Page 1

Type 6213 EV, 6281 EV

2/2-way solenoid valve

Operating Instructions

Page 2

1 OPERATING INSTRUCTIONS

The operating instructions contain important information.

▶ Read the operating instructions carefully and follow the safety

instructions in particular, and also observe the operating conditions.

▶ Operating instructions must be available to each user.

▶ The liability and warranty for the device are void if the operating

instructions are not followed.

1.1 Symbols

▶ designates an instruction to prevent risks.

→ designates a procedure which you must carry out.

Warning of injuries:

DANGER!

Imminent danger. Serious or fatal injuries.

WARNING!

Potential danger. Serious or fatal injuries.

CAUTION!

Danger. Minor or moderately severe injuries.

Warns of damage to property:

NOTE!

2 INTENDED USE

Incorrect use of the solenoid valve can be dangerous to people,

nearby equipment and the environment.

▶ The device type 6213 EV / 6281 EV is designed to control, shut o

and meter neutral media up to a viscosity of 21 mm

▶ Provided the cable plug is connected and installed correctly, e.g.

Bürkert Type 2508, the device satises protection class IP65 in

accordance with DIN EN 60529 / IEC 60529.

▶ Use according to the permitted data, operating conditions and

conditions of use specied in the contract documents and operating instructions.

▶ In the case of explosion-proof devices (see rating plate or addi-

tional plate) also follow the operating instructions for the coil /

pilot control.

▶ Correct transportation, correct storage and installation and careful

use and maintenance are essential for reliable and problem-free

operation.

▶ Use the device only as intended.

2

/s.

2.1 Denition of term

In these operating instructions, the term “device” always refers to the

Type 6213EV / 6281EV.

2

english

Page 3

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• local safety regulations - the operator is responsible for observing

these regulations, also with reference to the installation personnel.

Danger - high pressure.

▶ Before loosening the pipes and valves, turn o the pressure and

vent the pipes.

Risk of electric shock.

▶ Before reaching into the device or the equipment, switch o the

power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

Risk of burns/risk of re if used for a prolonged switch-on time

through hot device surface.

▶ Keep the device away from highly ammable substances and

media and do not touch with bare hands.

Risk of injury due to malfunction of valves with alternating

current (AC).

Sticking core causes coil to overheat, resulting in a malfunction.

▶ Monitor process to ensure function is in perfect working order.

Risk of short-circuit/escape of media through leaking screw

joints.

▶ Ensure seals are seated correctly.

▶ Carefully screw valve and pipelines together.

To prevent injury, ensure that:

▶ Do not make any external modications to the housing of the

device. Ensure that the system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the power supply or uidic supply, ensure

that the process is restarted in a dened or controlled manner.

▶ Do not put any loads on the body.

▶ The general rules of technology apply to application planning

and operation of the device.

english

3

Page 4

3.1 Warranty

2 (A)

1 (P)

2 (B)

1 (P)

The warranty is only valid if the device is used as intended in accor-

dance with the specied application conditions.

3.2 Information on the internet

The operating instructions and data sheets for type 6213 EV / 6281EV

can be found on the internet at:

www.buerkert.com

Type “6213” or “6281”

4 TECHNICAL DATA

4.1 Operating conditions

The following values are indicated on the type label:

• Voltage (Tolerance ± 10 %) / Current type

• Coil power consumption

(active power in W - at operating temperature)

• Operating pressure

• Body material: Brass (MS), Stainless steel (VA)

