Manufacturer:

burster präzisionsmesstechnik gmbh & co kg

Talstraße 1 - 5 P.O.Box 1432

76593 Gernsbach 76587 Gernsbach

Germany Germany

Tel.: (049) 07224 / 6450

Fax.: (049) 07224 / 64588

E-Mail: info@burster.com

www.burster.com

© 2012 burster

präzisionsmesstechnik gmbh & co kg

All rights reserved

Software version V3.01

Valid from: 18.06.2012

TRANS CAL

Model 7280

972-007280EN-5070-061518

TRANS CAL

Model 7280

Page 2

Note:

All information in the present documentation was prepared and compiled with great care and reproduced

subject to effective control measures. No warranty is provided for freedom from errors. We reserve the

right to make technical changes. The present information as well as the corresponding technical data

can change without notice. Reproduction of any part of this documentation or its processing or revision

using electronic systems is prohibited without the manufacturer’s prior written approval.

Components, devices and measured value sensors made by burster praezisionsmesstechnik (hereinafter

referred to as „product“) are the results of targeted development and meticulous research. As of the date

of delivery, burster provides a warranty for the proper condition and functioning of these products covering

material and production defects for the period specied in the warranty document accompanying the

product. However, burster excludes guarantee or warranty obligations as well as any liability beyond that

for consequential damages caused by improper use of the product, in particular the implied warranty

of success in the market as well as the suitability of the product for a particular purpose. Furthermore,

burster assumes no liability for direct, indirect or incidental damages as well as consequential or other

damages arising from the provision and use of the present documentation.

Model 7280TRANS CAL

Page 3

EG-Konformitätserklärung

EC- Declaration of Conformity according to EN ISO/IEC 17050-1:2004

burster pr äzisionsmes stechnik gmbh & co kg . Talstr. 1-5 . D-76593 Gernsbach (Postfach 1432 D-76587 Gernsbach) Tel. 07224/645-0 . Fax 645-88

www.burster.de

.

www.burster.com . info@burster.de

Sitz der Gesellschaft: HRA 530170 Mannheim . Komplementär: burster präzisionsmesstechnik Verwaltungs-GmbH . Sitz der Gesellschaft: Gernsbach HRB 530130 Mannheim

Geschäftsführer: Matthias Bu rster

.

Prokurist: Edgar Miggler

.

UST-Identnr.: DE 144 005 098

.

Steuernr. : 39454/105 03

Dresdner Bank AG Rastatt Kto . 06 307 073 00 BLZ 662 800 53

.

Volksbank Baden-Ba den*Rastatt eG Kto. 30 2 082 00 BLZ 662 90 0 00

Name des Herstellers:

burster präzisionsmesstechnik gmbh & co kg

Manufacturer’s Name:

Adresse des Herstellers:

Talstr. 1-5

Manufacturer’s Address:

76593 Gernsbach, Germany

erklärt unter alleiniger Verantwortung, dass das gelieferte Produkt

declares under sole responsibility that the product as originally delivered

Produktname:

Prüfgerät für Kraft, Drehmoment, Weg und Druck TRANS CAL

Product Name: Test instrument for force, torque, length and pressure TRANS CAL

Modellnummer(n) (Typ):

7280

Models Number / Type:

Produktoptionen:

Diese Erklärung beinhaltet obengenannte Produkte mit allen Optionen

Options This declaration covers all options of the above product(s)

mit den folgenden europäischen Richtlinien übereinstimmt und entsprechend das CE-Zeichen trägt:

complies with the requirements of the following applicable European Directives, and carries the CE marking accordingly:

2006/95/EC Elektrische Betriebsmittel zur Verwendung innerhalb bestimmter Spannungsgrenzen

Low Voltage Electrical Equipment designed for use within certain voltage limits

2004/108/EC Elektromagnetische Verträglichkeit

EMC Electromagnetic Compatibility

Obengenannte Produkte entsprechen folgenden harmonisierten Normen:

Above named products conform with the following product standards:

Sicherheit:

IEC 61010-1:2001 / EN 61010-1:2001 Messkategorie 1 Schutzklasse III; *

Safety requirements: CAT 1

Safety class 3

* Netzteil Ladestation 7280-Z001

Docking station

Schutzklasse 2

Safety class 2

EMV Störaussendung:

IEC/CISPR 11:2003 + A1:2004 + A2:2006 / EN 55011:2007 + A2:2007

EMC Generic emission:

EMV Störfestigkeit:

IEC 61326-1:2005 / EN 61326-1:2006

Industrie Bereich

EMC Generic immunity:

Industrial environment

Ergänzende Informationen:

/ Additional Information:

Das Produkt wurde in einer typischen Konfiguration getestet. Um optimale Störfestigkeit zu erreichen ist das Gerät über

geschirmte Leitungen anzuschließen. Verwenden Sie nur den angegebenen Batterietyp.

The product was tested in a typical configuration. In order to reach optimal electromagnetic immunity the device has to be conducted

with shielded line.

Do not mix with different types of battery. Always use specified battery.

Diese Konformitätserklärung betrifft alle nach Ausstellungsdatum ausgelieferten Produkte:

This DoC applies to above-listed products placed on the EU market after:

Gernsbach 09.07.2008 i.V. Alfred Großmann

Datum / date Quality Manager

Dieses Dokument ist entsprechend EN ISO/IEC 1705 0-1:2004 Abs. 6.1g ohne Unterschrift gültig / According EN ISO/IEC 1705 0 this document is valid without a signa ture.

TRANS CAL

Model 7280

Page 4

Model 7280TRANS CAL

Page 5

Operating Instruction

Checking Device for Force, Torque, Displacement

and Pressure

Model 7280 (from V3.01)

from serial number: 20218

TRANS CAL

Model 7280

Page 6

Identication

Residual risks which can occur during the operation with the 7280 are pointed out with following

symbols in this instruction:

Warning:

A note which indicates a possible risk of serious or life-threatening injuries. The accident

prevention regulations of the government safety organizations must be considered.

Caution:

A note that indicates a possible risk of damage to the product, process, the human or

the environment

Note:

Additional information

Important / Tip:

Reference to more detailed technical information

Health and safety protection

To ensure that our products are safe and they pose no health hazard, the following points must be

considered:

1. All relevant sections of this manual must be read carefully before beginning with the operation.

2. All warning labels on packages and containers must be observed.

3. Installations, operation, maintenance and repair work must be carried out by suitably trained

personnel in accordance with the given instructions. If any of these instructions are not met, the

user of the product bears the full responsibility for all consequences occurring from this failure

to comply.

