Burndy YAES-K Catalog Page

B-19

BURNDY

®

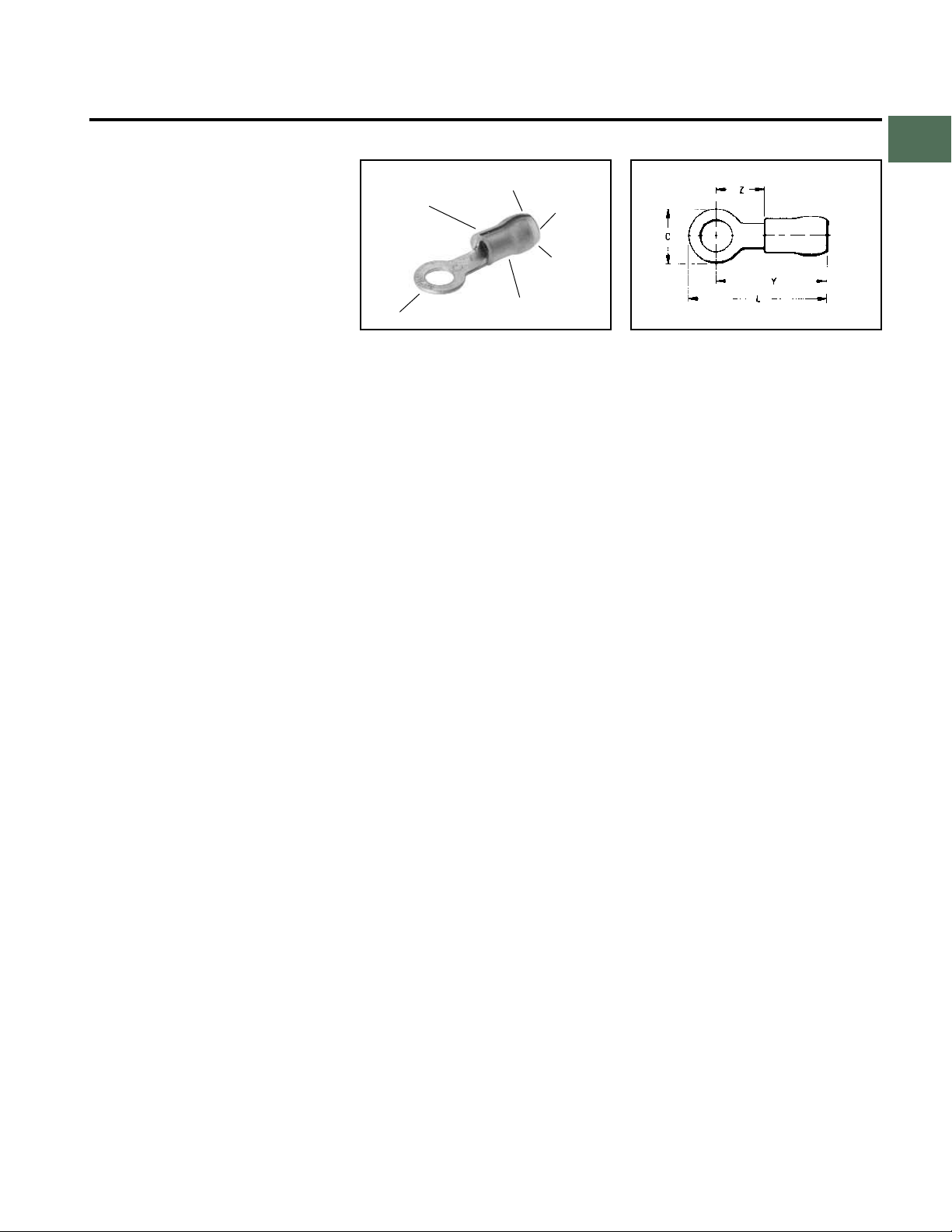

Small Terminals

Blue highlighted items are industry standard and most frequently ordered.

TYPE YAES-K

INSULUG™

NUCLEAR TERMINALS

AND SPLICES

Radiation Resistant

Insulated T

erminals,

Ring Tongue

Polyvinylidene (PVF

2) Insulated

200 Megarads, –60° through

150° C, 600 Volts

The type YAES-K, radiation resistant

KYNAR®insulated terminals are designed

and have been tested to meet the requirements for class 1E critical circuits as set by

the Nuclear Regulatory Commission (NRC).

