Page 1

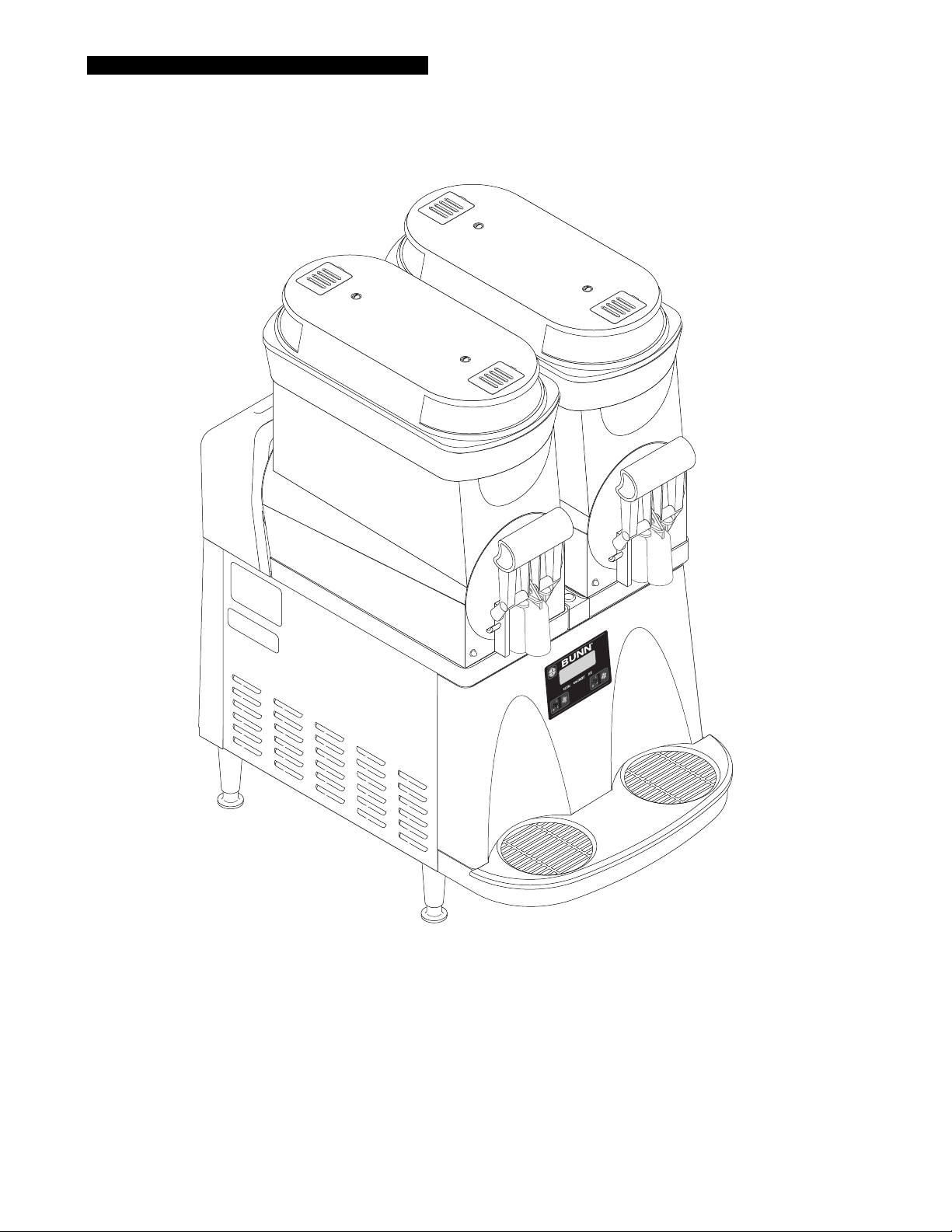

BUNN

®

ULTRA-2

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

32080.0000D 10/04 ©2002 Bunn-O-Matic Corporation

www.bunnomatic.com

Page 2

INTRODUCTION

This equipment dispenses granita-type and cold liquid drinks on demand from separate hoppers. Operating controls

are accessible only through password protection.

CONTENTS

Introduction & Warranty ............................................................................................... 2

User Notices ..................................................................................................................3

Site Preparation, Electrical Requirements ..................................................................... 3

Initial Setup ...................................................................................................................4

Operating Controls ........................................................................................................ 6

Programming ................................................................................................................ 7

Using the Dispenser for Granita-Type Products .......................................................... 18

Using the Dispenser for Cold Liquid Products ............................................................ 18

Other Recommendations For Your Dispenser ............................................................. 10

Recommended Daily Cleaning..................................................................................... 20

Required Regular Maintenance ................................................................................... 22

Schematic Wiring Diagrams ........................................................................................ 24

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis: parts

and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will

be commercially free of defects in material and workmanship existing at the time of manufacture and appearing

within the applicable warranty period. This warranty does not apply to any equipment, component or part that was

not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper

installation or operation, improper maintenance or repair, damage or casualty. This warranty is conditioned on the

Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601

or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the

defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from

BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are

not authorized to make modifications to this warranty or to make additional warranties that are binding on BUNN.

Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not

be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/

or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

2

34244 101804

Page 3

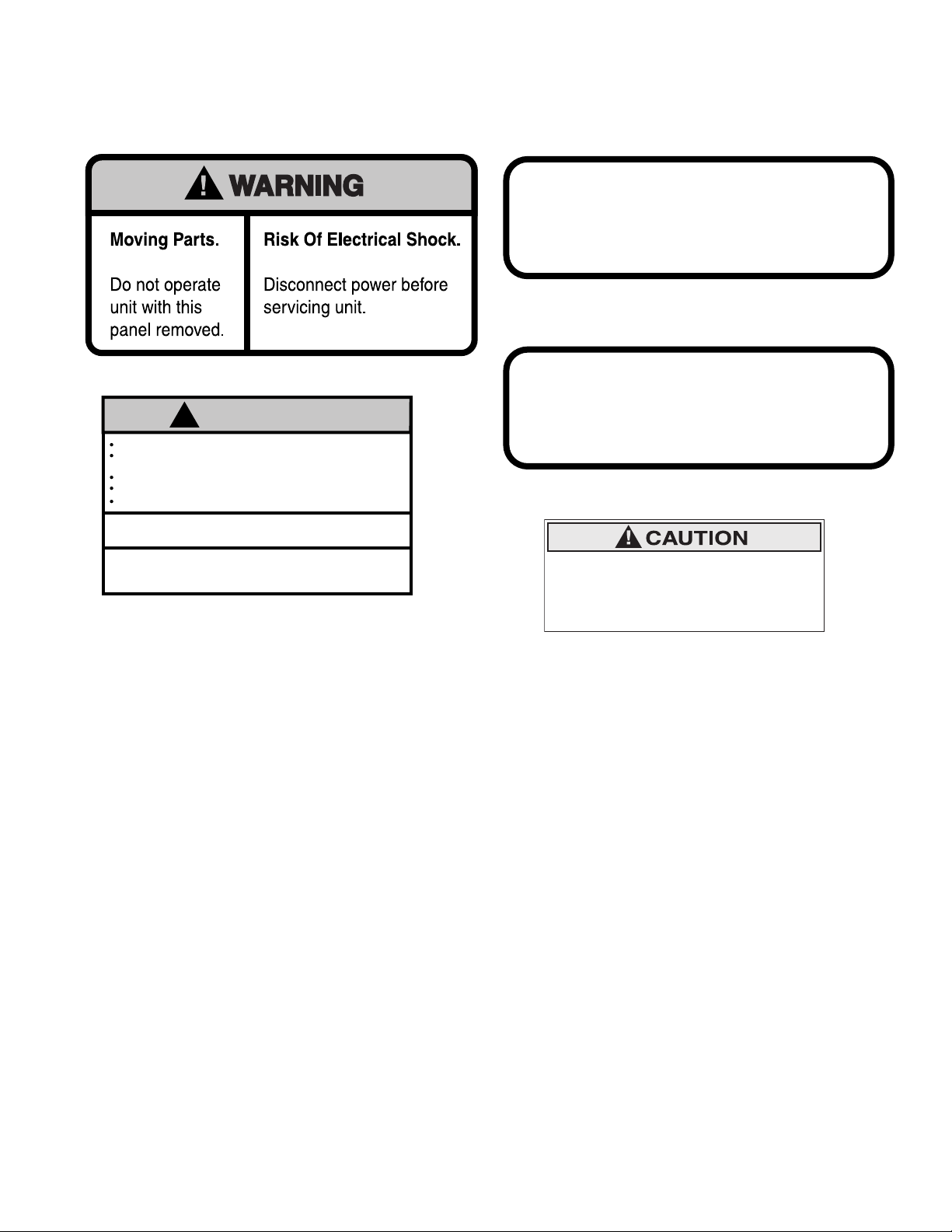

USER NOTICES

Carefully read and follow all notices on the equipment and in this manual. They were written for your protec-

tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels.

CHARGE

Type R404A, Amount 10 oz

Design Pressures: High 240 Low 34

32162.0000 (ULTRA-2)

27442.0000

CHARGE

! WARNING

DO NOT OVERLOAD CIRCUIT.

ALWAYS ELECTRICALLY GROUND THE CHASSIS

OR ADAPTOR PLUG.

DO NOT DEFORM PLUG OR CORD.

FOLLOW NATIONAL AND LOCAL ELECTRICAL CODES.

KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE OPERATING MANUAL

BEFORE USING THIS PRODUCT

00986.0002E 5/98 ©1994 Bunn-O-Matic Corporation

00986.0002

Type R404A, Amount 9.5 oz(269g)

Design Pressures: High 215 Low 40

29373.0000 (ULTRA-2A)

Risk of Electric Shock.

This equipment may have two power

supply cords. Unplug all cords before

moving or servicing this equipment.

29947.0000

SITE PREPARATION

The dispenser is very heavy. Place it on a sturdy counter or shelf capable of supporting at least 180 lbs. It is

for indoor use only.

The dispenser must have at least six inches of space behind it. This space is needed for airflow, air filter removal,

and cleaning. A clearance of at approximately six inches is recommended between the dispenser sides and the wall

or another appliance. The dispenser performs better if not placed near any heating appliance. Leave some space

so the dispenser can be moved for cleaning.

ELECTRICAL REQUIREMENTS

CAUTION – Improper electrical installation will damage components. An electrician must provide electrical service

as specified below.

Model ULTRA-2, This dispenser has an attached cordset and requires a 2-wire, grounded, individual branch circuit

rated 120 volts ac, 15 amp, single phase, 60 Hz. The mating connector must be a NEMA 5-15R.

(Refer to the dataplate for exact electrical requirements.)

Model ULTRA-2A, This dispenser has an attached cordset and requires a 2-wire, grounded, individual branch

circuit rated 230 volts ac, 10 amp, single phase, 50 Hz.

(Refer to the dataplate for exact electrical requirements.)

NOTE – Bunn-O-Matic does not recommend the use of any extension cord with these dispensers.

3

32080 040802

Page 4

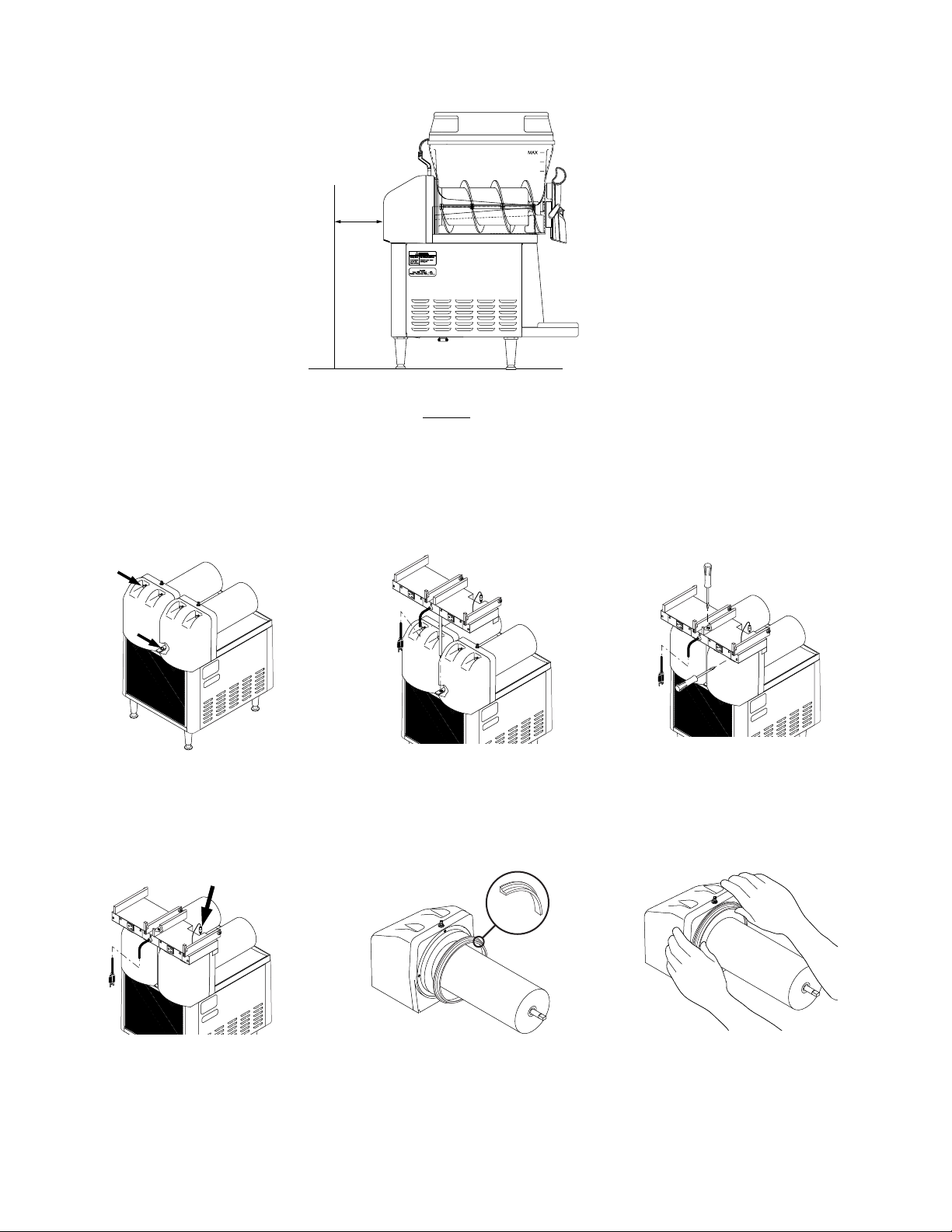

INITIAL SETUP

CAUTION – The dispenser is very heavy! Use care when lifting or moving it. Use at least two people to lift or

move the dispenser.

