Bunn-O-Matic DUAL, DUAL SH, SINGLE, SINGLE SH Service Manual

DUAL ®&

DUAL ® SH

(Serial # DUAL010000 - Up)

SINGLE ®&

SINGLE ® SH

R

E

T

A

W

HOT

ION

CAUT

!

ER

T

AN

C

E

D

D

R

A

AUTION

C

C

S

DI

!

F:

I

ED

Y

K

T

ED

P

H

AC

M

E

R

Y

E

R

M

C

ATC

N

.

D

C

R

I

E

C

D

R

H

FLA

E

T

S

W

.

H

C

IL

G

D

E

I

O

L

E

H

B

T

E

.

A

D

E

ON

E

H

D

.

E

S

POS

S

U

.

T

R EX

RY

EN

O

M

.

N

JU

LE

O

I

N

T

I

E

A

TS

R

S

EN

ISK

T

CORPO

R

IC

ON

T

Y

C

L

MA

-

L

O

-

OT

MP

E

NN

H

N

U

B

CO

E

5

8

R

9

O

FUN

1

A

T

E

LUR

I

FA

8

5

6

PN:

T

HO

S ARE

ACE

RF

SU

AND

MERS

AR

W

:

ON

I

AUT

C

OT WATER

H

N

TIO

AU

C

!

DECANTER

D

CAUTION

DISCAR

!

D

IF:

D

TY

P

RACKE

EM

RY

ME

ATCHE

. C

N

D

IC

E

H

FLA

TR

. SCR

W

D

OILED

LEC

HIGH

TE

. B

E

N

A

D

E

E

O

S

. H

ED

O

S

P

S

. U

NT

Y

R EX

ME

. O

ION

T

ELE

TENTS

RISKS INJUR

C CORPORA

TI

PLY

O-MA

-

NEL CON

UNN

B

5

8

9

FUN

1

ARE HOT

TO COM

FAILURE

8

: 65

PN

!

(Serial # SNG0005000 - Up)

gal

2

1⁄

1

1 gal

gal

2

⁄

1

READY

R

I

GRINDER

G

OR

H

T

SELECT

L

E

F

T

ON / WARMER

RT

STA

TER

A

W

OT

H

ION

START

T

CAU

!

MER

ON / WAR

FUNNEL CONTENTS

ARE HOT

PN: 658

FAILURE TO COMPLY RISKS INJURY

gal

2

⁄

1

1

1 gal

gal

2

⁄

1

R

SELECTO

READY

CAUTION

DISCARD DECANTER

!

IF:

. CRACKED

. SCRATCHED

. BOILED DRY

. HEATED WHEN EMPTY

. USED ON HIGH FLAME

. OR EXPOSED ELECTRIC

ELEMENTS

-MATIC CORPORATION

-O

1985 BUNN

WATER

HOT

CAUTION

!

R

ANTE

C

DE

SCARD

CAUTION

DI

:

!

F

I

Y

T

ED

P

ACKED

CH

Y

T

EM

CR

A

.

IC

LAME

ED DR

SCR

WHEN

.

GH F

D

E

HI

ELECTR

. BOIL

N

O

SED

. HEAT

S

USED

.

ENT

M

. OR EXPO

E

JURY

N

S

EL

I

RATION

O

P

OR

TENT

C

RISKS

TIC

A

Y

L

-M

T

P

-O

EL CON

NN

U

B

COM

5

8

9

1

FUNN

ARE HO

TO

E

UR

L

FAI

8

5

6

:

PN

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

T

O

H

S ARE

E

C

FA

R

U

S

D

AN

S

R

E

M

WAR

:

N

TIO

U

A

C

41976.0000 09/11 ©2009 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifications to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN

Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic,

Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design,

Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series,

Intellisteam, My Café, PowerLogic, Quality Beverage Equipment Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart

Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan,

A Partner You Can Count On, Air Brew, Air Infusion, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not

bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Digital Brewer Control, Nothing Brews Like a BUNN,

Pouring Profits, Signature Series, Tea At Its Best, Phase Brew, The Horizontal Red Line, trifecta, Ultra, Velocity Brew are

either trademarks or registered trademarks of Bunn-O-Matic Corporation.

Page 2

41976 050511

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection,testing,andrepairofelectricalequipmentshouldbeperformed only by qualied

service personnel.

• Allelectroniccomponentshave120-240voltacandlowvoltagedcpotentialontheirterminals.

Shorting of terminals or the application of external voltages may result in board failure.

• Intermittentoperationofelectroniccircuitboardsisunlikely.Boardfailurewillnormallybeper-

manent. If an intermittent condition is encountered, the cause will likely be a switch contact or

a loose connection at a terminal or crimp.

• Solenoidremovalrequiresinterruptingthewatersupplytothevalve.Damagemayresultifsole-

noids are energized for more than ten minutes without a supply of water.

• Theuseoftwowrenchesisrecommendedwheneverplumbingttingsaretightenedorloosened.

This will help avoid twists and kinks in the tubing.

• Makecertainthatallplumbingconnectionsaresealedandelectricalconnectionstightandiso-

lated.

• Thisbrewerisheatedatalltimes.Keepawayfromcombustibles.

WARNING

• Exerciseextremecautionwhenservicingelectricalequipment.

• Disconnectthebrewerfromthepowersourcewhenservicing,exceptwhenelectricaltestsare

specified.

• Followrecommendedserviceprocedures.

• Replaceallprotectiveshieldsorsafetynotices.

Problem

Probable Cause

Remedy

Equipment will not operate.

Brew cycle will not start.

1. No power or incorrect voltage.

1. No water

2. Water strainer/flow control

(.750 GPM)

(A1) Check the terminal block for

120 volts across the red and white

terminals and the black and white

terminals on 120V, 120/208 or

120/240 volt brewers.

