Datasheet DAC811KU, DAC811KP, DAC811JU-1K, DAC811JU, DAC811JP Datasheet (Burr Brown Corporation)

...

®

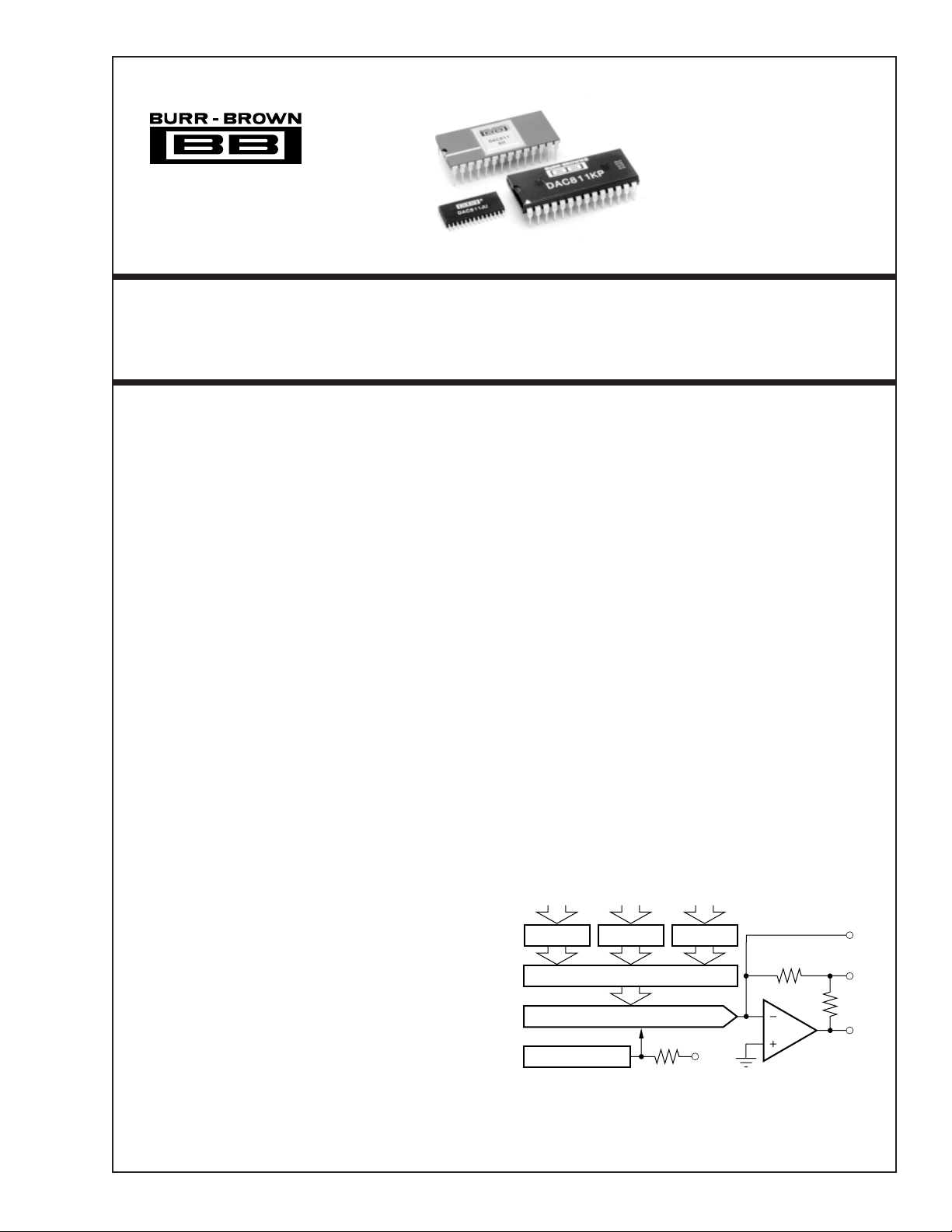

BPO

V

OUT

D/A Latch

Input Latch

4 MSBs

Input Latch Input Latch

4 LSBs

12-Bit D/A Converter

Voltage Reference

10V

R

F

S

J

R

F

R

BPO

For most current data sheet and other product

information, visit www.burr-brown.com

Microprocessor-Compatible

12-BIT DIGITAL-TO-ANALOG CONVERTER

DAC811

FEATURES

● SINGLE INTEGRATED CIRCUIT CHIP

● MICROCOMPUTER INTERFACE:

DOUBLE-BUFFERED LATCH

● VOLTAGE OUTPUT: ±10V, ±5V, +10V

● MONOTONICITY GUARANTEED OVER

TEMPERATURE

● ±1/2LSB MAXIMUM NONLINEARITY OVER

TEMPERATURE

● GUARANTEED SPECIFICATIONS AT ±12V

AND ±15V SUPPLIES

● TTL/5V CMOS-COMPATIBLE LOGIC

INPUTS

Input gating logic is designed so that loading the last

nibble or byte of data can be accomplished simultaneously with the transfer of data (previously stored in

adjacent latches) from adjacent input latches to the

D/A latch. This feature avoids spurious analog output

values while using an interface technique that saves

computer instructions.

The DAC811 is laser trimmed at the wafer level and

is specified to ±1/4LSB maximum linearity error (B,

K, and S grades) at 25°C and ±1/2LSB maximum over

the temperature range. All grades are guaranteed monotonic over the specification temperature range.

The DAC811 is available in six performance grades

and three package types. DAC811J and K are specified over the temperature ranges of 0°C to +70°C;

DAC811A and B are specified over –25°C to +85°C;

DAC811R and S are specified over –55°C to +125°C.

DESCRIPTION

The DAC811 is a complete, single-chip integratedcircuit, microprocessor-compatible, 12-bit digital-toanalog converter. The chip combines a precision voltage reference, microcomputer interface logic, and

DAC811J and K are packaged in a reliable 28-pin

plastic DIP or plastic SOIC package, while DAC811A,

B, R and S are available in a 28-pin 0.6" wide dualinline hermetically sealed ceramic side-brazed package (H package).

double-buffered latch, in a 12-bit D/A converter with

a voltage output amplifier. Fast current switches and a

laser-trimmed thin-film resistor network provide a

highly accurate and fast D/A converter.

Microcomputer interfacing is facilitated by a doublebuffered latch. The input latch is divided into three

4-bit nibbles to permit interfacing to 4-, 8-, 12-, or

16-bit buses and to handle right-or left-justified data.

The 12-bit data in the input latches is transferred to the

D/A latch to hold the output value.