Additional testing for compatibility under loss

of coolant accident (LOCA) conditions with

cross-link polyethylene (XLP) and

HYPALON®insulations was completed successfully. Compatibility with ethylene propylene rubber (EPR) insulation was determined

by analysis. Each terminal is manufactured of

pure electrolytic copper per QQ-C 576 and

bright tin-plated per MIL-T-10727 and meets

or exceeds SAE-AS7928 using stranded

copper AWG wire. The KYNAR®insulation

offers 200 megarad radiation resistance.

The Type YAES-K radiation resistant

KYNAR®- insulated terminals are suitable for

class 1E critical circuits and non-critical

nuclear associated applications.

Features and Benefits

• KYNAR®insulation.

〫 Provides 200 megarad radiation resist-

ance plus successfully tested for insulation compatibility.

• An integral one-piece copper barrel/insulation grip and wire strain relief

design.

〫 Provides improved physical strength

characteristics over a multi-piece

design.

• The KYNAR®insulation is locked in place.

〫 The insulation will not move or twist

off, thereby maintains proper dielectric

values.

• Manufactured from pure electrolytic

copper.

〫 Provides maximum conductivity, low

resistance and ductility for excellent

crimp forming properties.

• Bright tin-plated per MIL-T-10727.

〫 Provides durable long-lasting resistance

to corrosion.

• Deep inner barrel serrations.

〫 Provides excellent electrical conductivity

and tensile strength values.

• Brazed seam.

〫 Provides a stronger barrel design to

minimize any possible splitting and

eliminates folding.

• Smooth funnel entry.

〫 Easy wire insertion.

• Color coded terminals.

〫 Provides easy wire size identification

and inspection.

• Coded raised dots in the die area of the

connection after compression.

〫 Provides visual identification that the

correct tool and die were used for

proper installation.

• Inspection hole.

〫 Permits visual check for proper wire

insertion.

• Ring tongue design.

〫 Provides a secure termination under

screw head that cannot be removed

without the complete removal of the

screw.

• Multiple terminals may be stacked on a

common stud easily.

〫 Provides flexibility and versatility.

KYNAR - is a registered trademark of the Pennwalt Corp. for

Polyvinylindene Floride (PVF2)

HYPALON - Is a registered trademark of the E.I. DuPont

deNemours & Co., Inc.

