BK3'AND

BK3'PWS. "

"BANDSAWS'

.

~ Mk. II \ .

\

.

,

.'.:

.;

..

:.

.'.'.'..

',_,".:.q:'

.

,

.

,

'

..

,-~"'

.

. t'"

.•• -. _,.1 '.

·<.Y·

o ,.."

• I~. •

I

i

/

..

'.'

.

.

.

'

-. ,Specific,ations and

op~"ating ,/'"

Instructions . '/'.

.

'

BU

.I

These products are made to the'

highest possible standards. They are

fully guaranteed and suitable for both

professional and DIY use.

This bandsaw i's one of the most

versatile power saws available and

copes equally well with either straight

or intricate contour cuts on a wide

variety of materials.

The BK3 PLUS Mk. II includes

accessories to enable it to be

converted for use as a jig or fretsaw

thus providing three saws

in

one.

These accessories, whilst. supplied

as standard with the BK3 PLUS

Mk. II are available as optional extras

for the BK3 Mk II.

CON FORM'S TO

RADIO AND TV

SUPPRESSION

REQUIREMENTS

OF BS800: 1977

Key Featu res

Two blade speeds:

106m per min (350ft per min).

396m per min (1300h per min).

12" Throat and 3" depth of cut.

Table tilts through 45°

Range of 5 blades for wide variety of

materials.

Rugged die cast aluminium construction.

Completely self contained with built-in

motor, c/w power take off facility.

Mounted on base plate equipped with

rubber feet for stability.

Easily portable.

Compact and easily stored.

Unique safety cut off mains switch/dust

flap. .

Ideal for use in:

The home workshop

. General industrial use, trade and

engineering, maintenance and pattern

shops

Handicraft departments of schools and'

technical colleges

/

.'

/

)

/

/

/

/

..

\

,

'\

\

• 2

\

For a wide variety of applications:

Joinery, cabinet making

Model making

Household maintenance

Pattern making

Boat building

Shop fitting. exhibition and window

display

Manufacture of plastic components

Coach trimming, motor repairs.

Sandingllinishing

Onawide variety

of

materials:

Hardwoods

Softwoods

Chipboard

Mild Steel (up to 25mm thick)

Aluminium

Brass

Soft alloys (up to 75mm thick)

All plastic materials (including Formica,

Wareite, expanded polystyrene, perspex,

and thermo plastic floor tiles)

Leather

Cork

Haro rubber

Preparation for use

Wiring Instructions

Thewires in the mains lead are coloured in

accordance with the following code:

GREEN ANDYELLOW: EARTH

BLUE: NEUTRAL BROWN: LIVE

As the colours of the wires in the mains

lead of this appliance may not correspond

with the coloured markings identifying the

terminals in your plug proceed as follows:-

The wire which iscoloured green-and-

yellow must be connected tothe terminal

which ismarked with the letter 'E' or by the

earth symbol VW or coloured green or

green-and-yellow.

THIS APPLIANCE MUSTBE EARTHED

The wire which iscoloured blue must be

connected to the terminal which is marked

with the letter'N' or coloured black.

The wire which iscoloured brown must be

connected to the terminal which is marked

with the letter'L' or coloured red.

I!

a 13 amp (BS1363) plug is used a3 amp

fuse should be fitted,ifany other type 01

plug is used a 5 amp fuse must be fitted

j

~.

Fitting the saw table

1. Fit the semi-circular mounting arc to

the underside of the Bandsaw table

using the two screws provided.

2. Remove the table locking wing nuts

and washers from the two studs at the

rear of the machine and ensure the

angle indicator does not restrict the

table from being fitted

3. Hold the table horizontal with its slot in

Iine with the back of the blade. Carefully

gUide the table into position so that the

slot is towards you and the studs both

protrude through the slot in the mount-

ing arc underneath the table.

4. Replace the table locking wing nuts

with the washers beneath them. Press

down lightlyon the table to keep it in

contact with the table level adjustment

cam while tightening the wing nuts.

5. Set the angle indicatorto read 0" and

secure.

6. Check that the coloured centre plate

insert is correctly posiltoned in its

recess and that its upper surface is

flush with that of the table.

