Bunn-O-Matic ITB, ITCB, ITCB-DV HV, ITCB TWIN HV Operation Manual

ITB/ITCB

ITCB-DV HV

ITCB TWIN HV

Infusion Series

®

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

36748.0003B 06/11 ©2010 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specifi ed below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes fi rst.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Offi ce Box 3227, Springfi eld, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifi cations to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specifi ed above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profi ts, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN

Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line,

BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth,

DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet

Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, PowerLogic, Quality Beverage Equipment

Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard,

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, A Partner You Can Count On, Air

Brew, Air Infusion, Beverage Bar Creator, Beverage Profi t Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Digital Brewer Control, Nothing Brews Like a BUNN, Pouring Profi ts,

Signature Series, Tea At Its Best, Phase Brew, The Horizontal Red Line, trifecta, Ultra, Velocity Brew are either

trademarks or registered trademarks of Bunn-O-Matic Corporation.

2

36748.3 050511

INTRODUCTION

ITB

This equipment will brew tea into an awaiting dispenser or reservoir.

The ITB uses recipe settings to brew tea. It has an LCD for digital readout and programming. The user is able

to select regular or quick brew for tea programming. Other features include Pre-Infusion and Pulse Brew, quick

and standard brew, Energy Savings mode, BUNNLink compatible, Freshness Timer, Sanitation Alert, and brew

counters. Available in low profi le, dual dilution and sweetener models.

ITCB-DV/ITCB-DV HV

This equipment will brew either tea or coffee into an awaiting dispenser or reservoir. It can be easily confi gured

for 120V or 120/208V-120/240V (Refer to data plate for specifi c ratings). The brewer may have an auxiliary hot

water faucet that can be mounted on the front, left or right side.

ITCB HV TWIN

This equipment will brew either tea or coffee into an awaiting dispenser or reservoir in either the left or right

side brewing station. The brewer may have an auxiliary hot water faucet that can be mounted on the front, left

or right side.

This equipment is only for indoor use on a sturdy counter or shelf.

The Infusion Series combines BrewWISE, CDBC and Tea Brewers into one. ITCB is able to brew both tea

and coffee with recipe settings. It has an LCD for digital readout and programming along with the Smart Funnel

options for coffee. The user is able to select regular or quick brew for tea programming. Other features include:

Pre-Infusion, Pulse Brew, quick and standard brew, and BrewWISE, Energy Savings mode, BUNNLink compatible, Smart Reader compatible, Freshness Timer, Sanitation Alert, and sweetener with low product detection.

CONTENTS

Warranty .............................................................................................................2

Introduction ........................................................................................................3

User Notices .......................................................................................................4

Electrical Requirements (ITB/ITCB-DV) ...............................................................5

Electrical Requirements (ITCB-DV HV/TWIN) .....................................................6

Plumbing Requirements/Optional Sweetener ......................................................7

Operating Controls ..............................................................................................8

Initial Set-Up .......................................................................................................9

Tea Brewing ......................................................................................................10

Coffee Brewing ..................................................................................................10

Cleaning/Tank Drain ..........................................................................................11

Sanitizing Optional Sweetener ...........................................................................12

Programming ....................................................................................................13

ITB ................................................................................................................... 120V Infusion Tea Brewer

ITB-DD ................................................................................................................................. Dual Dilution

ITB-LP ...................................................................................................................... Low Profi le Machine

ITCB-DV ................................................................................................................................Dual Voltage

ITCB-DV HV .................................................................................................... Dual Voltage High Volume

ITCB-C-DV ..............................................................................................Dual Voltage Brewer for Canada

ITCBA .............................................................................................................................. 230 Volt Brewer

ITCBB .............................................................................................................................. 200 Volt Brewer

TWIN ................................................................................................................................2 Brew Stations