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

© 1983 Burr-Brown Corporation PDS-503K Printed in U.S.A. January, 2000

1

DAC811

®

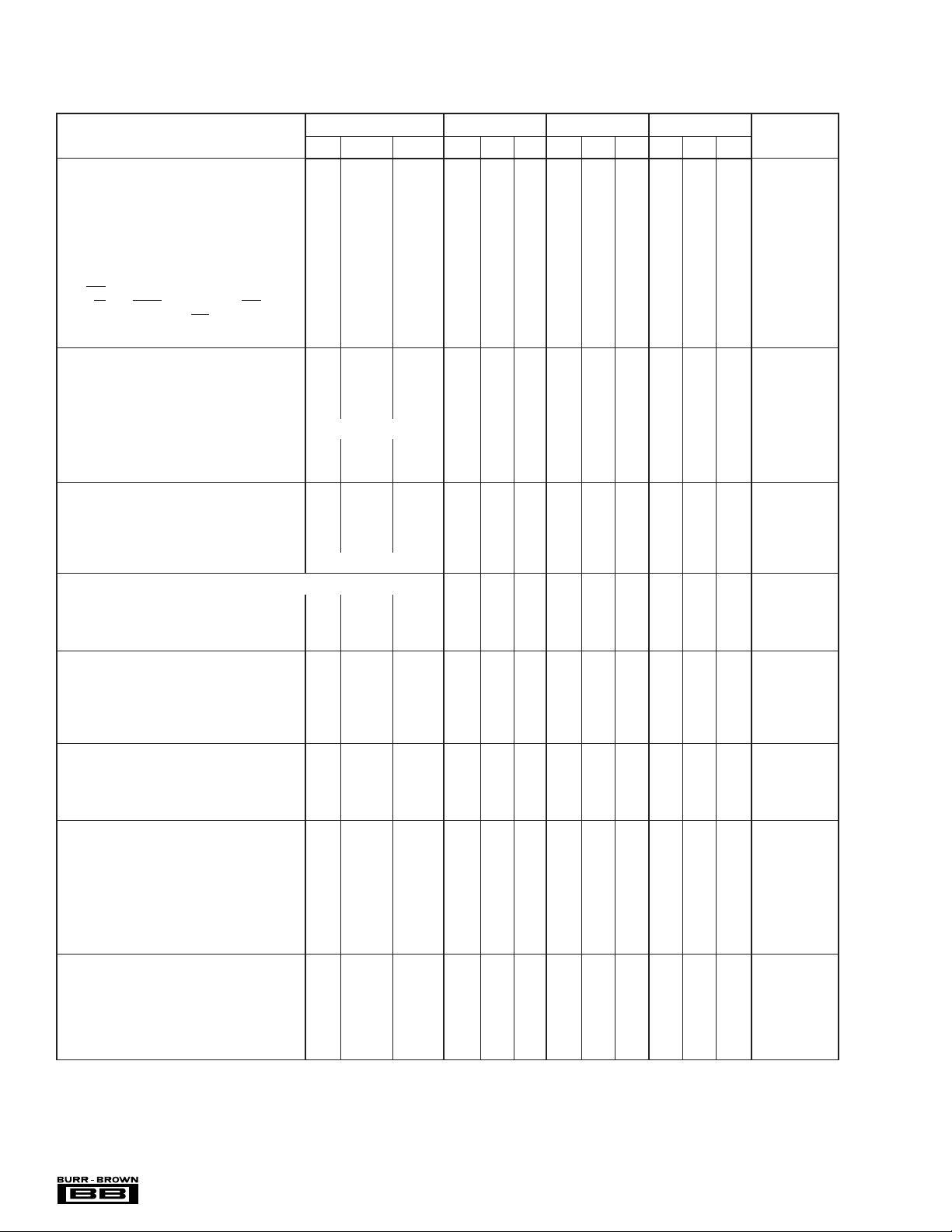

SPECIFICATIONS

At TA = +25°C. ±VCC = 12V or 15V, unless otherwise noted.

DAC811AH, JP, JU DAC811BH, KP, KU

DAC811RH DAC811SH

PARAMETER MIN TYP MAX MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

DIGITAL INPUT

Resolution 12 ✻✻✻Bits

(1)

Codes

Digital Inputs Over Temperature Range

V

IH

V

IL

I

, VI = +2.7V +10 ✻✻✻µA

IH

I

, VI = +0.4V ±20 ✻✻✻µA

IL

Digital Interface Timing Over Temperature Range

(2)

USB, BOB

✻✻✻

+2 +15 ✻✻✻✻✻✻VDC

0 +0.8 ✻✻✻✻✻✻VDC

tWP, WR Pulse Width 50 ✻✻✻ ns

t

1, NX and LDAC Valid to End of WR 50 ✻✻✻

AW

, Data Valid to End of WR 80 ✻✻✻ ns

DW

t

, Data Valid Hold Time 0 ✻ +10 ✻ ns

DH

nst

ACCURACY

Linearity Error ±1/4 ±1/2 ±1/8 ±1/4 ±1/4 ±1/2 ±1/8 ±1/4 LSB

Differential Linearity Error ±1/2 ±3/4 ±1/4 ±1/2 ±1/2 ±3/4 ±1/4 ±1/2 LSB

Gain Error

Offset Error

(3)

(3, 4)

±0.1 ±0.2 ✻✻ ✻✻ ✻✻ %

±0.05 ±0.15 ✻✻ ✻✻ ✻✻ % of FSR

(5)

Monotonicity Guaranteed ✻✻✻

Power Supply Sensitivity: +V

–V

CC

V

DD

CC

±0.001 ±0.003 ✻✻ ✻✻ ✻ ✻% of FSR/%V

±0.002 ±0.006 ✻✻ ✻✻ ✻ ✻% of FSR/%V

±0.0005 ±0.0015 ✻✻ ✻✻ ✻✻% of FSR/%V

CC

CC

DD

DRIFT (Over Specification Temperature Range)

Gain ±10 ±30 ±10 ±20 ±15 ±30 ±15 ±30 ppm/°C

Unipolar Offset ±5 ±10 ±5 ±7 ±5 ±10 ±5 ±7 ppm of FSR/°C

Bipolar Zero ±5 ±10 ±5 ±7 ±5 ±10 ±5 ±7 ppm of FSR/°C

Linearity Error Over Temperature Range ±1/2 ±3/4 ±1/4 ±1/2 ±1/2 ±3/4 ±1/4 ±1/2 LSB

Monotonicity Over Temperature Range Guaranteed ✻✻✻

SETTLING TIME

(6)

(to within ±0.01% of FSR of Final Value; 2kΩ load)

For Full Scale Range Change, 20V Range 3 4 ✻✻ ✻✻ ✻✻ µs

10V Range 3 4 ✻✻ ✻✻ ✻✻ µs

For 1LSB Change at Major Carry

Slew Rate

(6)

ANALOG OUTPUT

Voltage Range (±V

Bipolar ±5, ±10 ✻✻✻V

= 15V)

CC

(7)

1 ✻✻✻µs

812 ✻✻ ✻✻ ✻✻ V/µs

(8)

: Unipolar 0 to +10 ✻✻✻V

Output Current ±5 ✻✻✻ mA

Output Impedance (at DC) 0.2 ✻✻✻Ω

Short Circuit to Common Duration Indefinite ✻✻✻

REFERENCE VOLTAGE

Voltage +6.2 +6.3 +6.4 ✻✻✻✻✻✻✻✻✻ V

Source Current Available for External Loads +2 ✻✻✻ mA

Temperature Coefficient ±10 ±30 ±10 ±20 ±10 ±30 ±10 ±20 ppm/°C

Short Circuit to Common Duration Indefinite ✻✻✻

POWER SUPPLY REQUIREMENTS

Voltage: +V

–V

V

DD

Current (no load): +V

–V

V

DD

Potential at DCOM with Respect to ACOM

CC

CC

CC

CC

+11.4 +15 +16.5 ✻✻✻✻✻✻✻✻✻ VDC

–11.4 –15 –16.5 ✻✻✻✻✻✻✻✻✻ VDC

+4.5 +5 +5.5 ✻✻✻✻✻✻✻✻✻ VDC

+16 +25 ✻✻ ✻✻ ✻✻ mA

–23 –35 ✻✻ ✻✻ ✻✻ mA

(9)

+8 +15 ✻✻ ✻✻ ✻✻ mA

±0.5 ✻✻✻V

Power Dissipation 625 800 ✻✻ ✻✻ ✻✻ mW

TEMPERATURE RANGE

Specification: J, K 0 +70 ✻✻✻✻✻✻°C

A, B –25 +85 ✻✻✻✻✻✻°C

R, S –65 +150 ✻✻✻✻✻✻°C

–55 +125 ✻✻°C

Storage: J, K –60 +100 ✻✻✻✻✻✻°C

A, B, R, S –65 +150 ✻✻✻✻✻✻°C

✻ Specification same as DAC811AH.

NOTES: (1) USB = unipolar straight binary; BOB = bipolar offset binary. (2) TTL, LSTTL and 54/74 HC compatible. (3) Adjustable to zero with external trim

potentiometer. (4) Error at input code 000

represents the 3σ limit. Not 100% tested for this parameter. (7) At the major carry, 7FF

output swing is ±13.5V. Output swing for ±11.4V supplies is at least –8V to +8V. (9) The maximum voltage at which ACOM and DCOM may be separated without

for both unipolar and bipolar ranges. (5) FSR means full scale range and is 20V for the ±10V range. (6) Maximum

16

to 80016 and 80016 to 7FF16. (8) Minimum supply voltage required for ±10V

16

affecting accuracy specifications.