7. The table may be tilted at any angle

required up to 45

0

;

the angle is

Indicated on the mounting arc. To return

It to the nonzontai bnng the underneath

of the table back into contract with the

cam. A set squareISuseful to check the

level of the table In relation to the saw

blade. Should the table not be square to

the blade release the screw holding the

cam and adjust the table. Then push the

cam up to the table and re-tighten.

To assist in the control of the work

positioned on the table two fences are

available as optional accessories:

1. The Rip Fence is for rip and cross

cutting.

2. The Mitre Fence is invaluable for all

applications involving mitre joints.

4

The Blade

For optimum oertorrnance the blade

should be checked for tension and track-

ing prior to itsfirst use, when fitting a

replacement blade, and at regular inter-

vals thereafter. Both of these adjustments

require the cover plate to be removed.

This is easily achieved by rotating by a

Quarter of a turn each of the three locking

screws hOldmg the cover plate to the main

frame.

BEFORE REMOVING THISCOVERTHE

UNITSHOULDBE DISCONNECTED

FROM THE ELECTRICAL SUPPLY. 00

NOTATIEMPTTO RUN THE MACHINE

WITH THE COVER PLATE REMOVED.

Blade tension

CAUTION: Over-tensioning tends to shor-

ten the life of the blade. The tension should

be released when the machine is not in

use. Blade tension should never be

greater than is necessary to keep Ihe

blade on Itswheels and to transmit the

drive

Toadjust the blade tension turn the ten-

sion adjusting knob clock-wise to

increase tension. As a guide to correct

blade tension, note the curve that the

blade makes as it leaves the top wheel on

Itsway down to the table, screwing clock-

wise on the adiustrnent until the blade

leaves the top wheel in astraight vertical

IIne.At th ISpoint, screw the tension knob

down a further full turn, this should give

sufficient tension under normal

circumstances.

Blade tracking

The blade should always move centrally

over the top wheel. This can be checked

through the track viewing slot in the top of

the bandsaw frame.

Toadjust the blade tracking. manually

rotate the top driven wheel clockwise and

establish the degree of adjustment

required. Turn the blade tracking knob

clockwise (viewed from the rear face) to

cause the blade to track nearer the back of

the bandsaw frame.

Turn the knob anti-clockwise tocause the

blade to track nearer to the front of the

machine. The adjustment is correct when

the blade is moving centrally on the top

wheel as stated previously.

_.

II

.,

Blade guides

Toensure the best results from your

bandsaw the top blade guide assembly

must be set as close to the surface of the

workpiece as possible. This is achieved

simply by releasing the tension to the

blade ~uide adjustment knob and slidl ng

the gUide assembly either up or down to

the appropriate position.

The bottom blade guide assembly should

always be as close as practical to the bot-

tom of the table and only requires adjust-

ment when using the tilt facility.

The blades must run freely in both the top

and bottom guides and these should be

adjusted so that the teeth of the blade just

clear the front edge of the two cyhndrical

r,

guide blocks. The back bearing can then

be adjusted untilitis between O.5mmand

1mm away from the back of the blade.

Changing the blade .

Unscrew the tension adjusting knob

several turns to lower the top wheel

assembly. If thewheel does not move

freely it may be pulled down manua Ily

once the tension ing knob has been

loosened.

Liftthe used blade from the wheels and

carefully guide it through the slot in the

saw table.

Before fitting the new otace check that the

teeth on the blade are pOinting

downwards. If this is not the case, then it is

necessary to turn the blade inside out.

This can be easily achieved bygripping

the blaoe between the thumb and

forefinger of both hands and rotating each

hand in the opposite direction to the other.

Using care guide the replacement blade

through the slot in the table and locate it

on the two bottom wheels. Then rotate the

blade onto the top wheel with aclockwise

motion checking again that its teeth are

pointing both forward and downward,

Screw down the tension adjusting knob

suffeciently 10 keep the blade on the

wheels and position the blade in the top

and bottom blade guides. Now proceed to

adjust the blade tension, tracking and

guides in accordance with the instruc-

tions given previously.