(A2) Check the terminal block for 200

volts on "B Series" brewers or 240

volts on "A Series" brewers across

the red and black terminals.

(B) Check circuit breakers or fuses.

Check plumbing and shut-off

valves

(A) Direction of flow arrow must be

pointing towards brewer.

(B) Remove the strainer/flow control

and check for obstructions. Clear or

replace.

Page 3

41976 031709

TROUBLESHOOTING (cont.)

Problem

Probable Cause

Remedy

Brew cycle will not start (cont.)

Automatic refill will not operate

3. ON/OFF switch

4. Start switch

5. Timer

6. Dispense Valve

7. Control Assembly (Electronic)

8. Server not in place (SH models)

1. No water

2. Water strainer/flow control

Refer to Service - ON/OFF switch for

testing procedures.

Refer to Service - Start switch for

testing procedures.

Refer to Service - Timer for testing

procedures.

Refer to Service - Dispense valve

for testing procedures.

Refer to Service - Control assembly

for testing procedures.

Make sure server is in place and

server present lamp is lit.

Check plumbing and shut-off valves.

(A) Direction of flow arrow must be

pointing towards brewer.

3. Solenoid Valve

4. Limit thermostat (Electro/mechanical and Electronic)

5. Overflow protection switch

6. (A) Level control board & level

probe. (Electro/mechanical controlled)

(B) Electronic controls

(B) Remove the strainer/flow control

and check for obstructions. Clear or

replace.

Refer to Service - Solenoid valve for

testing procedures.

Refer to Service - Limit thermostat

for testing procedures.

Refer to Service - Overflow protection switch for testing procedures.

Refer to Service - Level control board

for testing procedures.

Refer to Service - Electronic controls

for testing procedures.

Page 4

41976 031709

TROUBLESHOOTING (cont.)

Problem

Probable Cause

Remedy

Beverage level will not adjust

(Selector switch in any position)

Water flows into tank continuously

(On/Off Switch "OFF").

Water flows into tank continuously

(ON/OFF switch "ON").

Water from tank is not hot

1. Brew Selector switch

1. Solenoid valve

2A. Level control board and level

probe (Electro/mechanical)

2B. Control assembly (Electronic)

3. Overflow protection switch

1. Timer

1. Limit thermostat

CAUTION - Do not eliminate or

bypass limit thermostat. Use only

replacement part #23717.0001

Refer to Service - Selector switch

for testing procedures.

Refer to Service - Solenoid valve for

testing procedures.

Refer to Service - Level control board

for test procedures.

Refer to Service - Control assembly

for testing procedures.

Refer to Service - Timer for testing

procedures.

Refer to Service - Overflow protection switch for testing procedures.

Refer to Service -Limit thermostat

for testing procedures.

2A. Control Thermostat (Electro/

mechanical)

2B. Control assembly (Electronic)

3. Contactor (Brewers with Recovery

Booster)

4. Tank heaters

5. Triac assembly (Electronic)

Refer to Service - Control Thermostat

for testing procedures.

Refer to Service - Control assembly

for testing procedure.

Refer to Service - Contactor for testing procedures.

Refer to Service - Tank heaters for

testing procedures.

Refer to Service - Triac assembly for

testing procedures.

Page 5

41976 031709

TROUBLESHOOTING (cont.)

Problem

Water from tank is not hot (cont.).

Server warmer is not hot.

Spitting or unusual steaming from

sprayhead or airvents.

Probable Cause

6. Relay (Brewers with Recovery

Booster)

1. ON/OFF switch

2. Warmer element

1A. Control thermostat (Electro/

mechanical)

1B. Control assembly (Electronic)

2. Triac assembly (Electronic)

3. Lime build-up

CAUTION - Tank and tank components should be delimed regularly

depending on local water conditions. Excessive mineral build-up on

stainless steel surfaces can initiate

corrosive reactions resulting in serious leaks.

Remedy

Refer to Service - Relay for testing

procedures.

Refer to Service - ON/OFF switch for

testing procedures.

Refer to Service - Warmer element

for testing procedures.

Refer to Service - Control thermostat

for testing procedures.

Refer to Service - Control assembly

for testing procedures.

Refer to Service - Triac assembly for

testing procedures.

Inspect the tank assembly for excessive lime deposits. Delime as

required.

Inconsistent beverage level in

server.

1. Strainer/flow control

2. Improper water pressure

Page 6

(A) Direction of flow arrow must be

pointing towards the brewer.

(B) Remove the strainer/flow control

and check for obstructions. Clear

or replace.

Check operating water pressure to

the brewer. It must be between 20

and 90 psi (138 and 620 kPa) .

41976 031709

TROUBLESHOOTING (cont.)

Problem

Inconsistent beverage level in

server (cont.).

Consistently high or low beverage

level in server.

Dripping from sprayhead.

Water overflows filter.

Probable Cause

3. Dispense valve

1. Timer adjustment

1. Dispense valve

1. Bypass valve

2. Needle Valve

3. Type of paper filters

Remedy

Refer to Service - Dispense valve for

testing procedures.

Adjust the timer as required to

achieve the recommended volume

for each brew cycle.

Refer to Service - Dispense valve

for testing procedures.

Refer to Installation & Operating

Guide, Initial Set-Up.

Refer to Installation & Operating

Guide, Initial Set-Up

BUNN paper filters should be used

for proper extraction.

Beverage overflows server.

Weak beverage.

4. No sprayhead

1. Beverage left in server

2. Timer adjustment

3. Dispense valve

1. Type of paper filters

2. Coffee

Check sprayhead

The brew cycle should be started

only with an empty server under

the funnel.

Adjust the timer as required to

achieve the recommended volume

for each brew cycle.

Refer to Service - Timer for testing

procedures.

Refer to Service - Dispense valve for

testing procedures.

BUNN paper filters should be used

for proper extraction.

A sufficient quantity of fresh drip

or regular grind should be used for

proper extraction.