®

DAC811

2

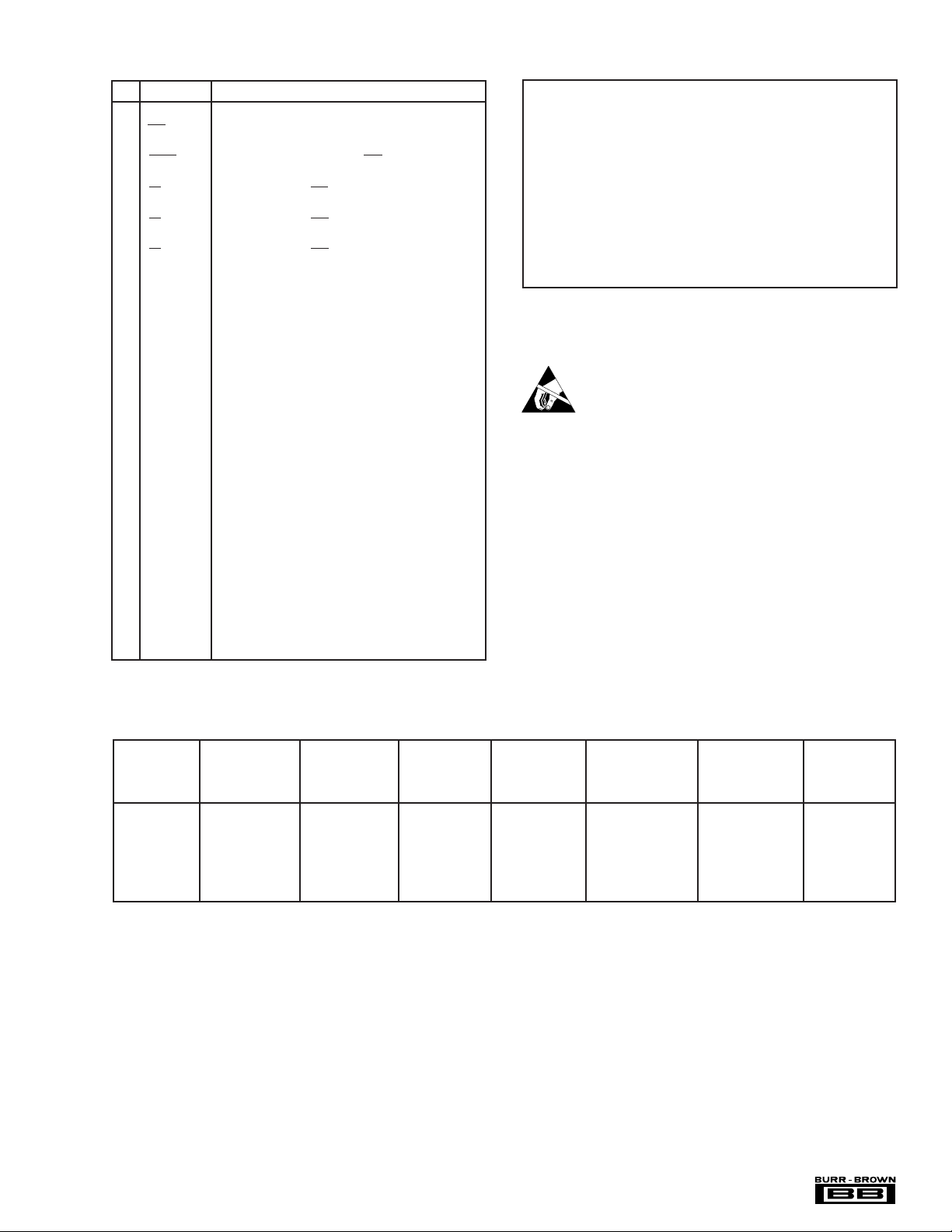

PIN DESCRIPTIONS

PIN

NAME FUNCTION

1+V

DD

2 WR Write, command signal to load latches. Logic low

3 LDAC Load D/A converter, enables WR to load the D/A

4N

A

5N

B

6N

C

7D

11

8D

10

9D

9

10 D

8

11 D

7

12 D

6

13 D

5

14 D

4

15 DCOM Digital common, V

16 D

0

17 D

1

18 D

2

19 D

3

20 +V

CC

21 –V

CC

22 Gain Adj To externally adjust gain.

23 ACOM Analog common, ±V

24 V

OUT

25 10V Range Connect to pin 24 for 10V range.

26 SJ Summing junction of output amplifier.

27 BPO Bipolar offset. Connect to pin 26 for bipolar

28 Ref Out 6.3V reference output.

Logic supply, +5V.

loads latches.

latch. Logic low enables.

Nibble A, enables WR to load input latch A (the

most significant nibble). Logic low enables.

Nibble B, enables WR to load input latch B. Logic

low enables.

Nibble C, enables WR to load input latch C (the

least significant nibble). Logic low enables.

Data bit 12, MSB, positive true.

Data bit 11.

Data bit 10.

Data bit 9.

Data bit 8.

Data bit 7.

Data bit 6.

Data bit 5.

supply return.

Data bit 1, LSB.

Data bit 2.

Data bit 3.

Data bit 4.

Analog supply input, +15V or +12V.

Analog supply input, –15V or –12V.

D/A converter voltage output.

operation.

DD

supply return.

CC

ABSOLUTE MAXIMUM RATINGS

+V

................................................................................................................................ 0 to +18V

CC

–V

to ACOM .......................................................................... 0 to –18V

CC

V

to DCOM .............................................................................. 0 to +7V

DD

V

to ACOM ......................................................................................±7V

DD

ACOM to DCOM .................................................................................. ±7V

Digital Inputs (Pins 2–14, 16–19) to DCOM ......................–0.4V to +18V

External Voltage Applied to 10V Range Resistor ............................ ±12V

Ref Out ............................................................. Indefinite Short to ACOM

External Voltage Applied to DAC Output ................................ –5V to +5V

Power Dissipation ........................................................................ 1000mW

Lead Temperature (soldering, 10s) ............................................... +300°C

Max Junction Temperature ............................................................ +165°C

Thermal Resistance,

Ceramic DIP .................................................................................. 65°C/W

NOTE: Stresses above those listed above may cause permanent damage to

the device. Exposure to absolute maximum conditions for extended periods

may affect device reliability.

θ

: Plastic DIP and SOIC ....................... 100°C/W

J-A

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation

to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric

changes could cause the device not to meet its published

specifications.

PACKAGE/ORDERING INFORMATION

MINIMUM

RELATIVE DIFFERENTIAL PACKAGE SPECIFICATION

PRODUCT (LSB) (LSB) PACKAGE NUMBER RANGE NUMBER

ACCURACY LINEARITY DRAWING TEMPERATURE ORDERING TRANSPORT

DAC811AH ±1/2 LSB 3/4 CerDIP-28 149 –25°C to +85°C DAC811AH Rails

DAC811JP ±1/2 LSB 3/4 DIP-28 215 0°C to +70°C DAC811JP Rails

DAC811JU ±1/2 LSB 3/4 SOIC-28 217 0°C to +70°C DAC811JU Rails

"" """ "DAC811JU/1K Tape and Reel

DAC811KP ±1/4 LSB 1/2 DIP-28 215 0°C to +70°C DAC811KP Rails

DAC811KU ±1/4 LSB 1/2 SOIC-28 217 0°C to +70°C DAC811KU Rails

NOTE: (1) Models with a slash (/) are available only in Tape and Reel in the quantities indicated (e.g., /1K indicates 1000 devices per reel). Ordering 1000 pieces

of “DAC811JU/1K” will get a single 1000-piece Tape and Reel.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

(1)