4. Before opening the device, it must be separated from any supply.

Qualied personnel

Qualied personnel are persons who are familiar wit the installation, operation and maintenance of the

7280 measuring amplier and also have the required qualications. The 7280 amplier is to be used

by qualied personnel according to the technical data in connection with the special safety rules and

regulations and use. In addition, the operation required for each individual application, legal and saftey

regulations. The 7280 measuring amplier shall only be used by qualied personnel according to the

specications and the following indicated safety regulations and rules. During the operation, the legal

and safety regulations, required for each individual application, must be considered in addition. This

also applies when using accessories.

Modication

The 7280 amplier may not be changed constructional or safety-related without our explicit

permission. burster präzisionsmesstechnik gmbh & co kg will not take responsibility for any

resulting damages. Repairs and modications of the printed boards are prohibited.

Model 7280TRANS CAL

Page 7

Contents

Page

1. General ............................................................................................................................9

1.1 Application ..........................................................................................................9

1.2 Description ..........................................................................................................9

2. Preparations for use ....................................................................................................11

2.1 Unpacking the device .......................................................................................11

2.2 Using the device for the rst time .....................................................................11

2.3 Mains operation ................................................................................................12

2.4 Safe and correct use .........................................................................................12

3. Controls and terminals ................................................................................................13

3.1 General ..............................................................................................................13

3.2 Program overview .............................................................................................13

3.3 Description of the key .......................................................................................14

3.4 Digital input .......................................................................................................15

3.5 Pin assignment ..................................................................................................16

4. Manual operation .........................................................................................................17

4.1 Menu description ..............................................................................................17

4.2 Measuring with 7280 .........................................................................................19

4.2.1 Negative zero output ........................................................................................ 19

4.2.2 Stored adjustment values ................................................................................ 19

4.3 Sensor parameters ............................................................................................20

4.4 ADJUST - adjustment menu .............................................................................20

4.5 Adjustment procedure.......................................................................................21

4.6 Operating and function principle of the data logger in 7280 amplier ..............23

4.7 Adjustments in the LOGG mode .......................................................................24

5. Remote ..........................................................................................................................25

5.1 Serial interface ..................................................................................................25

5.2 Read-out of current sensor parameters ............................................................26

5.3 Read-out complete status ................................................................................26

5.4 Read-out complete status ................................................................................27

5.5 Format of the serial interface output .................................................................29

5.6 Adjustments in the SCI mode ...........................................................................29

5.7 Transfer rate / specication RS232 (V.24) / USB ...............................................29

5.8 Link connection to USB ....................................................................................30

5.9 Measuring rate 1000/s and LOGG Mode 1 ms .................................................30

6. Technical data .............................................................................................................31

7. Programmer example ..................................................................................................33

8. Automatic OFF at battery / mains operation .............................................................37

TRANS CAL

Model 7280

Page 8

Contents

Seite

9. MISC ..........................................................................................................................37

9.1 Transportation ...................................................................................................37

9.2 Initiation and setup ............................................................................................37

9.3 Normal operation ..............................................................................................38

9.4 Maintenance and cleaning ................................................................................38

9.5 Disposal ............................................................................................................39

Model 7280TRANS CAL

Page 9

1.1 Application

The portable digital indicator model 7280 is a universal checking device for instrumentation

examination mechanical components like press, equipment of torque and so on. The employment

takes place in the ranges quality assurance, start-up and process monitoring. By high measuring

rates very fast reactions to the measuring signals are possible. A min./max. memory makes

further areas of application possible for the equipment. A universally congurable data logger

can store measured values up to 15288. By the possibility 10 parameter sets to deposit, are

possible different calibration data such as sensor designation and physical units. Measured

values or logging values can be spent over RS232-/USB interface at a PC or a printer. So that

the measurement chain is traceable, a proprietary calibration certicate can be provided. The

traceability of the calibration exists over the used reference normal.

1. General

1.2 Description

The model 7280 is mobile by battery or accu, can be operated however also with an external

power pack. A high measuring accuracy paired with fast measuring rate, 16 bit A/D converter

and a microprocessor are ensured by the employment by highly precise ampliers.

The pocket model 7280 support sensors on strain gage basis and active sensors to 10 V /

20 mA. Indicated on the 14 mm high LED main display will the current measured value, on a

second display directly under it can for example the peak value be read off. With the function

tare can be away-tared an existing basis load. For a force measuring chain we recommend to

attach the tension and compression load cell model 8524 to the digital indicator. Depending

upon can be selected between measuring range of 500 N and 200 kN (divides into 9 stages).

The reference measuring chain is completely congures and calibrated.

TRANS CAL

Model 7280

Page 10

Model 7280TRANS CAL

Page 11

2. Preparation for use

2.1 Unpacking the device

The device weights approx. 0.5 kg and due to this it is packed shockproof. Unpack it accurately

and check the completeness of the delivery.

This normally includes: 1 TRANS CAL model 7280

1 copy of this manual

Verify accurately, that there is no damage on the device.

If here is a suspicion, contact the manufacturer within 72 hours.

Retain the packaging for examination by a representative of the manufacturer and/or the deliverer.

Only ship the TRANS CAL in original packaging or in a container providing the same degree

of protection.

2.2 Using the device for the rst time

Warning: The device must never be switched on if it shows signs of damage during

shipping.

TRANS CAL

Model 7280

Page 12

2.3 Mains operation

Mains operation:

A plug-in power supply with controlled 6 V DC must be employed with min 1.5 A. For discharged

batteries the charging current will be approx. 290 mA. In this way, the accumulators are also

loaded simultaneously, also in the case of switched-off 7280.

During continuous operation on the net, it is recommended to remove the accumulators. For fast

loading to 100 % of the accumulators, an external loader (e.g. Ansmann 4 - 6) is recommended.

Prior to mains operation (disposable-) batteries must be removed from the

device, as they would be destroyed by the charging process and thus lead

to equipment damage !

Accumulator operation:

Use 4 x NiMH Mignon-Accumulators of min. 1600 mAh and 1.2 V correctly poled.

Accumulator charge time:

The accumulator charge time at accumulator-capacity of 2.7 Ah is approx. 9 - 10 h. At discharged

accumulators, the constant charging rate is approx. 290 mA. Charged accumulators are

recognized by the Minus-Delta-Peak-Procedure (overload protection).

Battery operation:

Use 4 x Mignon/AA batteries with 1.5 V

Never use a power supply plug when batteries are inserted !

Voltage supply:

If the admissible battery voltage falls below, the display starts to blink.

Safe and correct use

Caution:

- Protect the device from moisture dew, rain, snow...