3

36748.3 062111

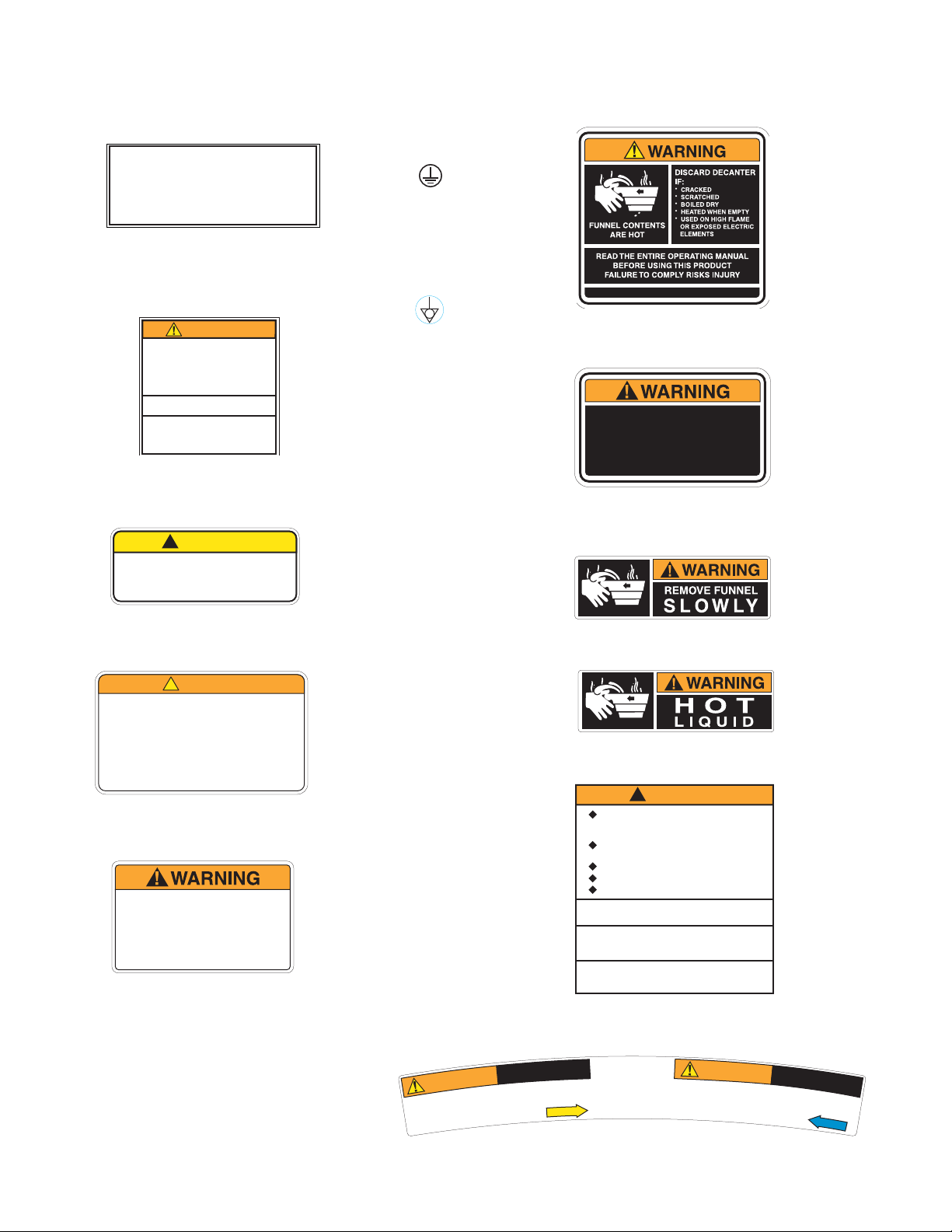

USER NOTICES

For 120/208V or 120/240 volt operation,

replace Power Supply Cord only with

Bunn-O-Matic part number 01699.0000.