• Seal material: FKM, EPDM, NBR

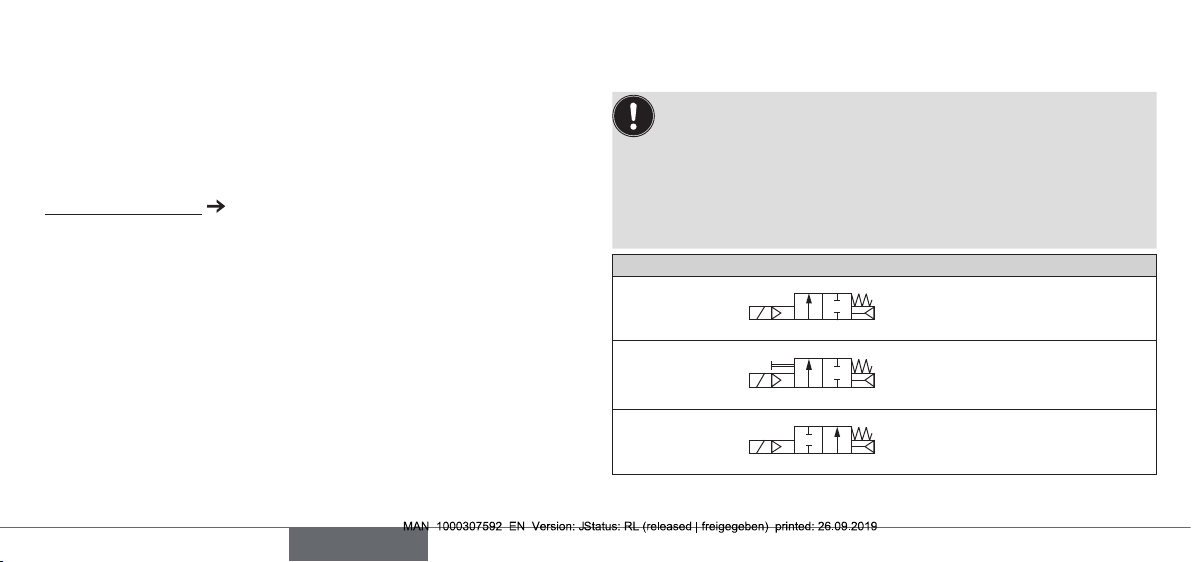

Circuit function:

A (NC)

2 (A)

A (NC)

1 (P)

2/2-way valve, normally

closed

2/2-way valve, normally

closed,

with manual override

B (NO)

2/2-way valve, normally

open

Protection class: IP65 with accordance with DIN EN 60529 / IEC

4

english

60529 with cable plug, e. g. Bürkert Type 2508

Page 5

Special instructions for valves circuit function B (NO) with

deaeration connection G1/8 on the coil (CF05/MX62):

The deenergized valve is open. The

medium also ows o via the deaeration

connection on the coil.

Valves of this design are therefore

suitable for relieving compressors only.

4.2 Application conditions

Ambient temperature: max. +55°C

Operating duration: Unless otherwise indicated on the type

label, the solenoid system is suitable for

continuous operation

Important information for functional reliability during continuous operation.

If standstill for a long period at least 1-2 activations per day

are recommended.

Service life: High switching frequency and high pres-

sures reduce the service life

Permitted medium temperature depending on coil and seal material:

Coil body

PA/EP

1)

Seal material Medium temperature

Polyamide PA FKM 0...+90°C

Epoxy EP (NA38) FKM 0...+120°C

Polyamide PA EPDM -30...+90°C

Epoxy EP (NA38) EPDM -30...+100°C

Polyamide PA NBR -10...+80°C

1) Marking PA and EP under electric connection

Permitted media depending on seal material:

Seal material Permitted media

2)

FKM Per-solutions, hot oils without additives, diesel

and heating oil without additives, detergent

solution

EPDM Oil and grease-free liquids, cold and warm

water

NBR Cold and warm water

2)

Gaseous media at low dierential pressures (e.g. compressed air and vacuum)

can also be actuated in consideration (or due to restriction) of a lower

tightness. We recommend prior clarication with our sales oce regarding

the possible application

english

5

Page 6

The following values must also be observed for valves with

6213EV A 10 EPDM MS

UL/UR approval:

Non-hazardous

uids (air and inert

gas)

Medium

temperature

-30...+120°C

-30...+100°C

(for 6213 DN40)

Ambient

temperature

-30...+55 °C

Water 0...+100°C 0...+55 °C

Fire protection

+5...+90 °C +5...+55 °C

service valve (PE48)

4.3 Conformity

In accordance with the EU Declaration of conformity, the solenoid

valve Type 6213 EV / 6281 EV is compliant with the EU Directives

(if applicable).

4.4 Standards

The applied standards, which verify conformity with the EU Directives,

can be found on the EU Type Examination Certicate and / or the EU

Declaration of Conformity (if applicable).

