Page 1

BrewWISE

DBC

®

®

BREWERS

WITH SMART FUNNEL

®

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

41746.0000D 04/10 ©2008 Bunn-O-Matic Corporation

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifications to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN

Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with the stylized red line, BUNNlink, Bunn-OMatic,

Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design, Cool Froth, DBC, Dr. Brew stylized Dr. design,

Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity, iMIX, Infusion Series,

Intellisteam, My Café, PowerLogic, Quality Beverage Equipment Worldwide, Safety-Fresh, savemycoffee.com, Scale-Pro,

Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in Beverage

Equipment Worldwide, ThermoFresh, 392, A Partner You Can Count On, Air Brew, Air Infusion, Beverage Bar Creator, Beverage Profit Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Digital Brewer

Control, Nothing Brews Like a BUNN, Pouring Profits, Respect Earth, Respect Earth with the stylized leaf and coffee cherry

design, Signature Series, Tea At Its Best, Phase Brew, The Horizontal Red Line, Titan, trifecta, Ultra, Velocity Brew are

either trademarks or registered trademarks of Bunn-O-Matic Corporation.

Page 2

41746 041410

Page 3

TABLE OF CONTENTS

Warranty .....................................................................................................................................2

Table of Contents ........................................................................................................................3

Troubleshooting ..........................................................................................................................4

Service Tools .............................................................................................................................15

Component Access ...................................................................................................................19

Control Board ......................................................................................................................19

Membrane Switch ................................................................................................................20

Dispense and Bypass Valves................................................................................................21

Refill Valves .........................................................................................................................22

Tank Heaters ........................................................................................................................24

Temperature Probe ..............................................................................................................25

Limit Thermostats ...............................................................................................................25

Warmer Elements ................................................................................................................26

Master Power Switch ...........................................................................................................26

SH Server Timer ..................................................................................................................27

Schematic (Wiring Diagram) .....................................................................................................28

Page 3

41746 040210

Page 4

TROUBLESHOOTING

OVERFLOW CUP

FULL. EMPTY CUP

SERVER NOT

IN PLACE

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection,testing, andrepair ofelectrical equipmentshould beperformed only by qualied

service personnel.

• Allelectroniccomponentshave120-240voltacandlowvoltagedcpotentialontheirterminals.

Shorting of terminals or the application of external voltages may result in board failure.

• Intermittentoperationofelectroniccircuitboardsisunlikely.Boardfailurewillnormallybeper-

manent. If an intermittent condition is encountered, the cause will likely be a switch contact or

a loose connection at a terminal or crimp.

• Solenoidremovalrequiresinterruptingthewatersupplytothevalve.Damagemayresultifsole-

noids are energized for more than ten minutes without a supply of water.

• Theuseoftwowrenchesisrecommendedwheneverplumbingttingsaretightenedorloosened.

This will help avoid twists and kinks in the tubing.

• Makecertainthatallplumbingconnectionsaresealedandelectricalconnectionstightandiso-

lated.

• Thisbrewerisheatedatalltimes.Keepawayfromcombustibles.

WARNING

• Exerciseextremecautionwhenservicingelectricalequipment.

• Disconnectthebrewerfromthepowersourcewhenservicing,exceptwhenelectricaltestsare

specified.

• Followrecommendedserviceprocedures.

• Replaceallprotectiveshieldsorsafetynotices.

Screen Displayed

(SH Models only)

Possible Cause

1. Overflow cup is full of water. This

could be caused by boiling. Refer to

SET TEMP and REFILL sections in

Programming Manual.

1. Soft Heat Server not correctly

positioned on base.

2. Not using a Soft Heat Server, and

the SERVER DETECT function is

activated (on).

Troubleshooting Procedures

Empty cup. Correct cause and

retry.

Position the server so that the connector pins on the server make contact with connector on the brewer.

Disable the SERVER DETECT function.

Page 4

41746 112008

Page 5

TROUBLESHOOTING (cont.)