6.0"

MIN.

1. Set the dispenser on a sturdy counter top. The dispenser requires a minimum of 6.0" air clearance at the rear

of the dispenser. For optimum performance, do not let warm air from surrounding machines blow on the

ULTRA -2.

NOTE – The dispenser should be level or slightly lower in front for proper operation.

2. Remove all shipping material, including the compressor support eyebolt, the cooling drum supports, the

“Do Not Lift Here” signs from the cooling drums, and the “Rinse Before Using” signs from each hopper.

For models without PAF (Powder Auto-Fill™), proceed to step #7.

3. Remove the rear plastic plug

from the trim strip between the

hopper drip trays and loosen

the auger motor cover screws.

6. Plug RCA cord into ULTRA base

unit. Proceed with steps 7 thru

12.

4. Place PAF platform assembly

on top of the motor covers and

install support rod into hole in

trim strip.

7. Install each hopper seal over

the flange at the rear of the

cooling drums as shown.

4

5. Tighten support rod from top

of platform. Retighten motor

cover screws.

8. Press the seals firmly into

place.

32080 021202

Page 5

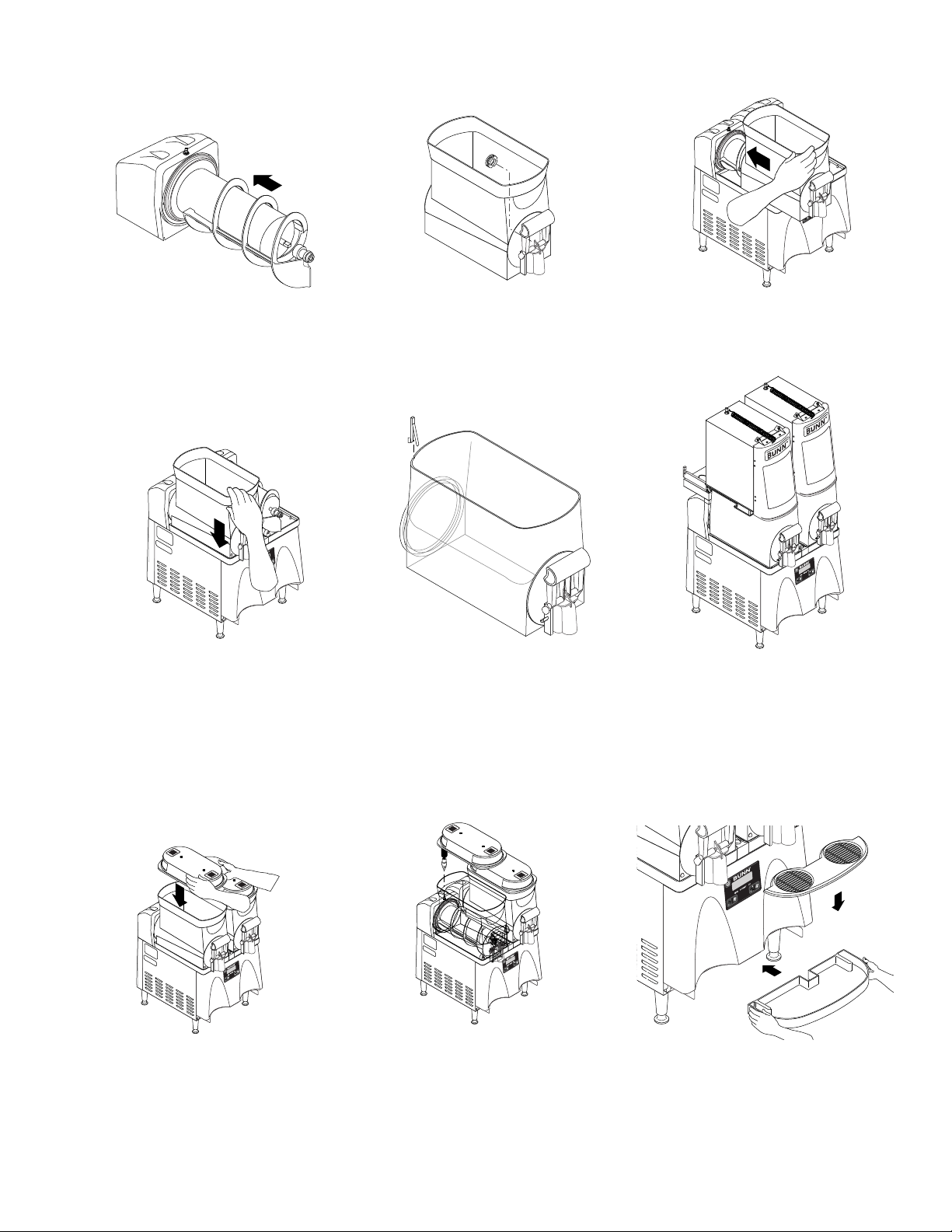

INITIAL SETUP (CONT.)

9. Align the auger shaft with the

flat fin of the auger. Push the

augers as far as they will go and

rotate them so the flat fin is facing up.

12. Slide them into place and push

them down until the hopper

lock plungers snap into place.

For models without PAF, proceed to step 15.

10. Install auger nose bushing into

inside front of hopper.

13. For models with PAF, install

level probes into slots at top

rear of PAF hoppers.

11. Thoroughly rinse the hoppers

and install them over the augers

and cooling drums.

14. Install PAF unit onto platform

and plug power cord into rear of

platform. Plug platform power

cord into proper outlet. (Refer to

PAF manual for water connections)(Proceed to step 17)

15. Set the lids on the hoppers. Lift

slightly and slide back or front

for filling.

16. Plug in the hopper lid lamp

cords.