MEDIA

®

3

DAC811

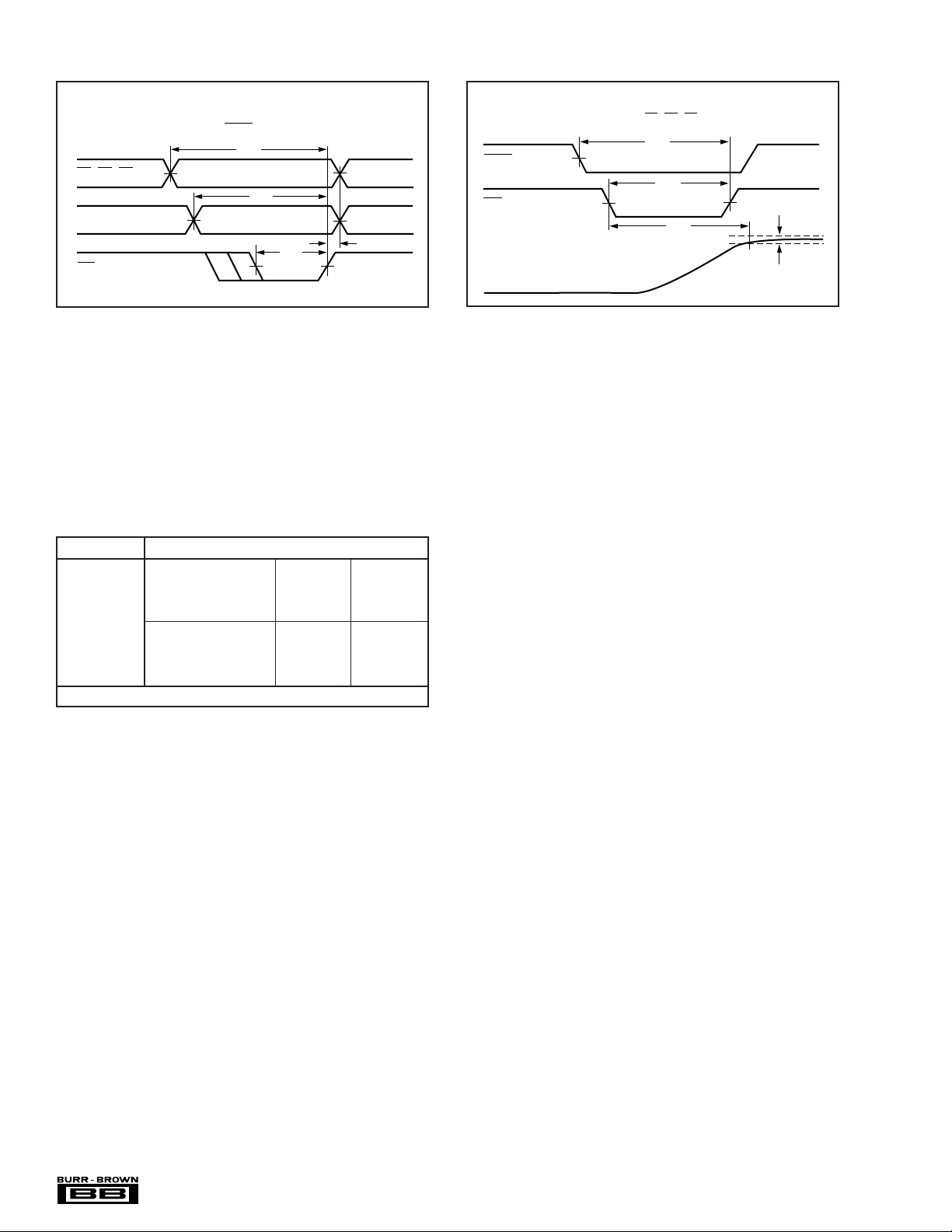

TIMING DIAGRAMS

Write Cycle #1

Load first rank from Data Bus: LDAC = 1

t

AW

N

, NB, N

C

A

t

DW

DB11–DB

0

t

DH

WR

t

WP

DISCUSSION OF

SPECIFICATIONS

INPUT CODES

The DAC811 accepts positive-true binary input codes.

DAC811 may be connected by the user for any one of the

following codes: USB (unipolar straight binary), BOB (bipolar offset binary) or, using an external inverter on the

MSB line, BTC (binary two’s complement). See Table I.

DIGITAL INPUT

Unipolar Bipolar Binary

MSB LSB

↓↓

111111111111 + Full Scale + Full Scale –1LSB

100000000000 + 1/2 Full Scale Zero – Full Scale

011111111111

000000000000 Zero – Full Scale Zero

NOTE: (1) Invert MSB of the BOB code with external inverter to obtain BTC code.

Straight Offset Two’s

Binary Binary

+ 1/2 Full Scale – 1LSB

TABLE I. Digital Input Codes.

LINEARITY ERROR

Linearity error as used in D/A converter specifications by

Burr-Brown is the deviation of the analog output from a

straight line drawn between the end points (inputs all 1s and

all 0s). The DAC811 linearity error is specified at ±1/4LSB

(max) at +25°C for B and K grades, and ±1/2LSB (max) for

A, J, and R grades.

DIFFERENTIAL LINEARITY ERROR

Differential linearity error (DLE) is the deviation from a

1LSB output change from one adjacent state to the next. A

DLE specification of 1/2LSB means that the output step size

can range from 1/2LSB to 3/2LSB when the input changes

from one state to the next. Monotonicity requires that DLE

be less than 1LSB over the temperature range of interest.

MONOTONICITY

A D/A converter is monotonic if the output either increases

or remains the same for increasing digital inputs. All grades

of DAC811 are monotonic over their specification temperature range.

®

DAC811

ANALOG OUTPUT

USB BOB BTC

Complement

–1LSB + Full Scale

(1)

Write Cycle #2

Load second rank from first rank: NA, N , NCB= 1

t

AW

LDAC

t

WP

WR

t

SET

±1/2LSB

DRIFT

Gain drift is a measure of the change in the full scale range

(FSR) output over the specification temperature range. Drift is

expressed in parts per million per degree centigrade

(ppm/°C). Gain drift is established by testing the full scale

range value (e.g., +FS minus –FS) at high temperature, +25°C,

and low temperature, calculating the error with respect to the

+25°C value, and dividing by the temperature change.

Unipolar offset drift is a measure of the change in output

with all 0s on the input over the specification temperature

range. Offset is measured at high temperature, +25°C, and

low temperature. The offset drift is the maximum change in

offset referred to the +25°C value, divided by the temperature change. It is expressed in parts per million of full scale

range per degree centigrade (ppm of FSR/°C).

Bipolar zero drift is measured at a digital input of 80016, the

code that gives zero volts output for bipolar operation.

SETTLING TIME

Settling time is the total time (including slew time) for the

output to settle within an error band around its final value

after a change in input. Three settling times are specified to

±0.01% of full scale range (FSR): two for maximum full

scale range changes of 20V and 10V, and one for a 1LSB

change. The 1LSB change is measured at the major carry

(7FF16 to 80016 and 80016 to 7FF16), the input transition at

which worst-case settling time occurs.

REFERENCE SUPPLY

DAC811 contains an on-chip 6.3V reference. This voltage

(pin 28) has a tolerance of ±0.1V. The reference output may

be used to drive external loads, sourcing at least 2mA. This

current should be constant for best performance of the D/A

converter.

