Page 1

Type 0121, 0330, 0331

(0124, 0125, 0332, 0333)

2/2- and 3/2-Way Solenoid Valve

2/2- und 3/2-Wege-Magnetventil

Électrovanne à 2/2 et 3/2 voies

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

Table of Contents

1 The operating instructions .................................................................................................. 2

2 Authorized use ..............................................................................................................................3

3 Basic safety instructions.......................................................................................................4

4 System description ....................................................................................................................5

5 Technical data................................................................................................................................6

6 Assembly

7 Electrical connection ............................................................................................................10

8 Disassembly

9 Maintenance, troubleshooting .......................................................................................12

10 Transportation, storage, disposal ................................................................................13

...........................................................................................................................................8

.................................................................................................................................12

1 THE OPERATING INSTRUCTIONS

The operating instructions contain important information.

▶▶

Read▶the▶instructions▶carefully▶and▶follow▶the▶safety▶instructions.▶

▶▶ Keep▶the▶instructions▶in▶a▶location▶where▶they▶are▶available▶to▶every▶

user.

The▶liability▶and▶warranty▶for▶the▶device▶are▶void▶if▶the▶operating▶

instructions▶are▶not▶followed.

1.1 Symbols

▶▶ Designates▶instructions▶for▶risk▶prevention.

▶→ Designates▶a▶procedure▶which▶you▶must▶carry▶out.

DANGER!

Immediate▶danger!▶Serious▶or▶fatal▶injuries.

WARNING!

Possible▶danger!▶Serious▶or▶fatal▶injuries.

CAUTION!

Danger!▶Moderate▶or▶minor▶injuries.

2

english

Page 3

NOTE!

Warns of damage to property.

Important▶tips▶and▶recommendations.

Refers▶to▶information▶in▶these▶operating▶instructions▶or▶in▶other▶

documentation.

1.2 Definitions of terms

In▶these▶instructions,▶the▶term▶"device"▶always▶refers▶to▶the▶Type▶0121,▶

0330,▶0331,▶(0124,▶0125,▶0332,▶0333).

2 AUTHORIZED USE

The device is designed to control, shut off and meter neutral

and aggressive media up to a viscosity of 37 mm²/s.

▶▶

Use▶according▶ to▶the▶ authorized▶data,▶ operating▶conditions▶ and▶

conditions▶of▶use▶specified▶in▶the▶contract▶documents▶and▶operating▶instructions.▶

▶▶ Provided▶the▶cable▶plug▶is▶connected▶ and▶ installed▶ correctly,▶e.g.▶

Bürkert▶Type▶2508,▶the▶device▶satisfies▶degree▶of▶protection▶IP65▶

in▶accordance▶with▶DIN▶EN▶60529▶/▶IEC▶60529.

Only operate the device

▶▶

when▶in▶perfect▶condition▶and▶always▶ensure▶proper▶storage,▶transportation,▶installation▶and▶operation.

▶▶ Use▶the▶device▶only▶as▶intended.

2.1 Restrictions

If▶exporting▶the▶device,▶observe▶any▶existing▶restrictions.

english

3

Page 4

3 BASIC SAFETY INSTRUCTIONS

These▶safety▶instructions▶do▶not▶make▶allowance▶for▶any▶contingencies▶

and▶events▶which▶may▶arise▶during▶assembly,▶operation▶and▶maintenance.

Risk of injury from high pressure in the system/device.

▶▶ Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶pressure▶

and▶vent/drain▶lines.

Risk of injury due to electrical shock.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶power▶supply▶

and▶secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶for▶

electrical▶equipment.

Risk of burns/risk of fire if used for a prolonged switch-on time

through hot device surface.

▶▶

Keep▶device▶away▶from▶highly▶flammable▶substances▶and▶media▶and▶

do▶not▶touch▶with▶bare▶hands.

Risk of injury due to malfunction of valves with alternating

voltage (AC).

Sticking▶core▶causes▶coil▶to▶overheat,▶resulting▶in▶a▶malfunction.

▶▶ Monitor▶process▶to▶ensure▶function▶is▶in▶perfect▶working▶order.

Risk of short-circuit/escape of media through leaking screw

joints.

▶▶

Ensure▶seals▶are▶seated▶correctly.

▶▶ Carefully▶screw▶valve▶and▶pipelines▶together.

4

english

Page 5

General hazardous situations.

To▶prevent▶injuries:

▶▶ In▶a▶potentially▶explosive▶area,▶the▶device▶may▶be▶used▶only▶in▶accor-

dance▶with▶the▶specification▶on▶the▶type▶label.▶For▶the▶use,▶observe▶

the▶supplementary▶instructions▶manual▶enclosed▶with▶the▶device▶with▶

safety▶instructions▶for▶the▶explosion-risk▶area.

▶▶ The▶enclosed▶UL▶instructions▶must▶be▶followed▶in▶the▶UL▶area.

▶▶ Do▶not▶carry▶out▶any▶external▶or▶internal▶modifications▶and▶do▶not▶

subject▶the▶device▶to▶mechanical▶loads▶(e.g.▶by▶placing▶objects▶on▶

it▶or▶standing▶on▶it).▶

▶▶ Secure▶the▶device▶against▶unintentional▶activation.

▶▶ Only▶trained▶technicians▶may▶perform▶installation▶and▶maintenance▶

work.

▶▶

The▶valves▶ must▶be▶ installed▶in▶ accordance▶with▶ the▶regulations▶

applicable▶in▶the▶country.

▶▶ After▶an▶interruption▶in▶the▶power▶supply,▶ensure▶that▶the▶process▶is▶

restarted▶in▶a▶controlled▶manner.

▶▶ Observe▶the▶general▶rules▶of▶technology.

4 SYSTEM DESCRIPTION

4.1 General description

The▶pivoted▶armature▶valves▶are▶direct▶acting▶2/2▶or▶3/2-way▶solenoid▶

valves▶in▶a▶wide▶variety▶of▶circuit▶functions▶and▶models.▶Solenoid▶system▶

and▶media▶ chamber▶are▶ separated▶ from▶ one▶ another▶by▶ a▶separating▶

diaphragm▶system.▶The▶valves▶are▶fast▶acting▶and▶have▶a▶long▶service▶life.

Type▶0121▶▶ ▶2/2▶or▶3/2-way▶solenoid▶valve,▶socket▶connection

Type▶0330▶▶ 2/2▶or▶3/2-way▶solenoid▶valve,▶socket▶connection

Type▶0331▶▶ 2/2▶or▶3/2-way▶solenoid▶valve,▶flange▶connection

Type▶0332▶▶ ▶Bistable▶2/2▶or▶3/2-way▶solenoid▶valve▶▶

with▶2▶coil▶windings,▶socket▶connection

Type▶0333▶▶ ▶Bistable▶2/2▶or▶3/2-way▶solenoid▶valve▶▶

with▶2▶coil▶windings,▶flange▶connection

Type▶0124▶▶ ▶2/2▶or▶3/2-way▶solenoid▶valve,▶socket▶connection

Type▶0125▶▶ ▶2/2▶or▶3/2-way▶solenoid▶valve,▶flange▶connection

english

5

Page 6

5 TECHNICAL DATA

The▶following▶values▶are▶indicated▶on▶the▶type▶label:

•▶Voltage (tolerance▶±10▶%) / current type

•▶Coil power consumption (active▶power▶in▶W▶-▶at▶operating▶

temperature)

•▶Pressure range

•▶Body material (MS=brass,▶VA=stainless▶steel,▶PV=PVC,▶

TE=PTFE,▶PP=polypropylene,▶PD=PVDF)

•▶Seal material▶(F=FKM,▶A=EPDM,▶B=NBR,▶C=FFKM)

5.1 Conformity

The▶Types▶0121,▶0330,▶0331,▶(0124,▶0125,▶0332,▶0333)▶are▶compliant▶

with▶the▶EC▶Directives▶according▶to▶the▶EC▶Declaration▶of▶Conformity.

5.2 Standards

The▶applied▶standards,▶which▶are▶used▶to▶demonstrate▶compliance▶with▶

the▶EC▶Directives,▶are▶listed▶in▶the▶EC▶type▶test▶certificate▶and/or▶the▶EC▶

Declaration▶of▶Conformity.▶

5.3 Operating conditions

Ambient▶temperature▶ ▶

▶ ▶ ▶Type▶0121▶▶ ▶ ▶ ▶ max.▶+50°C▶

Other▶types▶ ▶ ▶ ▶ max.▶+55°C

Duty▶cycle▶

for▶body▶material▶▶

▶ ▶ Brass▶or▶stainless▶steel▶▶ long-term▶operation,▶duty▶cycle▶100%▶

▶ ▶ Plastic▶▶▶ ▶ ▶ ▶ ▶ ▶max.▶permissible▶duty▶cycle▶▶

see▶data▶sheet

Important information for functional reliability.

If▶switched▶off▶for▶a▶long▶period,▶1-2▶switching▶actions▶are▶recommended▶prior▶to▶restart.

Service▶life▶

High▶switching▶frequency▶and▶high▶pressures▶reduce▶the▶service▶life.

