Page 1

查询DAC1221供应商

®

For most current data sheet and other product

information, visit www.burr-brown.com

16-Bit Low Power

DIGITAL-TO-ANALOG CONVERTER

FEATURES

● 16-BIT MONOTONICITY GUARANTEED

OVER –40°C TO +85°C

● LOW POWER: 1.2mW

● VOLTAGE OUTPUT

● SETTLING TIME: 2ms to 0.012%

● MAX LINEARITY ERROR: 30ppm

● ON-CHIP CALIBRATION

DAC1221

DAC1221

APPLICATIONS

● PROCESS CONTROL

● ATE PIN ELECTRONICS

● CLOSED-LOOP SERVO-CONTROL

● SMART TRANSMITTERS

● PORTABLE INSTRUMENTS

● VCO CONTROL

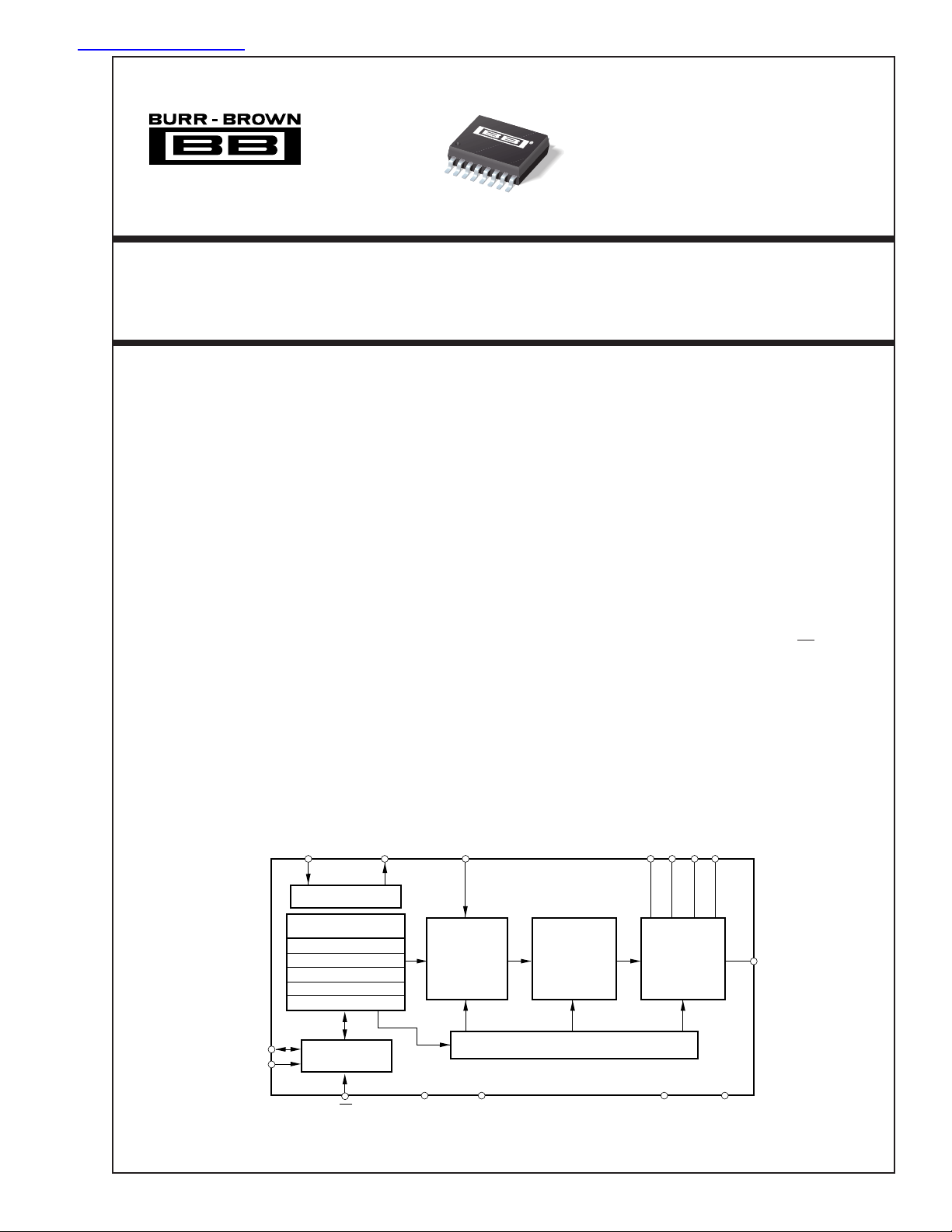

DESCRIPTION

The DAC1221 is a Digital-to-Analog (D/A) converter

offering 16-bit monotonic performance over the specified temperature range. It utilizes delta-sigma technology to achieve inherently linear performance in a

small package at very low power. The output range is

two times the external reference voltage. On-chip

calibration circuitry dramatically reduces offset and

gain errors.

X

IN

Clock Generator

Microcontroller

Instruction Register

Command Register

Data Register

Offset Register

Full-Scale Register

X

OUT

V

REF

Second-Order

∆∑

Modulator

The DAC1221 features a synchronous serial interface.

In single converter applications, the serial interface can

be accomplished with just two wires, allowing lowcost isolation. For multiple converters, a CS signal

allows for selection of the appropriate D/A converter.

The DAC1221 has been designed for closed-loop

control applications in the industrial process control

market, and high resolution applications in the test and

measurement market. It is also ideal for remote applications, battery-powered instruments, and isolated systems.

The DAC1221 is available in a SSOP-16 package.

