Page 1

查询REG113-3供应商

REG113

SBVS031D – MARCH 2001 – REVISED SEPTEMBER 2005

DMOS

400mA Low-Dropout Regulator

FEATURES

● CAP-FREE DMOS TOPOLOGY:

Ultra Low Dropout Voltage:

250mV typ at 400mA

Output Capacitor

not

Required for Stability

● UP TO 500mA PEAK, TYPICAL

● FAST TRANSIENT RESPONSE

●

VERY LOW NOISE:

28µVrms

● HIGH ACCURACY: ±1.5% max

● HIGH EFFICIENCY:

I

= 850µA at I

GND

Not Enabled: I

= 400mA

OUT

= 0.01µA

GND

● 2.5V, 2.85V, 3.0V, 3.3V, AND 5.0V OUTPUT VERSIONS

● OTHER OUTPUT VOLTAGES AVAILABLE UPON

REQUEST

● FOLDBACK CURRENT LIMIT

● THERMAL PROTECTION

● SMALL SURFACE-MOUNT PACKAGES:

SOT23-5 and MSOP-8

APPLICATIONS

● PORTABLE COMMUNICATION DEVICES

● BATTERY-POWERED EQUIPMENT

● PERSONAL DIGITAL ASSISTANTS

● MODEMS

● BAR-CODE SCANNERS

● BACKUP POWER SUPPLIES

DESCRIPTION

The REG113 is a family of low-noise, low-dropout linear

regulators with low ground pin current. Its new DMOS topology provides significant improvement over previous designs,

including low-dropout voltage (only 250mV typ at full load),

and better transient performance. In addition, no output

capacitor is required for stability, unlike conventional lowdropout regulators that are difficult to compensate and require expensive low ESR capacitors greater than 1µF.

Typical ground pin current is only 850µA (at I

and drops to 10nA when not enabled. Unlike regulators with

PNP pass devices, quiescent current remains relatively constant over load variations and under dropout conditions.

The REG113 has very low output noise (typically 28µVrms

for V

in portable communications equipment. Accuracy is maintained over temperature, line, and load variations. Key

parameters are tested over the specified temperature range

(–40°C to +85°C).

The REG113 is well protected—internal circuitry provides a

current limit which protects the load from damage, furthermore, thermal protection circuitry keeps the chip from being

damaged by excessive temperature. The REG113 is available in SOT23-5 and MSOP-8 packages.

= 3.3V with CNR = 0.01µF), making it ideal for use

OUT

Enable

V

IN

+

0.1µF

NR

(2)

REG113

GND

+

C

OUT

V

OUT

OUT

(1)

= 400mA)

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

NOTES: (1) Optional. (2) NR = Noise Reduction.

Copyright © 2001-2005, Texas Instruments Incorporated

www.ti.com

Page 2

ABSOLUTE MAXIMUM RATINGS

Supply Input Voltage, VIN.......................................................–0.3V to 12V

Enable Input Voltage, V

NR Pin Voltage, VNR.............................................................–0.3V to 6.0V

Output Short-Circuit Duration ......................................................Indefinite

Operating Temperature Range (T

Storage Temperature Range (T

Lead Temperature (soldering, 3s).................................................. +240°C

NOTE: (1) Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods may degrade

device reliability.

....................................................... –0.3V to V

EN

) ................................ –55°C to +125°C

J

) ................................... –65°C to +150°C

A

(1)

IN

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation

to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

PACKAGE/ORDERING INFORMATION

PRODUCT V

REG113xx-

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI website at www.ti.com.

(2) Output voltages from 2.5V to 5.1V in 50mV increments are available; minimum order quantities apply. Contact factory for details and availability.

yyyy/zzz

(1)

(2)

OUT

XX is package designator.

YYYY is typical output voltage (5 = 5.0V, 2.85 = 2.85V, A = Adjustable).

ZZZ is package quantity.