Degree▶of▶protection▶ ▶ ▶ ▶IP65▶in▶accordance▶with▶DIN▶EN▶60529▶

/▶IEC▶60529▶with▶correctly▶connected▶

and▶installed▶cable▶plug,▶e.g.▶Bürkert▶

Type▶2508

6

english

Page 7

5.4 Mechanical data

2 (A)

1 (P)

2 (A)

1 (P)

2(A)

1(P) 3(R)

4(B)

1(P) 3(R)

2(A)

1(P) 3(R)

2(A) 4(B)

2(A)

1(P) 3(R)

Dimensions▶ ▶ ▶ see▶data▶sheet

Coil▶material▶ ▶ ▶ epoxide

Connections▶ ▶ ▶ ▶G▶1/4▶▶

(NPT▶1/4,▶G▶1/8,▶G▶3/8,▶Rc▶1/4▶on▶request)

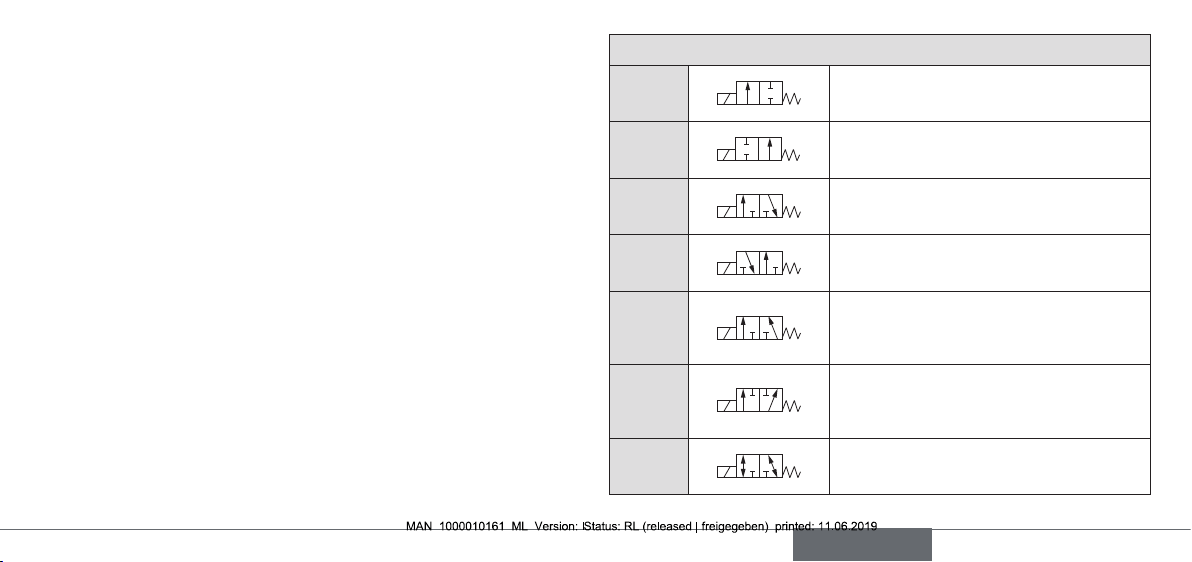

Circuit▶functions

A▶

(NC)

B▶

(NO)

2/2-way▶valve,▶▶

closed▶in▶rest▶position

2/2-way▶valve,▶▶

open▶in▶rest▶position

5.5 Fluidic data

Media▶ ▶ ▶ ▶ ▶ ▶aggressive,▶neutral,▶gaseous▶and▶liquid▶media,▶▶

which▶do▶not▶attack▶body▶and▶seal▶materials.▶

(see▶resistance▶table▶at▶www.buerkert.de).

Medium▶temperature▶for▶seal▶material▶

▶ ▶ ▶FKM▶ ▶ ▶ ▶ 0▶°C▶–▶+90▶°C▶

EPDM▶ ▶ ▶ ▶ -30▶°C▶–▶+▶90▶°C▶

NBR▶ ▶ ▶ ▶ 0▶°C▶–▶+▶80▶°C▶

FFKM▶ ▶ ▶ ▶ +5▶°C▶–▶+90▶°C

C▶

(NC)

D▶

(NO)

E

F

T

1(P)

3/2-way▶valve;▶closed▶in▶rest▶position,▶

output▶A▶unloaded

3/2-way▶valve,▶in▶rest▶position,▶output▶B▶

pressurized

3/2-way▶mixing▶valve;▶in▶rest▶position,▶

pressure▶connection▶P2▶connected▶to▶

output▶A,▶P1▶closed

3/2-way▶distribution▶valve,▶

in▶rest▶position,▶pressure▶connection▶P▶

connected▶to▶output▶B

3/2-way▶all▶purpose▶valve

english

7

Page 8

5.6 Electrical data

Connections▶ ▶ ▶ ▶DIN▶EN▶175301-803▶(DIN▶43▶650),▶shape▶A▶for▶

cable▶plug▶Type▶2508▶or▶2509

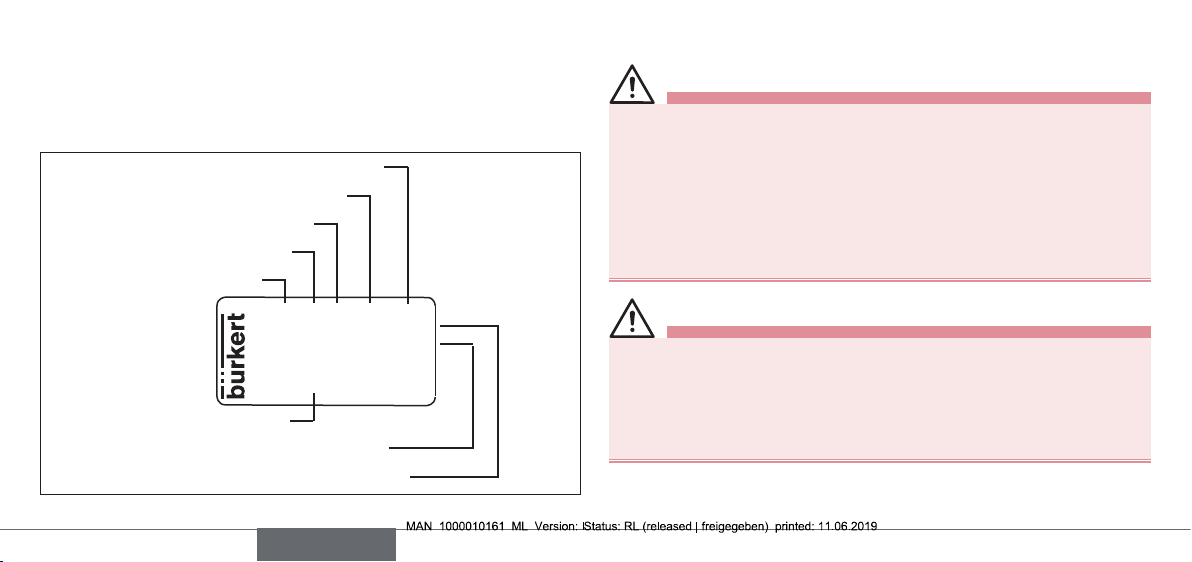

5.7 Type label

Body▶material

Seal▶material

Orifice

Circuit▶function

Type

0330▶C▶▶2.0▶▶FKM▶▶MS▶

G1/4▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶0-6▶bar▶

24V▶DC▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶8W

CE

00450000

Made▶in▶Germany

Identification▶number

Voltage,▶frequency,▶output

Port▶connection,▶nominal▶pressure

Fig. 1: Description of the type label (example)

W14UN

6 ASSEMBLY

DANGER!

Risk of injury from high pressure in the system/device.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶pressure▶

and▶vent/drain▶lines.

Risk of injury due to electrical shock.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶power▶supply▶and▶secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶for▶

electrical▶equipment.

WARNING!

Risk of injury from improper assembly.

▶▶

The▶assembly▶may▶be▶carried▶out▶only▶by▶trained▶technicians▶and▶

with▶the▶appropriate▶tools.

▶▶ Secure▶system▶against▶unintentional▶activation.

▶▶ Following▶assembly,▶ensure▶a▶controlled▶restart.

8

english

Page 9

6.1 Before installation

Installation position:

The▶installation▶position▶is▶optional.▶Preferably:▶Actuator▶at▶the▶top.

▶→ Prior▶to▶installation▶check▶pipelines▶for▶dirt▶and▶clean▶if▶necessary.

Dirt filter:▶To▶ensure▶that▶the▶solenoid▶valve▶functions▶reliably,▶a▶dirt▶filter▶(≤▶500▶µm)▶must▶be▶

installed▶in▶front▶of▶the▶valve▶input.

6.2 Installation

▶→ Observe▶flow▶direction:▶▶

Functioning▶of▶the▶device▶is▶only▶ensured▶if▶the▶circuit▶function▶is▶

maintained.

Deviceswith socket connection

▶→ Use▶PTFE▶tape▶as▶seal▶material.

▶→ Determine▶the▶maximum▶screw-in▶depth▶of▶the▶connecting▶threads▶

as▶this▶does▶not▶comply▶with▶any▶standard.

NOTE!

Caution risk of breakage.

Do▶not▶use▶the▶coil▶as▶a▶lifting▶arm.

▶▶

▶→ Hold▶the▶device▶with▶a▶suitable▶tool▶(open-end▶wrench)▶on▶the▶

body;▶screw▶into▶the▶pipeline.

Attaching▶the▶device:

▶→ Via▶bore▶holes▶M4x8▶(made▶from▶brass▶or▶stainless▶steel)▶or▶self-

tapping▶screws▶3.9▶DIN▶7970▶(made▶from▶plastic,▶max.▶screw-in▶

depth▶10▶mm)▶on▶the▶bottom▶side▶of▶the▶body▶at▶drill▶pattern▶

38x24.

Devices in flange model

Attaching▶the▶device:

▶→ Via▶supplied▶screws▶on▶basic▶devices▶or▶manifold.

▶→ Tighten▶fastening▶screws▶on▶the▶coil▶to▶a▶maximum▶torque▶of▶2▶Nm.

english

9

Page 10

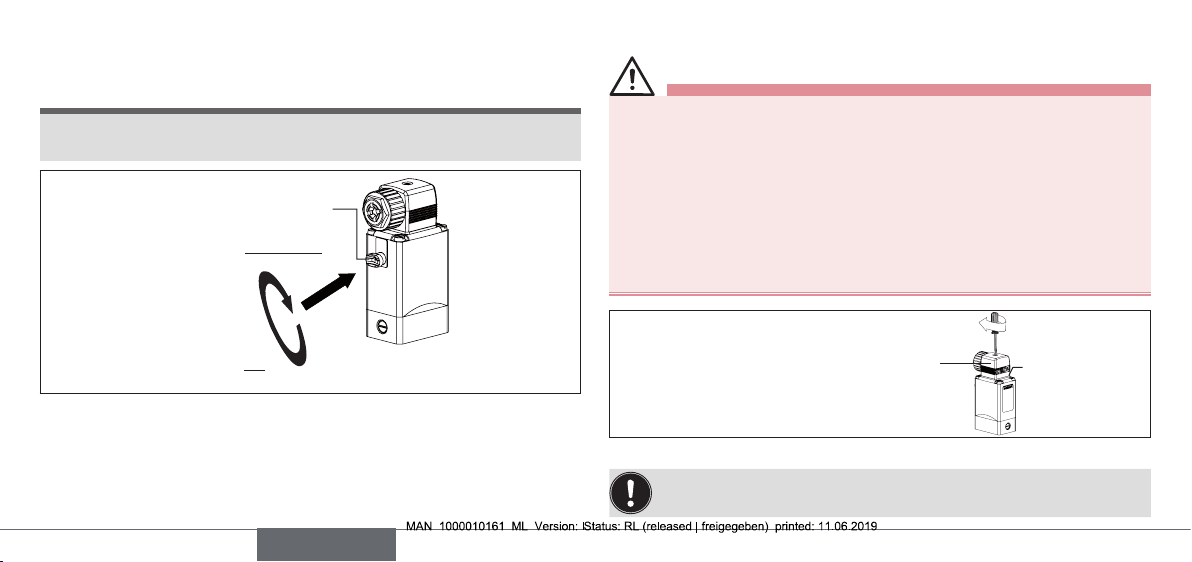

6.3 Manual control

2

NOTE!