5

17. Assemble the drip tray.

32080 021202

Page 6

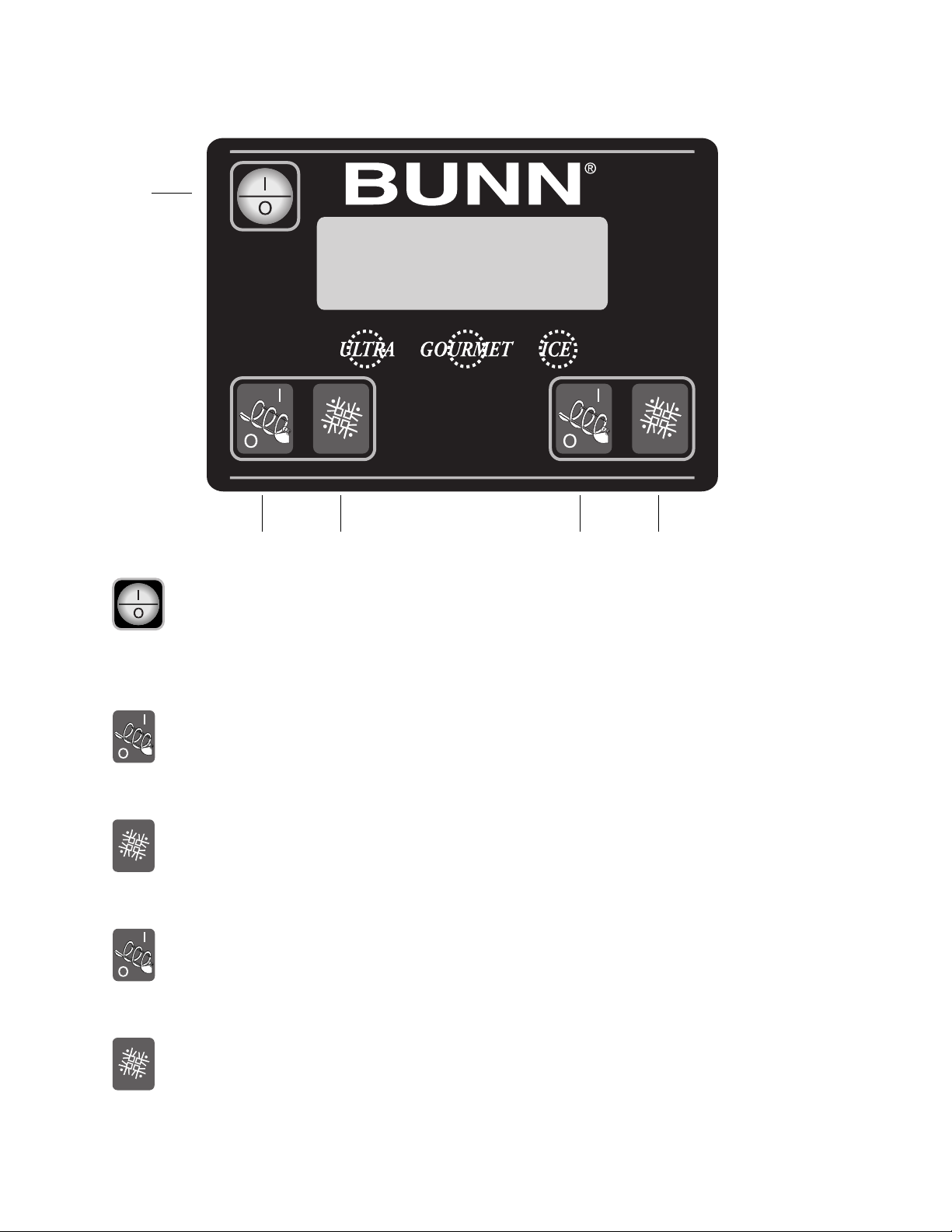

OPERATING CONTROLS

There are five of these switches that will be used for the operation of the dispenser.

1

2 3 4 5

1. switch (upper left corner of the control pad)

This switch is the ON/OFF toggle switch which powers up the dispenser and the LCD display. When ON

the Date and Time toggle back and forth continously except during programming.

2. (bottom left corner)

This is used to turn the left side auger motor ON or OFF.

3. (bottom left corner)

This is used to turn the left side ice control to OFF, ICE or CHILL.

4. (bottom right corner)

This is used to turn the right side auger motor ON or OFF.

5. (bottom right corner)

This is used to turn the right side ice control to OFF, ICE or CHILL.

6

32080 021202

Page 7

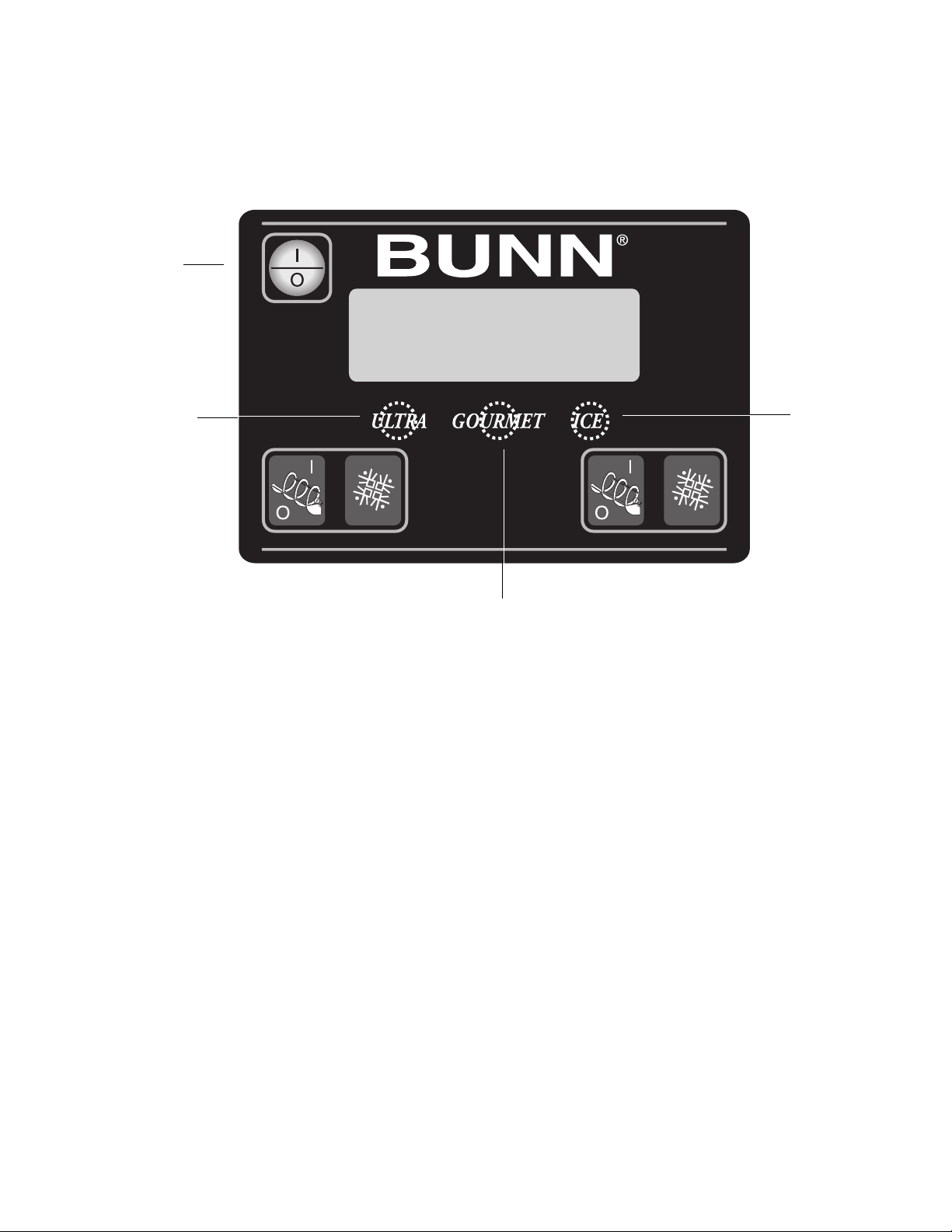

PROGRAMMING

Using the menu-driven display on the front of the dispenser, the operator has the ability to alter or modify

various parameters such as beverage consistency and set day/night “ON/OFF” times. The operator is also prompted

to check a variety of periodic service functions or even a step-by-step cleaning routine. There is also the opportunity to return all changes back to factory default settings.

Access to most controls can be password protected to allow only qualified personnel to make changes.