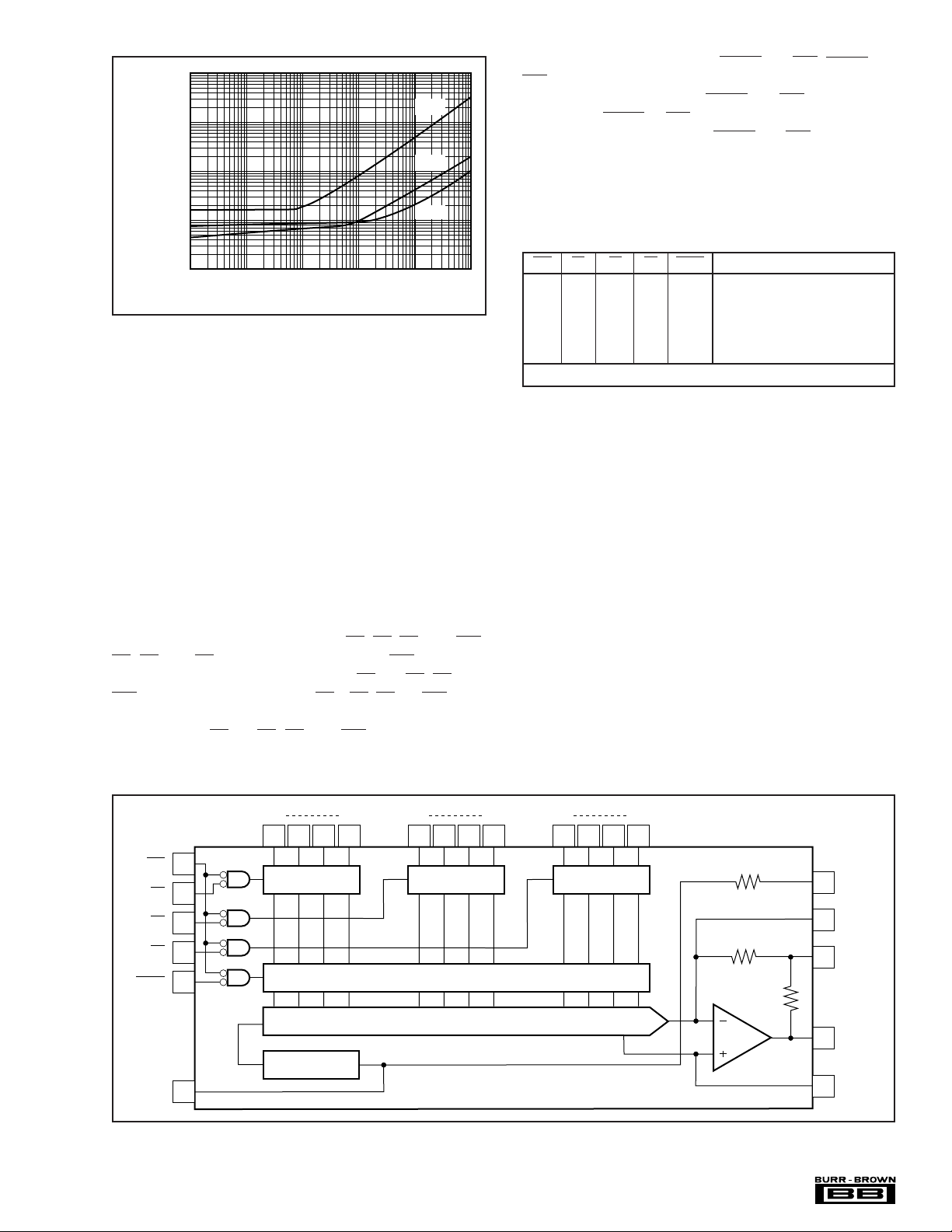

POWER SUPPLY SENSITIVITY

Power supply sensitivity is a measure of the effect of a

power supply change on the D/A converter output. It is

defined as a percent of FSR output change per percent of

change in either the positive, negative, or logic supply

voltages about the nominal voltages. Figure 1 shows typical

power supply rejection versus power supply ripple frequency.

4

1

–V

+V

CC

V

DD

CC

M1

0.1

0.01

0.001

Percent of FSR per Percent of

Change of Power Supply Voltage

0.0001

10 100 1k 10k 100k

Frequency (Hz)

FIGURE 1. Power Supply Rejection vs Power Supply Ripple

Frequency.

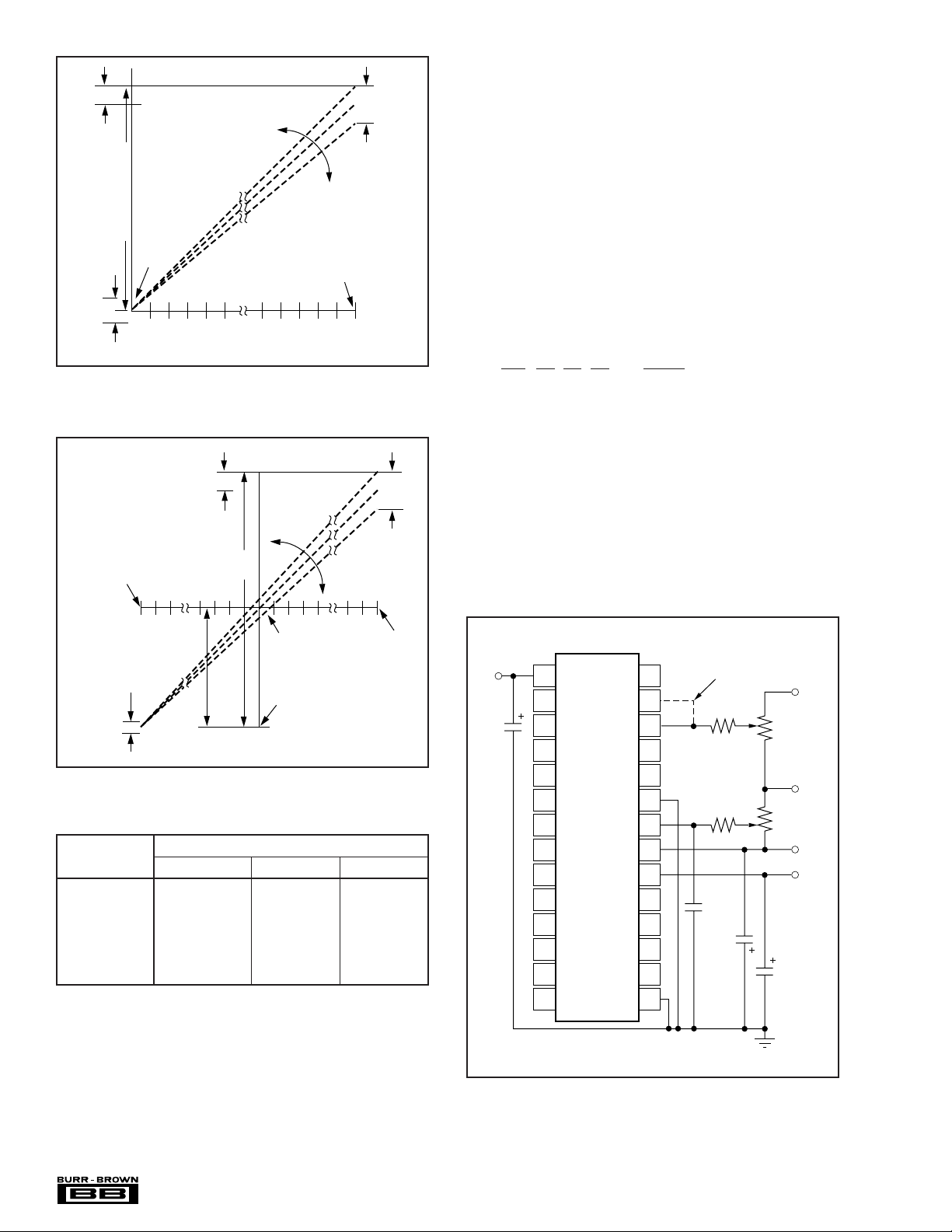

OPERA TION

DAC811 is a complete single IC chip 12-bit D/A converter.