When▶ the▶ manual▶control▶is▶locked,▶the▶valve▶ cannot▶be▶actuated▶

▶▶

electrically.

Manual▶control

Press

Turn

Fig. 2: Manual control

1

7 ELECTRICAL CONNECTION

DANGER!

Risk of injury due to electrical shock.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶power▶sup-

ply▶and▶secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶for▶

electrical▶equipment.

If the protective conductor is not connected, there is a risk of

electric shock.

▶▶

Always▶connect▶protective▶conductor▶and▶check▶electrical▶continuity▶

between▶coil▶and▶housing.

max.▶1▶Nm

Approved▶cable▶plug,▶e.g.▶Type▶

2508▶or▶other▶suitable▶cable▶plug▶

in▶accordance▶with▶▶

DIN▶EN▶175301-803▶shape▶A

Fig. 3: Connecting the cable plug to the power supply

Note▶the▶voltage▶and▶current▶type▶as▶specified▶on▶the▶type▶label.

Seal

10

english

Page 11

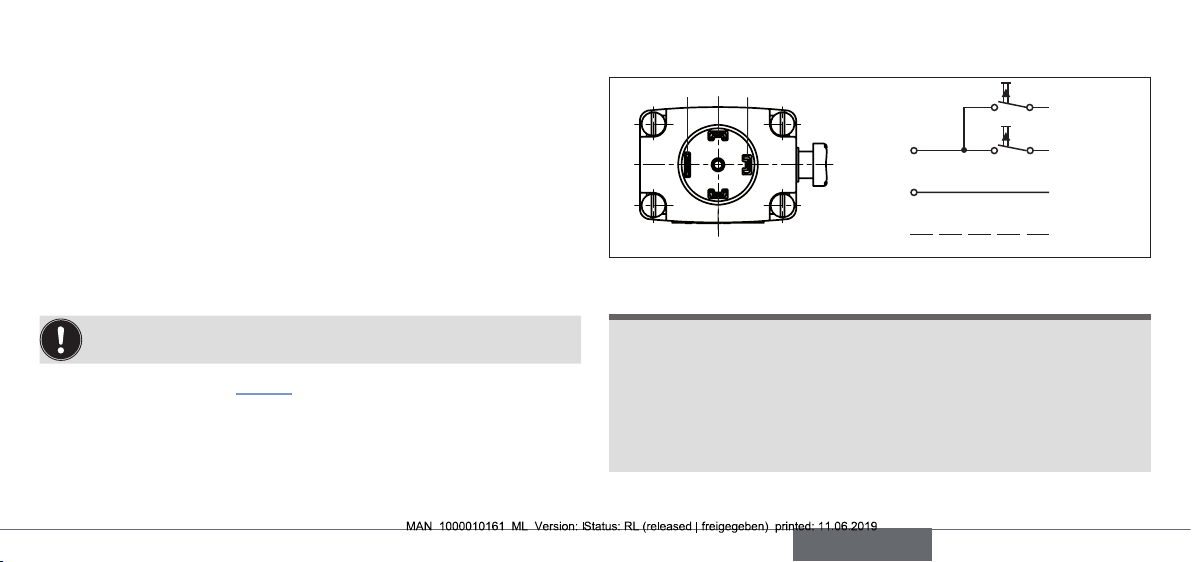

7.1 Standard model

▶→ Connect▶L1/+▶ and▶ N/–▶ to▶ terminals▶1▶ and▶ 2,▶independent▶ of▶the▶

polarity.

▶→ Connect▶protective▶conductor.

▶→ Attach▶seal▶and▶check▶for▶correct▶fit.

▶→ Tighten▶cable▶plug▶(Type▶2508▶or▶2509▶in▶accordance▶with▶DIN▶EN▶

175301-803▶(DIN▶43▶650),▶shape▶A,▶for▶order▶numbers▶ see▶data▶

sheet);▶while▶doing▶so,▶observe▶the▶maximum▶torque▶of▶1▶Nm.

▶→ Check▶electrical▶continuity▶between▶coil▶and▶body▶(protective▶con-

ductor▶function).

7.2 Pulse model (CF 02)

In▶accordance▶with▶the▶terminals▶on▶the▶valves,▶the▶connection▶

terminals▶in▶the▶cable▶plug▶are▶marked▶with▶the▶numbers▶1▶to▶3.

▶→ Connect▶as▶shown▶in▶“Fig.▶4”.▶Pulse▶on▶terminal▶1▶closes▶the▶valve;▶

pulse▶on▶terminal▶2▶opens▶the▶valve.

▶→ Attach▶seal▶and▶check▶for▶correct▶fit.

▶→ Tighten▶cable▶plug▶(Type▶2508▶or▶2509▶in▶accordance▶with▶DIN▶EN▶

175301-803▶(DIN▶43▶650),▶shape▶A,▶for▶order▶numbers▶ see▶data▶

sheet);▶while▶doing▶so,▶observe▶the▶maximum▶torque▶of▶1▶Nm.

▶→ Check▶electrical▶continuity▶between▶coil▶and▶body▶(protective▶con-

ductor▶function).

24 3

(=)▶∼

(+)▶L1

(–)▶N

1

Fig. 4: Electrical connection - pulse model (CF 02)

NOTE!

Prevent▶simultaneous▶pulsing▶on▶both▶coil▶windings.

▶▶

▶▶ Parallel▶to▶the▶ terminals,▶ no▶other▶consumers▶ (relay,▶etc.)▶ may▶ be▶

connected.

▶▶

The▶respective▶coil▶connection▶that▶does▶not▶carry▶current▶must▶be▶

galvanically▶isolated▶(open).

▶▶ In▶case▶two▶or▶more▶valves▶are▶connected▶in▶parallel,▶the▶use▶of▶two-

pole▶or▶multi-pole▶switches▶must▶ensure▶that▶this▶requirement▶is▶met.

PE

Terminal▶1

Terminal▶2

Terminal▶3

Protective▶

conductor

english

11

Page 12

8 DISASSEMBLY

DANGER!

Risk of injury from high pressure in the system/device.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶pressure▶

and▶vent/drain▶lines.

Risk of injury due to electrical shock.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶power▶

supply▶and▶secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶

for▶electrical▶equipment.

WARNING!

Risk of injury from improper disassembly.

▶▶

Disassembly▶may▶be▶carried▶out▶only▶by▶trained▶technicians▶and▶

with▶the▶appropriate▶tools.

Risk of injury from hazardous media.

▶▶

Before▶loosening▶lines▶or▶valves,▶flush▶out▶hazardous▶media,▶

depressurize▶and▶drain▶the▶lines.

9 MAINTENANCE, TROUBLESHOOTING

9.1 Safety instructions

DANGER!

Risk of injury from high pressure in the system.

▶▶

Turn▶off▶the▶pressure▶and▶vent▶the▶lines▶before▶loosening▶lines▶or▶

valves.

Risk of injury due to electrical shock.

▶▶

Before▶working▶on▶the▶system▶or▶device,▶switch▶off▶the▶power▶

supply▶and▶secure▶to▶prevent▶reactivation.

▶▶ Observe▶applicable▶accident▶prevention▶and▶safety▶regulations▶

for▶electrical▶equipment.

WARNING!

Risk of injury from improper maintenance work.

▶▶

Maintenance▶may▶be▶carried▶out▶only▶by▶trained▶technicians▶and▶

with▶the▶appropriate▶tools.

▶▶ Secure▶system▶against▶unintentional▶activation.

▶▶ Following▶maintenance,▶ensure▶a▶controlled▶restart.

12

english

Page 13

9.2 Malfunctions

If▶malfunctions▶occur,▶check▶whether:

▶→ the▶device▶has▶been▶installed▶according▶to▶the▶instructions,

▶→ the▶electrical▶and▶fluid▶connections▶are▶correct,

▶→ the▶device▶is▶not▶damaged,

▶→ all▶screws▶have▶been▶tightened,

▶→ the▶voltage▶and▶pressure▶have▶been▶switched▶on,

▶→ the▶pipelines▶are▶clean.

Malfunction Possible cause

Valve▶does▶not▶

switch

Valve▶does▶not▶close Inner▶compartment▶of▶the▶valve▶is▶dirty

9.2.1 Repairs

Repairs▶may▶only▶be▶carried▶out▶by▶the▶manufacturer.▶Operating▶data▶

may▶change▶if▶spare▶parts▶are▶replaced▶by▶the▶user.

Short▶circuit▶or▶coil▶interrupted

Medium▶pressure▶outside▶the▶permitted▶

pressure▶range

Manual▶control▶locked

Manual▶control▶locked

10 TRANSPORTATION, STORAGE,

DISPOSAL

NOTE!

Transport damage.

Inadequately▶protected▶devices▶may▶be▶damaged▶during▶

transportation.

Protect▶the▶ device▶against▶ moisture▶and▶ dirt▶in▶ shock-resistant▶

▶▶

packaging▶during▶transportation.▶

▶▶ Prevent▶the▶temperature▶from▶ exceeding▶ or▶ dropping▶ below▶ the▶

permitted▶storage▶temperature.

Incorrect storage may damage the device.

Store▶the▶device▶in▶a▶dry▶and▶dust-free▶location.

▶▶

▶▶ Storage▶temperature▶-40▶–▶+80°C.▶

Damage to the environment caused by parts contaminated

with media.

Dispose▶of▶the▶device▶and▶packaging▶in▶an▶environmentally▶friendly▶

▶▶

manner.

▶▶

Observe▶applicable▶disposal▶and▶environmental▶regulations.

english

13

Page 14

Inhaltsverzeichnis

1 Die Bedienungsanleitung .................................................................................................14

2 Bestimmungsgemäße Verwendung .........................................................................15

3 Grundlegende Sicherheitshinweise .........................................................................16

4 Systembeschreibung

5 Technische Daten....................................................................................................................18

6 Montage

7 Elektrischer Anschluss........................................................................................................22

8 Demontage

9 Wartung, Fehlerbehebung ................................................................................................24

10 Transport, Lagerung, Entsorgung ...............................................................................25

...................................................................................................................................................20

...................................................................................................................................24

............................................................................................................17

1 DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

▶▶

Anleitung▶sorgfältig▶lesen▶und▶die▶Hinweise▶zur▶Sicherheit▶beachten.▶

▶▶ Anleitung▶so▶aufbewahren,▶dass▶sie▶jedem▶Benutzer▶zur▶ Verfügung▶

steht.