C2AC2BC

First-Order

Switched

Capacitor Filter

C

1

Second-Order

Continuous

Time Post Filter

3

V

OUT

SDIO

SCLK

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

© 1999 Burr-Brown Corporation PDS-1519B Printed in U.S.A. May, 2000

Serial

Interface

CS DV

DGND AV

DD

Modulator Control

1

AGND

DD

DAC1221

®

Page 2

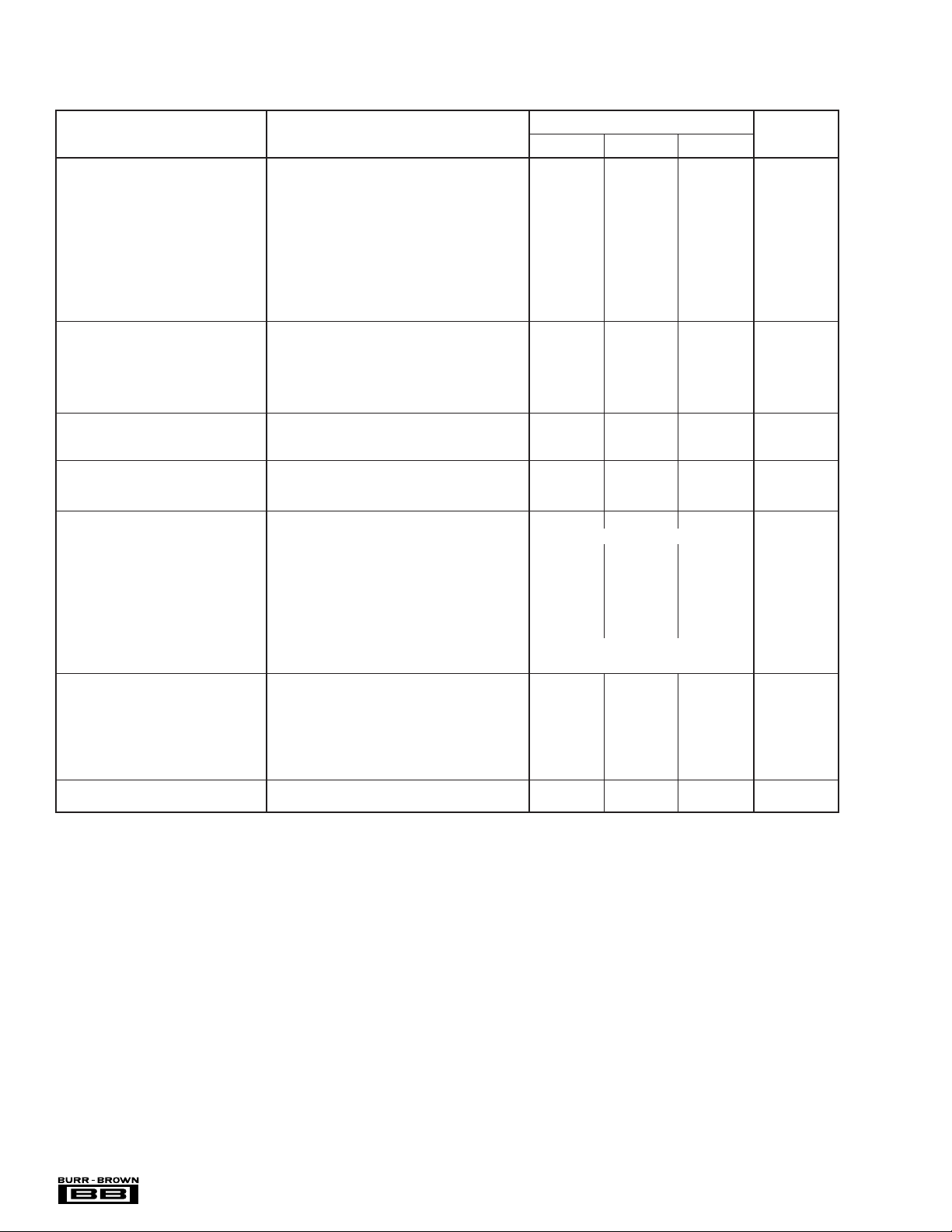

SPECIFICATIONS

All specifications T

PARAMETER CONDITIONS MIN TYP MAX UNITS

ACCURACY

Monotonicity 16 Bits

Linearity Error

Offset Error

Offset Error Drift

Midscale Error

Midscale Error Drift

Gain Error

Gain Error Drift

Power-Supply Rejection Ratio at DC, dB = –20log(∆V

to T

MIN

, AVDD = DVDD = +3V, f

MAX

= 2.5MHz, V

XIN

= +1.25V, C1 = 2.2nF, C2 = 150pF, C3 = 6.8nF, unless otherwise noted.

REF

DAC1221E

(1)

(2)

(3)

(2)

(3)

(2)

(3)

V

= 20mV, CALPIN = 1

OUT

V

= V

OUT

, CALPIN = 1

REF

CALPIN = 1

(6)

(6)

(6)

50 µV/°C

±20 µV

50 µV/°C

3 ppm/°C

/∆VDD)57dB

OUT

±30 ppm of FSR

±190 µV

0.015 %

ANALOG OUTPUT

Output Voltage

Output Current

(4)

(1)

0 2 • V

±0.25 mA

REF

Capacitive Load 500 pF

Short-Circuit Current ±10 mA

Short-Circuit Duration GND or V

DYNAMIC PERFORMANCE

Settling Time

(1,5)

To ±0.012% 1.8 2 ms

DD

Indefinite

Output-Noise Voltage 1Hz to 2kHz 45 µVrms

REFERENCE INPUT

Input Voltage 1.125 1.25 1.375 V

Input Impedance 1MΩ

DIGITAL INPUT/OUTPUT

Logic Family TTL-Compatible CMOS

Logic Levels (all except X

V

IH

V

IL

V

OH

V

OL

Input-Leakage Current ±10 µA

Frequency Range (f

X

IN

Data Format User Programmable Offset Two’s Complement

)

IN

2.0 DVDD + 0.3 V

–0.3 0.8 V

IOH = –0.8mA 2.4 V

IOL = 1.6mA 0.4 V

) 1.0 2.5 MHz

XIN

or Straight Binary

POWER SUPPLY REQUIREMENTS

Power-Supply Voltage 2.7 3.3 V

Supply Current

Analog Current 320 µA

Digital Current 70 µA

Power Dissipation Normal Mode 1.2 1.6 mW

Sleep Mode 0.25 mW

TEMPERATURE RANGE

Specified Performance –40 +85 °C

NOTES: (1) Valid from AGND + 20mV to 2 • V

low-pass filter with 2kHz corner frequency. (6) See Command Register for description of CALPIN.

. (2) Applies after calibration. (3) Recalibration can remove these errors. (4) Ideal output voltage. (5) Using external

