Page 1

®

For most current data sheet and other product

information, visit www.burr-brown.com

12-Bit, Parallel Input

DIGITAL-TO-ANALOG CONVERTER

DAC7621

®

DAC7621

FEATURES

● LOW POWER: 2.5mW

● FAST SETTLING: 7µs to 1 LSB

● 1mV LSB WITH 4.095V FULL-SCALE

RANGE

● COMPLETE WITH REFERENCE

● 12-BIT LINEARITY AND MONOTONICITY

OVER INDUSTRIAL TEMP RANGE

● ASYNCHRONOUS RESET TO 0V

APPLICATIONS

● PROCESS CONTROL

● DATA ACQUISITION SYSTEMS

● CLOSED-LOOP SERVO-CONTROL

● PC PERIPHERALS

● PORTABLE INSTRUMENTATION

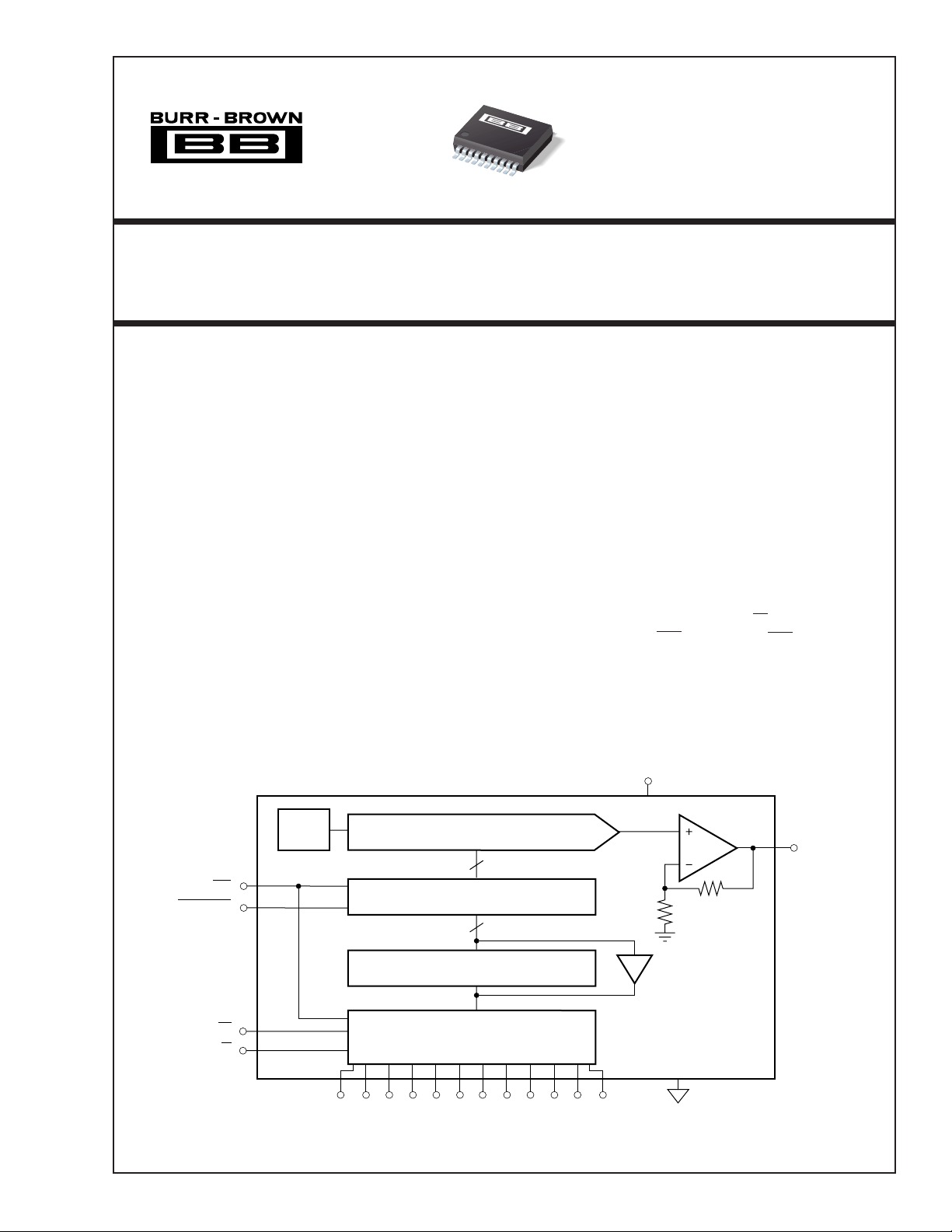

DESCRIPTION

The DAC7621 is a 12-bit digital-to-analog converter

(DAC) with guaranteed 12-bit monotonicity performance over the industrial temperature range. It requires a single +5V supply and contains an input

register, latch, 2.435V reference, DAC, and high speed

rail-to-rail output amplifier. For a full-scale step, the

output will settle to 1 LSB within 7µs. The device

consumes 2.5mW (0.5mA at 5V).

