Page 1

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

Type 6012

3/2-Way Mini Solenoid Valve

3/2-Wege-Mini-Magnetventil

Électrovanne mini à 3/2 voies

Address / Adresse

1. OPERATING INSTRUCTIONS

The operating instructions contain important information.

• Read the instructions carefully and follow the safety instructions in

particular, and also observe the operating conditions.

• Instructions must be available to each user.

• The liability and warranty for Type 6012 are void if the operating

instructions are not followed.

2. SYMBOLS

→ designates a procedure which you must carry out.

Warning of serious or fatal injuries:

DANGER!

In case of imminent danger.

WARNING!

In case of potential danger.

Warning of minor or moderately severe injuries:

CAUTION!

Warns of damage to property:

NOTE!

3. INTENDED USE

Incorrect use of the solenoid valve Type 6012 can be dangerous

to people, nearby equipment and the environment.

• The device is designed for blocking, dosing, filling and venting neutral

gaseous and liquid media.

• Do not use the device outdoors.

• Use according to the permitted data, operating conditions and conditions of use specified in the contract documents and operating

instructions. These are described in the chapter entitled “Technical

data”.

• The device may be used only in conjunction with third-party devices

and components recommended and authorised by Bürkert.

• Correct transportation, correct storage and installation and careful

use and maintenance are essential for reliable and problem-free

operation.

• Use the device only as intended.

3.1. Restrictions

If exporting the system/device, observe any existing restrictions.

english

4. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any contingencies and events which may arise during installation, operation and

maintenance.

Danger – high pressure!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of electric shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

Risk of burns/Risk of fire if used continuously through hot

device surface!

• Keep the device away from highly flammable substances and media

and do not touch with bare hands.

3.2. Approvals

The approval mark indicated on the Bürkert labels refers to the Bürkert

products.

e 1

03 5791

Devices which must bear the type approval mark were approved at the

Kraftfahrtbundesamt under the type approval number

e1*72/245*2006/96*5791*00

and are put into circulation with the indicated type approval mark. You

can obtain an extract of the type approval from the address below.

Bürkert Werke GmbH

Zulassungsbeauftragter,

Christian-Bürkert-Str. 13-17,

D-74653 Ingelfingen

english

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet:

www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet:

www.buerkert.de

Manuel d'utilisation et fiches techniques sur Internet :

www.buerkert.fr

© 2013 Bürkert Werke GmbH & Co. KG, 2013 - 2017

Operating Instr uctions 1706/20_EU-EN_00803160 / Original DE

Page 2

General hazardous situations.

To prevent injury, ensure that:

• The solenoid valve Type 6012 is not to be used in areas where there

is a risk of explosion.

• Do not supply the medium connectors of the system with aggressive

or flammable mediums.

• Do not put any loads on the body (e.g. by placing objects on it or

standing on it).

• Do not make any external modifications to the device bodies. Do not

paint the body parts or screws.

• Installation and repair work may be carried out by authorized technicians only and with the appropriate tools.

• After an interruption in the power supply or pneumatic supply, ensure

that the process is restarted in a defined or controlled manner.

• The device may be operated only when in perfect condition and in

consideration of the operating instructions.

• The general rules of technology apply to application planning and

operation of the device.

