Page 1

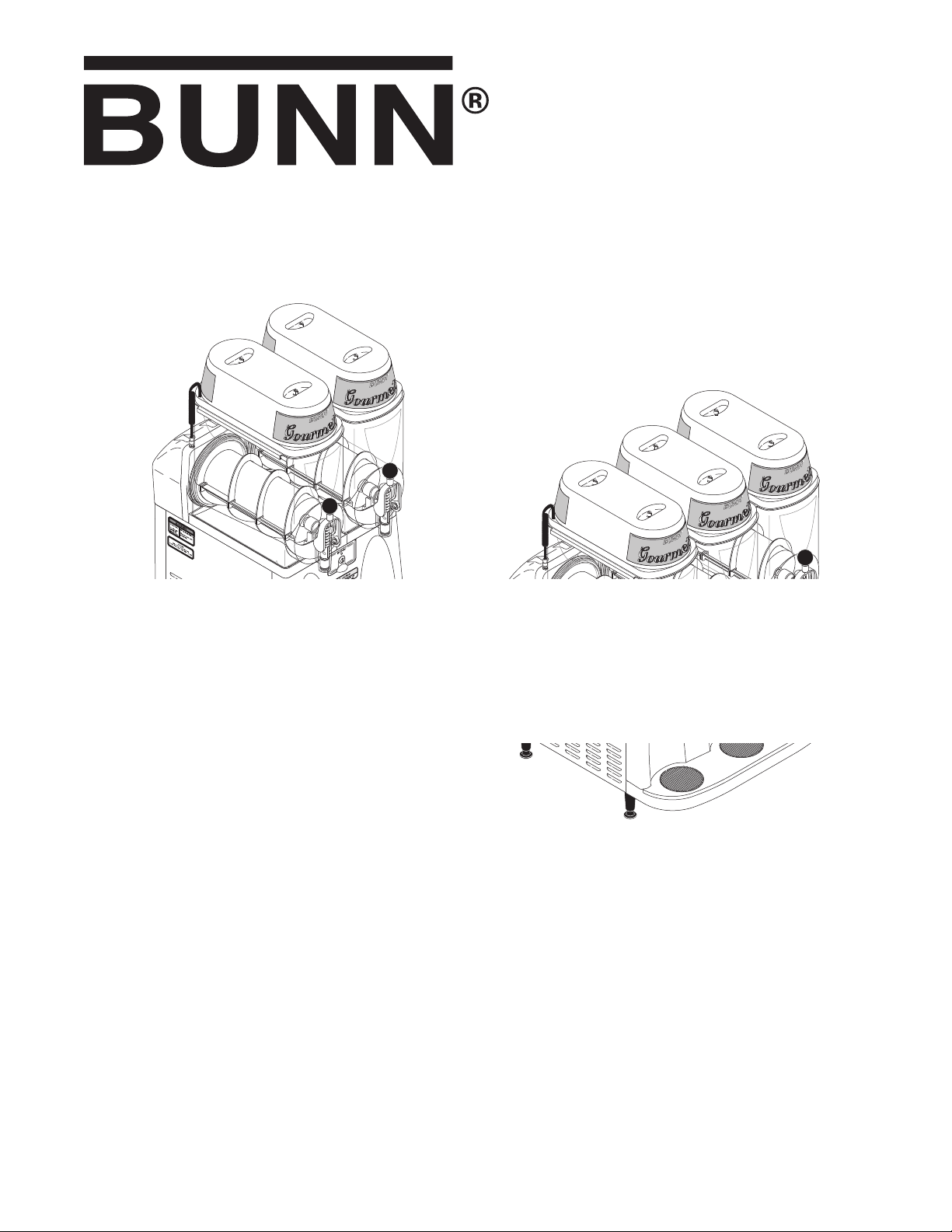

CDS-2

CDS-3

DISCONTINUED VERSION

The information in this manual

is no longer current.

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To obtain the Illustrated Parts Catalog, visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE,

and the quickest way to obtain the catalog. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper

copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

27646.0000N 04/08 ©1997 Bunn-O-Matic Corporation

www.bunnomatic.com

Page 2

INTRODUCTION

This equipment dispenses granita-type and cold liquid drinks on demand from separate hoppers. Operating

controls are accessible only to key operators.

CONTENTS

Introduction & Warranty .....................................................................................2

User Notices .......................................................................................................3

Site Preparation, Electrical Requirements & Initial Setup ...................................5

Operating Controls ..............................................................................................8

Using the Dispenser & Recommendations ........................................................10

Recommended Cleaning ..................................................................................12

Lubrication ........................................................................................................13

Faucet Handles ..................................................................................................14

Auger Assembly ................................................................................................15

Troubleshooting ................................................................................................16

Service ..............................................................................................................21

Refrigerant Flow Diagrams ................................................................................51

Schematic Wiring Diagrams ..............................................................................54

WARRANTY

Bunn-O-Matic Corp. (“Bunn”) warrants the equipment manufactured by it to be commercially free from defects in material and workmanship existing at the time of manufacture and appearing within one year from the

date of installation. In addition:

1.) Bunn warrants electronic circuit and/or control boards to be commercially free from defects in material

and workmanship for three years from the date of installation.

2.) Bunn warrants the compressor on refrigeration equipment to be commercially free from defects in mate-

rial and workmanship for two years from the date of installation.

3.) Bunn warrants that the grinding burrs on coffee grinding equipment will grind coffee to meet original

factory screen sieve analysis for three years from date of installation or for 30,000 pounds of coffee, whichever

comes first.

This warranty does not apply to any equipment, component or part that was not manufactured by Bunn or

that, in Bunn’s judgement, has been affected by misuse, neglect, alteration, improper installation or operation,

improper maintenance or repair, damage or casualty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn

are not authorized to make modifications to this warranty or to make additional warranties that are binding on

Bunn. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (217)

529-6601 or by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the

Buyer shall ship the defective equipment prepaid to an authorized Bunn service location. If Bunn determines, in

its sole discretion, that the equipment does not conform to the warranty, Bunn shall repair the equipment with no

charge for parts during the warranty period and no charge for labor by a Bunn Authorized Service Representative

during the warranty period. If Bunn determines that repair is not feasible, Bunn shall, at its sole option, replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE

SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS

SPECIFIED HEREIN, TO REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND.

In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost

sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

2

27646 060401

Page 3

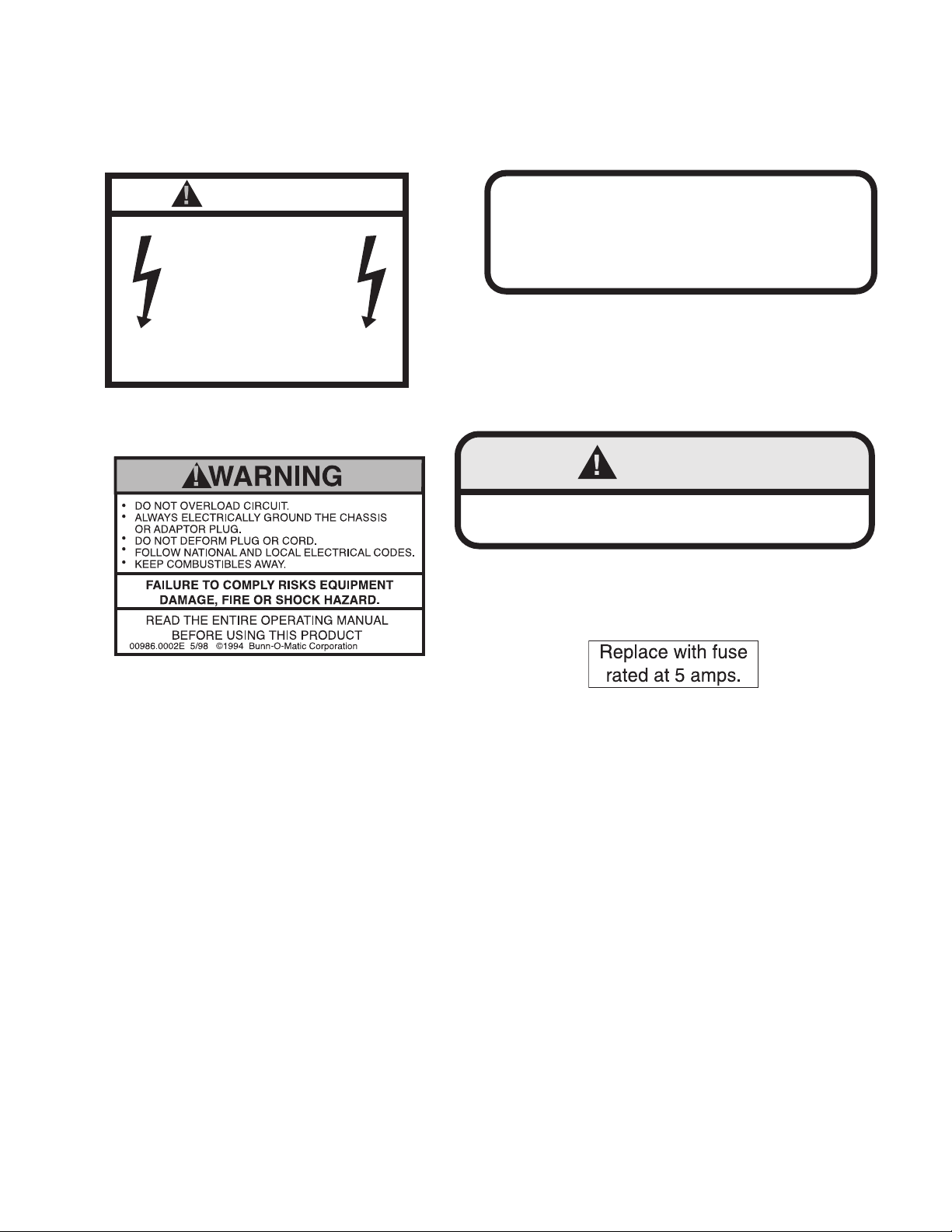

USER NOTICES

HAZARDOUS

VOLTAGE

DISCONNECT FROM

POWER SOURCE

BEFORE REMOVING!

WARNING

CHARGE

Type R22, Amount 8.4 oz

Design Pressures: High 210 Low 32

CAUTION

Instructional video that accompanies every

machine should be viewed before using

Carefully read and follow all notices on the equipment and in this manual. They were written for your protec-

tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels.

