Bunn-O-Matic SINGLE SH DBC Operation Manual

®

SINGLE

SH DBC

WITH SMART FUNNEL

Software Version 1.15

and all ending __.15

®

®

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit

the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain

the latest catalog and manual updates. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain

a paper copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

34025.0000D 02/09 ©2001 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifications to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

BrewWISE, BrewLOGIC, BrewMETER, BrewWIZARD, Bunn Gourmet, BUNN Gourmet Ice, BUNN Pour-O-Matic, BUNN,

Bunn-OMatic, Bunn-O-Matic, BUNNlink, BUNNserve, BUNNSERVE, BUNN Espress, Cool Froth, DBC, Dr. Brew, Dual, EasyClear, EasyGard, Easy Pour, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, IMIX, Infusion Series, Intellisteam,

Quality Beverage Equipment Worldwide, The Mark of Quality in Beverage Equipment Worldwide, My Café, PowerLogic,

Safety-Fresh, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, System

III, ThermoFresh, 392, AutoPOD, AXIOM, Beverage Profit Calculator, Beverage Bar Creator, BUNNsource, Coffee At Its

Best, Digital Brewer Control, Nothing Brews Like a BUNN, Pouring Profits, Pulse Wave, Signature Series, Smart Heat,

Tea At Its Best, The Horizontal Red Line, Titan, Ultra, are either trademarks or registered trademarks of Bunn-O-Matic

Corporation.

INTRODUCTION

This brewer incorporates a wireless interface system that allows the DBC Grinder to load certain information into the "programming chip" located inside the handle of the funnel. This information includes the name

of the coffee ground and what batch size will be brewed (small, medium, or large). Once the correct name and

amount of coffee is ground, the funnel is loaded into the brewer. The information from the funnel handle is then

transferred into the brewer. The brewer then takes this information and dispenses the amount of water preset in

the brewer for that particular coffee name and batch size. The brewer can also be programmed to adjust different

functions of the brewing process, such as brew temperature, brew volumes, bypass percentages, pulse brew,

etc. This allows the operator to program a certain "recipe" for each coffee name to be brewed.

Page 2

34025 012609

TABLE OF CONTENTS

User Notices ...............................................................................................................................4

Electrical and Plumbing Requirements .......................................................................................5

Operating Controls ......................................................................................................................6

Initial Setup .................................................................................................................................7

Coffee Brewing ............................................................................................................................7

Cleaning ......................................................................................................................................7

Glossary ......................................................................................................................................8

PROGRAMMING ........................................................................................................................9

Programming Switches ...............................................................................................................9

Programming the Brewer ..........................................................................................................10

PROGRAM FUNCTIONS (LEVEL 1) Brew Lockout ...................................................................10

PROGRAM FUNCTIONS (LEVEL 2) ...........................................................................................11

Set New Recipe (using a Smart Funnel

Set Brew Volumes ............................................................................................................12

Set By-Pass Percentages .................................................................................................13

Set Pulse Brew Times ......................................................................................................13

Set Preinfusion Times ......................................................................................................13

Set Drip Times .................................................................................................................14

Set New Recipe (using a Recipe Card) ............................................................15

Set New Recipe (no Smart Funnel® or G92T DBC Grinder) .................................................16

Review Recipes/Modify Recipes/Set up No Name Coffee ...................................................17

Set Brew Volumes ............................................................................................................18

Set Bypass Percentages ...................................................................................................19

Set Pulse Brew Times ......................................................................................................20

By Example ...............................................................................................................22

Enter Times ...............................................................................................................23

Set Preinfusion Times ......................................................................................................24

Set Drip Times .................................................................................................................25

Enable Ads ............................................................................................................................26

Set Temp (Brewing Temperature) ..........................................................................................26

Set Ready (Ready Temperature) ............................................................................................26

Refill (Adjust Sensitivity) .......................................................................................................27

Spray Oz/M (Read sprayhead flow rate) ................................................................................27

Bypass Oz/M (Read bypass flow rate) ...................................................................................27

Calibrate Flow .......................................................................................................................28

Calibrate Sprayhead Flow .................................................................................................28

Calibrate Bypass Flow ......................................................................................................29

Brew Counters (View/Reset) ..................................................................................................30

Funnel Detect ........................................................................................................................30

Server Detect ........................................................................................................................31

Service Tools .........................................................................................................................31

Test Outputs (Components) .............................................................................................32

Test Switches ...................................................................................................................32

Test Servers .....................................................................................................................33

Test Frequency ................................................................................................................33

Factory Defaults (Reset) .......................................................................................................34

Troubleshooting ........................................................................................................................35

Schematic (Wiring Diagram) .....................................................................................................46

®

and G92T DBC Grinder) .......................................12

Page 3

34025 012004

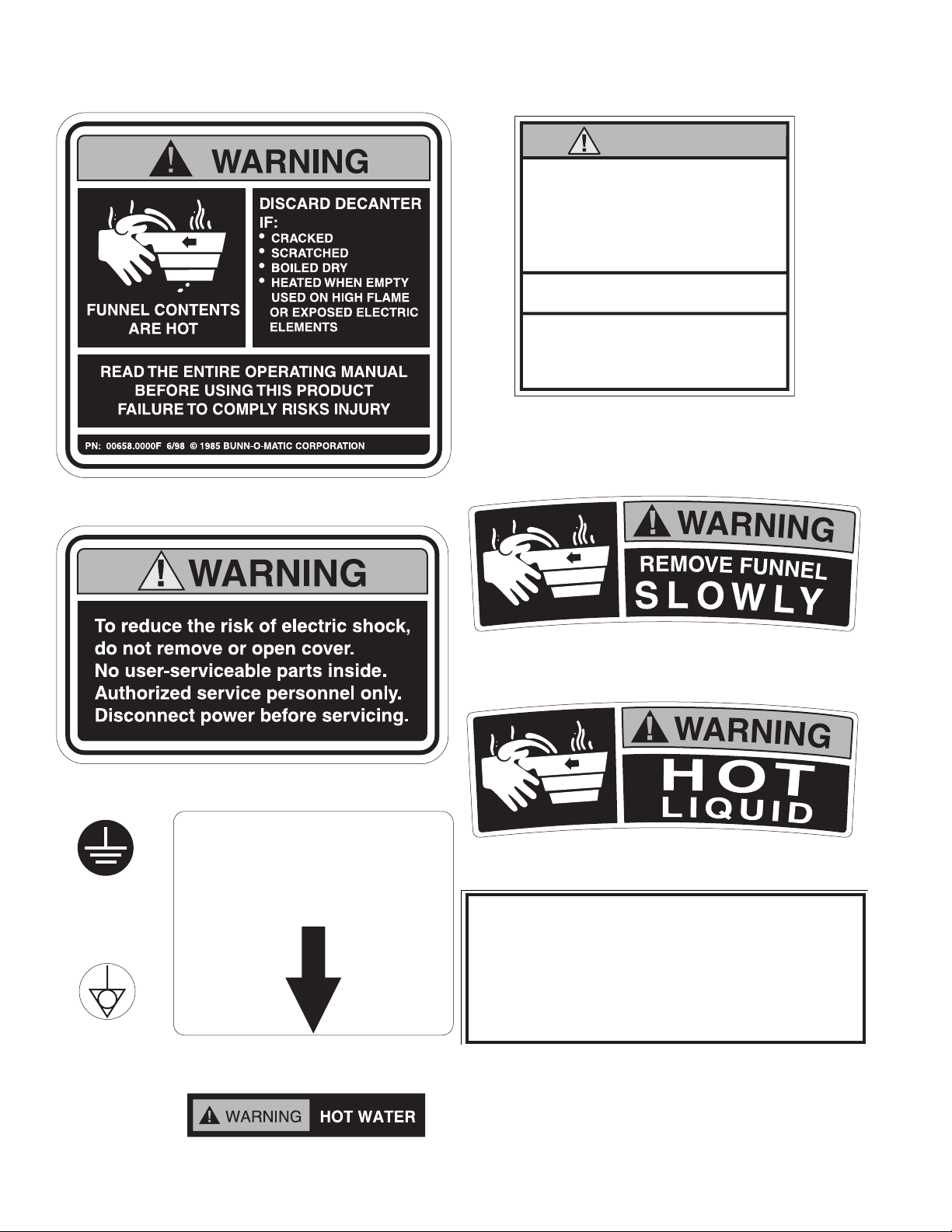

USER NOTICES

This equipment must be installed to comply

with the International Plumbing Code of the

International Code Council and the Food

Code Manual of the Food and Drug Administration (FDA). For models installed outside

the U.S.A., comply with the applicable

Plumbing /SanitationCode.