5. SYSTEM DESCRIPTION

5.1. General description

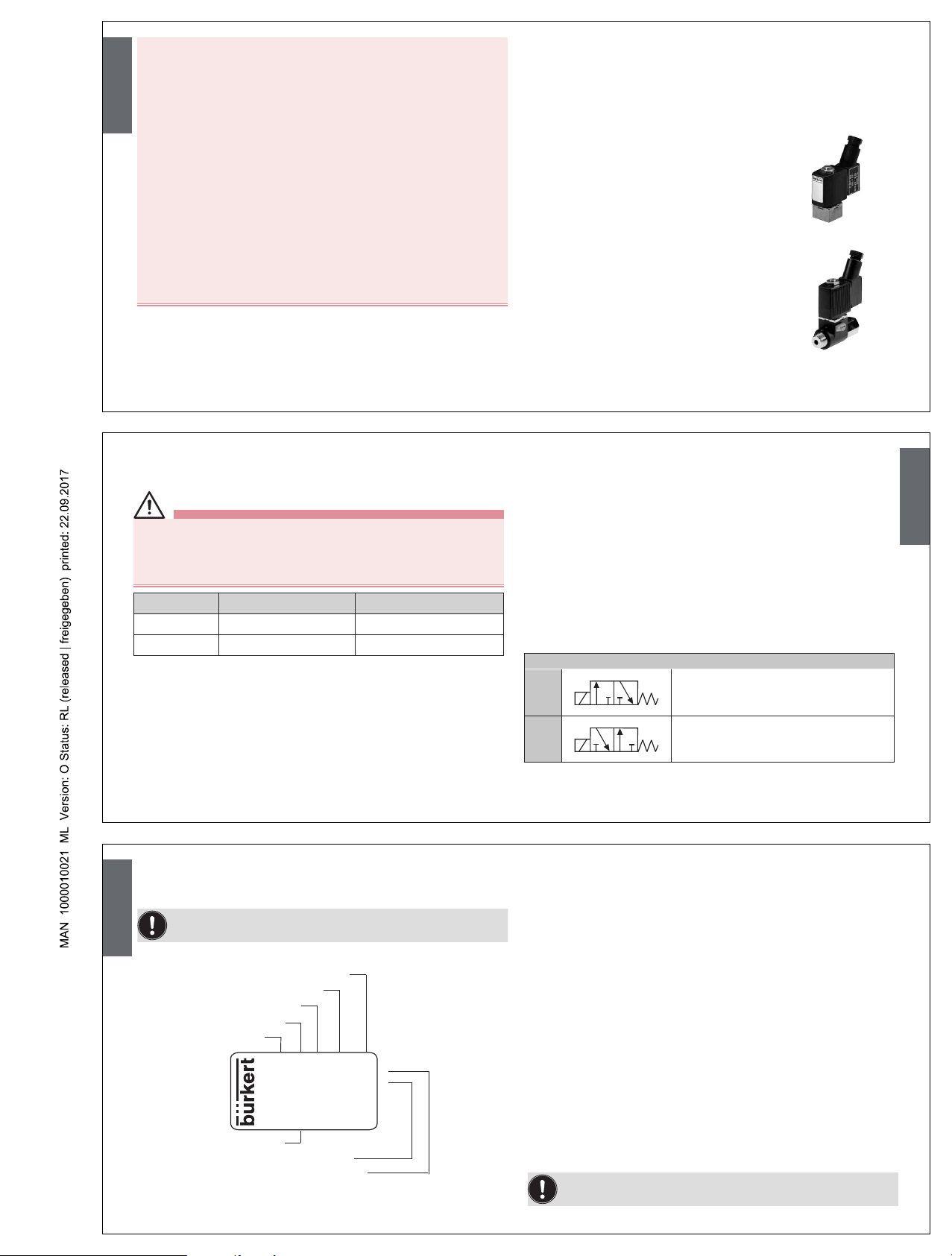

The direct-acting solenoid valve Type 6012 is available in two

designs.

Type 6012 is used for the blocking, dosing, filling

and venting of neutral gaseous and liquid media,

in particular for controlling single-acting pneumatic actuators or technical vacuum. The modular

designed valve can be installed individually or in a

block on the multiple manifold.

Type 6012P is used as a special pilot valve for

direct installation on the externally controlled

pneumatic actuators. It consists of the magnetic

actuator Type 6012 and a special connection

body with hollow screw which can be connected

directly to the control air connection of the

actuator. The valve features manual actuation as

standard.

english

6. TECHNICAL DATA

6.1. Operating conditions

WARNING!

Risk of injury!

Malfunction if used outside!

• Do not use Type 6012 outdoors and avoid heat sources which may

cause the allowable temperature range to be exceeded.

Type Ambient temperature Medium temperature

6012 -10 ... +55 °C -10 ... +100 °C

6012P -10 ... +40 °C -10 ... +60 °C

Media 6012: neutral gaseous and liquid media (e.g.

compressed air, Water, Hydraulic fluid, technical

Vacuum)

6012P: neutral gaseous media (e.g. compressed

air)

Viscosity max. 21 mm²/s

Protection class IP65 in accordance with EN 60529 with cable

plug

6.2. Conformity

In accordance with the EC Declaration of conformity, the solenoid valve

Type 6012 is compliant with the EC Directives.

6.3. Mechanical data

Dimensions See data sheet

Body material Type 6012: Brass, polyamide (PA),

Stainless steel 1.4305

Type 6012P: Polyamide (PA)