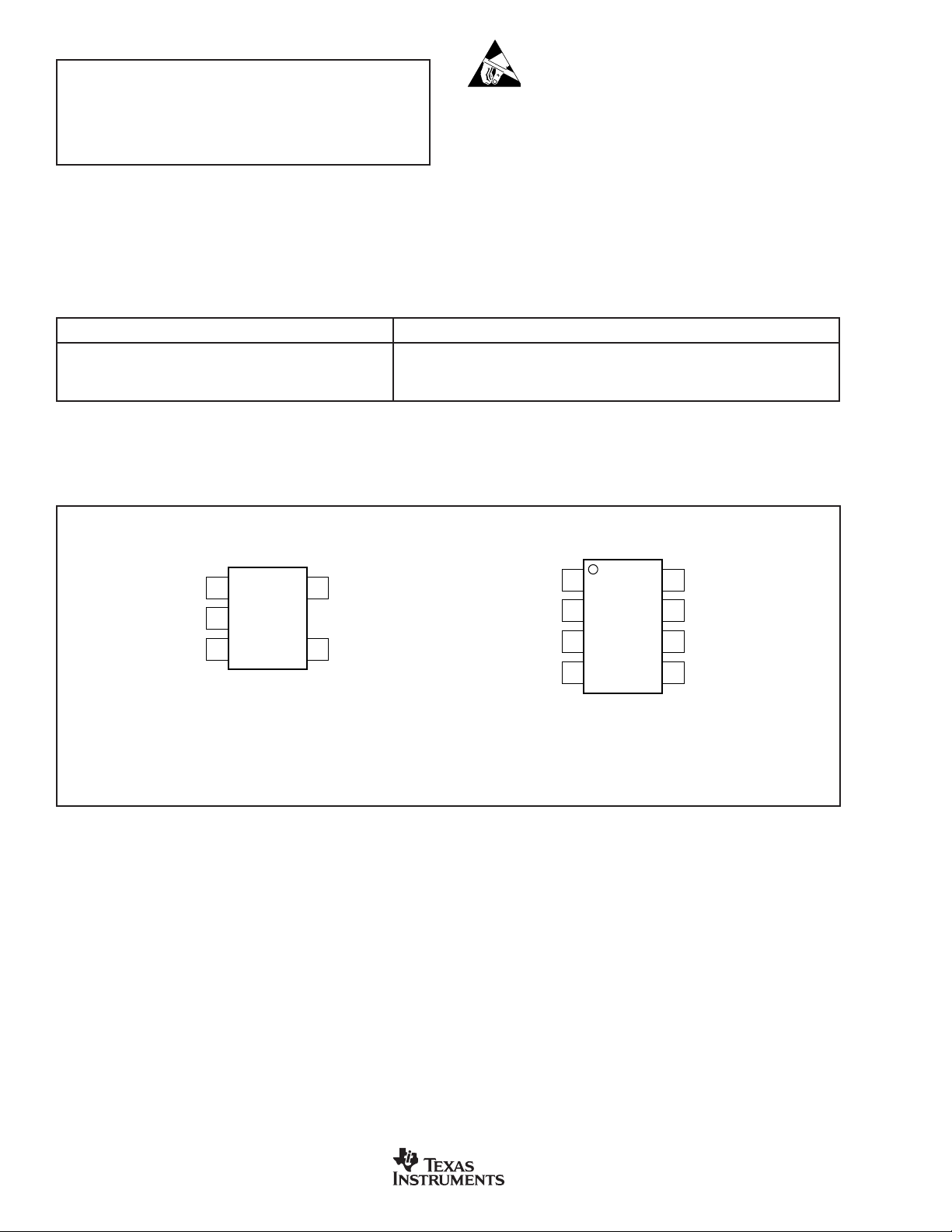

PIN CONFIGURATIONS

Top View

V

GND

Enable

IN

1

2

3

SOT

(N Package)

5

V

OUT

4

NR

Enable

V

V

OUT

NR

IN

1

2

3

4

(E Package)

MSOP

8

GND

7

GND

6

GND

5

GND

NOTE: Leads 5 through 8 are fused to the lead frame and can be

used for improved thermal dissipation.

2

www.ti.com

REG113

SBVS031D

Page 3

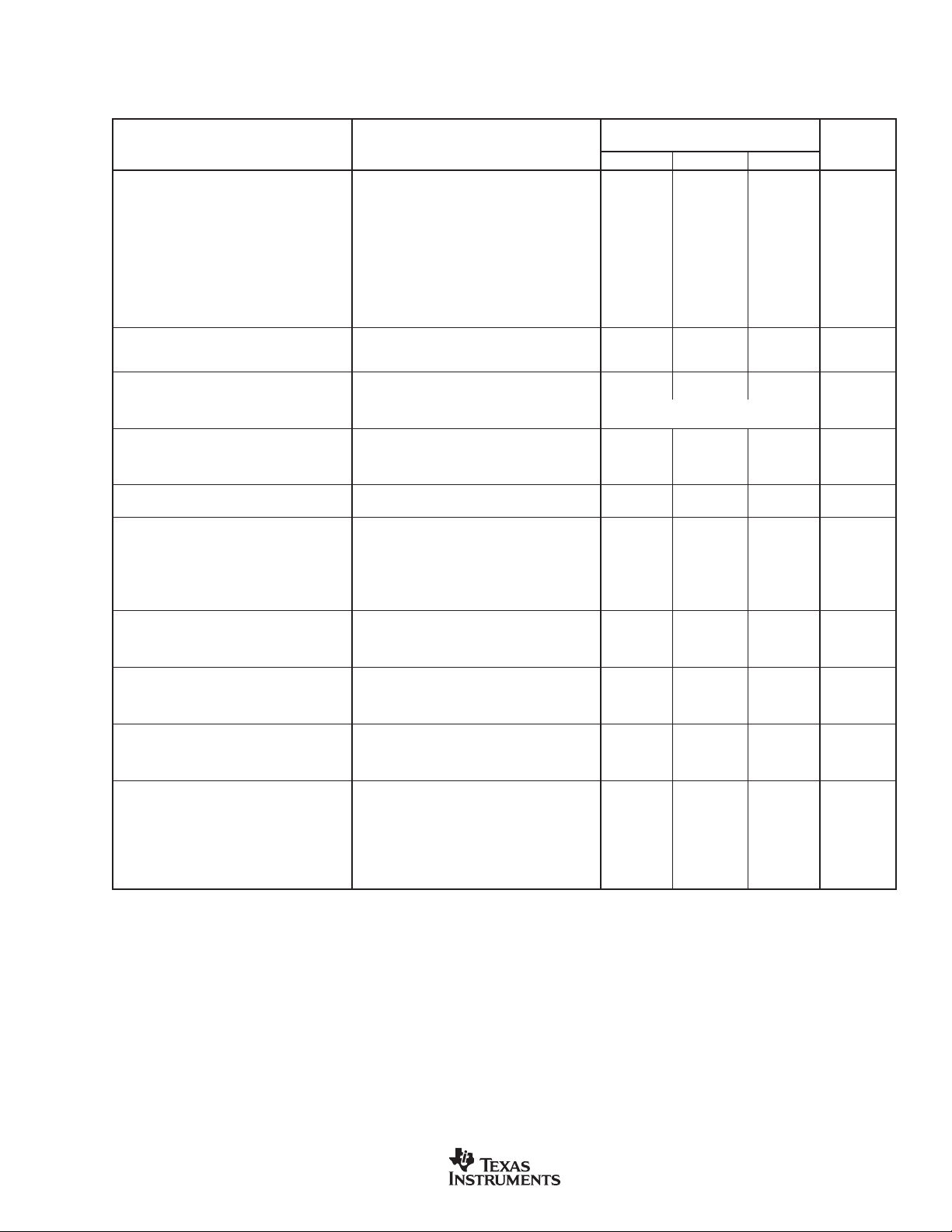

ELECTRICAL CHARACTERISTICS

Boldface limits apply over the specified temperature range, TJ = –40°C to +85°C.

