMPTY.

42

Page 45

Towing Loads

Belt Life

Use low forward gear when hauling or towing heavy cargo to extend

belt life.

Parking The Bush Hog Utility Vehicle

1. Stop the vehicle on a level surface.

2. When the engine has stopped, apply the parking brake.

3. Remove the ignition switch key to prevent unauthorized use.

WARNING

TOWING IMPROPERLY CAN ALTER VEHICLE HANDLING

AND MAY CAUSE LOSS OF CONTROL OR BRAKE INSTABILITY, WHICH CAN RESULT IN SERIOUS INJURY OR

DEATH. ALWAYS FOLLOW THESE PRECAUTIONS WHEN

TOWING:

NEVER LOAD MORE THAN 150 LBS. (68.1 kg) TONGUE

WEIGHT ON THE TOWING BRACKET.

DO NOT OPERATE VEHICLE FASTER THAN 10 MPH

(16 km/h) WHEN TOWING. TOWING A TRAILER INCREASES BRAKING DISTANCE.

DO NOT TOW MORE THAN THE RECOMMENDED 1,500

LB. WEIGHT FOR THE VEHICLE.

ATTACH A TRAILER TO THE HITCH BRACKET ONLY. DO

NOT ATTACH A TRAILER TO ANY OTHER LOCATION OR

YOU MAY LOSE CONTROL OF THE VEHICLE.

NEVER TOW A TRAILER ON A GRADE STEEPER THAN 15°.

WARNING

A ROLLING VEHICLE CAN CAUSE PROPERTY DAMAGE

AND SERIOUS INJURY. ALWAYS APPLY THE PARKING

BRAKE AFTER STOPPING THE ENGINE.

43

Page 46

WARNING

4-Wheel Drive

Your Bush Hog Utility Vehicle is equipped with an exclusive 4-wheel

drive system that can be activated by a switch on the dash board.

When the switch is off, the vehicle is in two-wheel drive at all times.

When the switch is in 4-wheel drive, the front wheels will automatically

engage anytime the rear wheels begin to lose traction. When the rear

wheels regain traction, the front wheels will automatically disengage.

The 4-wheel drive switch light indicates whether the vehicle is in 4wheel drive. There is no limit to the length of time the vehicle may remain in 4-wheel drive.

The 4-wheel drive switch may be turned on or off while the vehicle is

moving. If the switch is turned off while the front hubs are driving, they

will not release until the rear wheels regain traction.

Disengaging 4-Wheel Drive

Under certain conditions, it may be possible for one or both hubs to remain engaged unnecessarily. This condition causes increased steering effort and some vehicle speed restriction.

Take the following steps to disengage the 4-wheel drive system:

1. Stop the vehicle.

2. Shift to reverse and back up a minimum of 10 feet.

CAUTION

SWITCHING TO 4-WHEEL DRIVE WHILE THE REAR

WHEELS ARE SPINNING MAY CAUSE SEVERE DRIVE

SHAFT AND CLUTCH DAMAGE. ALWAYS SWITCH TO 4WHEEL DRIVE WHILE THE REAR WHEELS HAVE TRACTION OR ARE AT REST.

44

GASOLINE IS EXTREMELY FLAMMABLE AND CAN BE

EXPLOSIVE UNDER CERTAIN CONDITIONS. WHEN

PARKING INSIDE A GARAGE OR OTHER STRUCTURE,

BE SURE THAT THE STRUCTURE IS WELL VENTILATED

AND THAT THE VEHICLE IS NOT CLOSE TO ANY

SOURCE OF FLAME OR SPARKS, INCLUDING ANY APPLIANCE WITH PILOT LIGHTS.

Page 47

3. Stop completely.

4. Shift into forward and drive.

If the hubs remain engaged after following these instructions, return

the vehicle to your dealer for service.

NOISE EMISSION CONTROL SYSTEM

TAMPERING WITH NOISE CONTROL SYSTEEM IS PROHIBITED!