! CAUTION

As directed in the International Plumbing Code of the

International Code Council and the Food Code

Manual of the Food and Drug Administration (FDA),

this equipment must be installed with adequate

backflow prevention to comply with federal, state

and local codes. For models installed outside the

U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

WARNING

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND

THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL

ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE

OPERATING MANUAL BEFORE

USING THIS PRODUCT

00986.0000F 10/07 ©1994 Bunn-O-Matic Corporation

PN: 00658.0000G 02/08 © 1985 BUNN-O-MATIC CORPORATION

Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should

be kept in good condition. Replace any unreadable or damaged labels.

#00824.0002

#00656.0001

#00658.0000

#00824.0001 (CE ONLY)

To reduce the risk of electric shock,

do not remove or open cover.

No user-serviceable parts inside.

Authorized service personnel only.

#00986.0000 ITCB

Disconnect power before servicing.

37881.0000

#34072.0000 ITCB

Incorrect programming could result in accidental dispensing of HOT LIQUID.

Trained personnel are to follow instructions provided for

software programming.

Use of additional graphic layer requires disabling of

appropriate switches.

Read all instructions for additional graphic layer prior to

installing and programming.

39175.0000A 05/06 ©2006 Bunn-O-Matic Corporation

! WARNING

#39175.0000

Risk of Fire. Use a UL listed grounding

type attachment plug, rated 125/250

Vac, 30 A, 1 phase, 4 conductor. Plug

to be selected and installed only by

qualified service personnel.

38125.0000A 04/05 © 2005 Bunn-O-Matic Corporation

#38125.0000 TWIN

#03408.0000

#03409.0000

WARNING !

Fill water tank before turning - on -

thermostat or connecting appliance

to power source.

Use only on a properly protected

circuit capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE, OR SHOCK HAZARD

READ THE ENTIRE OPERATING MANUAL

BEFORE BUYING OR USING THIS PRODUCT

THIS APPLIANCE IS HEATED WHENEVER

CONNECTED TO A POWER SOURCE

00831.0000F 3/98 ©1998 BUNN-O-MATIC CORPORATION

#00831.0000 ITB

u

s

e

k

a

M

s

i

D

a

e

T

i

t

n

e

t

o

p

s

i

l

e

n

n

u

F

e

r

h

t

n

o

r

e

s

n

e

p

d

n

a

s

n

r

u

b

l

a

d

n

a

d

e

t

a

t

o

r

d

i

s

T

H

G

I

R

e

s

l

l

i

p

s

r

e

t

a

w

h

t

i

w

d

e

n

g

i

l

a

d

i

o

v

a

o

t

e

T

H

G

I

R

.

M

a

k

e

s

u

r

e

F

u

n

n

e

l

i

s

r

o

t

a

t

e

d

a

n

d

a

l

i

T

e

a

D

i

s

p

e

n

s

e

r

o

n

t

h

e

L

p

o

t

e

n

t

i

a

l

b

u

E

r

n

s

a

n

d

w

a

t

g

n

e

d

w

i

t

F

T

s

i

d

e

e

r

s

p

i

l

l

s

.