Die▶Haftung▶und▶Gewährleistung▶für▶das▶Gerät▶entfällt,▶wenn▶die▶

Anweisungen▶der▶Bedienungsanleitung▶nicht▶beachtet▶werden.

1.1 Darstellungsmittel

▶▶ markiert▶eine▶Anweisung▶zur▶Gefahrenvermeidung.

▶→ markiert▶einen▶Arbeitsschritt▶den▶Sie▶ausführen▶müssen.

GEFAHR!

Unmittelbare▶Gefahr!▶Schwere▶oder▶tödliche▶Verletzungen.

WARNUNG!

Mögliche▶Gefahr!▶Schwere▶oder▶tödliche▶Verletzungen.

VORSICHT!

Gefahr!▶Mittelschwere▶oder▶leichte▶Verletzungen.

14

deutsch

Page 15

HINWEIS!

Warnt vor Sachschäden.

Wichtige▶Tipps▶und▶Empfehlungen.

verweist▶auf▶Informationen▶in▶dieser▶Bedienungsanleitung▶oder▶

in▶anderen▶Dokumentationen.

1.2 Begriffsdefinition

Der▶in▶dieser▶Anleitung▶verwendete▶Begriff▶„Gerät“▶steht▶immer▶für▶Typ▶

0121,▶0330,▶0331,▶(0124,▶0125,▶0332,▶0333).

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Das Gerät ist zum Steuern, Absperren und Dosieren von neutralen und aggressiven Medien bis zu einer Viskosität von 37

mm²/s konzipiert.

▶▶

Für▶den▶Einsatz▶die▶in▶den▶Vertragsdokumenten▶und▶der▶Bedienungs-

anleitung▶spezifizierten▶zulässigen▶Daten,▶Betriebs-▶und▶Einsatzbe-

dingungen▶beachten.▶

▶▶ Mit▶einer▶sachgemäß▶angeschlossenen▶und▶montierten▶Gerätesteck-

dose,▶z.▶B.▶Bürkert▶Typ▶2508▶erfüllt▶das▶Gerät▶die▶Schutzart▶IP65▶nach▶

DIN▶EN▶60529▶/▶IEC▶60529.

Das Gerät

▶▶

nur▶in▶einwandfreiem▶Zustand▶betreiben▶und▶auf▶sachgerechte▶Lage-

rung,▶Transport,▶Installation▶und▶Bedienung▶achten.

▶▶ nur▶bestimmungsgemäß▶verwenden.

2.1 Beschränkungen

Bei▶der▶Ausfuhr▶des▶Geräts▶gegebenenfalls▶bestehende▶Beschränkungen▶

beachten.

deutsch

15

Page 16

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese▶Sicherheitshinweise▶ berücksichtigen▶keine▶ Zufälligkeiten▶und▶

Ereignisse,▶die▶bei▶Montage,▶Betrieb▶und▶Wartung▶auftreten▶können.

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶▶ Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶den▶Druck▶abschalten▶und▶

Leitungen▶entlüften/entleeren.

Verletzungsgefahr durch Stromschlag.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶die▶Spannung▶abschalten▶und▶

vor▶Wiedereinschalten▶sichern.

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶für▶

elektrische▶Geräte▶beachten.

Verbrennungsgefahr/Brandgefahr bei längerer Einschaltzeit

durch heiße Geräteoberfläche.

▶▶

Gerät▶von▶leicht▶brennbaren▶Stoffen▶und▶Medien▶fernhalten▶und▶nicht ▶

mit▶bloßen▶Händen▶berühren.

Verletzungsgefahr durch Funktionsausfall bei Ventilen mit

Wechselspannung (AC).

Festsitzender▶Kern▶bewirkt▶Spulenüberhitzung,▶die▶zu▶Funktionsausfall▶führt.

▶▶ Arbeitsprozess▶auf▶einwandfreie▶Funktion▶überwachen.

Kurzschlussgefahr/Austritt von Medium durch undichte

Verschraubungen.

▶▶

Auf▶einwandfreien▶Sitz▶der▶Dichtungen▶achten.

▶▶ Ventil▶und▶Rohrleitungen▶sorgfältig▶verschrauben.

16

deutsch

Page 17

Allgemeine Gefahrensituationen.

Zum▶Schutz▶vor▶Verletzungen▶ist▶zu▶beachten:

▶▶ Im▶explosionsgefährdeten▶Bereich▶darf▶das▶Gerät▶nur▶entsprechend▶

der▶Spezifikation▶ auf▶dem▶ Typschild▶eingesetzt▶ werden.▶Für▶ den▶

Einsatz▶muss▶die▶dem▶Gerät▶beiliegende▶Zusatzanleitung▶mit▶Sicher-

heitshinweisen▶für▶den▶Ex-Bereich▶beachtet▶werden.

▶▶ Im▶UL-Bereich▶muss▶die▶beiliegende▶UL-Anleitung▶beachtet▶werden.

▶▶ Am▶Gerät▶keine▶inneren▶oder▶äußeren▶Veränderungen▶vornehmen▶

und▶nicht▶mechanisch▶belasten▶(z.▶B.▶durch▶Ablage▶von▶Gegen-

ständen▶oder▶als▶Trittstufe).▶

▶▶ Vor▶unbeabsichtigem▶Betätigen▶sichern.

▶▶ Nur▶geschultes▶Fachpersonal▶darf▶Installations-▶und▶Instandhaltungs-

arbeiten▶ausführen.

▶▶ Die▶Ventile▶müssen▶gemäß▶der▶im▶Land▶gültigen▶Vorschriften▶installiert▶

werden.

▶▶

Nach▶Unterbrechung▶der▶elektrischen▶Versorgung▶für▶einen▶kontrol-

lierten▶Wiederanlauf▶des▶Prozesses▶sorgen.

▶▶ Die▶allgemeinen▶Regeln▶der▶Technik▶einhalten.

4 SYSTEMBESCHREIBUNG

4.1 Allgemeine Beschreibung

Die▶Klappankerventile▶ sind▶ein▶ direktwirkende▶2/2-▶ oder▶ 3/2-WegeMagnetventile▶in▶ vielfältigen▶Wirkungsweisen▶ und▶Ausführungen.▶

Magnetsystem▶und▶Mediumsraum▶sind▶durch▶ein▶Trennmembransystem▶

voneinander▶getrennt.▶Die▶Ventile▶sind▶schnellschaltend▶und▶haben▶eine▶

hohe▶Lebensdauer.

Typ▶0121▶ ▶ ▶2/2-▶oder▶3/2-Wege-Magnetventil,▶Muffenanschluss

Typ▶0330▶ ▶ 2/2-▶oder▶3/2-Wege-Magnetventil,▶Muffenanschluss

Typ▶0331▶ ▶ 2/2-▶oder▶3/2-Wege-Magnetventil,▶Flanschanschluss

Typ▶0332▶ ▶ ▶Bistabiles▶2/2-▶oder▶3/2-Wege-Magnetventil▶▶

mit▶2▶Spulenwicklungen,▶Muffenanschluss

Typ▶0333▶ ▶ ▶Bistabiles▶2/2-▶oder▶3/2-Wege-Magnetventil▶▶

mit▶2▶Spulenwicklungen,▶Flanschanschluss

Typ▶0124▶ ▶ ▶2/2-▶oder▶3/2-Wege-Magnetventil,▶Muffenanschluss

Typ▶0125▶ ▶ ▶2/2-▶oder▶3/2-Wege-Magnetventil,▶Flanschanschluss

deutsch

17

Page 18

5 TECHNISCHE DATEN

Folgende▶Werte▶sind▶auf▶dem▶Typschild▶angegeben:

•▶Spannung (Toleranz▶±10▶%) / Stromart

•▶Spulenleistung (Wirkleistung▶in▶W▶-▶betriebswarm)

•▶Druckbereich

•▶Gehäusewerkstoff (MS=Messing,▶VA=Edelstahl,▶PV=PVC,▶

TE=PTFE,▶PP=Polypropylen,▶PD=PVDF)

•▶Dichtwerkstoff▶(F=FKM,▶A=EPDM,▶B=NBR,▶C=FFKM)

5.1 Konformität

Die▶Typen▶0121,▶0330,▶0331,▶(0124,▶0125,▶0332,▶0333)▶sind▶konform▶zu▶

den▶EG-Richtlinien▶entsprechend▶der▶EG-Konformitätserklärung.

5.2 Normen

Die▶angewandten▶Normen,▶mit▶welchen▶die▶Konformität▶zu▶den▶Richtlinien▶

nachgewiesen▶wird,▶sind▶in▶der▶EG-Baumusterprüfbescheinigung▶und/

oder▶der▶EG-Konformitätserklärung▶nachzulesen.▶

5.3 Betriebsbedingungen

Umgebungstemperatur▶ ▶

▶ ▶ ▶Typ▶0121▶ ▶ ▶ ▶ ▶ ▶ max.▶+50°C▶

andere▶Typen▶ ▶ ▶ ▶ ▶ max.▶+55°C

Einschaltdauer▶

bei▶Gehäusewerkstoff▶▶

▶ ▶ Messing▶oder▶Edelstahl▶▶ ▶ Dauerbetrieb▶100%▶ED▶

▶ ▶ Kunststoff▶▶▶ ▶ ▶ ▶ ▶ ▶max.▶zulässige▶Einschaltdauer▶▶

siehe▶Datenblatt

Wichtiger Hinweis zur Funktionssicherheit.

Bei▶langem▶Stillstand▶wird▶eine▶Mindestbetätigung▶von▶▶

1–2▶Schaltungen▶vor▶Wiederanlauf▶empfohlen.

Lebensdauer▶

Hohe▶Schaltfrequenz▶und▶hohe▶Drücke▶verringern▶die▶Lebensdauer.