27444.0000

12559.0003

00986.0002

28720.0000

27443.0000

3

27646 120601

Page 4

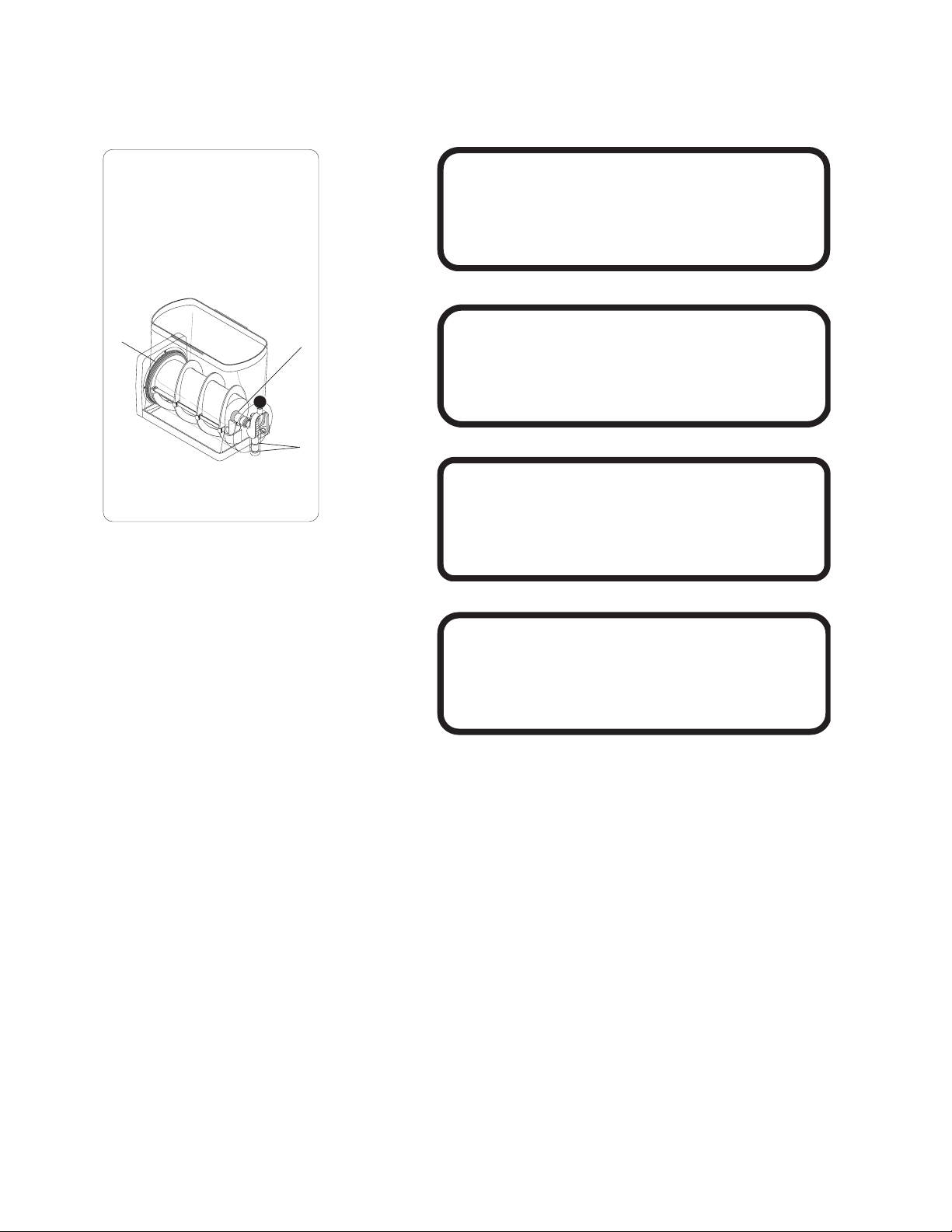

USER NOTICES (CONT.)

CHARGE

Type R22, Amount 8.4 oz

Design Pressures: High 210 Low 32

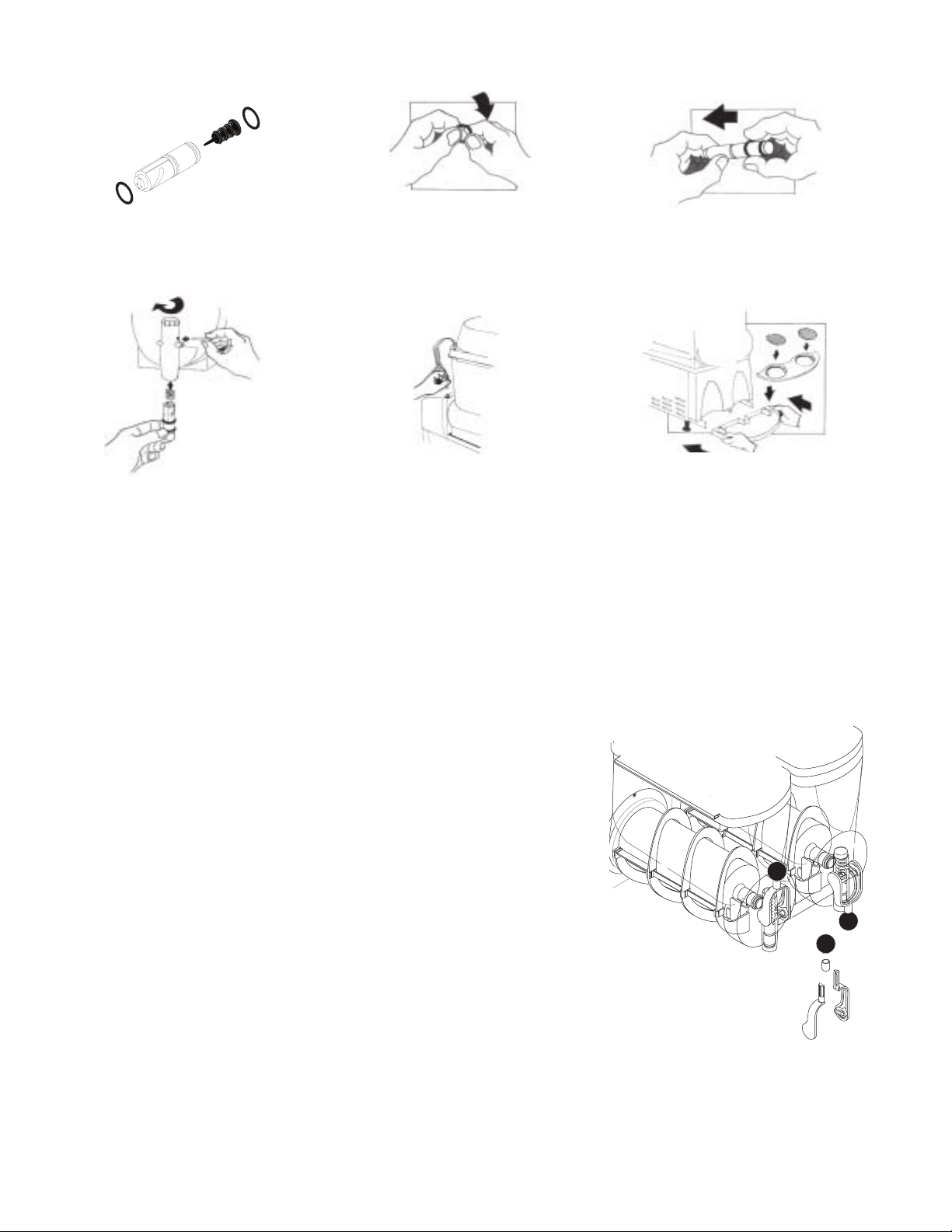

AFTER CLEANING &

BEFORE REASSEMBLY

LUBRICATION

1

2

3

27664.0000D 5/97 © 1996 BUNN-O-MATIC CORPORATION

1. Apply lubricant* on lip of auger seal where

contact is made with cooling drum.

2. Apply lubricant* on outside surface of

cooling drum seal or inside bore of hopper.

3. Apply lubricant* over o-rings on faucet spool

before inserting into faucet housing.

* Refer to product literature for Bunn

approved lubricant.

CHARGE

Type R404A, Amount 25 oz

Design Pressures: High 320 Low 44

CHARGE

Type R404A, Amount 9.5 oz (269 gm)

Design Pressures:

High 215 psi (15 bar) (1.48 MPa)

Low 40 psi (3 bar) (0.28 MPa)

CHARGE

Type R404A, Amount 22 oz

Design Pressures: High 380 Low 52

27444.0000 (CDS-2 Only)

29373.00000 (CDSA-2 Only)

27664.0000

28519.0000 (CDS-3 Prior to S/N CDS0019500)

29424.0000 (CDS-3 S/N CDS0019500 - UP)

4

27646 022500

Page 5

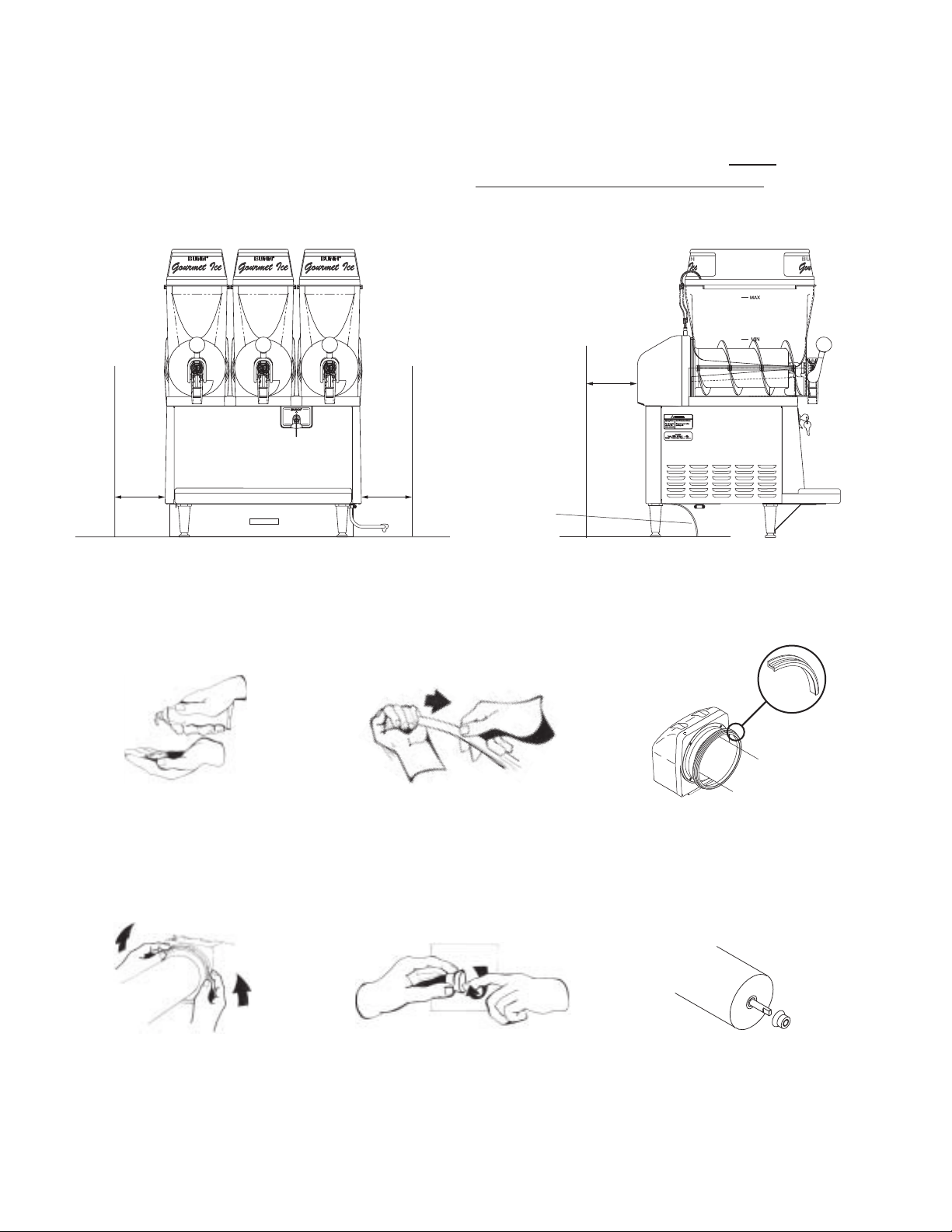

SITE PREPARATION

These dispensers are very heavy. Place them on a sturdy counter or shelf capable of supporting at least 180

lbs for the CDS2 and 250 lbs for the CDS3. They are for indoor use only.

The dispenser must have at least four inches of space behind it. This space is needed for airflow, air filter

removal, and cleaning. Minimal clearance is required between the dispenser sides and the wall or another appli-

ance. The dispenser performs better if not placed near any heating appliance. Leave some space so the dispenser

can be moved for cleaning.

ELECTRICAL REQUIREMENTS

CAUTION – Improper electrical installation will damage components. An electrician must provide electrical

service as specified below.

Model CDS-2, This dispenser has an attached cordset and requires a 2-wire, grounded, individual branch

circuit rated 120 volts ac, 15 amp, single phase, 60 Hz. The mating connector must be a NEMA 5-15R. (Refer

to the dataplate for exact electrical requirements.)

Model CDSA-2, This dispenser has an attached cordset and requires a 2-wire, grounded, individual branch

circuit rated 230 volts ac, 10 amp, single phase, 50 Hz. The mating connector must be a NEMA 5-15R. (Refer

to the dataplate for exact electrical requirements.)