5

Changing the blade speed

Your Bandsaw is supplied in the high

speed mode for cutting wood and

softer materials, and for finishing

operations in wood or metal using the

sandingflinishing belt. For operations

involving mild steel, alloys etc. the slow

speed mode is required to avoid undue

wear of the blade and10provide a

better

finish. .

To change the speed the following

procedure should be followed:

1. DISCONNECTTHE MACHINE FROM

THE MAINS SUPPLY

2.

Remove cover

plate

3. Slacken blade tension and remove

blade

4. Slacken off both motor secu ring

screws, swing motor forward and

remove timing ben

5. Remove screw from the centre of the

bottom/front wheet and remove wheel

6.

Fitalternative pulleyand secure with

screw

7. Fillonger timing belt around the

periphery of the front wheel and over

the motor pulley .

8. Swing the motor backwards toapply

tension to the belt, this is ideally set

when 5mm (3/16") movement occurs

at the centre of the top belt run,when

6

lightly pressed. Tighten motor screws.

I

...

'-~.-"-

9. Refit the blade and replace cover

N.B. When set at the slow speed the blade

runs on the top of the timing belt on the

drive wheel.

Using

the

machine

Rate of feed of work to blade

Rates of feed vary with the matenai being

cut and its thickness. Always allow the

blade to do the work and never apply

undue pressure sufficient to distort the

blade. A little experience will indicate the

correct rates of feed for materials of dif-

ferent hardness and thickness. Forcing

the rate of feed will shorten the life of your

bandsaw blades.

Safety Cut off Switch Cover

Both Bandsaws feature a dual purpose

safety cut oH/dust cover on, the switch.

To SWitch the machine on the cover

must be raised and the switch

depressed. However, the machine may

be switched

oH

easily and quickly by

merely tapping the yellow safety flap.

High speed materials .

With the machine set at high speeditis

suitable for profile cutting and cross cut-

ting of both hard and soft woods. At the

higher speed you will findthewoodwill cut

very easily and all you refforts can be

directed towards guiding thework past

the blade. On thicker sections of timber

(over 15mm) where a long cut along the

grain is to be made, itmay be desirable to

use the lower speed to obviate the

possibility of stalling the motor.

Low speed materials

The low speed is used primarily for steel

and other metals, but It is also advisable to

use t~e slow speed when cutting

olastrcs over Smm thick. If a high speed is

used when culling thick plastic material

substantial amounts of heat may be .

generated which will tend to weld the plas-

tic together beh ind the blade and even-

tuallycause the machine to stall.

Sanding and

lii'lishing

This is also carried outat the higher speed.

These belts are fitted to the machine in the

same way as the blade. However it is

advisable that the top and bottom blade

guide assemblies be removed completely

to avoid any damage to these items. When

fittin9 the finish ing belt ensure that the lap

joint Inthe belt is as shown in the sketch,

so as to avoid tearing the belt.

Whilst the belt can be used for finishing

operations without having any support to

the back taceot the belt, it is far more

effective if sorndoressure isapplied to this

back face by means of a suitably shaped

piece of wood or similar material.

".

\.

7

,I

t'

8

Maintenance

THIS PRODUCTSHOULD BE DISCON-

NECTED FROMTHE MAINS SUPPLY

WH ILST CARRYI NG OUT MAINTENAN-

CE,ADJUSTMENT OR THE REPLACE-

MENTOFANYWORN PARTS.

The 810 Mk.1I 8andsaw is supplied with

a new, all-British motor.

Manufactured to the most stringent

electrical and mechanical specifications,

it is more powerful than its predecessor

and is equipped with- a a power take-off

paint, at the rear, to accept the latest

Burgess accessory, the Disc Sanding

Attachment.

Contents:-

(i) 180mm

(7")

diameter sanding disc

(ii) Adjustable angle table from

0

0

to 45

0

which accepts the Burgess mitre

fence accessory

The purchase of a Disc Sanding

Attachment will extend even greater

versatility to the range of useful

applications for which your

BK3

Mk,11

may be used. The Attachment is

available now from your local stockist,

part no. 580800.

Cleaning

Dust ejection slots at the bottom of the

frame do much to minimise the accumula-

tion of sawdust but they may become

obstructed after prolonged periods.