The parallel interface is compatible with a wide variety

of microcontrollers. The DAC7621 accepts a 12-bit

parallel word, has a double-buffered input logic structure and provides data readback. In addition, two

control pins provide a chip select (CS) function and

asynchronous clear (CLR) input. The CLR input can

be used to ensure that the DAC7621 output is 0V on

power-up or as required by the application.

The DAC7621 is available in a 20-lead SSOP package

and is fully specified over the industrial temperature

range of –40°C to +85°C.

V

DD

SBAS107

Ref

CLR

LOADDAC

CS

R/W

D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

© 1998 Burr-Brown Corporation PDS-1502B Printed in U.S.A. March, 1999

12-Bit DAC

12

DAC Register

12

Input Register

12

I/O Buffer

DGND

DAC7621

V

OUT

Page 2

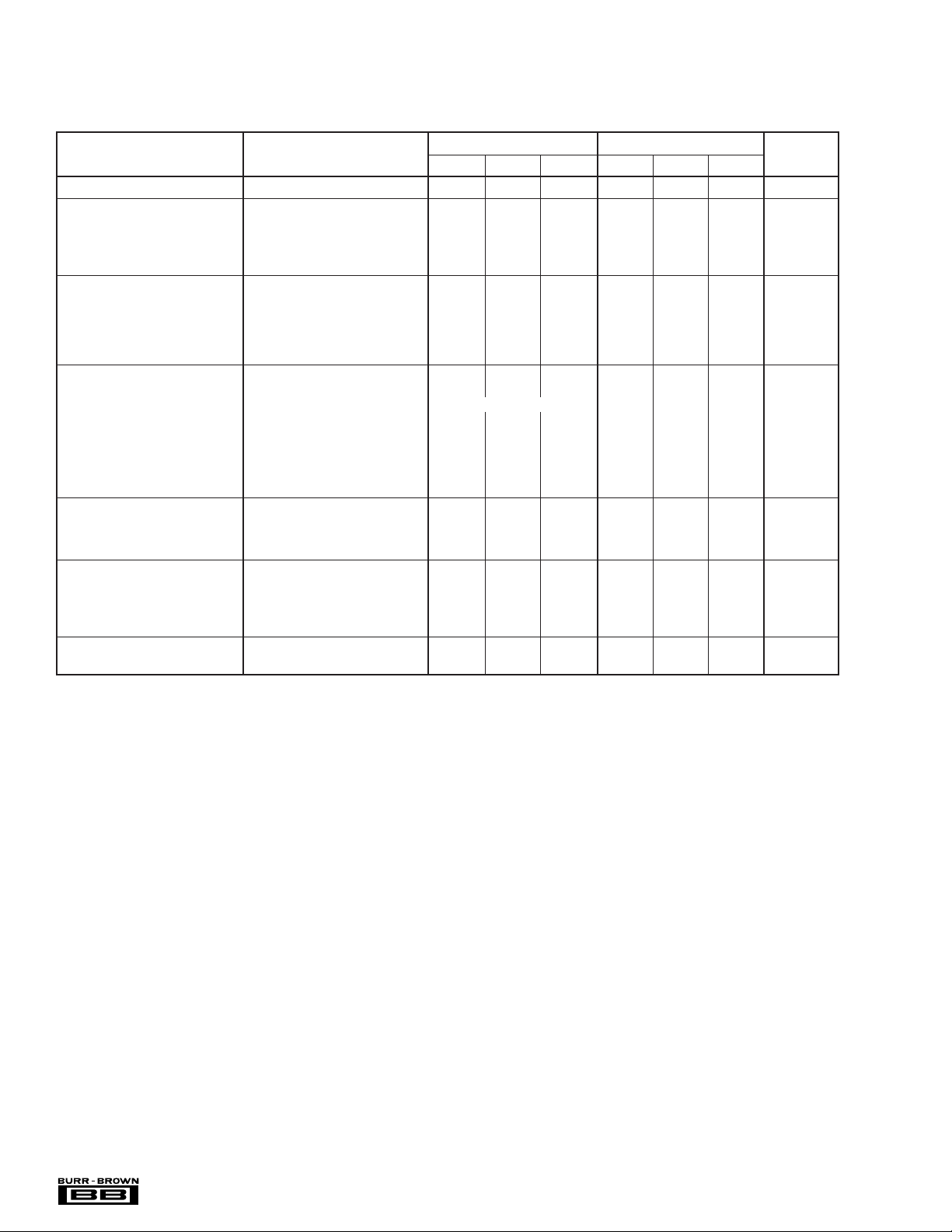

SPECIFICATIONS

ELECTRICAL

At TA = –40°C to +85°C, and VDD = +5V, unless otherwise noted.

