Page 1

®

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

42822.0001C 06/11 ©2010 Bunn-O-Matic Corporation

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specifi ed below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes fi rst.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Offi ce Box 3227, Springfi eld, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifi cations to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specifi ed above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profi ts, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

392, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN

Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line,

BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth,

DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet

Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, PowerLogic, Quality Beverage Equipment

Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com, Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard,

The Mark of Quality in Beverage Equipment Worldwide, ThermoFresh, Titan, A Partner You Can Count On, Air

Brew, Air Infusion, Beverage Bar Creator, Beverage Profi t Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Digital Brewer Control, Nothing Brews Like a BUNN, Pouring Profi ts,

Signature Series, Tea At Its Best, Phase Brew, The Horizontal Red Line, trifecta, Ultra, Velocity Brew are either

trademarks or registered trademarks of Bunn-O-Matic Corporation.

Page 2

42822.1 050511

Page 3

CONTENTS

Warranty .............................................................................................................2

Introduction ........................................................................................................3

User Notices .......................................................................................................3

Electrical Requirements ......................................................................................4

Plumbing Requirements .....................................................................................5

Initial Setup .........................................................................................................6

Coffee Brewing ....................................................................................................7

Adjusting Brewing Parameters ............................................................................8

Cleaning ............................................................................................................10

Front Panel Removal & Tank Draining ...............................................................11

Advanced Adjustments & Optional Settings ......................................................12

Schematic Wiring Diagram ...............................................................................20

INTRODUCTION

This equipment is factory set to brew approximately 2-16 ounces of coffee into a cup. It is only for indoor

use on a sturdy counter or shelf. Replace any unreadable or damaged labels.

!!!FOR USE BY TRAINED PERSONNEL ONLY!!!

IMPORTANT SAFE GUARDS

DO NOT: Pick up brewer by handles;

DO NOT: Allow untrained personnel to operate this equipment;

DO NOT: Use parts that show any signs of wear or damage;

DO NOT: Put plastic parts in dishwasher, or use corrosive or abrasive cleaners;

DO NOT: Fail to inspect brew chamber, brew cup, seals and related parts daily for damage/wear and tear;

DO NOT: Fail to do recommended preventive maintenance;

DO NOT: Operate brewer with missing or damaged parts;

DO NOT: Open brew chamber during brew cycle;

DO NOT: Open brew chamber when hot water is present;

USE CAUTION WHEN REMOVING BREW/GROUNDS CUP, HOT LIQUID MAY BE PRESENT.

RECOMMENDED PREVENTIVE MAINTENANCE

• SEALS/O-rings: Brew chamber top seal, brew cup upper & lower seals. Clean & inspect daily. Replace if

loose, cracked or damaged.

• Brew cup assembly & chamber: Clean & inspect daily. Replace if cracked or damaged.

• Check valve: Clean & inspect daily. Replace if cracked or damaged.

• Top clamp mechanism: Inspect daily for smooth operation. Clean & lube guides as needed to ensure

smooth operation.

USER NOTICES

WARNING HOT LIQUIDS

To reduce the risk of electric shock,

do not remove or open cover.

No user-serviceable parts inside.

Authorized service personnel only.

Disconnect power before servicing.

#37881.0000

Keep hands clear

during brew cycle.

HOT liquids can burn.

Keep hands clear

when closing brew chamber.

Moving parts can pinch.

#41177.0001

42822.1 060211

WARNING

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND

THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL

ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE

OPERATING MANUAL BEFORE

USING THIS PRODUCT

00986.0000F 10/07 ©1994 Bunn-O-Matic Corporation

#00824.0002

As directed in the International Plumbing Code of the

International Code Council and the Food Code

Manual of the Food and Drug Administration (FDA),

this equipment must be installed with adequate

backflow prevention to comply with federal, state

and local codes. For models installed outside the

U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

#00656.0001#00986.0002

Page 3

#37280.0001

TO AVOID DAMAGE AND INJURY

• DISCARD CHAMBER IF

CRACKED

• CLEAN WITH MILD NONABRASIVE SOAP AND

WATER

#43022.0000

Page 4

ELECTRICAL REQUIREMENTS

CAUTION - The brewer must be disconnected from the power source until specifi ed in Initial Set-Up.

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

100V & 120V

230 VOLT CE Model

230 VOLT UK Model

Models

Note: This electrical service consists of 2 current carrying conductors (L1 and Neutral) and a separate con-

ductor for chassis ground.

Electrical Hook-Up

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specifi ed.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked up, the brewer is ready for Initial Set-Up.

CE REQUIREMENTS

• This appliance must be installed in locations where it can be overseen by trained personnel.

• For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C.

• Appliance shall not be tilted more than 10° for safe operation.

• An electrician must provide electrical service as specifi ed in conformance with all local and national codes.

• This appliance must not be cleaned by water jet.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given instructions concerning use of

this appliance by a person responsible for its safety.

• Children should be supervised to ensure they do not play with the appliance.

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with

a special cord available from the manufacturer or its authorized service personnel in order to avoid a hazard.

• Machine must not be immersed for cleaning.