Therefore, after every few hours of running,

the front cover plate should be removed

and accumulations of sawdust be

removed both from the interior and from

around the machine, either by brushing,

by blowing with compressed air, or by

removing with a vacuum cleaner.

lubrication

Occasionally apply one or two spots of

good quality machi neoil to the spindles of

each of the three wheels.

ReplaCing

worn

drive belts

With the machine disconnected from the

mains and the blade removed a worn driv-

ing belt may be replaced by slackening

the two motor fixing studs, easing the belt

tension, and running it off both pulleys.

When a replacement belt has been fitted

apply sutlicient tension as described pre-

viously under the section describing

speed change.

,

l

,

Rectifying blade slip

Slade slip may occurifthe outer surface of

the driving belt (which also serves as a tyre

on the driving wheel at slow speed)

acquires a greasy coating from the blade.

This coating may be removed from the bell

and from the other two wheels by wiping

with a cloth which has been dampened in

white spirit.

Blade slip may also be caused by insuffi-

cient blade tension.

To rectify electrical failure

Sould any electrical fault occur, set the

switch on the front of the bandsaw to OFF,

disconnect the bandsaw from 'he electri-

cal supply and refer the matter to a compe-

tent electrician.

BK3 Plus Mk. II - The 3 in 1 Saw

As

a general purpose saw the BK3

Mk. !I can hardly be improved ·upon. But

with the addition of the Fretsaw/Jigsaw

attachment or Circle Cutting and Fence

attachment, available as optional extras

(or included as standard with BK3 Plus

Mk. II), it can be upgraded into a truly

universal three-in-one combination saw,

to expand your scope even further.

Thus, no matter whether you obtain

these attachments at the outset with a

BK3 Plus Mk. II or later, to add to a

BK 3 Mk.

tI,

the method of fitting and

operating them is identical. The only

diHerence is that. with the BK3 Plus

Mk. II, these extras come packed in a

handy plastic storage box, attached to

the frame. This should be unscrewed

before use and the screw holes plugged

with the rubber grommets provided. The

box can then be retained in the

workshop for storage of these valuable

attachments.

Your BK3 Plus Mk. II Bandsaw is

supplied with a new, all-British motor.

Manufactured to the most

9

stringent electrical and mechanical

specifications, it is more powerful than

its predecessor and is equipped with a

a power take-of point, at the rear, to

accept the latest Burgess accessory, the

Disc Sanding Attachment.

Contents:-

(i) 180mm

(7")

diameter sanding disc

(ii) Adjustable angle table from 00to 45°

which accepts the Burgess mitre

fence accessory

The purchase of a Disc Sanding

Attachment will extend even greater

versatility to the range of useful

applications for which your BK3 Plus

Mk.1I may be used. The Attachment is

available now from your local stockist,

part no. 580800.

Fretsaw/Jigsaw attachment

• Fretsawing facility for intricate internal

and external cuts

• Jigsawing Facility for internal and exter-

nal cuts in heavier materials

• Jigsaw blades capable of swinging

through 90° for longer length materials

• Includes fretsaw and Jigsaw blades

• Fretsaw/Jigsaw will cut wood,

10 plastics and light alloys

Method of Attachment

Disconnect 'rom mains. Slacken tension

and remove saw blade.

A

Remove

A.

Oil or grease regularly

B. Adjust to allow free running. Turnover by

hand to test

C.

Fretsaw blade

D. Fretsaw Blade Guide Block - Adjust

to allow the fretsaw blade to run in

the Vshaped channel.

A.

Push on eccentric&bush

11

12

A

For cutting 'rom the front

B.For cutting 'rom the side

-

A

Ensure that the blade guide rests on the

workpiece and is pushed forward to

support the blade.

B

Circle Cutting and Fence attachment

• For repeat circle cutting

• Invaluable for model and toymaking

• Attachment can be adapted for use as a

straight edged fence

This may be fitted to either the left or right

hand side of the top blade guide

assembly.

t. Raise the top blade guide above the

thickness of material to be cut

2. Using the allen key, remove the approp-

riate blade guide block

3. Insert the smaller end01the long bar

into the guide block with the lIal side

towards you. Adjust to the blade and

·tighten the allen screw

4. When the attachment isto be used on

the left of the saw see Diagram

A

5. Feed the material into the blade in a

straight line for a distance equal to the

recuued radius of circle.