MAIN ON/OFF

SWITCH

WARNING

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND

THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL

ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE

OPERATING MANUAL BEFORE

USING THIS PRODUCT

00986.0000F 10/07 ©1994 Bunn-O-Matic Corporation

The notices on this brewer should be kept in good condition. Replace unreadable or damaged labels.

00986.0000

00658.0000

37881.0000

00824.0000

00824.0001

39803.0000

20201.5600

03408.0004

03409.0004

00656.0000

34025 022509

Page 4

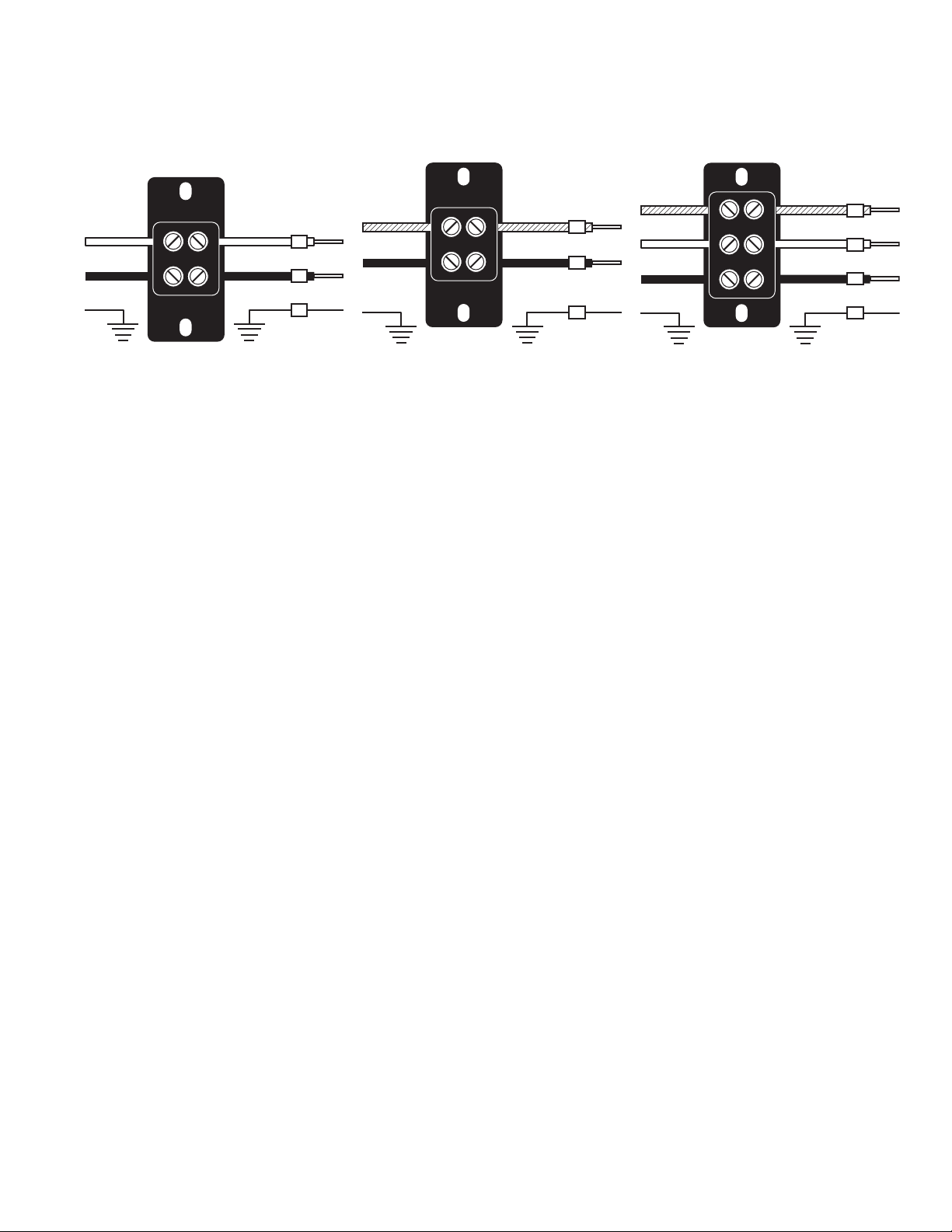

ELECTRICAL REQUIREMENTS

L2

L1

G

L2 RED

GREEN GREEN

L1 BLACK

L2 RED

L1 BLACK

L2

N

L1

G

L2 RED

WHITE

GREEN GREEN

NEUTRAL

L1 BLACK

L2 RED

WHITE

NEUTRAL

L1 BLACK

N

L1

G

WHITE

GREEN GREEN

NEUTRAL

L1 BLACK

WHITE

NEUTRAL

L1 BLACK

WARNING - The brewer must be disconnected from the power source until specified in Initial Set-Up.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

120 volt ac models

Note: This electrical service consists

of 2 current carrying conductors (L1

and Neutral) and a separate conductor for earth ground.

ELECTRICAL HOOK-UP (Models without power cord)

CAUTION – Improper electrical installation will damage electronic components. Damage caused by incorrect

electrical connections is not covered by warranty.

1. An electrician must provide electrical service as specified in conformance with all local, state and federal

electrical codes.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. Remove the front panel beneath the sprayheads to gain access to the terminal block.

4. Feed the cord through the strain relief and connect it to the terminal block.

5. Connect the brewer to the power source and verify the voltage at the terminal block before proceeding. Replace the front panel.

6. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked up, the brewer is ready for Initial Set-Up.

ELECTRICAL HOOK-UP (Models with power cord)

WARNING– If the power cord is ever damaged, it must be replaced by the manufacturer or its service agent

with a special cord available from the manufacturer or its service agent in order to avoid a hazard. Improper

electrical installation will damage electronic components. Damage caused by incorrect electrical connec-

tions is not covered by warranty.

1. An electrician must provide electrical service as specified in conformance with all local, state and federal

electrical codes.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

NOTE - The brewer is shipped without a plug on the power cord. Qualified service personnel must select

and install the proper UL listed grounding type attachment plug specified on the rear of the brewer.

3. Install the specified plug on the attached power cord.

4. Remove the front panel beneath the sprayheads to gain access to the terminal block.

5. Connect the brewer to the power source and verify the voltage at the terminal block before proceeding.

6. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumb-

WARNING – Electrical connections must be made as specified above. Failure to follow these instructions can

ing has been hooked up, the brewer is ready for Initial Set-Up.

result in personal injury, property or equipment damage.

200 and 230 volt ac models

Note: This electrical service consists

of 2 current carrying conductors (L1

and L2) and a separate conductor

for earth ground.

Page 5

120/208 & 120/240 volt ac models

Note: This electrical service consists

of 3 current carrying conductors

(Neutral, L1 and L2) and a separate

conductor for earth ground.