Page 4

42822.1 051110

Page 5

PLUMBING REQUIREMENTS

These brewers must be connected to a cold water system with operating pressure between 20 and 90 psi

(138 and 620 kPa) from a ½˝ or larger supply line. A shut-off valve should be installed in the line before the

brewer. Install a regulator in the line, when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345

kPa). The water inlet fi tting is ¼˝ fl are fi tting. Bunn-O-Matic does not recommend the use of a reverse-osmosis

or deionized water supply to this equipment.

NOTE - Bunn-O-Matic recommends ¼˝ copper tubing for installations of less than 25 feet and

3

⁄8" for more than

25 feet from the ½˝ water supply line. A tight coil of tubing in the water line will facilitate moving the brewer to

clean the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The

size and shape of the hole made in the supply line by this type of device may restrict water fl ow.

A water fi ltration system must be installed for brewers used in hard water areas.

As directed in the International Plumbing Code of the International Code Council and the Food Code Manual

of the Food and Drug Administration (FDA), this equipment must be installed with adequate backfl ow prevention to comply with federal, state and local codes. For models installed outside the U.S.A., you must

comply with the applicable Plumbing /Sanitation Code for your area.

NOTE - If a back fl ow preventer is required by code, a shock arrestor should be installed between back fl ow

preventer and dispenser. Installing the shock arrestor as close to the dispenser as possible will provide the best

results.

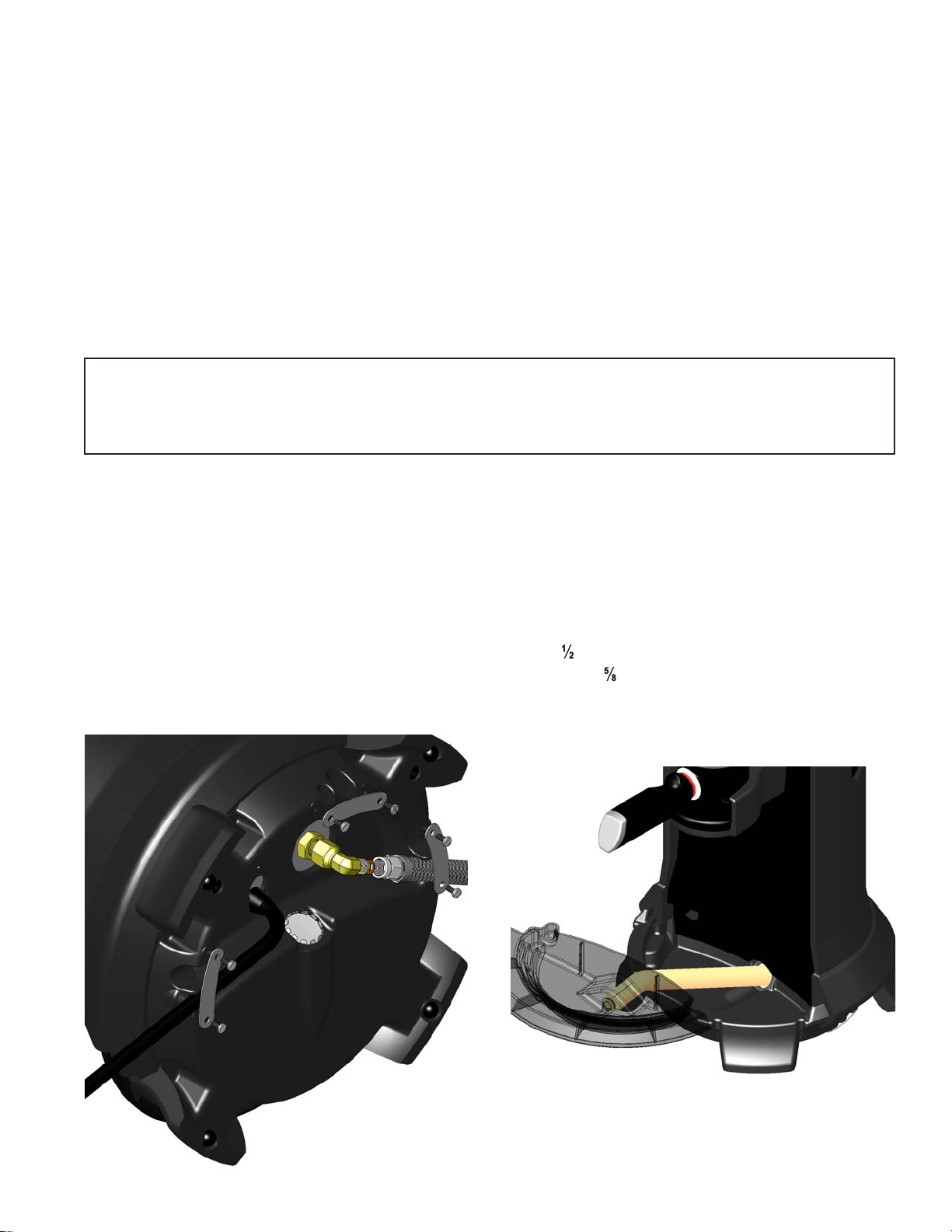

Plumbing Hook-Up

1. Flush the water line.

2. Securely attach ¼˝ water supply line to the el-

bow.