DAC7621E DAC7621EB

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

RESOLUTION 12 ✻ Bits

ACCURACY

Relative Accuracy

Differential Nonlinearity Guaranteed Monotonic –1 ±1/2 +1 –1 ±1/4 +1 LSB

Zero-Scale Error Code 000

Full Scale Voltage Code FFF

ANALOG OUTPUT

Output Current Code 800

Load Regulation R

Capacitive Load No Oscillation 500 ✻ pF

Short-Circuit Current ±20 ✻ mA

Short-Circuit Duration GND or V

DIGITAL INPUT

Data Format Parallel ✻

Data Coding Straight Binary ✻

Logic Family CMOS ✻

Logic Levels

V

IH

V

IL

I

IH

I

IL

DYNAMIC PERFORMANCE

Settling Time

DAC Glitch 5 ✻ nV-s

Digital Feedthrough 2 ✻ nV-s

POWER SUPPLY

V

DD

I

DD

Power Dissipation V

Power Supply Sensitivity ∆V

TEMPERATURE RANGE

Specified Performance –40 +85 ✻✻°C

(1)

H

H

≥ 402Ω, Code 800

LOAD

H

H

DD

–2 ±1/2 +2 –1 ±1/4 +1 LSB

–1 +1 +3 ✻✻✻ LSB

4.079 4.095 4.111 4.087 4.095 4.103 V

±5 ±7 ✻✻ mA

13 ✻✻ LSB

Indefinite ✻

0.7 • V

DD

0.3 • V

±10 ✻ µA

✻ V

DD

✻ V

±10 ✻ µA

(2)

(tS) To ±1 LSB of Final Value 7 ✻ µs

+4.75 +5.0 +5.25 ✻✻✻ V

VIH = 5V, VIL = 0V, No Load, at Code 000

= 5V, VIL = 0V, No Load 2.5 5 ✻✻ mW

IH

= ±5% 0.001 0.004 ✻✻%/%

DD

H

0.5 1 ✻✻ mA

✻ Same specification as for DAC7621E.

NOTES: (1) This term is sometimes referred to as Linearity Error or Integral Nonlinearity (INL). (2) Specification does not apply to negative-going transitions where

the final output voltage will be within 3 LSBs of ground. In this region, settling time may be double the value indicated.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

®

DAC7621

2

Page 3

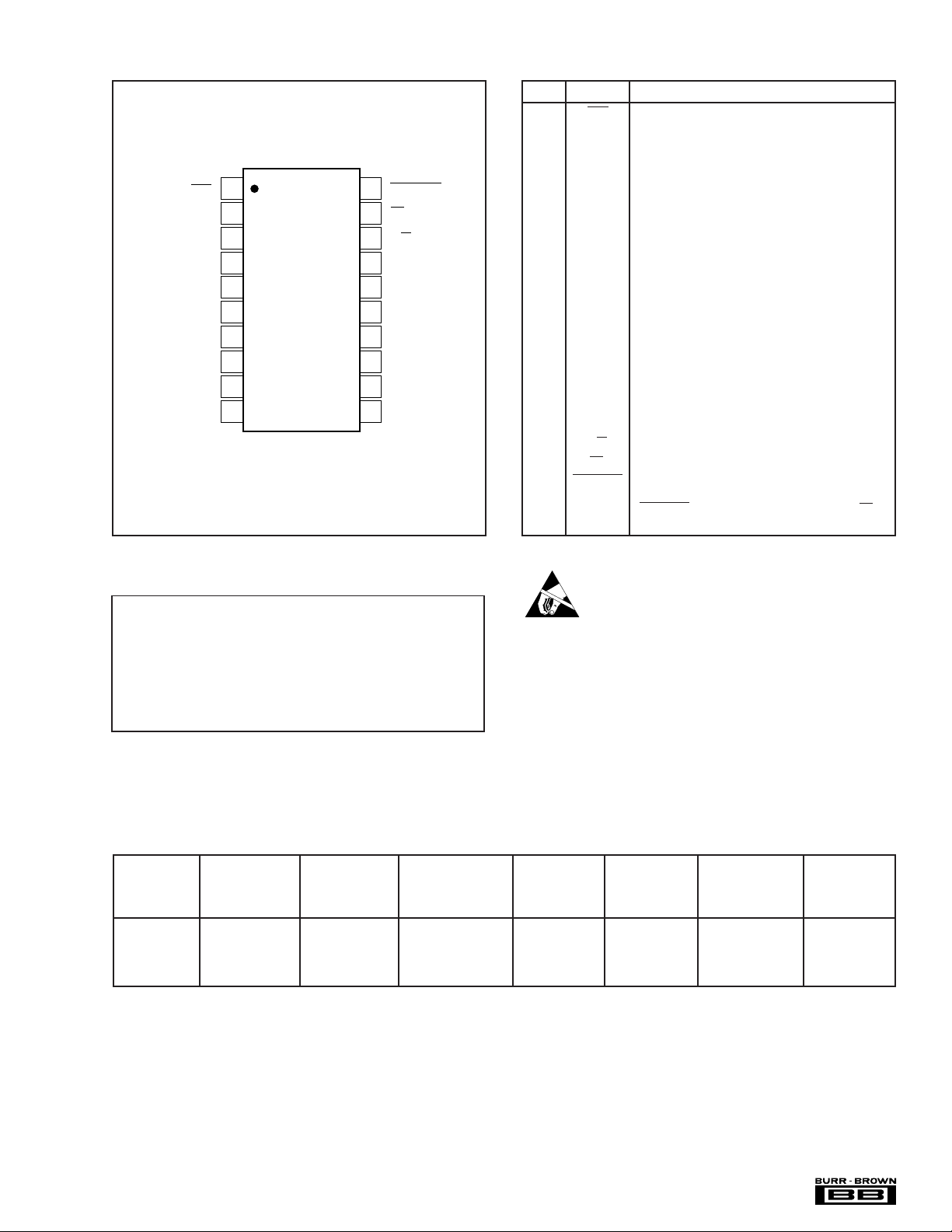

PIN CONFIGURATION

PIN DESCRIPTIONS

Top View SSOP

CLR

V

V

OUT

AGND

DGND

DB11 (MSB)