Schutzart▶ ▶ ▶ ▶ ▶ ▶ ▶ ▶IP65▶nach▶DIN▶EN▶60529▶/▶IEC▶

60529▶mit▶sachgemäß▶angeschlossener▶und▶montierter▶Gerätesteckdose,▶z.▶B.▶Bürkert▶Typ▶2508

18

deutsch

Page 19

5.4 Mechanische Daten

2 (A)

1 (P)

2 (A)

1 (P)

2(A)

1(P) 3(R)

4(B)

1(P) 3(R)

2(A)

1(P) 3(R)

2(A) 4(B)

2(A)

1(P) 3(R)

Abmessungen▶▶ ▶ ▶ siehe▶Datenblatt

Spulenwerkstoff▶ ▶ ▶ Epoxid

Anschlüsse▶ ▶ ▶ ▶ ▶G▶1/4▶▶

(NPT▶1/4,▶G▶1/8,▶G▶3/8,▶Rc▶1/4▶auf▶Anfrage)

Wirkungsweisen

A▶

(NC)

B▶

(NO)

2/2-Wege-Ventil;▶▶

in▶Ruhestellung▶geschlossen

2/2-Wege-Ventil;▶▶

in▶Ruhestellung▶offen

5.5 Fluidische Daten

Medien▶▶ ▶aggressive,▶neutrale,▶gasförmige▶und▶flüssige▶Medien,▶▶

die▶Gehäuse▶und▶Dichtwerkstoffe▶nicht▶angreifen▶(siehe▶

Beständigkeitstabelle▶unter▶www.buerkert.de).

Mediumstemperatur▶bei▶Dichtwerkstoff▶

▶ ▶ ▶FKM▶ ▶ ▶ ▶ ▶ 0▶°C▶...▶+90▶°C▶

EPDM▶ ▶ ▶ ▶ ▶ -30▶°C▶...▶+▶90▶°C▶

NBR▶ ▶ ▶ ▶ ▶ 0▶°C▶...▶+▶80▶°C▶

FFKM▶ ▶ ▶ ▶ ▶ +5▶°C▶...▶+90▶°C

C▶

(NC)

D▶

(NO)

E

F

T

deutsch

1(P)

3/2-Wege-Ventil;▶in▶Ruhestellung▶

geschlossen,▶Ausgang▶A▶entlastet

3/2-Wege-Ventil;▶in▶Ruhestellung▶

Ausgang▶B▶druckbeaufschlagt

3/2-Wege-Mischventil;▶in▶Ruhestellung▶

Druckanschluss,▶P2▶mit▶Ausgang▶A▶

verbunden,▶P1▶geschlossen

3/2-Wege-Verteilerventil;▶▶

in▶Ruhestellung▶Druckanschluss,▶P▶mit▶

Ausgang▶B▶verbunden

3/2-Wege-Ventil;▶universell▶einsetzbar

19

Page 20

5.6 Elektrische Daten

Anschlüsse▶ ▶ ▶ ▶DIN▶EN▶175301-803▶(DIN▶43▶650),▶Form▶A▶für▶

Gerätesteckdose▶Typ▶2508▶oder▶2509

5.7 Typschild

Gehäusewerkstoff

Dichtwerkstoff

Nennweite

Wirkungsweise

Typ

0330▶C▶▶2,0▶▶FKM▶▶MS▶

G1/4▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶0-6▶bar▶

24V▶DC▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶8W

CE

00450000

Made▶in▶Germany

Identnummer

Spannung,▶Frequenz,▶Leistung

Leitungsanschluss,▶Nenndruck

Bild 1: Beschreibung des Typschilds (Beispiel)

W14UN

6 MONTAGE

GEFAHR!

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶den▶Druck▶abschalten▶und▶

Leitungen▶entlüften/entleeren.

Verletzungsgefahr durch Stromschlag.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶die▶Spannung▶abschalten▶und▶

vor▶Wiedereinschalten▶sichern.

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶für▶

elektrische▶Geräte▶beachten.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage.

▶▶

Die▶Montage▶darf▶nur▶geschultes▶Fachpersonal▶mit▶geeignetem▶

Werkzeug▶durchführen.

▶▶ Anlage▶vor▶unbeabsichtigtem▶Betätigen▶sichern.

▶▶ Nach▶der▶Montage▶einen▶kontrollierten▶Wiederanlauf▶gewährleisten.

20

deutsch

Page 21

6.1 Vor dem Einbau

Einbaulage:

Die▶Einbaulage▶ist▶beliebig.▶Vorzugsweise:▶Antrieb▶oben.

▶→ Rohrleitungen▶vor▶dem▶Einbau▶auf▶Verschmutzungen▶überprüfen▶und▶

gegebenenfalls▶reinigen.

Schmutzfilter:▶Für▶die▶sichere▶Funktion▶des▶Magnetventils▶muss▶vor▶dem▶Ventileingang▶ein▶Schmutzfilter▶(≤▶500▶µm)▶eingebaut▶werden.

6.2 Einbau

▶→ Durchflussrichtung▶beachten:▶▶

Funktion▶des▶Geräts▶ist▶nur▶sichergestellt,▶wenn▶die▶Wirkungsweise▶eingehalten▶wird.

Gerät mit Muffenanschluss

▶→ Als▶Dichtwerkstoff▶PTFE-Band▶verwenden.

▶→ Maximale▶Einschraubtiefe▶der▶Anschlussgewinde▶ermitteln,▶da▶

diese▶keiner▶Norm▶entspricht.

HINWEIS!

Vorsicht Bruchgefahr.

Die▶Spule▶darf▶nicht▶als▶Hebelarm▶benutzt▶werden.

▶▶

▶→ Das▶Gerät▶mit▶geeignetem▶Werkzeug▶(Gabelschlüssel)▶am▶Gehäuse▶

festhalten,▶in▶die▶Rohrleitung▶einschrauben.

Befestigung▶des▶Geräts:

▶→ Über▶Bohrungen▶M4▶x▶8▶(Messing-▶oder▶Edelstahlausführung)▶

oder▶selbstschneidende▶Schrauben▶3,9▶DIN▶7970▶(Kunststoffausführung,▶max.▶Einschraubtiefe▶10▶mm)▶an▶Gehäuseunterseite▶am▶

Lochbild▶38▶x▶24.

Geräte in Flanschausführung

Befestigung▶des▶Geräts:

▶→ Über▶mitgelieferte▶Schrauben▶auf▶Grundgeräte▶oder▶Anschlussplatte.

▶→ Befestigungsschrauben▶an▶der▶Spule▶mit▶maximal▶2▶Nm▶anziehen.

deutsch

21

Page 22

6.3 Handbetätigung

2

HINWEIS!

Bei▶arretierter▶Handbetätigung▶kann▶das▶Ventil▶nicht▶elektrisch▶betätigt▶

▶▶

werden.

Handbetätigung

Drücken

Drehen

Bild 2: Handbetätigung

1

7 ELEKTRISCHER ANSCHLUSS

GEFAHR!

Verletzungsgefahr durch Stromschlag.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶die▶Spannung▶abschalten▶und▶

vor▶Wiedereinschalten▶sichern.

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶für▶

elektrische▶Geräte▶beachten.

Bei▶nicht▶angeschlossenem▶Schutzleiter▶besteht▶Stromschlaggefahr.

▶▶ Schutzleiter▶immer▶anschließen▶und▶elektrischen▶Durchgang▶zwischen▶

Spule▶und▶Gehäuse▶prüfen.

max.▶1▶Nm

Zugelassene▶Gerätesteckdose▶

z.▶B.▶Typ▶2508▶oder▶andere▶

geeignete▶Gerätesteckdose▶nach▶▶

DIN▶EN▶175301-803▶Form▶A

Bild 3: Elektrischer Anschluss der Gerätesteckdose

Spannung▶und▶Stromart▶laut▶Typschild▶beachten.

Dichtung

22

deutsch

Page 23

7.1 Standardausführung

▶→ L1/+▶bzw.▶N/–▶an▶ Klemmen▶ 1▶und▶2▶ unabhängig▶ von▶der▶ Polung▶

anschließen.

▶→ Schutzleiter▶anschließen.

▶→ Dichtung▶aufstecken▶und▶korrekten▶Sitz▶prüfen.

▶→ Gerätesteckdose▶(Typ▶2508▶oder▶2509▶nach▶DIN▶EN▶175301-803▶

(DIN▶43▶ 650),▶ Form▶ A,▶Bestellnummern▶ siehe▶Datenblatt)▶ festschrauben,▶dabei▶maximales▶Drehmoment▶1▶Nm▶beachten.

▶→ Elektrischen▶Durchgang▶ zwischen▶Spule▶ und▶Gehäuse▶ prüfen▶

(Funktion▶Schutzleiter).

7.2 Impulsausführung (CF 02)

Die▶Klemmen▶in▶ der▶ Gerätesteckdose▶sind▶entsprechend▶den▶

Klemmen▶am▶Ventil▶mit▶den▶Ziffern▶1▶bis▶3▶gekennzeichnet.

▶→ Wie▶in▶„Bild▶4“▶anschließen.▶Impuls▶auf▶Klemme▶1▶schließt▶das▶Ventil,▶

Impuls▶auf▶Klemme▶2▶öffnet▶das▶Ventil.

▶→ Dichtung▶aufstecken▶und▶korrekten▶Sitz▶prüfen.

▶→ Gerätesteckdose▶(Typ▶2508▶oder▶2509▶nach▶DIN▶EN▶175301-803▶

(DIN▶43▶ 650),▶ Form▶ A,▶Bestellnummern▶ siehe▶Datenblatt)▶ festschrauben,▶dabei▶maximales▶Drehmoment▶1▶Nm▶beachten.

▶→ Elektrischen▶Durchgang▶ zwischen▶Spule▶ und▶Gehäuse▶ prüfen▶

(Funktion▶Schutzleiter).

24 3

(=)▶∼

(+)▶L1

(–)▶N

1

Bild 4: Elektrischer Anschluss - Impulsausführung (CF 02)

HINWEIS!

Gleichzeitige▶Impulsgabe▶auf▶beide▶Spulenwicklungen▶vermeiden.

▶▶

▶▶ Parallel▶zu▶den▶Klemmen▶dürfen▶keine▶weiteren▶Verbraucher▶(Relais▶

und▶dergl.)▶geschaltet▶werden.

▶▶ Der▶jeweils▶nicht▶ spannungsbeaufschlagte▶ Spulenanschluss▶ muss▶

galvanisch▶getrennt▶(offen)▶sein.

▶▶ Sollten▶zwei▶oder▶mehr▶Ventile▶parallel▶geschaltet▶werden,▶ist▶durch ▶

Verwendung▶von▶2-▶oder▶mehrpoligen▶Schaltern▶sicherzustellen,▶dass▶

diese▶Forderung▶erfüllt▶ist.

PE

Klemme▶1

Klemme▶2

Klemme▶3

Schutzleiter

deutsch

23

Page 24

8 DEMONTAGE

GEFAHR!

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶den▶Druck▶abschalten▶und▶

Leitungen▶entlüften/entleeren.

Verletzungsgefahr durch Stromschlag.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶die▶Spannung▶abschalten▶und▶

vor▶Wiedereinschalten▶sichern.

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶

für▶elektrische▶Geräte▶beachten.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Demontage.