NO FUNNEL

PRESENT

TEMPERATURE

TOO LOW

CHECK FUNNEL

FOR FRESH COFFEE

PRESS BREW

TO BREW ANYWAY

TO CANCEL

PRESS ON/OFF

TO FINISH:

PRESS BREW

BREW STOPPED!

FUNNEL REMOVED?

Screen Displayed

Possible Cause Troubleshooting Procedures

1. SMART FUNNEL not fully inserted

into the funnel rails.

2. Not using a SMART FUNNEL,

and the FUNNEL DETECT function

is activated (on).

1. Water temperature in the tank

does not meet the SET READY

TEMPERATURE.

1. Brew funnel was not removed

after the previous brew cycle was

finished.

Position the funnel so that the sensor

is directly beneath the sensor coil on

the brewer.

Disable the FUNNEL DETECT function.

(a) Wait for the brewer to heat to the

proper temperature.

(b) Disable the BREW LOCKOUT

function.

Remove funnel, check contents, and

insert back into the funnel rails.

OR

1. Brew funnel was moved out of

position after the brew cycle was

started.

Press BREW to start a brew cycle

without removing the funnel.

To resume brewing, correctly position the funnel and press BREW

again. The brew cycle will resume

from the point it was interrupted.

OR

Press ON/OFF to terminate the

cycle.

Page 5

41746 112008

Page 6

TROUBLESHOOTING (cont.)

TO CANCEL

PRESS ON/OFF

TO FINISH:

PRESS BREW

BREW STOPPED!

SERVER REMOVED?

TO CANCEL

PRESS ON/OFF

TO FINISH:

PRESS BREW

BREW STOPPED!

IS SWITCH OFF?

CHECK HEATING

CIRCUIT

HEATING TIME

TOO LONG

Screen Displayed

1. Soft Heat Server was moved out

of position after the brew cycle was

started.

1. ON/OFF switch was pressed after

the brew cycle was started.

Troubleshooting ProceduresPossible Cause

To resume brewing, correctly

position the Soft Heat Server and

press BREW again. The brew cycle

resumes from the point it was interrupted.

OR

Press ON/OFF to terminate the brew

cycle.

To resume brewing, press BREW

again. The brew cycle resumes form

the point it was interrupted.

1. Tank Heater failure

2. Triac Failure

3. Control Board/Thermistor failure

OR

Press ON/OFF to terminate the brew

cycle.

Service Required. See TANK HEAT-

ERS.

Service Required. See

Service Required. See CONTROL

BOARD

Page 6

41746 112008

Page 7

TROUBLESHOOTING (cont.)

CHECK WATER

SUPPLY

FILL TIME TOO

LONG

CHECK FOR BAD

CONNECTIONS

TEMP SENSOR

OUT OF RANGE

CHECK WIRE FOR

SHORTS

TEMP SENSOR

OUT OF RANGE

Screen Displayed

1. Water shut off to brewer

2. Inlet Solenoid Valve failure

3. Control Board Failure

1. Temperature Sensor Probe wire(s)

broken or not making connection.

Troubleshooting ProceduresPossible Cause

Check water supply shut-off

Service required. See REFILL

VALVE.

Service required. See CONTROL

BOARD.

Check wire and connection of both

black and white wires of temperature

probe.

1. Temperature Sensor Probe

wire(s) shorted to housing, or to

each other.

Check to confirm that wire(s) are

not pinched between two surfaces

or connected to each other.

Page 7

41746 112008

Page 8

TROUBLESHOOTING (cont.)

Problem

Equipment will not operate.

Brew cycle will not start.

Possible Cause

1. No power or incorrect voltage.

1. No water

2. ON/OFF switch

3. Brew switch

4. Brew Valve

Troubleshooting Procedure

Measure the voltage at the terminal

block and confirm that it matches

the voltage specified on the brewer

data plate within +/- 10%.

Check plumbing and shut-off

valves

Test the ON/OFF switch. Refer to the

switch test procedures in SERVICE

TOOLS section.

Test the BREW switch. Refer to the

switch test procedures in SERVICE

TOOLS section.

