Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

Type 8643 PA

Power I/O-Box

with PROFIBUS PA profile 3.0

mit PROFIBUS PA Profil 3.0

avec PROFIBUS PA profil 3.0

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürker t Werke GmbH & Co. KG, 200 - 2017

Operating Instructions 1706/0_EU-EN_0080 / Original DE

Page 3

3

Contents

1 OPERATING INSTRUCTIONS ........................................................................................................................................................5

1.1 Symbols ......................................................................................................................................................................................5

2 AUTHORIZED USE .............................................................................................................................................................................6

2.1 Restrictions ...............................................................................................................................................................................6

2.2 Explosion protection approval ........................................................................................................................................6

3 BASIC SAFETY INSTRUCTIONS .................................................................................................................................................7

4 GENERAL INFORMATION ................................................................................................................................................................9

4.1 Contact Addresses ................................................................................................................................................................9

4.2 Warranty ......................................................................................................................................................................................9

4.3 Information on the Internet ...............................................................................................................................................9

4.4 Trademarks ...............................................................................................................................................................................9

5 SYSTEM DESCRIPTION ................................................................................................................................................................10

5.1 General Description ...........................................................................................................................................................10

5.1.1 Advantages and technical features ................................................................................................ 10

5.1.2 Application area ..................................................................................................................................11

5.1.3 Identification ........................................................................................................................................11

5.1.4 Cable connections on the body ......................................................................................................12

5.1.5 LED display ..........................................................................................................................................13

5.2 Technical Data ......................................................................................................................................................................13

5.3 Dimensions ............................................................................................................................................................................15

6 INSTALLATION ...................................................................................................................................................................................16

6.1 Safety instructions .............................................................................................................................................................16

6.2 Installation instructions ...................................................................................................................................................17

6.3 Cable glands ..........................................................................................................................................................................18

6.4 Electrical Connections .....................................................................................................................................................19

6.4.1 Safety instructions ..............................................................................................................................19

6.4.2 Overview of the terminals and outputs ..........................................................................................19

Type 8643 with PROFIBUS PA Profile 3.0

english

Type 8643 PA

Page 4

4

6.4.3 Supply connection ............................................................................................................................. 20

6.4.4 Connection of the SHIELD terminal ...............................................................................................21

6.4.5 Actuator terminals ..............................................................................................................................22

6.4.6 Sensor terminals .................................................................................................................................22

7 SETTING THE STATION ADDRESSES ..................................................................................................................................23

7.1 LED display .............................................................................................................................................................................23

7.2 Watchdog ................................................................................................................................................................................23

8 CONFIGURING THE NETWORK ................................................................................................................................................24

8.1 Storage allocation for user data transfer ...............................................................................................................24

8.2 System parameters ...........................................................................................................................................................24

8.2.1 Physical block......................................................................................................................................24

8.2.2 Transducer Block ................................................................................................................................32

8.2.3 Function block .....................................................................................................................................39

9 MALFUNCTIONS ...............................................................................................................................................................................45

10 PACKAGING AND TRANSPORT ...............................................................................................................................................46

11 STORAGE ..............................................................................................................................................................................................46

12 DISPOSAL ............................................................................................................................................................................................46

english

Type 8643 PA

Page 5

5

Operating Instructions

1 OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

▶ The operating instructions must be read and understood.

1.1 Symbols

DANGER!

Warns of an immediate danger!

▶ Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

▶ Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

▶ Failure to observe this warning may result in a medium or minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

indicates important additional information, tips and recommendations.

refers to information in these operating instructions or in other documentation.

→ designates a procedure which you must carry out.

english

Type 8643 PA

Page 6

6

Authorized use

2 AUTHORIZED USE

Unauthorized use of the Power I/O Box Type 8643 with PROFIBUS PA connection can be dangerous to

people, nearby equipment and the environment.

▶ The device is designed as a valve and sensor connection. Only sensors and valves may be connected which

comply with the technical specifications.

▶ During use observe the authorized data, the operating conditions and conditions of use specified in the con-

tract documents and operating instructions, as indicated in the EC-Type Examination Certificate.

▶ The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert.

▶ Correct transportation, correct storage and installation and careful use and maintenance are essential for reli-

able and faultless operation.

▶ Do not subject the body of the Power I/O Box Type 8643 to mechanical loads (e.g. by placing objects on it or

standing on it).

▶ Use the device only as intended.

2.1 Restrictions

If exporting the system, observe any existing restrictions.

2.2 Explosion protection approval

Any unauthorized changes to the Power I/O Box Type 8643 with PROFIBUS PA connection or to components

invalidate the explosion protection approval.

english

Type 8643 PA

Page 7

7

Basic Safety Instructions

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation, operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

Hazardous if used in explosion-risk area

Risk of explosion from electrical voltage!

The Power I/O Box Type 8643 is designed as ignition protection type Ex-e (increased safety).

▶ Before working on non-intrinsically safe circuits of the Power I/O Box Type 8643, always switch off the oper-

ating voltage of the system!

Danger of explosion due to internal charging of the Power I/O Box Type 8643!

When the power supply to the Power I/O Box Type 8643 is switched off, the internally stored charge will not be

completely dissipated for 4 minutes. To prevent an explosion, switch off the power supply before connecting or

disconnecting Ex-e terminals.

▶ Do not remove the cover from the connection terminals for Ex-e switching circuits until the connected Ex-e

circuits have been disconnected from the power supply for longer than 4 minutes.

Danger of explosion if the allowable ambient temperature ranges are exceeded!

▶ Observe the respective ambient temperature range which is based on the type designation (e.g. 8643-4-AL-

KS-F-I/O), according to the table in the EC-Type Examination Certificate.

Danger of explosion due to unauthorized combination of the ignition protection types!

Due to unauthorized combination of the ignition protection types, the device is not suitable for use in the

explosion-risk area. If the device is nevertheless used in this area, there is a danger of explosion!

▶ If the bus supply of the device was operated once in ignition protection type of increased safety (e), the bus

supply may no longer be intrinsically safe in the ignition protection type (i).

General hazardous situations.

To prevent injury, ensure that:

▶ That the system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a

defined or controlled manner.

▶ The device may be operated only when in perfect condition and in consideration of the operating instructions.

▶ The general rules of technology apply to application planning and operation of the device.

english

Type 8643 PA

Page 8

8

Basic Safety Instructions

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components which react sensitively to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects is hazardous to these components. In the worst case scenario,

they will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1 and 5-2 to minimise or avoid the possibility of

damage caused by sudden electrostatic discharge!

• Also ensure that you do not touch electronic components when the power supply voltage is present!

The Power I/O Box Type 8643 was developed with due consideration given to the accepted safety rules

and is state-of-the-art. Nevertheless, dangerous situations may occur.

Operate the Power I/O Box Type 8643 only when it is in perfect condition and in accordance with the

operating instructions.

The explosion protection approval is only valid if you use the Power I/O Box Type 8643 as indicated. If

you make any unauthorized changes, the explosion protection approval will be invalidated!

Information on the PROFIBUS PA

Detailed information on the start-up of a PROFIBUS PA line can be found in the PROFIBUS PA User and

Installation Guideline.

Internet: www.profibus.de

english

Type 8643 PA

Page 9

9

General Information

4 GENERAL INFORMATION

4.1 Contact Addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of these printed operating instructions.

And also on the internet at: www.burkert.com

4.2 Warranty

The warranty is only valid if the Power I/O Box Type 8643 is used as intended in accordance with the specified

application conditions.

4.3 Information on the Internet

Operating instructions and data sheet for the Power I/O Box Type 8643 with PA connection can be found on the

Internet at: www.burkert.com

4.4 Trademarks

NAMUR

Association of Users of Automation Technology in the Process Industry

english

Type 8643 PA

Page 10

10

System Description

5 SYSTEM DESCRIPTION

5.1 General Description

The Power I/O Box Type 8643 with PROFIBUS PA connection (stated below as the Power I/O Box Type 8643)

is used to connect binary signals to the PROFIBUS PA.

It is suitable for use in areas where there is a risk of explosion, authorized according to ATEX and IECEx for use in

Zone 1 and 21.

The device is available either in an aluminium or polyester body belonging to protection class IP65.

All cable glands are situated on the underside. There are two versions of the different bus concepts:

The device is supplied for the Ex-i bus (FISCO) via a voltage source, as the usable energy from the bus line is

severely restricted. However, the connection to an Ex-e bus is also possible.

5.1.1 Advantages and technical features

Advantages of the Power I/O Box

• Simple and safe installation.

• Reliable galvanic isolation between power supply, bus connection and the inputs or outputs.

• Reliable IP protection.

Technical features of the Power I/O Box

• Body: Polyester, powder-coated aluminium.

• Protection class: IP65 (as electronic module IP20/IP30)

• Temperature range from –20 to +55 °C (see table in the EC-Type Examination Certificate)

• Interfaces: PROFIBUS PA

• Outputs: 4x Ex-i DO; inputs: 8x Ex-i DI

• Approval according to ATEX: II 2 (1) G Ex e mb [ia IIC Ga] IIC T4 Gb

II 2 (1) D Ex tb [ia IIIC Da] IIIC T65 °C Db IP65

• Approval according to IECEx: Ex e mb [ia IIC Ga] IIC T4 Gb

Ex tb [ia IIIC Da] IIIC T65 °C Db IP65

english

Type 8643 PA

Page 11

11

System Description

5.1.2 Application area

The Power I/O Box Type 8643 is designed for remote use in an industrial environment, particularly in the areas of

the pharmaceutical industry, petrochemistry and fine chemistry.