- Protect the device from direct solar irradiation

- Protect the device from dust and pollution

- Protect the device from high and/or excessive ambient temperature

- Protect the device from excessive vibration

Model 7280TRANS CAL

Page 13

3.1 General

The device can be operated via the keyboard or via the RS232-/USB interface. The following

describes operation of the keyboard in a brief overview.

3. Controls and Terminals

Brief overview for the operation

3.2 Operating overview

MINUS

ESC (7280 switch off)

ENTER (7280 switch on)

1 MEASURE

measure mode

ESC

SENSOR_

sensor selection

ESC

MEASURE

2 SYSTEM

systemparameter

PLUS

MINUS

ESC

ENTER

ENTER

ENTER

2.1 LANG

language

MINUS

PLUS

2.2 INFO

info

MINUS

PLUS

2.3 SCI

interface

MINUS

MINUS

ENTER/ESC

ESC

ESC

PLUS

2.4 RATE

MINUS

ESC

PLUS

2.5 PASS

password for adjust

MINUS

PLUS

2.6 LCD

LCD contrast

MINUS

ENTER/ESC

PLUS

2.7 LOGG

data logger

MINUS

ESC

PLUS

2.8 DATE

date and time

ESC

PLUS MINUS

deutsch

english

francais

espanol

ENTER

ENTER

PLUS MINUS

SW no.

firmware version

PLUS MINUS

BAUD

Baudrate

ENTER

SCI MODE

for measure mode

PLUS MINUS

RATE

measuring rate

ENTER

AVERAGE

average value

brighter

darker

ENTER

PLUS MINUS

LOGGMODE

LOGGSEND

LOGG DEL

ENTER

PLUS MINUS

DATE

TIME

ENTER

ENTER/ESC

ENTER/ESC

ENTER/ESC

ENTER/ESC

ENTER/ESC

ENTER/ESC

ENTER/ESC

3 ADJUST

adjustment menue

PLUS

ENTER

ENTER

SENSOR_

sensor selection

ESC

ESC

3.01

ENTER

PLUS MINUS

2400, 4800, 9600

19200, 38400

115200

ENTER

PLUS MINUS

SCI off

Hand (ENTER)

AUTO

TRIGGER

ENTER

PLUS MINUS

mess / sec

1/10/100/1000

ENTER

PLUS MINUS

1, 2 4, 8, 16, 32

ENTER

PLUS MINUS

LOGG off

HAND

AUTO

DIAGRAM

WINDOW

ENTER

17.04.2012

14:30:00

ENTER

PLUS MINUS

POINT_DIS

100 % range, decpnt

UNIT

physic. unit

ADJUST

adjustment menue

DESIGN

sensor name

ESC

ACT wCON

aktive with control

ENTER

AKT nCON

aktive without control

MINUS

PLUS

MINUS

PAS wCON

passive with control

PAS nCON

passive without control

PLUS

PLUS

CURRENT

0-20 / 4-20 mA

PLUS

MINUS

ENTER/ESC

ENTER

ENTER/ESC

ENTER

ENTER/ESC

ENTER

ENTER/ESC

ENTER

ENTER/ESC

ENTER

Sensors

with control:

self adjustment

Sensors

without control:

sensitivity

or

adjustment

with

100 % load

Measure settings System settings

USB

RS232

ENTER/ESC

ENTER

INTERFAC

interface mode

PLUS MINUS

PLUS MINUS

PLUS MINUS

10 ms

100 ms

1 sec

10 sec

1 min

10 min

1 h

ENTER

ESC

ENTER

PLUS MINUS

1 ms

10 ms

100 ms

1 sec

10 sec

1 min

10 min

1 h

ENTER

ENTER

Adjustment settings

You must first enter the password (9373) under the menu iterm 2.5 to activate the adjustment settings.

TRANS CAL

Model 7280

Page 14

3.3 Description of the keys

Example:

In 7280 switch on

- The 7280 is switched on, when ENTER button is pressed.

Time and data

- control or correct time and date in SYSTEM menu

Edit language

-

Change in menu to 2 SYSTEM – 2.1 LANG. When ENTER button is pressed,

7280 is in selection mode. With the buttons PLUS and MINUS the language can

be selected. With ENTER the selected language will be saved. With ESC the

selected language will be discarded.

Edit time

-

Change in menu to 2 SYSTEM – 2.8 DATE. When ENTER button is pressed

TIME will appear on LCD. Press ENTER and you can edit the time. With PLUS

and MINUS button the hours can be adjusted. After ENTER the minutes can be

adjusted with PLUS and MINUS button. With ENTER the selected time will be

saved. With ESC the selected time will be discarded.

Chance into the measure mode

- From menu 1 MEASUR by pressing ENTER the list of all sensors is called up. By the keys

PLUS and/or. MINUS a sensor parameter set is being chosen, then. By pressing ENTER

the 7280 is being adjusted to this sensor parameter set. By pressing ESC it is possible

to switch back to menu 1 MEASUR from any mode.

Model 7280TRANS CAL

Page 15

Change measuring rate by measuring mode

- The measuring can be exited by pressing key ESC. After pressing key ESC again, the

7280 will return to menu 1 MEASUR. From there the menu 2 SYSTEM – 2.4 Rate can be

called up.Select entry RATE by key PLUS and/or MINUS. By pressing key ENTER the

set measuring rate is being displayed, rst.By key PLUS and/or MINUS a new measur-

ing rate can be set now. By ENTER the new measuring rate will be taken over, by ESC

the new measuring rate will be discarded.

Switch off 7280

- 7280 is switched off, when ESC button is pressed >3 seconds.

3.4 Digital input

The device has a voltaic isolated control input: Trigger. This input can be controlled by e.g. a

PLC, a remote switch, a foot switch etc. As 100 % control signal, following voltage levels must

be applied at the phone jack for the respective logic state:

Logic state Low level High level

Voltage level 0 V ... 2 V 3.5 V ... 27 V

State inactive active

Trigger input

- Depending on adjustment, data can be logged or interface data can be issued.

This input has a high sampling rate, thus very short pulses are detected.