DB10

DB9

DB8

DB7

1

2

DD

3

4

5

DAC7621E

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

LOADDAC

CS

R/W

DB0 (LSB)

DB1

DB2

DB3

DB4

DB5

DB6

PIN LABEL DESCRIPTION

1 CLR Reset. Resets the DAC register to zero. Active

2V

3V

4 AGND Analog Ground

5 DGND Digital Ground

6 DB11 Data Bit 11, MSB

7 DB10 Data Bit 10

8 DB9 Data Bit 9

9 DB8 Data Bit 8

10 DB7 Data Bit 7

11 DB6 Data Bit 6

12 DB5 Data Bit 5

13 DB4 Data Bit 4

14 DB3 Data Bit 3

15 DB2 Data Bit 2

16 DB1 Data Bit 1

17 DB0 Data Bit 0, LSB

18 R/W Read and Write Control

19 CS Chip Select. Active LOW.

20 LOADDAC Loads the internal DAC register. The DAC register

LOW. Asynchronous input.

Postive Power Supply

DD

DAC Output Voltage

OUT

is a transparent latch and is transparent when

LOADDAC is LOW (regardless of the state of CS or

CLK).

ABSOLUTE MAXIMUM RATINGS

VDD to GND .......................................................................... –0.3V to 6V

Digital Inputs to GND .............................................. –0.3V to V

to GND ........................................................... –0.3V to VDD + 0.3V

V

OUT

Power Dissipation ........................................................................ 325mW

Thermal Resistance,

Maximum Junction Temperature.................................................. +150°C

Operating Temperature Range ...................................... –40°C to +85°C

Storage Temperature Range ....................................... –65°C to +150°C

Lead Temperature (soldering, 10s) .............................................. +300°C

NOTE: (1) Stresses above those listed under “Absolute Maximum Ratings”

may cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability.

θ

........................................................... 150°C/W

JA

(1)

+ 0.3V

DD

ELECTROSTA TIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

PACKAGE/ORDERING INFORMATION

MINIMUM

RELATIVE DIFFERENTIAL SPECIFICATION PACKAGE

PRODUCT (LSB) (LSB) RANGE PACKAGE NUMBER

ACCURACY NONLINEARITY TEMPERATURE DRAWING ORDERING TRANSPORT

DAC7621E ±2 ±1 –40°C to +85°C 20-Lead SSOP 334 DAC7621E Rails

"" " " ""DAC7621E/1K Tape and Reel

DAC7621EB ±1 ±1 –40°C to +85°C 20-Lead SSOP 334 DAC7621EB Rails

"" " " ""DAC7621EB/1K Tape and Reel

NOTES: (1) For detailed drawing and dimension table, please see end of data sheet, or Appendix C of Burr-Brown IC Data Book. (2) Models with a slash (/) are

available only in Tape and Reel in the quantities indicated (e.g., /1K indicates 1000 devices per reel). Ordering 1000 pieces of “DAC7621E/1K” will get a single

1000-piece Tape and Reel. For detailed Tape and Reel mechanical information, refer to Appendix B of Burr-Brown IC Data Book.

(1)

NUMBER

(2)