Model CDS-3, This dispenser has an attached cordset and requires a 2-wire, grounded, individual branch

circuit rated 120 volts ac, 20 amp, single phase, 60 Hz. The mating connector must be a NEMA 5-20R. (Refer

to the dataplate for exact electrical requirements.)

Model CDSA-3, This dispenser has an attached cordset and requires a 2-wire, grounded, individual branch

circuit rated 230 volts ac, 15 amp, single phase, 50 Hz. The mating connector must be a NEMA 5-20R. (Refer

to the dataplate for exact electrical requirements.)

NOTE – Bunn-O-Matic does not recommend the use of any extension cord with these dispensers.

5

27646 122200

Page 6

6.0"

MIN.

6.0"

MIN.

6.0"

MIN.

DO NOT REMOVE

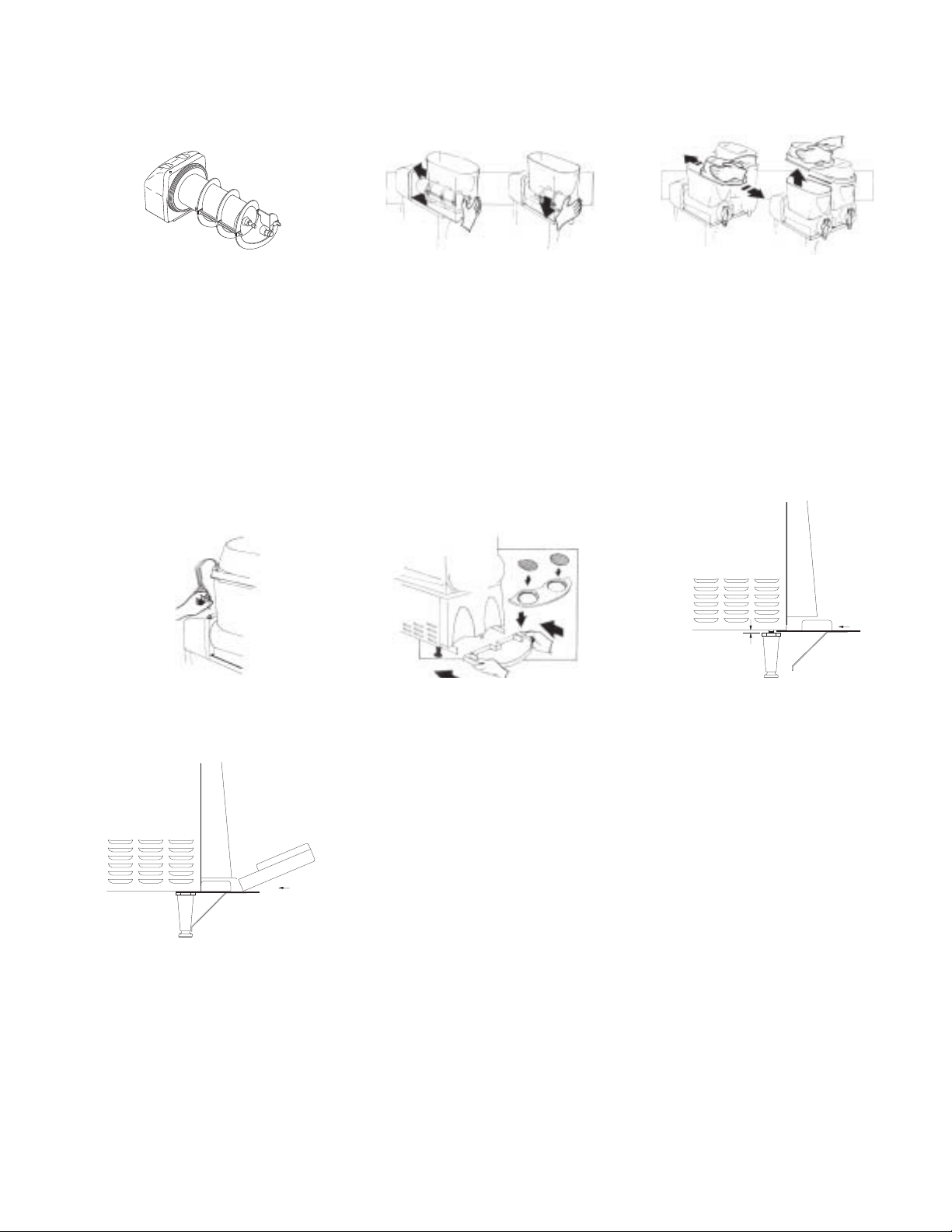

INITIAL SETUP

CAUTION – The dispenser is very heavy! Use care when lifting or moving it. Use at least two people to lift or

move the dispenser.

1. Set the dispenser on the counter where it will be used. The CDS-3 dispenser requires a minimum of 6.0”

air clearance on both sides and at the rear of the dispenser. For optimum performance, do not let warm air

from surrounding machines blow on the CDS-3 and DO NOT REMOVE VINYL DEFLECTOR.

NOTE – The dispenser should be level or slightly lower in front for proper operation.

Vinyl Deflector

2. Remove all shipping material, including the compressor support eye-bolts, the cooling drum supports, the

“Do Not Lift Here” signs from the cooling drums, and the “Rinse Before Using” signs from each hopper.

NOTE – Use BOM M2550.0000 lubricant where specified.

3. Squeeze some lubricant into

hand.

4. Apply a thin film of lubricant to

each cooling drum seal.

5. Install the seal over the flange

at the rear of each cooling drum

as shown.

6. Press the seals firmly into

place.

7. Apply a thin film of lubricant to

the inside of each auger shaft

seal.

6

8. Install the seals on the auger

shafts. Wipe the cooling drums

to remove any lubricant.

27646 022500

Page 7

INITIAL SETUP (CONT.)

APPROXIMATELY .25"

9. Align the auger shaft with the

flat fin of the auger. Push the

augers as far as they will go

and rotate them so the flat fins

are pointing up.

12. Plug in the hopper lid lamp

cables.

10. Thoroughly rinse the hoppers

and install them over the cooling drums with augers. Slide

them into place and push them

down as far as they will go.

As much as possible, keep

lubricant from the inside of the

hoppers. The cleaner you keep

the food zone, the cleaner the

product you’ll serve the customer.

13. (CDS-2 only) Assemble the drip

tray.

11. Set the lids on the hoppers.

Slide front-to-back or lift off for

filling.

14. (CDS-3 only) Loosen the two

front legs by turning counterclockwise to gain approximately .25” clearance. Install

the slots of the support bracket

over threaded studs of the legs

as shown in illustration. Tighten

the legs by turning clockwise to

secure the bracket in place.

15. (CDS-3 only) Install the drip

tray.

7

27646 022500

Page 8

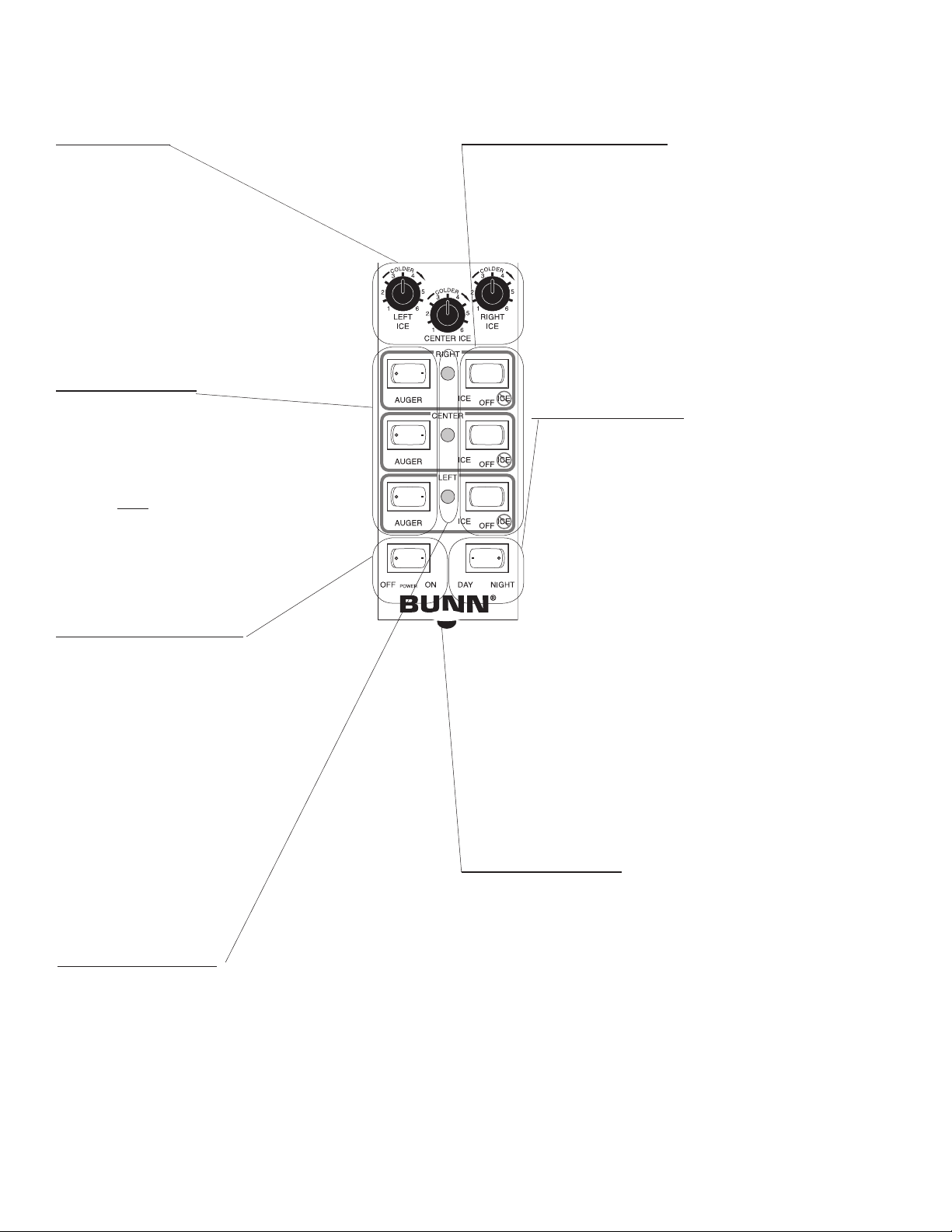

OPERATING CONTROLS

(CDS-3 Controls Illustrated)

ICE CONTROLS

Controls the consistency of the ice in the hoppers

when the DAY/NIGHT switch is in the left “DAY”

position and the ICE/OFF/NO-ICE switch is in the left

“ICE” position.

Turn this control clockwise to produce a

coarser ice or counterclockwise to produce

a finer ice. (The dispenser is set to deliver

satisfactory ice at a 1:00 setting.)

AUGER SWITCHES

”—” – This is the normal operating posi-

tion. Energizes the auger motor when in

the right position. The dispenser will cool

to the ice consistency or liquid temperature

presets only with the switch in the right

position.

“o” – Removes power from the auger motor when in the left position.

ICE/OFF/NO-ICE SWITCHES

ICE – This is the normal operating position. Freezes

and maintains the ice in the selected hopper to the

consistency set with the ICE control(s) when in the left

“ICE” position.

OFF – Provides no cooling to the selected hopper when in the center “OFF” position.

NO-ICE – Maintains cooling yet allows any ice

in the selected hopper to naturally thaw when

in the right “NO-ICE” position.

DAY/NIGHT SWITCH

DAY – This is the normal operating position.

The hoppers’ display lights will glow and the

electronic controls will maintain ice when the

switch is in the left “DAY” position, the individual hoppers’ ICE/OFF/NO-ICE switches are

in the left “ICE” position, and the individual

hoppers’ AUGER switches are in the right “—”

position.

POWER OFF/ON SWITCH

ON – This is the normal operating position. The dis-

penser is electrically energized when the switch is in

the right “ON” position. NOTE – The compressor will

start after a 3 minute 20 second delay on the CDS-2

will be kept cold in all hoppers when this switch is in the

right “NIGHT” position and the AUGER switches are in

the right “—”position.