Test the Brew valve. Refer to Testing

Individual Components in SERVICE

TOOLS section.

Automatic refill will not operate

or display shows FILL TIME TOO

LONG

5. Electronic Control Board

1. No water

2. Water strainer/flow control

(.750 GPM)

Substitute a control board known to

be in good working order.

Check plumbing and shut-off

valves.

(A) Direction of flow arrow must be

pointing towards direction of water

flow.

(B) Remove the strainer/flow control

and check for obstructions. Clear or

replace.

Page 8

41746 112008

Page 9

TROUBLESHOOTING (cont.)

Problem

Automatic refill will not operate or

display shows FILL TIME TOO LONG

(cont.)

Possible Cause

3. Refill Probe or Sensitivity Setting

Troubleshooting Procedure

Check the sensitivity setting. Refer to

Refill function. If the left three digit

number is less than the right number,

the machine “thinks” it is full and the

refill valve should be off. If the left

number is larger than the right, then

the refill valve will automatically be

turned on to fill the tank. The right

number is the threshold setting and

can be adjusted to compensate for

extreme water conditions: very pure,

low conductance water requires a

higher setting, while high mineral

content, high conductance water

requires a lower setting. Note that

the left number changes from a high

value when water is NOT touching

the refill probe to a low value when

water IS touching the probe. For best

operation, the right number should

be set to a value midway between

these low and high numbers. Before

changing the setting, confirm that the

refill probe is free of scale buildup

and the connection to it is secure.

Water flows into tank continuously

with power removed from brewer.

4. Refill Valve

5. Overflow Protection Switch

6. Electronic Control Board

1. Refill valve

Page 9

Test the Refill valve. Refer to Testing

Individual Components.

When this condition occurs, the

brewer will display OVERFLOW CUP

FULL. EMPTY CUP. The reason for

overfilling could be a defective refill

valve, an incorrect sensitivity setting,

(see above) or boiling.

Substitute a control board known to

be in good working order.

Foreign material lodged in valve,

holding it in open state.

41746 112008

Page 10

TROUBLESHOOTING (cont.)

Power

Water flows into tank continuously

with power applied to brewer.

Possible Cause

1. Refill Probe or Sensitivity Setting

Troubleshooting Procedures

Check the sensitivity setting. Refer to

Refill function. If the left three digit

number is less than the right number,

the machine “thinks” it is full and the

refill valve should be off. If the left

number is larger than the right, then

the refill valve will automatically be

turned on to fill the tank. The right

number is the threshold setting and

can be adjusted to compensate for

extreme water conditions: very pure,

low conductance water requires a

higher setting, while high mineral

content, high conductance water

requires a lower setting. Note that

the left number changes from a high

value when water is NOT touching

the refill probe to a low value when

water IS touching the probe. For best

operation, the right number should

be set to a value midway between

these low and high numbers. Before

changing the setting, confirm that the

refill probe is free of scale buildup

and the connection to it is secure.

Water will not heat or display shows

HEATING TIME TOO LONG

2. Electronic Control Board

1. Limit Thermostat

CAUTION - Do not eliminate or

bypass limit thermostat. Use only

replacement part #23717.0003.

2. Tank Heaters

Page 10

Substitute a control board known to

be in good working order.

Remove power from the brewer.

Press reset button on limit thermostat. Then check for continuity

through it.

Remove power from the brewer.

Check for continuity through the

tank heaters.

41746 112008

Page 11

TROUBLESHOOTING (cont.)

Problem

Water will not heat or display shows

HEATING TIME TOO LONG (cont.)

Possible Cause

3. Triac

4. Electronic Control Board

Troubleshooting Procedures

Remove power from the brewer.

Connect a voltmeter across one of

the tank heaters. Reapply power

to the brewer and refer to Testing

Individual Components. If the full

supply voltage is measured when

the tank heater is turned on, and

zero voltage is measured with the

triac off, then the triac is good. If

half the supply voltage is measured,

the triac is defective. If very low, or

zero voltage is measured, there could

be a defective triac or a defective

control board.