34025 022509

CE REQUIREMENTS

• This appliance must be installed in locations where it can be overseen by trained personnel.

• For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C.

• Appliance shall not be tilted more than 10° for safe operation.

• An electrician must provide electrical service as specied in conformance with all local and national codes.

• This appliance must not be cleaned by water jet.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given instructions concerning use of

this appliance by a person responsible for its safety.

• Children should be supervised to ensure they do not play with the appliance.

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with

a special cord available from the manufacturer or its authorized service personnel in order to avoid a hazard.

PLUMBING REQUIREMENTS

This brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138

and 620 kPa) from a 1⁄2" or larger supply line. A shut-off valve should be installed in the line before the brewer.

Install a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345 kPa). The

water inlet fitting is 1⁄4" flare or female quick connect.

NOTE: Bunn-O-Matic recommends 1⁄4" copper tubing for installations of less than 25 feet and 3⁄8" for more than 25

feet from the 1⁄2" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer

to clean the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The

size and shape of the hole made in the supply line by this type of device may restrict water flow.

This equipment must be installed to comply with the International Plumbing Code of the International

Code Council and the Food Code Manual of the Food and Drug Administration (FDA). For models installed outside the U.S.A., you must comply with the applicable Plumbing/Sanitation Code for your area.

PLUMBING HOOK-UP

1. Flush the water line and securely attach it to the flare fitting located on bottom of brewer.

2. Turn on the water supply.

Page 6

34025 022509

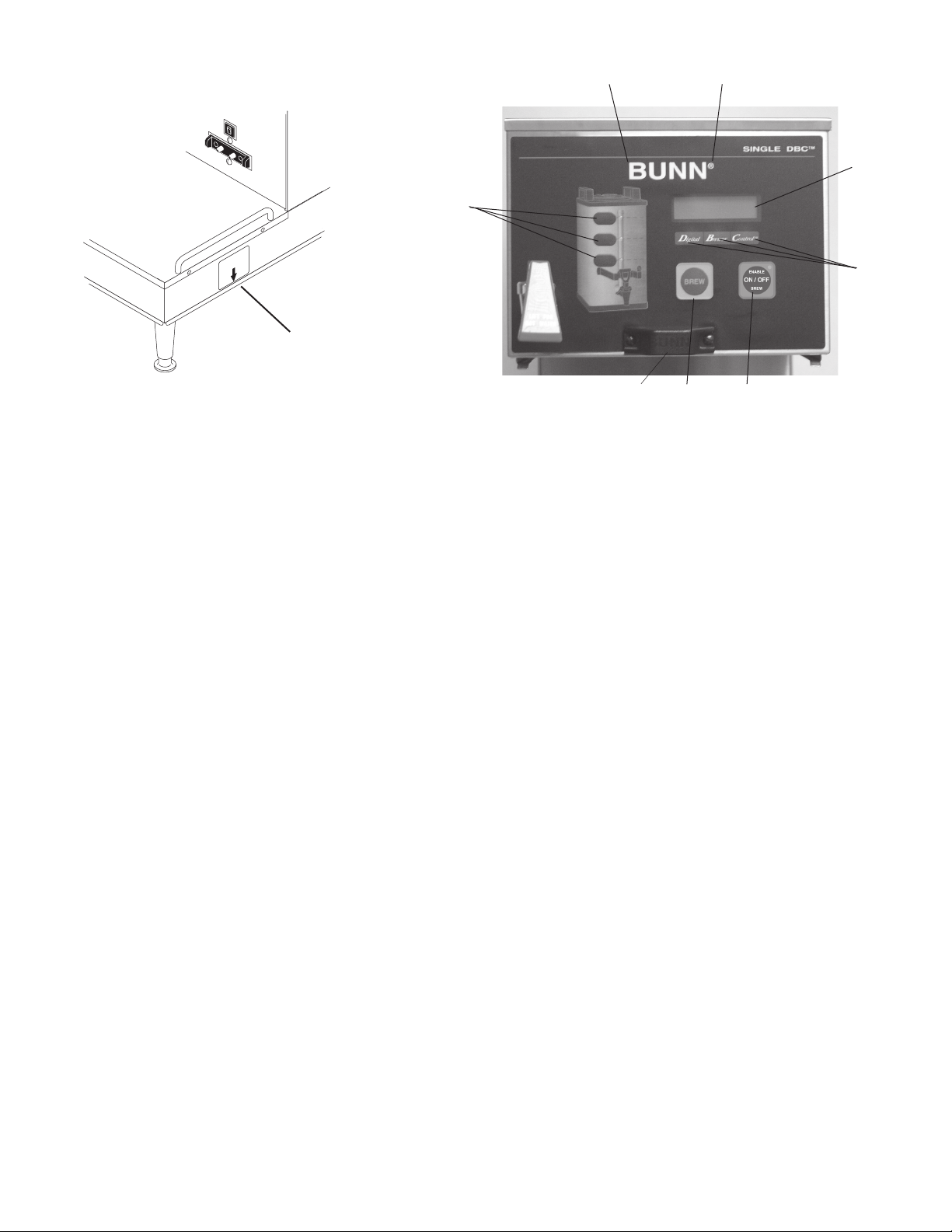

OPERATING CONTROLS

MAIN ON/OFF

SWITCH

j

e

f

b

g

a

P3853

h

d

c

P2437

OPERATING CONTROLS

(a) MAIN ON/OFF SWITCH

This switch, located under the brewer behind the right front leg, turns power on and off to all components

in the brewer.

(b) BATCH SELECTOR SWITCHES

Pressing the switch corresponding to the Small, Medium, or Large batch selects the amount of coffee to

be brewed. Pressing a different switch after a brew cycle has been initiated does not change the brew batch in

progress. Light indicates the selected batch to brew.

(c) ON/OFF SWITCH (ENABLE BREW)

Pressing the ON/OFF switch alternately turns the brewer on and off. Pressing this switch during the brew

cycle will interrupt the brew cycle, stopping the flow of water. Pressing this switch during the programming of

the brewer will exit the setup and return to the main screen.

(d) BREW SWITCH

Momentarily pressing and releasing this switch begins a brew cycle.

(e) PROGRAM SWITCH (Upper Right Hidden Switch)

Pressing and holding the upper right hidden switch allows entry to the programming menus. Pressing and

releasing the switch steps through each function screen during programming.

(f) FUNCTION SCREEN

This is the display which shows the various functions of the brewer and allows the programming to be accomplished.

(g) FUNCTION SCREEN SWITCHES

These are the hidden switches which are used to program the brewer.

(h) FUNNEL SENSING COIL

This is used to "receive" information from the Smart Funnel handle (coffee name and batch size), and also

from RECIPE CARDS.

(j) SCROLL BACKWARDS (Upper Left Hidden Switch)

The upper left corner of the B in BUNN can be used to scroll backwards through the function list.

34025 022509

Page 7

INITIAL SETUP

CAUTION: The brewer must be disconnected from the power source throughout the initial setup, except when

specified in the instructions.

1. Insert an empty funnel into the funnel rails of the brew station.

2. Place an empty server under the funnel.

3. Connect the brewer to the power source. Water will begin flowing into the tank and stop when the tank is

filled to its capacity. Display will show PLEASE WAIT...TANK FILLING until tank is filled with water.

4. Wait approximately twenty minutes for the water in the tank to heat to the proper temperature. Display will

show READY TO BREW...WATER TEMP: XXX˚ when tank is at operating temperature.

5. Place a small vessel beneath the faucet and open the faucet handle. Release it when you hear the tank refilling.

6. Water volumes have been preset at the factory. Refer to adjustments for the Set Brew Volumes section of

this manual should the volume need to be increased or decreased.