3. Secure cord and water supply line under the

retainer strap in any of the three locations as

needed. (Only 1 strap included)

4. Turn on the water supply.

Optional Drain Hook-Up

1. Remove drip tray and the chrome plug from the

base.

2. Drill out the auxiliary outlet of the drip tray with

a ½˝ drill bit.

3. Secure ½˝ hose to drip tray, routing it through

the opening in the base assembly.

4. Connect hose to drain line as needed.

5. Install drip tray.

Page 5

42822.1 051110

Page 6

-1000 213.8 101.0 200 93.3

-500 212.9 100.5 200 93.3

0 212.0 100.0 200 93.3

500 211.1 99.5 200 93.3

1000 210.2 99.0 200 93.3

1500 209.3 98.5 200 93.3

2000 208.4 98.0 200 93.3

2500 207.4 97.4 200 93.3

3000 206.5 96.9 199 92.8

3500 205.6 96.4 198 92.2

4000 204.7 95.9 197 91.7

4500 203.8 95.4 196 91.1

5000 202.9 94.9 195 90.6

5500 201.9 94.4 195 90.6

6000 201.0 93.9 194 90.0

6500 200.1 93.4 193 89.4

7000 199.2 92.9 192 88.9

7500 198.3 92.4 191 88.3

8000 197.4 91.9 190 87.8

8500 196.5 91.4 189 87.2

9000 195.5 90.8 188 86.7

9500 194.6 90.3 187 86.1

10000 193.7 89.8 186 85.6

Brew water temperature is factory set at 200o F (93.3o C)

Areas of high altitude will require lowering this temperature to prevent boiling. This chart should be used as a

guide when readjusting the brew water temperature.

Altitude

(Feet)

Boiling point

of water

o F o C

Recommended

water temperature

o F o C

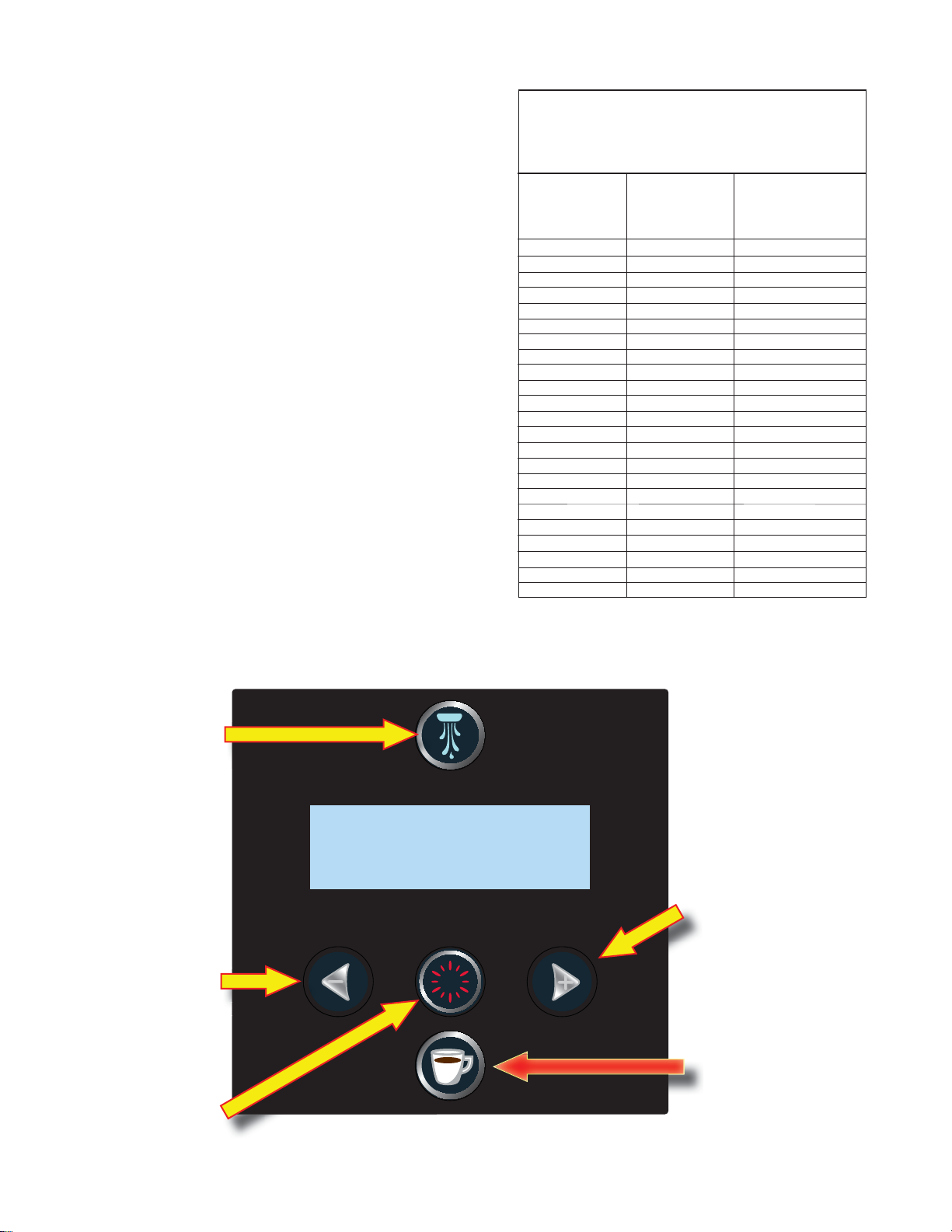

INITIAL SET-UP

1. Install check valve. Refer to pictures on page 10.

2. Install clear brew chamber and grounds cup, and lock

chamber in place.