▶▶

Die▶Demontage▶darf▶nur▶geschultes▶Fachpersonal▶mit▶geeignetem▶

Werkzeug▶durchführen.

Verletzungsgefahr durch gefährliche Medien.

▶▶

Vor▶dem▶Lösen▶von▶Leitungen▶oder▶Ventilen▶gefährliche▶Medien▶

ausspülen,▶die▶Leitungen▶druckfrei▶schalten▶und▶entleeren.

9 WARTUNG, FEHLERBEHEBUNG

9.1 Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage.

▶▶

Vor▶dem▶Lösen▶von▶Leitungen▶oder▶Ventilen▶den▶Druck▶abschalten▶

und▶Leitungen▶entlüften.

Verletzungsgefahr durch Stromschlag.

▶▶

Vor▶Arbeiten▶an▶Anlage▶oder▶Gerät,▶die▶Spannung▶abschalten▶und▶

vor▶Wiedereinschalten▶sichern.

▶▶ Die▶geltenden▶Unfallverhütungs-▶und▶Sicherheitsbestimmungen▶

für▶elektrische▶Geräte▶beachten.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Wartungsarbeiten.

▶▶

Die▶Wartung▶darf▶nur▶geschultes▶Fachpersonal▶mit▶geeignetem▶

Werkzeug▶durchführen.

▶▶ Anlage▶vor▶unbeabsichtigtem▶Betätigen▶sichern.

▶▶ Nach▶der▶Wartung▶einen▶kontrollierten▶Wiederanlauf▶gewährleisten.

24

deutsch

Page 25

9.2 Störungen

Überprüfen▶Sie▶bei▶Störungen▶ob

▶→ das▶Gerät▶vorschriftsmäßig▶installiert▶ist,

▶→ elektrischer▶/▶fluidischer▶Anschluss▶ordnungsgemäß▶ausgeführt▶ist,

▶→ das▶Gerät▶nicht▶beschädigt▶ist,

▶→ alle▶Schrauben▶fest▶angezogen▶sind,

▶→ Spannung▶und▶Druck▶anliegen,

▶→ die▶Rohrleitungen▶schmutzfrei▶sind.

Störung Mögliche Ursache

Ventil▶schaltet▶

nicht

Ventil▶schließt▶

nicht

9.2.1 Reparatur

Reparaturen▶grundsätzlich▶ vom▶ Hersteller▶ vornehmen▶ lassen.▶ Die▶

Betriebsdaten▶können▶ sich▶ändern,▶ wenn▶ Ersatzteile▶ vom▶ Anwender▶

ausgetauscht▶werden.

Kurzschluss▶oder▶Spulenunterbrechung

Mediumsdruck▶außerhalb▶zulässigen▶Druckbereich

Handbetätigung▶arretiert

Innenraum▶des▶Ventils▶verschmutzt

Handbetätigung▶arretiert

10 TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden.

Unzureichend▶geschützte▶Geräte▶können▶durch▶den▶Transport▶

beschädigt▶werden.

▶▶ Gerät▶vor▶ Nässe▶und▶Schmutz▶geschützt▶in▶einer▶stoßfesten▶Ver-

packung▶transportieren.▶

▶▶ Eine▶Über-▶bzw.▶Unterschreitung▶der▶zulässigen▶ Lagertemperatur▶

vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

▶▶

Gerät▶trocken▶und▶staubfrei▶lagern.

▶▶ Lagertemperatur▶-40▶…▶+80▶°C.▶

Umweltschäden durch von Medien kontaminierte Teile.

Gerät▶und▶Verpackung▶umweltgerecht▶entsorgen.

▶▶

▶▶ Geltende▶Entsorgungsvorschriften▶ und▶Umweltbestimmungen▶

einhalten.

deutsch

25

Page 26

Table des matières

1 Manuel d'utilisation.................................................................................................................26

2 Utilisation conforme ..............................................................................................................27

3 Consignes de sécurité fondamentales ..................................................................28

4 Description du système ......................................................................................................29

5 Caractéristiques techniques ...........................................................................................30

6 Montage

7 Raccordement électrique ..................................................................................................34

8 Démontage

9 Maintenance, dépannage..................................................................................................36

10 Transport, stockage, élimination ..................................................................................37

..........................................................................................................................................32

...................................................................................................................................36

1 MANUEL D'UTILISATION

Le manuel d'utilisation contient des informations importantes.

▶▶

Lire▶attentivement▶le▶manuel▶d'utilisation▶et▶tenir▶compte▶des▶consignes ▶

de▶sécurité.▶

▶▶ Conserver▶le▶manuel▶d'utilisation▶afin▶qu'il▶soit▶accessible▶à▶tous▶les▶

utilisateurs.

La▶responsabilité▶et▶la▶garantie▶légale▶concernant▶l'appareil▶sont▶

exclues▶en▶cas▶de▶non-respect▶du▶manuel▶d’utilisation.

1.1 Symboles

▶▶ identifie▶une▶consigne▶pour▶éviter▶un▶danger.

▶→ Identifie▶une▶opération▶que▶vous▶devez▶effectuer.

DANGER !

Danger▶imminent▶!▶Blessures▶graves▶ou▶mortelles.

AVERTISSEMENT !

Danger▶potentiel▶!▶Blessures▶graves▶ou▶mortelles.

ATTENTION !

Danger▶!▶Blessures▶légères▶ou▶de▶moyenne▶gravité.

26

français

Page 27

REMARQUE !

Met en garde contre des dommages matériels.

Conseils▶et▶recommandations▶importants.

renvoie▶à▶des▶informations▶dans▶ce▶manuel▶d'utilisation▶ou▶

dans▶d'autres▶documentations.

1.2 Définition des termes

Le▶terme▶«▶appareil▶»▶utilisé▶dans▶ces▶instructions▶désigne▶toujours▶le▶

type▶0121,▶0330,▶0331,▶(0124,▶0125,▶0332,▶0333).

2 UTILISATION CONFORME

L’appareil est conçu pour commander, arrêter et doser des

fluides neutres et agressifs jusqu’à une viscosité de 37 mm²/s.

▶▶ Lors▶de▶l'utilisation,▶il▶convient▶de▶respecter▶les▶données▶et▶conditions▶

d'utilisation▶et▶d'exploitation▶admissibles▶spécifiées▶dans▶le▶manuel▶

d'utilisation▶et▶dans▶les▶documents▶contractuels.▶

▶▶ Avec▶un▶connecteur,▶par▶ex.▶le▶type▶2508▶de▶Bürkert,▶connecté▶et▶

monté▶de▶manière▶conforme,▶ l’appareil▶ est▶conforme▶au▶degré▶de▶

protection▶IP65▶selon▶DIN▶EN▶60529▶/▶IEC▶60529.

Faire fonctionner l'appareil

▶▶

uniquement▶en▶ parfait▶état▶ et▶veiller▶ au▶ stockage,▶ au▶ transport,▶ à▶

l'installation▶et▶à▶l'utilisation▶conformes.

▶▶ uniquement▶de▶manière▶conforme.

2.1 Limitations

Lors▶de▶ l'exportation▶de▶ l'appareil,▶veuillez▶ respecter▶ les▶ limitations▶

éventuelles.

français

27

Page 28

3 CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces▶consignes▶de▶sécurité▶ne▶tiennent▶pas▶compte▶des▶hasards▶et▶des▶

événements▶pouvant▶ survenir▶ lors▶ du▶ montage,▶de▶ l'exploitation▶ et▶de▶

l'entretien.

Risque de blessures dû à la présence de haute pression dans

l'installation/l'appareil.

▶▶

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶pression▶et▶désaérer/vider▶les▶conduites.

Risque de choc électrique.

▶▶

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶tension▶

et▶empêcher▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appareils▶

électriques▶en▶ matière▶de▶ prévention▶ des▶ accidents▶ ainsi▶ qu'en▶

matière▶de▶sécurité.

Risque de brûlures/d'incendie lors d’une durée de fonctionnement prolongée dû à la surface brûlante de l’appareil.

▶▶

Tenir▶les▶substances▶et▶les▶fluides▶facilement▶inflammables▶à▶l'écart▶

de▶l'appareil▶et▶ne▶touchez▶pas▶ce▶dernier▶à▶mains▶nues.

Risque de blessure dû à une panne pour les vannes avec

tension alternative (AC).

Un▶noyau▶bloqué▶provoque▶la▶surchauffe▶de▶la▶bobine▶et▶donc▶une▶

panne.

Surveiller▶le▶bon▶fonctionnement▶du▶processus▶de▶travail.

▶▶

Risque de court-circuit/de sortie du fluide en présence de vissages non étanches.

▶▶

Veiller▶à▶l'installation▶correcte▶des▶joints.

▶▶ Visser▶soigneusement▶la▶vanne▶et▶les▶tuyaux.

28

français

Page 29

Situations dangereuses d'ordre général.

Pour▶prévenir▶les▶blessures,▶respectez▶ce▶qui▶suit▶:

▶▶ Dans▶une▶ zone▶exposée▶ à▶un▶ risque▶d'explosion,▶ l'appareil▶ doit▶

impérativement▶être▶installé▶conformément▶ à▶ la▶ spécification▶indiquée▶sur▶la▶ plaque▶signalétique.▶Les▶instructions▶supplémentaires▶

comportant▶des▶consignes▶de▶sécurité▶pour▶zone▶présentant▶des▶

risques▶d'explosion,▶fournies▶avec▶l'appareil,▶doivent▶être▶respectées▶

lors▶de▶l'utilisation▶de▶celui-ci.

▶▶ En▶zone▶UL,▶les▶instructions▶UL▶fournies▶avec▶l'appareil,▶doivent▶être▶

respectées.

▶▶

Ne▶pas▶soumettre▶l'appareil▶à▶des▶modifications▶extérieures▶ou▶

intérieures▶ni▶à▶des▶contraintes▶mécaniques▶(par▶ex.▶en▶déposant▶

des▶objets▶sur▶le▶corps▶ou▶en▶l'utilisant▶comme▶marche).▶

▶▶ Empêcher▶tout▶actionnement▶involontaire.

▶▶ Seul▶du▶ personnel▶qualifié▶ peut▶effectuer▶ l'installation▶et▶ la▶

maintenance.

▶▶

Les▶vannes▶doivent▶être▶installées▶conformément▶à▶la▶réglementation▶

en▶vigueur▶dans▶le▶pays▶respectif.

▶▶ Garantir▶un▶redémarrage▶contrôlé▶du▶processus▶après▶une▶coupure▶

de▶l'alimentation▶électrique.

▶▶ Respecter▶les▶règles▶générales▶de▶la▶technique.

