Burndy YAV, YAV box Catalog Page

B-21

BURNDY

®

Small Terminals

US: 1-800-346-4175 www.burndy.com Canada: 1-800-387-6487

Blue highlighted items are industry standard and most frequently ordered.

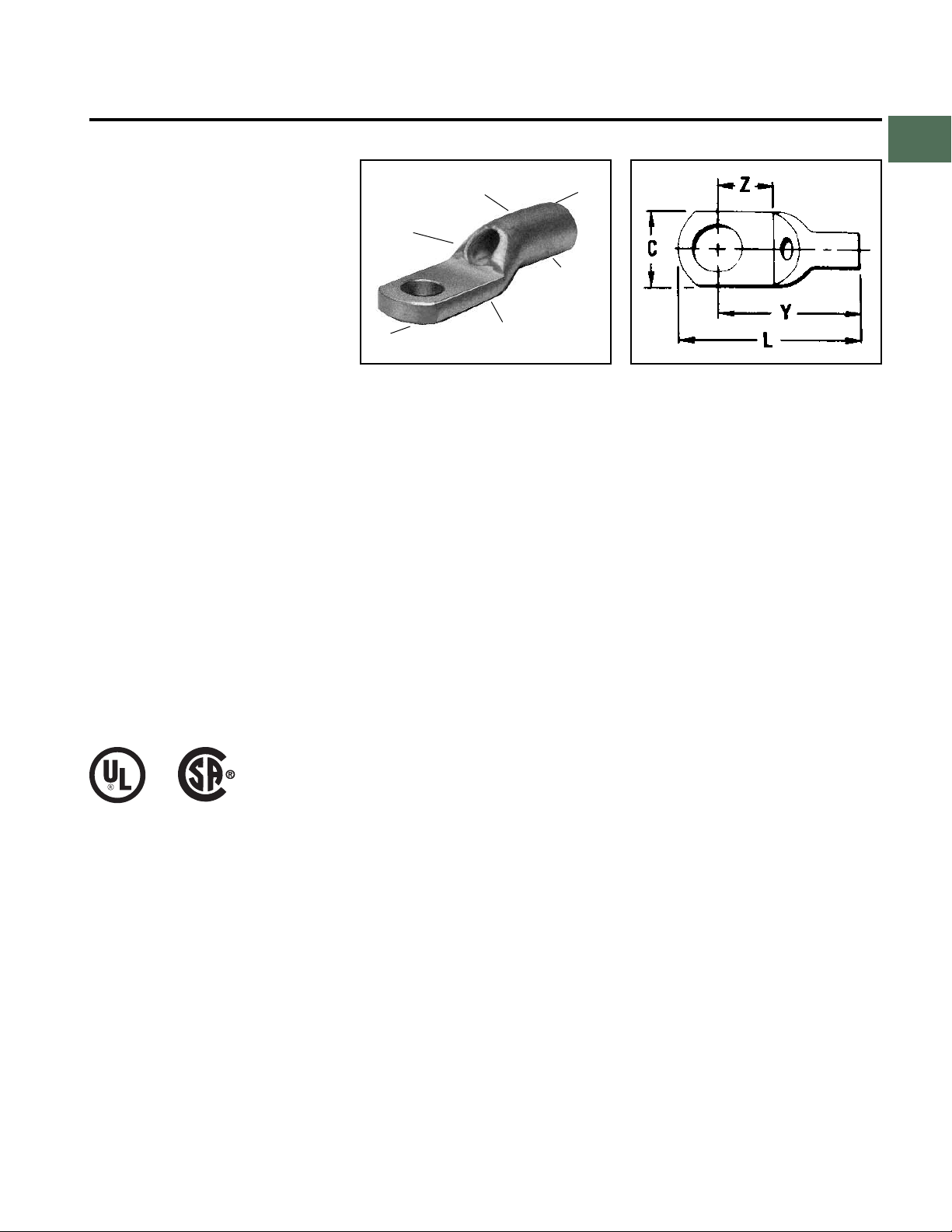

SEAMLESS

BARREL

ELECTRO-TIN

PLATED

DOUBLE THICK

TONGUE

CRIMP

INSPECTION

HOLE

BEVELED

ENTRY

(See table on following page for specifications)

TYPES YAV BOX

AND YAV

HYLUG™

Seamless Uninsulated

Compression Heavy Duty

Ring Tongue Terminal

#22-10 Stranded and Solid

Copper

HYLUG™ type YAV is a seamless,

heavy duty uninsulated com pres sion

ring tongue terminal manufactured from

pure electrolytic copper tubing and is

for use on copper commercial (code)

cable, type AN aircraft cable and extra

flexible conductors. Because of its

seamless design, the YAV HYLUG™

also accommodates solid conductors.