The chip contains a 12-bit D/A converter, voltage reference,

output amplifier, and microcomputer-compatible input logic

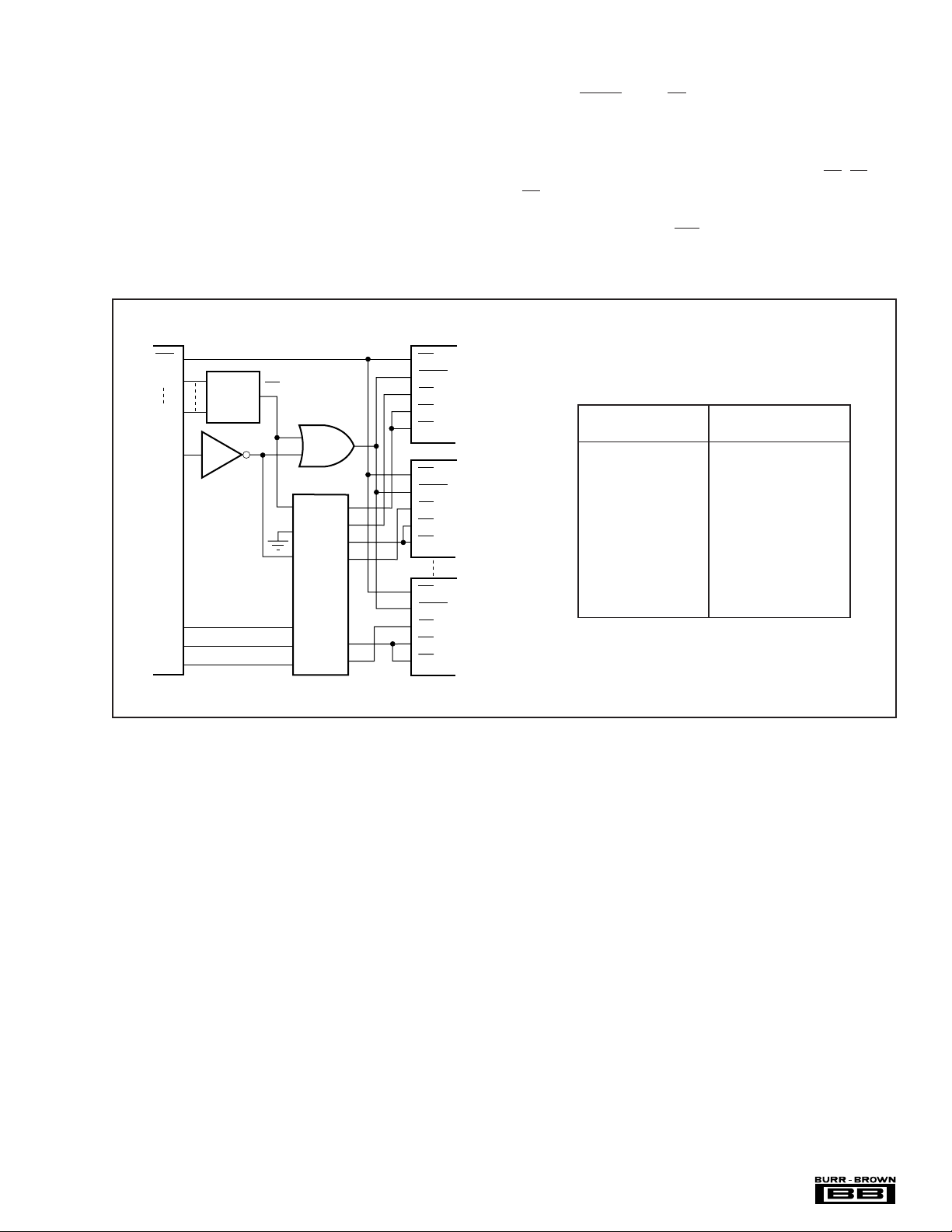

as shown in Figure 2.

The D/A latch is controlled by LDAC and WR. LDAC and

WR are internally NORed so that the latches transmit data to

the D/A switches when both LDAC and WR are at logic 0.

When either LDAC or WR are at logic 1, the data is latched

in the D/A latch and held until LDAC and WR go to logic 0.

All latches are level-triggered. Data present when the control signals are logic 0 will enter the latch. When any one of

the control signals returns to logic 1, the data is latched.

Table II is a truth table for all latches.

WR

NANBNCLDAC

1 X X X X No operation

0 0 1 1 1 Enables input latch 4MSBs

0 1 0 1 1 Enables input latch 4 middle bits

0 1 1 0 1 Enables input latch 4LSBs

0111 0

0 0 0 0 0 Makes all latches transparent

“X” = Don’t care.

OPERATION

Loads D/A latch from input latches

TABLE II. DAC813 Interface Logic Truth Table.

GAIN AND OFFSET ADJUSTMENTS

Figures 3 and 4 illustrate the relationship of offset and gain

adjustments to unipolar and bipolar D/A converter output.

INTERFACE LOGIC

Input latches A, B, and C hold data temporarily while a

complete 12-bit word is assembled before loading into the

D/A register. This double-buffered organization prevents the

generation of spurious analog output values. Each register is

independently addressable.

These input latches are controlled by NA, NB, NC, and WR.

NA, NB, and NC are internally NORed with WR so that the

input latches transmit data when both NA (or NB, NC) and

WR are at logic 0. When either NA, (NB, NC) or WR go to

logic 1, the input data is latched into the input registers and

held until both NA (or NB, NC) and WR go to logic 0.

D11 D8 D7

MSB LSB

7 8 9 10 11 12 13 14 19 18 17 16

N

N

N

LDAC

Ref Out

2WR

4

A

5

B

6

C

3

28

4-Bit Latch, A

Reference

4-Bit Latch, B 4-Bit Latch, C

12-Bit D/A Latch

12-Bit D/A Converter

OFFSET ADJUSTMENT

For unipolar (USB) configurations, apply the digital input

code that should produce zero voltage output, and adjust the

offset potentiometer for zero output. For bipolar (BOB,

BTC) configurations, apply the digital input code that should

produce the maximum negative output voltage and adjust

the offset potentiometer for minus full scale voltage. Example: If the full scale range is connected for 20V, the

maximum negative output voltage is –10V. See Table III for

corresponding codes.

D4 D3

D0

R

BPO

R

F

R

F

BPO

27

SJ

26

10V

25

Range

V

24

OUT

ACOM

23

FIGURE 2. DAC811 Block Diagram.

®

5

DAC811

1LSB

+ Full Scale

Range of

Gain Adjust

±12V OPERATION

The DAC811 is fully specified for operation on ±12V power

supplies. However, in order for the output to swing to ±10V,

the power supplies must be ±13.5V or greater. When operating with ±12VB supplies, the output swing should be

restricted to ±8V in order to meet specifications.

Gain Adjust

Analog Output

Full Scale Range

Range of

Offset Adj.

Offset Adjust Translates the Line

All Bits

Logic 0

Digital Input

Rotates the Line

All Bits

Logic 1

FIGURE 3. Relationship of Offset and Gain Adjustments

for a Unipolar D/A Converter.

+ Full Scale

1LSB

Range of

All Bits

Logic 0

Analog Output

Range of

Offset Adjust

Offset Adj.

Translates

the Line

≈ ±0.4%

Bipolar V

Offset

Full Scale

Range

MSB on All

Others Off

– Full Scale

Digital Input

Gain Adjust

Gain Adjust

Rotates the Line

All Bits

Logic 1

FIGURE 4. Relationship of Offset and Gain Adjustments

for a Bipolar D/A Converter.

ANALOG OUTPUT

DIGITAL INPUT 0 to +10V

MSB LSB

↓↓

111111111111 +9.9976V +4.9976V +9.9951V

100000000000 +5V 0V 0V

011111111111 +4.9976V –0.0024V –0.0049V

000000000000 0V –5V –10V

LSB 2.4mV 2.44mV 4.88mV

±5V ±10V

TABLE III. Digital Input/Analog Output.

LOGIC INPUT COMPATIBILITY

The DAC811 digital inputs are TTL, LSTTL, and 54/74HC

CMOS-compatible over the operating range of VDD. The

input switching threshold remains at the TLL threshold over

the supply range.

The logic input current over temperature is low enough to

permit driving the DAC811 directly from the outputs of

4000B and 54/74C CMOS devices.

Resistors of 47Ω should be placed in series with D0 through

D11, WR, NA, NB, NC and LDAC if edges are <10ns or if

the logic input is driven below ground by undershoot.