3. Place an empty container under the brew chamber.

4. Connect the brewer to the power source.

5. Press the brew start switch. Water will fl ow into the brew

tank. Some excess water will fl ow into the cup.

6. Wait approximately fi ve minutes for the water in the tank to

heat to the proper temperature. Display will show "HEAT-

ING" until tank reaches it's operating temperature. Some

water will drip from the brew chamber during this time;

this is due to expansion and should not occur thereafter.

Any excess water in the brew chamber will be automatically purged at the end of the initial setup.

7. Water volumes and fl ow settings have been preset at the

factory. Refer to "Adjusting Brewing Parameters" section

of this manual should the volume need to be increased

or decreased.

8. The brewer is now ready for use in accordance with the

instructions for Coffee Brewing.

NOTE: If brewer has been drained/moved, perform "Reset to

fi rst time" procedure on page 11.

OPERATING CONTROLS

Press this button to

rinse brew chamber

after each brew cycle.

RINSE

(-)/NO

PROGRAM/SELECT

Page 6

(+)/YES

BREW START

Press again to cancel.

42822.1 072810

Page 7

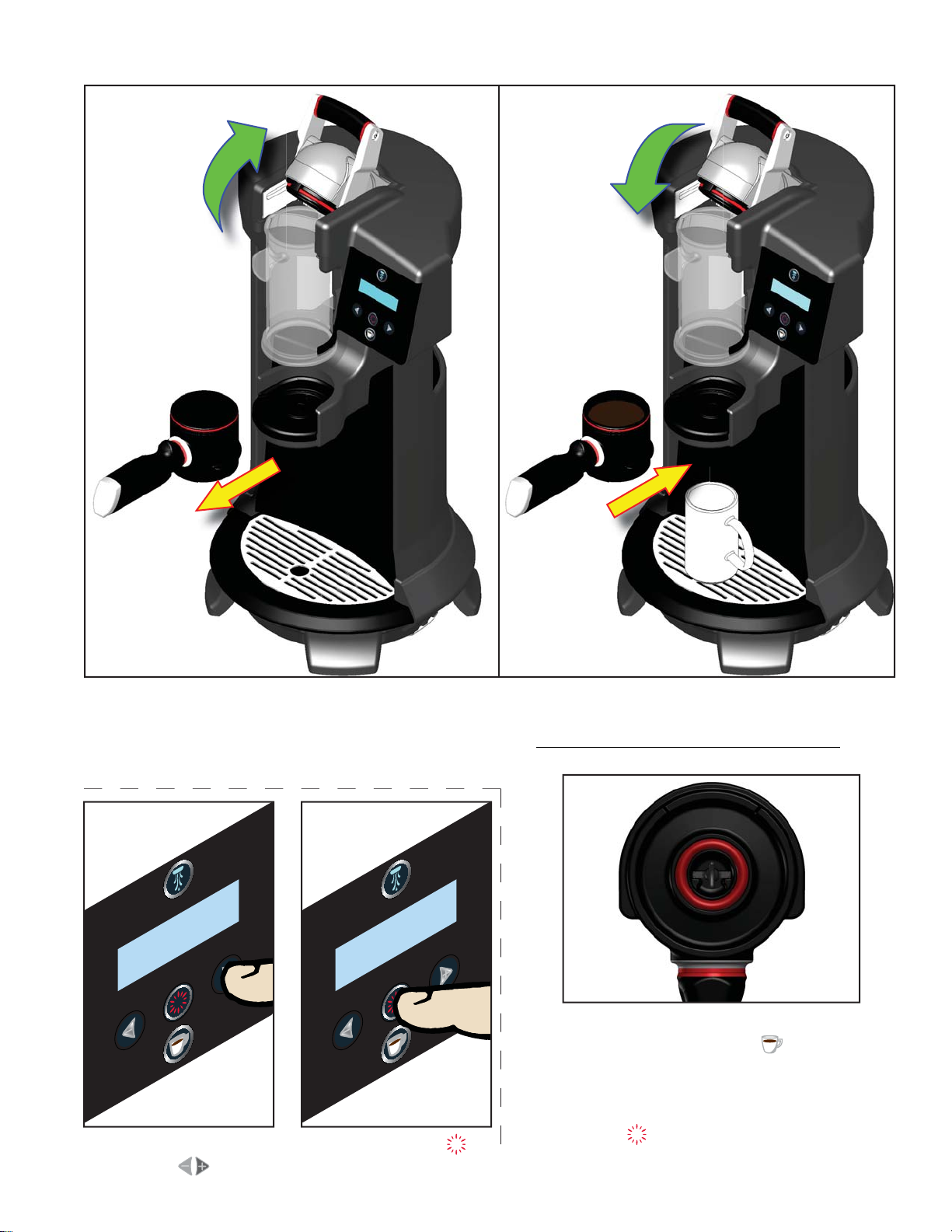

COFFEE BREWING

1. Lift handle all the way up.

2. Remove cup assembly. Verify screen is locked into

grounds cup. Fig 1.