The seamless tubing produces a double

thick tongue and a strong connector for

demanding applications that require

high reliability. Applications include

industrials, hospitals, electric utilities,

air craft, shipboard and marine, com puters, steel mills, mining equip ment

and other equipment that is subject to

vibration or requiring dependable elec trical performance.

The YAV-HYLUG™ terminals meet the

requirements of SAE-AS7928.

Features and Benefits

• Manufactured from seamless pure

electrolytic copper tubing.

〫 Provides maximum conductivity,

low resistance and excellent ductility

for crimping.

• Seamless tubular crimp barrel design.

〫 No seams to split resulting in a very

high quality electrical connection. Also

can be used on solid conductor.

• Double thick tongue.

〫 Provides a very strong terminal tongue.

• Produced from tubular copper.

〫 Extra copper material assures the com-

pression connector will operate cooler

than the conductors it connects.

• Internally bevelled barrel.

〫 Provides easy cable entry, especially

for flexible conductors.

• Inspection hole.

〫 Provides easy visual check for proper

conductor insertion.

• Electro-tin plated.

〫 Provides long lasting durable corrosion

resistance.

• Nickel plating available, add “NK” suffix.”

〫 Nickel plated HYLUGs™ provide high

temperature applications up to 650° F

continuous service and 750° F intermittent service.

B-22

Small Terminals BURNDY

®

Canada: 1-800-387-6487 www.burndy.com US: 1-800-346-4175

Blue highlighted items are industry standard and most frequently ordered.