MEDIA

3 DAC7621

®

Page 4

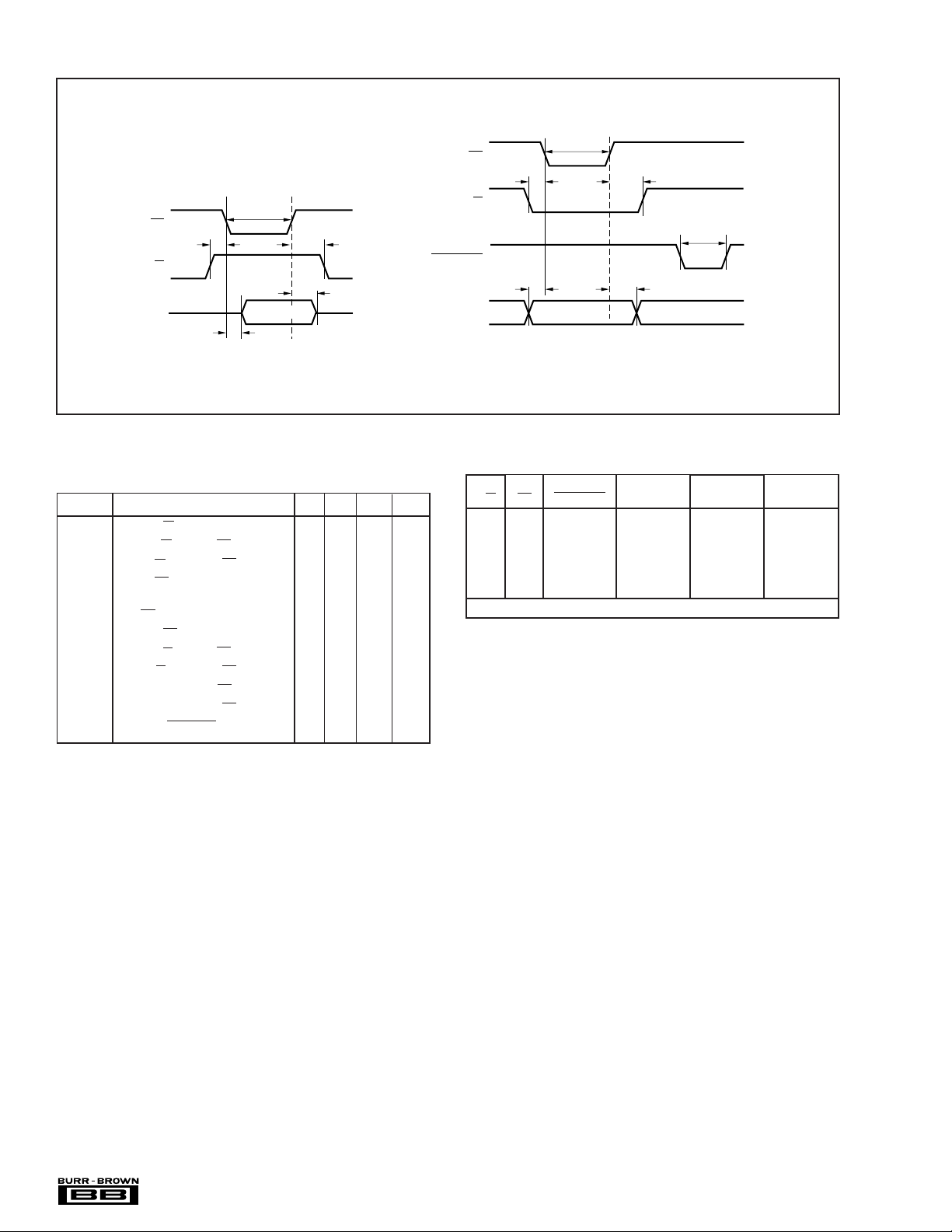

TIMING DIAGRAMS

CS

t

RDS

R/W

Data Out

t

RCS

Data Valid

t

CSD

t

t

RDH

DZ

CS

R/W

LOADDAC

Data In

t

WCS

t

WS

t

DS

t

WH

t

LWD

t

DH

Data Output Timing

TIMING SPECIFICATIONS

TA = –40°C to +85°C

SYMBOL

t

RCS

t

RDS

t

RDH

t

DZ

t

CSD

t

WCS

t

WS

t

WH

t

DS

t

DH

t

LWD

DESCRIPTION MIN TYP MAX UNITS

CS LOW for Read 200 ns

R/W HIGH to CS LOW 10 ns

R/W HIGH after CS HIGH 0 ns

CS HIGH to Data Bus 100 ns

in High Impedance

CS LOW to Data Bus Valid 100 160 ns

CS LOW for Write 50

R/W LOW to CS LOW 0 ns

R/W LOW after CS HIGH 5 ns

Data Valid to CS LOW 0 ns

Data Valid after CS HIGH 5 ns

LOADDAC LOW 50 ns

Digital Input Timing

LOGIC TRUTH TABLE

INPUT DAC

R/W CS LOADDAC REGISTER REGISTER MODE

L L L Write Write Write

L L H Write Hold Write Input

H L H Read Hold Read Input

X H L Hold Update Update

X H H Hold Hold Hold

X = Don’t Care.

®

DAC7621

4

Page 5

TYPICAL PERFORMANCE CURVES

1k

100

10

1

0.1

0.01

PULL-DOWN VOLTAGE vs OUTPUT SINK CURRENT

Delta V

OUT

(mV)

Current (mA)

0.001 0.01 0.1 1 10 100

85°C (mV)

–40°C

Data = 000

H

25°C

5.0

4.8

4.6

4.4

4.2

4.0

MINIMUM SUPPLY VOLTAGE vs LOAD

V

DD

Minimum (V)

Output Load Current (mA)

0.010 0.100 1.000 10.000

∆VFS = 1 LSB

Data = FFF

H

At TA = +25°, and VDD = 5V, unless otherwise specified.