6. Lower the top blade guide assembly

until the pin pierces the material. Then

tighten blade guide clamp knob.

7. Switch on and rotate the material to form

a Circle. ,

3

Place Trammel Pin Casting onto the long

rod usmg the hole nearest to the pin.

Adjust to the eucre you require. then

~Ightenthe allen screw. Make sure the pin

IS porntmq downwards and vertical.

When the attachment isto be used on the

right of the saw blade see Diagram B.

Diagram B

I •

14

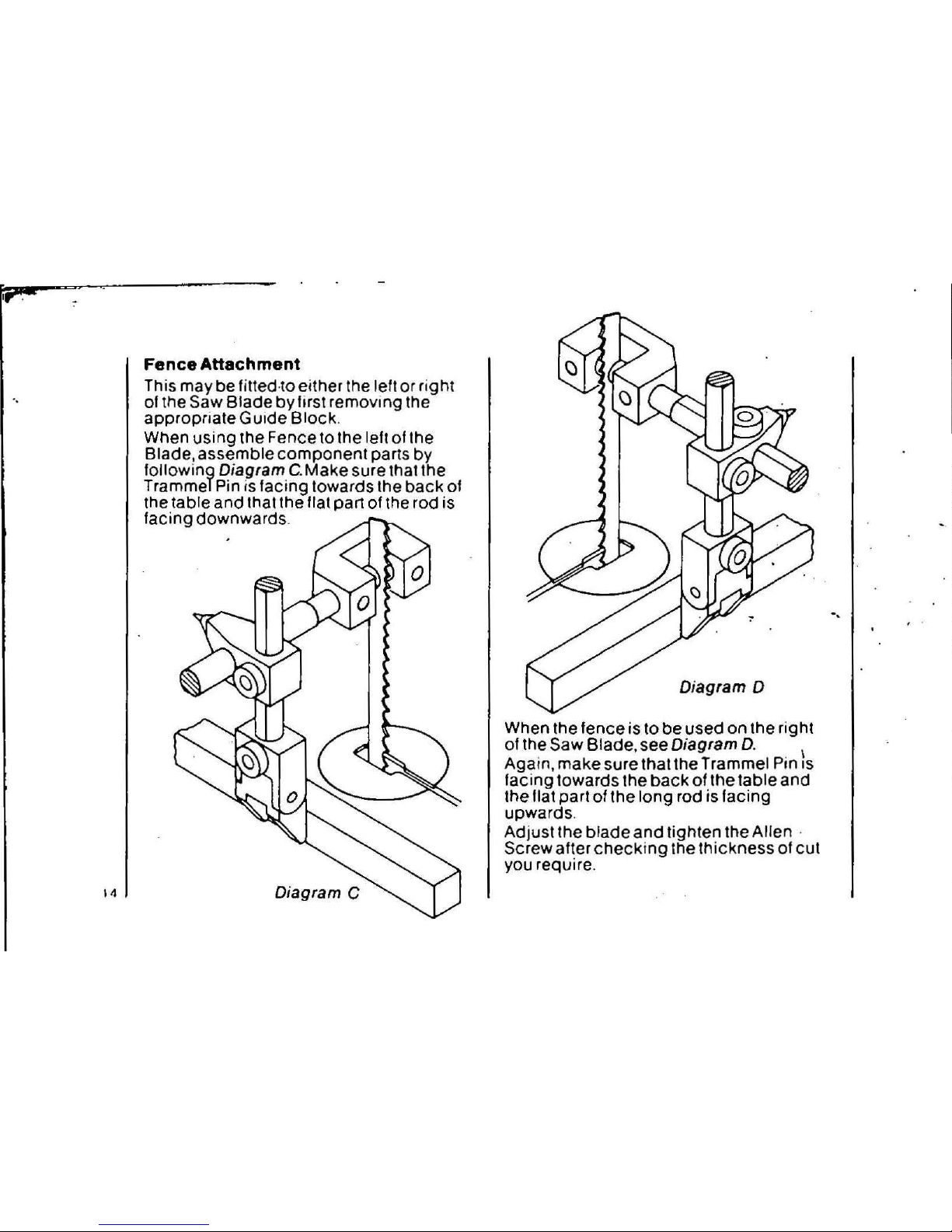

Fence Attachment

This may be tittedto eitner the left or right

of the Saw Blade byfirst removing the

appropnateGuide Block.