1

2

4

3

PROGRAMMING SWITCHES

To access the programming mode, and to scroll through the different function screens, hidden programming

switches are used. There are three of these switches that will be used for the setup of the dispenser.

1. I/O switch (upper left corner of the control pad)

This switch is the ON/OFF toggle switch which powers up the dispenser and the LCD display. This switch is

also used as back up switch in menu mode.

2. “GOURMET” (center under display)

Press and hold this switch 5 seconds to access the Menu Function Index. This switch is also used as “NEXT”

to scroll through the functions.

3. “ULTRA” (left under display)

When prompted by a selection from the menu to answer yes or no, the “ULTRA” switch is used to answer

“NO” or (-) minus.

4. “ICE” (right under display)

When prompted by a selection from the menu to answer yes or no, the “ICE” switch is used to answer “YES”

or (+) plus.

7

32080 021202

Page 8

PROGRAMMING THE DISPENSER

During normal operations, the Date, the Time, and the Serial Number toggle back and forth continuously. The

following function screens are in the order they appear from the menu display. Each screen will have instructions

and procedures to program the various functions of the dispenser.

HOME SCREEN

Displays the TIME, DATE, SERIAL NUMBER and ASSET NUMBER which toggle back and forth continuously.

10:45:30 AM

Off O f f

ULT00000001

Off O ff

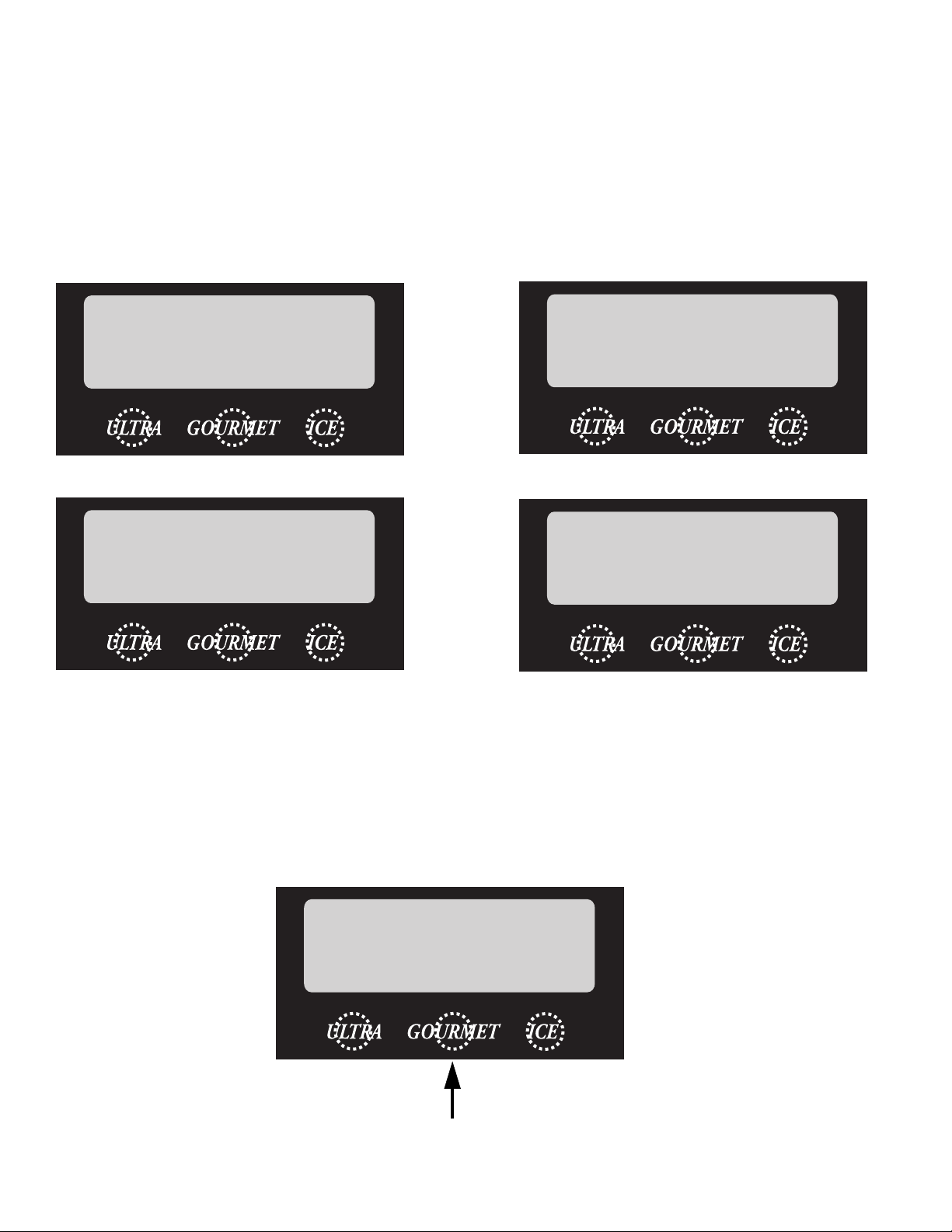

MENU FUNCTION INDEX

Press and hold for five seconds the GOURMET hidden switch to enter into the Menu Function Index. The following screens are in order that they appear from the menu display. Pressing NO (“ULTRA”) or NEXT (GOURMET”)

will advance to the next function. Press ON/OFF (“I/O”) will back up to the previous screen. A one minute time out

will return to the Home Screen.

JAN. 4, 2002

Off O ff

AN00000001

Off O f f

JAN. 4, 2002

Off O f f

8

32080 032702

Page 9

Cleaning Guide

This function leads the operator through a nine step cleaning process when answered YES (“ICE”). Depress

GOURMET to display the next cleaning instruction.

When entering this mode, the refrigeration system will automatically turn OFF. After step when hoppers are

drained, the augers will turn OFF. Three messages will display after advancing past the last cleaning instruction:

FINISH/NEXT, PLEASE WAIT, ULTRA VERSION #__.__.

CLEANING GUIDE

NO YES

DRAIN HOPPERS

NEXT

STEP 1

WASH FREEZING

BARRELS

STEP 4

RE-INSTALL

AUGERS

STEP 7

REMOVE HOPPERS

AUGERS & SEALS

STEP 2

WASH DRIP

TRAY

STEP 5

RE-INSTALL

HOPPERS & LIDS

STEP 8

WASH & SANITIZE

ALL PARTS

STEP 3

RE-INSTALL

HOPPER SEALS

STEP 6

REFILL WITH

PRODUCT

STEP 9

FINISH

NEXT

PLEASE WAIT ULTRA

VERSION # __.__

9

32080 021202

Page 10

Set Consistency

This function allows the operator to adjust the ice consistency, or torque of each auger when answered YES

(“ICE”). Two screens will appear for left and right. The operator can scroll through a range of a minimum of1

(ULTRA) to a maximum of 16 (ICE). Factory default is 10.

SET THICKNESS ?

NO YES

MIN LEFT 9 MAX

MIN RIGHT 5 MAX

10

32080 032702

Page 11

Test Augers

This function tests the operation of forward and reverse of each auger motor. Left auger appears first. Press

the ICE hidden switch to toggle between OFF, FORWARD and REVERSE. Press GOURMET hidden switch to

repeat the operation for the right auger motor. A one minute time out will return to the Home Screen.

TEST AUGERS ?