Hollow screw Type 6012P: Brass, nickel-plated

Sealing material FKM / EPDM

6.4. Fluidic data

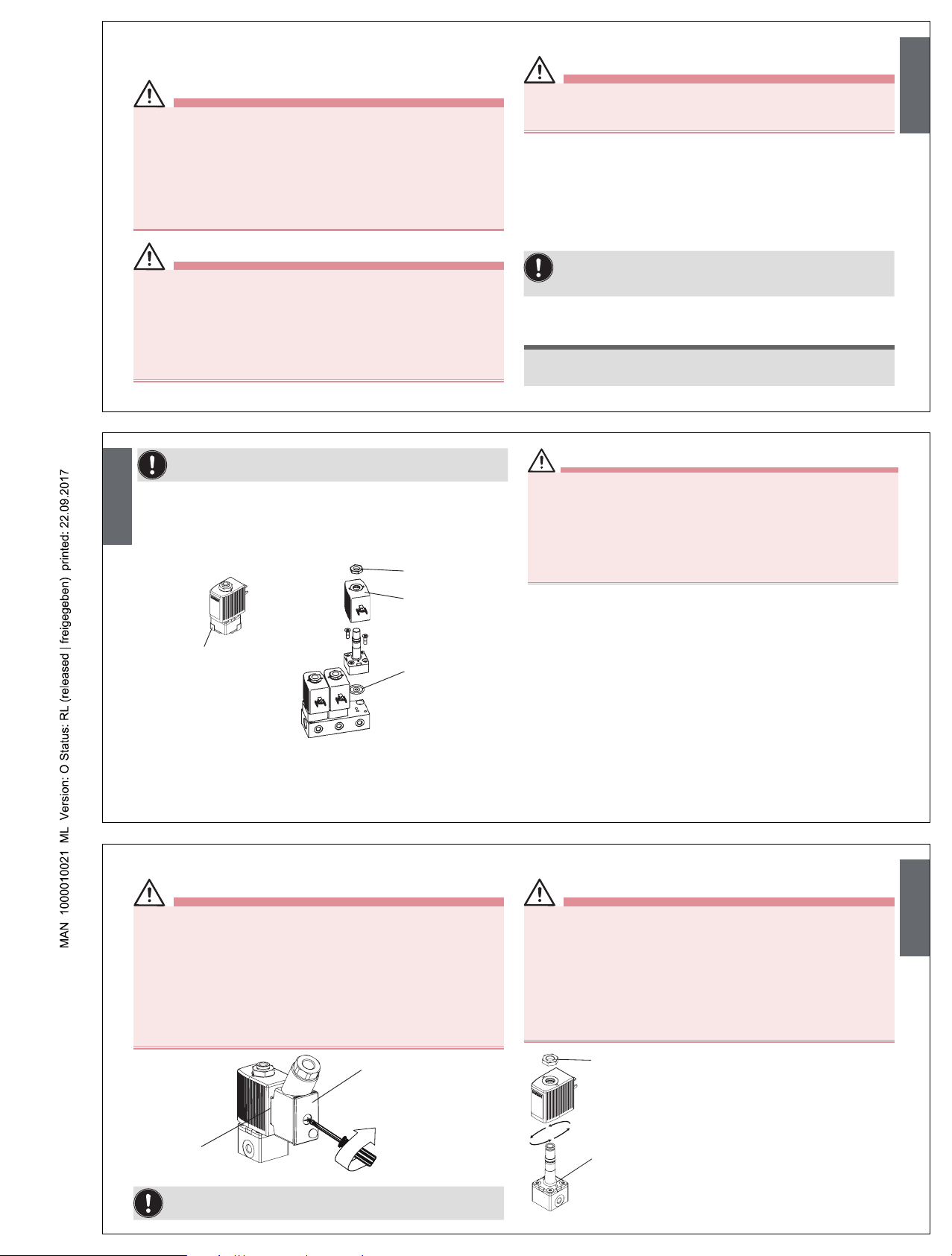

Circuit functions

C

(NC)

2(A)

1(P)

3(R)

3/2-way valve, direct-acting, normal

output A unloaded

D

(NO)

2(B)

1(P)

3(R)

3/2-way valve, direct-acting, normal

output B pressurized

Pressure range 0 – 16 bar

english

Line connectors Type 6012: M5, G1/8, Flange

Type 6012P: G1/8, G1/4

Hose connector ∅ 6 mm

Note the voltage and current type as specified on the type

label.

6.5. Type label (Example)

Identifications number

Voltage, Frequency output

Nominal connection pressure

Type

Circuit function

Orifice

Sealing material

Body material

6012 C 1,0 FKM MS

Made in Germany

CE

00450000

WXXXX

230V 50Hz 2W

G1/8 PN 0

-

7 bar

6.6. Electrical data

Connections DIN EN 175301-803 Form C:

for cable plug Type 2506

DIN 43650 Form B:

for cable plug Type 2507

Wire connection on request

Power supply 24 V DC ± 10 % -

max. residual ripple 10%

24 V / 50 Hz

110 / 230 / 50 Hz

Voltage tolerance ± 10%

Nominal output 4 W

Nominal operating mode 100% continuous operation

for block installation:

2 W continuous operation on request

4 W intermittent operation 60%

(30 min)

Note the voltage and current type as specified on the type

label.

english

Page 3

7. INSTALLATION

7.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

7.2. Fluid installation

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

Installation position: any, actuator preferably upwards.

Procedure:

→ Before installation, clean any possible dirt off the pipelines and

flange connections.

→ If required, install a dirt trap to prevent malfunctions. (Mesh size:

0.2 – 0.4 mm).

Pay attention to the flow direction of the valve!

from 1(P) → 2(A) (CF C) or

from 1(P) → 2(B) (CF D)

Body with threaded connection:

NOTE!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

english

Use PTFE tape as sealing material.

→ Hold the device with a suitable tool (Open-end wrench) on the

body and screw into the pipeline.

Valve with flanged connection:

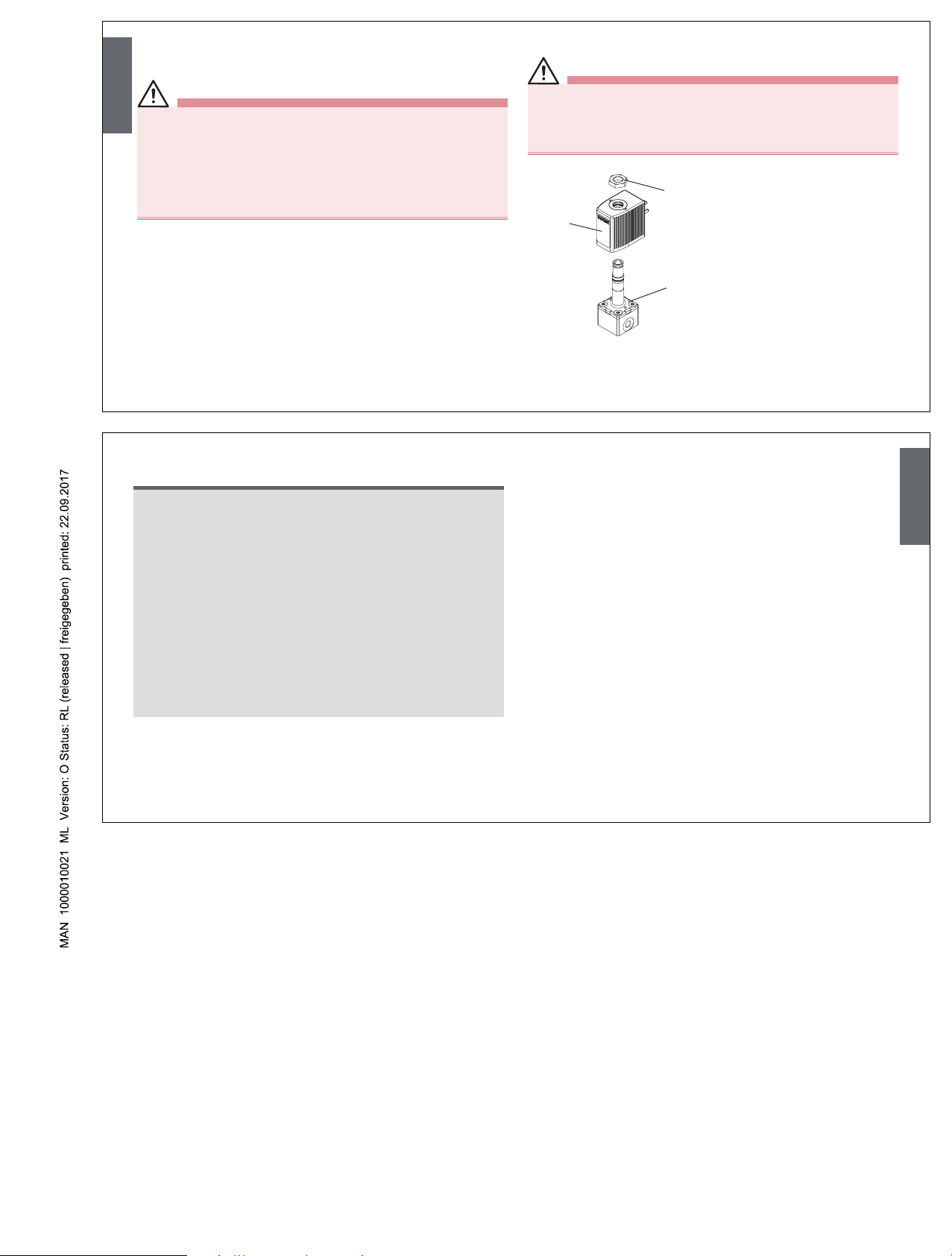

Seal

Nut

Coil

Cover plate

→ Remove the cover plate.

→ Loosen the nut on the coil and remove coil.

WARNING!

Danger – escaping medium!

Leaking connections if seals not seated properly, if manifold uneven

or if surface quality of the manifold inadequate.

• Make certain the seals included with delivery are properly seated in

the valve.

• Ensure that the manifold is even.

• Ensure that the surface quality of the manifold is adequate.

→ Insert the seal into the valve.

→ Screw the body onto the manifold.

→ Attach the coil and screw on the nut (Tightening torque:

max. 2.8 Nm).

english

7.3. Electrical connection of the cable plug

WARNING!

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

• Always connect protective conductor.

• Check electrical continuity between coil and body.

max. 0.30 Nm

Type 2506

Seal

Note the voltage and current type as specified on the type

label.

7.4. Installation of coil

WARNING!

Electric shock!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

• Check protective conductor contact after installing the coil.

Overheating, Risk of fire!

Connection of the coil without pre-assembled valve will result in

overheating and destroy the coil.

• Connect the coil with assembled valve only.

4 x 90°

Nut

max. 2.8 Nm

O-ring

The coil can be turned by 4 x 90°:

→ Loosen nut.

→ Turn coil.

→ Tighten nut with suitable tool

(Open-end wrench) (max. 2.8

Nm).

english

Page 4

8. MAINTENANCE, TROUBLESHOOTING

8.1. Safety instructions

WARNING!

Risk of injury from improper maintenance!

• Maintenance may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

8.2. Malfunctions

If malfunctions occur, check:

→ the line connectors,

→ the operating pressure,

→ the power supply and valve control.

If the valve still does not switch, please contact your Bürkert Service.

9. SPARE PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

• Use only original accessories and original spare parts from Bürkert.

Fitting

Coil

Nut

Coil and fitting can be ordered

complete by quoting the identification number of the device

(see type label).

Wearing part set on request.

english

10. TRANSPORT, STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -40 - 80 °C.

Damage to the environment caused by device components

contaminated with media.

• Observe applicable regulations on disposal and the environment.

english

Page 5

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

• Die Bedienungsanleitung sorgfältig lesen und Hinweise zur Sicherheit beachten.

• Anleitung muss jedem Benutzer zur Verfügung stehen.

• Die Haftung und Gewährleistung für Typ 6012 entfällt, wenn die

Anweisungen der Bedienungsanleitung nicht beachtet werden.

2. DARSTELLUNGSMITTEL

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

Warnung vor schweren oder tödlichen Verletzungen:

GEFAHR!

Bei unmittelbarer Gefahr.

WARNUNG!

Bei möglicher Gefahr.

Warnung vor leichten oder mittelschweren Verletzungen:

VORSICHT!

Warnung vor Sachschäden:

HINWEIS!

3. BESTIMMUNGSGEMÄSSER GEBRAUCH

Bei nicht bestimmungsgemäßem Einsatz des Magnetventils Typ

6012 können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Das Gerät ist zum Sperren, Dosieren, Füllen und Belüften von neutralen gasförmigen und flüssigen Medien konzipiert.

• Das Gerät nicht im Außenbereich einsetzen.

• Für den Einsatz die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten. Diese sind im Kapitel „Technische

Daten“ beschrieben.

• Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -komponenten einsetzen.

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

• Das Gerät nur bestimmungsgemäß einsetzen.

3.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

deutsch

4. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine Zufälligkeiten und

Ereignisse, die bei Montage, Betrieb und Wartung auftreten können.

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten

und Leitungen entlüften.

Gefahr durch elektrische Spannung!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung abschalten

und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für

elektrische Geräte beachten!

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch heiße

Geräteoberfläche!

• Das Gerät von leicht brennbaren Stoffen und Medien fernhalten

und nicht mit bloßen Händen berühren.

3.2. Zulassungen

Die auf den Bürkert Typschildern aufgebrachte Zulassungskennzeichnung bezieht sich auf die Bürkert Produkte.

e 1

03 5791

Geräte, die das Typgenehmigungszeichen tragen müssen, wurden

beim Kraftfahrtbundesamt unter der Typgenehmigungsnummer

e1*72/245*2006/96*5791*00

genehmigt und werden mit dem gezeigten Typgenehmigungszeichen in

den Verkehr gebracht. Einen Auszug der Typgenehmigung erhalten Sie

unter der unten stehenden Adresse.

Bürkert Werke GmbH

Zulassungsbeauftragter,

Christian-Bürkert-Str. 13-17,

D-74653 Ingelfingen

deutsch

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen/Sachschaden beachten:

• Das Magnetventil Typ 6012 darf nicht in explosionsgefährdeten

Bereichen eingesetzt werden.

• In die Medienanschlüsse des Systems keine aggressiven oder

brennbaren Medien einspeisen.

• Das Gehäuse nicht mechanisch belasten (z.B. durch Ablage von

Gegenständen oder als Trittstufe).