Key assignment:

Key Programming mode

▲ Scroll up

▼ Scroll down

ENTER Conrmation, one step forward in the menu

ESC Reject, one step back in the menu

TRANS CAL

Model 7280

Page 16

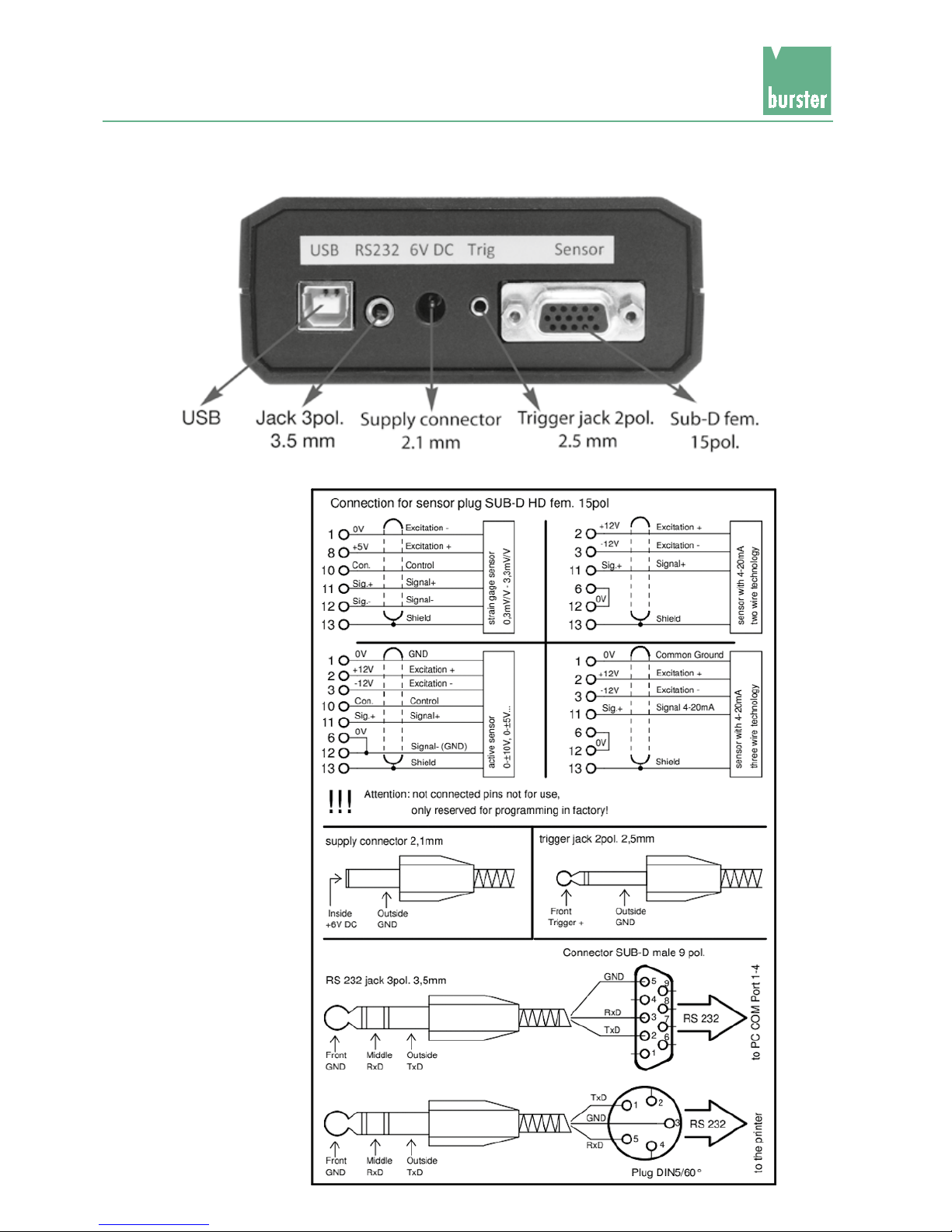

3.5 Pin assignment

Pin assignment of

the sensors

Model 7280TRANS CAL

Page 17

4. Manual Operation

4.1 Menu description

1 MEASURE Measuring mode

SENSOR__ Sensor selection for measuring mode, sensor 0 - 9

Selection of the sensor parameter set of the measurement. The

sensor parameter set must comply with the connected sensor.

2 SYSTEM All system parameters are stored in this menu column.

2.1 LANG Language adjustment

The menu language is available in English, German, French and

Spanish.

2.2 INFO Information query was factory-congured and is not modiable.

SW no. Firmware version

2.3 SCI Interface conguration

BAUD Baud rate adjustment; it must comply with the receiver (PC or printer).

SCI MODE The interface conguration only refers to the measuring mode, not

the log mode!

SCI off Interface switched off

HAND When pressing ENTER in the measuring mode, a measured value

is displayed.

AUTO1 Interval time, adjustable from 10 ms to 1 h (at high measuring rate

only possible with the highest baud rate).

TRIGGER At rising edge on the trigger input, in measuring mode a measured

value is displayed.

INTERFAC Interface selection

USB USB interface is activated

RS232 RS232 interface is activated

2.4 RATE Measuring rate1 and average value

RATE Measuring rate adjustment, selectable from 1/s to 1000/s. For fast

procedures (screw joint, insert press...) always select a fast measur-

ing rate, e.g. 1000/s, for very slow procedures select a small rate,

e.g. 1/s.

AVERAGE Average determination, the numbers indicate the average determina-

tion by the amount of measurements. Applicable for e.g. vibrations,

control oscillations...

2.5 PASS Password query

RATE Entering password 9373 allows to change to menu 3 ADJUST. Here,

the sensor parameters can be changed.

2.6 LCD LCD contrast adjustment

If the LCD becomes unreadable by external inuences, e.g. solar

radiation, heat or cold, the LCD contrast can be changed by press-

ing key ▲ or ▼.

1

If the SCI → AUTO interval time is shorter than the adjusted measuring rate, the same measured value

will be issued on the interface until a new value is entered.

TRANS CAL

Model 7280

Page 18

2.7 LOGG Data logger adjustments

LOGGMODE Data logger conguration

LOGG off Off-switch for logger operation, measuring mode possible, only.

Hand With each keystroke on ENTER a log value is accepted.

AUTO Adjustment of the measurement intervals for the automatic measured

value storing.

DIAGRAM With each rising edge of the trigger signal, a log value is accepted.

WINDOW The window operation is started by a rising trigger edge and can be

nished only by a falling edge. During this time, measured values

are stored in 1 ms raster in the data logger.

LOGGSEND Log values are issued through the interface, press ENTER twice.

LOGGDEL Log values are deleted after a safety query. Before deleting, please

assure that the data was received.

2.8 DATE Data and time adjustment

DATE Date

TIME Time

3 ADJUST Adjustmenu

This menu is active only, if the password has been entered in menu

mode 2.5 PASS. For the adjustment, the sensor must be connected

to the sensor socket.

Sensor__ Sensor number or the name of the sensor which shall be adjusted.

POINTDIS Final measurement value of the sensor with decimal indication e.g.

1000; 100.0; 10.00; 1,000. The numerical values are variable, 4 digits

are available. Change to menu mode POINTSDIS. After pressing

ENTER, the nal measurement value of the sensor can be entered.