When using the Fence to the left of the

Blade, assemble component parts by

following Diagram C.Make sure that the

Trammel Pin is facing towards the back of

the table and that the flat part of the rod is

facing downwards.

Diagram 0

When the fence is to be used on the rig hi

01the Saw Blade, see Diagram D. \

Again, make sure thai the Trammel Pin

IS

facing towards the back of the table and

the flat part of the long rod isfacing

upwards.

Adiust the blade and tighten the Allen·

Screw after checking the thickness of cut

you require.

.,

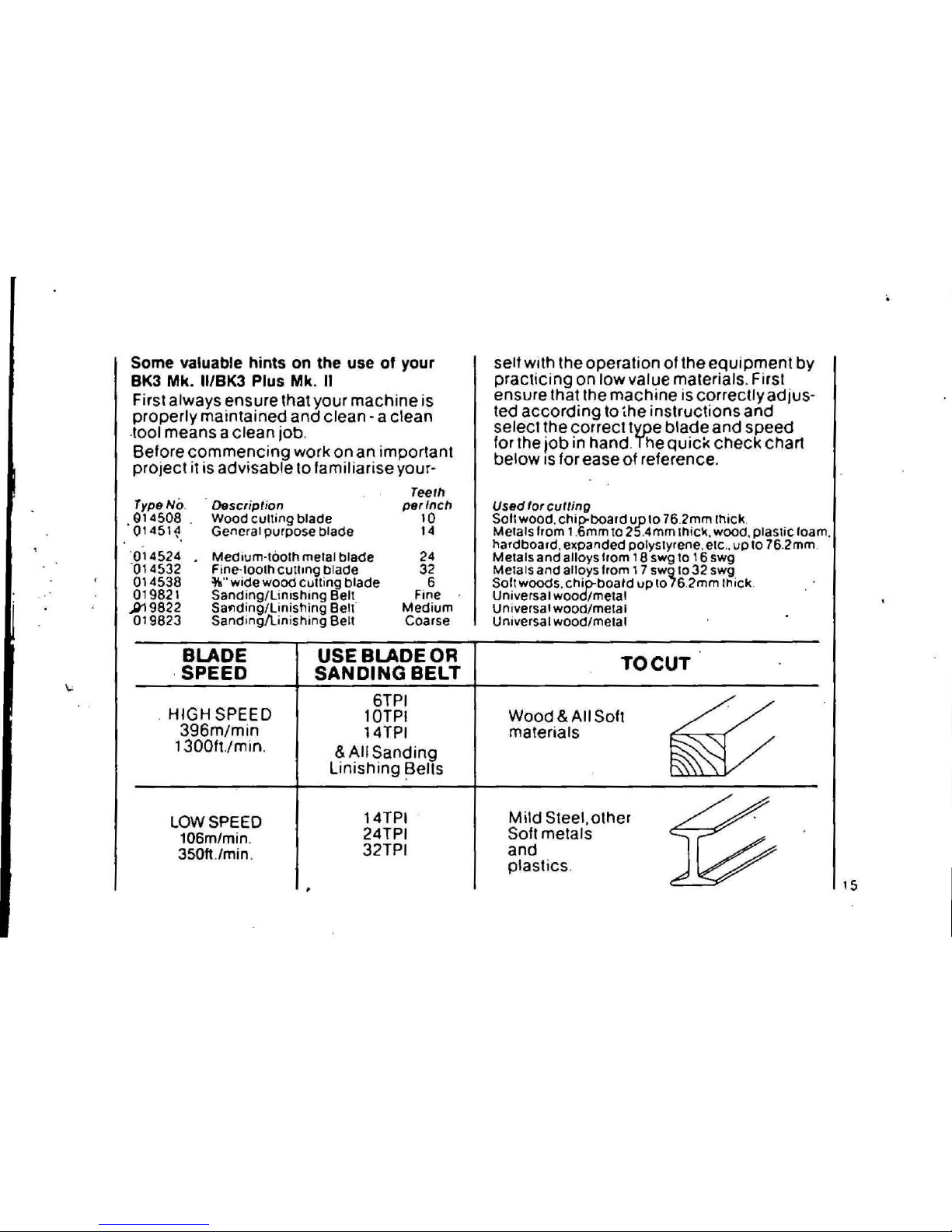

Some valuable hints on the use of your

BK3 Mk. II/BK3 Plus Mk. 11

First always ensure that your machine is

properly maintained and clean -a clean

.toot means a clean job.

Before commencing work on an important

project it is advisable to familiarise your-

Type

No.

. Q14508 .

01451~.

014524

'014532

014538

019821

;>19822

019823

Description

Wood culling blade

General purpose blade

Medium-tooth metal blade

Fine-tooth cutllng blade

~"wide wood cutting blade

Sanding/Linishing Belt

Saflding/Linistling Belt

Sanding/linishing Belt

Teet"

per Inch

10

14

24

32

6

Fine

Medium

Coarse

self with the operation01the equipment by

practicing on low value materials. First

ensure that the machine is correctly adjus-

ted according to the instructions and

select the correct type blade and speed

for the iob in hand. The

quic«

check chart

below IS for ease of reference.

Used for cutting

Solt wood. chip-board up\076.2mm Ihick.

Metals from 1.6mmto2S.4mm thicl(,

wooo.

plastic loam.

hardboard, expanded polystyrene, eic., up to 76.2mm

Me.als and alloys tram 18 swg to 16 swg

Metals and alloys from 17 swg to 32 swg

Sol. wOOds.

chio-noatd up

to76.2mm Ihick

Universal wood/metal

Universal wood/metal

Universal wood/metal

BLADE

.SPEED

USE BLADE OR

SANDING BELT

TO CUT

. HIGH SPEED

396m/min

1300ft./min.

6TPI

lQTPI

14TPI

& All Sanding