• Keine äußerlichen Veränderungen an den Gerätegehäusen vornehmen. Gehäuseteile und Schrauben nicht lackieren.

• Nur geschultes Fachpersonal darf Installations- und Instandhaltungsarbeiten ausführen.

• Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung für einen definierten oder kontrollierter Wiederanlauf

des Prozesses sorgen.

• Das Gerät nur in einwandfreiem Zustand und unter Beachtung der

Bedienungsanleitung betreiben.

• Für die Einsatzplanung und den Betrieb des Gerätes die allgemeinen Regeln der Technik einhalten.

5. SYSTEMBESCHREIBUNG

5.1. Allgemeine Beschreibung

Das direktwirkende Magnetventil Typ 6012 ist in zwei Ausführungen

verfügbar.

Typ 6012 wird zum Sperren, Dosieren, Füllen

und Belüften von neutralen gasförmigen und

flüssigen Medien verwendet, insbesondere zum

Steuern einfachwirkender Pneumatikantriebe oder

technisches Vakuum. Das modular aufgebaute

Ventil kann einzeln oder im Block auf Mehrfachanschlussplatte montiert werden.

Typ 6012P wird als spezielles Pilotventil zum

Direktanbau an fremdgesteuerte pneumatische

Antriebe verwendet. Es besteht aus dem Magnetantrieb vom Typ 6012 und einem speziellen

Anschlussgehäuse mit Hohlschraube, die direkt

an den Steuerluftanschluss des Antriebs angeschlossen werden kann. Das Ventil ist serienmäßig mit Handbetätigung ausgestattet.

deutsch

Page 6

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

WARNUNG!

Verletzungsgefahr!

Funktionsausfall bei Einsatz im Außenbereich!

• Typ 6012 nicht im Außenbereich einsetzen und Wärmequellen vermeiden, die zur Überschreitung des zulässigen Temperaturbereichs

führen können.

Typ Umgebungstempe-

ratur

Mediumstemperatur

6012 -10 ... +55 °C -10 ... +100 °C

6012P -10 ... +40 °C -10 ... +60 °C

Medien 6012: neutrale gasförmige und flüssige Medien (z. B.

Druckluft, Wasser, Hydrauliköl, technisches Vakuum)

6012P: neutrale gasförmige Medien

(z. B. Druckluft)

Viskosität max. 21 mm²/s

Schutzart IP65 nach EN 60529 mit Gerätesteckdose

6.2. Konformität

Das Magnetventil, Typ 6012 ist konform zu den EG-Richtlinien entsprechend der EG-Konformitätserklärung.

6.3. Mechanische Daten

Maße siehe Datenblatt

Gehäusematerial Typ 6012: Messing, Polyamid (PA),

Edelstahl 1.4305

Typ 6012P: Polyamid (PA)

Hohlschraube Typ 6012P : Messing, vernickelt

Dichtungsmaterial FKM / EPDM

6.4. Fluidische Daten

Wirkungsweisen

C

(NC)

2(A)

1(P)

3(R)

3/2 Wege-Ventil, direktwirkend,

stromlos Ausgang A entlastet

D

(NO)

2(B)

1(P)

3(R)

3/2 Wege-Ventil, direktwirkend,

stromlos Ausgang B druckbeaufschlagt

Druckbereich 0 ... 16 bar

deutsch

Leitungsanschlüsse Typ 6012: M5, G1/8, Flansch

Typ 6012P: G1/8, G1/4

Schlauchsteckverbinder

∅ 6 mm

Beachten Sie die auf dem Typschild angegebene Daten für

Spannung, Stromart und Druck.

6.5. Typschild (Beispiel)

Ident-Nr.

Spannung-Frequenz-Leistung

Anschluss-Nenndruck

Typ

Wirkungsweise

Nennweite

Dichtwerkstoff

Gehäusewerkstoff

6012 C 1,0 FKM MS

Made in Germany

CE

00450000

WXXXX

230V 50Hz 2W

G1/8 PN 0

-

7 bar

6.6. Elektrische Daten

Anschlüsse DIN EN 175301-803 Form C:

für Gerätesteckdose Typ 2506

DIN 43650 Form B:

für Gerätesteckdose Typ 2507

Litzenanschluss auf Anfrage

Spannungsversorgung 24 V DC ± 10 % -

max. Restwelligkeit 10 %

24 V / 50 Hz

110 / 230 / 50 Hz

Spannungstoleranz ± 10 %

Nennleistung 4 W

Nennbetriebsart Dauerbetrieb, ED 100 %

bei Blockmontage:

2 W Dauerbetrieb a. A.

4 W Aussetzbetrieb 60 %

(30 min)

Beachten Sie die auf dem Typschild angegebene Daten für

Spannung, Stromart und Druck.

deutsch

7. INSTALLATION

7.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten

und Leitungen entlüften.

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das System die elektrische Spannung abschalten

und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für

elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Die Installation darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Installation einen kontrollierten Wiederanlauf gewährleisten.

7.2. Fluidische Installation

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten

und Leitungen entlüften.

Einbaulage: beliebig, vorzugsweise Antrieb nach oben.

Vorgehensweise:

→ Vor der Montage Rohrleitungen und Flanschanschlüsse von even-

tuellen Verschmutzungen säubern.

→ Zum Schutz vor Störungen gegebenenfalls einen Schmutzfänger

einbauen (Maschenweite: 0,2 ... 0,4 mm).

Durchflussrichtung des Ventils beachten!

von 1(P) → 2(A) (WW C) oder

von 1(P) → 2(B) (WW D)

Gehäuse mit Gewindeanschluss:

HINWEIS!

Vorsicht Bruchgefahr!

• Die Spule darf nicht als Hebelarm benutzt werden.

deutsch

Page 7

Als Dichtungsmaterial PTFE-Band verwenden.