At TJ = +25°C, VIN = V

OUT

+ 1V, V

ENABLE

= 1.8V, I

= 5mA, CNR = 0.01µF, and C

OUT

OUT

PARAMETER CONDITION MIN TYP MAX UNITS

OUTPUT VOLTAGE

Output Voltage Range V

REG113-2.5 2.5 V

OUT

REG113-2.85 2.85 V

REG113-3 3.0 V

REG113-3.3 3.3 V

REG113-5 5.0 V

Accuracy ±0.5 ±1.5 %

Over Temperature

vs Temperature dV

vs Line and Load

Over Temperature

DC DROPOUT VOLTAGE

(2)

For all models I

Over Temperature I

/dT 50 ±2.3 ppm/°C

OUT

V

DROP

I

= 5mA to 400mA, VIN = (V

OUT

I

= 5mA to 400mA,

OUT

VIN = (V

I

= 5mA 4 10 mV

OUT

= 400mA 250 325 mV

OUT

= 400mA 410 mV

OUT

+ 0.6V) to 10V ±3.0 %

OUT

+ 0.4V) to 10V

OUT

VOLTAGE NOISE

f = 10Hz to 100kHz V

Without C

With C

OUTPUT CURRENT

Current Limit

NR

NR

(3)

Over Temperature 600 mA

Short-Circuit Current Limit I

n

I

CL

SC

CNR = 0, C

CNR = 0.01µF, C

= 0 23µVrms/V • V

OUT

= 10µF7µVrms/V • V

OUT

RIPPLE REJECTION

f = 120Hz 65 dB

ENABLE CONTROL

V

HIGH (output enabled) V

ENABLE

LOW (output disabled) –0.2 0.5 V

V

ENABLE

I

HIGH (output enabled) I

ENABLE

LOW (output disabled) V

I

ENABLE

Output Disable Time C

Output Enable Softstart Time C

ENABLE

ENABLE

V

= 1.8V to VIN, VIN = 1.8V to 6.5

ENABLE

= 0V to 0.5V 2 100 nA

ENABLE

= 1.0µF, R

OUT

= 1.0µF, R

OUT

= 13Ω 50 µs

LOAD

= 13Ω 1.5 ms

LOAD

THERMAL SHUTDOWN

Junction Temperature

Shutdown 160 °C

Reset from Shutdown 140 °C

GROUND PIN CURRENT

Ground Pin Current I

GND

Enable Pin LOW V

INPUT VOLTAGE V

Operating Input Voltage Range

(5)

IN

Specified Input Voltage Range V

Over Temperature V

I

= 5mA 400 500 µA

OUT

I

= 400mA 850 1000 µA

OUT

≤ 0.5V 0.01 0.2 µA

ENABLE

> 1.8V V

IN

> 1.8V V

IN

TEMPERATURE RANGE

Specified Range T

Operating Range T

Storage Range T

Thermal Resistance

SOT23-5 Surface-Mount

MSOP-8 Surface-Mount

J

J

A

θ

JA

θ

JC

θ

JA

Junction-to-Ambient 200 °C/W

Junction-to-Case 35

Junction-to-Ambient 160

NOTES: (1) The REG113 does not require a minimum output capacitor for stability. However, transient response can be improved with proper capacitor selection.

(2) Dropout voltage is defined as the input voltage minus the output voltage that produces a 2% change in the output voltage from the value at V

+ 1V at fixed load.

(3) Current limit is the output current that produces a 10% change in output voltage from VIN = V

(4) For V

(5) The REG113 no longer regulates when VIN < V

> 6.5V, see typical characteristic

ENABLE

I

ENABLE

OUT

vs V

+ V

ENABLE

DROP (MAX)

.

. In dropout, the impedance from VIN to V

(6) See Figure 7.

= 0.1µF

(4)

(1)

, unless otherwise noted.

REG113NA

REG113EA

425 500 575 mA

1.8 V

1.8 10 V

+ 0.4 10 V

OUT

+ 0.6 10 V

OUT

–40 +85 °C

–55 +125 °C

–65 +150 °C

+ 1V and I

OUT

±2.3 %

±1 ±2.3 %

OUT

OUT

200 mA

IN

1 100 nA

(6)

(6)

= 5mA.

OUT

is typically less than 1Ω at TJ = +25°C.