U.S. Federal law prohibits the following acts or the causing thereof:

1. The removal or rendering inoperative by any person other than

for purposes of maintenance, repair, or replacement of any

device or element of design incorporated into any new vehicle for

the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use or

2. The use of the vehicle after such device or element of design has

been removed or rendered inoperative by any person.

“AMONG THOSE ACTS PRESUMED TO CONSTITUTE TAMPERING ARE THE ACTS LISTED BELOW,”

1. Removal or alteration or the puncturing of the muffler or any

engine component which conducts removal of engine exhaust gases.

2. Removal or alteration or the puncturing of any part of the engine air

induction system.

3. Replacement of any vehicle parts with parts not in compliance with

federal regulations.

4. Lack of proper maintenance.

WARNING

OPERATING WITH ONLY ONE FRONT HUB ENGAGED

COULD RESULT IN LOSS OF CONTROL, ACCIDENT, AND

SEVERE INJURY OR DEATH.

WHEN HUB ENGAGEMENT SYMPTOMS ARE PRESENT,

USE THE DISENGAGING PROCEDURE BEFORE PROCEEDING.

45

Page 48

CAUTON

USFS Approved Spark Arrestor

The muffler on this vehicle was tested and approved in accordance

with the USFS Forest Service Stanedard 5100-1A.

SECTION III

MAINTENANCE AND LUBRICATION

Periodic Maintenance Schedule

Careful periodic maintenance will help keep your vehicle in the safest,

most reliable condition. Inspection, adjustment and lubrication intervals of important components are explained in the following schedule.

Maintenance intervals are based upon average operating conditions.

Vehicles subjected to severe use, such as operation in wet or dusty

areas, should be inspected and serviced more frequently. If you’re not

familiar with safe service and adjustment procedures, have a qualified dealer perform these operations.

Inspect, clean, lubricate, adjust or replace parts as necessary. When

inspection reveals the need for replacement parts, always use genuine

Bush Hog parts available from you Bush Hog dealer.

Maintenance Chart Key

ss

Perform these operations more often under severe use, such as in

dirty or wet conditions, to purge water or dirt contamination from

grease fillings and othe critical components.

H Emission Control System Service - NOTE: Some models may have

an additional California-only emissions warranty.

n Dealer service item.

46

EXHAUST SYSTEM COMPONENTS ARE VERY HOT DURING AND AFTER USE OF THE VEHICLE. HOT COMPONENTS CAN CAUSE SERIOUS BURNS AND CAN CAUSE

A FIRE.

DO NOT TOUCH HOT EXHAUST SYSTEM COMPONENTS.

USE CAUTION WHEN TRAVELING THROUGH TALL

GRASS, ESPECIALLY DRY GRASS.

Page 49

Periodic Maintenance Schedule

WARNING

Item Frequency Remarks

Brake System Pre-operation Inspect

Tires Pre-operation Inspect

Wheels Pre-operation Inspect

Frame nuts, bolts, Pre-operation Inspect

fasteners

Parking Brake Pre-operation Check lever adjustment

daily; adjust

Throttle Cable Pre-operation Inspect

Steering Pre-operation Inspect

Coolant/Level Daily Replace every two years

Headlamp Daily Inspect daily; apply dielec-

tric grease to donnector

when replaced

Taillamp Daily Inpect daily; apply dielectric

grease to socket when

replaced

s Air Filter- Main Weekly Inspect; replace if necessary

H Element

s Transmission Oil 25 hrs. Check level; change oil

annually

Battery 25 hrs. Check terminals; clean;

check fluid level

n Brake pad wear 25 hrs. Inspect periodically

s Engine breather 25 hrs. Inspect; replace annually

H filter and as needed

s General 25 hrs. Lubricate all fittings, pivots,

Lubrication cables

47

IMPROPERLY PERFORMIMNG THE PROCEDURES

MARKED WITH A

nn

COULD RESULT IN A COMPONENT

FAILURE AND LEAD TO SERIOUS INJURY OR DEATH.