→ Das Gerät mit einem Gabelschlüssel am Gehäuse festhalten und

in die Rohrleitung einschrauben.

Ventil mit Flanschanschluss:

Dichtung

Mutter

Spule

Verschlussplatte

→ Verschlussplatte entfernen.

→ Mutter der Spule lösen und Spule demontieren.

WARNUNG!

Gefahr durch Mediumsaustritt!

Undichte Anschlüsse bei ungenauem Sitz der Dichtungen, bei

unebener Anschlussplatte oder unzureichender Oberflächengüte der

Anschlussplatte.

• Achten Sie bei den mitgelieferten Dichtungen auf den richtigen Sitz

im Ventil.

• Achten Sie auf die Ebenheit der Anschlussplatte.

• Achten Sie auf ausreichende Oberflächengüte der Anschlussplatte.

→ Dichtung in das Ventil einlegen.

→ Gehäuse auf die Anschlussplatte schrauben.

→ Spule aufstecken und die Mutter befestigen

(Anziehdrehmoment: max. 2,8 Nm).

deutsch

7.3. Elektrischer Anschluss der Gerätesteckdose

WARNUNG!

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das System die elektrische Spannung abschalten

und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für

elektrische Geräte beachten!

Bei fehlendem Schutzleiterkontakt zwischen Spule und Gehäuse

besteht die Gefahr des Stromschlags!

• Schutzleiter immer anschließen.

• Elektrischer Durchgang zwischen Spule und Gehäuse prüfen.

max. 0,30 Nm

Typ 2506

Dichtung

Spannung und Stromart laut Typschild beachten.

7.4. Spulenmontage

WARNUNG!

Stromschlag!

Bei fehlendem Schutzleiterkontakt zwischen Spule und Gehäuse

besteht die Gefahr des Stromschlags!

• Schutzleiterkontakt nach der Spulenmontage prüfen.

Überhitzung, Brandgefahr!

Der Anschluss der Spule ohne vormontiertes Ventil führt zur Überhitzung und zerstört die Spule.

• Spule nur mit montiertem Ventil anschließen.

4 x 90°

Mutter

max. 2,8 Nm

O-Ring

Die Spule kann um 4 x 90° verdreht

werden:

→ Mutter lösen.

→ Spule verdrehen.

→ Mutter mit einem Gabelschlüssel

festdrehen (max. 2,8 Nm).

deutsch

8. WARTUNG, FEHLERBEHEBUNG

8.1. Sicherheitshinweise

WARNUNG!

Verletzungsgefahr bei unsachgemäßen Wartungsarbeiten!

• Die Wartung darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Wartung einen kontrollierten Wiederanlauf gewährleisten.

8.2. Störungen

Bei Störungen überprüfen:

→ die Leitungsanschlüsse,

→ den Betriebsdruck,

→ die Spannungsversorgung und Ventilansteuerung.

Falls das Ventil dennoch nicht schaltet, wenden Sie sich bitte an Ihren

Bürkert-Service.

9. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen

und Schäden am Gerät und dessen Umgebung verursachen.

• Nur Originalzubehör sowie Originalersatzteile der Firma Bürkert

verwenden.

Armatur

Spule

Mutter

Spule und Armatur können

komplett unter der Identnummer des Geräts bestellt

werden (siehe Typschild).

Verschleißteilsatz auf Anfrage.

deutsch

Page 8

10. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur

vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur: -40 … +80 °C

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

deutsch

Page 9

1. MANUEL D’UTILISATION

Manuel d’utilisation contiennent des informations importantes.

• Lire attentivement ce manuel et respecter les consignes de

sécurité.

• Le manuel doit être à disposition de chaque utilisateur.

• Nous déclinons toute responsabilité et n’accordons aucune garantie

légale pour le type 6012 en cas de non-respect des instructions

figurant dans ce manuel d’utilisation.

2. SYMBOLES

→ identifie une opération que vous effectuer.

Mise en garde contre les blessures graves ou mortelles :

DANGER !

En cas de danger imminent.

AVERTISSEMENT !

En cas de danger possible.

Mise en garde contre les blessures légères ou moyennement graves :

PRUDENCE !

Met en garde contre des dommages matériels:

REMARQUE !

3. UTILISATION CONFORME

L’utilisation non conforme de l’électrovanne, type 6012 peut présenter des dangers pour les personnes, les installations proches

et l’environnement.

• L’appareil est conçu pour couper, doser, remplir et aérer les fluides

neutres gazeux et liquides.

• N’utilisez pas l’appareil à l’extérieur.

• Lors de l’utilisation, il convient de respecter les données et conditions

d’utilisation et d’exploitation admissibles spécifiées dans les instructions de service et dans les documents contractuels. Celles-ci sont

décrites au chapitre « Caractéristiques techniques ».

• L’appareil peut être utilisé uniquement en association avec les

appareils et composants étrangers recommandés et homologués

par Bürkert.

• Les conditions pour l’utilisation sûre et parfaite sont un transport,

un stockage et une installation dans les règles ainsi qu’une parfaite

utilisation et maintenance.

• Veillez à ce que l’utilisation de l’appareil soit toujours conforme.

3.1. Limitations

Lors de l’exportation du système/de l’appareil, veuillez respecter les

limitations éventuelles existantes.

français

4. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte des hasards et des

événements pouvant survenir lors du montage, de l’exploitation et de

l’entretien.

Danger dû à la haute pression.

• Avant de desserrer les conduites et les vannes, coupez la pression

et purgez l’air des conduites.

Danger présenté par la tension électrique.

• Avant d’intervenir dans le système, coupez la tension et empêchez

toute remise sous tension par inadvertance.

• Veuillez respecter les réglementations en vigueur pour les appareils électriques en matière de prévention des accidents ainsi

qu’en matière de sécurité.

Risque de brûlures/d’incendie en fonctionnement continu dû à

des surfaces d’appareils brûlantes.