It satisfies the conditions for protection class IP65 (in aluminium or polyester body).

DANGER!

Risk of explosion from electrical voltage!

The Power I/O Box Type 8643 is designed as ignition protection type Ex-e (increased safety).

▶ Before working on non-intrinsically safe circuits of the Power I/O Box Type 8643, always switch off the oper-

ating voltage of the system!

If using the Power I/O Box Type 8643 in a control cabinet, ensure that

• the control cabinet is also authorized for use in an environment where there is a risk of explosion,

• the control cabinet is large enough for the lost heat to be discharged to the exterior in a suitable

manner,

• the internal temperature of the control cabinet does not exceed the allowable operating temperature of

the Power I/O Box Type 8643!

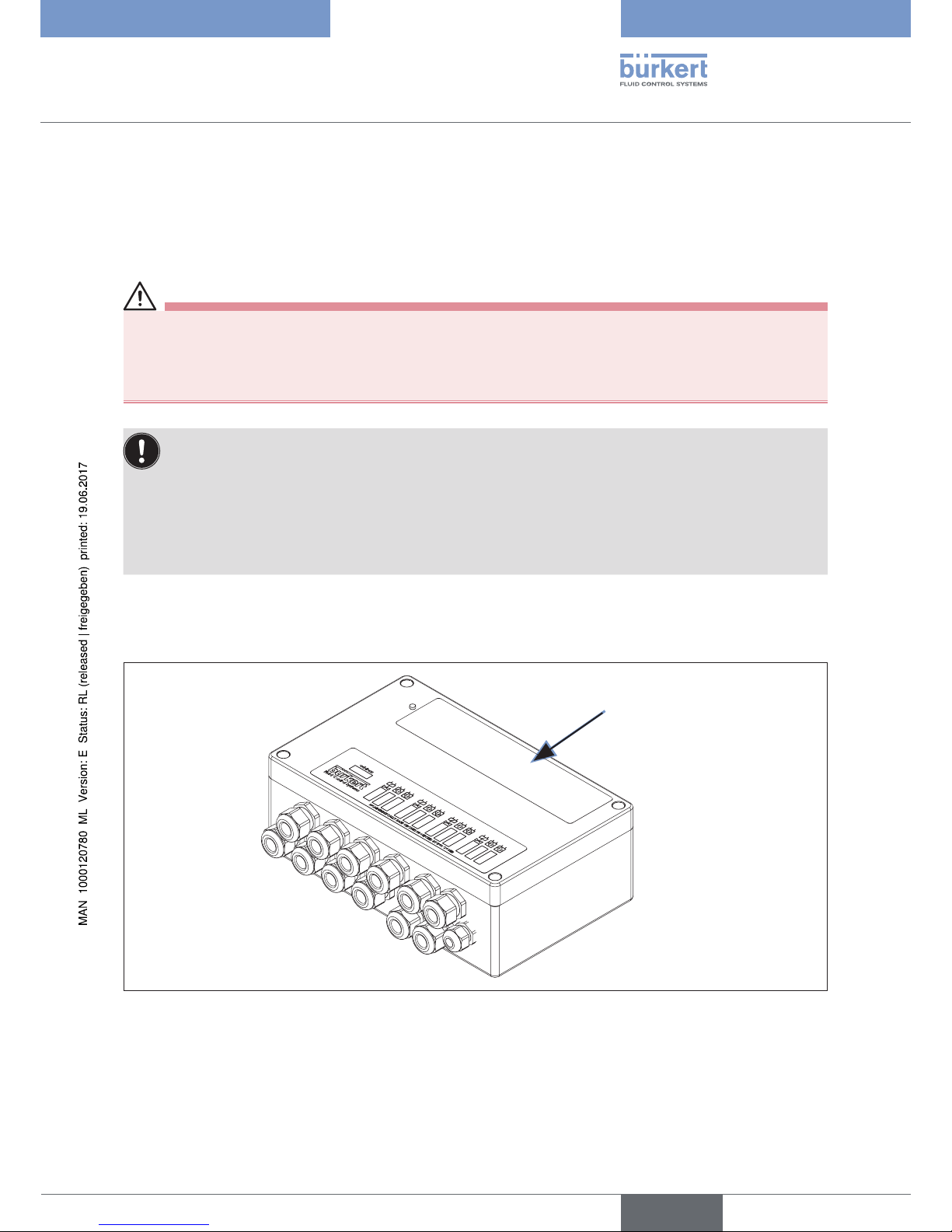

5.1.3 Identification

Profibus PA Interface: Digital I/O

Type label

Fig. 1: Location of the type label

english

Type 8643 PA

Page 12

12

System Description

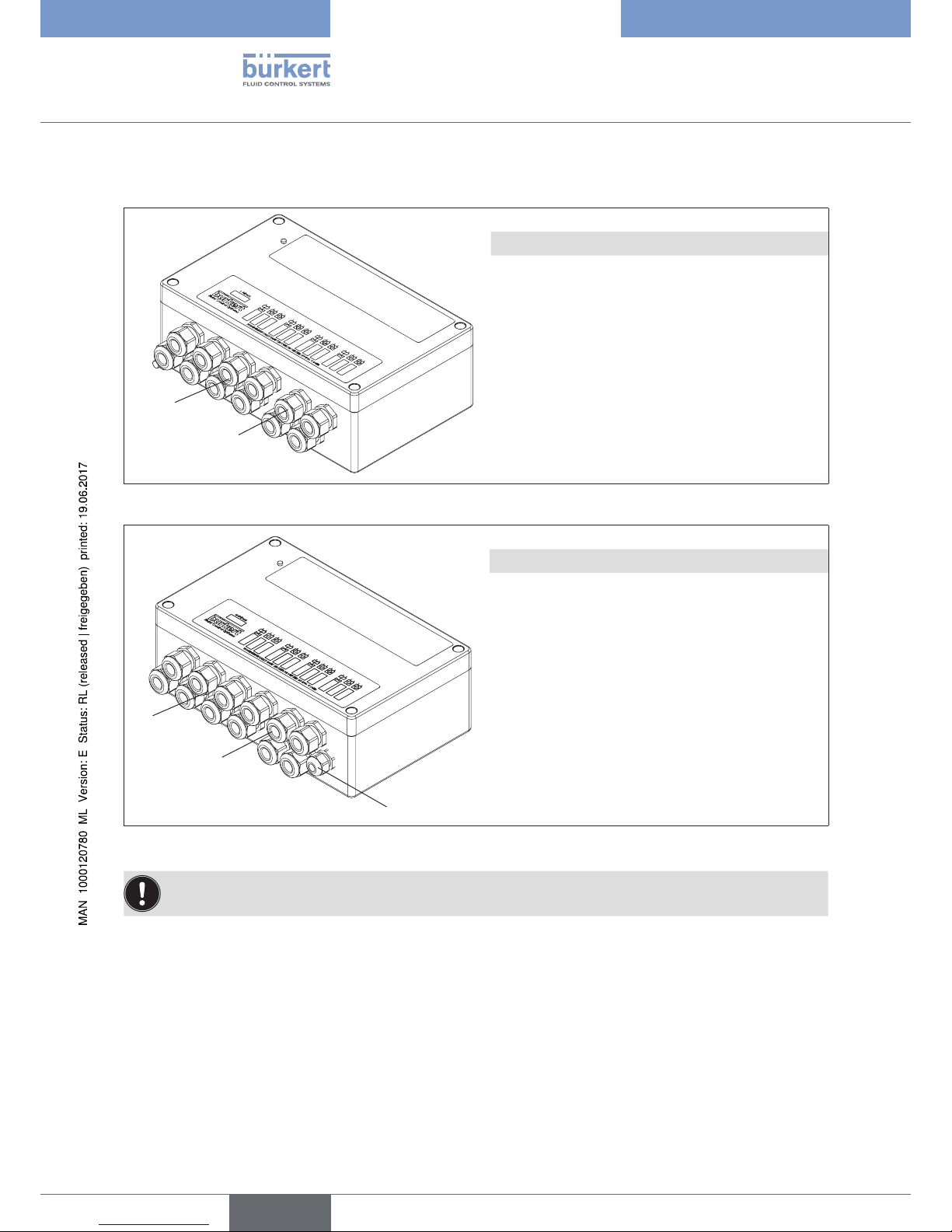

5.1.4 Cable connections on the body

1

2

Profibus PA Interface: Digital I/O

No. Designation

1

Cable glands for intrinsically safe circuits

(8 screw joints, blue)

2

Cable glands for bus and power supply

(4 screw joints, black)

Fig. 2: Location of the cable connections on the aluminium body of the device

1

2

3

Profibus PA Interface: Digital I/O

No. Designation

1

Cable glands for intrinsically safe circuits

(8 screw joints, blue)

2

Cable glands for bus and power supply

(4 screw joints, black)

3

Cable gland for earth cable PA

(potential equalisation)

Fig. 3: Location of the cable connections on the plastic body of the device

When delivered, the cable glands are covered with protective caps. These protective caps must remain

on the cable glands until the cables are connected to keep out dirt.

english

Type 8643 PA

Page 13

13

System Description

5.1.5 LED display

LED 1 green

LED 2

green

Fig. 4: Location of the LED display

LED 1 is lit when voltage is applied to the bus supply.

LED 2 is lit if the device is using cyclic data transfer.

LED 3 is lit if the device is not using cyclic data transfer

(only after Power on or if the Watchdog is active).

If neither LED 2 nor LED 3 is lit, check power supply!