4.5

OUTPUT SWING vs LOAD

4.0

3.5

3.0

2.5

2.0

1.5

Output Voltage (V)

1.0

0.5

0

10 100 1k 10k 100k

Load Resistance (Ω)

BROADBAND NOISE

Noise Voltage (1mV/div)

Code = FFF

BW = 2MHz

H

Time (2µs/div)

4.0

SUPPLY CURRENT vs LOGIC INPUT VOLTAGE

3.5

3.0

2.5

2.0

1.5

Supply Current (mA)

1.0

0.5

0

5 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5

Logic Voltage (V)

70

POWER SUPPLY REJECTION vs FREQUENCY

60

50

40

30

PSR (dB)

20

10

0

10 100 1k 10k 100k 1M

Frequency (Hz)

Data = FFF

VDD = 5V

H

±200mV AC

®

5 DAC7621

Page 6

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°, and VDD = 5V, unless otherwise specified.

SHORT-CIRCUIT CURRENT vs OUTPUT VOLTAGE

80

60

40

20

Positive

Current

Limit

Data = 800

Output tied to I

0

–20

Output Current (mA)

–40

–60

Negative

Current

Limit

–80

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Output Voltage (V)

MID-SCALE GLITCH PERFORMANCE

LOADDAC

(2mV/div)

OUT

V

SOURCE

V

OUT

4.0

SUPPLY CURRENT vs TEMPERATURE

V

= 3.5V

LOGIC

3.5

Data = FFF

No Load

3.0

H

2.5

H

2.0

1.5

Supply Current (mA)

1.0

0.5

VDD = 5.25V

VDD = 5.0V

VDD = 4.75V

0

–40 –30 –20 –10 0 10 20 30 40 50 60 70 80 90

Temperature (°C)

MID-SCALE GLITCH PERFORMANCE

LOADDAC

V

(2mV/div)

OUT

V

OUT

1V/div

7FFH to 800

Time (500ns/div)

LARGE-SIGNAL SETTLING TIME

CL = 110pF

R

LD

Time (20µs/div)

= No Load

L

V

OUT

800

H

H to

7FFH

Time (500ns/div)

RISE TIME DETAIL

LD

V

OUT

Output Voltage (1mV/div)

Time (10µs/div)

®

DAC7621

6

Page 7

TYPICAL PERFORMANCE CURVES (CONT)

0

10

20

30

40

50

60

–12

–8 –4 0 4 8 12

T.U.E = ΣINL = ZS + FS

Sample Size = 300 Units

T

A

= +25°C

Number of Units

TOTAL UNADJUSTED ERROR HISTOGRAM

3

2

1

0

–1

ZERO-SCALE VOLTAGE vs TEMPERATURE

Zero-Scale (mV)

Temperature (°C)

–50 0 25–25 50 75 100 125

At TA = +25°, and VDD = 5V, unless otherwise specified.

FALL TIME DETAIL

Output Voltage (1mV/div)

Time (10µs/div)

LONG-TERM DRIFT ACCELERATED BY BURN-IN

8

6

4

2

0

–2

–4

Output Voltage Change (mV)

–6

–8

0 400200 600 800 1000 1200

Hours of Operation at +150°C

144 Units

10.000

1.000

V

OUT

0.100

LD

min

avg

max

Noise (µV/√Hz)

0.010

OUTPUT VOLTAGE NOISE vs FREQUENCY

Data = FFF

10 100 1k 10k 100k

Frequency (Hz)

H

4.115

4.110

4.105

4.100

4.095

4.090

Full-Scale Output (V)

4.085

4.080

4.075

FULL-SCALE VOLTAGE vs TEMPERATURE

Avg + 3σ

Avg

Avg – 3σ

–50 0 25–25 50 75 100 125

Temperature (°C)

No Load

Sample Size = 300

®

7 DAC7621

Page 8

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°, and VDD = 5V, unless otherwise specified.

LINEARITY ERROR vs DIGITAL CODE

2.0

1.5

1.0

0.5

0

–0.5

Linearity Error (LSBs)

–1.0

–1.5

–2.0

0

512 1024 1536 2048 2560 3072 3584 4096

LINEARITY ERROR vs DIGITAL CODE

1

0.5

(at +25°C)

Code

(at +85°C)

DIFFERENTIAL LINEARITY ERROR vs DIGITAL CODE

2.0

1.5

1.0

0.5

0

–0.5

–1.0

–1.5

Differential Linearity Error (LSBs)

–2.0

0

512 1024 1536 2048 2560 3072 3584 4096

DIFFERENTIAL LINEARITY ERROR vs DIGITAL CODE

1

0.5

(at +25°C)

Code

(at +85°C)

0

Linearity Error (LSBs)

–0.5

–1.0

0

512 1024 1536 2048 2560 3072 3584 4096

LINEARITY ERROR vs DIGITAL CODE

1

0.5

0

Linearity Error (LSBs)

–0.5

–1.0

0

512 1024 1536 2048 2560 3072 3584 4096

Code

(at –40°C)

Code

0

–0.5

Differential Linearity Error (LSBs)

–1.0

0

512 1024 1536 2048 2560 3072 3584 4096

DIFFERENTIAL LINEARITY ERROR vs DIGITAL CODE

1

0.5

0

–0.5

Differential Linearity Error (LSBs)

–1.0

0

512 1024 1536 2048 2560 3072 3584 4096

Code

(at –40°C)

Code

®

DAC7621

8

Page 9

OPERATION

The DAC7621 is a 12-bit digital-to-analog converter (DAC)

complete with an input shift register, DAC register, lasertrimmed 12-bit DAC, on-board reference, and a rail-to-rail

output amplifier. Figure 1 shows the basic operation of the

DAC7621.