3. Fill with desired amount of ground coffee.

DECAF

HOUSE SPECIAL

<- <- SELECT ->->

7. Scroll through recipes

using arrow buttons.

<- <- SELECT ->->

8. Press "SELECT"

button for your recipe.

Page 7

4. Place brew cup under brew chamber.

5. Place cup on drip tray .

6. Push handle all the way down to lock brew

chamber.

FIG 1

9. A. If your brewing parameters are already set,

you may simply press the "BREW" button to start

a brew cycle.

B. To set up specifi c parameters for a particular

recipe, verify the recipe name is currently displayed.

Press "SELECT" , display will read "VOLUME".

CONTINUED ON NEXT PAGE

42822.1 031210

Page 8

ADJUSTING BREWING PARAMETERS

HOUSE SPECIAL

Press "-" to reduce or "+" to increase.

DEFAULT: 8 oz, RANGE: 2 - 16

-+

VOLUME 8 oz

PRE-WET

Adjust the desired brew volume.

Press "-" to reduce or "+" to increase.

DEFAULT: .0, Range: .0-1.0 seconds

-+

.0 Secs

PRE-INFUSION

Pre-wet of ambient water on top of the coffee grounds.

Press "-" to reduce or "+" to increase.

DEFAULT: 10, Range: OFF/ 1-100

-+

10%

Percent of overall brew volume during pre-infusion

stage.

FILL PAUSE

Press "-" to reduce or "+" to increase.

DEFAULT: 5, Range: 1-25 seconds

-+

5.0 Secs

Time delay after pre-infusion before remaining water is

introduced and brew continues.

EXTRACTION TIME

Press "-" to reduce or "+" to increase.

DEFAULT: 45, Range: 20-180 seconds

-+

45

Extraction time to start after the total brew water is added

to brew chamber.

TURBULENCE ON

Press "-" to reduce or "+" to increase.

DEFAULT: 5, Range: OFF/ 1-45

-+

TURBULENCE OFF

5

Turbulence air ON time.

Press "-" to reduce or "+" to increase.

DEFAULT: 10, Range: OFF/ 1-40

-+10

TURBULENCE POWER

Turbulence air OFF time.

Press "-" to reduce or "+" to increase.

DEFAULT: 4, Range: 1-7

-+4

Force of the air pump during turbulence.

PRESS OUT POWER

-+7

Press "-" to reduce or "+" to increase.

DEFAULT: 7, Range: 1-7

Force of the press-out air pump during fi nish.

Page 8

42822.1 040810

Page 9

ADJUSTING BREWING PARAMETERS (Continued)

PRESS OUT TIME

-+60

SET TEMP

- 200°F +

COFFEE BREWING (Continued)

Press "-" to reduce or "+" to increase.

DEFAULT: 60, Range: 20-70

LENGTH of the press-out time during fi nish.

Press "-" to reduce or "+" to increase tank target temp.

DEFAULT: 200°F (93°C)

Range: 165°F-208°F (74°C-98°C)

• DO NOT OPEN DURING BREWING

OR PRESSING CYCLES.

• IF FOR ANY REASON, WATER

REMAINS IN BREW CHAMBER,

DO NOT OPEN UNTIL IT COOLS

DOWN.

PRE-INFUSION

FlowCounter

10. Press brew button.

NOTE: Pressing brew button

again will cancel a brew cycle.

RINSING....

11. When brewing has fi nished, place an empty cup on

drip tray, press rinse.

Page 9

12. EMPTY BREW CUP

13. Thoroughly rinse brew cup.

42822.1 040810

Page 10

DAILY CLEANING

SPRAYHEAD REMOVAL CHECK VALVE REMOVAL

1

2

Lift handle. Remove brew chamber and

cup. Remove sprayhead.

1. Clean & lube guides as needed.

Clean & inspect parts daily.

Replace if loose, cracked or damaged.

3.

Remove the screen from brew cup by rotating ¼ turn

and pushing up from underneath. Thoroughly wash

(with mild detergent) and rinse the brew chamber,

sprayhead, cup and check valve. Wipe out the cap area

above sprayhead and around O-rings.

Push the check valve up from underneath

the cup support.

After cleaning, apply very light fi lm of silicon

lube (included) to O-rings & check valve (1-4)

4

STOP!

DO NOT LUBE

THIS O-RING

Thoroughly fl ush the check valve while pushing the

center poppet open with a probe.