NO YES

LEFT AUGER TEST

NEXT OFF

Select NEXT to repeat process for Right Auger Test.

Set Time and Date

Selecting YES (ICE) allows the operator to set the DATE (YY MM DD) and TIME (HR MIN SEC) for display on

the Home Screen.

LEFT AUGER TEST

NEXT FORWARD

LEFT AUGER TEST

NEXT REVERSE

YEAR 2002

(-) NEXT (+)

HOUR 10 AM

(-) NEXT (+)

SET DATE TIME ?

NO YES

MONTH 1

(-) NEXT (+)

MINUTE 45

(-) NEXT (+)

MONTH DAY 4

(-) NEXT (+)

SECOND 30

(-) NEXT (+)

11

32080 021202

Page 12

Password

From this screen, the operator must know the password before moving on to the remaining functions. The

range is from 0 - 9999 with the factory default being 0.

PASSWORD 0

(-) NEXT (+)

Set Night Time/Set Day Time

The setting of the Day/Night mode allows the dispenser to “power down” during off hours. The bottom

corners displaying “ICE” will change to “CHILL” during the night mode. During the night mode, the product will

be kept chilled to below 35°F. “ICE” reading will return after night mode elapses. With “OFF” representing 12:00

AM, the operator can scroll to the times desired for the night time mode to begin and end. (Some early models

displayed the word “DISABLED” in place of the word “OFF”).

SET NIGHT TIME

(-) OFF (+)

SET DAY TIME

(-) OFF (+)

NIGHT TIME MODE

CHILL CHILL

12

32080 022003

Page 13

This feature allows the machine to defrost the product during day time operation. The defrost minutes setting

will select the defrost time period. The freeze minutes setting will select the freeze time between defrost periods.

These modes when activated will function anytime the machine is in day mode operation. The machine will

automatically stay in the freeze mode for 2 hours after waking up from the night time mode. (This feature was not

offered on some early models).

DEFROST MINUTES

(-) OFF (+)

FREEZE MINUTES

(-) 60 (+)

Preventive Maintenance Complete?

This function is used to reset a reminder message Preventive Maintenance Due every six months. The machine will not shut down if service is not performed. When the service is performed and the message is answered

YES (ICE), the time and date is recorded for another six months to elapse. This feature can be DISABLED by

pressing (-) ULTRA hidden switch. (Some early models displayed the word “ENABLED” in place of the word

“ON”).

PM COMPLETE ?

NO YES

6 MONTH PM

(-) ON (+)

13

32080 022003

Page 14

Day To Clean Off (formerly Days....Disabled)

This function allows the operator to program a cleaning schedule from 1 to 14 days. The default screen is 0

or DISABLED. Selecting - or ULTRA will prompt the screen Days To Clean. Once a number of days is selected the

screen will prompt two functions, CLEAN MESSAGE ONLY or CLEAN LOCKOUT. On the day selected, the display

will toggle between DATE & TIME and CLEAN DUE TODAY. The dispenser will lock into night mode at midnight if

“Clean Lockout” is activated. To reset the Clean Due Today message or lockout, two functions must be performed. Either power off the dispenser using the I/O (ON/OFF) switch and allow the barrels or cooling drums to

warm over 50°F, or scroll to the Cleaning Guide and perform the cleaning service. The barrels will warm to over

50°F when cleaned with warm water and the message will disappear.

DAY TO CLEAN OFF

(-) NEXT (+)

CLN MESSAGE ONLY

(-) NEXT (+)

Consistency Adjust Lock

This is an option of locking the Set Consistency function by selecting + (YES) or - (NO).

DAYS TO CLEAN 14

(-) NEXT (+)

CLEAN LOCKOUT

(-) NEXT (+)

YES THICK ADJUST

(-) NEXT (+)

14

NO THICK ADJUST

(-) NEXT (+)

32080 022003

Page 15

Switches Enabled

This function allows the operator to lockout the touch pad. Selecting + (ON) provides no time delay on

switches except for the center (GOURMET) hidden switch. Selecting - (LOCKOUT) provides a five second hold to

wake up the touch pad and a two minute time frame from last button pressed to make adjustments before

returning to sleep mode (five second hold). (Some early models displayed the word “ENABLED” in place of the

word “ON” and the word “DISABLED” in place of the word “LOCKOUT”).

SWITCHES

(-) ON (+)

Set Password

This is the function to set the password using a range of 0 to 9999 (the factory default is 0). When the

password is set, the operator can only access the first four functions: Cleaning Guide, Set Consistency, Test

Augers and Set Date & Time.

SWITCHES

(-) LOCKOUT (+)

SET PASS WR 0

(-) NEXT (+)

15

SET PASS WR 9999

(-) NEXT (+)

32080 022003

Page 16

Restore Default?

Answering YES (ICE) to this function returns the unit back to preset factory constants.

1. Set Consistency ? 10

2. Set Night Time - DISABLED

3. Set Day Time - DISABLED

4. 6 Month PM - ENABLE

5. Days....Disabled - DISABLED

6. Torque Adjust Lock - YES

7. Switches Enabled - ENABLED

8. Set Password - 0

RESTORE DEFAULT ?

NO YES

ARE YOU SURE ?

NO YES

Install Date

The following three screens will scroll after advancing past the function “Restore Defaults”. The Install Date

and Time is recorded when the dispenser is powered on for the first 100 hours. The Install Date and Time cannot

be reset and is stored in permanent memory.

RESTORE DEFAULTS

253

INSTALL DATE

NOV. 28, 2001

3:55:25 AM

16

ULTRA

VERSION # __.__

32080 032702

Page 17

TEMP & TORQUE

Press and hold for five seconds the ULTRA and ICE hidden switches to display the TEMP & TORQUE. The

temperature of each cooling drum and the hot gas temperature will toggle back and forth. The auger torque is

displayed continuously. Press and release the ULTRA and ICE hidden switches to return to HOME SCREEN.

The TEMP & TORQUE mode is typically used for service.

DISPLAY

TEMP & TORQUE

0 0

36 36°

CLEAN FILTER

Monthly cleaning of the air filter is recommended. Should the air filter become dirty creating a high temperature

problem, the unit will shut down until service is completed to correct the problem.

0 0

67 67°h

NOTE: Severe conditions may require more frequent cleaning.

17

34244 101804

Page 18

USING THE DISPENSER FOR GRANITA-TYPE PRODUCTS

1. Lift the lid slightly for the selected hopper and slide back to gain access to the hopper.

2. Place the pre-mixed liquid product in the selected hopper.

3. a. Press and release the (ON/OFF) switch to power on the dispenser.

b. Press and release the Left and/or Right (ON/OFF) switch to start the Auger Motor.

c. Press and release the (OFF/ICE/CHILL) switch and select ICE to begin the cooling process for the

selected hopper.

4. Wait for the liquid to freeze to the desired consistency.

HINTS – Bunn-O-Matic recommends that the product in the dispenser be thawed each day, usually overnight.

The ice granules get too large and a consistent product is difficult to maintain if left frozen for an extended

period of time. Set the NIGHT mode for a few hours each night and return it to the DAY mode when the

product has thawed sufficiently. You’ll know it is in the NIGHT mode because the display will indicate NIGHT

MODE.