Page 7

41976 031709

TROUBLESHOOTING (cont.)

Problem

Weak beverage (cont.)

Probable Cause

3. Sprayhead

4. Funnel loading

5. Water temperature

Remedy

A clean sprayhead should be used

to properly wet the bed of ground

coffee in the funnel.

The BUNN paper filter should be

centered in the funnel and the bed

of ground coffee leveled by gentle

shaking.

Empty the server, remove its cover,

and place the server on the warmer.

Place empty funnel over the server

entrance, with ON/OFF switch in the

"ON" position press the start switch

and release it. Check the water

temperature immediately below

the sprayhead with a thermometer.

The reading should not be less than

195˚F(91˚C).

Brewer is making unusual noises.

1. Solenoid (Inlet)

2. Plumbing lines

3. Water supply

4. Tank Heater(s)

5. Contactor

The nut on back of the solenoid

must be tight or it will vibrate during

operation

Plumbing lines should not be resting

on the counter top.

(A) The brewer must be connected

to a cold water line.

(B) Water pressure to the brewer

must not be higher than 90 psi (620

kPa). Install a regulator if necessary

to lower the working pressure to approximately 50 psi (345 kPa).

Remove and clean lime off tank

heater(s).

Check for low voltage

Page 8

41976 031709

TROUBLESHOOTING (cont.)

Problem

Server will not heat

Probable Cause

1. Circuit breaker

2. Receptacle Contacts

3. Relay (Server Power) (Prior to

S.N. DUAL026000)

4. Transformer

5. Rectifier

Remedy

A) Check and reset if necessary

B) Refer to Service - Circuit breaker

for test procedures.

Clean or replace.

Refer to Service - Relay (Soft Heat)

for test procedures.

Refer to Service - Transformer for

test procedures.

Refer to Service - Rectifier for test

procedures.

Page 9

41976 031709

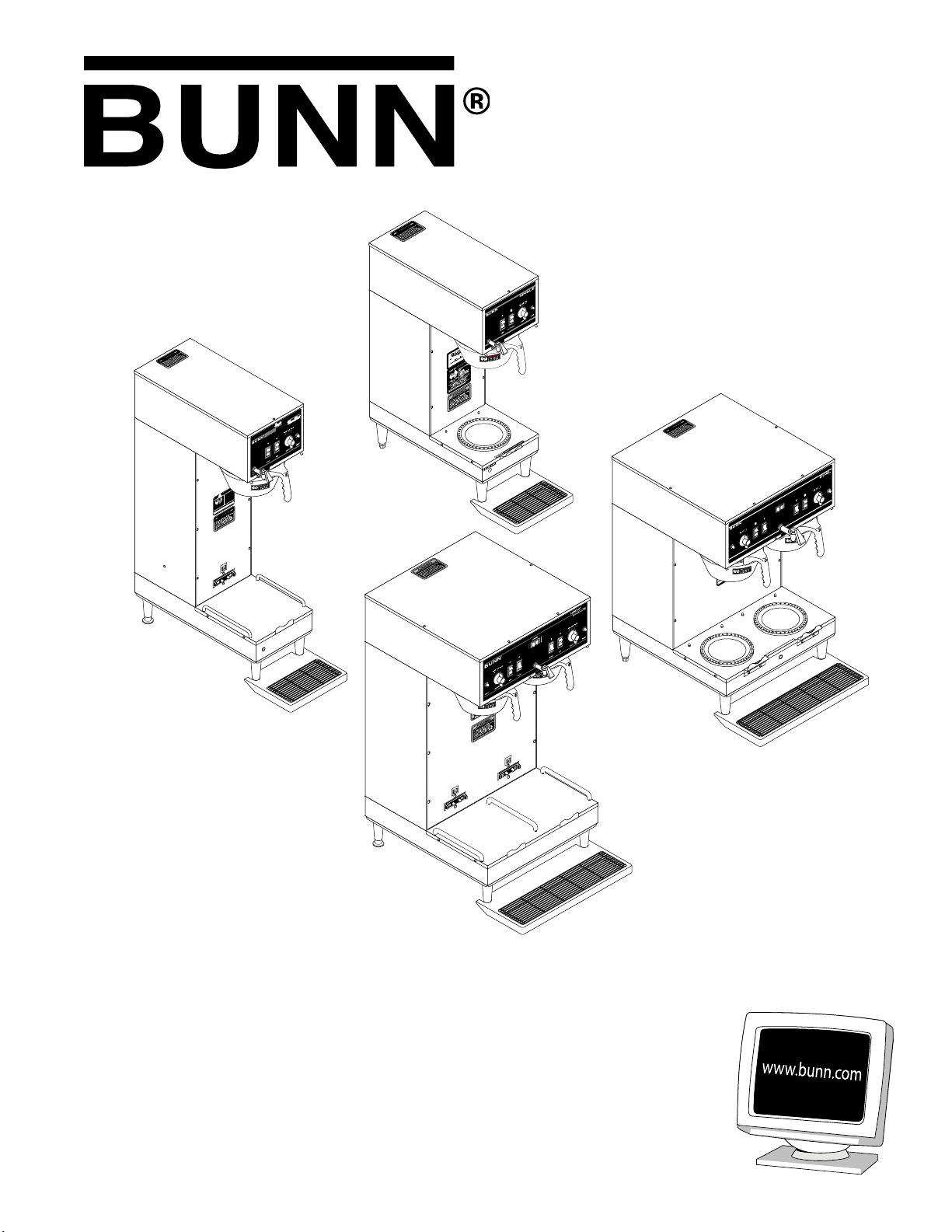

SERVICE

This section provides procedures for testing and

replacing various major components used in this

brewer should service become necessary. Refer to

Troubleshooting for assistance in determining the

cause of any problem. Illustrations shown are DUAL

brewers with SINGLE brewers similar except where

noted.

WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified

service personnel. The brewer should be unplugged

when servicing, except when electrical tests are required and the test procedure specifically states to

plug in the brewer.

COMPONENT ACCESS

WARNING - Unplug the brewer before the removal of

any panel or the replacement of any component.

All components are accessible by the removal of

the top cover, front access panel, warmer base plate

and/or server platform cover. The covers and panels

are attached with slotted head screws as follows:

SINGLE & SINGLE SH top cover (1) #4-40

Contents

Brewer Selector Switch ........................................ 12

Bypass Valve ........................................................ 11

Circuit Breakers .................................................... 14

Contactor Assembly ............................................. 15

Control Thermostat .............................................. 17

Dispense Valve ..................................................... 18

Grinder Selector Switch .......................................20

Level Control Board and Level Probe ...................21

Limit Thermostat ..................................................23

Main Power Switch ..............................................45

ON/OFF Switch (Warmer) ..................................... 24

Overflow Protection Switch .................................. 25

Receptacle ...........................................................26

Rectifiers .............................................................. 26

Relay .................................................................... 27

Solenoid ............................................................... 33

Start Switches (Brew) ..........................................35

Tank Heaters ........................................................36

Timers (Early Models) .......................................... 37

Digital Timer (Late Models) .................................. 40

Transformers........................................................42

Warmer Elements.................................................44

Wiring Diagrams .................................................. 46

DUAL & DUAL SH top cover (4) #4-40

SINGLE front access panel (4) #6-32

SINGLE SH front access panel (8) #6-32

DUAL front access panel (5) #6-32

DUAL SH front access panel (11) #6-32

SINGLE & DUAL warmer base (4) #6-32

SINGLE SH & DUAL SH server platform (4) #6-32

Page 10

41976 031709

SERVICE (cont.)

!

CAUTI

ON

HOT WATE

R

.

M

INUTES

BUNN-O-MATIC

P/N 2620- 120 VAC

.

MINUTES

BUNN-O-MATIC

P/N 2620- 120 VAC

1 gal

C

AUTI

ON:

WA

R

MERS

AN

D

S

URFA

C

ES

A

RE

H

O

T

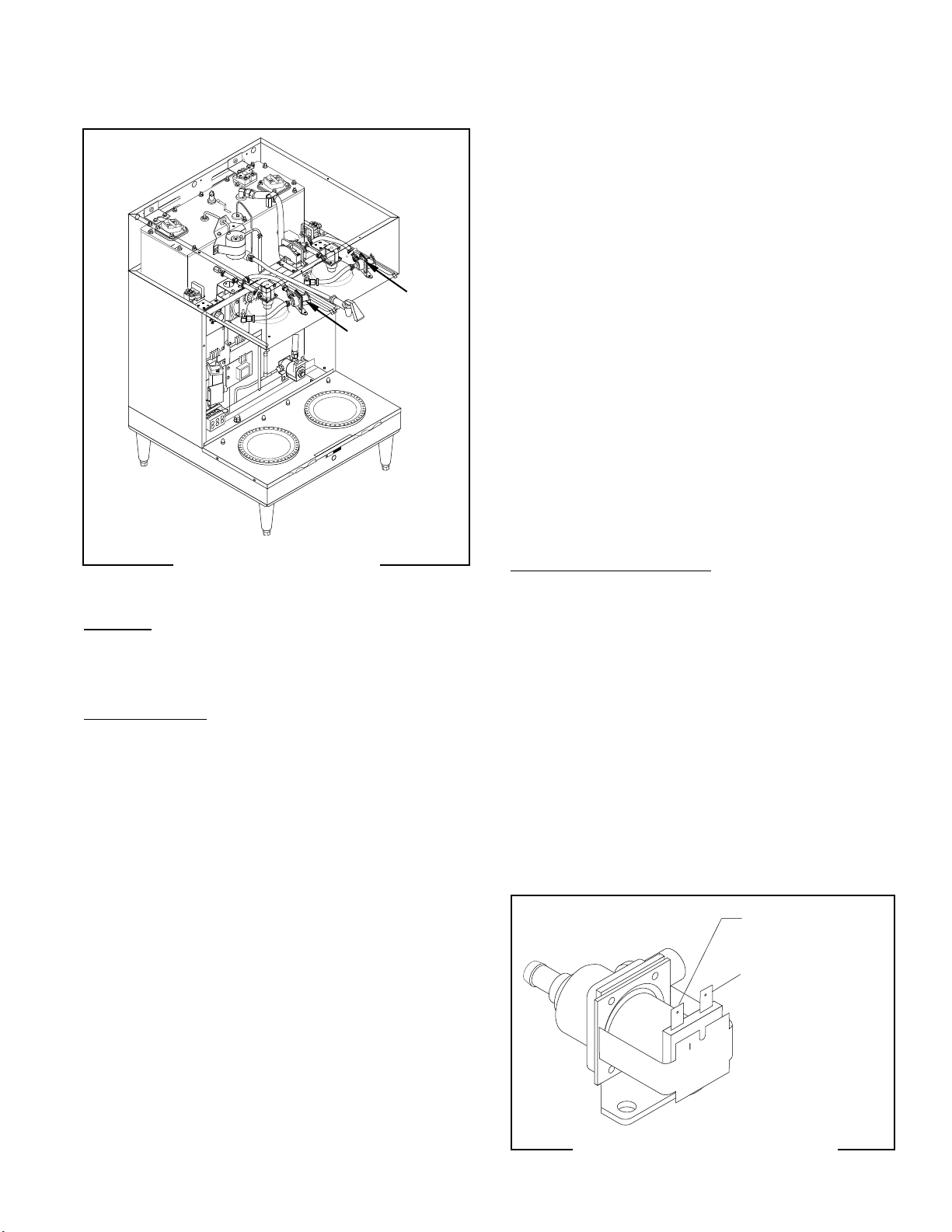

BYPASS VALVE

P773

FIG. 1 BYPASS VALVES

Location:

The bypass valves are located on the sprayhead

panel inside the hood.