REF

V

®

DAC1221

2

Page 3

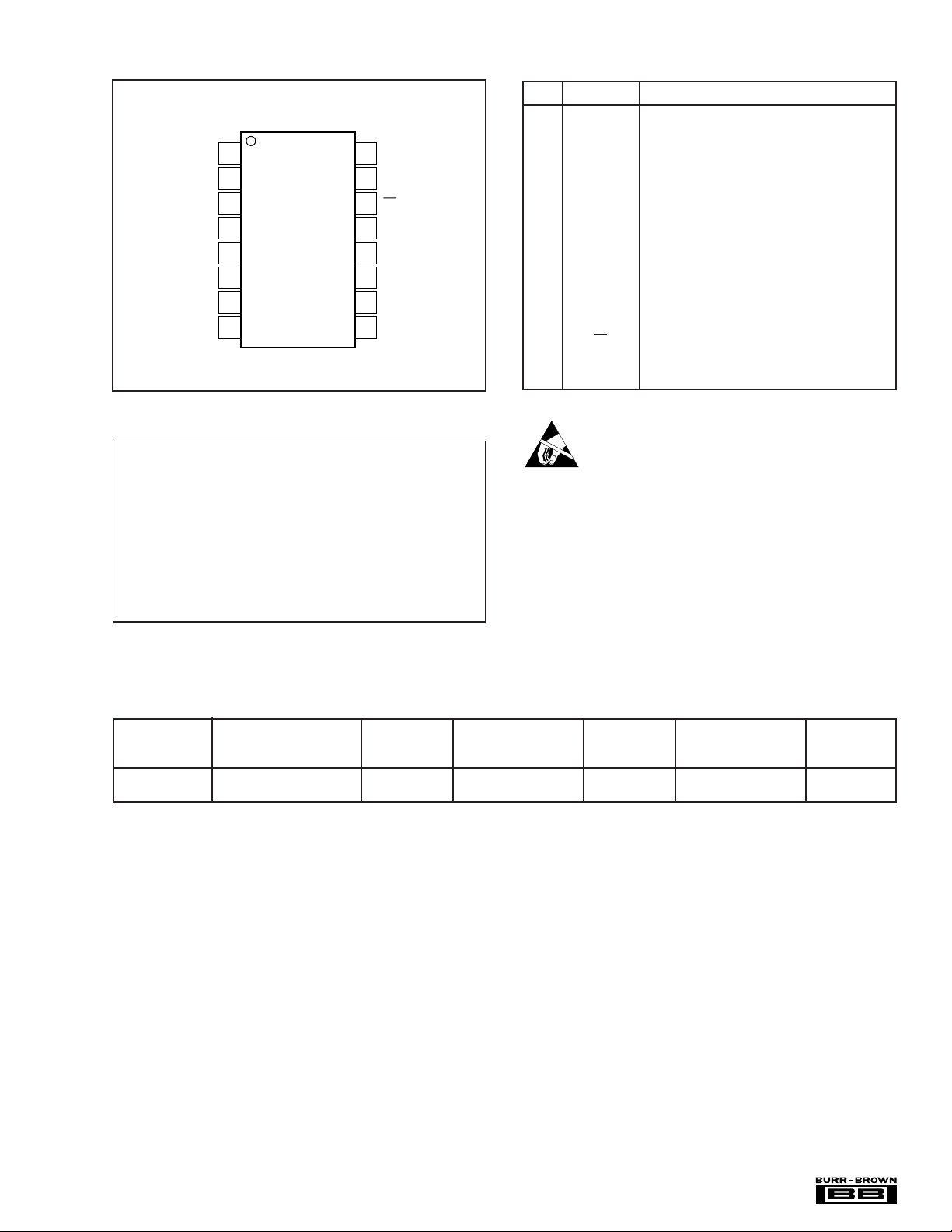

PIN CONFIGURATION

PIN DESCRIPTIONS

Top View SSOP

DV

1

DD

X

2

OUT

X

3

IN

4

DGND

AV

DNC

C

DD

C

3

2B

DAC1221E

5

6

7

8

ABSOLUTE MAXIMUM RATINGS

AV

to DVDD................................................................................... ±0.3V

DD

to AGND ........................................................................ –0.3V to 4V

AV

DD

to DGND ....................................................................... –0.3V to 4V

DV

DD

AGND to DGND ............................................................................... ±0.3V

Voltage to AGND .......................................................... 1.0V to 1.5V

V

REF

Digital Input Voltage to DGND .............................. –0.3V to DV

Digital Output Voltage to DGND ........................... –0.3V to DV

Package Power Dissipation ............................................. (T

Maximum Junction Temperature (T

Thermal Resistance,

SSOP-16............................................................................... 200°C/W

θ

JA

) ..................................... +150°C

JMAX

SCLK

16

SDIO

15

CS

14

AGND

13

V

12

REF

11

V

OUT

10

C

2A

9

C

1

(1)

+ 0.3V

DD

+ 0.3V

DD

– TA)/

JMAX

θ

JA

Lead Temperature (soldering, 10s) ............................................... +300°C

NOTE: (1) Stresses above those listed under “Absolute Maximum Ratings”

may cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability.

PIN NAME DESCRIPTION

1DV

2X

3X

OUT

IN

Digital Supply, +3V nominal

DD

Digital, System Clock Output

Digital, System Clock Input

4 DGND Digital Ground

5AV

Analog Supply, +3V nominal

DD

6 DNC Do Not Connect

7C

8C

2B

9C

10 C

11 V

12 V

2A

OUT

REF

Analog, Filter Capacitor

3

Analog, Filter Capacitor

Analog, Filter Capacitor

1

Analog, Filter Capacitor

Analog Output Voltage

Analog, Reference Input

13 AGND Analog Ground

14 CS Digital, Chip Select Input

15 SDIO Digital, Serial Data Input/Output

16 SCLK Digital, Clock Input for Serial Data Transfer

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation

to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric

changes could cause the device not to meet its published

specifications.

PACKAGE/ORDERING INFORMATION

PACKAGE SPECIFIED

PRODUCT PACKAGE NUMBER RANGE MARKING NUMBER

DRAWING TEMPERATURE PACKAGE ORDERING TRANSPORT

DAC1221E SSOP-16 322 –40°C to +85°C DAC1221E DAC1221E Rails

" " " " " DAC1221E/2K5 Tape and Reel

NOTE: (1) Models with a slash (/) are available only in Tape and Reel in the quantities indicated (e.g., /2K5 indicates 2500 devices per reel). Ordering 2500 pieces

of “DAC1221E/2K5” will get a single 2500-piece Tape and Reel.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

(1)