USING THE DISPENSER FOR COLD LIQUID PRODUCTS

1. Lift the lid slightly for the selected hopper and slide back to gain access to the hopper.

2. Place the pre-mixed liquid product in the selected hopper.

3. a. Press and release the (ON/OFF) switch to power on the dispenser.

b. Press and release the Left and/or Right (ON/OFF) switch to start the Auger Motor.

c. Press and release the (OFF/ICE/CHILL) switch and select CHILL to begin the cooling process for

the selected hopper.

4. Wait for the liquid to cool.

18

32080 021202

Page 19

OTHER RECOMMENDATIONS FOR YOUR DISPENSER

• Whether liquid concentrate or granulated powder, all product must be thoroughly mixed BEFORE adding it

to the hoppers.

• For best results with granita-type products, use only products with an apparent brix of 12 or higher. Some

products may work with an apparent brix as low as 9. Your experimentation with other products will be the

best guide in this area.

• Keep the pre-mixed liquid product refrigerated. This reduces cooling/freezing time in the dispenser.

• Keep the hoppers topped-off during peak serving periods. Add pre-mixed liquid product as it is dispensed.

This reduces the cooling/freezing time and assures you of always having product ready to dispense.

• Keep the product level in the hoppers higher than the auger. Air will become entrapped in the mixture

resulting in a clouded foamy consistency.

•You may find it beneficial to turn down the ice controls to keep the ice granules from growing too large.

Refer to

• Some products freeze at a lower temperature than others. You may notice frost or ice on the hoppers. This

is normal and should not be a concern.

• Humidity in the air may cause sweating on the outside surfaces of the hoppers. This is to be expected and

should not be a concern. The drip trays beneath the hoppers will capture this and cause it to flow to the

lower drip tray for disposal.

• Some noises are to be expected during normal operation of the dispenser. By becoming familiar with the

noises made during normal operation, you will be better able to listen for problems.

Programming The Dispenser

on page 11 for Setting the Consistency.

19

32080 021202

Page 20

RECOMMENDED DAILY CLEANING

NOTE – Turn the power OFF to the dispenser before proceeding.

1. Empty all product from the hoppers. Disconnect the hopper lid lamp cords and remove the lids.

2. Depress the hopper lock

plunger. Lift the hopper up

slightly.

5. Remove the cooling drum seal

from the rear of the drum.

3. Pull forward to remove.

6. Caution: The faucet valve is

under spring tension. Spread

one side of the handle first, then

the other and disconnect from

the hopper.

4. Pull the auger from the cooling

drum.

7. Carefully slide the faucet valve

up to remove the spring and

faucet seal. Extra care should

be taken when handling the seal

to prevent damage. Do not fold

the seal as this will cause damage to the Teflon® sealing surface.

8. Remove the auger nose bushing

from inside the hopper.

9. Care must be taken to ensure this surface does not get scratched during

cleaning. Deep scratches could cause leakage around the seal.

10. Place all parts in a clean sink with mild hot water (120°F) and sanitizer solution. Allow all parts to soak for at least

5 minutes. Carefully wash all components with a clean wash cloth in the hot water and sanitizer solution. Use a

clean, soft bristle brush as needed for the smaller components and tight areas. Do not immerse hopper lids. Use

a commercial sanitizer that has 100 ppm of available chlorine with a concentration level of at least 3% available

chlorine (KAY-5 Sanitizer). Follow the sanitizer’s mixing instructions to ensure 100 ppm of available chlorine.

11. Wash the drums, hopper drip trays, top covers, and outer enclosure using a clean wash cloth that has been

dampened in the hot water and sanitizer solution. Pay particular attention to the shaft area and make sure it

is thoroughly cleaned and sanitized.

12. Thoroughly rinse all surfaces with a clean wash cloth that has been dampened with hot water. Wipe dry with

a clean dry wash cloth before reassembling the dispenser.

NOTE – Although most parts are dishwasher safe, they may be affected by the chemicals in some commercial

sanitizing agents. Do not place the hopper nor hopper lids in a dishwasher. Rinse thoroughly before assembly.

20

32080 032702

Page 21

INSTALLATION

1. Install the seals over the flange

at the rear of the cooling drums

and press the seals firmly into

place as shown.

4. Thoroughly rinse the hoppers

and install them over the augers

and cooling drums.

2. Align the auger shafts with the

augers. Push the augers as far

as they will go and rotate them

so the flat face of the auger

shaft is aligned with the flat face

of the auger nose.

5. Slide them into place and push

them down until the hopper

lock plungers snap into place.

3. Install auger nose bushing into

inside front of hopper.

6. Set the lids on the hoppers and

plug in the hopper lid lamp

cords.

7. Position the faucet seal and re-

turn spring in the faucet valve.

10. Assemble the drip tray.

8. Slide the faucet valve assembly

into place on the hopper.

21

9. Press down on the valve to

compress the spring. Position

the faucet handle over the faucet valve one side at a time and

snap into place on the hopper.

32080 053102

Page 22

REQUIRED REGULAR MAINENANCE:

Semi Annual:

Bunn #34245.0000 is required to perform the semi

annual Preventive maintenance:

Note: Service caused by failure to perform required

maintenance is not covered by warranty.

The following instructions apply to one hopper only;

repeat each step for all hoppers.

Kit Contents

Inventory this kit for completeness before proceeding.

Part Number Qty. Description

27446.0000 2 Lamps, T-5 Wedgebase Min.

26781.0000 2 Auger Shaft Bushing (Blue)

26782.0001 2 Cooling Drum Seal

32079.0000 2 Hopper/Drum Seal

32268.0000 2 Seal, Faucet (Clear)

29563.0000 - Lubricant (“Krytox”)

28395.0000 1 Seal Insertion Tool

Auger Motor Cover

Run Capacitor

Auger Motor Assy

Auger Shaft Assy

Hopper/Drum Seal

INSTRUCTIONS

WARNING - Disconnect the dispenser from the power

source before the removal of any panel or the replacement of any component.

1. Drain, remove and clean hopper; refer to the Operating and Service Manual for proper cleaning procedures. Discard the hopper/drum seal and faucet seal.

2. Remove the #8 locking screws securing auger motor

cover to the cooling drum mount assembly; remove

cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right side

(viewed from front) of the auger motor mounting

bracket securing the auger motor run capacitor. Set

capacitor aside with wires attached.

4. Disconnect the auger motor terminal from the terminal on the main wiring harness.

5. Remove the remaining #8 locking screws securing

the cooling drum mounting bracket. Remove motor

with mounting bracket.

NOTE: When removing or installing motor and shaft

assembies, be sure the motor and shaft pins are turned

to a position that will clear the torque sensor circuit

board.

Cooling Drum

Auger Shaft Bushing

FIG 1

Cooling Drum Seal

P2528

22

34244 101804

Page 23

REQUIRED REGULAR MAINENANCE (Continued)

6. Pull the auger shaft assembly straight out of cooling drum.

Inspect the shaft for abnormal wear.

7. From the front of dispenser, remove the seal and blue bushing

from cooling drum and discard them.

8. Clean seal and bushing surfaces of the cooling drum very

thoroughly.

9. Refer to FIG 1, and slip new blue bushing into cooling drum.

10. Place seal on insertion tool #28395.0000 as shown in FIG 2.

Make sure open face of seal is toward cooling drum.

11. Apply a small amount of food grade lubricant (Bunn

#M2568.1000) to inside diameter of seal. Push seal into bore

until it is firmly seated; remove tool.