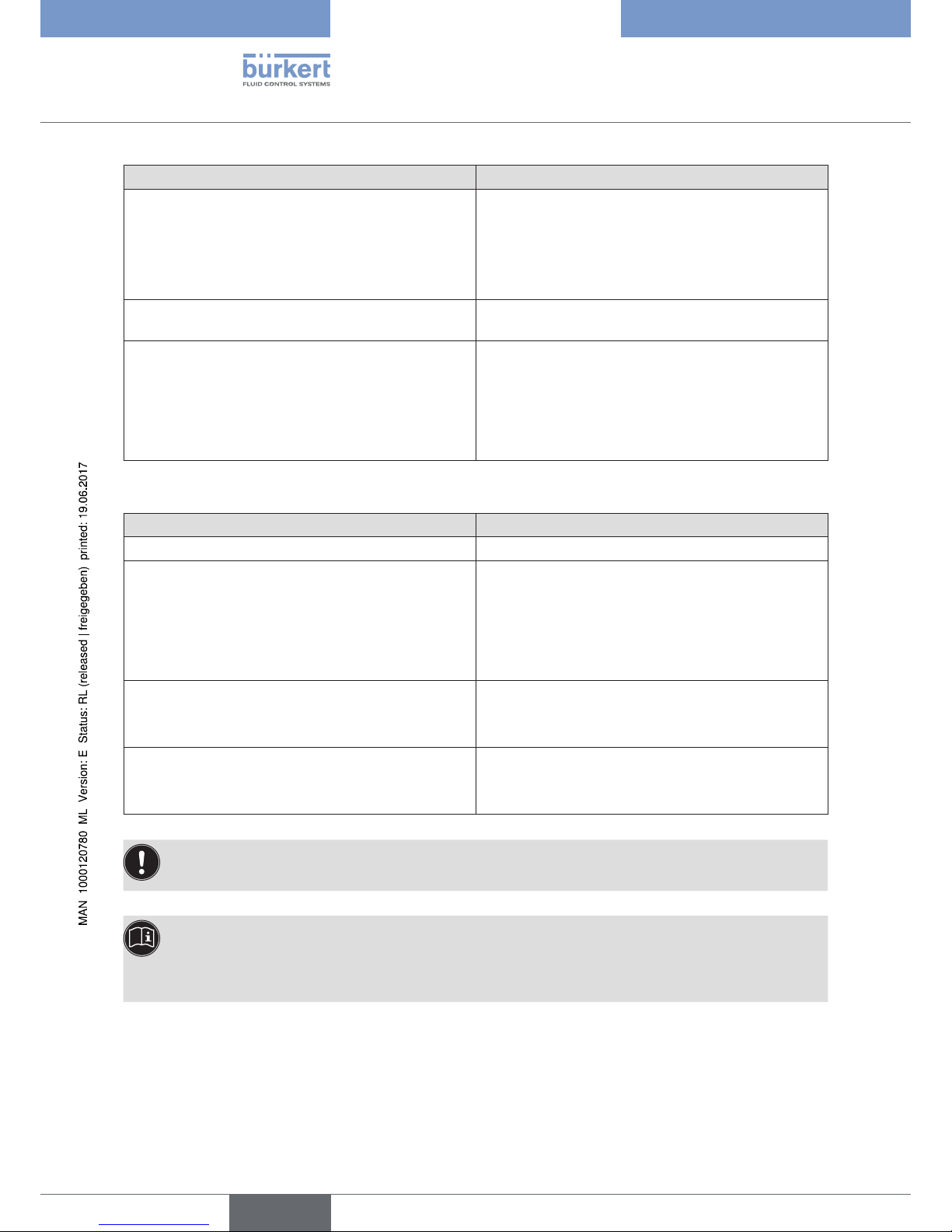

5.2 Technical Data

Designation Values

Body material Polyester, aluminium

Colour black

Ambient temperature -20 ... +60 °C

Cable entry Polyamide cable glands

Protection class IP 65 (DIN EN 60529)

Protection class 3 (DIN EN 61140 (vDE 0140-1))

Ignition protection identification (complete device) ATEX:

II 2 (1) G Ex e mb [ia IIC Ga] IIC T4 Gb

II 2 (1) D Ex tb [ia IIIC Da] IIIC T65 °C Db IP65

IECEx:

Ex e mb [ia IIC Ga] IIC T4 Gb

Ex tb [ia IIIC Da] IIIC T65 °C Db IP65

Power supply voltage 4-wire version

Auxiliary supply 24 V

17 ... 32 V DC

english

Type 8643 PA

Page 14

14

System Description

Designation Values

Max. power requirement

Bus voltage

Power consumption of bus

200 mA (17 V)

140 mA (24 V)

110 mA (32 V)

9 ... 32 V DC

12 mA /17 mA FDE

Inputs

8, intrinsically safe, NAMUR

(in accordance with EN 60947-5-6)

Outputs

Outputs for pilot valves

min. switching current

min. holding current

Internal resistance

Off-load voltage

4, intrinsically safe

30 mA

1)

15 mA

330 ohm

24 V

1)

Power reduction to holding current after minimum 50 ms.

Designation Values

Electrical connections for inputs and outputs Screw terminals (up to 2.5 mm²)

Field bus interface

Ignition protection type

Electrical connection

Communication in accordance with IEC 1158-2

in accordance with FISCO

EEx i

4 screw terminals bus (up to 2.5 mm²)

3 screw terminals shield

(1x directly and 2x capacitively earthed)

Auxiliary supply

Ignition protection type

Electrical connection

Increased safety EEX e

4 screw terminals (up to 2.5 mm²)

Device key (see type label)

polyester body

aluminium body

8643-4-PO-XX-X-XXX

8643-4-AL-XX-X-XXX

• The cable resistance to the sensors and actuators may be max. 20 Ω.

• The Power I/O Box Type 8643 may be supplied with low safety voltage in accordance with VDE 0631 only.

• The Power I/O Box Type 8643 satisfies the conditions of the EMC Law. EN61000-6-2 Interference

Resistance, EN61000-6-4 Interference Emission

• The safety-related maximum values for operation in explosion-risk area can be found in the Type

Examination Certificate in the Appendix.

english

Type 8643 PA

Page 15

15

System Description

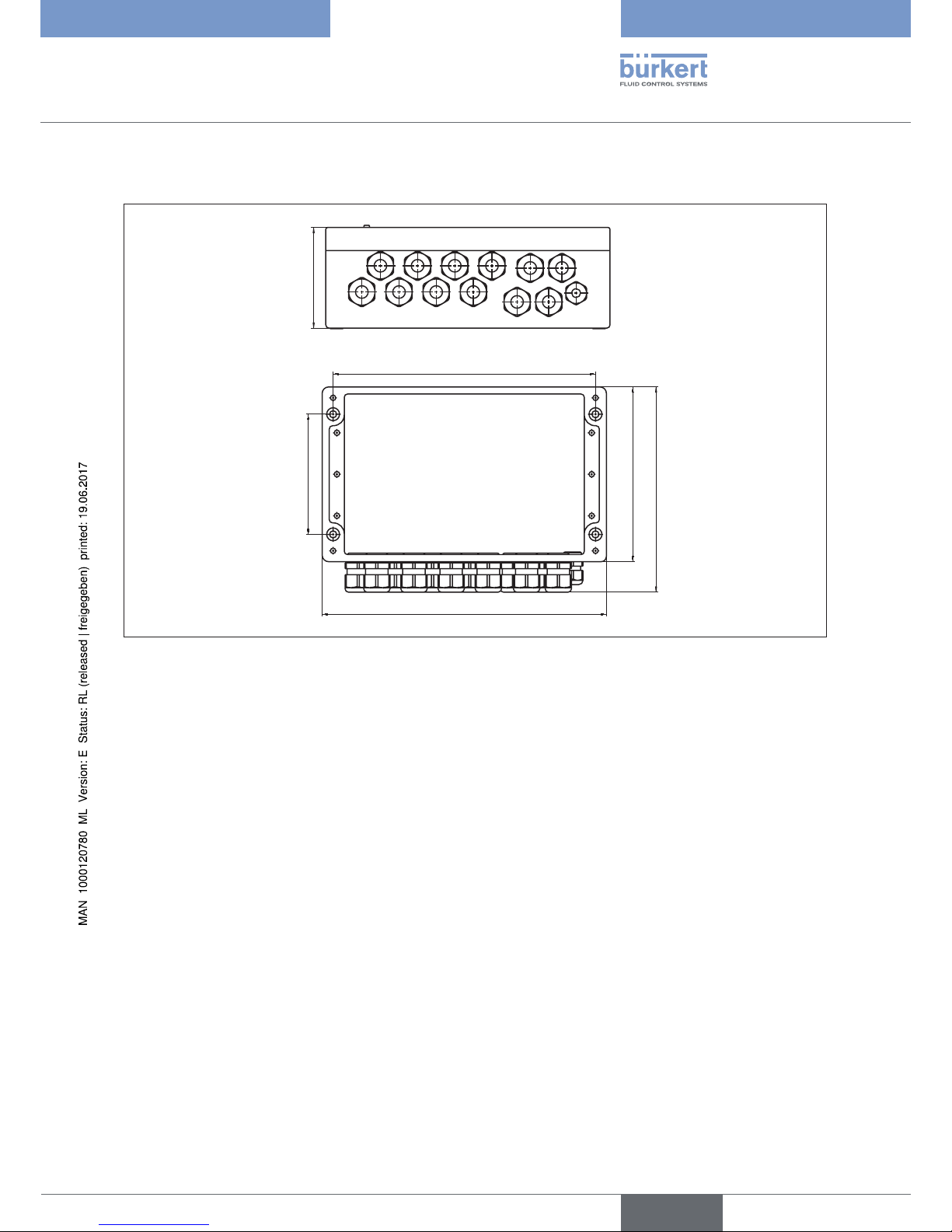

5.3 Dimensions

260

160

188

110

240

92

Fig. 5: Dimensions Type 8643

english

Type 8643 PA

Page 16

16

Installation

6 INSTALLATION

6.1 Safety instructions

DANGER!