Perform the above procedure for

testing triacs. If the voltage measured is very low or zero, then

substitute a control board known to

be in good working order.

Spitting or unusual steaming from

sprayhead or air vents. (Water too

hot)

1. Triac

2. Lime Buildup

CAUTION - Tank and tank components should be delimed regularly

depending on local water conditions. Excessive mineral buildup on

stainless steel surfaces can initiate

corrosive reactions resulting in serious leaks.

Remove power from the brewer.

Connect a voltmeter across one of

the tank heaters. Reapply power

to the brewer and refer to Testing

Individual Components. If the full

supply voltage is measured when

the tank heater is turned on, and

zero voltage is measured with the

triac off, then the triac is good. If

half the supply voltage is measured,

the triac is defective. If very low, or

zero voltage is measured, there could

be a defective triac or a defective

control board.

Inspect the tank assembly for excessive lime deposits. Delime as

required.

Page 11

41746 112008

Page 12

TROUBLESHOOTING (cont.)

Problem

Spitting or unusual steaming from

sprayhead or air vents. (Water too

hot) (cont.)

Inconsistent beverage level in

server.

Possible Cause

3. Electronic control board

1. Strainer/flow control (.750

GPM)

2. Improper water pressure

3. Brew Valve

Troubleshooting Procedures

Perform the previous procedure

for testing triacs. If the voltage

measured is very low or zero, then

substitute a control board known to

be in good working order.

(A) Direction of flow arrow must be

pointing towards the brewer.

(B) Remove the strainer/flow control

and check for obstructions. Clear or

replace.

Check operating water pressure to

the brewer. It must be between 20

and 90 psi (138 and 620 kPa).

Test the Brew Valve. Refer to Testing

Individual Components. Turn the

valve on for 30 seconds and collect

the water dispensed from the sprayhead. Repeat the test several times

to confirm a consistent volume of

dispensed water. If not consistent,

check the valve, tubing and sprayhead for lime buildup.

4. Bypass Valve

5. Lime buildup

Page 12

If bypass is being used on the

inconsistent brewing recipe, test

the Bypass Valve. Refer to Testing

Individual Components. Turn the

valve on for 30 seconds and collect

the water collected from the bypass

opening. Repeat the test several

times to confirm a consistent volume

of dispensed water. If not consistent,

check the valve, tubing and bypass

opening for lime buildup.

Inspect for lime buildup that could

block the tank, tank fittings, tubing,

valves and sprayhead.

41746 112008

Page 13

TROUBLESHOOTING (cont.)

Problem Possible Cause

Consistently high or low beverage

1. Brew Volume adjustment

level in server.

Dripping from sprayhead.

Water overflows filter.

1. Brew Valve

1. Type of paper filters

2. No sprayhead

Beverage overflows server.

1. Beverage left in server from previous brew

2. Brew Volume adjustment

Troubleshooting Procedures

Adjust the brew volume as required

to achieve the recommended volume

for each brew cycle.

Repair or replace leaky valve.

BUNN paper filters should be used

for proper extraction.

Check sprayhead

The brew cycle should be started

only with an empty server under

the funnel.

Adjust the brew volume as required

to achieve the recommended volume

for each brew cycle.

Weak beverage.

1. Type of paper filters

2. Coffee

3. Sprayhead

4. Funnel Loading

5. Water temperature

BUNN paper filters should be used

for proper extraction.

A sufficient quantity of fresh drip

or regular grind should be used for

proper extraction.

The correct B.O.M. sprayhead should

be used to properly wet the bed of

ground coffee in the funnel.

The BUNN paper filter should be

centered in the funnel and the bed

of ground coffee leveled by gentle

shaking.

Empty the server, remove its cover,

and place the server beneath the

sprayhead. Place empty funnel over

the server entrance, with ON/OFF

switch in the "ON" position press

the start switch and release it. Check

the water temperature immediately

below the sprayhead with a thermometer. The reading should not

be less than 195˚F (91˚C).