Test Procedures:

1. Disconnect the brewer from the power source and

place a server beneath the funnel.

2. Check the water level in the tank to confirm that it

is within 1/2" from the top of the tank.

3. Connect the brewer to the power source.

4. Check the bypass valve for coil action. Place the ON/

OFF switch in the "ON" position, press and release

the BREW switch. Listen carefully in the vicinity of

the bypass valve for a "clicking" sound as the coil

magnet attracts and repels the plunger.

5. Disconnect the brewer from the power source.

If the sound is heard as described, there may be a

blockage in the bypass valve or the water line to the

sprayhead. Remove the bypass valve and inspect for

wear, and remove waterborne particles.

If the sound is not heard as described, proceed to

#6.

6. Connect the voltmeter lead ends to the bypass valve

coil terminals. Connect the brewer to the power

source. With the selector switch in the 1 or 1-1/2

gallon position, place "ON/OFF" Switch in the "ON"

position. Press and release the brew switch. The

indication must be:

a.) 120 volts ac for two wire 120 volt models,

three wire 120/208 volt and three wire 120/240

volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

7. Disconnect the brewer from the power source.

If voltage is present as described, but no coil action is

observed, nor "clicking" heard, bypass valve is defective.

Replace valve and test again to verify repair.

If voltage is not present as described, refer to Wiring

Diagrams and check the brewer wiring harness. Also

check the control board for proper operation.

Removal and Replacement:

1. Remove the wires from the bypass valve.

2. Drain enough water from the tank so bypass valve

is above the water line.

3. Remove water lines from bypass valve.

4. Remove the two nuts retaining the bypass valve

inside the hood and remove bypass valve.

5. Remove hose barb fitting and attach to new bypass

valve.

6. Install new bypass valve with hose barb fitting.

7. Reconnect the water tubes and the wires to the

bypass valve.

8. Refer to Fig. 2 when reconnecting the wires.

NOTE: If one of the terminals is marked "I", connect

WHI/GRN wire to it.

WHI/GRN to Dispense

Valve

WHI/VIO to Brew

Selector Switch

P774

FIG. 2 BYPASS VALVE TERMINALS

Page 11

41976 031709

SERVICE (cont.)

START

ON / WAR

MER

SELECTOR

READY

R

EADY

ON / WAR

MER

START

1

1⁄2

ga

l1 g

al

1⁄2

gal

SELECTOR

1

1⁄2

g

al

1

g

al

1⁄2

gal

BREW SELECTOR SWITCH

FIG. 3 BREW SELECTOR SWITCHES

P775

12. Reconnect the pink wire to the grind switch.

13. Disconnect the tan wire from the left or right selector switch and tan wire from interface socket.

14. Check for continuity across the tan wires.

15. Reconnect the tan wires.

16. With the selector switch set at the medium and

large batch positions, disconnect the white/violet

from the bypass valve.

17. Check for continuity across the white/violet wire

and terminal on bypass valve.

18. Reconnect the white/violet wire to the terminal on

the bypass valve.

19. Disconnect the white/red wire from the dispense

valve.

20. Check for continuity across white/red wire and

terminal on dispense valve.

21. Reconnect white/red wire to the terminal on the

dispense valve.

Location:

The brew selector switch(es) are mounted in the

front panel of the hood.

Test Procedure (Early model Selector Switch):

1. Disconnect the brewer from the power supply.

2. Separate the connector on the selector switch

harness from the brew timer circuit board.

3. Carefully slide the plastic cover off of the connector

from the switch harness.

4. Check for continuity across the pink and tan wires

on the connector when the switch is in the small

batch position. Continuity must not be present in

any other switch position.

5. Check for continuity across the pink wire and gray

wire when the switch is in the medium batch position. Continuity must not be present in any other

position.

6. Reattach the connector to the brew timer circuit

board.

7. Disconnect the gray wire from the left or right

selector switch and gray wire from the interface

socket.

8. Check for continuity across the gray wires.

9. Reconnect the gray wires from the selector switches

and the interface socket.

10. Disconnect the pink wire from the left or right

selector switch to the grinder switch.

11. Check for continuity across the pink wire and the

terminal on the grind switch.

Page 12

If continuity is present as described the switch is

operating properly.

If continuity is not present as described replace switch

assembly.

Removal and Replacement:

1. Disconnect the connector on the selector switch

harness from the brewer timer circuit board.

2. Disconnect wires from the selector switch, interface

socket, dispense valve and bypass valve.

3. Loosen the set screw on the switch knob.

4. Remove the 9/16" nut and washer holding the

switch to the hood.

5. Remove the switch.

6. Install the new switch. The positioning tab must

be in the hole in the hood for proper switch and

knob alignment.

7. Install the knob so that the arrow lines up in the

large batch position when the switch is turned to

the full right position.

8. Reattach the connector to the brew timer circuit

board.

9. Refer to Fig. 4 when reconnecting the wires.

41976 031709

SERVICE (cont.)

BREW SELECTOR SWITCH (cont.)

WHI/VIO to By-Pass Valve

WHI/RED to Dispense Valve

GRY to Interface Socket

PNKtoInterfaceSocket

TAN to Interface Socket

To Timer

EARLY MODEL SELECTOR SWITCH

YEL to Timer

d

PNKtoGrinderInterface

BLU to Timer

ORN to Timer

GRY to Grinder Interface

TAN to Grinder Interface

4

3

2

1

b

PNK

TAN

GRY

5. Check for continuity across terminals (e) and (5).

When the selector switch is in the small batch

position, continuity should not be present. When

the selector switch is in the medium or large batch

positions, continuity should be present.

If continuity is present as described the switch is

operating properly.