7. The brewer is now ready for use in accordance with the coffee brewing instructions.

COFFEE BREWING

1. Insert a BUNN filter into the Smart Funnel.

2. If a grinder is not used to obtain the coffee grounds, pour the proper amount of fresh coffee grounds into

the funnel and level by gently shaking. Slide the funnel into the funnel rails and select batch size. Proceed to

step 5.

3. If a G9-2T DBC or MHG grinder is used with a compatible Smart Funnel, select the desired batch size on the

grinder. Grind the selected amount of fresh coffee into funnel and level grounds by gently shaking. It is not

necessary to select a size on the brewer.

4. Slide the funnel into the funnel rails. The brewer will read the size ground through the chip in the funnel

handle and will automatically select the correct size to brew.

5. Place an empty server under the funnel.

6. The ENABLE BREW switch must be ON. Momentarily press and release the "BREW" switch. If the brewer has

the funnel lock option and if it is activated, once a brew cycle has been started the funnel is locked in place.

There may be certain situations in which the brew cycle will not begin when the brew switch is pressed:

a) BREW TEMPERATURE TOO LOW - wait until heated or cancel BREW LOCKOUT option.

b) FUNNEL NOT IN PLACE (or using a standard brew funnel) - cancel FUNNEL DETECT option.

c) CHECK FUNNEL - remove funnel, empty previously brewed grounds and grind a new batch into funnel.

d) SERVER NOT IN PLACE - place Soft Heat Server, or cancel SERVER DETECT option.

7. If none of the above messages are displayed, the display will read NOW BREWING and the time remaining

in the brew cycle. Arrows will point to the side which is brewing. If both sides are brewing simultaneously,

the arrows will alternate from left to right on the display.

8. Following the BREW will be a countdown of DRIPPING time which shows the time remaining until the funnel

lock will release. Discard the grounds and filter only after visible dripping stops.

CLEANING

1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all

surfaces on Bunn-O-Matic equipment.

2. Check and clean the sprayhead. Use the pointed end of sprayhead cleaning tool (#38227.0000) to remove

any mineral deposits from the sprayhead holes.

3. Insert the long end of sprayhead cleaning tool into the sprayhead fitting, and rotate several times to remove

any mineral deposits from the fitting.

4. Insert the short end of sprayhead cleaning tool into the bypass fitting, and rotate several times to remove

any mineral deposits from the fitting.

NOTE: In hard water areas, this may need to be done daily. It will help prevent liming problems in the brewer

and takes less than a minute.

Page 8

34025 022509

GLOSSARY

AD CARD: An assembly consisting of a computer chip and an instruction label. Used for loading advertising

messages into the brewer.

BREW LOCKOUT: The inability to initiate a brew if the water temperature is less than the ready temperature

programmed into the brewer.

BYPASS: The process of diverting a portion of the brew water to the outside of the paper filter so that it does

not pass through the coffee grounds. This process is sometimes used to optimize the flavor of the finished

brew.

CHIP: A computer chip containing either recipes for specific coffee flavors or advertising messages which are

read by the sensing coils on the brewer. One chip is embedded in each Smart Funnel handle to carry the

coffee flavor name and batch size ground from the grinder to the brewer.

DRIP TIME: The length of time from when the water spray over the grounds ends, to the time that no water drips

from the funnel tip.

FACTORY DEFAULTS: The factory preset brew settings that were installed into the brewer's memory.

FIRST ON-TIME: During a pulse brew, this is the time set for the initial flow of water over the grounds.

FUNNEL DETECT: Sets the inability to initiate a brew cycle if the funnel is not properly inserted into the funnel

rails.

FUNNEL SENSING COIL: A sensor on the front hood of the brewer, which reads what name and batch size of

coffee was ground into the funnel and allows for the brewer to automatically set itself to what is read from

the funnel handle.

LAST ON-TIME: During a pulse brew, this is the time set for the second on-time, and each alternating on-time

for the remainder of the brew cycle.

MAIN SCREEN: The term used to describe the screen that is displayed when the brewer is not in use. This screen

is also displayed after exiting the programming mode.

NO-NAME COFFEE: The term for the recipe used by the brewer when there is no coffee name stored in the fun-

nel.

OFF-TIME: During a pulse brew or preinfusion, this is the time set for the length of time that the water is not

spraying over the grounds.

PREINFUSION: The process of beginning a brewing cycle with an initial spray of water onto the grounds followed

by a pause in the spray. After the programmed pause, the spray continues without interruption until the

end of the brewing cycle.

PULSE BREW: The process which allows the brew water to start, then stop, repeatedly, over the grounds in order

to derive the best flavor from the coffee. Pulse brew is also used in some instances to prevent a funnel

overflow.

RECIPE: Set of brewing parameters stored in the brewer. The parameters are unique for each coffee name and

include brew ounces, pulse brew, percent bypass, preinfusion and drip time.

RECIPE CARD: An assembly consisting of a computer chip and an instruction label. Used for loading a recipe

into the brewer and the companion BrewWISE Grinder.

SERVER DETECT: Sets the inability to initiate a brew cycle if the server is not properly placed on the stand below

the brew funnel.

®

SOFT HEAT

is placed on the brewer, and is connected through the receptacles on the brewer. The server contains a

temperature-controlled heater which maintains the coffee at a constant temperature.

: The type of server and brewer which are used as part of the Smart Funnel system. The server

Page 9

34025 012004

PROGRAMMING

READY TO BREW

WATER TEMP: 200°

Using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify various

brewing parameters such as brew temperatures, brew volumes, bypass percentages, etc. This allows for the

precise brewing of various flavors of coffee.

Programming of the brewer is achieved by entering a certain function. Then, by the use of hidden programming

switches, the operator can customize the brewing process to their specifications.