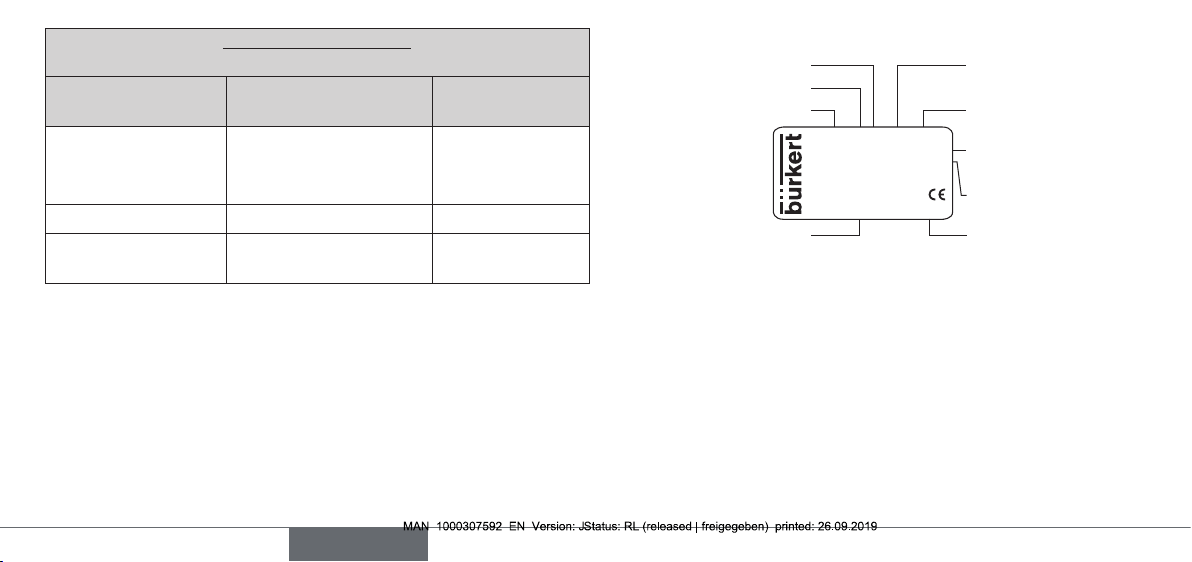

4.5 Type label (Example)

Orice Seal material

Circuit function

Typ e

G3/8 P

N0 -

10bar

W14 LU

Identication number

230V 50Hz 8W

Made in Germany

00221649

Body material

Connection thread,

operating pressure

Voltage, Frequency,

Power consumption

Manufacturer code

6

english

Page 7

5 INSTALLATION

5.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment.

▶ Before loosening the pipes and valves, turn o the pressure and

vent the pipes.

Risk of injury due to electrical shock.

▶ Before reaching into the system, switch o the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

Risk of injury from unintentional activation of the system and an

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

5.2 Before installation

Installation position: any, actuator preferably upwards.

Procedure:

→ Check pipelines for dirt and clean.

→ Install a dirt lter before the valve inlet (≤ 500 µm).

5.3 Installation

NOTE!

Caution risk of breakage.

▶ Do not use the coil as a lifting arm.

→ Hold the device with a open-end wrench on the body and screw

into the pipeline.

→ Observe direction of ow:

The arrow on the body indicates the direction of ow.

english

7

Page 8

5.4 Manual override

(optional Type 6281, Code HA15/HA17)

To control the valve manually, the hand lever under the coil must be

turned into the vertical position.

NOTE!

Caution.

▶ Do not overturn hand lever.

▶ When the hand lever is actuated, the valve can no longer be

switched electrically.

HA15

Opened position

Hand lever

HA17

Opened position

5.5 Electrical connection of the cable plug

WARNING!

Risk of injury due to electrical shock.

▶ Before reaching into the system, switch o the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock.

▶ Always connect protective conductor.

▶ Check electrical continuity between coil and body.

Procedure:

→ Tighten cable plug (for permitted types see data sheet), observing

max. torque 1 Nm.

→ Check that seal is tted correctly.