MEDIA

®

3

DAC1221

Page 4

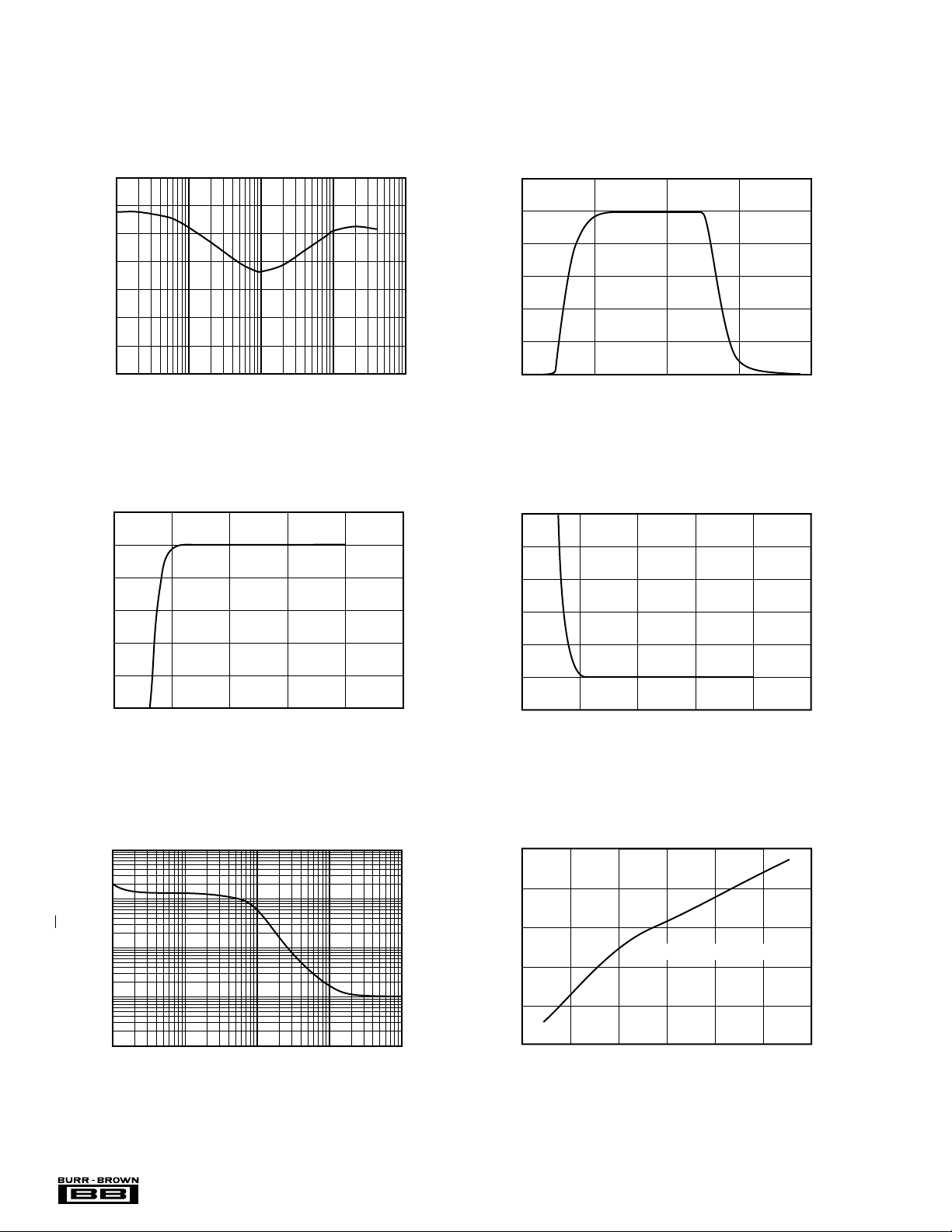

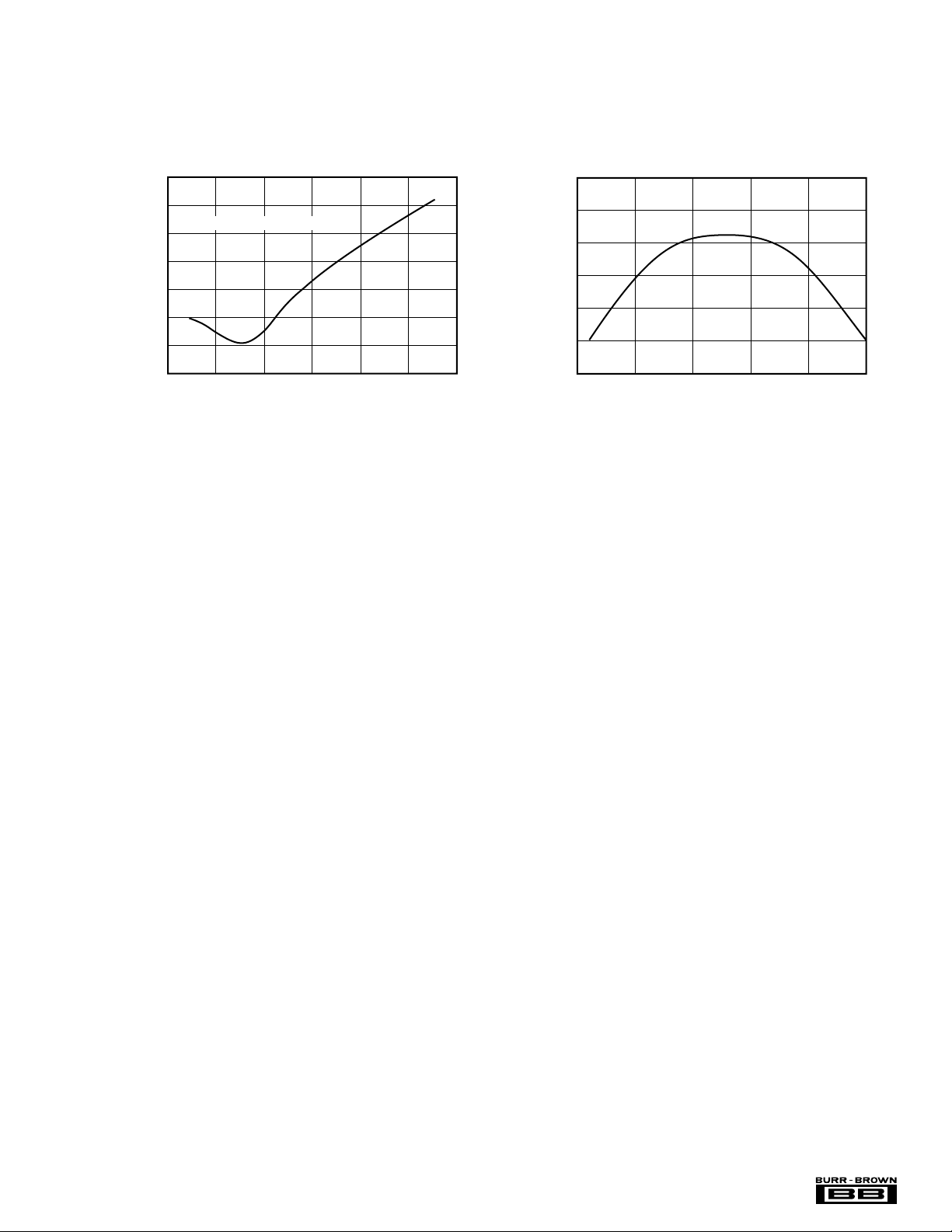

TYPICAL PERFORMANCE CURVES

FULL SCALE OUTPUT SWING

Time (ms)

01234

Output (V)

3.0

2.5

2.0

1.5

1.0

0.5

0

At TA = +25°C, AVDD = DVDD = +3.0V, f

POWER SUPPLY REJECTION RATIO vs FREQUENCY

70

60

50

40

30

PSRR (dB)

20

10

0

10 100 1000 10000 100000

Frequency (Hz)

SETTLING TIME: 20mV to FS

300

0

= 2.5MHz, V

XIN

= 1.25V, C1 = 2.2nF, C2 = 150pF and C3 = 6.8nF.

REF

1500

1200

SETTLING TIME: FS to 20mV

–300

–600

–900

∆ Around FS (µV)

–1200

–1500

0246810

Time (ms)

10000

1000

100

Noise (nv/√Hz)

10

1

OUTPUT NOISE VOLTAGE vs FREQUENCY

10 100 1000 10000 10000

Frequency (Hz)

900

600

300

∆ Around 20mV (µV)

0

–300

0246810

Time (ms)

4

2

0

–2

Offset (mV)

–4

–6

OFFSET vs TEMPERATURE

(can be corrected with calibration)

–25 25 75–50 0 50 100

Temperature (°C)

®

DAC1221

4

Page 5

LINEARITY ERROR vs CODE

16-Bit Input Code Normalized

0

0.2 0.4 0.6 0.8 1

Linearity Error (ppm of FSR)

25

20

15

10

5

0

–5

TYPICAL PERFORMANCE CURVES

At TA = +25°C, AVDD = DVDD = +3.0V, f

0.020

0.015

0.010

0.005

0.000

Gain Error (%)

–0.005

–0.010

–0.015

–50 –25

GAIN ERROR vs TEMPERATURE

(can be corrected with calibration)

0507525 100

Temperature (°C)

= 2.5MHz, V

XIN

= 1.25V, C1 = 2.2nF, C2 = 150pF and C3 = 6.8nF.