OUT

µVrms

µVrms

°C/W

°C/W

V

= V

IN

OUT

REG113

SBVS031D

www.ti.com

3

Page 4

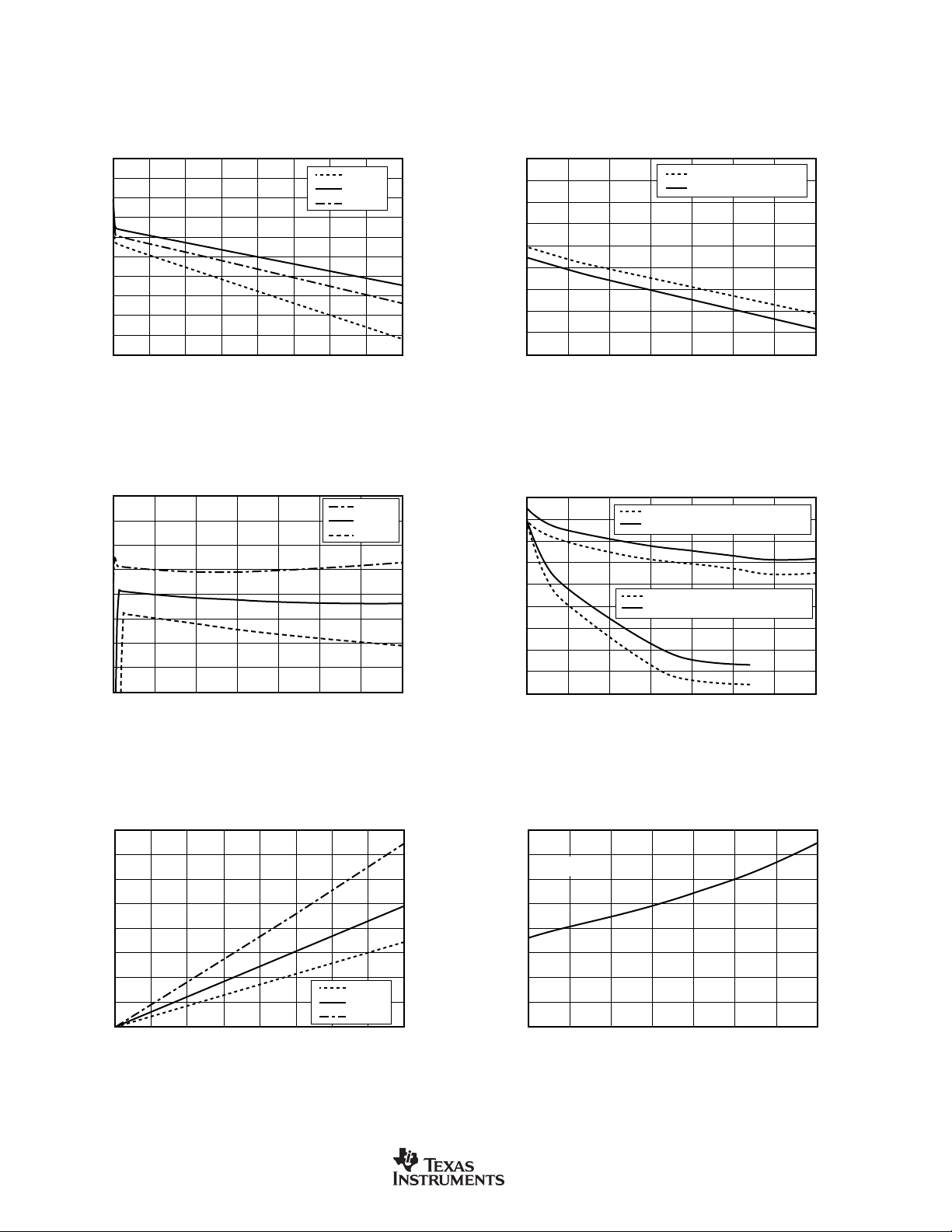

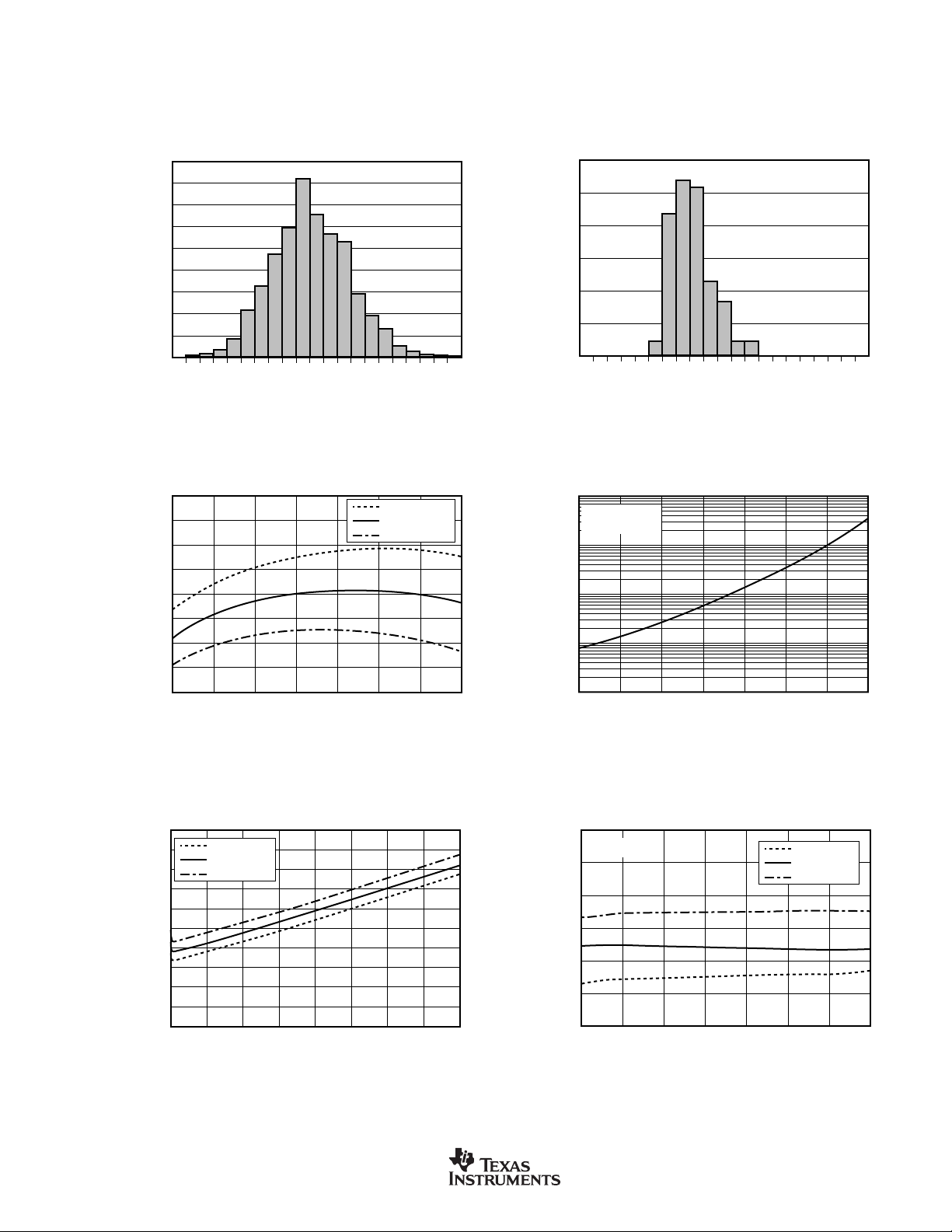

TYPICAL CHARACTERISTICS

For all models, at TJ = +25°C and V

= 1.8V, unless otherwise noted.

ENABLE

1.0

0.8

0.6

OUTPUT VOLTAGE CHANGE vs I

(Referred to I

= 200mA at +25°C)

OUT

OUT

–55°C

+25°C

+125°C

0.4

0.2

0

–0.2

–0.4

–0.6

Ouput Voltage Change (%)

–0.8

–1.0

0 50 100 150 200 250 300 350 400

Output Current (mA)

LINE REGULATION

40

(Referred to V

= V

IN

OUT

+ 1V at IO = 200mA)

30

20

10

0

–10

–20

Ouput Voltage Change (mV)

–30

–40

01234567

VIN – V

OUT

(V)

5mA

200mA

400mA

LOAD REGULATION vs TEMPERATURE

(V

= V

+ 1V)

IN

0

–0.1

OUT

I

I

OUT

OUT

= 40mA to 400mA

= 5mA to 400mA

–0.2

–0.3

–0.4

–0.5

–0.6

Ouput Change (%)

–0.7

–0.8

–0.9

–50 –25 0 25 50 75 100 125

Temperature (°C)

LINE REGULATION vs TEMPERATURE

0

–0.05

–0.10

I

= 200mA, (V

OUT

I

= 200mA, (V

OUT

+ 1V) < VIN < 10

OUT

+ 0.4V) < V

OUT

–0.15

–0.20

–0.25

–0.30

–0.35

Ouput Change (%)

= 400mA, (V

OUT

I

= 400mA, (V

OUT

+ 1V) < VIN < 10

OUT

+ 0.4V) < VIN < 10

OUT

I

–0.40

–0.45

–0.50

–50 –25 0 25 50 75 100 125

Temperature (°C)

IN

< 10

400

DC DROPOUT VOLTAGE vs OUTPUT CURRENT

350

300

250

200

150

100

DC Dropout Voltage (mV)

50

0

0 50 100 150 200 250 350300 400

4

Output Current (mA)

–55°C

+25°C

+125°C

www.ti.com

400

DC DROPOUT VOLTAGE vs TEMPERATURE

350

I

= 400mA

OUT

300

250

200