4 DESCRIPTION DU SYSTÈME

4.1 Description générale

Les▶électrovannes▶ à▶armature▶battante▶sont▶des▶électrovannes▶2/2▶ou▶

3/2▶voies▶à▶action▶ directe▶ disponibles▶ dans▶de▶nombreuses▶variantes▶

d'exécution▶et▶de▶fonctionnement.▶Le▶système▶magnétique▶et▶l'espace▶

réservé▶au▶fluide▶sont▶séparés▶l'un▶de▶l'autre▶par▶un▶système▶de▶séparation▶

à▶membrane.▶Les▶vannes▶sont▶à▶commutation▶rapide▶et▶ont▶une▶longue▶

durée▶de▶vie.

Type▶0121▶▶ ▶électrovanne▶2/2▶ou▶3/2▶voies,▶raccord▶manchon

Type▶0330▶▶ électrovanne▶2/2▶ou▶3/2▶voies,▶raccord▶manchon

Type▶0331▶▶ électrovanne▶2/2▶ou▶3/2▶voies,raccord▶à▶bride

Type▶0332▶▶ ▶électrovanne▶bistable▶2/2▶ou▶3/2▶voies▶▶

avec▶2▶bobinages,▶raccord▶manchon

Type▶0333▶▶ ▶électrovanne▶bistable▶2/2▶ou▶3/2▶voies▶▶

avec▶2▶bobinages,▶corps▶de▶à▶bride

Type▶0124▶▶ ▶électrovanne▶2/2▶ou▶3/2▶voies,▶raccord▶manchon

Type▶0125▶▶ ▶électrovanne▶2/2▶ou▶3/2▶voies,raccord▶à▶bride

français

29

Page 30

5 CARACTÉRISTIQUES TECHNIQUES

Les▶valeurs▶suivantes▶sont▶indiquées▶sur▶la▶plaque▶signalétique▶:

•▶Tension (tolérance▶±10▶%) / type de courant

•▶Puissance de bobine (puissance▶active▶en▶W▶-▶à▶l’état▶chaud)

•▶Plage de pression

•▶Matériau du corps (MS=laiton,▶VA=acier▶inox,▶PV=PVC,▶

TE=PTFE,▶PP=Polypropylène,▶PD=PVDF)

•▶Matériau du joint▶(F=FKM,▶A=EPDM,▶B=NBR,▶C=FFKM)

5.1 Conformité

Les▶types▶0121,▶0330,▶0331,▶(0124,▶0125,▶0332,▶0333)▶sont▶conformes▶

aux▶directives▶CE▶conformément▶à▶la▶déclaration▶de▶conformité▶CE.

5.2 Normes

Les▶normes▶utilisées,▶avec▶lesquelles▶la▶conformité▶avec▶les▶directives▶CE▶

sont▶prouvées,▶figurent▶dans▶l'attestation▶CE▶de▶type▶et/ou▶la▶déclaration▶

de▶conformité▶CE.▶

5.3 Conditions d'exploitation

Température▶ambiante▶ ▶

▶ ▶ ▶Type▶0121▶▶ ▶ ▶ ▶ ▶ max.▶+50°C▶

autres▶types▶ ▶ ▶ ▶ ▶ max.▶+55°C

Facteur▶de▶marche▶

pour▶matériau▶du▶corps▶▶

▶ ▶ laiton▶ou▶acier▶inox▶▶ ▶ ▶ marche▶continu▶100%▶ED▶

▶ ▶ plastique▶▶ ▶ ▶ ▶ ▶ ▶ ▶facteur▶de▶marche▶max.▶autorisée▶voir▶

fiche▶technique

Remarque importante pour la sécurité de fonctionnement.

Dans▶le▶cas▶d’un▶arrêt▶de▶longue▶durée,▶il▶est▶recommandé▶de▶

procéder▶à▶1▶-▶2▶commutations▶minimum▶avant▶le▶redémarrage.

Durée▶de▶vie▶

Une▶fréquence▶élevée▶de▶commutation▶ainsi▶que▶des▶pressions▶

élevées▶réduisent▶la▶durée▶de▶vie.

Degré▶de▶protection▶ ▶ ▶ ▶ ▶IP65▶selon▶DIN▶EN▶60529▶/▶IEC▶

60529▶avec▶un▶connecteur▶connecté▶

et▶monté▶de▶manière▶conforme,▶par▶

ex.▶le▶type▶2508▶de▶Bürkert

30

français

Page 31

5.4 Caractéristiques mécaniques

2 (A)

1 (P)

2 (A)

1 (P)

2(A)

1(P) 3(R)

4(B)

1(P) 3(R)

2(A)

1(P) 3(R)

2(A) 4(B)

2(A)

1(P) 3(R)

Dimensions▶ ▶ ▶ ▶ voir▶fiche▶technique

Matériau▶de▶la▶bobine▶▶ Résine▶époxy

Raccords▶ ▶ ▶ ▶ ▶ ▶G▶1/4▶(NPT▶1/4,▶G▶1/8,▶G▶3/8,▶Rc▶1/4▶sur▶

demande)

Fonctions

A▶

(NF)

B▶

(NO)

Vanne▶2/2▶voies▶;▶▶

fermée▶en▶position▶de▶repos

Vanne▶2/2▶voies▶;▶▶

ouverte▶en▶position▶de▶repos

5.5 Données fluidiques

Fluides▶▶ ▶fluides▶liquides▶et▶gazeux,▶agressifs,▶neutres▶n'attaquant▶ni▶

le▶corps▶ni▶le▶matériau▶du▶joint▶(voir▶le▶tableau▶de▶résistance▶

chimique▶Bürkert▶www.buerkert.de).

Température▶du▶fluide▶pour▶le▶matériau▶du▶joint▶

▶ ▶ ▶FKM▶ ▶ ▶ ▶ ▶ 0▶°C▶...▶+90▶°C▶

EPDM▶ ▶ ▶ ▶ ▶ -30▶°C▶...▶+▶90▶°C▶

NBR▶ ▶ ▶ ▶ ▶ 0▶°C▶...▶+▶80▶°C▶

FFKM▶ ▶ ▶ ▶ ▶ +5▶°C▶...▶+90▶°C

français

C▶

(NF)

D▶

(NO)

E

F

T

1(P)

Vanne▶3/2▶voies▶;▶fermée▶en▶position▶de▶

repos,▶sortie▶A▶déchargée

Vanne▶3/2▶voies▶;▶en▶position▶de▶repos▶

pression▶appliquée▶sur▶sortie▶B

Vanne▶mélangeuse▶3/2▶voies▶;▶pression▶

appliquée▶en▶position▶de▶repos,▶P2▶

reliée▶à▶la▶sortie▶A,▶P1▶fermée

Distributeur▶3/2▶voies▶;▶pression▶

appliquée▶en▶position▶de▶repos,▶P▶reliée▶

à▶la▶sortie▶B

Vanne▶à▶3/2▶voies▶;▶utilisation▶

universelle

31

Page 32

5.6 Caractéristiques électriques

Connexions▶ ▶ ▶ ▶DIN▶EN▶175301-803▶(DIN▶43▶650),▶forme▶A▶

pour▶le▶connecteur▶type▶2508▶ou▶2509

5.7 Plaque signalétique

Matériau▶du▶corps

Matériau▶du▶joint

Diamètre▶nominal

Fonction

Type

0330▶C▶▶2,0▶▶FKM▶▶MS▶

G1/4▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶0-6▶bar▶

24V▶DC▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶▶8W

CE

00450000

Made▶in▶Germany

Numéro▶d'identification

Tension,▶fréquence,▶puissance

Raccord▶de▶conduite,▶pression▶nominale

Fig. 1 : Description de la plaque signalétique (exemple)

W14UN

6 MONTAGE

DANGER !

Risque de blessures dû à la présence de haute pression dans

l'installation/l'appareil.

▶▶

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶pression▶et▶désaérer/vider▶les▶conduites.

Risque de choc électrique.

▶▶

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶tension▶

et▶empêcher▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appa-

reils▶électriques▶en▶matière▶de▶prévention▶des▶accidents▶ainsi▶

qu'en▶matière▶de▶sécurité.

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme.

▶▶

Le▶montage▶doit▶être▶effectué▶uniquement▶par▶un▶personnel▶quali-

fié▶et▶habilité▶disposant▶de▶l'outillage▶approprié.

▶▶ Empêcher▶tout▶actionnement▶involontaire▶de▶l'appareil.

▶▶ Garantir▶un▶redémarrage▶contrôlé▶après▶le▶montage.

32

français

Page 33

6.1 Avant le montage

Position de montage :

Position▶de▶montage▶indifférente.▶De▶préférence▶:▶avec▶actionneur▶en▶

haut.

▶→ Préalablement▶au▶montage,▶vérifier▶si▶les▶tuyaux▶ne▶présentent▶pas▶

de▶salissures▶et▶les▶nettoyer▶le▶cas▶échéant.

Filtre à impuretés :▶Pour▶un▶fonctionnement▶fiable▶

de▶l'électrovanne,▶il▶convient▶de▶monter▶un▶filtre▶à▶

impuretés▶avant▶l'entrée▶de▶la▶vanne▶(≤▶500▶µm).

6.2 Montage

▶→ Respecter▶le▶sens▶du▶débit▶:▶▶

la▶fonction▶de▶l'appareil▶n'est▶assurée▶que▶si▶le▶fonction▶est▶

respecté.

Appareils avec raccord manchon

▶→ Utilisez▶une▶bande▶PTFE▶comme▶matériau▶du▶joint.

▶→ Calculer▶la▶profondeur▶de▶vissage▶maximale▶du▶filetage▶de▶raccor-

dement▶car▶celui-ci▶n'est▶pas▶normé.

REMARQUE !

Attention risque de rupture.

▶▶

La▶bobine▶ne▶doit▶pas▶être▶utilisée▶comme▶levier.

▶→ Maintenez▶l'appareil▶sur▶le▶corps▶à▶l'aide▶d'un▶outil▶approprié▶(clé▶à▶

fourche)▶et▶vissez-le▶dans▶la▶tuyauterie.

Fixation▶de▶l'appareil▶:

▶→ A▶l'aide▶de▶perçages▶M4▶x▶8▶(exécution▶en▶laiton▶ou▶en▶acier▶inox)▶

ou▶à▶l'aide▶de▶vis▶autotaraudeuses▶3,9▶DIN▶7970▶(version▶en▶plastique,▶profondeur▶de▶vissage▶max.▶10▶mm)▶sur▶la▶face▶inférieure▶du▶

corps▶au▶gabarit▶de▶trou▶38▶x▶24.