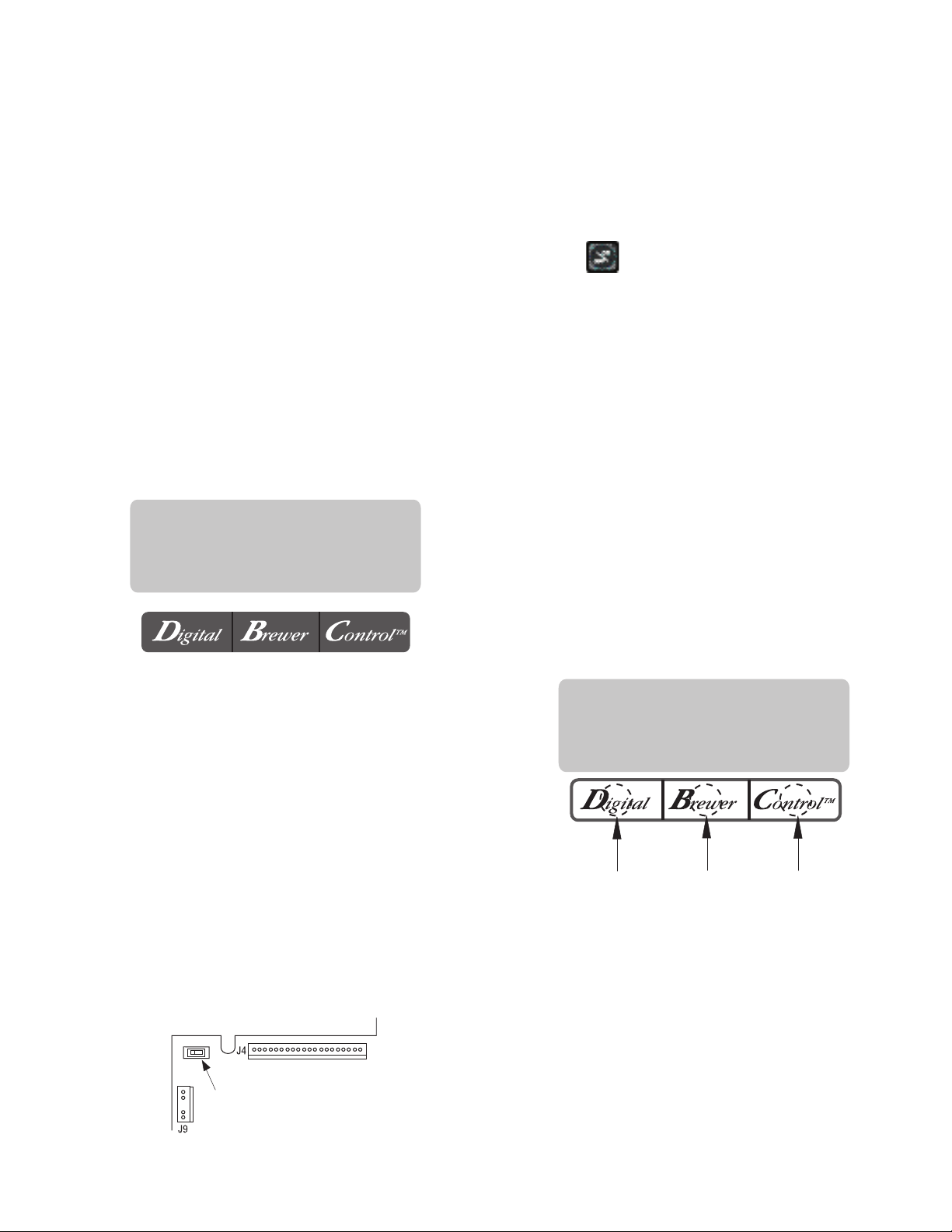

PROGRAMMING SWITCHES

To access the programming mode, and to scroll through the different function screens, hidden programming

switches are used. There are five of these switches that will be used for the setup of the brewer.

2

3 4 5

1. ® symbol (upper right of the BUNN logo)

This is used to access the programming mode and is also used to scroll forward through the function list.

1

P2450

2. Upper left corner of the "B" in the BUNN logo

This is used to scroll backwards through the function list.

3. "Digital" (lower left under the display)

This is used to select options that appear on the display during programming.

4. "Brewer" (center under the display)

This is used to select options that appear on the display during programming.

5. "Control" (lower right under the display)

This is used to select options that appear on the display during programming.

Page 10

34025 100501

PROGRAMMING THE BREWER

PROGRAM

ENABLE

DISABLE

The programming of the brewer is divided into two levels. There is one function in Level 1. All other functions

are accessed in Level 2.

The following function screens are in order of appearance. Each screen will have instructions on how to

access, and the procedures to program the various functions of the brewer.

IMPORTANT PROGRAMMING NOTES

- READ CAREFULLY -

To exit the programming mode at any time, press and release the pad located on the front switch panel.

The display will return to the MAIN SCREEN.

If none of the five programming switches are pressed within one minute during the setup of the brewer,

the programming of the function screen that is being set will be exited and the display will return to the MAIN

SCREEN.

Always remember to place a container and funnel under the sprayhead when operating the brewer during

the set-up of PULSE BREW - SET BY EXAMPLE, CALIBRATE FLOW and testing the brew and bypass valves in

SERVICE TOOLS/TEST OUTPUTS.

MAIN SCREEN

READY TO BREW

WATER TEMP: 200°

This screen will be shown when the brewer is ready

for use. The screen displays the water temperature

in the tank. When the water in the tank reaches the

correct set temperature, the display will change from

HEATING to READY TO BREW.

PROGRAMMING LOCKOUT SWITCH (mounted on

main control board)

This switch can be set to prevent access to the

programming levels of the brewer. Once all the correct brew settings are programmed, the operator can

set the switch to the "DISABLE" position to prohibit

anyone from changing the settings.

PROGRAMMING

SWITCH

P2424

Page 11

PROGRAM FUNCTIONS - LEVEL 1

BREW LOCKOUT

This function allows the operator to prevent or

allow brewing if the water temperature is less than

the set READY temperature.

To access this function screen press and hold the

® symbol. Release the ® when the display reads:

BREW LOCKOUT?

NO DONE YES

Press here

for NO

Press here

for DONE

The YES or NO should be flashing. Select YES to

prevent brewing if the water temperature is below the

set READY temperature. Select NO to permit brewing

at any water temperature.

When finished, press and release DONE. This

will exit this function screen and return to the MAIN

SCREEN on the display.

Press here

for YES

34025 022509

PROGRAMMING THE BREWER (cont.)

ARE YOU CREATING OR CHANGING A RECIPE FOR A

COFFEE NAME PREVIOUSLY USED IN THIS BREWER?

REFER TO NAME LIST

IN GRINDER MANUAL

CONTACT BUNN-O-MATIC

FOR ASSISTANCE

GO TO REVIEW RECIPES

AND FOLLOW INSTRUCTIONS

TO VIEW A LIST OF EXISTING RECIPES,

GO TO REVIEW RECIPES

AND FOLLOW THE INSTRUCTIONS

GO TO SET NEW RECIPE

AND FOLLOW THE

INSTRUCTIONS

YOU WILL ENTER

THE NO NAME

BREW SETTINGS

YOU WILL MODIFY AN

EXISTING RECIPE

DOES THE GRINDER HAVE THE

NAME IN ITS MEMORY?

FOLLOW INSTRUCTIONS

ON THE RECIPE CARD

HAVE YOU RECEIVED A RECIPE CARD

CONTAINING THE NEW RECIPE?