150

100

DC Dropout Voltage (mV)

50

0

–50 –25 0 25 50 75 100 125

Junction Temperature (°C)

REG113

SBVS031D

Page 5

TYPICAL CHARACTERISTICS (Cont.)

0

10

20

30

40

50

60

70

80

90

100

5

15

25

35

45

55

65

75

85

95

30

25

20

15

10

5

0

Percentage of Units (%)

V

OUT

Drift (ppm/°C)

OUTPUT VOLTAGE DRIFT HISTOGRAM

For all models, at TJ = +25°C and V

= 1.8V, unless otherwise noted.

ENABLE

18

OUTPUT VOLTAGE ACCURACY HISTOGRAM

16

14

12

10

8

6

Percentage of Units (%)

4

2

0

0.0

0.2

–1.0

–0.8

–0.6

–0.4

–0.2

0.4

Error (%)

OUTPUT VOLTAGE vs TEMPERATURE

0.8

(Referred to I

0.6

0.4

= 200mA at +25°C)

OUT

I

I

I

OUT

OUT

OUT

0.2

0

–0.2

–0.4

Output Voltage Change (%)

–0.6

–0.8

–50 –25 0 25 50 75 100 125

Temperature (°C)

0.6

0.8

= 5mA

= 200mA

= 400mA

1.0

GROUND PIN CURRENT, NOT ENABLED

vs TEMPERATURE

1µ

V

= 0.5V

ENABLE

V

= V

+ 1V

IN

OUT

100n

(A)

10n

GND

I

1n

100p

–50 25–25 0 50 75 100 125

Temperature (°C)

REG113

1000

GROUND CURRENT vs LOAD CURRENT

V

= 2.5V

900

800

OUT

= 3.3V

V

OUT

= 5.0V

V

OUT

700

600

(µA)

500

GND

I

400

300

200

100

0

0 50 100 150 200 250 300 350 400

Load Current (mA)

SBVS031D

www.ti.com

1000

GROUND CURRENT vs TEMPERATURE

I

950

= 400mA

OUT

V

OUT

V

OUT

V

OUT

900

(µA)

850

GND

I

800

750

700

–50 –25 0 25 50 75 100 125

Temperature (°C)

= 2.5V

= 3.3V

= 5.0V

5

Page 6

TYPICAL CHARACTERISTICS (Cont.)

For all models, at TJ = +25°C and V

= 1.8V, unless otherwise noted.