Appareils avec raccord à bride

Fixation▶de▶l'appareil▶:

▶→ A▶l'aide▶des▶vis▶fournies▶sur▶l'appareil▶initial▶ou▶sur▶l’embase.

▶→ Serrer▶les▶vis▶de▶fixation▶sur▶la▶bobine▶à▶2▶Nm▶maximum.

français

33

Page 34

6.3 Commande manuelle

2

REMARQUE !

▶▶ Lorsque▶la▶commande▶manuelle▶est▶enclenchée,▶la▶vanne▶ne▶peut▶

pas▶être▶actionnée▶électriquement.

Commande▶manuelle

Appuyer

Tourner

Fig. 2 : Commande manuelle

1

7 RACCORDEMENT ÉLECTRIQUE

DANGER !

Risque de choc électrique.

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶tension▶

▶▶

et▶empêcher▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appareils▶

électriques▶en▶ matière▶de▶ prévention▶ des▶ accidents▶ ainsi▶ qu'en▶

matière▶de▶sécurité.

Risque de choc électrique lorsque le conducteur de protection

n’est pas raccordé.

▶▶

Raccorder▶toujours▶le▶conducteur▶de▶protection▶et▶vérifier▶le▶passage▶

électrique▶entre▶la▶bobine▶et▶le▶corps.

max.▶1▶Nm

Connecteurs▶autorisés▶par▶ex.▶

type▶2508▶ou▶autres▶connec-

teurs▶adéquats▶selon▶DIN▶ISO▶

175301-803▶forme▶A

Fig. 3 : Raccordement électrique du connecteur

Respecter▶la▶tension▶et▶le▶type▶de▶courant▶selon▶la▶plaque▶

signalétique.

Joint

34

français

Page 35

7.1 Version standard

▶→ Connecter▶L1/+▶et/ou▶N/–▶aux▶bornes▶1▶et▶2▶indépendamment▶de▶

la▶polarité.

▶→ Raccorder▶le▶conducteur▶de▶protection.

▶→ Placer▶le▶joint▶et▶contrôler▶sa▶position▶correcte.

▶→ Visser▶à▶fond▶ le▶ connecteur▶(type▶2508▶ ou▶ 2509▶suivant▶DIN▶ EN▶

175301-803▶(DIN▶43▶650),▶forme▶A,▶références▶voir▶fiche▶technique),▶

respecter▶le▶couple▶de▶serrage▶maximum▶de▶1▶Nm.

▶→ Contrôler▶le▶passage▶du▶courant▶entre▶la▶bobine▶et▶le▶corps▶(fonction▶

du▶conducteur▶de▶protection).

7.2 Version à impulsions (CF 02)

Les▶bornes▶de▶raccordement▶dans▶le▶connecteur▶sont▶identifiées▶

à▶l'aide▶des▶chiffres▶1▶à▶3▶suivant▶les▶bornes▶de▶la▶vanne.

▶→ Raccorder▶comme▶indiqué▶sur▶«▶Fig.▶4▶».▶L'impulsion▶sur▶la▶borne▶1▶

ferme▶la▶vanne,▶l'impulsion▶sur▶la▶borne▶2▶ouvre▶la▶vanne.

▶→ Placer▶le▶joint▶et▶contrôler▶sa▶position▶correcte.

▶→ Visser▶à▶fond▶ le▶ connecteur▶(type▶2508▶ ou▶ 2509▶suivant▶DIN▶ EN▶

175301-803▶(DIN▶43▶650),▶forme▶A,▶références▶voir▶fiche▶technique),▶

respecter▶le▶couple▶de▶serrage▶maximum▶de▶1▶Nm.

▶→ Contrôler▶le▶passage▶du▶courant▶entre▶la▶bobine▶et▶le▶corps▶(fonction▶

du▶conducteur▶de▶protection).

24 3

(=)▶∼

(+)▶L1

(–)▶N

1

Fig. 4 : Raccordement électrique - Version à impulsion (CF 02)

REMARQUE !

▶▶ Éviter▶l'émission▶simultanée▶d'impulsion▶sur▶les▶deux▶bobines.

▶▶ Aucun▶autre▶consommateur▶(relais▶et▶autres)▶ne▶doit▶être▶commuté▶

parallèlement▶aux▶bornes.

▶▶ La▶connexion▶de▶la▶bobine,▶qui▶n'est▶pas▶alimentée▶en▶pression,▶doit▶

être▶isolée▶électriquement▶(ouverte).

▶▶ Si▶deux▶ vannes▶ou▶ plus▶doivent▶ être▶ commutées▶ parallèlement,▶

s'assurer▶par▶l'utilisation▶de▶commutateurs▶à▶2▶ou▶plusieurs▶pôles▶

que▶cette▶obligation▶est▶remplie.

PE

Borne▶1

Borne▶2

Borne▶3

Conducteur▶

de▶protection

français

35

Page 36

8 DÉMONTAGE

DANGER !

Risque de blessures dû à la présence de haute pression dans

l'installation/l'appareil.

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶pres-

▶▶

sion▶et▶désaérer/vider▶les▶conduites.

Risque de choc électrique.

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶ten-

▶▶

sion▶et▶empêcher▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appa-

reils▶électriques▶en▶matière▶de▶prévention▶des▶accidents▶ainsi▶

qu'en▶matière▶de▶sécurité.

AVERTISSEMENT !

Risque de blessures dû à un démontage non conforme.

Le▶démontage▶doit▶être▶effectué▶uniquement▶par▶un▶personnel▶

▶▶

qualifié▶et▶habilité▶disposant▶de▶l'outillage▶approprié.

Risque de blessures dû à des fluides dangereux.

▶▶

Avant▶de▶desserrer▶les▶conduites▶et▶les▶vannes,▶rincer▶les▶fluides▶

dangereux,▶couper▶la▶pression▶et▶purger▶les▶conduites.

9 MAINTENANCE, DÉPANNAGE

9.1 Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute pression dans

l'installation.

Avant▶de▶desserrer▶les▶conduites▶ou▶les▶vannes,▶couper▶la▶pres-

▶▶

sion▶et▶purger▶l’air▶des▶conduites.

Risque de choc électrique.

Avant▶d'intervenir▶dans▶l'installation▶ou▶l'appareil,▶couper▶la▶ten-

▶▶

sion▶et▶empêcher▶toute▶remise▶sous▶tension▶par▶inadvertance.

▶▶ Veuillez▶respecter▶les▶réglementations▶en▶vigueur▶pour▶les▶appa-

reils▶électriques▶en▶matière▶de▶prévention▶des▶accidents▶ainsi▶

qu'en▶matière▶de▶sécurité.

AVERTISSEMENT !

Risque de blessures dû à des travaux d'entretien non conformes.

▶▶ L'entretien▶doit▶être▶effectué▶uniquement▶par▶un▶personnel▶quali-

fié▶et▶habilité▶disposant▶de▶l'outillage▶approprié.

▶▶ Empêcher▶tout▶actionnement▶involontaire▶de▶l'appareil.

▶▶ Garantir▶un▶redémarrage▶contrôlé▶après▶l'entretien.

36

français

Page 37

9.2 Pannes

En▶présence▶de▶pannes,▶vérifiez

▶→ que▶l'appareil▶est▶installé▶dans▶les▶règles,

▶→ que▶le▶raccord▶électrique▶et▶fluidique▶est▶correct,

▶→ que▶l'appareil▶n'est▶pas▶endommagé,

▶→ que▶toutes▶les▶vis▶sont▶bien▶serrées,

▶→ que▶la▶tension▶et▶la▶pression▶sont▶disponibles,

▶→ que▶les▶tuyauteries▶sont▶propres.

Panne Cause possible

La▶vanne▶ne▶

s’enclenche▶

pas

La▶vanne▶ne▶

se▶ferme▶pas

9.2.1 Réparation

Les▶réparations▶sur▶l'appareil▶doivent▶être▶effectuées▶uniquement▶par▶le▶

fabricant.▶Les▶données▶de▶service▶peuvent▶changer▶lorsque▶l'utilisateur▶

remplace▶des▶pièces▶de▶rechange.

Court-circuit▶ou▶coupure▶de▶la▶bobine

Pression▶du▶fluide▶hors▶de▶la▶plage▶de▶pression▶autorisée

Actionnement▶commande▶manuelle

Intérieur▶de▶la▶vanne▶encrassé

Actionnement▶commande▶manuelle

10 TRANSPORT, STOCKAGE,

ÉLIMINATION

REMARQUE !

Dommages dus au transport.

Les▶appareils▶insuffisamment▶protégés▶peuvent▶être▶endommagés▶

pendant▶le▶transport.

▶▶ Transporter▶l'appareil▶à▶l'abri▶de▶l'humidité▶et▶des▶impuretés▶et▶dans▶

un▶emballage▶résistant▶aux▶chocs.▶

▶▶ Veiller▶à▶ce▶que▶la▶température▶de▶stockage▶ne▶se▶situe▶ni▶au-dessus▶

ni▶en▶dessous▶de▶la▶température▶de▶stockage▶admissible.

Un mauvais stockage peut endommager l'appareil.

Stocker▶l'appareil▶au▶sec▶et▶à▶l'abri▶des▶poussières.

▶▶

▶▶ Température▶de▶stockage▶de▶-40▶à▶+80▶°C.▶

Dommages sur l'environnement causés par des pièces d'appareil contaminées par des fluides.

Éliminer▶l'appareil▶et▶l'emballage▶dans▶le▶respect▶de▶l'environnement.

▶▶

▶▶ Respecter▶les▶prescriptions▶en▶matière▶d'élimination▶des▶déchets▶

et▶de▶protection▶de▶l'environnement▶en▶vigueur.

français

37

Page 38

Bürkert▶Fluid▶Control▶Systems▶

Sales▶Center▶

Christian-Bürkert-Str.▶13-17▶

D-74653▶Ingelfingen▶

Tel.▶▶+▶49▶(0)▶7940▶-▶10▶91▶111▶

Fax▶▶+▶49▶(0)▶7940▶-▶10▶91▶448▶

E-mail:▶info@burkert.com

International address

www.burkert.com

Manuals▶and▶data▶sheets▶on▶the▶Internet:▶www.burkert.com▶

Bedienungsanleitungen▶und▶Datenblätter▶im▶Internet:▶www.buerkert.de▶

Manuels▶d'utilisation▶et▶fiches▶techniques▶sur▶Internet▶:▶www.buerkert.fr

© Bürker t Werke GmbH & Co. KG, 2014 - 2019

Operating Instructions 1906/05_ EU-ML _00893047 / Original DE

www.burkert.com

Loading...

Loading...