• Tenez les substances et les fluides facilement inflammables à l’écart

de l’appareil et ne touchez pas ce dernier à mains nues.

3.2. Homologations

Le marquage d’homologation apposé sur les plaques signalétiques

Bürkert se rapporte aux produits Bürkert.

e 1

03 5791

Les appareils devant porter l’homologation ont été autorisés par l’office

fédéral sous le numéro

e1*72/245*2006/96*5791*00

et sont mis sur le marché avec cette homologation. Vous pouvez obtenir

un extrait de cette homologation à l’adresse mentionnée ci-dessous.

Bürkert Werke GmbH

Zulassungsbeauftragter,

Christian-Bürkert-Str. 13-17,

D-74653 Ingelfingen

français

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• L’électrovanne type 6012 ne doit pas être utilisée dans des zones

présentant des risques d’explosion.

• N’alimentez pas les raccords du système en fluides agressifs ou

inflammables.

• Ne soumettez pas le corps à des contraintes mécaniques (par ex.

pour déposer des objets ou en l’utilisant comme marche).

• N’apportez pas de modifications à l’extérieur du corps de l’appareil.

Ne laquez pas les pièces du corps et les vis.

• Les travaux d’installation et de maintenance doivent être effectués

uniquement par des techniciens qualifiés et habilités disposant de

l’outillage approprié.

• Après une interruption de l’alimentation électrique ou pneumatique,

un redémarrage défini ou contrôlé du processus doit être garanti.

• L’appareil doit être utilisé uniquement en parfait état et en respectant

les instructions de service.

• Les règles générales de la technique sont d’application pour planifier

l’utilisation et utiliser l’appareil.

5. DESCRIPTION DU SYSTÈME

5.1. Description générale

L’électrovanne à action directe type 6012 est disponible en deux

versions.

Le type 6012 est utilisé pour couper, doser,

remplir et aérer les fluides neutres gazeux et

liquides et en particulier pour commander des

actionneurs pneumatiques simple effet ou le vide

technique. La vanne modulaire peut être montée

seule ou dans un bloc sur des embases multiples.

Le type 6012P est utilisé comme vanne pilote

spéciale à monter directement sur des actionneurs pneumatiques à commande extérieure. Elle

est composée d’une électrovanne du type 6012

et d’un corps de raccordement spécial avec vis

creuse pouvant être raccordée directement sur

l’air de commande de l’actionneur. De série, la

vanne est dotée d’une commande manuelle.

français

Page 10

6. CARACTÉRISTIQUES TECHNIQUES

6.1. Conditions d’exploitation

AVERTISSEMENT !

Risque de blessures.

Panne lors de l’utilisation à l’extérieur.

• N’utilisez pas le type 6012 à l’extérieur et évitez les sources de chaleur

susceptibles d’entraîner un dépassement de la plage de température

admissible.

Type Température

ambiante

Température

du fluide

6012 -10 ... +55 °C -10 ... +100 °C

6012P -10 ... +40 °C -10 ... +60 °C

Fluides 6012: fluides neutres gazeux et liquides (par ex. Air

comprimé, eau, huile hydraulique, vide technique)

6012P: fluides neutres gazeux (par ex. Air comprimé)

Viscosité 21 mm²/s maxi

Type de protection IP65 selon EN 60529 avec prise d’appareil

6.2. Conformité

L‘électrovanne type 6012 est conforme aux directives CE sur la base

de la déclaration de conformité CE.

6.3. Caractéristiques mécaniques

Dimensions voir fiche technique

Matériau du corps Type 6012 : laiton, polyamide (PA),

acier inoxydable 1.4305

Type 6012P : polyamide (PA)

Vis creuse Type 6012P : laiton, nickelé

Matériau d’étanchéité FKM / NBR

6.4. Données fluidiques

Fonction

C

(NC)

2(A)

1(P)

3(R)

Vanne à 3/2 voies, à action directe,

sortie A normalement fermée

D

(NO)

2(B)

1(P)

3(R)

Vanne à 3/2 voies, à action directe,

sortie B normalement ouverte

Plage de pression 0 – 16 bar

français

Raccords de conduite Type 6012 : M5, G1/8, bride

Type 6012P : G1/8, G1/4 Connecteur enfichable

pour tuyau souple ∅ 6 mm

Respectez les données indiquées sur la plaque signalétique

pour la tension, le type de courant et la pression.

6.5. Plaque signalétique (Exemple)

N° ID

Tension-Fréquence-Puissance

Raccord-Pression nominale

Type

Fonction

Diamètre nominal

Matériau du joint

Matériau du corps

6012 C 1,0 FKM MS

Made in Germany

CE

00450000

WXXXX

230V 50Hz 2W

G1/8 PN 0

-

7 bar

6.6. Caractéristiques électriques

Raccordements DIN EN 175301-803 forme C :

pour prise d’appareil, type 2506

DIN 43650 forme B :

pour prise d’appareil, type 2507

Raccordement pour torons sur demande

Alimentation en tension 24 V DC ± 10 % -

ondulation résiduelle maxi 10 %

24 V / 50 Hz

110 / 230 / 50 Hz

Tolérance de tension ± 10 %

Puissance nominale 4 W

Mode opératoire nominal 100% fonctionnement continu

en montage dos à dos 2 W fonctionnement:

continu sur demande

4 W fonctionnement

intermittent 60 %

(30 min)

Respectez les données indiquées sur la plaque signalétique

pour la tension, le type de courant et la pression.

français

7. INSTALLATION

7.1. Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute pression dans

l'installation.

• Avant de desserrer les conduites et les vannes, coupez la pression

et purgez l’air des conduites.

Risque de choc électrique.

• Avant d'intervenir dans le système, coupez la tension et empêchez

toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour les appareils

électriques en matière de prévention des accidents ainsi qu’en matière

de sécurité !

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme.