ENABLE

80

RIPPLE REJECTION vs FREQUENCY

I

= 2mA

I

OUT

OUT

= 100mA

C

I

OUT

OUT

= 2mA

= 10µF

I

OUT

C

OUT

= 100mA

= 10µF

70

60

50

40

30

Ripple Rejection (dB)

20

10

C

= 0µF

OUT

0

10 100 1k 10k 100k 10M1M

Frequency (Hz)

60

RMS NOISE VOLTAGE vs C

OUT

REG113-5.0

50

40

REG113-3.3

30

20

Noise Voltage (µVrms)

10

C

OUT

10Hz < BW < 100kHz

0

= 0.01µF

REG113-2.5

0.1 1 10

C

(µF)

OUT

30

RIPPLE REJECTION vs (V

– V

IN

25

20

15

10

Frequency = 100kHz

Ripple Rejection (dB)

C

= 10µF

OUT

5

V

= 3.3V

OUT

I

= 100mA

OUT

0

1.0 0.9 0.60.8 0.7 0.5 0.4 0.3 00.2 0.1

VIN – V

OUT

(V)

RMS NOISE VOLTAGE vs C

110

100

90

80

REG113-3.3

REG113-5.0

70

60

50

REG113-2.5

Noise Voltage (µVrms)

40

C

= 0µF

OUT

30

10Hz < BW < 100kHz

20

1 100 1k10

CNR (pF)

NR

OUT

)

10k

10

I

= 100mA

OUT

C

= 0µF

NR

(µV/√Hz)

N

e

1

0.1

C

C

= 0µF

OUT

C

0.01

10 100 1k 10k 100k

OUT

OUT

= 1µF

= 10µF

10

I

= 100mA

OUT

C

= 0.01µF

NR

1

(µV/√Hz)

N

e

0.1

0.01

10 100 1k 10k 100k

Frequency (Hz)

NOISE SPECTRAL DENSITY

6

www.ti.com

NOISE SPECTRAL DENSITY

C

Frequency (Hz)

OUT

C

= 0µF

C

= 1µF

OUT

= 10µF

OUT

REG113

SBVS031D

Page 7

TYPICAL CHARACTERISTICS (Cont.)

For all models, at TJ = +25°C and V

= 1.8V, unless otherwise noted.

ENABLE

3.5

CURRENT LIMIT FOLDBACK

3.0

V

= 3.3V

OUT

2.5

2.0

I

1.5

Output Voltage (V)

1.0

I

SC

0.5

0

0 50 100 150 200 250 300 350 400 450 500 550

Output Current Limit (mA)

LOAD TRANSIENT RESPONSE

REG113-3.3

C

= 0

OUT

C

= 10µF

500mV/div

OUT

CL

V

= 4.3V

IN

600

CURRENT LIMIT vs TEMPERATURE

550

500

450

400

350

ICL (Current Limit)

I

(Short-Circuit Current)

SC

300

250

Output Current (mA)

200

150

100

–50 –25 0 25 50 75 100 125

Temperature (°C)

LINE TRANSIENT RESPONSE

REG113-3.3

I

= 400mA

C

= 0

C

OUT

OUT

= 10µF

V

OUT

V

OUT

25mV/div

OUT

V

OUT

V

OUT

400mA

40mA

1V/div1V/div

C

R

LOAD

OUT

TURN-ON

= 0µF

= 660Ω

10µs/div

250µs/div

C

R

OUT

LOAD

= 10µF

= 13Ω

V

= 0µF

C

OUT

= 13Ω

R

LOAD

REG113-3.3

= V

+ 1V

IN

OUT

C

= 0.01µF

NR

I

OUT

V

OUT

V

ENABLE

5.3V

4.3V

1V/div1V/div

R

C

OUT

LOAD

= 0µF

= 660Ω

50µs/div

TURN-OFF

200µs/div

C

R

OUT

LOAD

= 10µF

= 13Ω

C

OUT

R

LOAD

= 1.0µF

= 13Ω

REG113-3.3

V

IN

V

OUT

V

ENABLE

REG113

SBVS031D

www.ti.com

7

Page 8

TYPICAL CHARACTERISTICS (Cont.)

For all models, at TJ = +25°C and V

I

10µ

1.0µ

(A)

100n

ENABLE

I

T = +125°C

10n

1n

678910

ENABLE

T = +25°C

T = –55°C

= 1.8V, unless otherwise noted.

ENABLE

vs V

ENABLE

V

(V)

ENABLE

BASIC OPERATION

V

= 3.0V

OUT

R

LOAD

500mV/div

POWER-UP/POWER-DOWN

= 12Ω

1s/div

The REG113 series of LDO (low dropout) linear regulators

offers a wide selection of fixed output voltage versions and

an adjustable output version. The REG113 belongs to a

family of new generation LDO regulators that use a DMOS

pass transistor to achieve ultra low-dropout performance

and freedom from output capacitor constraints. Ground pin

current remains under 1mA over all line, load, and temperature conditions. All versions have thermal and over-current

protection, including foldback current limit.

The REG113 does not require an output capacitor for

regulator stability and is stable over most output currents

and with almost any value and type of output capacitor up

to 10µF or more. For applications where the regulator output

current drops below several milliamps, stability can be

enhanced by adding a 1kΩ to 2kΩ load resistor, using

capacitance values smaller than 10µF, or keeping the effective series resistance greater than 0.05Ω including the

capacitor ESR and parasitic resistance in printed circuit

board traces, solder joints, and sockets.

Although an input capacitor is not required, it is a good

standard analog design practice to connect a 0.1µF low

ESR capacitor across the input supply voltage; this is

recommended to counteract reactive input sources and

improve ripple rejection by reducing input voltage ripple.

Figure 1 shows the basic circuit connections for the fixed

voltage models.

Enable

V

IN

0.1µF

REG113

In Out

Gnd NR

C

0.01µF

NR

Optional

V

OUT

C

OUT

FIGURE 1. Fixed Voltage Nominal Circuit for the REG113.