Linishing ~elts

14TPI

24TPI

32TPI

LOW SPEED

106m/min.

350ft.lmin.

Wood&All

Soft

materials

Mild Steel,other

Soft metals

and

plastics.

15

16

BK3 Mk. II and BK3 Plus Mk. II

Cutting with the bandsawISstraight

tor-

ward - simply by g~iding thework mto the

moving blade, always ens unng that

tingers are well ctea rof the blade. If a cut is

required near the edge of a material one

hand can beused toguide it,whilsta

piece of wood held in the other hand can

add valuable suport and assistance wilh

complete safety.

In all cutting operations the work should

befed intothebladeata steady rate and

back trackinq (i.e.pulling the work back

from the moving blade) should be

avoided, or at least reduced to a minimum.

This is best accomplished by planning

your cuts beforehand.

Bu rgess bandsaw blades are very flexible,

but very complicated cuts and small

radius curves are best accomplished with

the aid of pre-drilled holes combined with

a few tangential or radial cuts. This techni-

que will achieve excellent results without

putting undue tension on the blade and

blade gUide assembly.

Hints on the use of BK3 Plus Mk. II

For internal cuts using either the Fretsaw

or Jigsaw blade, a hole must be drilled in

the material through which to teed the .

appropriate blade.

Toaccomplish this, raise the upper blade

gUide assembly as far as possible and

feed the material over the fitted blade.

When using Ihefretsaw blade on materials

over

Va"

thick, u.s advisable to feed the

blade through the material, prior to fitting

to the machine, to avoid damaging the

blade.

With the material in place the upper blade

guide should then be lowered to the

worksurlace to provide adequate support.

Cutting can then commence, taking care

not to force the rate of feed. Letthe saw do

the work.

Where the internal cut is particularly com-

plex and intricate it is advisable to pre-dri II

holes in strategic positions to facilitate

sawing.