NIGHT – Use this position at night. The hoppers’ display lights will be out yet the liquid

and a 6 minute 30 second delay on the CDS-3.

OFF – All electrical components of the dispenser are

without power when the switch is in the left “OFF”

position.

NOTE: When Day/Night Timer is used, the Day/Night

Switch in the control drawer must be kept in the “DAY”

position.

POWER INDICATOR (Located on the front of the

drawer)

Glows to show that the POWER OFF/ON Switch is in the

right “ON” position.

STATUS INDICATORS

The electronic controls continuously diagnose the operational status of the dispenser and indicate as listed:

FLASHING 50% ON / 50% OFF – Glows while preparing for coolant to flow to the selected hopper. (Flashes for

10-seconds, then glows steady for two minutes.)

STEADY GLOW – Glows for two minutes before coolant flows to the selected hopper, then continues to glow

while coolant flows.

The electronics also sense and indicate error conditions in the dispenser as listed:

ONE FLASH EVERY FOUR SECONDS – Cooling is needed by the selected hopper, but the auger isn’t turning. Try

placing the AUGER switch for the selected hopper in the right “—” position.

8

27646 022500

Page 9

OPERATING CONTROLS (Cont.)

TWO FLASHES EVERY FOUR SECONDS – A temperature error is being sensed. Call Bunn-O-Matic for Sup-

port.

THREE QUICK FLASHES – Low auger torque is being sensed. Call Bunn-O-Matic for Support.

FOUR QUICK FLASHES – High auger torque is being sensed. Call Bunn-O-Matic for Support.

DAY/NIGHT TIMER

The quartz driven timer offers 24-hour programming with 96 actuators that operate in 15-minute incre-

ments. All actuators can be individually set to the inside or outside position. The timer is located behind the

right side panel.

SETTING TIME

1. Locate marker on the inner (stationary) dial that points to

outer dial. The marker is at approximately the two O’clock

position.

2. Turn outer dial clockwise until the marker is pointing to the

correct time. The clock hands will turn with the outer dial

indicating the same time as the marker. NOTE - the outer dial

has AM and PM settings.

SETTING NIGHT TIME MODE

1. Locate the actuators positioned around the outer dial. Inward

position indicates day time mode and outer position indicates

night time mode.

2. Determine the desired times that night time mode is to begin

and end.

3. Position all actuators between begin and end times in the

outer position.

EXAMPLE: Night Time Mode is 11:00 PM - 7:00 AM

Place the actuator at 11:00 PM to the outside position. Con-

tinue placing actuators to the outside position counterclock

wise around the dial to 7:00 AM. All actuators from 7:00 AM

to 11:00 PM must be in the inside position.

NOTE: For Day/Night Timer to operate, the Day/Night Switch

in the control drawer must be kept in the “DAY” position.

P1948

Shown in

“Night Time”

Mode

P1947

Shown in “Day

Time” Mode

9

27646 022500

Page 10

USING THE DISPENSER FOR GRANITA-TYPE PRODUCTS

1. Slide the lid for the selected hopper to the front or back to gain access to the hopper.

2. Place the premixed liquid product in the selected hopper.

3. Simply press all switches to the center of the control drawer for granita products.

a. Place the POWER OFF/ON switch in the right “ON” position.

b. Place the auger switch for the selected hopper in the right “—” position.

c. Place the DAY/NIGHT switch in the left “DAY” position.

d. Place the ICE/OFF/NO-ICE switch in the left “ICE” position.

4. Wait for the liquid to freeze to the desired consistency.

HINTS – Bunn-O-Matic recommends that the product in the dispenser be thawed each day, usually overnight.

The ice granules get too large and a consistent product is difficult to maintain if left frozen for an extended

period of time. Place the DAY/NIGHT switch in the right “NIGHT” position for a few hours each night. Then

return it to the left “DAY” position when the product has thawed sufficiently. You’ll know it is in the night

position because the hopper lid lights are out.

USING THE DISPENSER FOR COLD LIQUID PRODUCTS

1. Slide the lid for the selected hopper to the front or back to gain access to the hopper.

2. Place the premixed liquid product in the selected hopper.

3. Simply place all switches to the center of the control drawer except the ICE/OFF/NO-ICE switch.

a. Place the POWER OFF/ON switch in the right “ON” position.

b. Place the auger switch for the selected hopper in the right “—” position.

c. Place the DAY/NIGHT switch in the left “DAY” position.

d. Place the ICE/OFF/NO-ICE switch in the right “NO-ICE” position.

4. Wait for the liquid to cool.

10

27646 022500

Page 11

OTHER RECOMMENDATIONS FOR YOUR DISPENSER

• Whetherliquidconcentrateorgranulatedpowder,allproductmustbethoroughlymixedBEFOREaddingit

to the hoppers.

• Forbestresultswithgranita-typeproducts,useonlyproductswithanapparentbrixof12orhigher.Some

products may work with an apparent brix as low as 9. Your experimentation with other products will be the

best guide in this area.

• Keepthepremixedliquidproductrefrigerated.Thisreducescooling/freezingtimeinthedispenser.

• Keepthehopperstopped-offduringpeakservingperiods.Addpremixedliquidproductasitisdispensed.

This reduces the cooling/freezing time and assures you of always having product ready to dispense.

• Keeptheproductlevelinthehoppershigherthantheauger.Airwillbecomeentrappedinthemixtureresult-

ing in a clouded foamy consistency.

• Youmaynditbenecialtoturndowntheicecontrolstokeeptheicegranulesfromgrowingtoolarge.

Refer to the operating controls on page 1-6.

• Someproductsfreezeatalowertemperaturethanothers.Youmaynoticefrostoriceonthehoppers.This

is normal and should not be a concern.

• Humidityintheairmaycausesweatingontheoutsidesurfacesofthehoppers.Thisistobeexpectedand

should not be a concern. The drip trays beneath the hoppers will capture this and cause it to flow to the

lower drip tray for disposal.

• Somenoisesaretobeexpectedduringnormaloperationofthedispenser.Bybecomingfamiliarwiththe

noises made during normal operation, you will be better able to listen for problems.

11

27646 022500

Page 12

RECOMMENDED DAILY CLEANING (SUGAR & ALCOHOL PRODUCTS!)

NOTE – Close the control drawer before proceeding.

1. Empty all product from the hoppers.

2. The driptray should be cleaned as needed for proper presentation of the product.

3. MixapacketofKay-5Sanitizerdilutedwithtwo-gallonsofwarm(120°F)waterforeachhopper.

4. Open the lids and add the solution.

5. Allow the solution to work for about five minutes with the dispenser on the ”NIGHT” position.

6. Drain the sanitizing solution from the hoppers and completely rinse each with clean water.

7. Wash the underside of hopper covers or powder autofill dispensers with hot water and a mild detergent

solution. Rinse all surfaces and apply some commercial sanitizing agent. Do not immerse hopper lids.

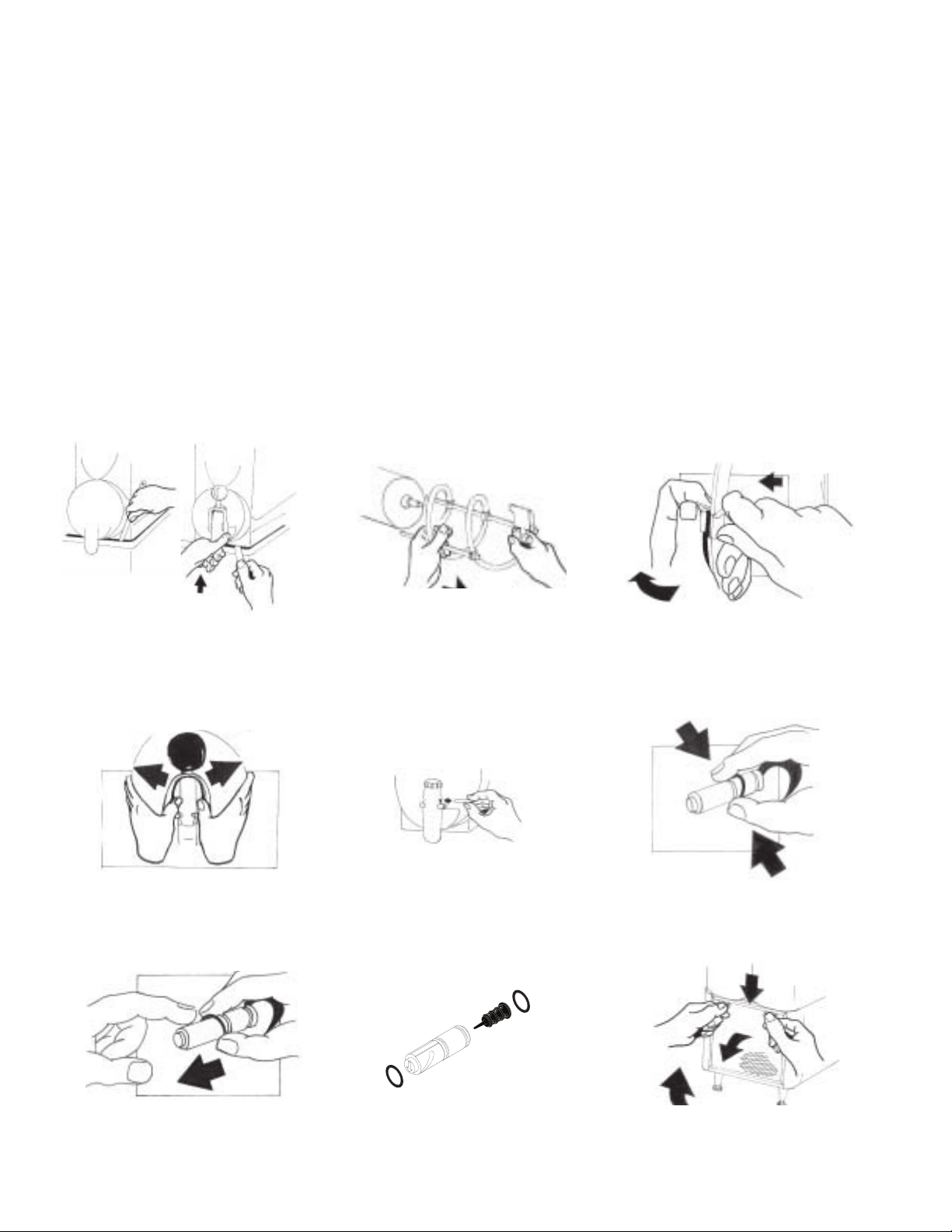

NOTE – The hoppers and augers should be removed and disassembled for cleaning at least once a week using

the procedure below.

RECOMMENDED WEEKLY CLEANING (SUGAR & ALCOHOL BASED PRODUCTS!)

RECOMMENDED DAILY CLEANING (DAIRY PRODUCTS!)

NOTE – Close the control drawer before proceeding.

1. Empty all product from the hoppers. Disconnect the hopper lid cords and remove the lids.

2. Lift the hopper up slightly, then

use a hard plastic utensil to pry

it up. Pull forward to remove.

5. Spread the sides of the dis-

pense handle and pull it off to

remove the faucet pieces.

3. Pull the auger from the cool-

ing drum. Remove the auger

shaft seal from the front of the

cooling drum and the cooling

drum seal from the rear of the

drum.

6. Push the metal pin out through

the faucet. Unscrew the plastic

cap, and push the faucet spool

and spring out the bottom.

4. Disassemble the auger for

cleaning by spreading apart

the latches and removing each

piece.

7. Squeeze the O-rings to free

them from the grooves in the

faucet spool.

8. Roll the O-rings off of the faucet

spool.

9. Remove the black plug from the

faucet spool for cleaning. Do

not use tools to remove this.

12

10. Pull down, then out on the

air filter at the rear of the dispenser.

27646 022500

Page 13

RECOMMENDED WEEKLY CLEANING (CONT.)

11. Wash all components with a wash cloth in mild hot water and detergent solution. Do not immerse hopper

lids.

12. Wash the drums, hopper drip trays, top covers, and outer enclosure using a clean wash cloth that has been

dampened in a mild solution of detergent and hot water.