REF

®

5

DAC1221

Page 6

THEORY OF OPERATION

V

REF

C

2A

C

1

C

3

C

2B

12

11

10

9

7

8

DAC1221

C

3

6.8nF

C

1

2.2nF

C

2

150pF

NOTE: C1 and C2 should be NPO type capacitors.

ANALOG OPERATION

The DAC1221 is a precision, high dynamic range, selfcalibrating, 16-bit, delta-sigma digital-to-analog converter.

It contains a second-order delta-sigma modulator, a firstorder switched-capacitor filter, a second-order continuoustime post filter, a microcontroller including the Instruction,

Command and Calibration registers, a serial interface, and a

clock generator circuit.

The design topology provides low system noise and good

power-supply rejection. The modulator frequency of the

delta-sigma D/A converter is controlled by the system clock.

The DAC1221 also includes complete onboard calibration

that can correct for internal offset and gain errors.

The calibration registers are fully readable and writable.

This feature allows for system calibration. The various

settings, modes, and registers of the DAC1221 are read or

written via a synchronous serial interface. This interface

operates as an externally clocked interface.

DEFINITION OF TERMS

Differential Nonlinearity Error—The differential

nonlinearity error is the difference between an actual step

width and the ideal value of 1 LSB. If the step width is

exactly 1 LSB, the differential nonlinearity error is zero.

A differential nonlinearity specification of less than 1 LSB

guarantees monotonicity.

Drift—The drift is the change in a parameter over temperature.

Full-Scale Range (FSR)—This is the magnitude of the

typical analog output voltage range which is 2 • V

For example, when the converter is configured with a 1.25V

reference, the full-scale range is 2.5V.

Gain Error—This error represents the difference in the

slope between the actual and ideal transfer functions.

Linearity Error—The linearity error is the deviation of the

actual transfer function from an ideal straight line between

the data end points.

Least Significant Bit (LSB) Weight—This is the ideal

change in voltage that the analog output will change with a

change in the digital input code of 1 LSB.

Monotonicity—Monotonicity assures that the analog output

will increase or stay the same for increasing digital input

codes.

Offset Error—The offset error is the difference between the

expected and actual output, when the output is zero. The

value is calculated from measurements made when

V

= 20mV.

OUT

Settling Time—The settling time is the time it takes the

output to settle to its new value after the digital code has

been changed.

f

—The frequency of the crystal oscillator or CMOS-

XIN

compatible input signal at the XIN input of the DAC1221.

REF

The system clock is divided down to provide the sample

clock for the modulator. The sample clock is used by the

modulator to convert the multi-bit digital input into a 1-bit

digital output stream. The use of a 1-bit DAC provides

inherent linearity. The digital output stream is then converted into an analog signal via the 1-bit DAC and then

filtered by the 1st-order switched-capacitor filter.

The output of the switched-capacitor filter feeds into the

continuous time filter. The continuous time filter uses external capacitors, C1 and C2, to adjust the settling time. The

connections for capacitors are shown in Figure 1. C1 connects to V

connected between C3 and V

. C2 connects between the C2 pins. C3 is

REF

, and is used for calibration.

REF

.

FIGURE 1. Capacitor Connections.

CALIBRATION

The DAC1221 offers a self-calibration mode which automatically calibrates the output offset and gain. The calibration is performed once and then normal operation is resumed. In general, calibration is recommended immediately

after power-on and whenever there is a “significant” change

in the operating environment. The amount of change which

should cause re-calibration is dependent on the application.

Where high accuracy is important, re-calibration should be

done on changes in temperature and power supply.

After a calibration has been accomplished, the Offset Calibration Register (OCR) and the Full-Scale Calibration Register (FCR) contain the results of the calibration.

Note that the values in the calibration registers will vary

from configuration to configuration and from part to part.

®

DAC1221

6

Page 7

Self Calibration

A self-calibration is performed after the bits “01” have been

written to the Command Register Operation Mode bits

(MD1 and MD0). This initiates a self-calibration on the next

clock cycle. The offset correction code is determined by a

repeated sequence of auto-zeroing the calibration comparator to the offset reference and then comparing the DAC

output to the offset reference value. The end result is the

averaged, Offset Two’s Complement adjusted, and placed in

the OCR. The gain correction is done in a similar fashion,

except the correction is done against V

to eliminate

REF

common-mode errors. The FCR result represents the gain

code and is not Offset Two’s Complement adjusted.

The calibration function takes between 300ms and 500ms

(for f

= 2.5MHz) to complete. Once calibration is initi-

XIN

ated, further writing of register bits is disabled until calibration completes. The status of calibration can be verified by

reading the status of the Command Register Operation Mode

bits (MD1 and MD0). These bits will return to normal mode

“00” when calibration is complete.

It is recommended that the output be connected during

calibration. The output isolation is controlled by the CALPIN

bit in the CMR register. Setting the CALPIN bit will connect

the output and clearing the bit will disconnect and isolate the

output. Although it is recommended to connect the output

during calibration, the load impedance should be such that

the DAC1221 is not required to sink any current, but is able

to source up to the specified maximum.

Output Mode

The output of the DAC1221 can be synchronously reset.

By setting the CLR bit in the CMR, the data input register

is cleared to zero. This will result in an output of 0V when

DF = 1, or V

when DF = 0.

REF

The settling time is determined by the DISF and ADPT bits

of the command register. The default state of DISF = 0 and

ADPT = 0 enables fast settling, unless the output step is

small (≈ 40mV). However, the DAC1221 can be forced to

always use fast settling if the ADPT bit is set to 1. If DISF

is set to 1, all fast settling is disabled.

The CRST bit of the CMR can be used to reset the offset and

calibration registers. By setting the CRST bit, the contents of

the calibration registers are reset to 0.

REFERENCE INPUT

The reference input voltage of 1.25V can be directly connected to V

REF

pin.

The recommended reference circuit for the DAC1221 is

shown in Figure 2.

DIGITAL OPERATION

SYSTEM CONFIGURATION

The DAC1221 is controlled by 8-bit instruction codes (INSR)

and 16-bit command codes (CMR) via the serial interface,

which is externally clocked.

The DAC1221 Microcontroller (MC) consists of an ALU

and a register bank. The MC has three states: power-on

reset, calibration, and normal operation. In the power-on

reset state, the MC resets all the registers to their default

states. In the calibration state, the MC performs offset and

gain self-calibration. In the normal state, the MC performs

D/A conversions.

The DAC1221 has five internal registers, as shown in Table I.

Two of these, the Instruction Register (INSR) and the

Command Register (CMR), control the operation of the

converter. The Instruction Register utilizes an 8-bit instruction code to control the serial interface to determine whether

the next operation is either a read or a write, to control the

word length, and to select the appropriate register to

read/write. Communication with the DAC1221 is controlled

via the INSR. Under normal operation, the INSR is written

as the first part of each serial communication. The instruction that is sent determines what type of communication will

occur next. It is not possible to read the INSR. The Command Register has a 16-bit command code to set up the

INSR Instruction Register 8 Bits

DIR Data Input Register 16 Bits

CMR Command Register 16 Bits

OCR Offset Calibration Register 24 Bits

FCR Full-Scale Calibration Register 24 Bits

TABLE I. DAC1221 Registers.