Page 13

41746 112008

Page 14

TROUBLESHOOTING (cont.)

Problem

Weak beverage (cont.)

Brewer is making unusual noises.

Possible Cause Troubleshooting Procedures

6. Incorrect Recipe

Consider adjusting bypass percentage, preinfusion, or pulse brew.

Contact Bunn-O-Matic for suggestions.

1. Solenoid (Inlet)

The nut on back of the solenoid

must be tight or it will vibrate during

operation

2. Plumbing lines

Plumbing lines should not be resting

on the counter top.

3. Water Supply

(A) The brewer must be connected

to a cold water line.

(B) Water pressure to the brewer

must not be higher than 90 psi (620

kPa). Install a regulator if necessary

to lower the working pressure to approximately 50 psi (345 kPa).

4. Tank Heaters.

Remove and clean lime off tank

heaters.

Page 14

41746 112008

Page 15

TROUBLESHOOTING (cont.)

SERVICE TOOLS

This function allows the testing of individual com-

ponents and the ability to check switches for proper

function. This function also tests the Soft Heat server's

status on the brewer (in place or removed), and the

funnel sensor coil's frequency (diagnostic tool for

troubleshooting purposes only).

Testing individual components (outputs):

This will allow the operator to test the operation

of individual components and outputs of the brewer.

The components that can be individually tested are as

follows:

SINGLE Brewers

Brew Valve

Bypass Valve

Funnel Lock (Optional)

Server (SH models only)

Refill Valve

Tank Heaters

Heater Contactor

DUAL Brewers

Left Brew Valve

Left Bypass

Left Funnel Lock (Optional)

Left Server (SH models only)

Right Brew Valve

Right Bypass

Right Funel Lock (Optional)

Right Server (SH models only)

Refill Valve

Tank Heaters

Heater Contactor

Procedure to test components (outputs):

1. Place brew funnel(s) into rails on the brewer (both

sides on DUAL brewers).

2. Place server(s) beneath the brew funnel(s).

3. Press and hold the upper right hidden switch until

display reads UNITS. Release the switch. Continue

to press and release switch until SERVICE TOOLS

appears.

4. Press YES to run tests on various components

and outputs within the brewer. Pressing NO will

exit this function and advance to next function

screen.

5. The display should read TEST OUTPUTS.

Page 15

6. Press and release YES. The display should read:

BREW VALVE on SINGLE brewers

LEFT BREW VALVE on DUAL brewers.

7. To test BREW VALVE, press ON. If the brew valve

is functional, water should run from the brewer

(left side on DUAL brewers)

8. Press OFF to end flow of water.

9. Press NEXT to advance to the next component to

be tested.

NOTE: To bypass testing any component, press NEXT

to advance to the next one, without testing the previous component.

10. To test BREW BYPASS on SINGLE brewers or LEFT

BREW BYPASS on DUAL brewers, press ON. If the

bypass valve is functional, water should run from

the brew bypass (left side on DUAL brewers).

11. Press OFF to end flow of water.

12. Press NEXT to advance to the next component to

be tested.

13. To test FUNNEL LOCK on SINGLE brewers or LEFT

FUNNEL LOCK on DUAL brewers, press ON. If the

funnel lock is functional, the lock will come down

to hold the funnel in place.

14. Press OFF to retract the funnel lock.

15. Press NEXT to advance to the next component to

be tested.

16. (SH models only) To test SERVER on SINGLE

brewers or LEFT SERVER on DUAL brewers, press

ON. If the server and the sensor are functional, the

light on the lower right corner of the server will

illuminate.

17. Press OFF to end testing of server.

18. Press NEXT to advance to the next component to

be tested.

19. For DUAL brewers, follow steps 7 through 16 to

test the right side components.

20. To test REFILL VALVE, press ON. If the refill valve

is functional, the sound of the valve operating will

be heard.

21. Press OFF to end testing of refill valve.

22. Press NEXT to advance to the next component to

be tested.

23. To test TANK HEATERS, connect a voltmeter across

each of the tank heaters to check for voltage.