13. Thoroughly rinse all surfaces with a clean wash cloth that has been dampened with hot water. Wipe dry with

a clean dry wash cloth before reassembling the dispenser.

14. Remove the lower drip tray assembly. Wash and thoroughly rinse all pieces before reinstallation.

NOTE – Although most parts are dishwasher safe, they may be affected by some commercial sanitizing agents.

Do not place the hopper nor hopper lids in a dishwasher.

LUBRICATION

NOTE – Use BOM M2550.0000 lubricant where specified.

1. Squeeze some lubricant into

hand.

4. Press the seals firmly into

place.

7. Align the auger shafts with the

flat fin of the augers. Push the

augers as far as they will go and

rotate them so the flat fins are

pointing up.

2. Apply a thin film of lubricant to

each cooling drum seal.

5. Apply a thin film of lubricant to

the inside of each auger shaft

seal.

8. Thoroughly rinse the hoppers

and install them over the cooling drums with augers. Slide

them into place and push them

down as far as they will go.

As much as possible, keep

lubricant from the inside of the

hoppers. The cleaner you keep

the food zone, the cleaner the

product you’ll serve the customer.

3. Install the seals over the flange

at the rear of the cooling drums

as shown.

6. Install the seals on the auger

shafts. Wipe the cooling drums

to remove any excess lubricant.

9. Set the lids on the hoppers.

13

27646 022500

Page 14

LUBRICATION (cont.)

10. Reinstall the black plug into the

faucet spool. Do not lubricate

the plug.

13. Reinstall the plastic caps,

springs, spools, and metal

pins. Spread the dispense

handles and reinstall them.

NOTE – When reinstalling the faucet

caps, they MUST be twisted as

far as they will go. (Past the

point where it clicks.)

11. Apply a thin film of lubricant to

each faucet spool O-ring.

14. Plug in the hopper lid lamp

12. Slide the O-rings onto the

spools.

15. Assemble the drip tray.

cables.

NOTE – The faucet spool plugs, faucet O-rings, cooling drum hopper seals,

and auger shaft seals are to be replaced whenever they appear worn

or damaged. Bunn-O-Matic recommends their replacement at least

every six-months. Refer to page 24 for replacement instructions.

FAUCET HANDLES

Dispensing from the hoppers will occur when the faucet handles are

installed with the handles in the upright position. (shown, left hopper)

Dispensing from the hoppers will not occur when the handles are installed upside-down. (shown, right hopper) You may consider this handle

position when the product in the hoppers is not yet ready to serve. Just

spread the handles or disassemble them as shown, and install them upside

down.

DISASSEMBLY

1. Unscrew the balls from the handle assemblies. Turn them in a counterclockwise direction until they are no longer attached to the handles.

2. Remove the metal sleeves from the assemblies.

3. Separate the two halves of the handles and remove them from the

faucet bodies.

ASSEMBLY

1. Place the two halves of the handles on the faucet bodies. Check that the faucet dowel pins are in place all

the way through the faucet bodies. The dowel pins must be captured by the keyholes in the handle halves.

2. Place the metal sleeves over the threads and install the balls by turning them in a clockwise direction.

14

27646 122200

Page 15

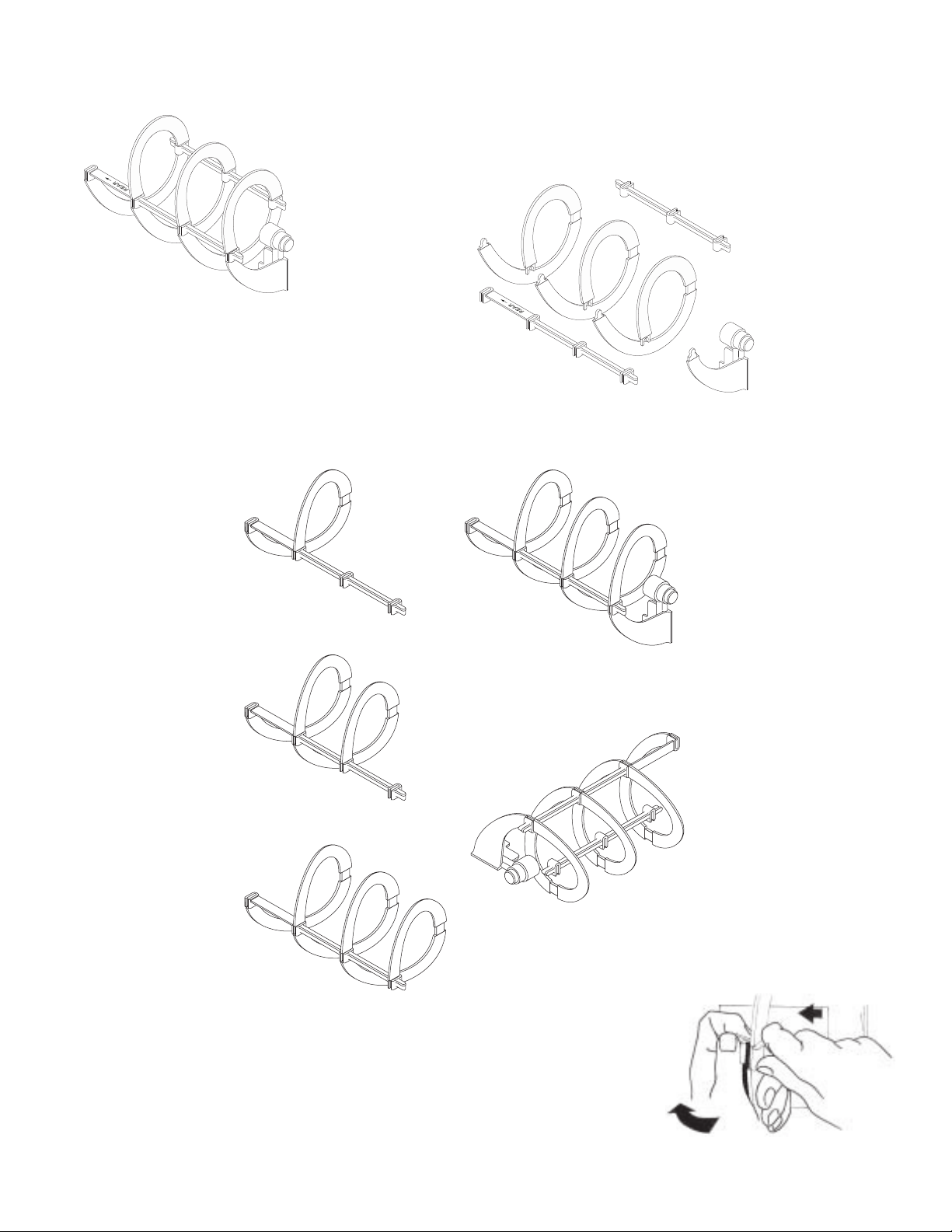

AUGER ASSEMBLY & DISASSEMBLY (EARLY AUGERS ONLY)

The augers may look intimidating at first glance. But there are really just a

few pieces snapped together. Please familiarize yourself with this procedure. It’ll

make cleaning and routine maintenance easier. The augers should be taken apart

for cleaning and then reassembled for use.

Short Auger Latch

Auger Sections (3 req’d.)

ASSEMBLY

1. Snap one of the auger sections

to the long auger latch.

2. Snap another auger section

in place.

Long Auger Latch

Auger Nose

4. Snap the auger nose onto the

last section installed.

5. With the long auger latch on

top, place the short auger

latch inside the augers and

snap it onto the assembly.

3. Snap the third auger

section in place.

DISASSEMBLY

1. Firmly pull the auger section connections apart at each slot in the long auger latch.

2. Firmly pull the connection between the auger section and auger nose apart.

3. Separate the slots in the short auger latch as you remove the auger sections.

15

27646 022500

Page 16

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection,testing,andrepairofelectricalequipmentshouldbeperformedonlybyqualiedserviceperson-

nel.

• Allelectroniccomponentshave120voltacand/orlowvoltagedcpotentialontheirterminals.Shortingof

terminals or the application of external voltages may result in board failure.

• Intermittentoperationofelectroniccircuitboardsisunlikely.Boardfailurewillnormallybepermanent.If

an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Keepawayfromcombustibles.

WARNING – • Exerciseextremecautionwhenservicingelectricalequipment.

• Unplugthedispenserwhenservicing,exceptwhenelectricaltestsarespecied.

• Followrecommendedserviceprocedures

• Replaceallprotectiveshieldsorsafetynotices

PROBLEM

Doesn’t work

(Switches do nothing, auger not

turning, no hopper lid lights, no fan,

no compressor sound.)

Hopper Lid Lights not on

PROBABLE CAUSE

1. No power or incorrect voltage to

the dispenser

2. ON/OFF Switch

1. DAY/NIGHT Switch

REMEDY

(A) Check for proper voltage at the

wall outlet.

(B) Check circuit breakers or fuses.

(A) The ON/OFF Switch must be in

the “ON” position.

(B) Refer to Service - Dispenser ON/

OFF Switch for testing procedures.

See page 37.

(A) The DAY/NIGHT Switch must be

in the “DAY” position.

(B) Refer to Service - DAY/NIGHT

Switch for testing procedures. See

page 36.

2. Lamp Cord Assembly

16

(A) The lamp cord must be plugged

into the lamp cord connector.

(B) Refer to Service - Lamp Cord

Assembly for testing procedures.

See page 42.

27646 122200

Page 17

TROUBLESHOOTING (cont.)

PROBLEM

PROBABLE CAUSE

REMEDY

Hopper Display Lights not on

(cont.)

Auger Motor won’t turn

3. Circuit Breaker

4. Lamps

5.Transformer

6. Lamp Holder/Socket Assy

1. Auger ON/OFF Switch(es)

(A) The circuit breaker must not be

tripped.

(B) Refer to Service - Circuit Breaker

for testing procedures. See page

27.

Remove the lamps and check for

continuity across the base and tip.

Replace if necessary.

Refer to Service - Transformer for

testing procedures. See page 49.

Refer to Service - Lamp Holder/Sock-

et Assembly for testing procedures.

See page 44.

(A) The auger switch must be in the

“ON” position.

Fan not spinning (With adjustment

Board L.E.D.s ON steadily for two

minutes)

Fan spins after compressor shuts

off

2. Auger Motor Capacitor(s)

3. Auger Motor(s)

1. Fan Motor

1. Time Delay

(B) Refer to Service - Auger ON/OFF

Switch(es) for testing procedures.

See page 26.

Refer to Service - Auger Motor

Capacitor(s) for testing procedures.

See page 23.

Refer to Service - Auger Motor(s) for

testing procedures. See page 22.

Refer to Service - Fan Motor for test-

ing procedures. See page 39.

The fan motor will run for approximately two minutes after compressor

shuts off.

17

27646 122200

Page 18

TROUBLESHOOTING (cont.)

PROBLEM

PROBABLE CAUSE

REMEDY

Compressor not running

(With Adjustment Board L.E.D.s ON

steadily for two minutes)

1. Power cord

2. Fuse

3. Contactor

4. Electronic Control

5. Compressor Start Relay

6. Thermal Overload Protector

The dispenser must not be connected

with an extension cord. Refer to

Electrical Requirements.

Refer to Service - Fuse and Fuse

Holder for testing procedures. See

page 40.

Refer to Service - Contactor for test-

ing procedures. See page 34.

Refer to Service - Electronic Control

for testing procedures. See page

38.

Refer to Service - Compressor Start

Relay for testing procedures. See

page 28 (CDS-2) or 31 (CDS-3).

Refer to Service - Compressor Ther-

mal Overload Protector for testing

procedures. See page 28 (CDS-2)

or 31 (CDS-3).

Compressor runs but will not cool

(With adjustment Board L.E.D.s

flashing once every 4 seconds)

Compressor runs but will not cool

(With adjustment Board L.E.D.s

flashing twice every 4 seconds)

Compressor runs but will not cool

(With adjustment Board L.E.D.s

flashing 3, or 4 times every 4

seconds)

7. Compressor Start Capacitor

8. Compressor

1. Auger not turning

1. Temperature Sensor Assembly

1. Torque Sensor Circuit Board

Refer to Service - Compressor Start

Capacitor for testing procedures. See

page 28 (CDS-2) or 31 (CDS-3).