Page 10

42822.1 010411

Page 11

FRONT PANEL REMOVAL AND TANK DRAINING

WARNING: DISCONNECT BREWER FROM POWER SOURCE BEFORE PANEL REMOVAL.

Remove drip tray. Remove two screws.

Lower the panel as far as it will go.

TANK DRAINING RESET TO FIRST TIME SETUP

WARNING

DISCONNECT BREWER

FROM WATER SUPPLY

BEFORE DRAINING

Pull drain hose out as shown. Slide clamp

back and remove plug. Refer to programming section and enter "Factory Blowout"

mode. Allow tank to drain into sink or

suitable container.

Push the top down to clear the brew chamber support arm, then pull the top out fi rst.

NOTE: If tank was drained, follow this procedure

before connecting brewer to power source.

Disconnect brewer from power source. Connect to

water supply. Install brew cup & chamber. Push and

hold both arrow buttons while plugging in the brewer.

When display reads "SET TO FIRST TIME UP", release

arrow buttons. Place a minimum 40 oz. container under

brew chamber. Press brew start button to begin cycle.

If tank was empty, it will expel only 20 oz. If tank was

still full, it will expel 40 oz.

Page 11

42822.1 040810

Page 12

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

LEVEL "2"

Press and hold both arrows until display reads "RECIPE

CHANGES" "ENABLED - LOCKED".

PROGRAM MODE DEFAULT RANGE

1. Recipe Changes Enabled Enabled/Locked

2. Change Recipe Name

3. Add Recipe Name

4. Delete Recipe Name

5. Set Language Eng English/Spanish/French

6. Units English English/Metric

7. Base Temperature Disabled Enabled/ Disabled

8. Brew Lockout Yes YES/NO

9. Ready Degrees 5°F below "SET" temp

10. 1st Rinse Air On OFF OFF/1-60

11. 2nd Rinse Air On 60 OFF/1-60

12. 2nd Rinse Time 2.0 OFF/1-4.0

13. Rinse Air Power 7 OFF/1-7

14. Brew Count Total (Non reset-able)

15. Brew Count Total (Reset-able)

16. Enter Service #

17. Service Tools

18. Factory Defaults

RECIPE CHANGES

1.

ENABLED LOCKED

Press to "ENABLE" adjustment, or to "LOCK".

Press "SELECT" to advance to next screen.

ChangeRecipeName

2.

NO YES

HOUSE SPECIAL

A

CHANGE

NEXT

DECAF

HOUSE SPECIAL_

B

By default "ENABLED" will be fl ashing to indicate that the

brewing parameters may be accessed/changed. Selecting

"LOCKED" will prevent changes to the brewing parameters, but can still be accessed for viewing.

Select "YES" to change/modify a recipe's name. Select "NO"

to advance to "ADD RECIPE NAME".

"CHANGE" will advance to next screen to modify the name

that is displayed. "NEXT" advances to the next recipe name

that has been programmed into memory. Default is "HOUSE

SPECIAL" & "DECAF" only.

Use the UP/DOWN buttons to scroll through alpha/numeric

digit for that position. Use the button to move curser

to the next digit to the right. Press the to move curser

to the left. Once you are fi nished changing the name, scroll

all the way to the right to advance to next screen.

3.

ADD RECIPE NAME?

NO YES

Allows you to add additional names to the default list.

Select "YES"

Page 12

42822.1 072810

Page 13

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

A

B

ADD COFFEE NAME?

CUSTOM FromList

House Special

Decaf

Colombia

Costa Rica

Ethiopia

Kona

Kenya

Sumatra

CUSTOM NAME_

Selecting "CUSTOM" will allow you to custom type your own

name by scrolling through digits as described above.

Or you can scroll through a pre programmed list.

Guatemala

Brazil

Mocha Java

Mexico

Peru

Tanzania

Yemen

Nicaragua

Use the UP/DOWN buttons to scroll through alpha/numeric

digit for that position. Use the button to move curser to

the next digit to the right. Press the to move curser to

the left. Once you are fi nished writing the name, scroll all

the way to the right to advance to next screen.

El Salvador

Papua New Guinea

Rwanda

Burundi

Honduras

Ecuador

Panama

4.

5.

CUSTOM NAME

C

D

DeleteRecipeName

SET LANGUAGE ?

SelectPREV NEXT

CUSTOM NAME

SAVE ?NO YES

DONENO YES

DONENO YES

Scroll through the list. When you fi nd the name you are

looking for, press "SELECT"

To save the selected name, press "YES"

Allows you to delete a recipe name from the default list.

Press "YES" to access language selections..

Page 13

42822.1 072810

Page 14

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

6.

7.

ENGLISH

A

A

(-) SELECT (+)

UNITS

METRIC DONE ENG

BASE TEMPERATURE

ENABLE DISABLE

BASE TEMPERATURE

(-) 175°F (+)

Press "-" or to toggle between ENGLISH, SPANISH, or

FRENCH. Press "SELECT" to advance to next screen.

DEFAULT: ENGLISH

Press for "METRIC" or for "ENGLISH".

Units of measurement will change from °F to °C; oz to

milliliters; etc.