With keys ▲ and/or ▼ the rst digit can be edited, go to the next

gure by pressing ENTER. When all 4 digits are edited, the decimal

point gets shifted by keys ▲ and/or ▼. Press ENTER to complete

the entry, the nal value will then be stored in the 7280 measuring

amplier.

UNIT Entry of the physical unit e.g. kg, Ncm, t, gr, kN, Nm, bar...

ADJUST Sensor type selection (active with 100 % control signal, active without

100 % control signal, passive with 100 % control signal, passive

without 100 % control signal, 4-20 mA.

DESIG Name of the sensor e.g. sensor 1, 2, 3, DR-2112, silo, tank, mixer,

scale 1, motor, test 1...

Model 7280TRANS CAL

Page 19

4.2 Measuring with 7280

Measuring with 7280

selected sensor is: Force sensor with meas. range 200 kN

Sens.: 2 mV/V

Designation e.g.: Squeezer

Parameter set: Sensor no.: 3

Option: 100 % Cal. control

In order to be able to now measure with this sensor, the sensor „SQUEEZER“ is selected in

the measuring mode. During a measurement, a minimum and maximum value buffer can be

called up with the arrow keys, the in each case displayed minimum or maximum value can

be deleted with ENTER.

If the measured value should be sent through an interface to a pc or printer, the baud rate

must be adjusted to the receiver and the operating mode must be chosen in the case of SCI-

MODE. For example: HAND, a measured value with time is displayed during every keystroke

on ENTER while measuring.

Should data be logged, adjust operating mode in the logger mode, e.g. choose AUTO and

range time e.g. 10 sec and enter the measuring mode. A measured value with time is now stored

every 10 sec. In the mode LOGGSEND, these data then can be sent through the interface.

ENTER

4.2.1 Negative zero output

With no sensor parameter set, a negative zero output from the sensor can be entered (manually by hand). A negative zero output can only read in directly from the sensor with teach-in

(function adjustment).

4.2.2 Stored adjustment values

The stored adjustment value are not displayed. This will only stored inside the device and can´t

be changed manually.

Key assignment:

Key Measuring mode

▲ Press = TARA

▼ MEASURING --- MIN --- MAX --- MEASURING

at MEASURING: send data

at LOGG: store measured value

at MIN: delete MIN

at MAX: delete MAX

ESC Back to menu / Press 3 sec. Press = Off

TRANS CAL

Model 7280

Page 20

4.3 Sensor parameters

After the password (9373) input in the system, the sensor can be applied in the calibrating menu.

Following parameters are available:

Sensor_ Sensor no 3 Sensor 0 - 9 possible

POINTDIS 200.0 Adjust meas. range and decimal point (max. 9999)

UNIT _kN 1 – 3 digit unit possible

DESIGN Squeezer up to 8 digit name (or numbers) freely optional

ADJUST PAS_nCON Select passive without cal. control

0 % LOAD Relieve sensor 0% value of sensor, indication 0 is assigned

100 % CON Autom. calibration 100 % value of sensor will be assigned to

indication 200 kN

SAVE ENTER or ESC Conrm or reject

4.4 ADJUST Adjustment menu

3 ADJUST Adjustment menu

This menu is active only, if the password has been entered in menu

mode 2.5 PASS. For the adjustment, the sensor must be connected

to the sensor socket.

Sensor_ Sensor number or the name of the sensor which shall be adjusted.

POINTDIS Final measurement value of the sensor with decimal indication e.g.

1000; 100,0; 10.00; 1.000; ...

The numerical values are variable, 4 digits are available. Change to

menu mode POINTDIS. After pressing ENTER, the nal measurement value of the sensor can be entered. With keys ▲ and/or▼ the

rst digit can be edited, go to the next gure by pressing ENTER.

When all 4 digits are edited, the decimal point gets shifted by keys

▲ and/or▼. Press ENTER to complete the entry, the nal value will

then be stored in the 7280 measuring amplier.

Model 7280TRANS CAL

Page 21

UNIT Entry of the physical unit, e.g. Kg, Ncm, t, kN, Nm, bar ...

DESIG Name of the sensor, e.g. 1, 2, 3, DR 2112, silo, tank, mixer, scale1,

motor, test1...

ADJUST Sensor type selection:

ACTIVE without control signal, for transmitter 0-10 V

CURRENT for transmitter 4-20 mA.

PASSIVE without control signal

, for strain gauge (load) sensors

4.5 Adjustment procedure

ACT nCON Active sensor without 100 % control signal

with following adjustment possibilities:

- adjust 0 % load and 100 % load

- adjust 0 % load and enter hub

(100 % load in V - 0 % load in V)

- enter 0 % load in V and the hub

(100 % load in V - 0 % load in V)

Select between 0 % load or nominal value by pressing ▲ or ▼

0 % LOAD unload sensor

or NOMVALUE input of the nominal value in V

Select between load or nominal value by pressing ▲ or ▼

100 % LOAD Adjustment by 100 % load (apply nominal load)

or NOMVALUE input of the nominal value in V

SAVE Query for takeover of the adjusted data

PAS nCON Passive Sensor without 100 % control signal

with following adjustment possibilities:

- adjust 0 % load and 100 % load

- adjust 0 % load and enter 100 % load in mV/V

- enter 0 % load in mV/V and 100 % load in mV/V

Select between load or nominal value by pressing ▲ or ▼

0 % LOAD unload sensor.

or NOMVALUE input of the nominal value in mV/V

Select between 100 % load or nominal value by pressing ▲ or ▼

100 % LOAD adjustment by load (apply nominal load).

or NOMVALUE input of the nominal in mV/V

SAVE Query for takeover of the adjusted data

TRANS CAL

Model 7280

Page 22

Adjustment procedure

CURRENT Sensor with 4 ... 20 mA

with following adjustment possibilities:

- adjust 0 % load and 100 % load

- adjust 0 % load and 100 % load in mA

- enter 0 % load in mA and 100 % load in mA

Select between 0 % load or nominal value by pressing ▲ or ▼

0 % LOAD unload sensor

or NOMVALUE input of the nominal value in mA (xed value 4-20 mA)

Select between 100 % load or nominal value by pressing ▲ or ▼

100 % LOAD adjustment by 100 % load (apply nominal load / nominal torque)

or NOMVALUE input of the nominal value in mA

SAVE Query for takeover of the adjusted data

If a sensor cannot be selected and/or does not change to the measuring

mode, there was a false adjustment for this sensor / parameter set. → Readjustment

Model 7280TRANS CAL

Page 23

4.6 Operating and function principle of the

date logger in 7280 measuring amplier

The data logger can, if the 7280 measuring amplier is not in the measuring mode, be read by

the menu option 2.7 LOGG - SENDING or by the command „A“ via the interface. Outside of the

measuring mode the data logger is deleted only by the menu option 2.7 LOGG - DELETION.