Refer to Service - Compressor for

testing procedures. See page 28

(CDS-2) or 31 (CDS-3).

Refer to Troubleshooting - Auger Mo-

tor Won’t Turn on previous page.

Refer to Service - Temperature Sensor Assembly for testing procedures.

See page 47.

Refer to Service - Torque Sensor

Circuit Board for testing procedures.

See page 48.

18

27646 122200

Page 19

TROUBLESHOOTING (cont.)

PROBLEM

Compressor runs but will not cool

(With adjustment Board L.E.D.s

flashing 3, or 4 times every 4

seconds) (cont.)

Product Won’t Freeze

PROBABLE CAUSE

2. Air Filter or Condenser

3. Refrigerant

1. DAY/NIGHT Switch

2. Sugar content of product

3. Voltage Divider

REMEDY

The air filter and condenser MUST be

cleaned regularly. Any dust buildup

will affect cooling ability.

Have a qualified service person check

the refrigerant charge.

(A) The DAY/NIGHT Switch must be

in the “DAY” position.

(B) Refer to Service - DAY/NIGHT

Switch for testing procedures. See

page 36.

Bunn recommends the use of products with an apparent brix of 12 or

higher.

Refer to Service - Voltage Divider for

testing procedures. See page 50.

Product freezes but ice granules are

too fine or too large

Dispenser is making unusual noises.

(Some noises are a normal occurance

with this type of device. You need to

become familiar with those that are

normal, to determine when they have

become unusual.)

1. Ice adjustment

2. Sugar content of product

1. Lubrication

2. Cooling Drum(s)

Turn the Ice control for the desired

hopper a small amount clockwise

to increase the ice granule size or

counterclockwise to decrease the

ice granule size.

Adjust the sugar content of the

product. Increasing the apparent

brix results in finer ice granules.

Decreasing the apparent brix results

in larger ice granules.

Always lubricate the dispenser as

directed in this manual before reassembling and using the dispenser.

Use the cooling drum support to

determine that the auger shaft is still

the proper distance from the hopper

drip tray. The cooling drum may be

gently lifted to return it to the necessary horizontal position. Refer to

Service - Cooling Drum Alignment.

See page 35.

19

27646 122200

Page 20

TROUBLESHOOTING (cont.)

PROBLEM

Dispenser is making unusual noises.

(Some noises are a normal occurance

with this type of device. You need to

become familiar with those that are

normal, to determine when they have

become unusual.) (cont.)

Product is leaking into the inside of

the drum.

PROBABLE CAUSE

3. Fan Motor

4. Auger Motor(s)

1. Worn Shaft

2. Worn Seals

REMEDY

Remove the air filter at the rear of the

dispenser and listen for fan motor

noise. Replace the motor if excessively noisy.

Place the Auger switches in the “ON”

position and the ICE/OFF/NO-ICE

switches in the “OFF” position. Listen

for auger motor noise. Replace the

motor if excessively noisy.

Replace Shaft. Refer to Service - Au-

ger Shaft Assembly. See page 24.

Replace Cooling Drum Seal. Refer

to Service - Auger Shaft Assembly.

See page 24.

20

27646 122200

Page 21

SERVICE

This section provides procedures for testing and replacing various major components used in this dispenser

should service become necessary. Refer to Troubleshooting for assistance in determining the cause of any prob-

lem.

WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified service

personnel. The dispenser should be disconnected from the power source when servicing, except when electrical

tests are required and the test procedure specifically states to connect the dispenser to the power source.

COMPONENT ACCESS

WARNING - Disconnect the dispenser from the power source before the removal of any panel or the replacement

of any component.

All components are accessible by removal of the auger motor cover, lower drip tray, front cover and the left

and right side covers.

Refer to the contents listing for component location.

Contents

Auger Motors ....................................................................................................22

Auger Motor Capacitors ....................................................................................23

Auger Shaft Assembly .......................................................................................24

Auger ON/OFF Switches ....................................................................................26

Circuit Breaker ..................................................................................................27

Compressor (CDS-2) ........................................................................................28

(Compressor, Compressor Start Capacitor, Compressor Start Relay, Thermal Overload Protector)

Compressor (CDS-3) ........................................................................................31

(Compressor, Compressor Start Capacitor, Compressor Start Relay, Thermal Overload Protector)

Contactor ..........................................................................................................34

Cooling Drum Alignment ...................................................................................35

Day/Night Switch ..............................................................................................36

Dispenser ON/OFF Switch .................................................................................37

Electronic Control .............................................................................................38

Fan ....................................................................................................................39

Fuse and Fuse Holder ........................................................................................40

ICE/OFF/NO ICE Switch .....................................................................................41

Lamp Cord Assembly ........................................................................................42

Lamp Cord Connector .......................................................................................43

Lamp Holder/Socket Assembly .........................................................................44

L.E.D./Adjustment Board ...................................................................................45

Solenoids ..........................................................................................................46

Temperature Sensor Assembly .........................................................................47

Torque Sensor Circuit Board .............................................................................48

Transformer .....................................................................................................49

Voltage Divider ..................................................................................................50

Coolant Schematics ..........................................................................................51

Electrical Schematics ........................................................................................54

21

27646 122200

Page 22

SERVICE(CONT.)

AUGER MOTORS

FIG. 1 AUGER MOTORS

P1341

Location

The auger motors are located at the upper rear of

the dispenser chassis inside the auger motor covers.

4. Disconnect the auger motor terminal from the

terminal on the main wiring harness.

5. Remove the three remaining #8 locking screws

securing the auger motor mounting bracket to

cooling drum mounting bracket.

6. Remove motor with mounting bracket, drip tray, split

pin and torsion spring bearing as an assembly.

NOTE: When removing or installing the motor be sure

the split pin in the motor shaft is turned to a position

that will clear the torque sensor circuit board.

7. Install new motor with mounting bracket, drip tray,

split pin and torsion spring bearing using three #8

locking screws onto the cooling drum bracket.

8. Install the auger motor capacitor on the lower right

side of the auger mounting bracket, using the remaining #8 locking screw.

9. Connect the auger motor terminal to the terminal

on the main wiring harness.

10. Refer to Fig. 2 when reconnecting the wires.

Test Procedures

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the motor to be tested.

3. With a voltmeter, check the voltage across the

white/brown wire for the left motor, the white/blue

wire for the right motor, or the grey wire for the

center motor and the white/black wire. Place the

appropriate auger switch in the “-” (“ON”) position.

Connect the dispenser to the power supply. The

indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt models.

4. Disconnect the dispenser from the power supply.

If voltage is present as described, replace the motor.

If voltage is not present as described, refer to the Wiring

Diagram and check the dispenser wiring harness.

Removal and Replacement

1. Remove the two #8 locking screws securing the

auger motor cover to the cooling drum mount assembly.

2. Remove the cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right

side of the auger motor mounting bracket securing

the auger motor run capacitor. Set capacitor aside

with wires attached.

22

FIG. 2 AUGER MOTOR TERMINALS

P1321

27646 022500

Page 23

SERVICE (CONT.)

AUGER MOTOR CAPACITOR

FIG. 3 AUGER MOTOR CAPACITORS

P1341

Location:

The auger motor capacitors are located on the lower

right side of the auger motor mounting bracket inside

the auger motor covers.

Removal and Replacement

1. Remove the two #8 locking screws securing the

auger motor cover to the cooling drum mount

assy.

2. Remove the cover and set aside for reassembly.

3. Disconnect the wires from the auger motor capacitor terminals.

4. Remove the #8 locking screw on the lower right

side of the auger motor mounting bracket securing

the auger motor capacitor.

5. Install a new capacitor on the lower right side of

the auger mounting bracket and secure with a #8

locking screw.

6. Reconnect the wires to the capacitor terminals.

7. Refer to Fig. 4 when reconnecting the wires.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the capacitor to be

tested.

3 With a voltmeter, check for voltage across the

white/blue wire on the right capacitor, the white

/brown wire on the left capacitor, or the grey wire

on the center capacitor and the white/black wire

on the auger motor terminal. Place the appropriate

auger switch in the “-” (“ON”) position. Connect the

dispenser to the power source.The indication must

be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagram and the dispenser wiring harness.

5. Check for continuity across the auger motor capacitor terminals.

P1324

FIG. 4 AUGER MOTOR CAPACITOR TERMINALS

If continuity is present as described, reconnect the

wires to the auger motor capacitor.

If continuity is not present as described, replace the

auger motor capacitor.

23

27646 022500

Page 24

SERVICE (cont.)

AUGER SHAFT ASSEMBLY

Auger Shaft Assy

Auger Shaft Bushing

Cooling Drum Seal

Auger Shaft Seal

Hopper Drum Seal

P1758

FIG. 5 AUGER SHAFT ASSEMBLY

Location:

The Auger Shaft Assembly is located in each of the

cooling drums.

Removal and Replacement:

1. Drain, remove and clean hopper; refer to the Rec-

ommended Daily Weekly Cleaning Section of this

manual, page 12, for proper cleaning procedures.

Discard the auger shaft seal, hopper/drum seal and

faucet spool o-rings.

2. Remove the #8 locking screws securing auger

motor cover to the cooling drum mount assembly;

remove cover and set aside for reassembly.

3. Remove the #8 locking screw on the lower right side

(viewed from front) of the auger motor mounting

bracket securing the auger motor run capacitor. Set

capacitor aside with wires attached.

4. Disconnect the auger motor terminal from the

terminal on the main wiring harness.

5. Remove the remaining #8 locking screws securing

the auger motor mounting bracket to cooling drum

mounting bracket.

6. Remove motor with mounting bracket, drip tray (if

present) split pin and torsion spring bearing as an

assembly.

NOTE - When removing or installing motor and shaft

assemblies, be sure the split pins are turned to a position that will clear the torque sensor circuit board.

7. Pull the auger shaft assembly straight out of cooling drum. Inspect the shaft for abnormal wear or

scoring.

8. From the front of dispenser, remove the seal and

blue bushing from cooling drum and discard

them.

9. Clean seal and busing surfaces of the cooling

drum very thoroughly. All old lubricant must be

removed.

10. Refer to Fig 6A and slip new blue bushing into

cooling drum. Lightly lube I.D. of bushing

with #M2550.0000 “Lubri-lm” provided in Kit

#28106.0000 (CDS-2) or #28106.0001 (CDS-3). Do

not use anything such as a cotton swab that might

leave lint or unravel. DON NOT GET ANY LUBE ON

THE SEAL COUNTERBORE SURFACE.

11. Lightly lube I.D. of new cooling drum seal with

#M2550.0000, provided in kit. Use care not to get

any lube on O.D. of seal. Place seal on insertion

tool #28395.0000, as shown in Fig. 6B. Make sure

open face of seal is toward cooling drum.

12. Push seal into bore until it is firmly seated; remove

tool.

13. Clean the auger shaft assembly, then wipe a small

amount of #M2550.0000 “Lubri-film” (provided in

kit) over the first two inches of the front end of the

shaft.

14.Place a small amount of #29563.0000 “Krytox”

lubricant (provided in kit in a plastic cap) on the

end of the motor shaft (about 1 1/2”) and a thin

film in the groove. Install auger shaft assembly onto

the motor shaft. See Fig. 6C. Do not use too much

“Krytox”lubricant.

NOTE - This is the only place “Krytox” lubricant is

used.

15. Assemble motor/shaft assembly as shown in Fig.

6C, then install assembly into cooling drum. Make

sure the pins do not hit the sensor board and cooling drum seal is not dislodged as the shaft passes

through.

16. Secure motor and capacitor to the cooling drum

mounting bracket. Install rear motor cover.

17. Refer to Initial Setup for hopper assembly and

installation procedures. Be sure to use new hopper/drum seal, auger shaft seal and faucet spool

o-rings when reassembling.