Hazardous if used in explosion-risk area

Risk of explosion from electrical voltage!

The Power I/O Box Type 8643 is designed as ignition protection type Ex-e (increased safety).

▶ Before working on non-intrinsically safe circuits of the Power I/O Box Type 8643, always switch off the

operating voltage of the system!

Danger of explosion due to internal charging of the Power I/O Box Type 8643!

When the power supply to the Power I/O Box Type 8643 is switched off, the internally stored charge will not

be completely dissipated for 4 minutes. To prevent an explosion, switch off the power supply before connecting

or disconnecting Ex-e terminals.

▶ Do not remove the cover from the connection terminals for Ex-e switching circuits until the connected Ex-e

circuits have been disconnected from the power supply for longer than 4 minutes.

Danger of explosion if the allowable ambient temperature ranges are exceeded!

▶ Observe the respective ambient temperature range which is based on the type designation

(e.g. 8643-4-AL-KS-F-I/O), according to the table in the EC-Type Examination Certificate.

Danger of explosion due to unauthorized combination of the ignition protection types!

Due to unauthorized combination of the ignition protection types, the device is not suitable for use in the

explosion-protected area. If the device is nevertheless used in this area, there is a danger of explosion!

▶ If the bus supply of the device was operated once in ignition protection type of increased safety (e), the bus

supply may no longer be intrinsically safe in the ignition protection type (i).

WARNING!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only and with the appropriate tools!

▶ Observe the national regulations which apply to the installation/operation of electrical equipment in areas

where there is a risk of explosions!

Risk of injury from unintentional activation of the system and an uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

english

Type 8643 PA

Page 17

17

Installation

NOTE!

Electrostatic sensitive components / modules.

The Power I/O Box Type 8643 contains electronic components which respond sensitively to electrostatic discharge (ESD).

Contact with electrostatically charged persons or objects is hazardous to these components. In the worst case

scenario, they will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 100 015 – 1 to minimize or avoid the possibility of damage

caused by sudden electrostatic discharge!

• Do not touch the electronic components while the power supply voltage is on!

Function restriction

The function of the device may be restricted without potential equalisation.

• Connect the earth terminal point on the body to the potential equalisation (PA).

6.2 Installation instructions

NOTE!

• The allowable technical data must not be exceeded.

• Preferred installation position:

Cable glands face downwards!

• The cable glands on the body have a metric thread.

• Use only shielded lines to supply the bus!

• Place the bus line shields on the designated screw terminals as short as possible!

• When the work is complete, carefully close the body again!

This device complies with the EMC Directive of the Council of the European Union No. 2004/108/EG.

Follow the installation instructions to satisfy the conditions of this directive.

english

Type 8643 PA

Page 18

18

Installation

6.3 Cable glands

WARNING!

Danger of explosion!

No explosion protection if cable glands are defective or wrong.

▶ Replace defective cable glands only with Ex-authorized (EEx e II) cable glands with adequate application

temperature range (see Type Examination Certificate).

• At the factory all cable glands are sealed with a plug (protection class IP65).

• Seal all unused cable glands with a plug to maintain IP protection (IP65).

M16 x 1.5 potential equalisation PA

(with plastic body)

4 black M20 x 1.5 cable glands bus and power supply

8 blue M20 x 1.5 cable glands for intrinsically safe circuits

(sensor/actuator outputs)

Fig. 6: Cable glands

The body features eight blue cable glands for the intrinsically safe circuits and four black glands for the bus and

power supply with increased safety.

The bus and power supplies each have two M20x1.5 glands to loop through the supply lines.

For sensors and actuators each output (with two sensors) has an M20x1.5 cable gland.

Devices with plastic body have an M16x1.5 cable gland for the internal earth connection (PA).

Devices with metal body (e.g. aluminium) have an earth connection on the outside of the body.

english

Type 8643 PA

Page 19

19

Installation

6.4 Electrical Connections

6.4.1 Safety instructions

NOTE!

No function if reverse polarity.

▶ Pay attention to the polarity of the terminals!

The device is protected against polarity reversal.

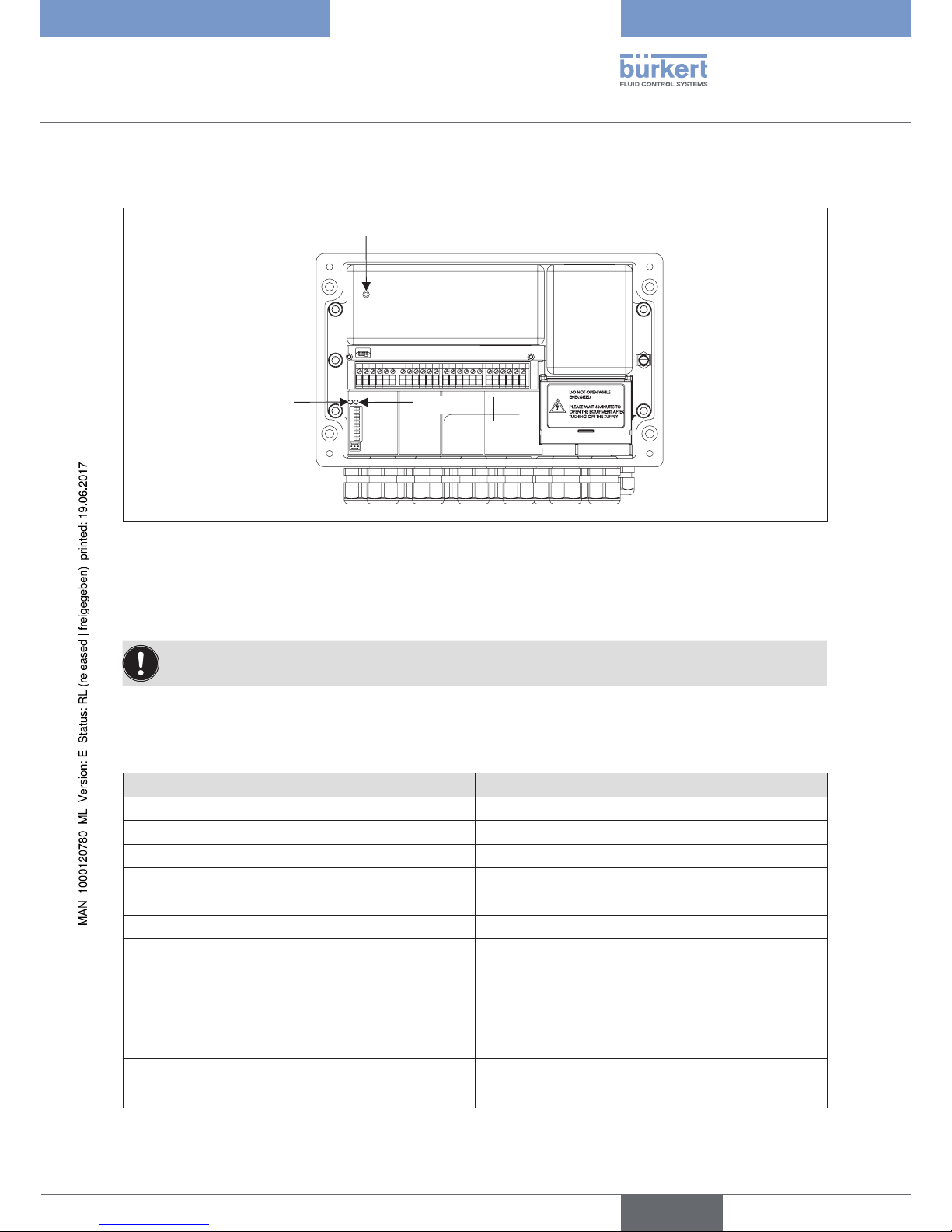

6.4.2 Overview of the terminals and outputs

LED module

Address

BUS

Power supply 24 V DC

Bus

Shield

Actuators and Sensors

Fig. 7: Overview of terminals and outputs

english

Type 8643 PA

Page 20

20

Installation

6.4.3 Supply connection

Terminal 24 V DC

Connection for the power supply in the ignition protection type EEx e II. Max. connected loads see EC Type

Examination Certificate.

Bus terminal

Connection for the bus supply in accordance with IEC 1158-2.

There are two options available depending on the device model.

DANGER!

Danger of explosion due to unauthorized combination of the ignition protection types!

Unauthorized combination of the ignition protection types may cause hazardous situations!

▶ If the bus supply of the device was operated once in ignition protection type of increased safety (e), the bus

supply may no longer be intrinsically safe in the ignition protection type (i).

Bus supply with increased safety

Ignition protection type: EEx e II

• Intrinsically safe bus supply

Ignition protection type EEx ia IIC or ignition protection type EEx ia IIB

english

Type 8643 PA

Page 21

21

Installation

6.4.4 Connection of the SHIELD terminal

Connection for the cable shield of the bus line.

There are two options available for connection of the cable shield.

8. Direct earthing to the body (PA)

Connection of the cable shield:

→ Connect cable shield to the right terminal.

9. Capacitive earthing to the body (PA)

To discharge EMC interference to the earth potential, a capacitor with a capacity <10 nF is installed in the device.