If the 7280 measuring amplier is in the measuring mode, the data logger can be read with the

command „A“ and be deleted with the command „B“.

If the measuring mode is being switched on from the menu option 1 MEASURING-sensor

selection, the starting time of the measurement, the current sensor designation, the nal value

of the measuring range, the adjusted measuring rate and the logger mode (e.g.: AUTO 1 ms)

are saved in the logger.

NOTE: All previous measured values are deleted here!

With the read-out of the data logger via the serial interface different adjustments of the 7280

are sent.

a.) letter head

b.) starting time of the measurement

c.) sensor designation

d.) display nal value

e.) adjusted measuring rate

f.) adjusted logger mode

g.) thereafter the measured values

In the HAND MODE the measured values are always logged with the time. With the data in the

AUTOMODE the measured value is logged. A time can be assigned to each measured value

by the indicated starting time.

Since in GRAPHS and in the WINDOW MODE trigger events smaller than 1 sec can occur, an

additional time log is not possible.

TRANS CAL

Model 7280

Page 24

4.7 Adjustments in the LOGG mode

LOGG OUT Here the data logger is switched off. the logg mode in the measur-

ing mode is switched to “LOGG OUT” as soon as the entire data

logger has been edited.

HAND In this mode a measured value is written into the data logger when

the enter key was pressed at the 7280. By an additional logg of time,

there is a assignment for each measured value.

AUTO In this mode in the adjusted delay a measured value is written into

the data logger. By the stored starting time there is a time assignment for each measured value.

GRAPH In this mode at a trigger event a measured value is written into the

logger. Since the trigger pulses occur in 10 ms raster, an additional

logg of the time is not possible. The ank of the trigger pulse must

stand on HIGH for 4 ms at last. Afterwards on LOW for at least 6 ms.

WINDOW This mode reacts to in increasing and/or decreasing anks. At an

increasing ank the logging of the measured values is started. From

now on the measured values are written in the data logger with 1

ms raster. A decreasing ank ends the recording.

Memory depth of data logger - see chapter 5.1

Trigger Signal

Read values

Model 7280TRANS CAL

Page 25

5. Remote

5.1 Serial interface

For the serial data transmission the 7280 measuring amplier uses a RS232 or

an USB interface. The PC manages the USB interface as a virtual COM port.

For the use of the USB interface, must have a windows operating system (2k,

XP, Vista, 7) and the burster präzsionsmesstechnik gmbh & co kg USB driver

must be installed (see chapter 3 - further documentation). After the driver

installation, the virtual COM port can be used as described below.

Transfer rate / specication RS232 (V.24) / USB

Parity: none

Number of data bits:

8 (1 Byte) 8N1

Stop bit: 1

Baud rate adjustable (2400, 4800, 9600, 19200, 38400, 115200 Baud)

In the USB mode, the baud rate in the 7280 measuring amplier and the

connected device must match.

Protocol overview

Via the serial interface, the 7280 measuring amplier can issue the measured values individually

or automatically. The commands can be send to the 7280 measuring amplier via a termal

program or a PLC.

Following commands are available:

Command overview

ASCII HEX Description in measuring not in measuring

mode mode

k 0x6B ENTER

I 0x6C ▲

m 0x6D ▼

n 0x6E ESC

A 0x41 Read-out data logger

C 0x43 Read-out current sensor parameters

D 0x44 Read-out status

E 0x45 Read-out complete status

g 0x67 Change protocol setup

0 0x30 Continuous measured value query (signed integer)

1 0x31 Query of max. value (signed integer)

2 0x32 Query of min. value (signed integer)

3 0x33 Tare of display

4 0x34 Reset max. value

5 0x35 Reset min. value

6 0x36 Actuate 100 % 100 % control signal -

for sensors with 100 % control resistance

7 0x37 Switch-off 100 % 100 % control signal

for sensors with 100 % control resistance

B 0x42 Delete data logger

a 0x61 Write time

b 0x62 Read-out time

c 0x63 Write company head

e 0x65 Write all sensor parameters (not supported yet)

f 0x66 Read-all sensor parameters (not supported yet)

In Menu 3: ADJUST → UNIT and ADJUST → DESIG the

adjustments can be changed by the commands “I” and “m”

}

TRANS CAL

Model 7280

Page 26

5.2 Read-out of current sensor parameters

Sensor designation 8 Byte ASCII

Final displayed value 2 Byte compressed BCD-gure

Unit 3 Byte ASCII

Sensor type and digit 1 Byte 0xAB: A ... Sensor type, B ... digit (binary coded)

Sensor type:

0xXXXX XXXX

||||

0000 ... active with 100% 100% control signal adjust 0% load and 100% load

0001 ... active without 100% 100% control signal adjust 0% load and 100% load

0010 ... active without 100% 100% control signal adjust 0% load and 100% load V

0011 ... active without 100% 100% control signal adjust 0% load V and 100% load V

0100 ... passive with 100% 100% control signal adjust 0% load and 100% load

0101 ... passive without 100% 100% control signal adjust 0% load and 100% load

0110 ... passive without 100% 100% control signal adjust 0% load V and 100% load mV

0111 ... passive without 100% 100% control signal adjust 0% load mV and 100% load mV/V

1000 ... current adjust 0% load and 100% load

1001 ... current adjust 0% load and 100% load mA

1010 ... current adjust 0% load mA and 100% load mA

Digit:

0xXXXX XXXX

||||

|000 ... _5000___

|001 ... _5,000__

|010 ... _50,00__

|011 ... _500,0__

|100 ... 5,000___

0%load 2 Byte HEX value (MSB/LSB)

100% load 2 Byte HEX value (MSB/LSB)