24

27646 122200

Page 25

SERVICE (cont.)

AUGER SHAFT ASSEMBLY(cont.)

Lightly lube the bushing I.D.

with M2550.0000 “LubriFilm”

Do NOT get any Lube on this

surface

Lube about 1 1/2” of

shaft and in the groove

with#29563.0000“Krytox” Lubricant

Auger Shaft Assy

Lube about 2.0” of shaft

with #M2550.0000 “Lubri-film”

FIG. 6A AUGER SHAFT BUSHING

Open face of seal away

from tool

Cooling Drum Seal

Seal Insertion Tool

P1759

P1761

FIG. 6C MOTOR/SHAFT ASSEMBLY

FIG. 6B COOLING DRUM SEAL

P1760

25

27646 122200

Page 26

SERVICE (cont.)

AUGER ON/OFF SWITCHES

P1343

FIG. 7 AUGER ON/OFF SWITCHES

Location:

The auger switches are located inside the dispenser

drawer.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the white/green wire from the switch

to be tested and white/black wire from contactor

located on the outside bottom of the component

bracket .

3. With a voltmeter, check the voltage across the white/

green and the white/black wires and the “ON/OFF”

switch in the “ON” position. Connect the dispenser

to the power source. The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt models.

4. Disconnect the dispenser from the power source.

If continuity is present as described, the auger switch

is operating properly.

If continuity is not present as described, replace the

auger switch.

Removal and Replacement:

1. Pull the dispenser drawer out until the drawer hits

the drawer stop. Using a screwdriver gently pry up

on the drawer stop and remove the drawer from

the dispenser.

2. Remove the four #8-32 locking screws securing

the switch panel to the drawer.

3. Lift the switch panel with wires and L.E.D./adjustment board out as an assembly.

4. Turn switch panel over and remove the wires from

the auger switch that is to be replaced.

5. Compress the clips on the back of the control panel

and gently push switch through the opening.

6. Push the new switch into the opening, with the “o”

on the switch to the outside, until the clips snap

into position.

7. Reconnect the wires to the switch. Refer to Fig. 8

when reconnecting wires.

8. Position the switch panel inside the drawer and

secure with four #8-32 locking screws.

9. Reinstall drawer.

If voltage is present as described, reconnect the white/

black wire to the contactor and proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagram and check the dispenser wiring harness.

5. Remove the white/blue wire from the right auger

switch, the white/brown wire from the left auger

switch, or the grey wire from the center auger

switch.

6. With the auger switch to be tested in the “ON”

position check for continuity across the terminals.

Continuity must not be present when the switch is

in the “OFF” position.

26

FIG. 8 AUGER SWITCH TERMINALS

P1336

27646 122200

Page 27

R22

SERVICE (cont.)

CIRCUIT BREAKER

5. Push the new circuit breaker into the opening in

the component bracket until the clips snap into

position.

6. Reconnect the wires to the circuit breaker.

7. Position the component bracket in chassis and

secure with four #8-32 locking screws.

8. Refer to Fig. 10 when reconnecting the wires.

RED from Transformer

FIG.9CIRCUITBREAKER

P1342

Location:

The circuit breaker is located inside the dispenser

on the upper left side of the component bracket.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Remove the wires from the circuit breaker.

3. Check for continuity between the terminals. Continuity must be present between the terminals.

If continuity is present as described the circuit breaker

is functioning properly.

If continuity is not present as described, press the reset

button and repeat step #3, if continuity is not present

as described, replace the circuit breaker.

Removal and Replacement:

1. Remove the four #8-32 locking screws securing

the component bracket to the chassis.

2. Tip the top of the component bracket forward far

enough to allow access to the rear of the circuit

breaker.

3. Remove the wires from the circuit breaker.

4. Compress the clips on the back side of the component bracket and gently push the circuit breaker

through the opening in the component bracket.

RED from Main Harness

P1330

FIG.10CIRCUITBREAKERTERMINALS

27

27646 122200

Page 28

R22

R22

R22

SERVICE (cont.)

COMPRESSOR & COMPONENTS (CDS-2)

FIG. 11 COMPRESSOR ASSY

Location:

The compressor assy is located inside the front

of the dispenser chassis.

1 4

3 2 5 6

120V COMPRESSORS

P1342

Test Procedures:

WARNING: The compressor start capacitor must be

properly discharged before proceeding.

Compressor Start Relay: Refer to FIG. 12

1. Disconnect the dispenser from the power source.

2. Remove compressor terminal cover retainer (6)

and compressor terminal cover (5).

3. Disconnect the black wire from the thermal overload protector (3) and white/black wire from the

compressor start relay (1).

4. With a voltmeter, check voltage across the black

wire and the white/black wire and the ON/OFF

switch in the “ON” position, DAY/NIGHT switch in

the “DAY” position and the ICE/OFF/NO ICE switch

in the “ICE” position. Connect the dispenser to the

power source. The indication must be 120 volts ac

for two wire 120 volt models or 230 volts ac for

two wire 230 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #6.

If voltage is not present as described, refer to the Wiring

Diagram and check the dispenser wiring harness.

6. Disconnect the two black wires from the compressor start capacitor.

7. Remove relay from the compressor.

8. Check for continuity across the upper left terminal

and the right pin socket on the rear of the relay.

If continuity is present as described, the compressor

start relay is operating properly.

4

3

1

5 6 7

230V COMPRESSORS

FIG. 12 COMPRESSOR ELECTRICAL COMPONENTS

1. Compressor Start Relay

2. Overload Protector Retainer

3. Thermal Overload Protector

4. Compressor Start Capacitor

5. Compressor Terminal Cover

6. Compressor Terminal Cover Retainer

7. Compressor Run Capacitor

P1344

If continuity is not present as described, replace relay.

Compressor:

1. With the compressor start relay (1) removed, disconnect the black wire from the compressor.

2. Check for continuity across the terminal on the

compressor and the left pin on the compressor.

If continuity is present as described, the electrical part

of the compressor is operating properly.

If continuity is not present as described, replace the

compressor.

Thermal Overload Protector:

1. Check for continuity across the terminals on the

thermal overload protector (3).

If continuity is present as described, the thermal overload protector is operating properly.

If continuity is not present as described, replace the

thermal overload protector.

28

27646 122200

Page 29

SERVICE (cont.)

COMPRESSOR & COMPONENTS (CDS-2) (cont.)

Compressor Start Capacitor:

1. Check for continuity across the terminals on the

compressor start capacitor.

If continuity is present as described, the start capacitor

is operating properly.

If continuity is not present as described, replace the

capacitor.

NOTE: If all the electrical components are operating

properly and the compressor does not operate, there is an

internal mechanical problem. Replace the compressor.

11. Position the component bracket in the chassis and

secure with four #8-32 locking screws.

12. Reconnect tubes from the condenser and the accumulator to the compressor.

13. Evacuate the system.

NOTE: When replacing the compressor it is recommended that the dryer also be replaced.

14. Recharge 120V system with 8.4 oz. of Type R22

refrigerant. Design Pressures: High 210 - Low 32

Recharge 230V system with 9.5 oz. of Type 404A

refrigerant. Design Pressures: High 215 - Low 40

NOTE: The charging of the system must be done by a

licensed refrigeration repair person.

Removal and Replacement:

Compressor Assy:

NOTE: Before removal of any refrigeration component

the refrigerant in the system must be reclaimed by a

licensed refrigeration repair person.

1. Disconnect the tubes from the condenser and the

accumulator.

2. Disconnect the compressor wiring harness from the

dispenser main wiring harness.

3. Remove the four .25-20 keps nuts and washers securing the compressor to the chassis. Set nuts and

washers aside for reassembly.

4. Remove the four #8-32 locking screws securing the

component bracket to the dispenser chassis.

5. Disconnect the wires from the circuit breaker, fuse

holder, transformer, electronic control and the contactor.

6. Remove component bracket with circuit breaker, fuse

holder, transformer, electronic control and contactor

as an assembly. Set component bracket and screws

aside for reassembly.

7. From the right side of the dispenser lift the compressor assembly over the four studs in the chassis and

remove compressor.

8. Install new compressor over the four studs in the

dispenser chassis with the fill valve to the left side

of the dispenser.

9. Secure compressor to the dispenser chassis using

four .25-20 keps nuts and washers.

10. Reconnect the wires to the components on the component bracket and plug the main wiring harness into

the electronic control.

NOTE: When reconnecting wires refer to Fig. 10 for

circuit breaker, Fig. 34 for fuse holder, Fig. 51 for transformer and Fig. 22 for contactor.

Compressor Start Capacitor: Refer to FIG. 12

WARNING: The compressor start capacitor must be

properly discharged before proceeding.

1. Remove terminal cover retainer (6) and terminal

cover (5). Set aside for reassembly.

2. Disconnect the two leads from the capacitor.

3. Pry the end of the capacitor mounting bracket off of

the boss on the capacitor and remove the capacitor.

4. Install new capacitor on the capacitor mounting

bracket.

5. Refer to Fig. 13 and reconnect the wires to the capacitor.

6. Reinstall terminal cover (5) and cover retainer (6).

120V DISPENSERS

230V DISPENSERS

FIG. 13 COMPRESSOR START CAPACITOR

29

TERMINALS

27646 122200

P1340

Page 30

SERVICE (cont.)

COMPRESSOR & COMPONENTS (CDS-2) (cont.)

Compressor Start Relay: Refer to FIG. 12

1. Remove the terminal cover retainer (6) and the

terminal cover (5)

WARNING: The compressor start capacitor must be

properly discharged before proceeding.

2. Disconnect the wires from the compressor start

relay.

3. Pull relay (1) off of the compressor pins and discard.

4. Push new relay onto the compressor pins.

5. Refer to Fig. 14 and reconnect the wires.

6. Reinstall terminal cover (5) and cover retainer (6).

Compressor Thermal Overload Protector (230V):

Refer to FIG. 12

1. Remove terminal cover retainer (6) and terminal

cover (5).

2. Disconnect the black wire from the thermal overload

protector.

3. Pull thermal overload protector off of the compressor

pin and discard.

4. Push new thermal overload protector onto the compressor pin.

5. Refer to Fig. 15 and reconnect the wire.

6. Reinstall terminal cover (5) and cover retainer (6).

120V DISPENSERS

120V DISPENSERS

230V DISPENSERS

P1338

FIG. 14 COMPRESSOR START RELAY

TERMINALS

Compressor Thermal Overload Protector (120V): Refer

to FIG. 12

1. Remove terminal cover retainer (6) and terminal

cover (5).

2. Disconnect the wire from thermal overload protector

to the compressor and the wire from the compressor

wiring harness to the thermal overload protector.

3. Remove overload protector retainer (2) and thermal

overload protector (3) as an assembly.

4. Remove retainer (2) from overload protector (3) and

discard overload protector.

5. Install retainer (2) on new overload protector (3).

6. Install retainer (2) and overload protector (3) on the

compressor terminal bracket.

7. Refer to Fig. 15 and reconnect the thermal overload

protector wires.

8. Reinstall terminal cover (5) and cover retainer (6).

230V DISPENSERS

FIG. 15 THERMAL OVERLOAD PROTECTOR

TERMINALS

Compressor Run Capacitor (230V Dispensers Only):

Refer to FIG. 12

1. Remove terminal cover retainer (6) and terminal

cover (5).

2. Disconnect the run capacitor leads.

3. Remove the #6 crimptite screw securing the run

capacitor to the rear of the component bracket.

4. Remove run capacitor and discard.

5. Place new run capacitor on the rear of component

bracket and secure with #6 crimptite screw.

6. Refer to Fig. 15A and reconnect the wires.

FIG. 15A COMPRESSOR RUN CAPACITOR

TERMINALS

30

P1339

P1816

27646 122200

Page 31

SERVICE (cont.)

COMPRESSOR & COMPONENTS (CDS-3)

2 3

FIG. 16 COMPRESSOR &

COMPONENT LOCATIONS

Location:

The compressor assy is located inside the front

of the dispenser chassis.

1

P1558.30

3. Disconnect the black wire to the thermal overload

protector (4), the white and black or red wires to

the compressor.