DEFAULT: ENGLISH (Flashing)

Press for "ENABLE" or for "DISABLE".

When enabled, will allow different temperatures for recipes. NOTE: Will disable BREW LOCKOUT screen.

DEFAULT: DISABLE (Flashing)

Press "-" to reduce or "+" to increase base temp.

Range: 75° to 205°.

DEFAULT: 175°

8.

9.

10.

BREW LOCKOUT ?

NO DONE YES

READY DEGREES

(-) 5°F (+)

1st RINSE AIR ON

-+OFF Secs

1st RINSE TIME

A

-+60

Press "-" for "NO" or "YES".

Setting to "YES" will only allow brewing at or above the

"READY DEGREES" screen.

DEFAULT: YES (Flashing)

Press "-" to reduce or "+" to increase ready degrees.

Sets the minimum temperature allowable to start a brew

cycle. Range: 2° to 20° below the "SET" temperature.

Amount of press out time during auxiliary rinse mode.

DEFAULT: OFF (Turning "ON" this screen, will activate the

sub screen)

Range: OFF/ 1-60

Auxiliary rinse mode.

DEFAULT: 60

Range: OFF/ 1-4.0

Page 14

42822.1 072810

Page 15

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

11.

12.

13.

14.

2nd RINSE AIR ON

-+

60 Secs

2nd RINSE TIME

-+

2.0 Secs

RINSE AIR POWER

-+- - - - - - -7

BrewCount 1500

NEXT

Amount of press out time during primary rinse mode.

DEFAULT: 60

Range: OFF/ 1-60

Primary rinse mode. "OFF" is equal to push & hold. Numbers represent seconds it will continue to rinse when

button is released.

DEFAULT: 2.0

Range: OFF/ 1-4.0

Adjust force of "PRESS OUT"

DEFAULT: 7

Range: OFF/1-7

Total brew counter (Can not be reset)

15.

16.

BrewCount 1500

RESET

ENTER SERVICE #

NO YES

NEXT

_

A

Brew counter (Can be reset)

Press "YES" if you would like to program a phone number

for a factory authorized service department that will be

displayed if the brewer should encounter a fault code.

Use the UP/DOWN buttons to scroll through numeric digit

for that position. Use the button to move curser to the

next digit to the right. Press the to move curser to the

left. Once you are fi nished programming the number, scroll

all the way to the right to advance to next screen.

Page 15

42822.1 072810

Page 16

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

SERVICE TOOLS

17.

"FACTORY DEFAULTS"

NO

Skip to

A

"TEST SWITCHES"

(1)

(2)

YES

TEST OUTPUTS ?

NO YES

Skip to

ON NEXT OFF

TURBULENCE PUMP

ON NEXT OFF

SERVICE TOOLS allows testing of load components and

switches.

It should only be used by trained technicians.

Allows testing of load components by manually turning

them ON/OFF. PLACE A CONTAINER UNDER DISPENSE

AREA--- WARNING: HOT WATER COULD DISPENSE DURING SOME TEST MODES!

VENT VALVE

(3)

(4)

(5)

(6)

PRESS OUT PUMP

ON NEXT OFF

RINSE WATER

ON NEXT OFF

BrewChamberFILL

ON NEXT OFF

LEDs

ON NEXT OFF

Page 16

42822.1 072810

Page 17

(7)

(8)

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

TankHeater RELAY

ON NEXT OFF

TankHeater TRIAC

ON NEXT OFF

TEST SWITCHES

B

NO YES

NOTHING PRESSED

(1)

BREW CHAMBER IN

(2)

CALIBRATE FLOW ?

C

Skip to "CAL TEMPERATURE

NO YES

SENSOR"

Allows testing of the membrane switches & brew chamber

safety switch

read "PRESS PROGRAM TO EXIT" then change to "NOTHING PRESSED".

Display will show when a button is pressed.

Opening/closing the brew chamber during the "TEST

SWITCHES" mode will display the status of the safety

switch.

OUT = open

IN = closed

Press the "PROGRAM" button to exit.

Use of this test allows user to "tell" the brew exactly how

many ounces are collected during a 10 second "test" brew

mode.

. Press "YES" to enter test mode. Display will

(1)

(2)

(3)

!!! CAUTION !!!!

CONTAINER MUST

HOLD 10 OUNCES

PRESS

BREW TO START

Use a measuring container that will hold at least 10 ounces.

Place container in position on drip tray.

Press "BREW" button to start.

Page 17

42822.1 072810

Page 18

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

(4)

(5)

(6)

(7)

BREWING

HOT LIQUIDS!!!!

DO NOT OPEN!!!!

HOT LIQUIDS!!!!

ENTER OZ 10.0

(-) (+)DONE

FlowCounts/ 10oz

352

There will be several warning & informational screens during this test mode.

DO NOT OPEN BREW CHAMBER OR REMOVE CONTAINER

UNTIL FINISHED.

Entire process (including press out) takes approximately

2 - 2½ minutes.

When the test fi nishes, use the +/- buttons to enter the

amount of water captured in the measuring container.

Press "DONE" when fi nished.

This screen shows the calculation of fl ow meter pulses

based on aproximately 10 ounces.