5.3 Read-out complete status

Status 2 Byte general error condition of the 7280 measuring amplier

Model 7280TRANS CAL

Page 27

5.4 Read-out complete status

Status 2 Byte General error condition of the 7280 measuring amplier

Meas. rate 1 Byte 0x01 ... 1000/sec

0x02 ... 100/sec

0x03 ... 10/sec

0x04 ... 1/sec

Average value 1 Byte 0x01 ... x/1

0x02 ... x/2

0x04 ... x/4

0x08 ... x/8

0x10 ... x/16

0x20 ... x/32

SCI_MODE 1 Byte 0x00 ... interface is off mode

0x04 ... hand mode

0x08 ... automatic mode

0x0C ... trigger mode

SCI_MODE_DELAY 1 Byte 0x02 ...10 ms

0x03 ... 100 ms

0x04 ... 1 s

0x05 ... 10 s

0x06 ... 1 min

0x07 ... 10 min

0x08 ... 1 h

LOGGMODE 1 Byte 0x00 ... logger is off mode

0x04 ... hand mode

0x08 ... automatic mode

0x0C ... DIAGRAM mode

0x10 ... windows mode

LOGGMODE_DELAY 1Byte 0x01 ... 1 ms

0x02 ... 10 ms

0x03 ... 100 ms

0x04 ... 1 s

0x05 ... 10 s

0x06 ... 1 min

0x07 ... 10 min

0x08 ... 1 h

Language 1 Byte 0x00 ... GERMAN

0x02 ... ENGLISH

0x04 ... FRENCH

0x06 ... SPANISH

Protocol status 1 Byte 0xXXXX XXXX (binary coded)

|||| ||||

|||||||1...donotsendnalcharacter

|||| ||1 ... send CR/LF

|||| |1 ... send CR

|||| 1 ... send LF

Write time:

Write time is identical to data block receipt of time. However, the data block for writing is protected with a check sum and the referring weighted check sum.

Read time:

With following read-out:

DAY.MONTH.YEAR

2xSpace

HOURS:MINUTES:SECONDS

TRANS CAL

Model 7280

Page 28

Write company head:

The entry ends either if 256 characters are received or if the character ETX (0x03) Strg-C is

contained in the character string.

Read company head:

By this command, the company head, which is stored in the 7280 measuring amplier, is read-out.

Write all parameters:

The writing data block of all sensor parameters is identical with the receiving data block for

reading all parameters. However, for the writing of the sensor parameters a check sum and

the referring weighted check sum is required.

Read all parameters:

The read-out of all parameters from sensor 1 to sensor 10 occurs in following sequence:

Sensor designation

Final displayed value

Unit

Sensor type (adjustment type) / decimal point

Adjustment values 0 % load, 100 % load with 2 Bytes each

See command “read current sensor parameters”.

Change protocol setup:

Protocol status 1 Byte

0xXXXX XXXX (binary coded)

|||| ||||

|||||||1 ...donotsendnalcharacter

|||| ||1 ... send CR/LF

|||| |1 ... send CR

|||| 1 ... send LF

Calculation of the check sum (CS) and the weighted check sum (gewCS):

The calculation occurs via all parameter bytes (without the command byte). At the CS all bytes

are added (overows are not considered here). For the calculation of the gewCS, the CS is

added to the gewCS. At overow, the gewCS is incremented by 1.

Model 7280TRANS CAL

Page 29

5.5 Format of the serial interface output

Operation via serial interface/USB

Output format in SCI mode:

HAND Sign, value, unit, time and CRLF

AUTO 10 ms value (signed integer) and CRLF

100 ms value (signed integer) and CRLF

1 s Sign, value, unit, time and CRLF

10 s Sign, value, unit, time and CRLF

1 min Sign, value, unit, time and CRLF

10 min Sign, value, unit, time and CRLF

1 h Sign, value, unit, time and CRLF

TRIGGER value (signed integer) and CRLF

Output format in LOGG mode:

HAND Sign, measured value, unit, time and CRLF

AUTO Sign, measured value, unit and CRLF

DIAGRAM Sign, measured value, unit and CRLF

WINDOW Sign, measured value, unit and CRLF

5.6 Adjustments in the SCI mode

SCI off: With this adjustment, measured values transfer from the 7280 measuring

amplier is disabled, but the 7280 measuring amplier can be controlled

via the 7280 commands.

HAND: In this mode a measured value is issued via the serial interface when

ENTER is pressed at the 7280 measuring amplier.

AUTO: In this mode a measured value is issued via the serial interface in the

adjusted delay.

TRIGGER: At a trigger event in this mode, a measured value is issued via the

serial interface. The trigger pulses can occur in 10 ms raster. The ank of

the trigger pulse must be on HIGH for at least 4 ms. Then it must be

on LOW for at least 6 ms.

5.7 Transfer rate / specication RS232 (V.24) / USB

Parity: none

Number of data bits: 8 (1 Byte)

Stop bit: 1

Baud rate: adjustable (2400; 4800; 9600; 19200; 38400; 115200

In the USB mode, the baud rate in the 7280 measuring amplier

and in the connected device must match.

TRANS CAL

Model 7280

Page 30

5.8 Link connection to USB

To establish a connection between 7280 an PC, the user can install the USB driver on his PC.

7280 in 2.3 SCI/INTERFACE choose “USB” as the interface and in 2.3 SCI/BAUD set the desired

BAUD rate. Then connect the 7280 to your PC and start the software. Under the menu point

settings/interface select the COM port with the name “XXXXX USB Sensor” and select in the

same menu the same BAUD rate as in 7280. After that, the communication is established and

can be used exactly as directed by the RS232 interface.

5.9

Measuring rate 1000/s and LOGG Mode 1 ms

During a measurement at a rate of 1000/s and active LOGGING mode with 1 ms can read via

the PC software in the section Data Logger no readings. This is because, that the measurement

values are written 10 x faster in the devices internal memory, as they can be output via interface.

Model 7280TRANS CAL

Page 31

6. Technical Data

Accuracy: 0.1 % F.S. ± 1 digit

Measuring rate: 1 / 10 / 100 / 1000 sec.

Average values: x/1, x/2, x/4, x/8, x/16, x/32

Display counts: ± 9.999 + 3 dig. unit

Zero point alignment: automatic/manual

Sensor selection for measurement mode: 10

Data logger mode: window, diagram, manual, auto

Memory values: max. 15288

Bridge restance of the strain gauges: 350 ... 2000 Ω

Sensitivity, passive: ± 3.3 mV/V

Sensitivity, active: ± 10 V

Input resistance: approx. 100 kΩ

Sensitivity, current: 0/4 ... 20 mA an at 75 Ω

Connection technology: 2 or 3 wire

Voltage supply passive/active: 5 V / 20 mA ± 12 V / over 100 mA

± 12 V altogether max. 120 mA

Working time with 50 % circle duration with accus:

passive sensors > 20 h

active sensors > 8 h

Nominal temperature range: + 15 °C ... + 35 °C

Range of operating temperature: + 5 °C ... + 45 °C

Storage temperature range: - 10 °C ... + 70 °C

Dimensions (D x W x H): 200 x 100 x 40 [mm]

Protection class: IP40

TRANS CAL

Model 7280

Page 32

Model 7280TRANS CAL

Page 33

Given : Load cell model 8524-6050 strain gauge 350 Ω

Range: 50 kN

Output signal : 1.5016 mV/V

Zero output without tting parts: 0.0020 mV/V

Adjustment procedure

The 7280 gets activated by pressing the ENTER key.