INTERFACE

Figure 1 shows the basic connection between a

microcontroller and the DAC7621. The interface consists of

a Read/Write (R/W), data, and a load DAC signal

(LOADDAC). In addition, a chip select (CS) input is available to enable the DAC7621 when there are multiple devices. The data format is Straight Binary. An asynchronous

clear input (CLR) is provided to simplify start-up or periodic

resets. Table I shows the relationship between input code

and output voltage.

DAC7621 Full-Scale Range = 4.095V

Least Significant Bit = 1mV

DIGITAL INPUT CODE ANALOG OUTPUT

STRAIGHT OFFSET BINARY

FFF

H

801

H

800

H

7FF

H

000

H

TABLE I. Digital Input Code and Corresponding Ideal

Analog Output.

(V) DESCRIPTION

+4.095 Full Scale

+2.049 Midscale + 1 LSB

+2.048 Midscale

+2.047 Midscale – 1 LSB

0 Zero Scale

The digital data into the DAC7621 is double-buffered. This

means that new data can be entered into the DAC without

disturbing the old data and the analog output of the converter. At some point after the data has been entered into the

serial shift register, this data can be transferred into the DAC

register. This transfer is accomplished with a HIGH to LOW

transition of the LOADDAC pin. However, the LOADDAC

pin makes the DAC register transparent. If new data becomes available on the bus register while LOADDAC is

LOW, the DAC output voltage will change as the data

changes. To prevent this, CS must be returned HIGH prior

to changing data on the bus.

At any time, the contents of the DAC register can be set to

000H (analog output equals 0V) by taking the CLR input

LOW. The DAC register will remain at this value until CLR

is returned HIGH and LOADDAC is taken LOW to allow

the contents of the input register to be transferred to the

DAC register. If LOADDAC is LOW when CLR is taken

LOW, the DAC register will be set to 000H and the analog

output driven to 0V. When CLR is returned HIGH, the DAC

register and the analog output will respond accordingly.

DIGITAL-TO-ANALOG CONVERTER

The internal DAC section is a 12-bit voltage output

device that swings between ground and the internal reference voltage. The DAC is realized by a laser-trimmed

R-2R ladder network which is switched by N-channel

MOSFETs. The DAC output is internally connected to

the rail-to-rail output operational amplifier.

Clear

+5V

10µF

+

0.1µF

0V to

+4.095V

FIGURE 1. Basic Operation of the DAC7621.

Data Bus

DAC7621E

1

CLR

2

V

3

V

4

AGND

5

DGND

6

DB11

7

DB10

8

DB9

9

DB8

10

DB7

DD

OUT

LOADDAC

CS

R/W

DB0

DB1

DB2

DB3

DB4

DB5

DB6

20

19

18

17

16

15

14

13

12

11

Load DAC

Chip Select

Read/Write

Data Bus

9 DAC7621

®

Page 10

Buffer

Bandgap

Reference

2.435V

FIGURE 2. Simplified Schematic of Analog Portion.

R-2R DAC

2R

2R

2R

2R

R

R

R

2R

R

1

Output Amplifier

R

2

OUTPUT AMPLIFIER

A precision, low-power amplifier buffers the output of the

DAC section and provides additional gain to achieve a 0V

to 4.095V range. The amplifier has low offset voltage, low

noise, and a set gain of 1.682V/V (4.095/2.435). See Figure

2 for an equivalent circuit schematic of the analog portion

of the DAC7621.

The output amplifier has a 7µs typical settling time to ±1

LSB of the final value. Note that there are differences in the

settling time for negative-going signals versus positivegoing signals.

The rail-to-rail output stage of the amplifier provides the

full-scale range of 0V to 4.095V while operating on a

supply voltage as low as 4.75V. In addition to its ability to

drive resistive loads, the amplifier will remain stable while

driving capacitive loads of up to 500pF. See Figure 3 for an

equivalent circuit schematic of the amplifier’s output driver

and the Typical Performance Curves section for more information regarding settling time, load driving capability, and

output noise.

V

DD

P-Channel

V

OUT

POWER SUPPLY

A BiCMOS process and careful design of the bipolar and

CMOS sections of the DAC7621 result in a very low power

device. Bipolar transistors are used where tight matching

and low noise are needed to achieve analog accuracy, and

CMOS transistors are used for logic, switching functions

and for other low power stages.

If power consumption is critical, it is important to keep the

logic levels on the digital inputs (R/W, CLK, CS, LOADDAC,

CLR) as close as possible to either VDD or ground. This will

keep the CMOS inputs (see “Supply Current vs Logic Input

Voltages” in the Typical Performance Curves) from shunting current between VDD and ground.

The DAC7621 power supply should be bypassed as shown

in Figure 1. The bypass capacitors should be placed as close

to the device as possible, with the 0.1µF capacitor taking

priority in this regard. The “Power Supply Rejection vs

Frequency” graph in the Typical Performance Curves section shows the PSRR performance of the DAC7621. This

should be taken into account when using switching power

supplies or DC/DC converters.