If several devices are connected in parallel with capacitive shield earthing, the energy stored in the capacitors in

the event of a fault must not exceed the authorized limit values (see IEC/EN 60079-11) of the valid gas group. To

determine the stored energy, the maximum authorized bus voltage must be taken into consideration.

Connection of the cable shield:

→ Connect cable shield to the left 2 terminals.

→ Connect the shield in a continuous manner.

→ Earth the shield at a point in the bus line.

The terminals for the bus and power supply have a cover to protect against unintentional contact.

Body terminals

Connection for the potential equalisation (PA).

Electromagnetic compatibility

To ensure an adequate discharge of EMC interference, connect the earth terminal to the potential equalisation

(PA) via a shortest possible line. If this is not possible, use suitable measures to prevent electromagnetic interference from unduly influencing the Power I/O Box Type 8643.

Connecting cable:

• minimum cross-section: 2.5 mm²

• maximum length: 0.5 m

To ensure that the body is not leaking, the outer diameter of the connecting cable must be min. 4 mm for

the plastic body.

english

Type 8643 PA

Page 22

22

Installation

6.4.5 Actuator terminals

The Power I/O Box Type 8643 has power-reduced outputs. This means that the current required to activate

the actuator is provided at the switching moment and reduced to the holding current after a specified time.

The actuator outputs are designed as ignition protection type ia.

Terminal designation

Polarity + -

Output 1 1 2

Output 2 7 8

Output 3 13 14

Output 4 19 20

6.4.6 Sensor terminals

The Power I/O Box Type 8643 has eight NAMUR sensor inputs; two sensors are always assigned to one actuator

output.

The sensors signal back the end positions of a connected process valve. However, they can also signal back

other process values independently of the actuator outputs (e.g. operator buttons, scraper end positions..).

The sensor inputs are designed as ignition protection type ia.

Output Sensor Terminal designation

Polarity + Polarity -

1

1.1 3 4

1.2 5 6

2

2.1 9 10

2.2 11 12

3

3.1 15 16

3.2 17 18

4

4.1 21 22

4.2 23 24

english

Type 8643 PA

Page 23

23

Setting the station addresses

7 SETTING THE STATION ADDRESSES

DIP switches 1 to 7 Bit 1 to Bit 7

The DIP switches are not read in until the device is switched on.

In the case of the PROFIBUS PA each station receives an address. These addresses are set with the DIP

switches 1 to 7.

The permitted address area is between 3 and 124.

Settings:

2

0

2

1

2

2

2

3

2

4

2

5

2

6

DIP -1 DIP -2 DIP -3 DIP -4 DIP -5 DIP -6 DIP -7 Address

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

ON

ON

OFF

ON

ON

ON

OFF

ON

ON

ON

OFF

ON

ON

ON

OFF

ON

ON

ON

3

:

:

124

125

126

* Delivery status: Address 126

If switch 8 is in the ON position, the internal address is used! This address can be set via the field bus.

7.1 LED display

The LED flashes if the device is using cyclic data transfer.

The LED lights up briefly when the device is connected.

If the device establishes an internal fault, the LED stays on constantly.

7.2 Watchdog

To improve fault detection, we recommend operating the device using cyclic data transfer with “DP watchdog”.

perm. address

range 3 ... 124

english

Type 8643 PA

Page 24

24

Configuring the network

8 CONFIGURING THE NETWORK

8.1 Storage allocation for user data transfer

Basis: Handbook for your PLC

→ To implement the correct settings of the configuration program, copy the device-specific file (buer6521.GSD)

from Bürkert into the directory which contains the configuration software. To read in and process the configuration, please read the documentation for your PLC or your control system.

Further information on the storage allocation can be found in the handbook.

8.2 System parameters

All profile data refers to the profile version 3.0 class B.

This is where you will also find detailed documentation on the parameters.

• When writing parameters, ensure that the power is on!

8.2.1 Physical block

8.2.1.1. Slot 0

Parameter type:

N

Non-volatile parameter which must be observed in the operating cycle.

However, it does not belong to the static updating code.

S

Static, non-volatile; the version counter ST_REV is increased during the write

process.

D (dynamic)

The value is calculated in the block or read from another block.

C (constant)

The parameter does not change.

english

Type 8643 PA

Page 25

25

Configuring the network

Abs. index Length

(byte)

Type Description

17

2 N ST_REV

18

32 S TAG_DESC

19

2 S STRATEGY

20

1 S ALERT_KEY

21

1 S TARGET_MODE

22

3 N/S

(RCAS)

MODE_BLK

23

8 D ALARM_SUM (not yet in the profile)

24

16 C SOFTWARE_REVISION

25

16 C HARDWARE_REVISION

26

2 C DEVICE_MAN_ID

27

2 C DEVICE_ID

28

16 N Serial number

29

4 D DIANOSIS

30

6 D DIANOSIS_EXTENSION

31

4 C DIANOSIS_MASK

32

6 C DIANOSIS_MASK_EXTENSION

35

2 S FACTORY_RESET

36

32 S DESCRIPTOR

37

32 S DEVICE_MESSAGE

38

16 S DEVICE_INSTAL_DATE

39

1 S LOCAL_OP_ENA

40

1 S IDENT_NUMBER

69

17 D VIEW_1

Table 1: Physical block Slotindex 0

english

Type 8643 PA

Page 26

26

Configuring the network

8.2.1.2. Description of the standard parameters

These parameters are included in the physical block, in the function block and in the transducer block.

Parameter Description

ALARM_SUM

This parameter includes the current status of the block alarm. The parameter

ALARM_SUM is not yet supported.

ALERT_KEY

This parameter includes the identification number of the plant unit. As a result, the

location (plant unit) of an event can be detected.

MODE_BLK

This parameter includes the current mode and the permitted and normal mode of the

block.

ST_REV

A module has static parameters which are not changed by the process. Values are

assigned to these parameters during the configuration or optimisation. The values

of the parameters ST_REV must increase by 1 whenever a static block parameter is

changed. As a result, the parameter revision can be checked.

STRATEGY

Arrangement of the function module. The STRATEGY field can be used to group

blocks.

TAG_DESC

Each block can be assigned a written TAG description. TAG_DESC is the address

of the block. TAG_DESC must be unique and standard in the field bus system.

TARGET_MODE

The TARGET_MODUS includes the required mode which is usually specified by a

control application or by operating personnel.

8.2.1.3. Properties of the standard parameters

Rel. Index Variable Data type Storage Size Access

1

ST-REV Unsigned 16 N 2 r,w

2

TAG_DESC Octet String * S 32 r,w

3

STRATEGY Unsigned 16 S 2 r,w

4

ALERT_KEY Unsigned 8 S 1 r,w

5

TARGET_MODE Unsigned 8 S 1 r,w

6

MODUS_BLK

current

permitted

normal

DS-37

N**

Cst

Cst

3 r

7

ALARM_SUM DS-42 8 r

Table 2: Assignments of the standard parameters

* The preferred data type should be Visible String

** N-accepted mode = RCAS

english

Type 8643 PA

Page 27

27

Configuring the network

Abbreviations:

Storage (requested storage class)

N

Non-volatile parameter which must be observed in the operating cycle. However, it does

not belong to the static updating code.

S

Static, non-volatile; the version counter ST_REV is increased during the write process.

D (dynamic)

The value is calculated in the block or read from another block.

Cst (constant)

The parameter does not change.

Access

r

read access

w

write access

The standard parameter View Object

Rel. Index Variable View_1 View_2 View_3 View_4

1

ST-REV 2

2

TAG_DESCRIPTION

3

STRATEGY

4

ALERT_KEY

5

TARGET_MODUS

6

MODUS_BLK 3

7

ALARM_SUM 8

Table 3: View Object of the standard parameters

Mode structure

This data structure consists of character strings for current, set and normal modes.

Data type: Mode

Key attributes: Index = 37

Indicator: Number of the elements

Indicator: List of the elements

E Name of the element Data type (index) Size (byte)

1

current Unsigned 8 - (5) 1

2

permitted Unsigned 8 - (5) 1

3

normal Unsigned 8 - (5) 1

Table 4: List of the elements of the mode structure

english

Type 8643 PA

Page 28

28

Configuring the network

Out of service (O/S)

The block was not specified. If the initial value was specified during a certain failsafe value, the last value or the configured fail-safe value is retained.

Manual l (Man)

The output block is specified directly by the user by means of an interface

command.

Automatic (Auto)

The Invert parameter is used to form the output value.

Remote Cascade

(RCas)

The set-point block was set by a control application which works on an interface

device via the remote cascade parameter RCAS_IN.

The version of a function block or transducer block is checked by the mode parameter. Values of the subindex

mode are defined as follows:

1. Target

This is the mode which is requested by the user. The values which are authorized by parameters of the permitted

mode, are limited for target. The modes are specified by the bit string in the following manner:

Bit Mode

7

Out of service (O/S) - MSB

4

Manual (Man)

3

Automatic (Auto)

1

Remote - Cascade (RCas)

The “automatic” modes which are used in this profile are Auto and RCas; manual mode: Man. In the O/S mode

the normal algorithm is not implemented and each pending alarm is deleted.

2. Current

This is the present mode of the module which may differ from the target mode which is based on operating

conditions.

Alarm sum structure

This data structure consists of data which combines the 16 alarms.