HAVE AN AUTHORIZED BUSH HOG DEALER PERFORM

THESE SERVICES.

Page 50

Item Frequency Remarks

Engine Cylinder 25 hrs. Re-torque required at first

Head/Cylinder service only

Base Fasteners

s Engine Oil-Level 25 hrs. Check level daily; break-in

service at 25 hrs.

s Engine Oil - 100 hrs. Change oil at 100 hours;

H Change more often in cold weather

use

s Oil Filter 100 hrs. Replace with oil change

H

H Engine breather 100 hrs. Inspect

hose

Carburetor Float 50 hrs. Drain bowl periodically and

Bowl prior to storage

n Throttle Cable 50 hrs. Inspect; adjust, lubricate,

replace if necessary

H Choke (Enricher) 50 hrs. Inspect;adjust, replace if

Cable necessary

Shift Linkage 50 hrs. Inspect; adjust

n Drive Belt 50 hrs. Inspect; adjust, replace if

necessary

n Steering 50 hrs. Inspect; lubricate

s Front Suspension 50 hrs. Inspect; lubricate, tighten

Fasteners

s Rear Suspension 50 hrs. Inspect; tighten fsteners

Engine Mounts 300 hrs. Inspect

n Valve Clearance 300 hrs. Inspect; adjust

H Spark Plug 100 hrs. Inspect; replace if necessary

n Ignition Timing 100 hrs. Inspect and adjust as needed

H

n Front Hub Bearings 100 hrs Check at 100 hrs. and

replace as needed

48

Page 51

Item Frequency Remarks

n Fuel System 100 hrs. Check for leaks at fuel cap

H lines, fuel valve, filter, pump

and carburetor.Replace

lines every two years.

Fuel Filter 100 hrs. Replace annually

Spark Arrestor 100 hrs. Clean out

s Front Gearcase Oil 100 hrs. Check monthly; change

annually

n Clutches (drive 100 hrs. Inspect; clean

and driven)

n Brake Fluid 200 hrs. Change every two years

n Front Wheel 300 hrs. Inspect; replace if necessary

Bearings

H Idle Speed As required Adjust

Engine Side Cover As required Drain moisture after driving

in water.

n Toe Adjustment As required Periodic inspection, adjust

when parts are replaced

49

Page 52

MAINTENANCE AND LUBRICATION

Lubrication Recommendations

NOTE: Hours are based on 10 mph average. If service is due at 20

hours, the equivalent odometer reading would be 200 miles. Perform

all services at whichever reading is reached first.

Lubrication Chart

Item Lube Method Frequency

Engine Oil SAE 10W-30, Add to proper level Check level daily

API SJ for on dipstick

gereral use

Brake Fluid DOT 3 or 4 Maintain level be- As required; change

tween fill lines every 200 hrs.

Transaxle Oil SAE 80W-90 Refill to middle of Check monthly;

w/LSD additive sight window change every 100 hrs.

Front Differential Mobil 424 Refill to check plug Every 100 hrs.

Right Angle SAE 80W-90 Refill to middle of Every 100 hrs.

Drive w/LSD additive sight window

Lube Fittings: Lithium Based Grease with grease Every 25 hrs.

Top of Front Grease gun

Struts, Swing

Arm Pivots,

Pillow Block

on Driveshaft

MIXING BRANDS OR USING A NON-RECOMMENDED OIL

MAY CAUSE SERIOUS ENGINE DAMAGE

CAUTON

WARNING

VEHICLE OPERATION WITH INSUFFICIENT, DETERIORATED, OR CONTAMINATED ENGINE OIL WILL CAUSE

ACCELERATED WEAR AND MAY RESULT IN ENGINE

SEIZURE, ACCIDENT, AND INJURY. ALWAYS PERFORM

THE MAINTENANCE PROCEDURES AS OUTLINED IN THE

PERIODIC MAINTENANCE SCHEDULE.

50

Page 53

Engine Oil

Maintain the engine oil at the proper level to ensure a properly functioning engine, and change the oil and oil filter every 100 hours or

every six months, whichever comes first. Dirt and metal particles collect in the oil, and oil loses its lubricative quality if used too long.