7

2

31

4

+3V

0.10µF

OPA336

100Ω

6

+

10µF 0.1µF

To V

REF

Pin

+3V

87.6kΩ

20kΩ

REF1004-1.2

+

10µF 0.10µF

FIGURE 2. Recommended External Voltage Reference Circuit for Best Low Noise Operation with the DAC1221.

7

DAC1221

®

Page 8

DAC1221 operation mode, settling mode and data format.

The Data Input Register (DIR) contains the value for the

next conversion. The Offset and Full-Scale Calibration Registers (OCR and FCR) contain data used for correcting the

internal conversion value after it is placed into the DIR. The

data in these two registers may be the result of a calibration

routine, or they may be values which have been written

directly via the serial interface.

INSTRUCTION REGISTER (INSR)

Each serial communication starts with the 8 bits of INSR

being sent to the DAC1221. The read/write bit, the number

of bytes (n), and the starting register address are defined in

Table II. When the n bytes have been transferred, the

instruction is complete. A new communication cycle is

initiated by sending a new INSR (under restrictions outlined

in the Interfacing section).

MSB LSB

R/W MB1 MB0 0 A3 A3 A1 A0

NOTE: INSR is a write-only register with the MSB (Most Significant Byte and

Bit) written first, independent of the BD bit.

TABLE II. Instruction Register.

R/W (Read/Write) Bit—For a write operation to occur, this

bit of the INSR must be 0. For a read, this bit must be 1, as

shown:

R/W

0 Write

1 Read

MB1, MB0 (Multiple Bytes) Bits—These two bits are used

to control the word length (number of bytes) of the read or

write operation, as shown:

or the write operation for the CMR register. If the next

location is reserved in Table III, the results are unknown.

Reading or writing continues until the number of bytes

specified by MB1 and MB0 have been transferred.

A3 A2 A1 A0

0 0 0 0 Data Input Register Byte 1 MSB

0 0 0 1 Data Input Register Byte 0 LSB

0 0 1 0 Reserved

0 0 1 1 Reserved

0 1 0 0 Command Register Byte 1 MSB

0 1 0 1 Command Register Byte 0 LSB

0 1 1 0 Reserved

0 1 1 1 Reserved

1 0 0 0 Offset Cal Register Byte 2 MSB

1 0 0 1 Offset Cal Register Byte 1

1 0 1 0 Offset Cal Register Byte 0 LSB

1 0 1 1 Reserved

1 1 0 0 Full-Scale Cal Register Byte 2 MSB

1 1 0 1 Full-Scale Cal Register Byte 1

1 1 1 0 Full-Scale Cal Register Byte 0 LSB

1 1 1 1 Reserved

TABLE III. A3 - A0 Addressing.

COMMAND REGISTER (CMR)

The CMR controls all of the functionality of the DAC1221.

The new configuration is latched in on the negative transition of SCLK for the last bit of the last byte of data being

written to the command register. The organization of the

CMR is comprised of 16 bits of information in 2 bytes of 8

bits each.

MSB Byte 1

ADPT CALPIN 1 0 1

Byte 0 LSB

0 CLR DF DISF BD MSB MD1 MD0

0

CRST 0

TABLE IV. Command Register.

MB1 MB0

0 0 1 Byte

0 1 2 Bytes

1 0 3 Bytes

A3 – A0 (Address) Bits—These four bits select the beginning register location that will be read from or written to, as

shown in Table III. Each subsequent byte will be read from

or written to the next higher location (increment address). If

the BD bit in the Command register is set, each subsequent

byte will be read from or written to the next lower location

(decrement address). This bit does not affect INSR register

®

DAC1221

ADPT (Adaptive Filter Disable) Bit—The ADPT bit determines if the adaptive filter is enabled or disabled. When

the Adaptive Filter is enabled, the DAC1221 does fast

settling only when there is an output step of larger than

≈ 40mV. For small changes in the data, fast settling is not

necessary. When ADPT = 1, the Adaptive Filter is disabled

and the DAC1221 will not look at the size of a step to

determine the necessity of using fast settling. In either case,

fast settling can be defeated if DISF = 1.

ADPT

0 Enabled (default)

1 Disabled

8

Page 9

CALPIN (Calibration Pin) Bit—

The CALPIN bit deter-

mines if the output is isolated or connected during calibration.

CALPIN

0 Output Isolated (default)

1 Output Connected

CRST (Calibration Reset) Bit—The CRST bit resets the

offset and full-scale calibration registers, as shown:

Care must be observed in reading the Command Register if

the state of the BD bit is unknown. If a two byte read is

started at address 0100 with BD = 0, it will read 0100, then

0101. However, if BD = 1, it will read 0100, then 0011. If

the BD bit is unknown, all reads of the command register are

best performed as read commands of one byte.

MSB (Bit Order) Bit—The MSB bit controls the order in

which bits within a byte of data are read or written (either

most significant bit first or least significant bit first), as

follows:

CRST

0 OFF (default)

1 Reset

CLR (Clear) Bit—The CLR bit synchronously resets the

data input register to zero. The analog output will be based

on the DF bit—if 1, the output will be 0V; if 0, the output

will be V

REF

.

DF (Data Format) Bit—The DF bit controls the format of

the input data, shown in hexadecimal (either Offset Two’s

Complement or Straight Binary), as shown:

Input Code

Offset Two's Straight

Complement Binary V

DF = 0 DF = 1

(default)

8000 0000 0

0000 8000 V

7FFF FFFF 2 • V

OUT

REF

REF

DISF (Disable Fast Settling) Bit—The DISF bit disables

the fast settling option. If this bit is zero the fast settling

performance is determined by the ADPT bit.

DISF

0 Fast Settling (default)

1 Disable Fast Settling

BD (Byte Order) Bit—The BD bit controls the order in

which bytes of data are transferred (either most significant

byte first (MSBF) or least significant byte first (LSBF)), as

shown:

BD bit: 0 (default) 1 0 (default) 1

register

INSR write only write only MSBF MSBF

CMR MSBF LSBF MSBF MSBF

DIR MSBF LSBF MSBF LSBF

OCR MSBF LSBF MSBF LSBF

FCR MSBF LSBF MSBF LSBF

read write

MSB

0 MSB First (default)

1 LSB First

MD1 – MD0 (Operating Mode) Bits—The Operating

Mode bits control the calibration functions of the DAC1221.

The Normal Mode is used to perform conversions. The SelfCalibration Mode is a one-step calibration sequence that

calibrates both the offset and full scale.

MD1 MD0

0 0 Normal Mode

0 1 Self-Cal

1 0 Sleep (default)

1 1 Reserved

Offset Calibration Register (OCR)

The OCR is a 24-bit register containing the offset correction

factor that is used to apply a correction to the digital input

before it is transferred to the modulator. The results of the

self-calibration process will be written to this register.