OR

OR

NO

NO

DON'T KNOW

NO

YES

YES

YES

DON'T

KNOW

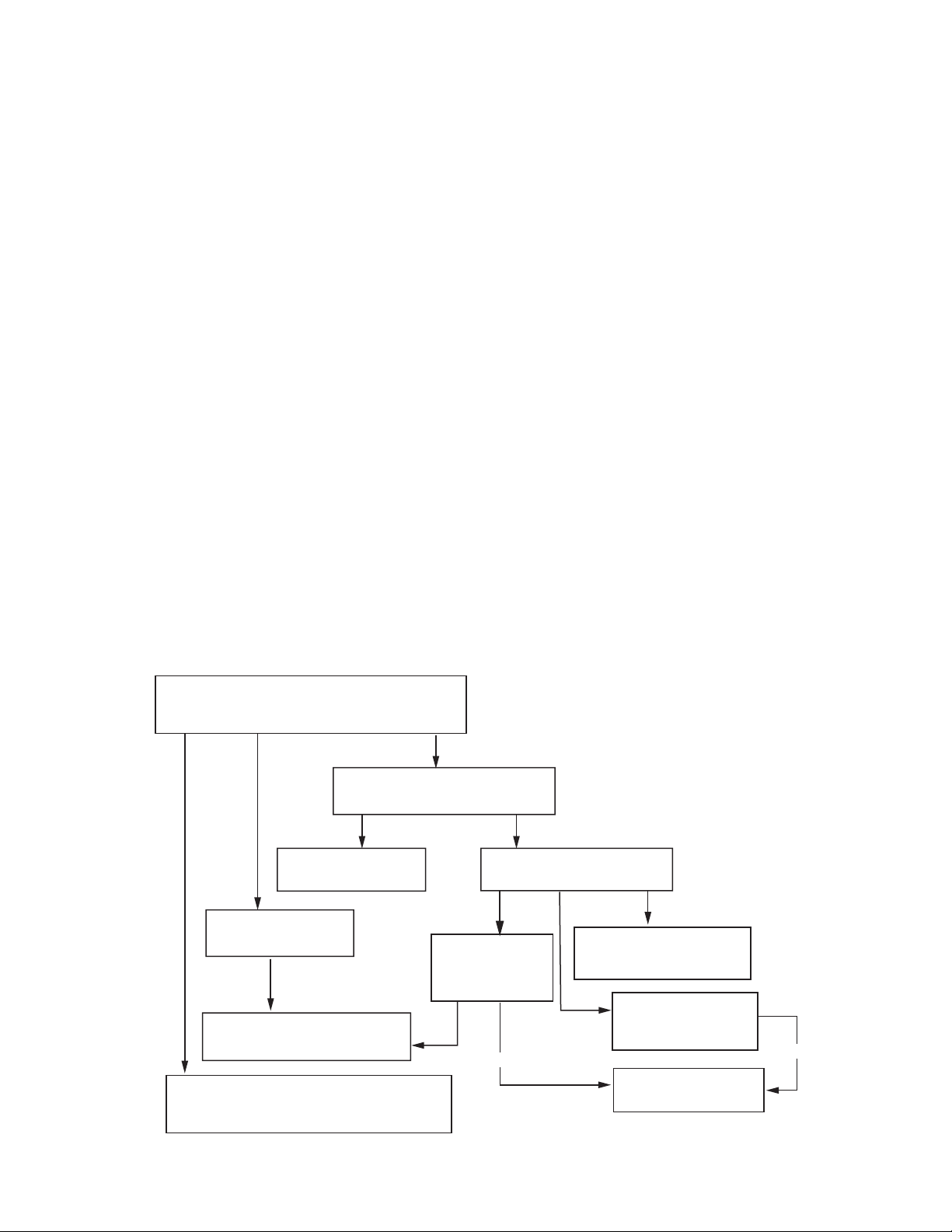

PROGRAM FUNCTIONS - LEVEL 2

There are three methods of programming the

various brewing parameters of the SINGLE SH with

®

Smart Funnel

Brewer.

METHOD 1:

Using a Smart Funnel and a G92T DBC Grinder:

Certain coffee NAMES are stored in the G92T

DBC's memory. When a particular name of coffee is

ground into the Smart Funnel, that name and the batch

size selected are transferred from the grinder to the

programming chip located in the funnel's handle. The

funnel is then inserted into the brewer's funnel rails.

The sensor coil on the brewer reads the information

contained in the handle. This then allows the operator

to set the BREW VOLUMES, BYPASS PERCENTAGES,

PULSE BREW TIMES, PREINFUSION TIMES and

DRIP-OUT TIMES for that particular coffee NAME.

Each coffee NAME can be set individually to provide

optimum brewing quality.

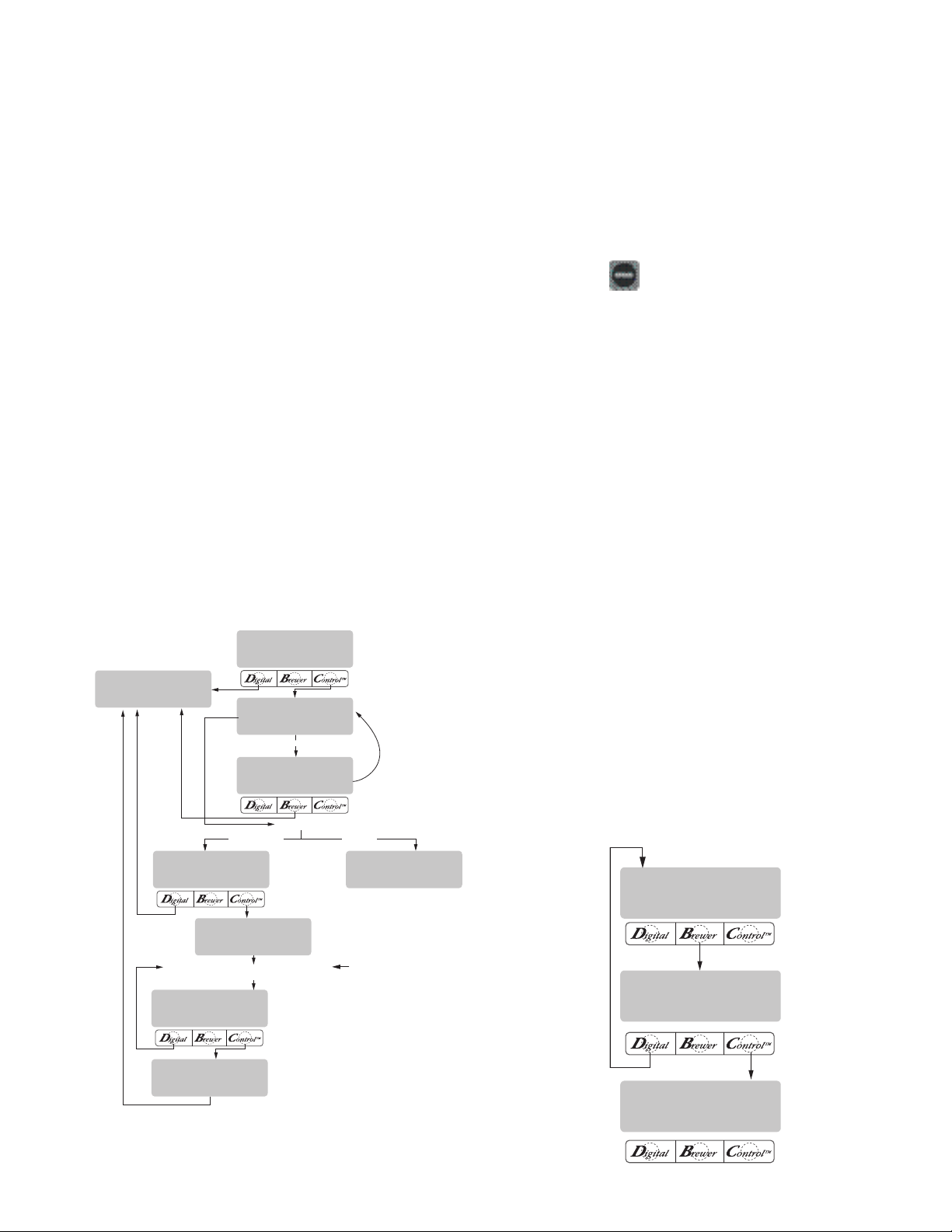

RECIPES

This diagram allows for the creating, modifying,

or viewing of recipes in the brewer.

METHOD 2:

Using a RECIPE CARD to enter all of the brew settings at one time:

If using a coffee flavor not in the G92T DBC's

memory, the customer can obtain a RECIPE CARD

from the factory with all the information needed to set

up that particular coffee flavor. This includes the name

of the coffee, BREW VOLUMES, BYPASS PERCENT-

AGES, PULSE BREW TIMES, PREINFUSION TIMES,

and DRIP-OUT TIMES.

METHOD 3:

Not using a Smart Funnel and/or a G92T DBC

Grinder:

This allows the operator to enter ONE set of brew-

ing parameters in the event a Smart Funnel and/or a

G92T DBC is not used with the SINGLE SH Brewer.

This is referred to as a NO NAME coffee flavor. If the

brewer does not read the information in the funnel

handle, it automatically selects the NO NAME brewing

parameters set up prior to brewing. This includes the

BREW VOLUMES, BYPASS PERCENTAGES, PULSE

BREW TIMES, PREINFUSION TIMES and DRIP-OUT

TIMES for the three batch sizes.

Page 12

P2438

34025 012004

MUST GRIND INTO

FUNNEL FIRST

(COFFEE NAME)

SETUP COMPLETE

BEGIN SETUP OF

(COFFEE NAME)

QUIT SETUP?