If continuity is not present as described replace switch

assembly.

Removal and Replacement:

1. Disconnect all wires from the brew selector

switch.

2. Loosen the set screw on the switch knob.

3. Remove the 9/16" nut and washer holding the

switch to the hood.

4. Remove the switch.

5. Install the new switch. The positioning tab must

be in the hole in the hood for proper switch and

knob alignment.

6. Install the knob so that the arrow lines up in the

large batch position when the switch is turned to

the full right position.

7. Refer to Fig. 4 when reconnecting the wires.

e

WHI/VIO to

By-Pass Valve

5

LATE MODEL SELECTOR SWITCH

WHI/RED to

Dispense Valve

P1388

FIG. 4 BREW SELECTOR SWITCH TERMINALS

Test Procedure (Late model Selector Switch):

1. Disconnect the brewer from the power supply.

2. Disconnect all wires from the brew selector

switch.

3. Check for continuity across terminals (b) and (1)

when the switch is in the small batch position.

Continuity must not be present in any other switch

position.

4. Check for continuity across terminals (b) and (2)

when the switch is in the medium batch position.

Continuity must not be present in any other position.

Page 13

41976 031709

SERVICE (cont.)

CIRCUIT BREAKERS

Removal and Replacement:

1. Remove the wires from the circuit breaker.

2. Compress the clips on the back side of the server

platform and gently push the circuit breaker through

the opening in the server platform.

3. Push the new circuit breaker into the opening in the

server platform until the clips snap into position.

4. Reconnect the wires to the circuit breaker.

TER

HOT WA

ON

TI

U

CA

!

N

TIO

ARD DECANTER

CAU

DISC

:

!

IF

ED

CK

PTY

M

E

RA

M

RY

C

ATCHED

.

A

RIC

FL

T

ED D

SCR

WHEN E

.

IGH

OIL

H

B

ELEC

TED

.

EA

ED

H

S

D ON

.

PO

SE

X

U

.

E

R

ENTS

O

.

N

TIO

NJURY

ELEM

ORA

NTS

RP

CO

NTE

MATIC

-

MPLY RISKS I

5 BUNN-O

8

19

O CO

FUNNEL CO

ARE HOT

E T

AILUR

F

658

PN:

5. Refer to Fig. 6 when reconnecting the wires.

BLU/BLKtoTransformer#12

FIG.5CIRCUITBREAKERS

P1361

(SH Brewers only)

Location

The circuit breakers are located on the lower front

of the brewer, mounted on the server platform just

above the spring contact receptacle assembly.

Test Procedures:

1. Disconnect the dispenser from the power

source.

2. Remove the wires from the circuit breaker.

3. Check for continuity between the terminals. Continuity must be present between the terminals.

If continuity is present as described the circuit breaker

is functioning properly.

If continuity is not present as described, press reset

button and repeat step #3, if continuity is not present

as described, replace the circuit breaker.

BLU/BLKtoRectier"AC"

P1330

FIG.6CIRCUITBREAKERTERMINALS

Page 14

41976 031709

SERVICE (cont.)

CONTACTOR ASSEMBLY

S

.

MINUTE

BUNN-O-MATIC

20- 120 VAC

P/N 26

wire 120/208 volt models and three wire 120/240

volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

5. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #6.

gal1 ga

1⁄2

1

l

gal

1⁄2

READY

SELECTOR

/ WARMER

ON

P/N 2620- 120 VAC

ON / WA

SELECTOR

Y

EAD

R

l1 gal

a

g

2

1⁄

1

l

ga

2

1⁄

.

MINUTES

BUNN-O-MATIC

START

START

RMER

If voltage is not present as described, refer to the Wiring

Diagrams and check the brewer wiring harness.

6. Check for continuity between the two black wires

of the contactor coil.

If continuity is present as described, reconnect one

black wire to red or white wire from the terminal block

and the other black wire to the black wire from the

T

O

H

S ARE

RFACE

AND SU

S

ER

ARMER

AT

W

W

ON:

HOT

I

T

ON

I

CAU

UT

CA

!

control thermostat. Reinstall capillary tube into the

tank to a line 7" above the bulb and proceed to #7.

If continuity is not present as described, replace the

contactor.

P796

FIG. 7 CONTACTOR ASSEMBLY

Location:

The contactor assembly is located inside the hood

just to the rear of the dispense valve (Right side for

DUAL and DUAL SH models).

Test Procedures:

Mechanical Thermostat (Brewers with or without

Recovery Booster)

1. Disconnect the brewer from the power source.

2. Disconnect the white wire of the two pole 120V terminal block, white wire of the three pole 120/208V

or 120/240V or the red wire of the two pole 200V

or 240V terminal block and the black wire of the

contactor coil. Disconnect the black wire of the

control thermostat from the remaining black wire

of the contactor coil.

3. Gently remove the capillary bulb and grommet

from the tank.

4. With a voltmeter, check the voltage across the white

wire from the terminal block on 120, 120/208,

120/240 volt units or the red wire from 200 or

240 volt units and the black wire from the control

thermostat when the thermostat is turned clockwise

to the "FULL ON" position. Connect the brewer to

the power source. The indication must be:

a.) 120 volts ac for two wire 120 volt models, three

Page 15

7. Locate the white wire or red wire on L1 terminal

and black wire on the L2 terminal on the contactor.

8. With a voltmeter, carefully check the voltage across

the white or red and black wires. The indication

must be:

a.) 120 volts ac for two wire 120 volt models, 208

volts ac for three wire 120/208 volt models and

240 volts ac for three wire 120/240 volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

9. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #10.

If voltage is not present as described, refer to the Wiring

Diagrams and check brewer wiring harness.

10. Check for continuity across the terminals on the

left side of the contactor by manually closing the

contacts. Continuity must not be present when the

contact is released.