BRAZED SEAM

ON BARREL

WIRE SIZE

INTEGRAL

SUPPORT

INSULATION

SMOOTH

FUNNEL

ENTRY

COLOR CODED

KYNAR INSULATION

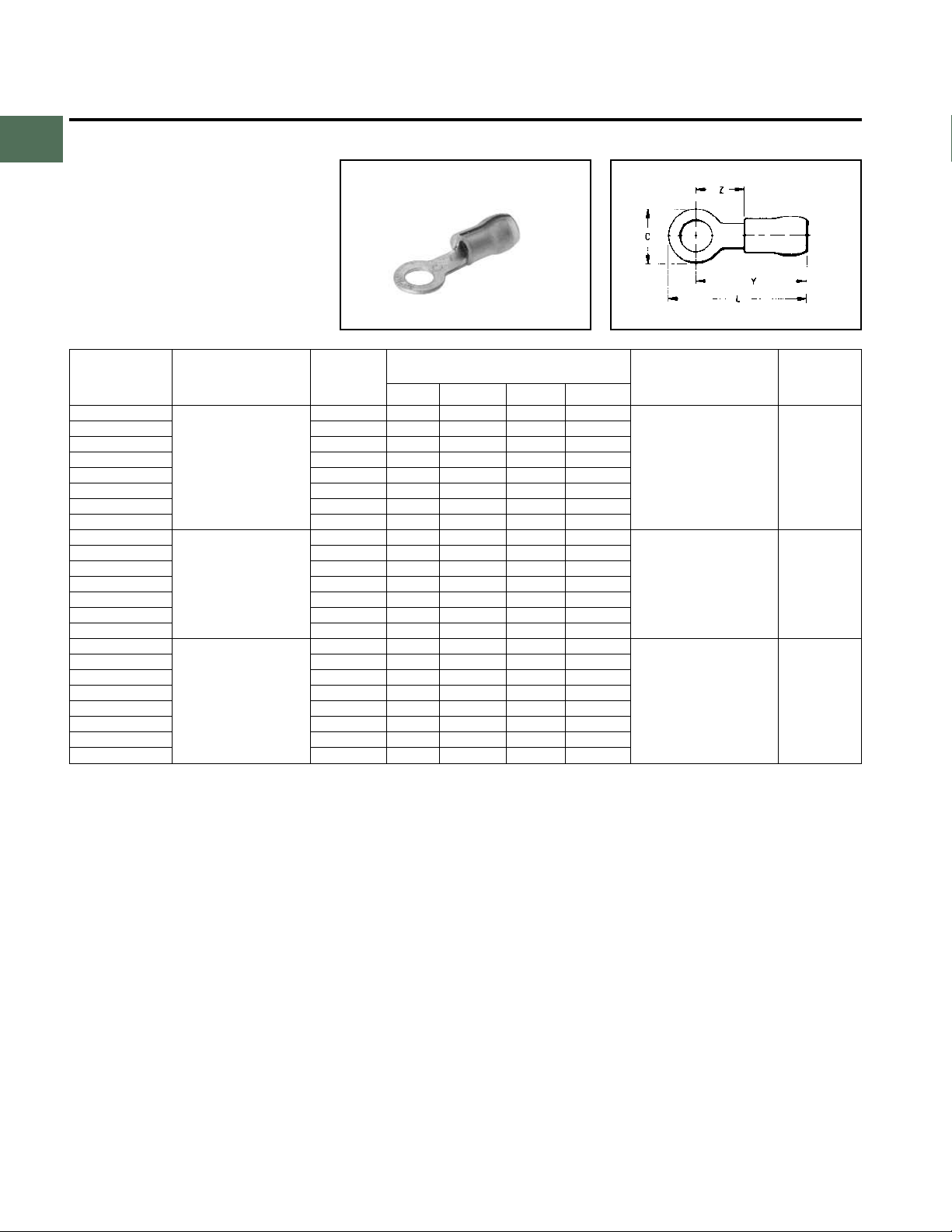

B-20

Small Terminals BURNDY

®

Blue highlighted items are industry standard and most frequently ordered.

TYPE YAES-K

(Continued)

INSULUG™

Wire

Catalog Wire Stud Dimensions Installation Strip

Number Range Size C L Max. Y Max. Z Min. Tooling Length

YAES18K48 4 .23 .76 .64 .20 Ratchet Tool:

YAES18K-1 6 .23 .76 .64 .20 MR10G6

YAES18K-2 22-18 AWG str. 6 .25 .87 .74 .29 Crimp Mark:

YAES18K-49 Max. Insul. 8 .31 .91 .76 .29 (1) Small Dot

YAES18K-3 Dia. Accom.: .120 10 .31 .91 .76 .29 Red Groove

7/32

YAES18K-50 Color Code: Red 1/4 .46 1.09 .86 .41

YAES18K-4 5/16 .46 1.09 .86 .41 Calibration Gauge:

YAES18K-5 3/8 .53 1.18 .91 .45 PG-373-1

YAES14K-6 6 .25 .77 .65 .22 Ratchet Tool:

YAES14K-7 16-14 AWG str. 6 .31 .91 .76 .29 MR10G6

YAES14K-53 Max. Insul. 8 .31 .91 .76 .29 Crimp Mark:

YAES14K-8 Dia. Accom.: .153 10 .31 .91 .76 .29 (2) Small Dots 7/32

YAES14K-54 Stock Thickness: .032 1/4 .46 1.09 .86 .41 Blue Groove

YAES14K-9 Color Code: Blue 5/16 .46 1.09 .86 .41 Calibration Gauge:

YAES14K-10 3/8 .53 1.18 .91 .45 PG-371-1

YAES10K-11 6 .38 1.12 .94 .26 Ratchet Tool:

YAES10K-11T1 6 .31 1.09 .94 .26 MR10G6

YAES10K-56

12-10 AWG str.

8 .38 1.12 .94 .26 Crimp Mark:

YAES10K-12

Max. Insul.

10 .38 1.12 .94 .26 (1) Large Dot

YAES10K-57

Dia. Accom.: .210

1/4 .53 1.32 1.06 .37

3/8

YAES10K-13

Stock Thickness: .040

5/16 .53 1.32 1.06 .37

YAES10K-14

Color Code: Yellow

3/8 .58 1.34 1.05 .40 Calibration Gauge:

YAES10K-58 1/2 .72 1.41 1.06 .45 PG-372-1

Loading...

Loading...