The OCR is both readable and writable via the serial interface. For applications requiring a more accurate calibration,

a calibration can be performed, the results averaged, and a

more precise offset calibration value written back to the

OCR.

The actual OCR value will change from part to part and with

configuration, temperature, and power supply.

In addition, be aware that the contents of the OCR are not

used to directly correct the digital input. Rather, the correction is a function of the OCR value. This function is linear

and two known points can be used as a basis for interpolating intermediate values for the OCR.

The results of calibration are averaged, Offset Two's Complement adjusted, and placed in the OCR.

MSB Byte 2

OCR23 OCR22 OCR21 OCR20 OCR19 OCR18 OCR17 OCR16

Byte 1

OCR15 OCR14 OCR13 OCR12 OCR11 OCR10 OCR9 OCR8

Byte 0

OCR7 OCR6 OCR5 OCR4 OCR3 OCR2 OCR1 OCR0

LSB

TABLE V. Offset Calibration Register.

9

®

DAC1221

Page 10

Full-Scale Calibration Register (FCR)

The FCR is a 24-bit register which contains the full-scale

correction factor that is applied to the digital input before it

is transferred to the modulator. The contents of this register

will be the result of a self-calibration, or written to by the

user.

The FCR is both readable and writable via the serial interface. For applications requiring a more accurate calibration,

a calibration can be performed, the results averaged, and a

more precise value written back to the FCR.

The actual FCR value will change from part to part and with

configuration, temperature, and power supply.

In addition, be aware that the contents of the FCR are not

used to directly correct the digital input. Rather, the correction is a function of the FCR value. This function is linear

and two known points can be used as a basis of interpolating

intermediate values for the FCR. The contents of the FCR

are in unsigned binary format. This is not affected by the DF

bit in the Command Register.

MSB Byte 2

FCR23 FCR22 FCR21 FCR20 FCR19 FCR18 FCR17 FCR16

Byte 1

FCR15 FCR14 FCR13 FCR12 FCR11 FCR10 FCR9 FCR8

Byte 0 LSB

FCR7 FCR6 FCR5 FCR4 FCR3 FCR2 FCR1 FCR0

TABLE VI. Full-Scale Calibration Register.

Data Input Register (DIR)

The DIR is a 16-bit register which contains the digital input

value (see Table VII). The register is latched on the falling

edge of the last bit of the last byte sent. The contents of the

DIR are then loaded into the modulator. This means that the

DIR register can be updated after sending 1 or 2 bytes, which

is determined by the MB1 and MB0 bits in the Instruction

Register. The contents of the DIR can be Offset Two’s

Complement or Straight Binary.

MSB Byte 1

DIR15 DIR14 DIR13 DIR12 DIR11 DIR10 DIR9 DIR8

Byte 0 LSB

DIR7 DIR6 DIR5 DIR4 DIR3 DIR2 DIR1 DIR0

TABLE VII. Data Input Register.

SLEEP MODE

The Sleep Mode is entered after the bit combination 10 has

been written to the CMR Operation Mode bits (MD1 and

MD0). This mode ends when these bits are changed to a

value other than 10.

Communication with the DAC1221 can continue during

Sleep Mode. When a new mode (other than Sleep) has been

entered, the DAC1221 will execute a very brief internal

power-up sequence of the analog and digital circuitry. In

addition, the settling of the external V

and other circuitry

REF

must be taken into account to determine the amount of time

required to resume normal operation.

Once serial communication is resumed, the Sleep Mode is

exited by changing the MD1 - MD0 bits to any other mode.

When a new mode (other than Sleep) has been entered, the

DAC1221 will execute a very brief internal power-up sequence of the analog and digital circuitry. In addition, the

settling of the external V

and other circuitry must be

REF

taken into account to determine the amount of time required

to resume normal operation.

SERIAL INTERFACE

The DAC1221 includes a flexible serial interface which can

be connected to microcontrollers and digital signal processors in a variety of ways. Along with this flexibility, there is

also a good deal of complexity. This section describes the

trade-offs between the different types of interfacing methods

in a top-down approach—starting with the overall flow and

control of serial data, moving to specific interface examples,

and then providing information on various issues related to

the serial interface.

Reset, Power-On Reset and Brown-Out

The DAC1221 contains an internal power-on reset circuit. If

the power supply ramp rate is greater than 50mV/ms, this

circuit will be adequate to ensure the device powers up

correctly. Due to oscillator settling considerations, communication to and from the DAC1221 should not occur for at

least 25ms after power is stable.

If this requirement cannot be met or if the circuit has brownout considerations, the timing diagram of Figure 3 can be

used to reset the DAC1221. This accomplishes the reset by

controlling the duty cycle of the SCLK input.

Sleep mode is the default state after power on or reset. The

output is high impedance during sleep mode.

®

DAC1221

10

Page 11

I/O Recovery

If serial communication stops during an instruction or data

transfer for longer than 100ms (for f

= 2.5MHz), the

XIN

DAC1221 will reset its serial interface. This will not affect

the internal registers. The main controller must not continue

the transfer after this event, but must restart the transfer from

the beginning. This feature is very useful if the main controller can be reset at any point. After reset, simply wait 200ms

(for f

= 2.5MHz) before starting serial communication.

XIN

Isolation

The serial interface of the DAC1221 provides for simple

isolation methods. An example of an isolated two-wire

interface is shown in Figure 4.

Using CS

The serial interface may make use of the CS signal, or this

input may simply be tied LOW. There are several issues

associated with choosing to do one or the other. The CS

signal does not directly control the tri-state condition of the

SDIO output. These signals are normally in the tri-state

condition. They only become active when serial data is

being transmitted from the DAC1221. If the DAC1221 is in

the middle of a serial transfer and the SDIO is an output,

taking CS HIGH will not tri-state the output signal.

If there are multiple serial peripherals utilizing the same

serial I/O lines and communication may occur with any

peripheral at any time, the CS signal must be used. The CS

signal is then used to enable communication with the

DAC1221.

TIMING

The maximum serial clock frequency cannot exceed the

DAC1221 XIN frequency divided by 10. Table VIII and

Figures 5 through 9 define the basic digital timing characteristics of the DAC1221. Figure 5 and the associated timing

symbols apply to the XIN input signal. Figures 6 through 9

and associated timing symbols apply to the serial interface

signals (SCLK, SDIO, and CS). The serial interface is

discussed in detail in the Serial Interface section.

t

2

SCLK

t

1

FIGURE 3. Resetting the DAC1221.

DV

DD

C

1X

5.6pF

XTAL

C

2X

5.6pF

AV

DD

t1: > 512 • t

Reset On

C

2

Falling Edge

C

1

Isolated

Power

Opto

Coupler

Opto

Coupler

t

2

t

3

DAC1221

DV

1

DD

2

X

OUT

3

X

IN

4

DGND

5

AV

DD

6

DNC

7

C

3

8

C

2B

SCLK

SDIO

CS

AGND

V

REF

V

OUT

C

2A

C

1

t

4

16

15

14

13

12

11

10

9

C

3

t2: > 10 • t

t3: > 1024 • t

t4: ≥ 2048 • t

V

REF

< 800 • t

< 1800 • t

< 2400 • t

XIN

XIN

XIN

XIN

XIN

XIN

XIN

P1.1

P1.0

8051

= Isolated

= DGND

= AGND

FIGURE 4. Isolation for Two-Wire Interface.