12. Place a small amount of #29563.0000 “Krytox” lubricant

(provided in kit in a plastic cap) on the end of the motor shaft

(about 1 1/2") and a thin film in the groove. Install auger shaft

assembly onto the motor shaft. See FIG 3. Do not use too

much “Krytox” lubricant.

NOTE: This is the only place “Krytox” lubricant is used.

13. Assemble motor/shaft assembly as shown in FIG 3, then

install assembly into cooling drum. Make sure the pins do not

hit the sensor board and cooling drum seal is not dislodged as

the shaft passes through.

14. Secure motor and capacitor to the cooling drum mounting

bracket. Install rear motor cover.

15. Refer to the Installation and Operating Manual for hopper

assembly and installation procedures. Install new hopper/

drum seals and faucet seals included in the kit. See FIG 1 & 4.

16. Remove and clean condenser air filter. See FIG 5.

17. Refer to the Installation and Operating Manual, “Menu Func-

tion Index”. Scroll to menu “PM Complete?” and answer

“YES” to reset the reminder message “PM Due”.

Open face of seal

away from tool

Cooling Drum Seal

Seal Insertion Tool

P1760

FIG 2

Auger Shaft Assy

Lube about 1 1/2" of shaft and in the

groove with #29563.0000 “Krytox”

Lubricant

P2529

FIG 3

Faucet Seal

FIG 4

P2531

23

P2532

FIG 5

34244 101804

Page 24

SCHEMATIC WIRING DIAGRAM ULTRA-2

J2-1

1

LEFT

LAMP

ASSY

RIGHT

LAMP

ASSY

GRN

BLK

NL

WHI

I/O

ULTRA

GOURMET

I/O I/O

MEMBRANE

SWITCH

ICE

120 VOLTS AC

2 WIRE

SINGLE PHASE

60 HZ

J2-5

J2-10

O

N

T

R

O

L

B

O

A

R

D

C

J3-1

J3-5

J3-10

J3-12

J2-16

J5-1

J5-5

J5-10

J5-15

J5-20

J5-24

J6-1

RED/BLK

BRN/WHI

BRN/BLK

BLK

WHI

VIO

WHI/BLU

WHI/BLK-22

YEL-22

BLU-22

WHI/BLK-22

WHI/RED

GRY

BRN-20

RED-20

ORN

BLU/BLK

WHI/BLK

TAN-22

PNK-22

WHI/GRY-22

WHI/GRN-22

WHI-22

BLK-22

SHIELD

12

WHI/RED-22

WHI/BLK-22

PNK-22

TAN-22

WHI-22

GRY-22

VIO-22

BLU-22

GRN-22

YEL-22

ORN-22

BLK-22

1

32082.0000B 01/02 © 2002 BUNN-O-MATIC CORPORATION

D

I

S

P

L

A

Y

16

LEFT

AUGER

RIGHT

AUGER

MM

BLK

RED

WHI

1

BLK

RED

4

1

WHI

BRN/WHI

BRN/BLK

BRN/BLK

BRN/WHI

WHI/RED

RED/BLK

RED/BLK

WHI/RED

WHI

WHI

4

VIO

BLK

RED

1

WHI/VIO-22

WHI/BLK-22

C

LAMP

RELAY

WHI/YEL

BLU/BLK

BLK

RED

1

WHI/VIO-22

WHI/BLK-22

BLK

GRY

FAN

MOTOR

LEFT

SOL.

5

AMP

CIRCUIT

BREAKER

WHI

BRN-20

BLK

WHI

RIGHT

SOL.

WHI

RED-20

WHI/BLU

TRANSFORMER

BLK

WHI

WHI/BLK

ORN WHI

C

COMPRESSOR RELAY

1

CLOCK

BLU-22

LEFT

TORQUE

SENSOR

BLU-22

WHI/BLK-22

11

RIGHT

TORQUE

SENSOR

TAN-22

WHI/BLK-22

11 1

t°

LEFT

PNK-22

t°

RIGHTt°HOT

GAS

YEL-22

WHI/BLK-22

WHI/ORN

BLK

COMPRESSOR ASSY

LIMIT

THERM.

GRN/YEL-16

COMPRESSOR

MOTOR

RUN

START

2

3

56

WHI

N

PTC

4

1

ASSY

24

32080 021502

Page 25

I/O

ULTRA

GOURMET

I/O I/O

MEMBRANE

SWITCH

ICE

230 VOLTS AC

2 WIRE

SINGLE PHASE

50 HZ

SCHEMATIC WIRING DIAGRAM ULTRA-2A

J2-1

J2-5

J2-10

12

WHI/RED-22

WHI/BLK-22

PNK-22

TAN-22

WHI-22

GRY-22

VIO-22

BLU-22

GRN-22

YEL-22

ORN-22

BLK-22

1

SHIELD

32082.0001B 05/02 © 2002 BUNN-O-MATIC CORPORATION

J2-16

J3-1

J3-5

J3-10

J3-12

RED/BLK

J5-1

BRN/WHI

J5-5

J5-10

J5-15

J5-20

J5-24

J6-1

BRN/BLK

BLK

WHI

VIO

WHI/BLU

WHI/BLK-22

YEL-22

BLU-22

WHI/BLK-22

WHI/RED

GRY

BRN-20

RED-20

ORN

BLU/BLK

WHI/BLK

TAN-22

PNK-22

WHI/GRY-22

WHI/GRN-22

WHI-22

BLK-22

C

O

N

T

R

O

L

B

O

A

R

D

BRN

GRN/YEL

BLK

EMI

FILTER

BLK

NLGND

BLU

WHI

WHI

LEFT

1

D

I

S

P

L

A

Y

16

LEFT

AUGER

RIGHT

AUGER

MM

BLK

RED

WHI

1

BLK

RED

4

1

WHI

BRN/WHI

BRN/BLK

BRN/BLK

BRN/WHI

WHI/RED

RED/BLK

RED/BLK

WHI/RED

WHI

WHI

4

VIO

LAMP

ASSY

BLK

RED

1

WHI/VIO-22

WHI/BLK-22

C

LAMP

RELAY

RIGHT

LAMP

ASSY

WHI/YEL

BLU/BLK

BLK

RED

1

WHI/VIO-22

WHI/BLK-22

BLK

GRY

FAN

MOTOR

LEFT

SOL.

5

AMP

CIRCUIT

BREAKER

WHI

BRN-20

BLK

WHI

RIGHT

SOL.

WHI

RED-20

WHI/BLU

LIGHTS

TRANSFORMER

WHI/BLK

WHI

C

1

CLOCK

BLU-22

LEFT

TORQUE

SENSOR

BLU-22

WHI/BLK-22

11

RIGHT

TORQUE

SENSOR

TAN-22

WHI/BLK-22

11 1

t°

LEFT

PNK-22

t°

RIGHTt°HOT

GAS

YEL-22

ORN

WHI/BLK-22

WHI/ORN

WHI/BLU

COMPRESSOR RELAY

BLK

COMPRESSOR ASSY

LIMIT

THERM.

START

3

PTC

4

GRN/YEL-16

ASSY

R

CIRCUIT BOARD

TRANSFORMER

COMPRESSOR

MOTOR

RUN

2

56

N

1

BLK

WHI

25

WHI/BLK

WHI

32080 053102

Loading...

Loading...