11. Check for continuity across the terminals on the

right side of the contactor by manually closing the

contacts. Continuity must not be present when the

contact is released.

If continuity is present as described, the contactor is

operating properly.

41976 031709

SERVICE (cont.)

CONTACTOR ASSEMBLY (cont.)

If continuity is not present as described, replace the

contactor.

Test Procedures :

Electronic Control (Brewers w/Recovery Booster)

1. Disconnect the brewer from the power source.

2. Disconnect the gray wire from the black wire on

the rear of the contactor coil and white /brown wire

from the black wire on the front of the contactor

coil.

3. With a voltmeter, check the voltage across the

gray wire and white/brown wire with both "ON/

OFF" switches in the "ON" position. Connect the

brewer to the power source and press both start

switches. The indication must be:

a.) 120 volts ac for three wire 120/208 volt models

and three wire 120/240 volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

4. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagrams and check brewer wiring harness.

5. Disconnect the blue and red wires from the contactor terminals. Check for continuity across the

terminals of the contactor by manually closing the

contacts. Continuity must not be present when the

contact is released.

3. Securely install the new contactor inside the

hood.

4. Refer to Fig. 8 when reconnecting the wires.

WHI L1 to Terminal Block

(White Insert)

RED L1 to Terminal Block

(Red Insert)

BLKL2toLimitThermostat

BLKto WHI Lead from the Two

Pole 120V Terminal Block

BLKtoWHILeadfromtheThree

Pole 120/208V or 120/240V

Terminal Block

BLKtoREDLeadfrom the Two

Pole 200V or 240V Terminal

Block

BLK T2 to TankHeater

RED T1 to Tank Heater

BLKto BLK Lead from

Thermostat

P828

SINGLE and SINGLE SH models

DUAL and DUAL SH models

RED L1 to Terminal Block

(Red Insert)

BLKL2toTerminalBlock

(Black Insert)

BLKtoWHILeadfromthe

Three Pole 120/208V or

120/240V Terminal Block

BLKtoREDLeadfromthe

Two Pole 200V or 240V

Terminal Block

MECHANICAL THERMOSTAT W/RECOVERY BOOSTER

BLKT2toLeftTankHeater

BLKT2toRightTankHeater

RED T1 to Left Tank Heater

RED T1 to Right Tank Heater

BLKtoBLKLeadfromThermostat

If continuity is present as described, reconnect the

blue and red wires to the contactor terminals. Connect one black lead from the contactor coil to the gray

wire and the white/brown wire to the remaining black

lead of the contactor coil. The contactor is operating

properly.

If continuity is not present as described, replace the

contactor.

Removal and Replacement:

1. Remove all wires from the contactor.

2. Remove the two #10-32 slotted head screw securing contactor to the inside of the hood.

Page 16

RED T1 to Terminal Block (Red

Insert)

BLU L1 to Left Tank

Heater

BLKtoGRYonRelay

ELECTRONIC CONTROL W/RECOVERY BOOSTER

BLKtoWHI/BRNtoLeft

Dispense Valve

FIG. 8 CONTACTOR TERMINALS

P778

41976 031709

SERVICE (cont.)

CONTROL THERMOSTAT

Location:

The control thermostat is located inside the lower

left front of the brewer on the component bracket.

1. Disconnect the brewer from the power source.

2. Locate the blue wire on the control thermostat.

3. With a voltmeter, check the voltage across the

blue wire on the control thermostat and the white

insert on the two or three pole 120V, 120/208V,

120/240V terminal block and the red insert on

two pole 200V, 240V terminal block. Connect the

brewer to the power source. The indication must

be:

a.) 120 volts ac for two wire 120V models, three

wire 120/208 volt models and three wire 120/240

volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

4. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagrams and check brewer wiring harness.

5. Locate the black wires from the control thermostat.

6. Gently remove the capillary bulb and grommet

from the tank.

7. With a voltmeter, check the voltage across the

black wires of the control thermostat and the white

insert on the two pole or three pole 120V, 120/208V,

120/240V terminal blocks and the red insert on two

pole 200V, 240V terminal blocks when the control

thermostat is turned "ON" (fully clockwise). Connect

the brewer to the power source. The indication

must be:

a.) 120 volts ac for two wire 120V models, three

wire 120/208 volt models and three wire 120/240

volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

Voltage must not be indicated across these ter-

minals when the thermostat is turned "OFF" (fully

counterclockwise).

8. Disconnect the brewer from the power source.

If voltage is present as described, reinstall the capillary

tube into the tank to the line 7" above the bulb, the

control thermostat is operating properly.

If voltage is not present as described, replace the

thermostat.

l

1 ga

l

a

g

2

1⁄

ELECTOR

S

WARMER

P/

.

UTES

C

N

I

A

M

N-O-MATIC

BUN

P/N 2620- 120 V

WA

/

N

O

TOR

LEC

E

S

EADY

R

l

a

g

2

⁄

1

1

l

1 ga

l

ga

1⁄2

.

UTES

N

I

AC

MATIC

M

N-O-

BUN

20- 120 V

N 26

START ON /

T

R

A

T

S

RMER

T

O

H

ARE

CES

A

F

D SUR

AN

RS

R

ARME

W

N:

IO

T

ON HOT WATE

I

CAU

CAUT

!

FIG. 9 CONTROL THERMOSTAT

al

g

2

1⁄

1

READY

Removal and Replacement:

1. Remove wires from the control thermostat.

2. Remove the thermostat capillary bulb by firmly

pulling up on the capillary tube at the tank lid. This

will disengage the grommet from the tank lid.

3. Remove the #8-32 slotted head screw holding the

control thermostat to the component bracket.

4. Slide the grommet to the line 7" above the bulb on

the new capillary tube.

5. Insert the capillary bulb through the hole in the

tank lid and press the grommet firmly and evenly

so that the groove in the grommet fits into the tank

lid.