h

t

o

a

v

o

i

d

L

E

F

T

S

D

I

U

Q

I

L

T

O

H

G

N

I

N

R

A

W

#41995.0000 ITB DD

4

36748.3 113010

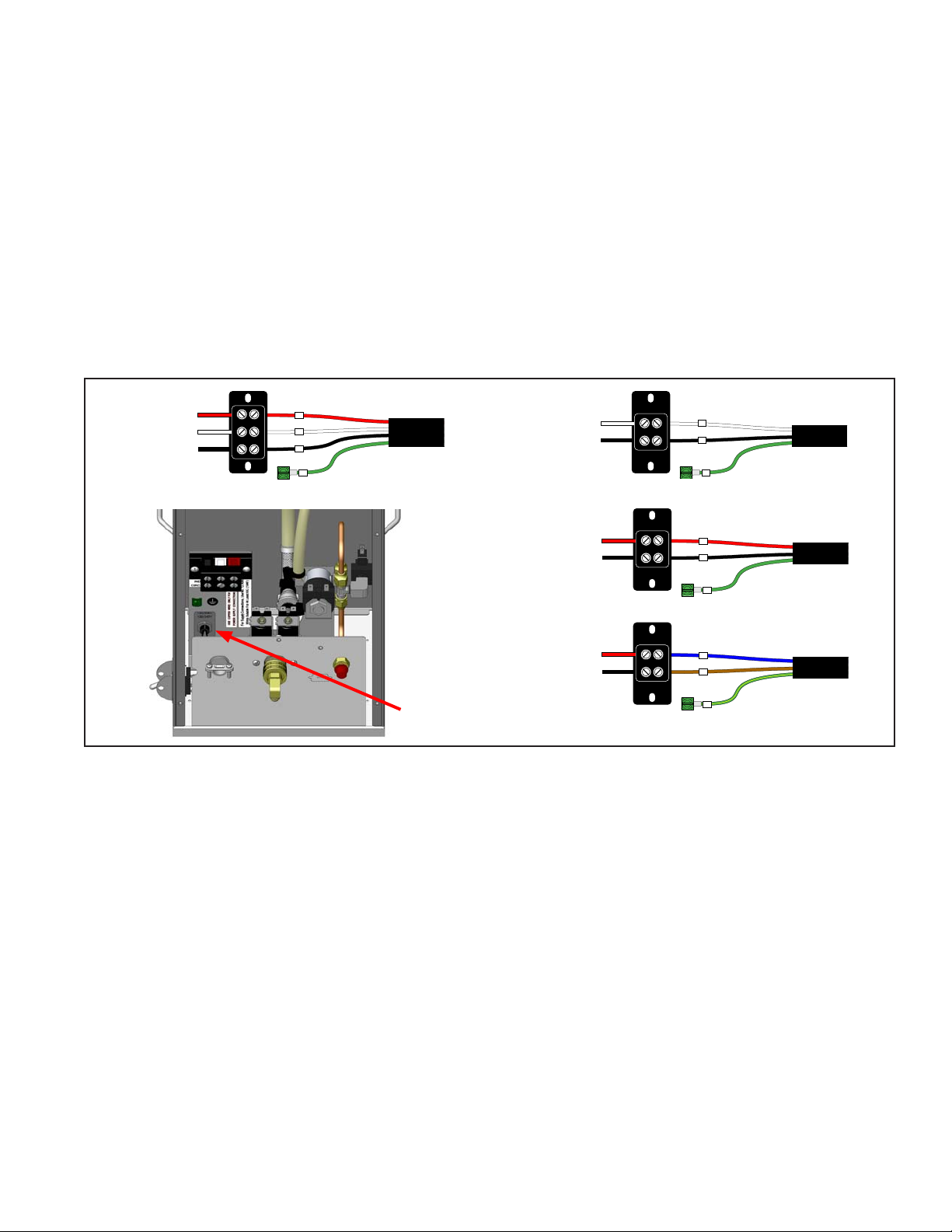

ELECTRICAL REQUIREMENTS ITB & ITCB-DV

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit

requirements.

“Optional Field Wiring ratings are located on the machine near the dataplate.”

WARNING - The brewer must be disconnected from the power source until specifi ed.

WARNING - The power cord must be UL Listed, Flexible Cord Type SO, SJO, SJTO, HSJO or SJOW, Rated 90°

C, and the attachment plug cap must be UL Listed, in order to avoid a hazard. The Power Supply Cord must

be at least 3 feet long and maximum 6 feet long (measured from Strain Relief to end of the Attachment

Plug Cap).

ITB - 120V models require 2-wire, grounded service rated 120 volts AC, 15 amp, single phase, 60Hz.