Suggested break-in oil change is at 25 hours, or one month, whichever

comes first. Severe use operation requires more frequent service. Severe use includes continuous duty in dusty or wet conditions, and cold

weather operation. NOTE: Severe use/cold weather operation is when

all operating is at below 10°F and/or when operating between 10°F

and 30°F if most trips are slow speed and less than five miles. Always

change the oil filter when changing oil.

Oil Check

The engine oil can be checked and/or refilled by folding the bottom

seat cushion up and forward exposing the engine.

1. Position the vehicle on a level surface.

2. Start the engine and let it idle for 20 - 30 seconds.

3. Stop the engine and fold the seat forward.

4. Remove the dipstick and wipe it clean with a clean cloth.

5. Replace the dipstick completely into the engine.

6. Remove the dipstick and check to see that the oil level is

between the full and add marks. Add oil if necessary. Do not overfill.

NOTE: A rising oil level between checks in cool weather driving can indicate moisture collecting in the crankcase. If the oil level is above the full

mark, change the oil.

Oil Dipstick

Oil Filler Cap

51

Page 54

Engine Oil and Filter Change

1. Run the engine two or three minutes until warm. Stop the engine.

2. Clean the area around the drain plug at the bottom of the

crankcase.

3. Place a drain pan beneath the engine and remove the drain plug.

Allow the oil to drain completely.

4. Clean drain hole and replace the drain plug. Torque to 14 ft. lbs.

5. Remove the oil filter and clean the sealing surface area.

6. Lubricate the new filter 0-ring with clean engine oil.

7. Install the new filter and turn by hand until filter gasket contacts

the sealing surface, then turn an additional 1/2 turn.

8. Remove the dipstick and fill the engine with approximately 1-1/2

quarts of SAE 10W-30, API SJ motor oil. Replace the dipstick.

9. Start the engine and check for leaks at the drain plug and oil filter.

10. Stop the engine and check the oil level on the dipstick.

11. Dispose of used oil and filter properly.

Transaxle

The transaxle oil should be changed every 100 hours.

1. Park the vehicle on a level surface.

2. Remove the drain plug from the transaxle and let oil drain into a

drain pan. Dispose of used oil properly.

3. Clean drain hole and replace the drain plug.

4. Refill transaxle with Mobilube HD LS 80W-90 (or equivalent) to

the middle of sight window. If the transaxle does not have a sight

window, refill to top of check plug.

CAUTION

HOT OIL CAN CAUSE SERIOUS BURNS. DO NOT

ALLOW OIL TO COME INTO CONTACT WITH SKIN.

52

Page 55

Front Differential

The front differential oil should be changed every 100 hours If the vehicle is used in wet conditions, the oil should be checked more frequently. If the oil has a milky appearance, it should be changed as

soon as possible. Failure to properly maintain this area can result in

premature wear or possible failure of the front differential components.

Oil Check

1. With the vehicle on a level surface, remove the fill plug and check

the lubricant level. Oil should be filled until it overflows from the

fill plug.

2. Replace the fill plug and tighten.

Oil Change

1. Support the vehicle securely with a jack stand.

2. Remove the front tire on the driver’s side.

3. Remove the fill plug.

4. Remove the drain plug located on the bottom right-hand side and

drain the oil into a drain pan. Discard the used oil properly.

5. Clean and reinstall the drain plug.

6. Add Mobil 424 oil to 3/4” below the threads of the fill plug hole.

7. Reinstall the fill plug and tighten. Check for leaks.

Front Differential

53

Page 56

Right Angle Drive

The right angle drive oil should be changed every 100 hours.

1. With the vehicle on a level surface remove the fill plug and drain

plug and drain oil into a drain pan. Discard the used oil properly.

2. Refill the drive box with SAE 80W-90 w/LSD additive, to the middle of the sight window.

Oil Change

1. Remove the combination breather/fill plug from the top

of the case.