Data type Alarm sum

Key attributes Index = 42

Attributes Number of elements =4

Attributes List of elements (indicated below)

E Name of the element Data type (index) Size (byte)

1

current Octet String - (10) 2

2

not acknowledged Octet String - (10) 2

3

not signalled Octet String - (10) 2

4

switched off Octet String - (10) 2

Table 5: List of elements and the sum structure

english

Type 8643 PA

Page 29

29

Configuring the network

The bits of the bit string are assigned to the following alarms:

Bit

Alarm

0

Discrete alarm (LSB)

1

HI_HI_Alarm

2

HI_Alarm

3

LO_LO_Alarm

4

LO_Alarm

5

reserved

6

reserved

7

Block Alarm (e.g. increase of St_Rev)

8-15

reserved

8.2.1.4. Parameter description of the physical block

Parameter Parameter description

DEVICE_ID

Identification of the field device

DEVICE_MAN_ID

Identification code of the field device manufacturer (Bürkert = 120)

DEVICE_SER_NUM

Serial number of the manufacturer

DIANOSIS

Precise information on the device, coded bit by bit.

DIANOSIS_MASK

Definition of supported DIAGNOSIS information bits

0 = not supported

1 = supported

DIA_MEM_CHKSUM

Storage error

DIA_CONF_INVAL

Invalid configuration

DIA_WARMSTART

Warm start

DIA_COLDSTART

Cold start

HARDWARE_REVISION

Version number of the hardware for the field device

SOFTWARE_REVISION

Version number of the software for the field device

DIANOSIS_EXTENSION

Additional diagnosis for device manufacturer

DIANOSIS_MASK_

EXTENSION

Definition of supported information

FACTORY_RESET

1 Reset to standard values

2506 Warm start

2712 Reset the bus address, IDENT_NUMBER_SELECTOR is not reset

Parameter

Parameter description

DESCRIPTOR

User-definable text to describe the device within the application

english

Type 8643 PA

Page 30

30

Configuring the network

Parameter Parameter description

DEVICE_MESSAGE

User-definable message to describe the device within the application or system

LOCAL_OP_ENA

0 No local operation

DEVICE_INSTAL_DATE

Date the device was installed

IDENT_NUMBER

Selection of the GSD file

0 Specific to profile

1 Specific to manufacturer (standard value)

VIEW_1

includes the variables:

ST_REV

MODE_BLK

ALARM_SUM

DIANOSIS

Abbreviations:

Storage (requested storage class)

N

Non-volatile parameter which must be observed in the operating cycle.

However, it does not belong to the static updating code.

D (dynamic)

The value is calculated in the block or read from another block.

Cst (constant)

The parameter does not change.

S

Static, non-volatile; the version counter ST_REV is increased during the write process.

Access

r

read access

w

write access

Abs. index Variable Data type Storage Length Access

24

SOFTWARE_REVISION OctetString Cst 16 r

25

HARDWARE_REVISION OctetString Cst 16 r

26

DEVICE_MAN_ID OctetString Cst 2 r

27

DEVICE_ID OctetString Cst 2 r

28

Serial number OctetString Cst 16 r

29

DIANOSIS OctetString Byte =

4 MSB = 1 more

diagnosis available

D 4 r

30

DIANOSIS_EXTENSION OctetString D 6 r

31

DIANOSIS_MASK OctetString Cst 4 r

32

DIANOSIS_MASK_

EXTENSION

OctetString Cst 6 r

35

FACTORY_RESET Unsigned16 S 2 r/w

36

DESCRIPTOR OctetString S 32 r/w

37

DEVICE_MESSAGE OctetString S 32 r/w

38

DEVICE_INSTAL_DATE OctetString S 16 r/w

39

LOCAL_OP_ENA Unsigned8 N 1 r/w

english

Type 8643 PA

Page 31

31

Configuring the network

Abs. index Variable Data type Storage Length Access

40

IDENT_NUMBER Unsigned8 S 1 r/w

Table 6: Assignments of the standard parameters

All parameters of the physical block are acyclic!

Parameter structure of the bit string DIAGNOSIS

Bit Notation Description *

4

DIA_MEM_CHKSUM Storage checksum error R

10

DIA_CONF_INVAL Configuration not valid R

11

DIA_WARMSTART Repeated start request

(warm start request)

A

12

DIA_COLDSTART Restart request (cold start

request)

A

Table 7: Diagnosis of the parameter coding of the Physical Block

Coding of the diagnosis parameters

Values of the diagnosis bits:

0 = not set

1 = set

* = display class:

R = display is active for as long as the reason of the message is available.

A = display is automatically reset after the read process.

The standard parameter View Object

Rel. Index Variable View_1 View_2 View_3 View_4

1

ST_REV 2

2

TAG_DESCRIPTION

3

STRATEGY

4

ALERT_KEY

5

TARGET_MODUS

6

MODUS _BLK 3

7

ALARM_SUM 8

Table 8: View Object of the standard parameters

english

Type 8643 PA

Page 32

32

Configuring the network

Rel. Index Parameter notation Operation

Dynamic

VIEW_1

Operation

Static VIEW_2

All Dynamic

VIEW_3

Other Static

VIEW_4

8

SOFTWARE_REVISION

9

HARDWARE_REVISION

10

DEVICE_MAN_ID

11

DEVICE_ID

12

DEVICE_SER_NUM

13

DIANOSIS 4

14

DIANOSIS_EXTENSION

15

DIANOSIS_MASK

16

DIANOSIS_MASK_

EXTENSION

Table 9: Display objects of the physical block

8.2.2 Transducer Block

Abbreviations:

Storage

N

Non-volatile parameter which must be observed in the operating cycle. However, it does

not belong to the static updating code.

S

Static, non-volatile; the version counter ST_REV is increased during the write process.

D (dynamic)

The value is calculated in the block or read from another block.