L2 RED L2 RED

WHITE

NEUTRAL

L1 BLACK

L1 BLACK

L2

WHITENEUTRAL

N

L1

GREEN

G

POWER CORD

WHITE

NEUTRAL

L1 BLACK

L1 BLACK

WHITENEUTRAL

N

L1

GREEN

G

POWER CORD

120/208-240V 3 WIRE + GROUND 120V 2 WIRE + GROUND

ITCB DV

ONLY

DUAL VOLT

TOGGLE SWITCH

L2 RED L2 RED

L1 BLACK

L1 BLACK

L2

L1

GREEN

G

240V 2 WIRE + GROUND

L2 RED NEUTRAL BLUE

L1 BLACK

L1 BROWN

N

L1

GREEN/YELLOW

G

230V 2 WIRE + GROUND

POWER CORD

POWER CORD

ELECTRICAL HOOK-UP (All Models)

CAUTION – Improper electrical installation will damage electronic components. Damage caused by incor-

rect electrical connections is not covered by warranty.

1. An electrician must provide electrical service.

2. Determine the available on-site electrical service.

3. (Steps 3 & 9 apply to DV models only) Select the desired unit voltage based on the available on-site elec-

trical service.

4. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

5. Remove the back panel to gain access to the terminal block.

6. Feed the power cord through the strain relief and connect it to the terminal block(s).

7. Connect the power cord to the terminal block as shown.

8. Before proceeding, verify the voltage at the fi eld wiring terminal block.

9. Set voltage switch to the appropriate position and replace the access panel.

10. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumb-

ing has been hooked up, the brewer is ready for Initial Set-Up.