P779

6. Carefully bend the capillary tube so that the tube

and bulb inside the tank are in the vertical position.

41976 031709

Page 17

SERVICE (cont.)

CONTROL THERMOSTAT (cont.)

NOTE - The capillary tube must be clear of any electri-

cal termination and not kinked.

7. Using a #8-32 slotted head screw fasten the control

thermostat to the component bracket.

8. Refer to Fig. 10 when reconnecting the wires.

9. Adjust the control thermostat as required.

DISPENSE VALVE

gal1 ga

1⁄2

1

l

gal

1⁄2

READY

SELECTOR

ON / WARMER

RT

P/N 2620- 120 VAC

S

.

MINUTE

BUNN-O-MATIC

20- 120 VAC

P/N 26

RMER

ON / WA

SELECTOR

Y

READ

al1 gal

g

2

⁄

1

1

l

ga

2

1⁄

.

MINUTES

BUNN-O-MATIC

STA

START

BLU to Ready Light(s)

BLU to Overflow Protection Switch

BLKtoBLKLeadofContactorCoil

BLKtoReadyLight(s)

FIG. 10 CONTROL THERMOSTAT

TERMINALS

P780

FIG. 11 DISPENSE VALVE

P796

Location:

Dispense valves are located inside the hood in the

center of each sprayhead panel.

Test Procedures:

1. Disconnect the brewer from the power source.

2. Disconnect the wires from the right dispense valve

and check the voltage across the white/violet wire

and white/green wire. Connect brewer to the power

source. Place the "ON/OFF" switch in the "ON"

position, press and release the start switch. The

indication must be:

a.) 120 volts ac for two wire 120V models, three

wire 120/208 volt models and three wire 120/240

volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

3. Disconnect brewer from the power source.

4. Disconnect the wires from the left dispense valve

and check voltage across the white/red wire and

the white/brown wire. Connect the brewer to the

power source. Place the "ON/OFF" switch in the "ON"

position and press and release the start switch.

The indication must be:

a.) 120 volts ac for two wire 120V models, three

wire 120/208 volt models and three wire 120/240

volt models.

b.) 200 to 240 volts ac for two wire 200 or 240

volt models.

5. Disconnect brewer from power source.

Page 18

41976 031709

SERVICE (cont.)

DISPENSE VALVE (cont.)

If voltage is present as described in steps 2 & 4 proceed to #6.

If voltage is not present as described, refer to the Wiring

Diagrams and check brewer wiring harness.

6. Check for continuity across the dispense valve coil

terminals.

If continuity is present as described, reconnect the

wires to the dispense valve and proceed to #7

If continuity is not present as described, replace the

dispense valve.

7. Check the dispense valve for coil action. Connect

the brewer to power source. Place the ON/OFF"

switch in the "ON" position, press and release the

start switch. Listen carefully in the vicinity of the

dispense valve for a "clicking" sound as the coil

magnet attracts and repels the plunger.

8. Disconnect the brewer from the power source.

WHI/VIO to Right Timer TL1

WHI/VIO to Right ON/OFF Switch

WHI/RED to Right Brew Selector Switch

WHI/GRN to Right Timer TL4

WHI/GRN to Right By-Pass Valve

SINGLE Brewers & RIGHT on DUAL Brewers

WHI/RED to Left Timer TL1

WHI/RED to Left Brew Selector Switch

WHI/RED to Left ON/OFF Switch

WHI/BRN to Left Timer TL4

WHI/GRN to Left By-Pass Valve

LEFT on DUAL Brewers

FIG. 12 DISPENSE VALVE TERMINALS

P782

If the sound is heard as described, there may be a

blockage in the dispense valve or the water line to the

dispense valve. Remove the dispense valve and inspect

for wear, and remove waterborne particles.

If the sound is not heard as described, replace the

dispense valve.

Removal and Replacement:

1. Disconnect wires and water tubes from dispense

valve.

2. Drain enough water from the tank so the dispense

valves are above the water line.

3. Remove dispense valve from the sprayhead

panel.

4. Install new dispense valve.

5. Reconnect the water lines and the wires to the

dispense valve.

6. Refer to Fig. 12 when reconnecting wires.

Page 19

41976 031709

SERVICE (cont.)

GRINDER SELECTOR SWITCH

gal

2

⁄

1

1

1 gal

gal

⁄2

1

DY

A

RE

R

SELECTO

RMER

RT ON / WA

l

ga

2

1⁄

1

1 gal

al

g

2

⁄

1

START

N / WARMER

O

R

SELECTO

READY

FIG. 13 GRINDER SELECTOR SWITCH

(DUAL and DUAL SH BREWERS only)

Location:

The grinder selector switch is located in the upper

center on the front of the hood.

STA

P786

PNKtoPNKLeadfrom

Right Brew Selector Switch

PNKtoPNKLeadfromInterface

Socket

PNKtoPNKLeadfrom

Left Brew Selector Switch

P787

FIG. 14 GRINDER SELECTION

SWITCH TERMINALS

Test Procedure:

1. Disconnect the brewer from the power source.

2. Remove all wires from the switch terminals.

3. Place the selector switch in the left position.

4 Check for continuity across the center and right

terminals on the rear of the switch.

5. Continuity must not be present across the center

and left terminals on the rear of the switch.

6. Check the bottom row, then the top row of terminals.

If continuity is present as described proceed to #7.

If continuity is not present as described replace the

switch.

7. Place the selector switch in the right position.

8. Check for continuity across the center and left

terminals on the rear of the switch.

9. Continuity must not be present across the center

and right terminals on the rear of the switch.

10. Check the bottom row, then the top row.

If continuity is present as described, reconnect the

wires, the switch is operating properly.

If continuity is not present as described, replace the

switch.

11. Refer to Fig. 14 when reconnecting the wires.

Page 20

41976 031709

Loading...

Loading...