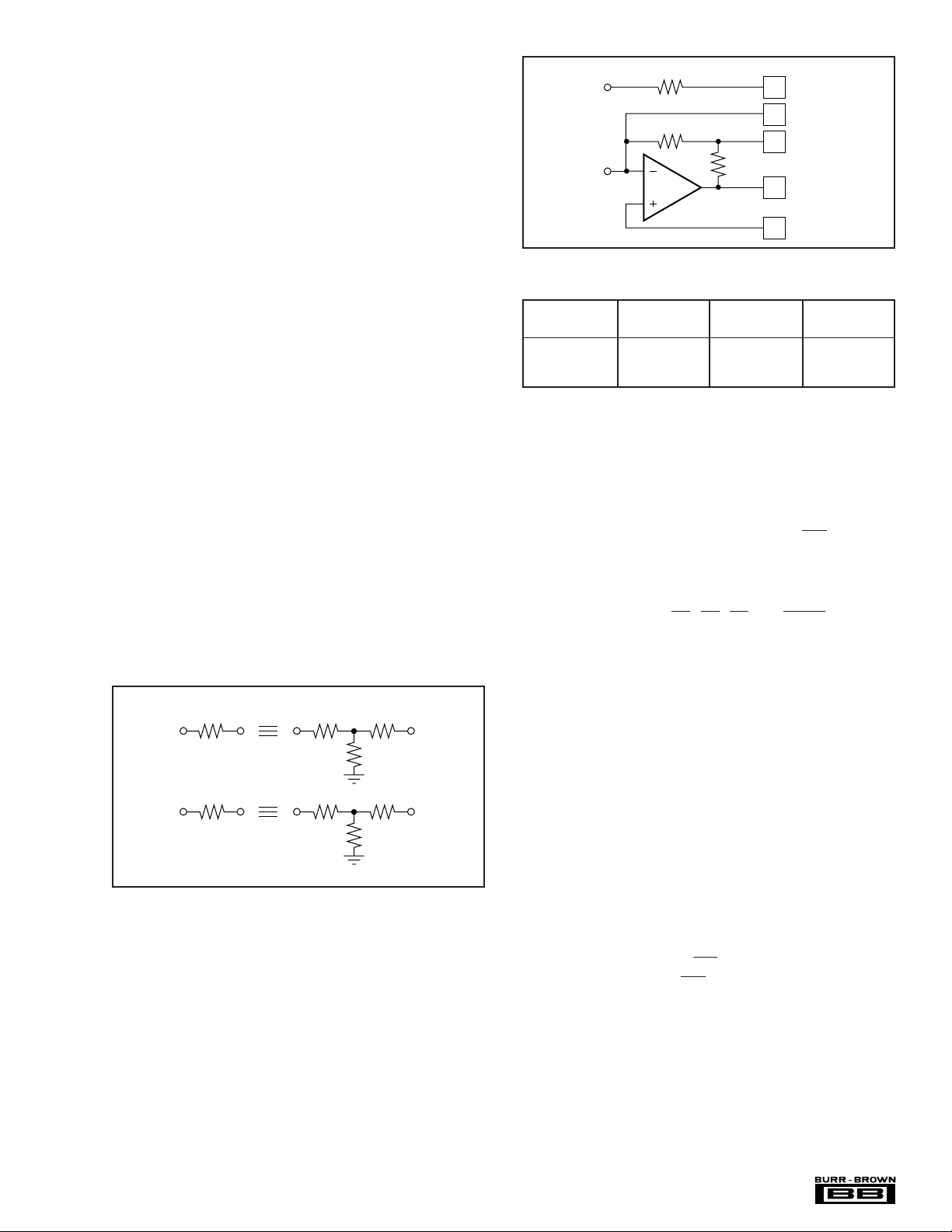

INSTALLATION

POWER SUPPLY CONNECTIONS

For optimum performance and noise rejection, power supply

decoupling capacitors should be added as shown in Figure 5.

These capacitors (1µF tantalum recommended) should be

located close to the DAC811.

Connect for

V

DD

1µF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

V

DD

Summing

Junction

Gain Adjust

BPO

V

OUT

ACOM

–V

CC

+V

CC

DCOM

28

27

26

25

24

23

22

21

20

19

18

17

16

15

Bipolar Operation

1MΩ

3.9MΩ

0.0022µF

1µF

10k to

100k

10k to

100k

1µF

–V

CC

Ω

Ω

+V

CC

Ω

Ω

–V

CC

+V

CC

GAIN ADJUSTMENT

For either unipolar or bipolar configurations, apply the

digital input that should give the maximum positive voltage

output. Adjust the gain potentiometer for this positive full

scale voltage. See Table III for positive full scale voltages.

®

DAC811

FIGURE 5. Power Supply, Gain, and Offset Potentiometer

Connections.

6

DAC811 features separate digital and analog power supply

returns to permit optimum connections for low noise and

high speed performance. The analog common (pin 23) and

digital common (pin 15) should be connected together at one

point. Separate returns minimize current flow in low level

signal paths if properly connected. Logic return currents are

not added into the analog signal return path. A ±0.5V

difference between ACOM and DCOM is permitted for

specified operation. High frequency noise on DCOM with

respect to ACOM may permit noise to be coupled through to

the analog output; therefore, some caution is required in

applying these common connections.

The Analog Common is the high quality return for the D/A

converter and should be connected directly to the analog

reference point of the system. The load driven by the output

amplifier should be returned to the Analog Common.

EXTERNAL OFFSET AND GAIN ADJUSTMENT

Offset and Gain may be trimmed by installing external

Offset and Gain potentiometers. Connect these potentiometers as shown in Figure 5. TCR of the potentiometers

should be 100ppm/°C or less. The 1MΩ and 3.9MΩ resistors (20% carbon or better) should be located close to the

DAC811 to prevent noise pickup. If it is not convenient to

use these high value resistors, an equivalent “T” network, as

shown in Figure 6, may be substituted in each case. The

Gain Adjust (pin 22) is a high impedance point and a

0.001µF to 0.01µF ceramic capacitor should be connected

from this pin to Analog Common to reduce noise pickup in

all applications, including those not employing external gain

adjustment. Excessive capacitance on the Gain Adjust or

Offset Adjust pin may affect slew rate and settling time.

1MΩ

3.9MΩ

100kΩ 100kΩ

12kΩ

180kΩ 180kΩ

10kΩ

From Voltage

Reference

From D/A

Converter

5.36kΩ

4.26kΩ

4.26kΩ

Bipolar Offset

27

26

Summing Junction

10V Range

25

V

24

OUT

23

Analog Common

FIGURE 7. Output Amplifier Voltage Range Scaling Circuit.

OUTPUT DIGITAL CONNECT CONNECT

RANGE INPUT CODES PIN 25 TO PIN 27 TO

0 to +10V USB 24 23

±5 BOB or BTC 24 26

±10V BOB or BTC NC 26

TABLE IV. Output Range Connections.

APPLICATIONS

MICROCOMPUTER BUS INTERFACING

The DAC811 interface logic allows easy interface to microcomputer bus structures. The control signal WR is derived

from external device select logic and the I/O Write or

Memory Write (depending upon the system design) signals

from the microcomputer.

The latch enable lines NA, NB, NC and LDAC determine

which of the latches are enabled. It is permissible to enable

two or more latches simultaneously, as shown in some of the

following examples.

The double-buffered latch permits data to be loaded into the

input latches of several DAC811s and later strobed into the

D/A latch of all D/As, simultaneously updating all analog

outputs. All the interface schemes shown below use a base

address decoder. If blocks of memory are used, the base

address decoder can be simplified or eliminated altogether.

For instance, if half the memory space is unused, address

line A15 of the microcomputer can be used as the chip select

control.

FIGURE 6. Equivalent Resistances.

OUTPUT RANGE CONNECTIONS

Internal scaling resistors provided in the DAC811 may be

connected to produce bipolar output voltage ranges of ±10V

and ±5V or a unipolar output voltage range of 0 to +10V.

The 20V range (±10V bipolar range) is internally connected.

Refer to Figure 7. Connections for the output ranges are

listed in Table IV.