• Le montage doit être effectué uniquement par un personnel qualifié

et habilité disposant de l’outillage approprié.

Risque de blessures dû à la mise en marche involontaire de l'installation et le redémarrage non contrôlé.

• Empêchez tout actionnement involontaire de l'installation.

• Garantissez un redémarrage contrôlé après le montage.

7.2. Installation fluide

DANGER !

Risque de blessures dû à la présence de haute pression dans

l'installation.

• Avant de desserrer les conduites et les vannes, coupez la pression

et purgez l’air des conduites.

Position de montage : au choix, de préférence avec l’actionneur vers

le haut.

Procédure à suivre :

→ Avant le montage, nettoyer la tuyauterie et les raccordements à

bride afin d’enlever les éventuelles saletés.

→ Installez éventuellement un collecteur de boues comme protection

contre les dysfonctionnements (Mailles : 0,2 ... 0,4 mm).

Respectez le sens du débit de la vanne :

de 1(P) → 2(A) (fonction C) ou de 1(P) → 2(B) (fonction D)

Corps avec raccord fileté :

REMARQUE !

Attention risque de rupture.

• La bobine ne doit pas être utilisée comme levier.

français

Page 11

Utilisez une bande PTFE comme matériau d’étanchéité.

→ Maintenez l’appareil sur le corps à l’aide d’un outil approprié (clé

à fourche) et vissez-le dans la tuyauterie.

Vanne avec raccord à bride :

Joint

Écrou

Bobine

Plaque de fermeture

→ Enlevez la plaque de fermeture.

→ Desserrez l’écrou de la bobine et démontez celle-ci.

AVERTISSEMENT !

Danger dû à la sortie de fluide.

Raccords non étanches dus à une mauvaise position des joints,

une plaque de raccordement non plane ou d’une qualité de surface

insuffisante.

• Veillez au positionnement correct des joints fournis dans la vanne.

• Veillez à la planéité de la plaque de raccordement.

• Veillez à une qualité de surface suffisante de la plaque de

raccordement.

→ Placez le joint dans la vanne.

→ Vissez le corps sur l’embase.

→ Mettez la bobine en place et serrez l’écrou (couple de serrage :

2,8 Nm maxi).

français

7.3. Raccordement électrique de la prise de

l’appareil

AVERTISSEMENT !

Risque de choc électrique.

• Avant d'intervenir dans le système, coupez la tension et empêchez

toute remise sous tension par inadvertance.

• Veuillez respecter les réglementations en vigueur pour les appareils

électriques en matière de prévention des accidents ainsi qu’en matière

de sécurité.

Il y a risque de choc électrique en l'absence d'un contact du conducteur

de protection entre la bobine et le corps.

• Raccordez toujours le conducteur de protection.

• Contrôlez le passage du courant entre la bobine et le corps.

max. 0,30 Nm

Type 2506

Joint

Respectez la tension et le type de courant selon la plaque

signalétique.

7.4. Montage de la bobine

AVERTISSEMENT !

Choc électrique.

Il y a risque de choc électrique en l’absence d’un contact du

conducteur de protection entre la bobine et le corps.

• Contrôlez le contact du conducteur de protection après montage

de la bobine.

Surchauffe, risque d’incendie.

Le raccordement de la bobine sans vanne en amont entraîne la surchauffe et la destruction de la bobine.

• Raccorder la bobine uniquement avec la vanne montée.

français

4 x 90°

Écrou

max. 2,8 Nm

Joint

La vanne peut être tournée 4 x 90° :

→ Desserrez l’écrou.

→ Tournez la bobine.

→ Serrez l’écrou à fond avec un

outil approprié (clé à fourche)

(2,8 Nm maxi).

8. MAINTENANCE, DÉPANNAGE

8.1. Consignes de sécurité

AVERTISSEMENT !

Risque de blessures dû à des travaux de maintenance non

conformes.

• La maintenance doit être effectué uniquement par un personnel

qualifié et habilité disposant de l’outillage approprié.

Risque de blessures dû à la mise en marche involontaire de l’installation et le redémarrage non contrôlé.

• Empêchez tout actionnement involontaire de l’installation.

• Garantissez un redémarrage contrôlé après la maintenance.

8.2. Pannes

En présence de pannes, vérifiez :

→ les raccords de conduite,

→ la pression de service,

→ l’alimentation en tension et la commande de la vanne.

Si malgré tout la vanne ne fonctionne pas, veuillez contacter votre

service après-vente Bürkert.

français

Page 12

9. PIÈCES DE RECHANGE

PRUDENCE !

Risque de blessures, de dommages matériels dus à de mauvaises pièces.

De mauvais accessoires ou des pièces de rechange inadaptées

peuvent provoquer des blessures et endommager l’appareil ou son

environnement.

• Utilisez uniquement des accessoires ainsi que des pièces de

rechange d’origine de la société Bürkert.

Robinetterie

Bobine

Écrou

La bobine et la robinetterie

peuvent être commandées

au complet sous le numéro

d’identification d’appareil

(voir plaque signalétique).

Jeu de pièces d’usure sur

demande

10. TRANSPORT, STOCKAGE, ÉLIMINATION

REMARQUE !

Dommages dus au transport.

Les appareils insuffisamment protégés peuvent être endommagés

pendant le transport.

• Transportez l’appareil à l’abri de l’humidité et des impuretés et

dans un emballage résistant aux chocs.

• Évitez le dépassement vers le haut ou le bas de la température de

stockage admissible.

Un mauvais stockage peut endommager l’appareil.

• Stockez l’appareil au sec et à l’abri des poussières !

• Température de stockage : -40 ... +80 °C.

Dommages à l’environnement causés par des pièces d’appareil contaminées par des fluides.

• Respectez les prescriptions en matière d’élimination des déchets

et de protection de l’environnement en vigueur.

français

www.burkert.com

Loading...

Loading...