3.5

3.0

V

OUT

2.5

2.0

1.5

Output Voltage (V)

1.0

0.5

0

0 50 100 150 200 250 300 350 400 450 500 550

CURRENT LIMIT FOLDBACK

= 3.3V

I

SC

Output Current Limit (mA)

I

CL

FIGURE 2. Foldback Current Limit of the REG113-3.3 at 25°C.

INTERNAL CURRENT LIMIT

The REG113 internal current limit has a typical value of

500mA. A foldback feature limits the short-circuit current to

a typical short-circuit value of 200mA. A curve of V

versus I

is given in Figure 2, and in the Typical Charac-

OUT

teristics section.

8

OUT

www.ti.com

ENABLE

The Enable pin is active high and compatible with standard

TTL-CMOS levels. Inputs below 0.5V (max) turn the regulator off and all circuitry is disabled. Under this condition,

ground pin current drops to approximately 10nA. When not

used, the Enable pin can be connected to V

.

IN

REG113

SBVS031D

Page 9

OUTPUT NOISE

A precision bandgap reference is used to generate the

internal reference voltage, V

. This reference is the domi-

REF

nant noise source within the REG113 and generates approximately 29µVrms in the 10Hz to 100kHz bandwidth at the

reference output. The regulator control loop gains up the

reference noise, so that the noise voltage of the regulator is

approximately given by:

V Vrms

=µ

N

Since the value of V

is 1.26V, this relationship reduces to:

REF

V

=

N

Connecting a capacitor, C

RR

+

12

=µ •29

29

2

R

Vrms

µ

•23

V

OUT

V

, from the Noise Reduction (NR)

NR

Vrms

V

V

OUT

REF

(1)

(2)

pin to ground (as shown in Figure 3) forms a low-pass filter

for the voltage reference. For C

= 10nF, the total noise in

NR

the 10Hz to 100kHz bandwidth is reduced by approximately

a factor of 2.8 for V

shown in Figure 4, and as

= 3.3V. This noise reduction effect is

OUT

RMS Noise Voltage vs C

NR

in the

Typical Characteristics section.

Noise can be further reduced by carefully choosing an output

capacitor, C

with very low (< 0.22µF) or very high (> 2.2µF) values of C

(see the

. Best overall noise performance is achieved

OUT

RMS Noise Voltage vs C

typical characteristic).

OUT

OUT

The REG113 uses an internal charge pump to develop an

internal supply voltage sufficient to drive the gate of the

DMOS pass element above V

. The charge-pump switching

IN

noise (nominal switching frequency = 2MHz) is not measurable at the output of the regulator over most values of I

and C

OUT

.

OUT

DROPOUT VOLTAGE

The REG113 uses an N-channel DMOS as the pass element. When (V

(V

), the DMOS pass device behaves like a resistor;

DROP

therefore, for low values of (V

to-output resistance is the Rds

(typically 600m

– V

IN

Ω

). For static (DC) loads, the REG113 will

) is less than the dropout voltage

OUT

– V

IN

ON

), the regulator input-

OUT

of the DMOS pass element

110

100

90

80

REG113-3.3

70

REG113-2.5

60

50

Noise Voltage (Vrms)

40

C

OUT

30

10Hz < BW < 100kHz

20

0.1 100 1k10 10k

RMS NOISE VOLTAGE vs C

REG113-5.0

= 0µF

CNR (pF)

NR

FIGURE 4. Output Noise versus Noise Reduction Capacitor.

typically maintain regulation down to a (VIN – V

) voltage

OUT

drop of 250mV at full rated output current. In Figure 5, the

bottom line (DC dropout) shows the minimum V

to V

IN

OUT

voltage drop required to prevent dropout under DC load

conditions.

600

500

400

300

200

Dropout Voltage (mV)

100

0

0 50 100 150 200 250 350300 400

DROPOUT VOLTAGE vs I

Dropout for 0mA to I

DC Dropout

I

OUT

OUT

(mA)

OUT

Transient

FIGURE 5. Transient and DC Dropout.

NR

Enable

FIGURE 3. Block Diagram.

REG113

SBVS031D

C

NR

(optional)

(1.26V)

REG113

V

IN

Low-Noise

Charge Pump

V

REF

www.ti.com

Over-Current

Over Temp

Protection

DMOS

Output

GND

V

OUT

9

Page 10

For large step changes in load current, the REG113 requires

a larger voltage drop across it to avoid degraded transient

response. The boundary of this transient dropout region is

shown as the top line in Figure 5. Values of V

IN

to V

OUT

voltage

drop above this line insure normal transient response.

In the transient dropout region between DC and Transient,

transient response recovery time increases. The time required to

recover from a load transient is a function of both the magnitude

and rate of the step change in load current and the available

headroom V

tions (full-scale load change with (V

to V

IN

voltage drop. Under worst-case condi-

OUT

IN

– V

) voltage drop close

OUT

to DC dropout levels), the REG113 can take several hundred

microseconds to re-enter the specified window of regulation.

TRANSIENT RESPONSE

The REG113 response to transient line and load conditions

improves at lower output voltages. The addition of a capacitor

(nominal value 0.47µF) from the output pin to ground may

improve the transient response. In the adjustable version, the

addition of a capacitor, C

(nominal value 10nF), from the

FB

output to the adjust pin also improves the transient response.

THERMAL PROTECTION

Power dissipated within the REG113 can cause the junction

temperature to rise, however, the REG113 has thermal

shutdown circuitry that protects the regulator from damage.

The thermal protection circuitry disables the output when

the junction temperature reaches approximately 160°C,

allowing the device to cool. When the junction temperature

cools to approximately 140°C, the output circuitry is again

enabled. Depending on various conditions, the thermal

protection circuit can cycle on and off. This limits the

dissipation of the regulator, but can have an undesirable

effect on the load.