4. With a voltmeter, check voltage across the black wire

removed from the thermal overload protector and

the white wire with the ON/OFF switch in the “ON”

position, DAY/NIGHT switch in the “DAY” position

and the ICE/OFF/NO ICE switch in the “ICE” position. Connect the dispenser to the power source.

The indication must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #6.

If voltage is not present as described, refer to the Wiring

Diagram and check the dispenser wiring harness.

6. Disconnect the two black wires from the compressor start capacitor.

7. Check for continuity across contacts 1 & 2 of the

relay.

If continuity is present as described, the compressor

start relay is operating properly.

4

5

6

7

FIG. 17 COMPRESSOR THERMAL

P1819

OVERLOAD PROTECTOR LOCATION

1. Compressor Start Relay

2. Compressor Start Capacitor

3. Compressor Run Capacitor

4. Thermal Overload Protector

5. Overload Protector Retainer

6. Compressor Terminal Cover

7. Compressor Terminal Cover Retainer

Test Procedures:

Compressor Start Relay: Refer to FIG. 17

WARNING: The compressor capacitors must be prop-

erly discharged before proceeding.

1. Disconnect the dispenser from the power source.

2. Remove the compressor terminal cover retainer

(7) and compressor terminal cover (6).

If continuity is not present as described, replace relay.

Compressor:

1. With the compressor start relay (1) removed, disconnect the black or red wire from the compressor.

2. Check for continuity across the terminal on the

compressor and the left pin on the compressor.

If continuity is present as described, the electrical part

of the compressor is operating properly.

If continuity is not present as described, replace the

compressor.

Thermal Overload Protector:

1. Check for continuity across the terminals on the

thermal overload protector.

If continuity is present as described, the thermal overload protector is operating properly.

If continuity is not present as described, replace the

thermal overload protector.

Compressor Start Capacitor:

1. Check for continuity across the terminals on the

compressor start capacitor.

If continuity is present as described, the start capacitor

is operating properly.

If continuity is not present as described, replace the

capacitor.

31

27646 122200

Page 32

SERVICE (cont.)

COMPRESSOR & COMPONENTS (CDS-3) (cont.)

Compressor Run Capacitor:

1. Check for continuity across the terminals on the

compressor run capacitor.

If continuity is present as described, the run capacitor

is operating properly.

If continuity is not present as described, replace the

capacitor.

NOTE: If all the electrical components are operating properly and the compressor does not operate,

there is an internal mechanical problem. Replace the

compressor.

Removal and Replacement:

Compressor Assy:

NOTE: Before removal of any refrigeration component

the refrigerant in the system must be reclaimed by a

licensed refrigeration repair person.

1. Disconnect the tubes from the condenser, accumulator also remove access valve and tube..

2. Disconnect the compressor wiring harness from

the dispenser main wiring harness.

3. Remove the four .312”-18 screws, keps nuts and

washers securing the compressor to the chassis.

Set screws, nuts and washers aside for reassembly.

4. Remove the four #8-32 locking screws securing

the component bracket to the dispenser chassis.

5. Pull the component bracket, with wires attached,

out of the chassis far enough to gain access to the

compressor.

6. Disconnect the compressor wiring harness from

the compressor.

7. Remove the two #8-32 screws securing the contactor mounting bracket to the dispenser base.

8. Remove the contactor mounting bracket, contactor,

contactor cover and the compressor wiring harness

as an assembly. Set aside for reassembly.

9. Disconnect the fan leads from the main wiring

harness.

10. Remove the three #6 thread cutting screws securing the fan to the condenser shroud. Remove the

fan and set aside for reassembly.

11. Slide the compressor out the right side of the

dispenser.

12. Remove the four grommets and sleeves from

the old compressor and install them on the new

compressor.

13. Slide new compressor into position on the dispenser

chassis, with the tube connections to the front.

14. Secure compressor to the dispenser chassis using

four .312”-18 screws, washers and nuts.

15. Install the fan on the condenser shroud and secure

with three #6 thread cutting screws.

16. Reconnect the leads on the fan to the main harness.

17. On dispensers serial number CDS0019500 - up

install the contactor bracket, contactor, contactor

cover and compressor wiring harness as an assembly. Secure contactor bracket to the chassis

using two #8-32 screws.

18. Refer to Fig.17A and reconnect the wires to the

compressor.

19. Position the component bracket in the chassis and

secure with four #8-32 locking screws.

20. Reconnect tubes from the condenser and the

accumulator to the compressor, also reconnect

access valve and tube.

21. Evacuate the system.

NOTE: When replacing the compressor it is recommended that the dryer also be replaced.

22. Dispensers prior to serial number CDS0019500

recharge system with 25 oz. of Type R404A refrigerant. Design Pressures: High 320 - Low 44

Dispensers serial number CDS0019500 - up re-

charge system with 22 oz of type R404A refrigerant.

Design Pressures: High 380 - Low 52

NOTE: The charging of the system must be done by a

licensed refrigeration repair person.

RED from

Relay T2

WHI from

Relay T4

BLKfrom

Relay T-5

FIG. 17A COMPRESSOR TERMINALS

P1819

32

27646 122200

Page 33

SERVICE (cont.)

5

6

4

1

2

COMPRESSOR & COMPONENTS (CDS-3) (cont.)

Compressor Start Capacitor:

WARNING: The compressor start capacitor must be

properly discharged before proceeding.

1. Disconnect the two leads on the compressor start

capacitor.

2. Loosen the capacitor retaining strap and remove

the capacitor.

3. Securely install new start capacitor under the retaining strap.

4. Refer to Fig. 18 and reconnect the wires to the start

capacitor.

Compressor Run Capacitor:

WARNING: The compressor run capacitor must be

properly discharged before proceeding.

1. Disconnect the three leads from the compressor

run capacitor.

2. Loosen the capacitor retaining strap and remove

the capacitor.

4. Securely install new run capacitor under the retaining strap.

5. Refer to Fig. 18 and reconnect the wires to the

relay.

BLKtoCompressor

Relay T6

BLKtoCompressor

Relay T1

BLK

BLKtoCompressor

Relay T2

T4 WHI from Compressor

and Main Harness

T4BLKfromRunCapacitor

T5BLKfromCompressor

Thermal Overload Protector

and Main Harness

T1BLKfromStartCapacitor

T2BLKfromRunCapacitor

T2 Red from Compressor

P1820

FIG. 19 COMPRESSOR RELAY TERMINALS

Compressor Thermal Overload Protector: Refer to

FIG. 17

1. Remove terminal cover retainer (7) and terminal

cover (6).

2. Remove the wire from thermal overload protector

from the compressor wiring harness to the thermal

overload protector.

3. Remove overload protector retainer (5) and thermal

overload protector (4) as an assembly

4. Remove retainer (5) from overload protector (4)

and discard overload protector.

5. Install retainer (5) on new overload protector (2).

6. Install retainer (5) and overload protector (4) on

the compressor terminal bracket.

7. Refer to Fig. 20 and reconnect the thermal overload

protector wires.

8. Reinstall terminal cover (6) and cover retainer

(7).

START

FIG. 18 COMPRESSOR CAPACITOR TERMINALS

Compressor Start Relay

WARNING: The compressor start capacitor must be

properly discharged before proceeding.

RUN

P1817

BLKtoCompressorRelayT5

P1821

FIG. 20 THERMAL OVERLOAD PROTECTOR

TERMINALS

1. Disconnect the wires from the compressor relay.

2. Remove the #6-32 screw securing the relay to the

rear of the component bracket.

3. Remove and discard relay.

4. Install new relay on the rear of the component

bracket and secure with a #6-32 screw.

5. Refer to Fig. 19 and reconnect the wires.

33

27646 122200

Page 34

SERVICE (cont.)

R22

CONTACTOR - ELECTRONIC CONTROL

P1342

FIG. 21 CONTACTOR - ELECTRONIC CONTROL

Location:

The contactor is located inside the dispenser chas-

sis on the lower outside of the component bracket.

Test Procedures:

1. Disconnect the dispenser from the power

source.

2. Disconnect white/black wire from contactor terminal #0 (terminal #2, on CDS-3 first type contactor)

and brown/black from terminal #1.

3. With a voltmeter, check the voltage across the

white/black wire and the brown/black wire and

the ON/OFF switch in the “ON” position. Connect

the dispenser to the power source. The indication

must be:

a) 120 volts ac for 120 volt models.

b) 230 volts ac for 230 volt models.

4. Disconnect the dispenser from the power

source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the

Wiring Diagram and check the dispenser wiring harness.

5. Check for continuity across contactor terminals

#0 & #1 (#1 & #2, CDS-3 first type contactor).

If continuity is present as described reconnect the

white/black wire and the brown/black wire to the

contactor and proceed to #6.

If continuity is not present as described, replace the

contactor.

6. Disconnect the black wires from contactor terminals #6 & #8 (#5 & #6, CDS-3 first type contactor).

7. With ON/OFF switch in the “ON” position, connect

the dispenser to the power source and check for

continuity across terminals on contactor.

If continuity is not present as described, on CDS-3 first

type contactors, replace contactor. If continuity is not

present between terminals #6 & #8 as described on all

CDS-2 contactors and CDS-3 second type contactors,

check for continuity across terminals #2 and #4.

If continuity is present as described, disconnect the

dispenser from power source and reconnect black

wires to terminals #2 and #4, the contactor will operate properly.

If continuity is not present as described, replace the

contactor.

Removal and Replacement:

1. Disconnect the wires from the contactor.

2. Remove the two #8-32 locking screws securing

the contactor to the component bracket. Remove

and discard contactor.

3. Install the new contactor on the component bracket

using two #8-32 locking screws.

4. Refer to Fig. 22 and reconnect the wires.

Terminal #4

Terminal #2

Terminal #6

BLKfromMain

Harness/Power Cord

Terminal #8

BLKfromCompressor

Harness

Terminal #0

WHI/BLKfromMainHarness/

Power Cord/Compressor

Terminal #1

BRN/BLK from Main

Harness/Control Board

ALL CDS-2 CONTACTORS

CDS-3 SECOND TYPE CONTACTORS

Terminal #2

Terminal #1

BRN/BLK from Main

Harness/Control Board

Terminal #5

BLKfromCompressor

Harness

WHI/BLKfromMainHarness/

Power Cord/Compressor

Terminal #6

BLKfromMain

Harness/Power Cord

CDS-3 FIRST TYPE CONTACTORS

FIG. 22 CONTACTOR TERMINALS

34

P1333

27646 122200

Page 35

SERVICE (cont.)

COOLING DRUM ALIGNMENT

Ledge

Boss

FIG. 23 COOLING DRUM SHIPPING SUPPORT

Legs

FIG.24CHECKINGALIGNMENT

P1510

The “A” shaped Cooling Drum Shipping Supports,

removed during Initial Set-Up should be kept and used

as a tool to reset the alignment of the cooling drums

should it ever be required.

Symptoms:

Squeaky Operation, hopper lifts or won’t seat properly,

hopper is pushed to one side or the other.

To check alignment

1. Place the “A” shaped support on the auger shaft

with the ledge under the cooling drum.

2. Lift the cooling drum while rotating the support into

a vertical position. The boss on the very bottom

will drop into the hopper drip tray’s drain hole.

When in its proper position, the cooling drum will

cause a slight pressure on the hopper drip tray drain

hole and the two legs will be equidistant from the

hopper drip tray.

If adjustment is needed, remove the support and gently

force the free end of the evaporator in the direction

the adjustment is needed.

Reinstall the support, check the alignment, and readjust the cooling drums as required.

35

27646 122200

Page 36

SERVICE (cont.)

DAY/NIGHT SWITCH

FIG. 25 DAY/NIGHT SWITCH

P1343

Location:

The DAY/NIGHT switch is located inside the dis-

penser drawer on the right front of the control panel.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the white/green wire from the switch

and the white/black wire from contactor located on

the outside bottom of the component bracket .

3. With a voltmeter, check the voltage across the

white/green and the white/black and the ”ON/OFF“