The following screen is displayed:

1 MEASUR

By pressing ▲ or▼ you get to the next screen.

2 SYSTEM

Now press ENTER the following screen is displayed:

2.1 LANG

By pressing several times ▲ or▼ until you get to the following screen:

2.5 PASS

By pressing ENTER you takes to the entering of the password:

0 0 0 0

After entering the password (9373), the sensor can be applied in the adjustment menu. (When

the beam is below a paragraph you can change this by pressing of ▲ or▼).

You get to screen:

3 ADJUST

After pressing ENTER you get to the sensor selection 0 - 9, CURRENT, active, sensor test

SENSOR 1

7. Programmer Example

TRANS CAL

Model 7280

Page 34

Given : Load cell model 8524-6050 strain gauge 350 Ω

Range: 50 kN

Output signal : 1.5016 mV/V

Zero output without tting parts: 0.0020 mV/V

After selection of e.g. „SENSOR 1“ and after push of ENTER you get into the mode the sensor

can be applied in Adjust measuring range and decimal point (POINTDIS), UNIT and name of

the sensor (DESIGN).

POINTDIS

By pressing ▲ or▼ you get to the following screens:

UNIT

ADJUST

DESIGN

After pressing SENSOR 1 and ENTER you get the following screen e.g.

10.00 Nm

Now in this example the number e.g. 50.00 can be set by pressing of ▲ or▼. If the beam is

below the count this can be changed by pressing of ▲ or▼. The changed count is taken by

press of ENTER.

After pressing 4 times ENTER you can set the decimal point by pressing ▲ oder▼. If the desired decimal point reached you can taken this by press of ENTER.

Now return to the following screen:

POINTDIS

By pressing ▲ you get to the next screen:

UNIT

Model 7280TRANS CAL

Page 35

Given : Load cell model 8524-6050 strain gauge 350 Ω

Range: 50 kN

Output signal: 1.5016 mV/V

Zero output without tting parts: 0.0020 mV/V

After pressing ENTER you get the following screen e.g.

_Nm

Now in this example the unit kN can be set by pressing ▲ or▼. If the beam is below the letter

this can be changed by pressing ▲ or ▼. The changed letter is taken by press of ENTER.

Now return to the screen:

UNIT

By pressing 2 times ▲ you arrive the following screen:

DESIGN

After pressing ENTER you get the following screen:

SENSOR 1

Now it can be changed as for the designation of the UNIT e.g. Place 1 or similar.

By pressing 1 times ▼ you arrive the following screen:

ADJUST

After pressing ENTER you get the following screen:

ACT nCON

ACT wCON

PAS nCON

PAS wCON

CURRENT

With ▲ or▼ you can toggle through these screens.

TRANS CAL

Model 7280

Page 36

Given : Load cell model 8524-6050 strain gauge 350 Ω

Range: 50 kN

Output signal : 1.5016 mV/V

Zero output without tting parts: 0.0020 mV/V

We choose for the above sensor the menu „PAS nCON“ ---> passive sensor without control.

After pressing ENTER you get the following screen:

0 % LOAD

Or after pressing ▼ you get the second entry menu (0 %)

NOM VAL

After pressing ENTER you can enter the zero value:

0.020 mV/V

After pressing ENTER you can enter the output signal (sensitivity (100 %) NOM VALUE, in this

example 1.502 mV/V. If the entering of the value ended the next is “save?”. Press ENTER to

complete the entry, the nal value will then be stored in the 7280 measuring amplier.

After 0 % LOAD

Now you can choose between two menus

100 % LOAD

or

the second entry menu (100 %) NOM VAL

After pressing ENTER you can enter the 100 % value

1.502 mV/V

If the entering of the value ended the next is “save?”. Press ENTER to complete the entry, the

nal value will then be stored in the 7280 measuring amplier.

Load cell is connected and

the zero value is stored

with ENTER.

The characteristic data

is entered according

data sheet. In this case

0.020 mV/V.

Load cell is connected and

the zero value is stored

with ENTER.

Load cell is connected and

the 100 % value is stored

with ENTER.

Model 7280TRANS CAL

Page 37

8. Automatic OFF at Battery /

mains Operation

When the 7280 is connected to the interface and there is no measurement, the automatic OFF

function is still active.

After a short time OFF is operative.

Only during a measurement, this function is blocked. If there a short pause, the 7280 switches

itself OFF.

9. MISC

9.1 Transportation

Note:

Only transport well packed devices

The device shall not be placed loosely in the package

Protect the device from humidity.

9.2 Initiation and setup

Safety measures before installing:

Caution:

The device may not be connected to mains, directly. The supply voltage is

6 V DC with minimum 1.8 A.

Cable connection

Caution:

Never connect voltage levels to the unused pins!

TRANS CAL

Model 7280

Page 38

9.3 Normal operation

EMC

Caution:

The device may not be exposed to a higher EMC than determined by the

standard!

Cable

Caution:

Never separate the connectors by pulling on the cables; always pull the plug,

directly!

Storage

Note:

Only store the device in dry and dust-free rooms.

Take out the batteries during the storage.

9.4 Maintenance and cleaning

Cleaning

Caution:

Before cleaning, separate the device from voltage supply.

Caution:

Clean the housing with a soft and slightly damp cloth. Do not use solvents as

they may damage the front panel labeling and the display.

When cleaning, ensure that no liquid enters the device or connections.

Model 7280TRANS CAL

Page 39

Battery change

Caution:

Note the correct polarity of the batteries.

Preventive maintenance and inspection

Note:

Check the plug connections.

Repair

Note:

The device do not contain any parts that need or can be serviced by the user.

Repairs may exclusively ba carried out by burster präzisionsmesstechnik gmbh

& co kg. If assumed that safe operation of the device is no longer possible,

it must be taken out of operation immediately and also be secured against

inadvertent operation. Especially if:

- the device is visibly damaged

- the device is no longer functional

- parts of the device are loose

- the connecting lines show visible defects

9.5 Disposal

Battery disposal:

As an end user, you are required by law (battery ordinance) to return all used batteries

and rechargeable batteries; the disposal through household waste is prohibited. By

buying the herein described device you are concerned by this law. Please dispose of

your batteries and rechargeable batteries correctly. Hand them to waste disposal sites

either at your premises or at our company or at any place where batteries/rechargeable batteries are sold.

Equipment disposal:

Please fulll your legal obligations and dispose of unserviceable equipment in accordance with applicable legal requirements. Thus you contribute to environmental

protection.

Loading...

Loading...