Access

r

read access

w

write access

Transfer type

a

acyclic

cyc

cyclic

english

Type 8643 PA

Page 33

33

Configuring the network

8.2.2.1. Slot 1 (valve 1)

Abs. index Variable Data type Storage Length Access

81

ST_REV Unsigned16 N 2 r/w

82

TAG_DESC OctedString S 32 r/w

83

STRATEGY Unsigned16 S 2 r/w

84

ALERT_KEY Unsigned8 S 1 r/w

85

TARGET_MODE Unsigned8 S 1 r/w

86

MODE_BLK DS-37 N/S (RCAS) 3 r

87

ALARM_SUM (not yet in the profile) DS-42 D 8 r

88

VALVE_MAN OctedString S 16 r/w

89

ACTUATOR_MAN OctedString S 16 r/w

90

VALVE_SER_NUM OctedString S 16 r/w

91

ACTUATOR_SER_NUM OctedString S 16 r/w

92

VALVE_ID OctedString S 16 r/w

93

ACTUATOR_ID OctedString S 16 r/w

94

ACTUATOR_ACTION Unsigned8 S 1 r/w

95 TRAVEL_COUNT Unsigned16 N 2 r/w

96

TRAVEL_COUNT_LIM Unsigned16 N 2 r/w

105

TRAVEL_TIME_CLOSE_OPEN Unsigned16 N 2 r/w

106

TRAVEL_TIME_OPEN_CLOSE Unsigned16 N 2 r/w

109

TRAVEL_TIME_CLOSE_OPEN_TOL Unsigned16 S 2 r/w

110

TRAVEL_TIME_OPEN_CLOSE_TOL Unsigned16 S 2 r/w

111

SELF_CALIB_CMD Unsigned8 N 1 r/w

112

SELF_CALIB_STATUS Unsigned8 N 1 r

113

SENSOR_WIRE_CHECK Unsigned8 S 1 r/w

124

VIEW 13

Table 10: Parameter of the Transducer Block Slot 1

english

Type 8643 PA

Page 34

34

Configuring the network

8.2.2.2. Slot 2 (valve 2)

Abs. index Variable Data type Storage Length Access

81

ST_REV Unsigned16 N 2 r/w

82

TAG_DESC OctedString S 32 r/w

83

STRATEGY Unsigned16 S 2 r/w

84

ALERT_KEY Unsigned8 S 1 r/w

85

TARGET_MODE Unsigned8 S 1 r/w

86

MODE_BLK DS-37 N/S (RCAS) 3 r

87

ALARM_SUM (not yet in the profile) DS-42 D 8 r

88

VALVE_MAN OctedString S 16 r/w

89

ACTUATOR_MAN OctedString S 16 r/w

90

VALVE_SER_NUM OctedString S 16 r/w

91

ACTUATOR_SER_NUM OctedString S 16 r/w

92

VALVE_ID OctedString S 16 r/w

93

ACTUATOR_ID OctedString S 16 r/w

94

ACTUATOR_ACTION Unsigned8 S 1 r/w

95

TRAVEL_COUNT Unsigned16 N 2 r/w

96

TRAVEL_COUNT_LIM Unsigned16 N 2 r/w

105

TRAVEL_TIME_CLOSE_OPEN Unsigned16 N 2 r/w

106

TRAVEL_TIME_OPEN_CLOSE Unsigned16 N 2 r/w

109

TRAVEL_TIME_CLOSE_OPEN_TOL Unsigned16 S 2 r/w

110

TRAVEL_TIME_OPEN_CLOSE_TOL Unsigned16 S 2 r/w

111

SELF_CALIB_CMD Unsigned8 N 1 r/w

112

SELF_CALIB_STATUS Unsigned8 N 1 r

113

SENSOR_WIRE_CHECK Unsigned8 S 1 r/w

124

VIEW 13

Table 11: Parameter of the Transducer Block Slot 2

english

Type 8643 PA

Page 35

35

Configuring the network

8.2.2.3. Slot 3 (valve 3)

Abs. index Variable Data type Storage Length Access

81

ST_REV Unsigned16 N 2 r/w

82

TAG_DESC OctedString S 32 r/w

83

STRATEGY Unsigned16 S 2 r/w

84

ALERT_KEY Unsigned8 S 1 r/w

85

TARGET_MODE Unsigned8 S 1 r/w

86

MODE_BLK DS-37 N/S (RCAS) 3 r

87

ALARM_SUM (not yet in the profile) DS-42 D 8 r

88

VALVE_MAN OctedString S 16 r/w

89

ACTUATOR_MAN OctedString S 16 r/w

90

VALVE_SER_NUM OctedString S 16 r/w

91

ACTUATOR_SER_NUM OctedString S 16 r/w

92

VALVE_ID OctedString S 16 r/w

93

ACTUATOR_ID OctedString S 16 r/w

94

ACTUATOR_ACTION Unsigned8 S 1 r/w

95

TRAVEL_COUNT Unsigned16 N 2 r/w

96

TRAVEL_COUNT_LIM Unsigned16 N 2 r/w

105

TRAVEL_TIME_CLOSE_OPEN Unsigned16 N 2 r/w

106

TRAVEL_TIME_OPEN_CLOSE Unsigned16 N 2 r/w

109

TRAVEL_TIME_CLOSE_OPEN_TOL Unsigned16 S 2 r/w

110

TRAVEL_TIME_OPEN_CLOSE_TOL Unsigned16 S 2 r/w

111

SELF_CALIB_CMD Unsigned8 N 1 r/w

112

SELF_CALIB_STATUS Unsigned8 N 1 r

113

SENSOR_WIRE_CHECK Unsigned8 S 1 r/w

124

VIEW 13

Table 12: Parameter of the Transducer Block Slot 3

english

Type 8643 PA

Page 36

36

Configuring the network

8.2.2.4. Slot 4 (valve 4)

Abs. index Variable Data type Storage Length Access

81

ST_REV Unsigned16 N 2 r/w

82

TAG_DESC OctedString S 32 r/w

83

STRATEGY Unsigned16 S 2 r/w

84

ALERT_KEY Unsigned8 S 1 r/w

85

TARGET_MODE Unsigned8 S 1 r/w

86

MODE_BLK DS-37 N/S (RCAS) 3 r

87

ALARM_SUM (not yet in the profile) DS-42 D 8 r

88

VALVE_MAN OctedString S 16 r/w

89

ACTUATOR_MAN OctedString S 16 r/w

90

VALVE_SER_NUM OctedString S 16 r/w

91

ACTUATOR_SER_NUM OctedString S 16 r/w

92

VALVE_ID OctedString S 16 r/w

93

ACTUATOR_ID OctedString S 16 r/w

94

ACTUATOR_ACTION Unsigned8 S 1 r/w

95

TRAVEL_COUNT Unsigned16 N 2 r/w

96

TRAVEL_COUNT_LIM Unsigned16 N 2 r/w

105

TRAVEL_TIME_CLOSE_OPEN Unsigned16 N 2 r/w

106

TRAVEL_TIME_OPEN_CLOSE Unsigned16 N 2 r/w

109

TRAVEL_TIME_CLOSE_OPEN_TOL Unsigned16 S 2 r/w

110

TRAVEL_TIME_OPEN_CLOSE_TOL Unsigned16 S 2 r/w

111

SELF_CALIB_CMD Unsigned8 N 1 r/w

112

SELF_CALIB_STATUS Unsigned8 N 1 r

113

SENSOR_WIRE_CHECK Unsigned8 S 1 r/w

124

VIEW 13

Table 13: Parameter of the Transducer Block Slot 4

english

Type 8643 PA

Page 37

37

Configuring the network

8.2.2.5. Description of the block parameters of the transducer

• Suitable for solenoid valve application;

• Two proximity switches for each solenoid outlet;

• The input signals indicate the ON/OFF status of the valve.

Parameter Description

VALVE_MAN

Name of the valve manufacturer

ACTUATOR_MAN

Name of the actuator manufacturer

VALVE_SER_NUM

Serial number of the valve belonging to the device

ACTUATOR_SER_NUM

Serial number of the actuator belonging to the device

VALVE_ID

Identification of the valve (valve type)

ACTUATOR_ID

Identification of the actuator (actuator type)

ACTUATOR_ACTION

Safety position if actuator or valve has power failure:

0 not initialized

1 open

2 closed

TRAVEL_COUNT

Number of cycles from “open” to “closed” and from “closed” to “open”. The number

range of the TRAVEL_COUNT exceeds the storage capability of the EEPROM

TRAVEL_COUNT_LIM

Limit of the parameter TRAVEL_COUNT; if 0, TRAVEL_COUNT_LIM is not processed. If the LIMIT values are exceeded, the corresponding bit in the parameter

CHECK_BACK is set.

TRAVEL_TIME_CLOSE_

OPEN

Set-point value for the time in seconds between the change of status from CLOSED

to OPEN; if 0, the time is not processed. If the time is exceeded, the corresponding

bit in the parameter CHECK_BACK is set. Times less than 0.5 seconds cannot be

monitored.

TRAVEL_TIME_OPEN_

CLOSE

Set-point value for the time in seconds between the change of status from OPEN to

CLOSED; if 0, the time is not processed. If the time is exceeded, the corresponding

bit in the parameter CHECK_BACK is set. Times less than 0.5 seconds cannot be

monitored.

TRAVEL_TIME_CLOSE_

OPEN_TOL

Maximum time difference between TRAVEL_TIME_CLOSE_OPEN and the current

switching time

TRAVEL_TIME_OPEN_

CLOSE_TOL

Maximum time difference between TRAVEL_TIME_OPEN_CLOSE and the current

switching time

SELF_CALIB_CMD

Device-specific calibration

- - - - - - x y

y = 0 de-energized active

y = 1 energized active

x = 0 Sensor 1 displays “Valve open”

x = 1 Sensor 1 displays “Valve closed”

SELF_CALIB_STATUS

Result or status of the device-specific calibration (depending on manufacturer)

0 Standard setting

english

Type 8643 PA

Page 38

38

Configuring the network

Parameter Description

SENSOR_WIRE_CHECK

Activation of the line break or short-circuit detection

List of permissible values:

0 Line break or short-circuit detection activated

1 Line break detection activated Short-circuit detection not activated

2 Line break detection not activated Short-circuit detection activated

3 Line break or short-circuit detection not activated

The standard parameter View Object

Rel. Index Variable View_1 View_2 View_3 View_4

1

ST-REV 2

2

TAG_DESCRIPTION

3

STRATEGY

4

ALERT_KEY

5

TARGET_MODUS

6

MODUS_BLK 3

7

ALARM_SUM 8

Table 14: View Object of the standard parameters

english

Type 8643 PA

Page 39

39

Configuring the network

8.2.3 Function block

8.2.3.1. Slot 1 (valve 1)

Abs. index Variable Data type Storage Length Access Transfer

type

17

ST_REV Unsigned16 N 2 r/w a

18

TAG_DESC OctedString S 32 r/w a

19

STRATEGY Unsigned16 S 2 r/w a

20

ALERT_KEY Unsigned8 S 1 r/w a

21

TARGET_MODE Unsigned8 S 1 r/w a

22

MODE_BLK DS-37 N/S (RCAS) 3 r a

23

ALARM_SUM

(not yet in the profile)

DS-42 D 8 r a

24

Batch DS-67 D 10 r/w a

25

SP_D cyclic value bit 0

(LSB) valve position

DS-34 D 2 r/w a/cyc

26

OUT_D value bit 0

(LSB) valve position

DS-34 D 2 r

28

READ_BACK_D

(cyclic possible)

DS-34 D 2 r a/cyc

30

RCAS_IN_D

(cyclic possible)

value bit 0 (LSB)

valve position

DS-34 D 2 r/w a/cyc

33

CHANNEL

(only one value possible)

Unsigned16 S 2 r/w a

34

INVERT Unsigned16 S 1 r/w a

35

FSAVE_TIME Float S 4 r/w a

36

FSAVE_TYPE Unsigned8 S 1 r/w a

37

FSAVE_VAL_D Unsigned8 S 1 r/w a

38

RCAS_OUT_D

(cyclic possible)

DS-34 D 2 r a,cyc

39

SIMULATE DS-51 S 3 r/w a

49

CHECK_BACK

(cyclic possible)

BitString D 3 r a,cyc

50

CHECK_BACK_MASK BitString N 3 r a

79

VIEW_1

Table 15: Function block Slot 1

english

Type 8643 PA

Page 40

40

Configuring the network

8.2.3.2. Slot 2 (valve 2)

Abs. index Variable Data type Storage Length Access Transfer

type

17

ST_REV Unsigned16 N 2 r/w a

18

TAG_DESC OctedString S 32 r/w a

19

STRATEGY Unsigned16 S 2 r/w a

20

ALERT_KEY Unsigned8 S 1 r/w a

21

TARGET_MODE Unsigned8 S 1 r/w a

22

MODE_BLK DS-37 N/S (RCAS) 3 r a

23

ALARM_SUM

(not yet in the profile)

DS-42 D 8 r a

24

Batch DS-67 D 10 r/w a

25

SP_D cyclic value bit 0

(LSB) valve position

DS-34 D 2 r/w a/cyc

26

OUT_D value bit 0

(LSB) valve position

DS-34 D 2 r a

28

READ_BACK_D

(cyclic possible)

DS-34 D 2 r a/cyc

30

RCAS_IN_D

(cyclic possible)

value bit 0 (LSB)

valve position

DS-34 D 2 r/w a/cyc

33

CHANNEL

(only one value possible)