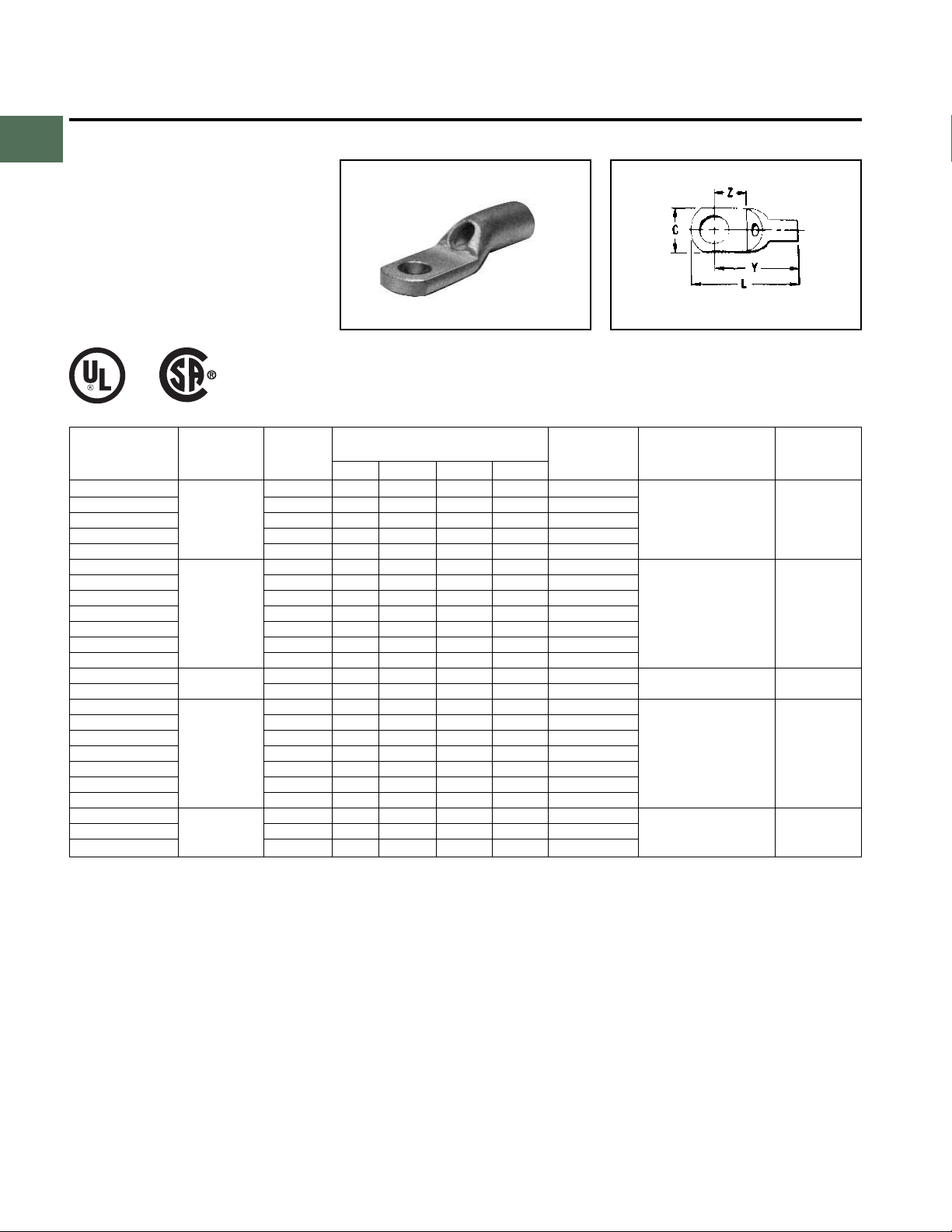

TYPES YAV BOX

AND YAV

HYLUG™

Seamless Uninsulated

Compression Heavy Duty

Ring Tongue Terminal

■ Use #14 groove

† UL Listed for 14 Str. to #10 Sol. & Str. when installed with

MR8G98 and Y8MRB-1 tools only.

* Class 1 & 2 connectors.

Bulk Wire

Catalog Wire Stud Dimensions Catalog Installation Strip

Number Range Size C L Max. Y Max. Z Min. Number Tooling Length

YAV18-T4 BOX 3, 4 .19 .62 .54 .16 YAV18-T4 Non-Ratchet:

YAV18-L33 BOX

22-18

4-6 .25 .67 .55 .18 YAV18-L33 Y10D, Y10-22

YAV18-T5 BOX

Str.

4-6 .31 .76 .61 .24 YAV18-T5 Ratchet: 9/32

YAV18-T1 BOX

and

6-8 .31 .76 .61 .24 YAV18-T1 MR8G98, MR8-9Q,

YAV18 BOX

Sol.

8-10 .31 .76 .61 .24 YAV18 Y8MRB-1, MR20

YAV14-L33 BOX 4-6 .25 .71 .59 .18 YAV14-L33

YAV14-T5 BOX 20-14 4-6 .31 .79 .64 .24 YAV14-T5 Non-Ratchet:

YAV14-T1 BOX Str. 6-8 .31 .79 .64 .24 YAV14-T1 Y10D, Y10-22

YAV14-L36 BOX 8-10 .29 .74 .59 .18 YAV14-L36 Ratchet: 9/32

YAV14 BOX 20-12 8-10 .31 .79 .64 .24 YAV14 MR8G98, MR8-9Q,

YAV14-T2 BOX Sol. 1/4 .42 .99 .75 .32 YAV14-T2 Y8MRB-1, MR20

YAV14-T3 BOX 5/16 .44 .99 .75 .32 YAV14-T3

YAV12-G2 BOX ■ 14-12 8-10 .30 .82 .67 .24 YAV12-G2 Y10D, Y8MRB-1

YAV12-G3 BOX ■ Str. 1/4 .36 1.00 .76 .34 YAV12-G3 M8ND w/N14HT

9/32

YAV10-T7 BOX 4-6 .30 .93 .78 .24 YAV10-T7 *

YAV10-T11 BOX

†14 Str.

6-8 .38 .97 .79 .26

YAV10-T11

Non-Ratchet:

YAV10-L36 BOX

12-10

8-10 .29 .86 .71 .23 YAV10-L36

Y10D, Y10-22

YAV10 BOX 8-10 .38 .97 .79 .26 YAV 10 *

Ratchet:

7/16

YAV10-T3 BOX

Str.

1/4 .47 1.10 .87 .32

YAV10-T3

MR8G98, MR8-9Q,

YAV10-T2 BOX

and

5/16 .53 1.13 .87 .31 YAV10-T2 *

Y8MRB-1, MR20,

YAV10-T4 BOX

Sol.

3/8 .56 1.18 .90 .35

YAV10-T4 *

N10HT, N10HT-24

YAV9C-L36 BOX 8-10 .31 .97 .83 .15 YAV9C-L36 Ratchet:

YAV9C-T9 BOX

10-9

1/4 .44 1.19 .95 .31

YAV9C-T9 MR8-9Q, 7/16

YAV9C-T4 BOX

Str.

5/16 .52 1.27 1.02 .36 — Y8MRB-1

Loading...

Loading...