5

36748.3 113010

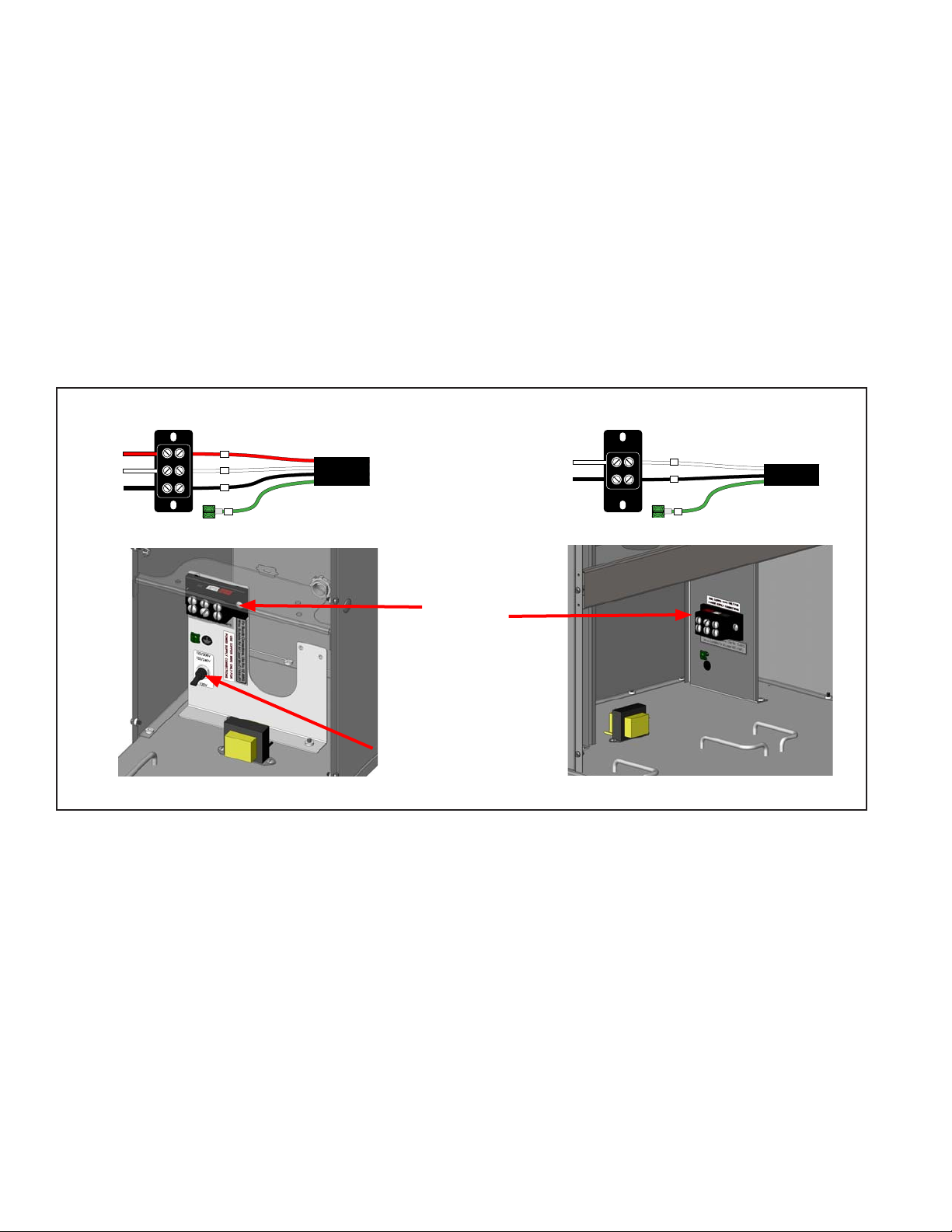

ELECTRICAL REQUIREMENTS ITCB-DV HV & TWIN

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit

requirements.

“Optional Field Wiring ratings are located on the machine near the dataplate.”

WARNING - The brewer must be disconnected from the power source until specifi ed.

WARNING - The power cord must be UL Listed, Flexible Cord Type SO, SJO, SJTO, HSJO or SJOW, Rated 90° C,

and the attachment plug cap must be UL Listed, in order to avoid a hazard. The Power Supply Cord must be at

least 3 feet long and maximum 6 feet long (measured from Strain Relief to end of the Attachment Plug Cap).

ITCB HV TWIN - requires 3-wire, grounded service rated 120/208-240 volts AC, 30 amp, single phase,

60Hz.

ITCB-DV HV - 120V models require 2-wire, grounded service rated 120 volts AC, 15 amp, single phase,

60Hz. or 3-wire, grounded service rated 120/208-240 volts AC, 20 amp, single phase, 60Hz.

ITCB-DV HV & TWIN ITCB-DV HV ONLY

L2 RED L2 RED

WHITE

NEUTRAL

L1 BLACK

L1 BLACK

L2

WHITENEUTRAL

N

L1

GREEN

G

POWER CORD

WHITE

NEUTRAL

L1 BLACK

L1 BLACK

WHITENEUTRAL

N

L1

GREEN

G

POWER CORD

120/208-240V 3 WIRE + GROUND 120V 2 WIRE + GROUND

Terminal

Block

L2 RED L2 RED

L1 BLACK

L1 BLACK

L2

L1

GREEN

G

POWER CORD

240V 2 WIRE + GROUND

ITCB-DV HV

DUAL VOLT

TOGGLE SWITCH

L2 RED NEUTRAL BLUE

L1 BLACK

L1 BROWN

N

L1

GREEN/YELLOW

G

230V 2 WIRE + GROUND

ITCB-DV HV TWIN

POWER CORD

ELECTRICAL HOOK-UP (All Models)

CAUTION – Improper electrical installation will damage electronic components. Damage caused by incor-

rect electrical connections is not covered by warranty.

1. An electrician must provide electrical service.

2. Determine the available on-site electrical service.

3. (Steps 3 & 9 apply to DV models only) Select the desired unit voltage based on the available on-site electrical service.

4. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

5. Remove the front panel to gain access to the terminal block.

6. Feed the power cord through the strain relief and connect it to the terminal block.

7. Connect the power cord to the terminal block as shown.

8. Before proceeding, verify the voltage at the fi eld wiring terminal block.

9. Set voltage switch to the appropriate position and replace the access panel.

10. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing has been hooked up, the brewer is ready for Initial Set-Up.

6

36748.3 113010

Loading...

Loading...