Unsigned16 S 2 r/w a

34

INVERT Unsigned16 S 1 r/w a

35

FSAVE_TIME Float S 4 r/w a

36

FSAVE_TYPE Unsigned8 S 1 r/w a

37

FSAVE_VAL_D Unsigned8 S 1 r/w a

38

RCAS_OUT_D

(cyclic possible)

DS-34 D 2 r a,cyc

39

SIMULATE DS-51 S 3 r/w a

49

CHECK_BACK

(cyclic possible)

BitString D 3 r a,cyc

50

CHECK_BACK_MASK BitString N 3 r a

79

VIEW_1

Table 16: Function block Slot 2

english

Type 8643 PA

Page 41

41

Configuring the network

8.2.3.3. Slot 3 (valve 3)

Abs. index Variable Data type Storage Length Access Transfer

type

17

ST_REV Unsigned16 N 2 r/w a

18

TAG_DESC OctedString S 32 r/w a

19

STRATEGY Unsigned16 S 2 r/w a

20

ALERT_KEY Unsigned8 S 1 r/w a

21

TARGET_MODE Unsigned8 S 1 r/w a

22

MODE_BLK DS-37 N/S (RCAS) 3 r a

23

ALARM_SUM

(not yet in the profile)

DS-42 D 8 r a

24

Batch DS-67 D 10 r/w a

25

SP_D cyclic value bit 0

(LSB) valve position

DS-34 D 2 r/w a/cyc

26

OUT_D value bit 0

(LSB) valve position

DS-34 D 2 r a

28

READ_BACK_D

(cyclic possible)

DS-34 D 2 r a/cyc

30

RCAS_IN_D

(cyclic possible)

value bit 0 (LSB)

valve position

DS-34 D 2 r/w a/cyc

33

CHANNEL

(only one value possible)

Unsigned16 S 2 r/w a

34

INVERT Unsigned16 S 1 r/w a

35

FSAVE_TIME Float S 4 r/w a

36

FSAVE_TYPE Unsigned8 S 1 r/w a

37

FSAVE_VAL_D Unsigned8 S 1 r/w a

38

RCAS_OUT_D

(cyclic possible)

DS-34 D 2 r a,cyc

39

SIMULATE DS-51 S 3 r/w a

49

CHECK_BACK

(cyclic possible)

BitString D 3 r a,cyc

50

CHECK_BACK_MASK BitString N 3 r a

79

VIEW_1

Table 17: Function block Slot 3

english

Type 8643 PA

Page 42

42

Configuring the network

8.2.3.4. Slot 4 (valve 4)

Abs. index Variable Data type Storage Length Access Transfer

type

17

ST_REV Unsigned16 N 2 r/w a

18

TAG_DESC OctedString S 32 r/w a

19

STRATEGY Unsigned16 S 2 r/w a

20

ALERT_KEY Unsigned8 S 1 r/w a

21

TARGET_MODE Unsigned8 S 1 r/w a

22

MODE_BLK DS-37 N/S (RCAS) 3 r a

23

ALARM_SUM

(not yet in the profile)

DS-42 D 8 r a

24

Batch DS-67 D 10 r/w a

25

SP_D cyclic value bit 0

(LSB) valve position

DS-34 D 2 r/w a/cyc

26

OUT_D value bit 0

(LSB) valve position

DS-34 D 2 r a

28

READ_BACK_D

(cyclic possible)

DS-34 D 2 r a/cyc

30

RCAS_IN_D

(cyclic possible)

value bit 0 (LSB)

valve position

DS-34 D 2 r/w a/cyc

17

ST_REV Unsigned16 N 2 r/w a

18

TAG_DESC OctedString S 32 r/w a

19

STRATEGY Unsigned16 S 2 r/w a

20

ALERT_KEY Unsigned8 S 1 r/w a

21

TARGET_MODE Unsigned8 S 1 r/w a

22

MODE_BLK DS-37 N/S (RCAS) 3 r a

23

ALARM_SUM

(not yet in the profile)

DS-42 D 8 r a

24

Batch DS-67 D 10 r/w a

25

SP_D cyclic value bit 0

(LSB) valve position

DS-34 D 2 r/w a/cyc

26

OUT_D value bit 0

(LSB) valve position

DS-34 D 2 r a

28

READ_BACK_D

(cyclic possible)

DS-34 D 2 r a/cyc

30

RCAS_IN_D

(cyclic possible)

value bit 0 (LSB)

valve position

DS-34 D 2 r/w a/cyc

Table 18: Function block Slot 4

english

Type 8643 PA

Page 43

43

Configuring the network

8.2.3.5. Description of the block parameters of the function block

Parameter

Description

READBACK_D

This parameter returns the position of the valve and the sensors.

Bit 7 6 5 4 3 2 1 0

0 0 Do not initialize

0 1 Closed

1 0 Open

1 1 On the move

Status sensor 1

Short-circuit sensor

No-load sensor 1

Status sensor 2

Short-circuit sensor

No-load sensor 2

1 = active

0 = inactive

SP_D

Set-point value

Bit 0 in the value specifies the valve position. The transferred status must be a

“good” status, e.g. 0x80.

OUT_D

Process value of the valve position. Bit 0 in the value indicates the valve position.

RCAS_IN_D

Set-point value in the RCAS status (Remote Cascade). Bit 0 in the value specifies

the valve position. The transferred status must be a “good” status, e.g. 0x80.

RCAS_OUT_D

Process value of the valve position in the RCAS status. Bit 0 in the value indicates

the valve position.

CHANNEL

Indicates the transducer block. There are channels 1-4. The function blocks are permanently assigned.

INVERT

Inverts the set-point value in the AUTO or RCAS status0 = do not invert1 = invert

FSAVE_TIME

Time in seconds after which the “Failsave” action starts following a break in the

cyclic communication. The maximum value for this time is approx. 18 hours.

FSAVE_TYP

Response to “Fail save”

0 = Valve retains the last status

1 = Valve switches according to FSAVE_VAL_D

2 = Isolate valve

FSAVE-VAL-D

Valve position in “Fail save”, if selected.

SIMULATE

Allows the simulation of READBACK_D

english

Type 8643 PA

Page 44

44

Configuring the network

Parameter

Description

CHECK_BACK

Information on the device

Bit Information

0 in “Fail save” position

8 Valve opens

9 Valve closes

16 Number of switching cycles specified in TRAVEL_COUNT_LIM is

exceeded.

20 Time to close exceeded.

21 Time to open exceeded.

1 = active

0 = inactive

CHECK_BACK_MASK

Specification of the information supported in the CHECK_BACK

1 = supported

0 = not supported

8.2.3.6. Structure of the cyclic data

The selection options of the cyclic data in the GSD file are indicated below:

The device operates with the GSD for 8643 as well as with the GSD for 8642.

Module=“EMPTY” 0x00

EndModule

Module=“SP_D” 0xA1

EndModule

Module=“SP_D_READBACK_D” 0xC1, 0x81, 0x81, 0x83

EndModule

Module=“SP_D_CHECKBACK_D” 0xC1, 0x81, 0x82, 0x92

EndModule

Module=“SP_D_READBACK_D_CHECKBACK_D” 0xC1, 0x81, 0x84, 0x93

EndModule

Module=“RCAS_IN_D_RCAS_OUT_D” 0xC1, 0x81, 0x81, 0x8C

EndModule

Module=“RCAS_IN_D_RCAS_OUT_D_CHECKBACK” 0xC1, 0x81, 0x84, 0x9C

EndModule

Module=“SP_D_READBACK_D_RCAS_IN_D_RCAS_0” 0xC1, 0x83, 0x86, 0x9F

EndModule

The description of the data can be found in the previous chapter. The sequence corresponds to that of the

function block.

english

Type 8643 PA

Page 45

45

Malfunctions

9 MALFUNCTIONS

Malfunction Possible cause Remedial action

Valves do not switch: No or inadequate oper-

ating voltage.

→ Check the electrical connection.

→ Ensure the operating voltage according to type plate.

Inadequate or no

pressure supply.

→ Design the pressure supply with the largest possible

volume (even for upstream devices such as pressure

controllers, maintenance units, shut-off valves, etc.).

Minimum operating pressure ≥ 2.5 bar

Valves switch with a

delay or blow off at the

deaeration connections:

Inadequate or no

pressure supply.

→ Design the pressure supply with the largest possible

volume (even for upstream devices such as pressure

controllers, maintenance units, shut-off valves, etc.).

Minimum operating pressure ≥ 2.5 bar

Deaeration of the

exhaust air ducts inadequate due to too small

or dirty silencers (back

pressures).

→ Use appropriately sized silencers or expansion tanks.

→ Clean dirty silencers.

Impurities or foreign

objects in the pilot valve

or main valve.

→ Apply pulsed pressure to the exhaust air ducts to blow

out the impurities; install a new pilot valve or main

valve if this procedure is unsuccessful.

english

Type 8643 PA

Page 46

46

Packaging and Transport

10 PACKAGING AND TRANSPORT

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against wet and dirt in shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage temperature.

• Protect the electrical interfaces of the coil and the pneumatic connections from damage by placing protective

caps on them.

11 STORAGE

NOTE!

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -20 … 60 °C.

12 DISPOSAL

→ Dispose of the device and packaging in an environmentally friendly manner.

NOTE!

Damage to the environment caused by device components contaminated with media.

• Observe applicable regulations on disposal and the environment.

Observe national waste disposal regulations.

english

Type 8643 PA

Page 47

Page 48

www.burkert.com

Loading...

Loading...