YES

INSERT FUNNEL

WITH NEW NAME

REVIEW RECIPES?

NO YES

(COFFEE NAME)

NO YES

3 BATCHES DONE?

NO YES

SET NEW RECIPE?

NO YES

2 SEC.

CYCLES THROUGH

TWO SCREENS

FUNNEL

CONTAINS NAME

FUNNEL CONTAINS

NO NAME

SETUP BREW VOLUMES, BYPASS, PULSE BREW,

PREINFUSION, DRIPOUT TIME

SEE SEPARATE DIAGRAMS

FOR SETUP INSTRUCTIONS

FUNNEL DETECTED

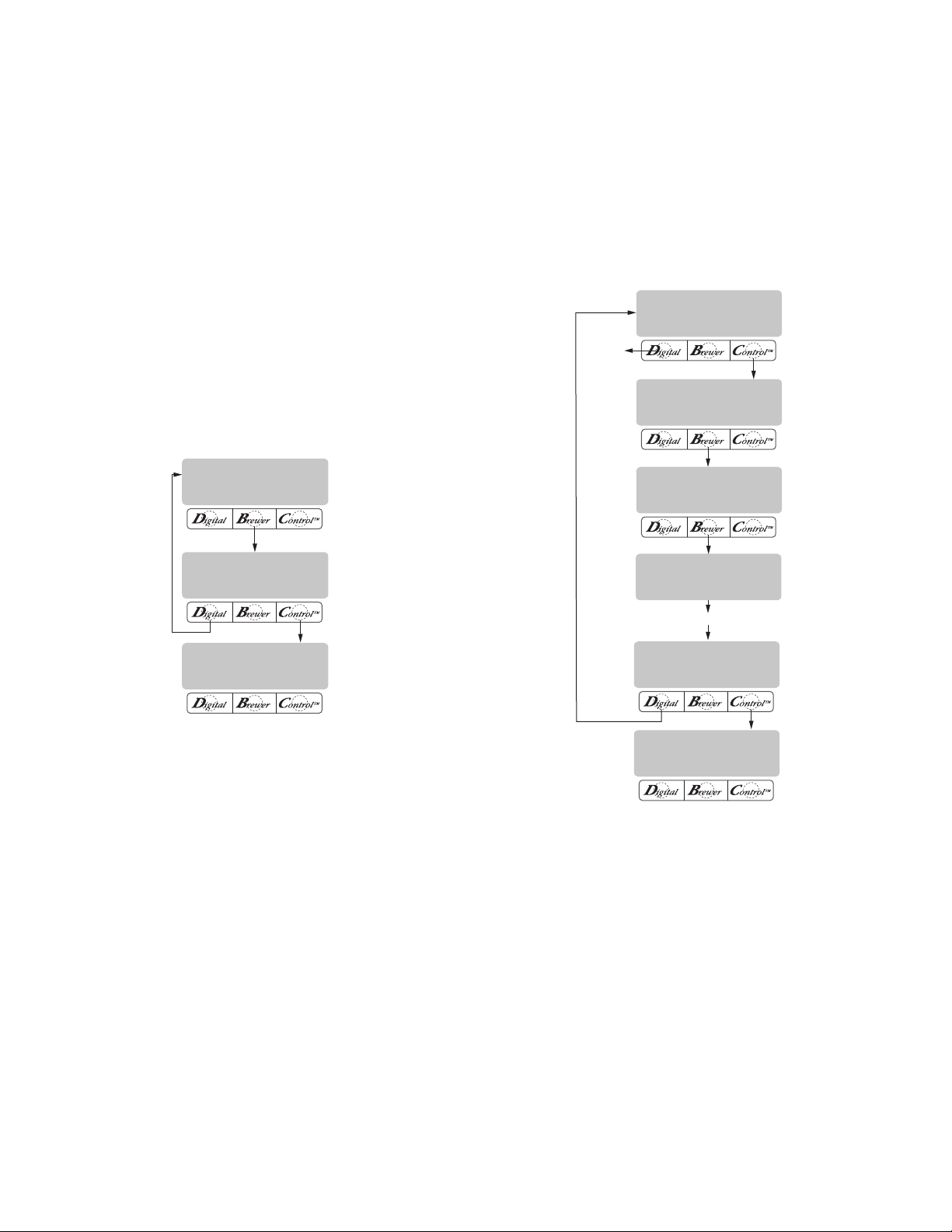

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

BREW OZ. XX.X

(-) DONE (+)

% BYPASS XX.X

(-) DONE (+)

3 BATCHES DONE?

NO YES

SET NEW RECIPE

Using a Smart Funnel and a G92T DBC Grinder:

This function allows the operator to set BREW VOLUMES, BYPASS PERCENTAGES, PULSE BREW TIMES,

PREINFUSION TIMES and DRIP-OUT TIMES for each

coffee name preset in the grinder's memory.

Certain coffee NAMES are stored in the G92T

DBC's memory. When a particular name of coffee is

ground into the Smart Funnel, that name and the batch

size selected are transferred from the grinder to the

programming chip located in the funnel handle. The

funnel is then inserted into the brewer's left side funnel

rails. The sensor coil on the brewer reads the information contained in the handle. The name of the coffee

flavor will then appear on the display. This then allows

the operator to set the BREW VOLUMES, BYPASS

PERCENTAGES, PULSE BREW TIMES, PREINFUSION

TIMES and DRIP-OUT TIMES for that particular coffee

NAME. It also allows the operator to set other brewing

parameters, such as BREW TEMPERATURE, READY

TEMPERATURE, BREW LOCKOUTS, etc. Each coffee

NAME can be set individually to provide optimum

brewing quality.

Procedure for Setting the Recipe:

NOTE: Before beginning setup, place a server beneath

the sprayhead.

1. Insert the funnel into the grinder and select a batch

size to grind. It is not necessary to have coffee beans

in the hopper(s) in order to program the brewer.

The coffee name is pre-selected and stored in the

grinder's memory for the side being ground.

2. Press the

pad. When the grinder stops grind-

ing, remove the funnel.

3. On the brewer, press and hold the ® pad until the

display reads SET NEW RECIPE. Release the ®

pad.

4. Press and release YES. The display should read

INSERT FUNNEL WITH NEW NAME, then QUIT

SETUP? These two displays will repeatedly

cycle.

5. Insert the funnel into the rails of the brewer. The

display should read the NAME of the coffee that

was ground into the funnel, along with a NO and

YES. If the NAME on the display is correct, press

YES.

6. If, for some reason, the name of the coffee from

the grinder did not load properly into the funnel,

or if a grind has not yet been done, the display will

read MUST GRIND INTO FUNNEL FIRST. It will be

necessary to grind another batch following steps

1 and 2.

7. If the grind is acknowledged by the brewer, the

display will read BEGIN SETUP OF (COFFEE

NAME). Then the screen will display BREW OZ.

and a batch light will be blinking. (Refer to page

19 for description of BREW OZ. function).

P2439

P2415

34025 022509

Page 13

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

% BYPASS XX.X

(-) DONE (+)

3 BATCHES DONE?

NO YES

SET PULSE BREW?

NO YES

ON TIME X:XX

(-) DONE (+)

OFF TIME X:XX

(-) DONE (+)

ON OFF

X:XX X:XX

DRIP TIME X:XX

(-) DONE (+)

3 BATCHES DONE?

NO YES

SET PREINFUSION?

NO YES

ADVANCES

TO NEXT

FUNCTION

5 SEC. DELAY

SET NEW RECIPES (cont.)

8. Using (-) and (+), set the amount of brew water,

in ounces, to be dispensed over the grounds for

that particular batch size.