→ Connect protective conductor and check electrical continuity

between coil and body.

Closed position

8

english

Closed position

Page 9

Note the voltage and current type as specied on the type

label.

Seal

max. 1 Nm

Authorized cable plug e.g. Type 2508 or

other suitable cable plug in accordance

with DIN EN 175301-803 Form A

Pulse version (optional, Code CF 16):

• Valve opens when current pulse min. 50 ms:

– on Pin 1, + on Pin 2

• Valve closes when current pulse min. 50 ms:

+ on Pin 1, – on Pin 2

6 MAINTENANCE, TROUBLESHOOTING

6.1 Safety instructions

WARNING!

Risk of injury from improper maintenance.

▶ Maintenance may be carried out by authorized technicians only

and with the appropriate tools.

Risk of injury from unintentional activation of the system and an

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

6.2 Installation of the coil

WARNING!

Risk of injury due to electrical shock.

2

1

▶ Before reaching into the system, switch o the power supply and

secure to prevent reactivation.

▶ During installation ensure that the coil is situated rmly on the

body cover so that the protective conductor connection of the

coil is connected to the valve body.

▶ Check protective conductor contact after installing the coil.

english

9

Page 10

Escaping medium.

When a sticking nut is loosened, medium may escape.

▶ Do not tighten sticking nut any further.

Overheating, risk of re.

Connection of the coil without pre-assembled valve will result in

overheating and destroy the coil.

▶ Connect the coil with pre-assembled valve only.

Procedure:

→ Connect coil body to the core guide pipe.

→ Screw on coil with nut. Observe torque.

NOTE!

Device will be damaged if the wrong tools are used.

Always use a wrench to tighten nut. If other tools are used (e.g.

pliers), the device may be damaged.

→ Check protective conductor.

Nut

Core guide pipe

O-ring

Locking pin

+

Torque for fastening nut:

Coil type Coil width Torque

AC10 32 mm resp. 40 mm 5 Nm

AC19 42 mm 10 Nm

Observe

torque for

fastening nut

(See table) !

10

english

Page 11

6.3 Malfunctions

If malfunctions occur, check whether:

→ the device has been installed according to the instructions,

→ the electrical and uid connections are correct,

→ the device is not damaged,

→ all screws have been tightened,

→ the voltage and pressure have been switched on,

→ the pipelines are clean.

Valve does not switch

Possible cause:

• Short circuit or coil interrupted.

• Core or core area dirty.

• Medium pressure outside the permitted pressure range.

Valve does not close

Possible cause:

• Internal space of the valve is dirty.

• Small control bore in the diaphragm blocked.

• Valve opened by manual control.

7 SPARE PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect parts.

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

▶ Use only original accessories and original spare parts from

Bürkert.

7.1 Ordering spare parts

Replacement part sets

When ordering replacement part sets, quote the sets SET 1, SET 3 or

SET 7 and the identication number of the device.

english

11

Page 12

7.2 Overview of replacement part sets

6213 EV

Coil set

SET 1

6281 EV

Coil set

SET 1

6281 EV (MX62)

Compressor relief valve NO

Coil set

SET 1

Plunger tube

Wearing

parts set

SET 3

The composition of the spare part sets may dier from the diagram

depending on the model of valves.

12

english

set SET 7

Wearing

par

ts set

SET 3

Plunger tube set

SET 7

Wearing parts set

SET 3

Page 13

8 TRANSPORT, STORAGE, DISPOSAL

NOTE!

Transport damages.

Inadequately protected equipment may be damaged during

transport.

▶ During transportation protect the device against wet and dirt in

shock-resistant packaging.

▶ Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

▶ Store the device in a dry and dust-free location.

▶ Storage temperature: -40...+80°C.

Damage to the environment caused by device components

contaminated with media.

▶ Observe applicable regulations on disposal and the

environment.

→ Dispose of the device and packaging in an environmentally

friendly manner.

english

13

Page 14

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@burkert.com

International address

www.burkert.com

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet : www.burkert.fr

© Bürker t Werke GmbH & Co. KG, 2013-2019

Operating Instructions 1909/11_EU-ML_0 0805875 / Original DE

www.burkert.com

Loading...

Loading...