The jigsaw blade is particularly useful for

heavier materials and can be pivoted

thrOUQh45° to accommodate longer

material. The upper blade guide support is

not required for the heavier gauge jigsaw

blade.

Advisory service

We are very willing to advise on, and give

assistance in developing techniques for

carrying out unusual culling operations.

We are also always interested to know of

any special techniques which have been

developed independently by bandsaw

users among our customers.

Tooisthatturn passing

interest into lasti ng

pleasures

No matter Ifa job is tackled reluctantly,

simply because it is a chore that has to be

done, or with enthusiasm because it prom-

ises to be a pleasure, the chosen tool can

make or mar both the experience and the

results.

That's why Burgess take great pains to

ensure that every tool they sell brings its

owner the satisfaction of a job well done,

over and over again.

Byeasing your task, improving your skills

and increasing your enjoyment, they have

the habit of bringing out creative and prac-

tical abilities you never knew you had, so

turning fleeting interests mto fife long

hobbies

Artist or craftsman, amateur or pro-

fessional, Burgess have a way to help

active individuals of all ages realise their

potennai to the full.

Tools available from Burgess include:

BANDSAWS

CIRCULAR SAWS

SITE SAWS

MITRE SAWS

ENGRAVERS- VIBROAND ROTARY,

TOOLS AND KITS

SOLDERING IRONSt5.2S,40WATI

AND2SWATIKIT

SOLDERINGAND CRAFT KIT

SPRAYE RS -AI RLESS AN D

COMPRESSOR

BENCH GRINDERS •

SHARPENERS

12V ~C ROTARYTOOLS -THE ROTOOL

RANGE

GUARANTEE

Burgess Power Tools guarantee their pro-

ducts for one year from the date of

purchase. Anydefect during this period

not due to accident or abuse will be

repaired free of charge. The statutory

rights of the consumer are not affected.

Burgess Power Tools Ltd.

Sapcote, England. LE-"96JW

/

BK3 SPARE PARTS LIST

Key No.

Part

No.

Description

I

I

014823

Timing Pulley&Rollpin

I

12 019804

Timing Belt. 204 XL

(Low Speed)

12a 019805

Timing Belt, 120 XL

,

"

(High Speed)

13

01 1100 Top Wheel Casting Assy

14

011106

Securing Bolt

~

"

15

014814 Wheel Shaft (2)

15a 014824

Wheel Shalt&Wheel Shaft Screw

16

014815

Circlip (2) .

17 01II 10

Washer •

18

01,111

Lock Nut

~

19 011200

Tension Knob Assy

...

20

011211 Securing Knob

'~.

<,

y~.~;,

011300

Tracking Knob Assy

019913

Blade Shield Clamp

23

012000 Bolt

24 012206

Lock Washer

25 012400

Switch

.....

..

26

012500

Switthbox

27 012600

Screws (3)

0,

&§

28 012801

Cable

29

250150

Cable Clamp

30 •

013100

Terminal Block

~-.KeyNo. Part No. Description

31---010105 Quarter turn cover

I 019910 Frame

plate lasteners (3)

2 ·014811

Pointer

'.

32 013701

MOlor Screws

I

..

'

.

Screw

33

013900

Trunion Stud (4)

3

010206

Centre Plate

34 014100

WingNut (2)

4

,

010S11

Table c/w Centre Plate

35

014300 Cam

5 019738

Base Plate c/w

36 019911

Frame&Base complete

..

6

010112

Base edge finishing strip

37

250151

Cable Clamp Screw

7 019912 Cover Plate

38 019500

Upper Blade Guide Assy

8 019732

Motor (220/240V 50Hz)

,

39

700073

Guide Blocks (Set 4) + Centre Plate

019756 Motor (1OOV50Hz)

40

019620

Bearing Shaft)

t~

019746

MOlor (1DOV60Hz)

Bearing

)

f

019745

Motor (1 10V 50Hz)

Circlip )

9 010704

Wheel

I'-

41 019600

Lower Blade Guide Assy

10

010802

Drive Wheel

42 019621

Roller)

(Low Speed)

RoliPin)

10a 019817

Drive Wheel

43

019606 LockNut

High Speed)

•

44

019623

Insulating Pad

•

....

Loading...

Loading...