2. Remove the drain plug from the bottom of the case

and drain the oil into a pan. Discard the used oil properly.

3. Clean and replace the drain plug and fill the right angle

drive with Mobilube HD LS 80W-90 (or equivalent) - Refill

to the center of the sight window.

4. Replace the breather/fill plug and tighten. Check for leaks.

Right Angle Drive

54

Page 57

Constantly Variable Transmission (CVT)

Do not modify any component of the CVT system. Doing so may reduce its strength so that a failure may occur at a high speed. The CVT

system has been precision balanced. Any modification will cause the

system to be out of balance, creating vibration and additional loads on

components.

The CVT system rotates at high speeds, creating large amounts of

force on clutch components. Extensive engineering and testing has

been conducted to ensure the safety of this product. However, as the

owner, you have the following responsibilities to make sure this system

remains safe:

Always follow all recommended maintenance procedures. See your

dealer if required.

This CVT system is intended for use on the Bush Hog utility vehicle.

Do not install it on any other product.

Always make sure the CVT housing is securely in place during operation.

CVT Drying

There may be some instances when water is accidently ingested into the

CVT system Use the following instructions to dry it out before operating.

1. Shift the transmission into neutral and apply full throttle for no longer

than 10 seconds and repeat as necessary. This will expel the moisture and air dry the belt and clutches.

2. Allow the engine RPM to settle to idle speed, then shift the transmission to the lowest available range.

3. Test for belt slippage. If the belt slips, repeat the process.

4. Take the vehicle to your dealer for service as soon as possible.

WARNING

FAILURE TO COMPLY WITH THE INSTRUCTIONS IN THIS

WARNING CAN RESULT IN SEVERE INJURY OR DEATH.

55

Page 58

Vehicle Immersion

If it is impossible to take your vehicle to a dealer before starting it, follow the steps outlined below.

Honda Engines

1. Move the vehicle to dry ground, or at least to a water level below

the floor.

2. Disconnect the fuel pump wires.

3. Remove the spark plugs.

4. Loosen the carburetor drain screw by turning the screw counterclockwise to allow fuel to drain from the fuel bowl . This screw is

accessible with a long handled screwdriver from above, and

behind the engine.

5. Turn the engine over several times with the electric starter.

6. Dry the spark plugs and reinstall, or install new spark plugs.

7. Tighten the carburetor drain screw.

8. Connect the fuel pump wires.

9. Attempt to start the engine. If necessary, repeat the drying procedure.

NOTE: Water damage to electrical components may necessitate replacement of that component.

CAUTION

IF YOUR VEHICLE BECOMES IMMERSED, MAJOR ENGINE DAMAGE CAN RESULT IF THE VEHICLE IS NOT

THOROUGHLY INSPECTED. TAKE THE VEHICLE TO

YOUR DEALER BEFORE STARTING THE ENGINE.

56

Page 59

Engine Air Filter

We recommend that the air filter be cleaned every 25 hours and replaced once a year.

1. The air filter is accessible from the right side of the vehicle, below

the passenger seat. Loosen both fastening clips and remove the

housing cover. There is an outer and inner filter that may then be

pulled out for service or replacement.

2. Inspect the filter housing and clean out any debris or moisture.

3. Replace the filter elements or install new ones.

NOTE: Service the air filter more frequently if the vehicle is operated

in wet conditions or at high throttle openings for extended periods.

CVT Enclosure Air Filter

We recommend that the air filter be cleaned every 25 hours and replaced once a year

The CVT filter is accessible by folding the seat forward. The filter housing is located on the driver’s side above the gas tank.

1. Remover the two wing nuts and remove the housing cover.

2. Remover the filter element, clean the inside of the housing and

reinstall the filter or install a new one.

Engine Air Filter Housing

CVT Air Filter Housing

57

Page 60

Fuel Filter

Your Bush Hog utility vehicle is equipped with an in-line fuel filter that

should be replaced by your dealer after every 100 hours of operation.Do not attempt to clean the fuel filter.