C

D

E

CALIBRATE FLOW ?

NO YES

CAL TEMPERATURE

NO SENSOR? YES

FACTORY BLOWOUT

NO SENSOR? YES

Use of this test allows user to "tell" the brew exactly how

many ounces are collected during a 10 second test mode.

Temperature probe calibration should only be used by

authorized service technicians when replacing the CBA or

temperature probe. Refer to service manual.

WARNING: ALLOW TANK TO COOL FIRST. USE THIS MODE

FOR TANK DRAINING ONLY. HAVE DRAIN HOSE IN SINK

OR CONTAINER BEFORE PRESSING "YES".

DISCONNECT BREWER

FROM WATER SUPPLY

BEFORE DRAINING

Page 18

42822.1 072810

Page 19

ADVANCED ADJUSTMENTS & OPTIONAL SETTINGS

18.

Exit back to

main screen

A

B

Exit back to

main screen

C

FACTORY DEFAULTS

NO YES

WILL REPLACE ALL

BREW SETTINGS

ARE YOU SURE ?

NO YES

PLEASE WAIT

RESTORE DEFAULTS _ _

Reset all brew settings, calibrations, temperature adjustments and coffee names/recipes back to factory presets.

D

TRIFECTA

VERSION xx.xx

Exit back to

main screen

EXIT PROGRAM MODE TO MAIN SCREEN

Displays Model and Software version:

Page 19

42822.1 072810

Page 20

SCHEMATIC WIRING DIAGRAM TRIFECTA

TANK

FLOW METER

(SIG)

(GND)

(+12V)

BLU/BLK

WHI

YEL

BLK

RED

AIR PUMP

AIR VENT

SOLENOID

SOL

12VDC

TANK HEATER

MOTOR

M

WHI/BLU

WHI/BLU

1

J4

1

J7

THERMOSTAT

BRN

ORN

+-

1

J3

t°

LIMIT

(+12V)

(GND)

J5

156

B

L

K

BREW

INTLK

SWITCH

WHI/VIO

WHI/VIO

J11

10

WHI

BLK

LED

RED +

BLK -

1

J1

J6

1 WHI - Rx: 0 to +5vdc

2 BLK - Board Ground

3 RED - Tx: 0 to +3.4vdc

4 GRN - +12 to +18vdc (non reg supply)

(-)

4

2

(+ .5V HOT-4.5V COLD)

J2

J6

DISPLAY

GRN

RED

4

3

1

WHI

BLK

3

2

1

BLU/BLK

WHI

Earth Ground

BLK

WHI

POWER CORD

42830.0000C 11/10 ©2010 BUNN-O-MATIC CORPORATION

HEATER

BLK

GRN

WHI

Chassis Ground

J9

1

4

BREW

CHAMBER

WHI

FILL

1

3

RED

BRN

3

6

WHI

SOLSOL

120VAC SOLENOIDS

J12

2

J8

4

BREW

CHAMBER

RINSE

BRN

VIO

1

(GND)

(+12V)

BRN

ORN

PRESS

M

OUT

PUMP

100-120V AC

2 WIRE + GND

SINGLE PHASE

Page 20

42822.1 010411

Page 21

SCHEMATIC WIRING DIAGRAM TRIFECTA

TANK

FLOW METER

(SIG)

(GND)

(+12V)

THERMAL FUSE

THERMAL FUSE

BLU/BLK

LIMIT

LIMIT LIMIT

THERMOSTAT THERMOSTATTHERMOSTAT

WHI

AIR PUMP

MOTOR

M

AIR VENT

SOLENOID

SOL

12VDC

1

YEL

BLK

RED

1

THERMOSTAT

TANK HEATER

230VAC

BRN

ORN

WHI/BLU

WHI/BLU

+-

1

J4

J7

J3

t°

(GND)

(+12V)

J5

156

B

L

K

BREW

INTLK

SWITCH

WHI/VIO

WHI/VIO

J11

10

LED

BLK -

J1

J6

1 WHI - Rx: 0 to +5vdc

2 BLK - Board Ground

3 RED - Tx: 0 to +3.4vdc

4 GRN - +12 to +18vdc (non reg supply)

RED +

1

WHI

BLK

(-)

J2

4

2

(+ .5V HOT-4.5V COLD)

3

1

J6

GRN

RED

WHI

BLK

4

2

DISPLAY

3

1

BLU/BLK

WHI

Earth Ground

GRN/YEL

42830.0001B 11/10 ©2010 BUNN-O-MATIC CORPORATION

BRN

BLU

POWER CORD

HEATER

BRN

GRN/YEL

Chassis Ground

BLU

J9

1

4

BREW

CHAMBER

RED

WHI

FILL

1

3

BRN

3

6

WHI

SOLSOL

230VAC SOLENOIDS

J12

2

J8

4

BREW

CHAMBER

RINSE

BRN

VIO

1

(GND)

(+12V)

BRN

ORN

PRESS

M

OUT

PUMP

230V AC CE

2 WIRE + GND

SINGLE PHASE

Page 21

42822.1 010411

Loading...

Loading...