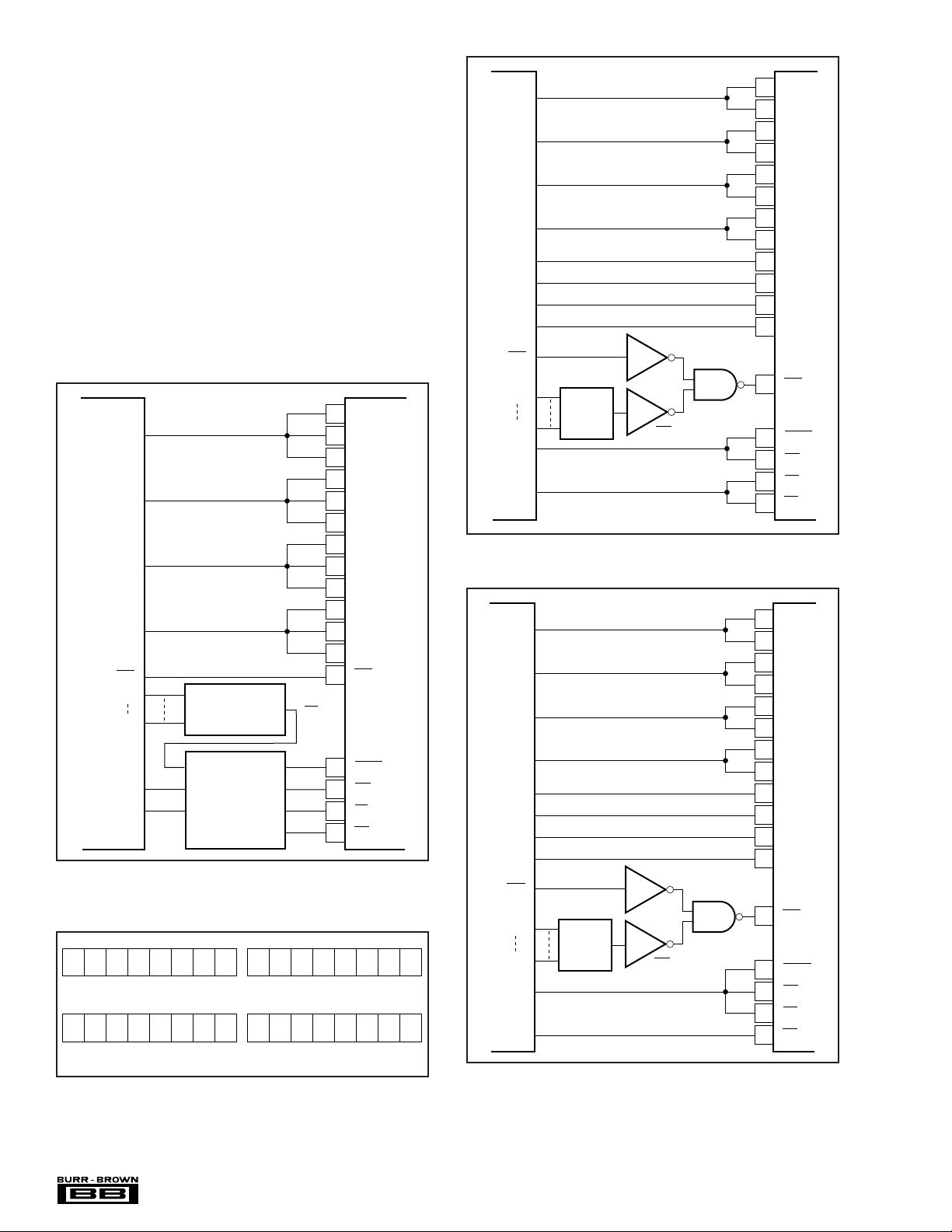

4-BIT INTERFACE

An interface to a 4-bit microcomputer is shown in Figure 8.

Each DAC811 occupies four address locations. A 74LS139

provides the two-to-four decoder and selects it with the base

address. Memory Write (WR) of the microcomputer is

connected directly to the WR pin of the DAC811. An 8205

decoder is an alternative to the 74LS139.

7

DAC811

®

8-BIT INTERFACE

The control logic of DAC811 permits interfacing to rightjustified data formats, as illustrated in Figure 9. When a

12-bit D/A converter is loaded from an 8-bit bus, two bytes

of data are required. Figures 10 and 11 show an addressing

scheme for right-justified and left-justified data respectively.

The base address is decoded from the high-order address

bits. A0 and A1 address the appropriate latches. Note that

adjacent addresses are used. For the right-justified case,

X1016 loads the 8LSBs, and X0116 loads the 4MSBs and

simultaneously transfers input latch data to the D/A latch.

Addresses X0016 and X1116 are not used.

Left-justified data is handled in a similar manner, shown in

Figure 11. The DAC811 still occupies two adjacent locations in the microcomputer's memory map.

D0

16

D4

7

6

5

4

CS

(Chip

Select)

14

D8

10

D1

17

D5

13

D9

9

D2

18

D6

12

D10

8

D3

19

D7

11

D11

7

2

WR

LDAC

3

N

4

N

5

N

6

DAC811

A

B

C

DB0

DB1

DB2

DB3

Microcomputer

WR

A

N

A

2

A

1

A

0

Base

Address

Decoder

1

EN

3

A

1

2

A

0

1/2

74LS139

Y

3

Y

2

Y

1

Y

0

FIGURE 8. Addressing and Control for 4-Bit Microcom-

puter Interface.

X X X X D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

a. Right-Justified

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

b. Left-Justified

XXXX

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

Microcomputer

WR

A

15

A

2

A

1

A

0

Base

Address

Decoder

CS

16

10

17

18

19

14

13

12

11

FIGURE 10. Right-Justified Data Bus Interface.

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

Microcomputer

WR

A

15

A

2

A

1

A

0

Base

Address

Decoder

CS

14

13

12

11

10

16

17

18

19

D0

D8

D1

D9

9

D2

D10

8

D3

D11

7

D4

D5

D6

DAC811

D7

2

WR

LDAC

3

N

4

A

N

5

B

N

6

C

D4

D5

D6

D7

D8

D0

D9

9

D1

D10

8

D2

D11

7

2

3

4

5

6

D3

WR

LDAC

N

A

N

B

N

C

DAC811

FIGURE 9. 12-Bit Data Format for 8-Bit Systems.

®

DAC811

FIGURE 11. Left-Justified Data Bus Interface.

8

INTERFACING MULTIPLE DAC811s

IN 8-BIT SYSTEMS

Many applications, such as automatic test systems, require

that the outputs of several D/A converters be updated simultaneously. The interface shown in Figure 12 uses a 74LS138

decoder to decode a set of eight adjacent addresses, to load

the input latches of four DAC811s. The example shows a

right-justified data format.

A ninth address using A3 causes all DAC811s to be updated

simultaneously. If a particular DAC811 is always loaded

last—for instance, D/A #4—A3 is not needed, thus saving

eight address spaces for other uses. Incorporate A3 into the

base address decoder, remove the inverter, connect the

common LDAC line to NC of D/A #4, and connect D1 of the

74LS138 to +5V.

12- AND 16-BIT MICROCOMPUTER INTERFACE

For this application, the input latch enable lines, NA, NB and

NC, are tied low, causing the latches to be transparent. The

D/A latch, and therefore DAC811, is selected by the address

decoder and strobed by WR.

WR

A

15

A

4

A

3

Microcomputer

A

2

A

1

A

0

Base

Address

Decoder

CS

4

5

6

3

2

1

74LS138

G

2A

G

2B

G

1

C

B

A

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

15

14

13

12

11

10

9

7

WR

LDAC

N

C

N

B

N

A

WR

LDAC

N

C

N

B

N

A

WR

LDAC

N

C

N

B

N

A

DAC811

(1)

DAC811

(2)

DAC811

(4)

FIGURE 12. Interfacing Multiple DAC811s to an 8-Bit Bus.

ADDRESS BUS

A3 A2 A1 A0 OPERATION

0 0 0 0 Load 8 LSB – D/A #1

0 0 0 1 Load 4 MSB – D/A #1

0 0 1 0 Load 8 MSB – D/A #2

0 0 1 1 Load 4 MSB – D/A #2

0 1 0 0 Load 8 MSB – D/A #3

0 1 0 1 Load 4 MSB – D/A #3

0 1 1 0 Load 8 MSB – D/A #4

0 1 1 1 Load 4 MSB – D/A #4

1 X X X Load D/A Latch—All D/A

®

9

DAC811

Loading...

Loading...