9. When finished, press another batch size and repeat

step #8 for that size. Continue setting all batch

sizes.

10. When finished setting all batch sizes, press and

release DONE. The display should read 3 BATCH

SIZES DONE?

11. If the three batch sizes are not correct, press

and release NO to return to the BREW OUNCES

setup screen and repeat steps 8 through 10. If

the three batch sizes are correct, press YES. This

will advance to the % BYPASS function. (Refer to

page 20 for description of % BYPASS function.)

17. If setting pulse brew by ENTER TIMES (entering

known times) press NO. The display should read

ENTER TIMES. Press and release YES and proceed

with the setup instructions for SETTING PULSE

BREW - ENTER TIMES, page 24. After SET PULSE

BREW has been accomplished, the next function

will be SET PREINFUSION. (Refer to page 25 for

description of SET PREINFUSION function.

12. Using (-) and (+) set the amount of bypass water

(percentage) to be dispensed around the grounds

for that particular batch size.

13. When finished, press another batch size and repeat

step #12 for each batch to be set.

14. When finished setting each batch size, press

DONE. The display should read 3 BATCHES

DONE?

15. If the three batch sizes are not correct, press and

release NO to return to the % BYPASS setup screen

and repeat steps 12 through 15. If they are correct, press YES. This will advance to SET PULSE

BREW. (Refer to page 21 for description of SET

PULSE BREW function.

16. To SET PULSE BREW, if setting pulse brew BY

EXAMPLE (brewing into a funnel) press YES and

proceed with the setup instructions for SETTING

PULSE BREW - BY EXAMPLE, on page 23.

P2416

P2417

18. To SET PREINFUSION press YES in the SET PRE-

INFUSION screen to proceed. The display should

now read ON TIME and a batch light will be blink-

ing.

19. Using (-) and (+), set the amount of time the brew

water will initially presoak the grounds for that

particular batch size.

20. When finished, press another batch size and repeat

until all three batch sizes are set.

21. When finished, press DONE. The display should

now read OFF TIME and a batch light will be blink-

ing.

Page 14

34025 022509

(COFFEE NAME)

SETUP COMPLETE

DRIP TIME X:XX

(-) DONE (+)

3 BATCHES DONE?

NO YES

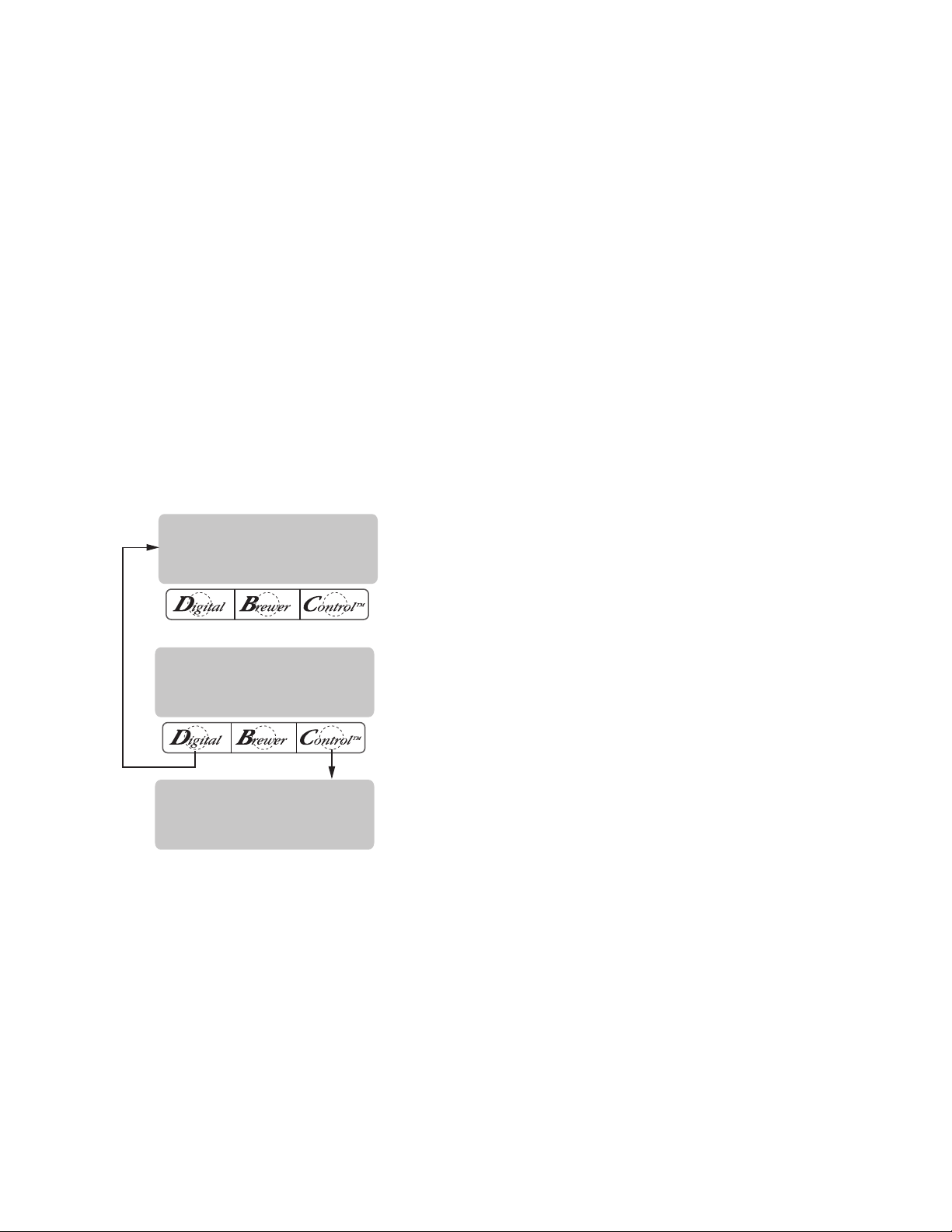

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET NEW RECIPES (cont.)

22. Using (-) and (+), set the amount of time the brew

cycle will delay (after the presoak cycle shuts off)

before resuming brewing.

23. When finished, press another batch size and repeat

until all three batch sizes are set.

24. When finished setting all batch sizes, press DONE.

The display will show the ON and OFF TIMES that

were entered for a particular batch size. After a 5

second delay, the display should read 3 BATCHES

DONE.

25. If the three batches are not complete, press NO in

order to return to SET PREINFUSION, and repeat

steps 19 through 24.

26. If the three batches are correct, press YES. This

will advance to the next function, SET DRIP TIME.

(Refer to page 26 for description of SET DRIP

TIME function.)

27. The display should now read DRIP TIME, along

with either the word OFF, or a time will be showing.

A batch light should also be blinking.

28. Using (-) and (+), set the amount of time from

when the brew spray ends to when the funnel is

emptied of hot liquid for that batch size.

NOTE: Set to OFF to prevent funnel locks from engaging

(to disable this function), for a particular batch size.

To set to OFF, continue to press and release (-) until

OFF appears on the screen.

29. When finished, press another batch size and repeat

step 28 until all three sizes are set.

30. When finished setting all batch sizes press DONE.

The display should read 3 BATCHES DONE?.

31. If the three batch sizes are not correct, press NO to

return to the DRIP TIME setup screen and repeat

steps 28 through 30.

32. If the three batch sizes are correct, press YES.

The screen should show the name of the coffee

being programmed (modified) along with SETUP

COMPLETE.

32. After a 5 second delay, the display will advance to

the next coffee name in the brewer's memory. If

no other coffee names are present, the display will

read THAT WAS THE LAST RECIPE, and return to

the REVIEW RECIPES screen.

P2418

34025 022509

Page 15

Loading...

Loading...