11

®

DAC1221

Page 12

SYMBOL DESCRIPTION MIN NOM MAX UNITS

f

XIN

t

XIN

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

14

t

15

SDIO as Output to Rising Edge of First SCLK for Register Data 4 • t

Falling Edge of Last SCLK for Register Data to SDIO Tri-State 4 • t

Data In Valid to SCLK Falling Edge (Setup) 40 ns

SCLK Falling Edge to Data In Not Valid (Hold) 20 ns

Data Out Valid After Rising Edge of SCLK (Hold) 0 ns

SCLK Rising Edge to New Data Out Valid (Delay)

Falling Edge of Last SCLK for INSR to Rising Edge of First 13 • t

Falling Edge of CS to Rising Edge of SCLK 11 • t

Falling Edge of Last SCLK for INSR to SDIO as Output 8 • t

Falling Edge of Last SCLK for Register Data to Rising Edge 41 • t

of First SCLK of next INSR (CS Tied LOW)

Rising Edge of CS to Falling Edge of CS (Using CS) 22 • t

XIN Clock Frequency 1 2.5 MHz

XIN Clock Period 400 1000 ns

XIN Clock High 0.4 • t

XIN Clock LOW 0.4 • t

SCLK HIGH 5 • t

SCLK LOW 5 • t

(1)

SCLK for Register Data ns

XIN

XIN

XIN

XIN

XIN

XIN

XIN

XIN

XIN

XIN

XIN

50 ns

10 • t

XIN

6 • t

XIN

NOTE: (1) With 10pF load.

TABLE VIII. Digital Timing Characteristics.

t

3

t

XIN

t

t

1

2

X

IN

SCLK

SDIO

t

4

t

5

t

t

6

7

t

8

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

FIGURE 5. XIN Clock Timing. FIGURE 6. Serial Input/Output Timing.

SCLK

SDIO

SDIO

t

9

Write Register Data

Read Register Data

t

14

FIGURE 7. Serial Interface Timing (CS always LOW).

CS

SCLK

SDIO

SDIO

t

10

t

9

Write Register Data

Read Register Data

IN7IN0IN1INMIN1 IN0IN7

IN7OUT0OUT1OUTMIN1 IN0IN7

t

15

t

10

IN7IN0IN1IN0IN1IN7 INM

IN7OUT0OUT1IN0IN1IN7 OUTM

FIGURE 8. Serial Interface Timing (using CS).

®

DAC1221

12

Page 13

CS

t

SCLK

SDIO

10

IN7

SDIO is an input SDIO is an output

FIGURE 9. SDIO Input to Output Transition Timing.

IN0

t

t

11

12

t

13

OUT MSB OUT0

t

9

Start

Writing

CS

state

LOW

External device

generates 8

serial clock cycles

and transmits

instruction register

data via SDIO

External device

generates n

serial clock cycles

and transmits

specified

register data

via SDIO

More

instructions?

From Read

flowchart

CS taken HIGH

for t

periods

15

minimum

(or CS tied LOW)

HIGH

CS

state

LOW

Yes No

Is next

instruction

a read?

HIGH

Start

Reading

CS

state

HIGH

LOW

External device

generates 8 serial

clock cycles and

transmits instruction

register data

via SDIO

SDIO input to

output transition

External device

generates n serial

clock cycles and

receives specified

register data via SDIO

SDIO transitions to

tri-state condition

To Write

flowchart

CS taken HIGH

for t

periods

15

minimum

(or CS tied LOW)

CS

state

LOW

HIGH

No

End

Yes

To Read

flowchart

FIGURE 10. Flowchart for Writing and Reading Register Data.

13

More

instructions?

No

End

Yes No

Is next

instruction

a Write?

Yes

To Write

flowchart

DAC1221

®

Page 14

LAYOUT

POWER SUPPLIES

The DAC1221 requires the digital supply (DVDD) to be no

greater than the analog supply (AVDD) +0.3V. In the majority

of systems, this means that the analog supply must come up

first, followed by the digital supply and V

observe this condition could cause permanent damage to the

DAC1221.

Inputs to the DAC1221, such as SDIO or V

be present before the analog and digital supplies are on.

Violating this condition could cause latch-up. If these signals are present before the supplies are on, series resistors

should be used to limit the input current.

The best scheme is to power the analog section of the design

and AVDD of the DAC1221 from one +3V supply, and the

digital section (and DVDD) from a separate +3V supply. The

analog supply should come up first. This will ensure that

SCLK, SDIO, CS and V

do not exceed AVDD, that the

REF

digital inputs are present only after AVDD has been established, and that they do not exceed DVDD.

The analog supply should be well regulated and low noise.

For designs requiring very high resolution from the DAC1221,

power supply rejection will be a concern. See the “PSRR vs

Frequency” curve in the Typical Performance Curves section of this data sheet for more information.

The requirements for the digital supply are not as strict.

However, high frequency noise on DVDD can capacitively

couple into the analog portion of the DAC1221. This noise

can originate from switching power supplies, very fast

microprocessors, or digital signal processors.

If one supply must be used to power the DAC1221, the

AVDD supply should be used to power DVDD. This connection can be made via a 10Ω resistor which, along with the

decoupling capacitors, will provide some filtering between

DVDD and AVDD. In some systems, a direct connection can

be made. Experimentation may be the best way to determine

the appropriate connection between AVDD and DVDD.

. Failure to

REF

, should not

REF

GROUNDING

The analog and digital sections of the design should be

carefully and cleanly partitioned. Each section should have

its own ground plane with no overlap between them. AGND

should be connected to the analog ground plane, as well as

all other analog grounds. DGND should be connected to the

digital ground plane, and all digital signals referenced to this

plane.

The DAC1221 pinout is such that the converter is cleanly

separated into an analog and digital portion. This should

allow simple layout of the analog and digital sections of the

design.

For a single converter system, AGND and DGND of the

DAC1221 should be connected together, underneath the

converter. Do not join the ground planes. Instead, connect

the two with a moderate signal trace. For multiple converters, connect the two ground planes at one location, as central

to all of the converters as possible. In some cases, experimentation may be required to find the best point to connect

the two planes together. The printed circuit board can be

designed to provide different analog/digital ground connections via short jumpers. The initial prototype can be used to

establish which connection works best.

DECOUPLING

Good decoupling practices should be used for the DAC1221

and for all components in the design. All decoupling capacitors, and specifically the 0.1µF ceramic capacitors, should

be placed as close as possible to the pin being decoupled. A

1µF to 10µF capacitor, in parallel with a 0.1µF ceramic

capacitor, should be used to decouple AVDD to AGND. At a

minimum, a 0.1µF ceramic capacitor should be used to

decouple DVDD to DGND, as well as for the digital supply

on each digital component.

®

DAC1221

14

Loading...

Loading...