In addition to offering guaranteed performance with VDD in

the 4.75V to 5.25V range, the DAC7621 will operate with

reduced performance down to 4.5V. Operation between

4.5V and 4.75V will result in longer settling time, reduced

performance, and current sourcing capability. Consult the

“VDD vs Load Current” graph in the Typical Performance

Curves section for more information.

N-Channel

AGND

FIGURE 3. Simplified Driver Section of Output Amplifier.

®

DAC7621

10

Page 11

APPLICATIONS

POWER AND GROUNDING

The DAC7621 can be used in a wide variety of situations—

from low power, battery operated systems to large-scale

industrial process control systems. In addition, some applications require better performance than others, or are particularly sensitive to one or two specific parameters. This

diversity makes it difficult to define definite rules to follow

concerning the power supply, bypassing, and grounding.

The following discussion must be considered in relation to

the desired performance and needs of the particular system.

A precision analog component requires careful layout, adequate bypassing, and a clean, well-regulated power supply.

As the DAC7621 is a single-supply, +5V component, it will

often be used in conjunction with digital logic,

microcontrollers, microprocessors, and digital signal processors. The more digital logic present in the design and the

higher the switching speed, the more difficult it will be to

achieve good performance.

The DAC7621 has separate analog ground and digital ground

pins. The current through DGND is mostly switching transients and are up to 4mA peak in amplitude. The current

through AGND is typically 0.5mA.

For best performance, separate analog and digital ground

planes with a single interconnection point to minimize

ground loops. The analog pins are located adjacent to each

other to help isolate analog from digital signals. Analog

signals should be routed as far as possible from digital

signals and should cross them at right angles. A solid analog

ground plane around the D/A package, as well as under it in

the vicinity of the analog and power supply pins, will isolate

the D/A from switching currents. It is recommended that

DGND and AGND be connected directly to the ground

planes under the package.

If several DAC7621s are used, or if sharing supplies with

other components, connecting the AGND and DGND lines

together at the power supplies once, rather than at each chip,

may produce better results.

The power applied to VDD should be well regulated and lownoise. Switching power supplies and DC/DC converters will

often have high-frequency glitches or spikes riding on the

output voltage. In addition, digital components can create

similar high frequency spikes as their internal logic switches

states. This noise can easily couple into the DAC output

voltage through various paths between VDD and V

OUT

.

As with the GND connection, VDD should be connected to

a +5V power supply plane or trace that is separate from the

connection for digital logic until they are connected at the

power entry point. In addition, the 10µF and 0.1µF capacitors shown in Figure 4 are strongly recommended and

should be installed as close to VDD and ground as possible.

In some situations, additional bypassing may be required

such as a 100µF electrolytic capacitor or even a “Pi” filter

made up of inductors and capacitors—all designed to essentially lowpass filter the +5V supply, removing the high

frequency noise (see Figure 4).

100µF

Digital Circuits

+5V

GND

+

+

10µF

Analog

Components

Other

0.1µF

DAC7621

V

DD

AGND

DGND

+5V

Power

Supply

+5V

GND

Optional

FIGURE 4. Suggested Power and Ground Connections for a DAC7621 Sharing a +5V Supply with a Digital System with a

Single Ground Plane.

11 DAC7621

®

Page 12

PACKAGE OPTION ADDENDUM

www.ti.com

16-Mar-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

DAC7621E ACTIVE SSOP DB 20 68 Green (RoHS &

no Sb/Br)

DAC7621E/1K ACTIVE SSOP DB 20 1000 Green (RoHS &

no Sb/Br)

DAC7621E/1KG4 ACTIVE SSOP DB 20 1000 Green (RoHS &

no Sb/Br)

DAC7621EB ACTIVE SSOP DB 20 68 Green (RoHS &

no Sb/Br)

DAC7621EB/1K ACTIVE SSOP DB 20 1000 Green (RoHS &

no Sb/Br)

DAC7621EB/1KG4 ACTIVE SSOP DB 20 1000 Green (RoHS &

no Sb/Br)

DAC7621EBG4 ACTIVE SSOP DB 20 68 Green (RoHS &

no Sb/Br)

DAC7621EG4 ACTIVE SSOP DB 20 68 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 13

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to

discontinue any product or service without notice. Customers should obtain the latest relevant information

before placing orders and should verify that such information is current and complete. All products are sold

subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent

TI deems necessary to support this warranty. Except where mandated by government requirements, testing

of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible

for their products and applications using TI components. To minimize the risks associated with customer

products and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent

right, copyright, mask work right, or other TI intellectual property right relating to any combination, machine,

or process in which TI products or services are used. Information published by TI regarding third-party

products or services does not constitute a license from TI to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or

other intellectual property of the third party, or a license from TI under the patents or other intellectual

property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices.

Reproduction of this information with alteration is an unfair and deceptive business practice. TI is not

responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for

that product or service voids all express and any implied warranties for the associated TI product or service

and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...