Any tendency to activate the thermal protection circuit indicates excessive power dissipation or an inadequate heat sink.

For reliable operation, junction temperature should be limited

to 125°C, maximum. To estimate the margin of safety in a

complete design (including heat sink), increase the ambient

temperature until the thermal protection is triggered. Use

worst-case loads and signal conditions. For good reliability,

thermal protection should trigger more than 35°C above the

maximum expected ambient condition of the application. This

produces a worst-case junction temperature of 125°C at the

highest expected ambient temperature and worst-case load.

The internal protection circuitry of the REG113 is designed to

protect against overload conditions and is not intended to

replace proper heat sinking. Continuously running the REG113

into thermal shutdown will degrade reliability.

POWER DISSIPATION

The REG113 is available in two different package configurations. The ability to remove heat from the die is different for each

package type and, therefore, presents different considerations

in the printed circuit board (PCB) layout. On the MSOP-8

package, leads 5 through 8 are fused to the lead frame and may

be used to improve the thermal performance of the package.

The PCB area around the device that is free of other components moves the heat from the device to the ambient air.

Although it is difficult or impossible to quantify all of the

variables in a thermal design of this type, performance data for

several simplified configurations are shown in Figure 6. In all

cases the PCB copper area is bare copper, free of solder resist

mask, and not solder plated. All examples are for 1-ounce

copper and in the case of the MSOP-8, the copper area is

connected to fused leads 5 to 8. See Figure 7 for thermal

resistance for varying areas of copper. Using heavier copper

can increase the effectiveness in removing the heat from the

device. In those examples where there is copper on both sides

of the PCB, no connection has been provided between the two

sides. The addition of plated through holes will improve the heat

sink effectiveness.

MAXIMUM POWER DISSIPATION vs TEMPERATURE

3.0

Condition 1

2.5

2.0

1.5

1.0

Power Dissipation (W)

0.5

0

–50 –25 0 25 50 75 100 125

Ambient Temperature (°C)

CONDITION PACKAGE PCB AREA

1 MSOP-8 1 sq. in. Cu, 1 Side 71

2 MSOP-8 0.25 sq. in. Cu, 1 Side 90

3 SOT-23-8 None 200

FIGURE 6. Maximum Power Dissipation versus Ambient Tem-

perature for the Various Packages and PCB Heat

Sink Configurations.

Condition 2

Condition 3

θ

JA

10

www.ti.com

REG113

SBVS031D

Page 11

THERMAL RESISTANCE vs PCB COPPER AREA

160

150

140

130

120

110

100

90

80

70

60

Thermal Resistance,

JA

(°C/W)

θ

012345

Copper Area (inches

2

)

Power dissipation depends on input voltage, load conditions, and duty cycle and is equal to the product of the

average output current times the voltage across the output

element (V

IN

to V

voltage drop):

OUT

PVV I

=•( – )

DIN

OUT OUT

(3)

Power dissipation can be minimized by using the lowest possible

input voltage necessary to assure the required output voltage.

FIGURE 7. Thermal Resistance versus PCB Area for the MSOP-8.

REG113

SBVS031D

www.ti.com

11

Page 12

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

REG113EA-2.5/250 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA-2.5/2K5 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA-2.85/250 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA-2.85/2K5 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA-3.3/250 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA-3.3/2K5 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA-3/250 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA-3/2K5 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA-3/2K5G4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA-5/250 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA-5/250G4 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA-5/2K5 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA-5/2K5G4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA285250G4 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA2852K5G4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113EA33250G4 ACTIVE MSOP DGK 8 250 Green (RoHS &

REG113EA332K5G4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

REG113NA-2.5/250 ACTIVE SOT-23 DBV 5 250 Green (RoHS &

REG113NA-2.5/250G4 ACTIVE SOT-23 DBV 5 250 Green (RoHS &

REG113NA-2.5/3K ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

REG113NA-2.5/3KG4 ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

REG113NA-2.85/250 ACTIVE SOT-23 DBV 5 250 Green (RoHS &

REG113NA-2.85/3K ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

REG113NA-2.85/3KG4 ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

REG113NA-3.3/250 ACTIVE SOT-23 DBV 5 250 Green (RoHS &

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

no Sb/Br)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

14-Mar-2006

(3)

Addendum-Page 1

Page 13

PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

REG113NA-3.3/250G4 ACTIVE SOT-23 DBV 5 250 Green (RoHS &

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

14-Mar-2006

(3)

no Sb/Br)

REG113NA-3.3/3K ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-3.3/3KG4 ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-3/250 ACTIVE SOT-23 DBV 5 250 Green (RoHS&

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-3/250G4 ACTIVE SOT-23 DBV 5 250 Green (RoHS&

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-3/3K ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-3/3KG4 ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-5/250 ACTIVE SOT-23 DBV 5 250 Green (RoHS&

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA-5/3K ACTIVE SOT-23 DBV 5 3000 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

REG113NA2.85/250G4 ACTIVE SOT-23 DBV 5 250 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

(1)

The marketing status values aredefined as follows:

ACTIVE: Product device recommended fornew designs.

LIFEBUY: TI has announced thatthe device will be discontinued,and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announcedbut is not in production.Samples may or may not be available.

OBSOLETE: TI has discontinued theproduction of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availabilityinformation and additional product contentdetails.

TBD: The Pb-Free/Green conversion planhas not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Freeproducts are suitable for usein specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb donot exceed 0.1% by weightin homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be availablefor release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annualbasis.

Addendum-Page 2

Page 14

Page 15

Page 16

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2006, Texas Instruments Incorporated

Loading...

Loading...