24. Press ON. The correct voltage should be present

at the heater terminals.

25. Press OFF to end testing of the tank heaters.

41746 112008

Page 16

TROUBLESHOOTING (cont.)

SERVICE TOOLS (cont.)

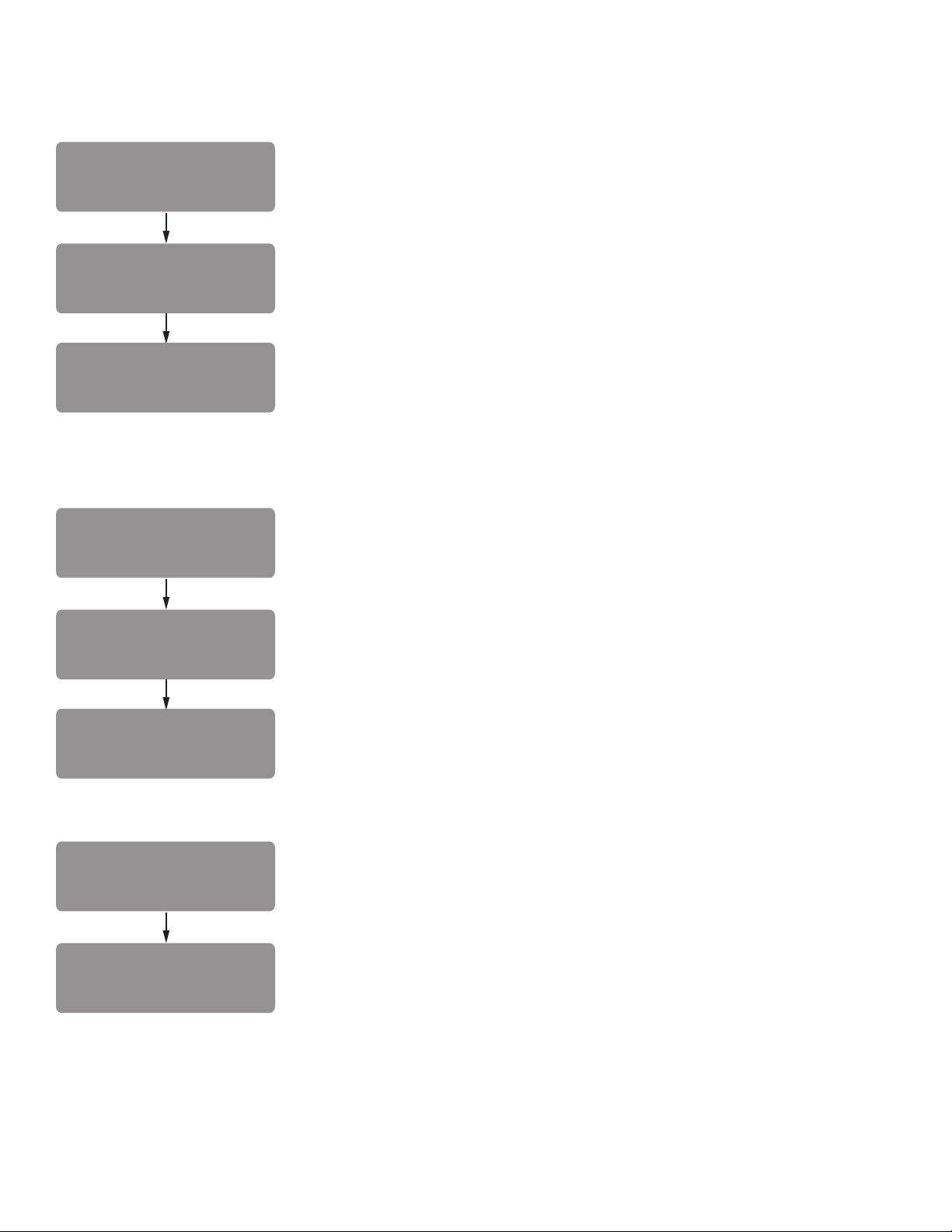

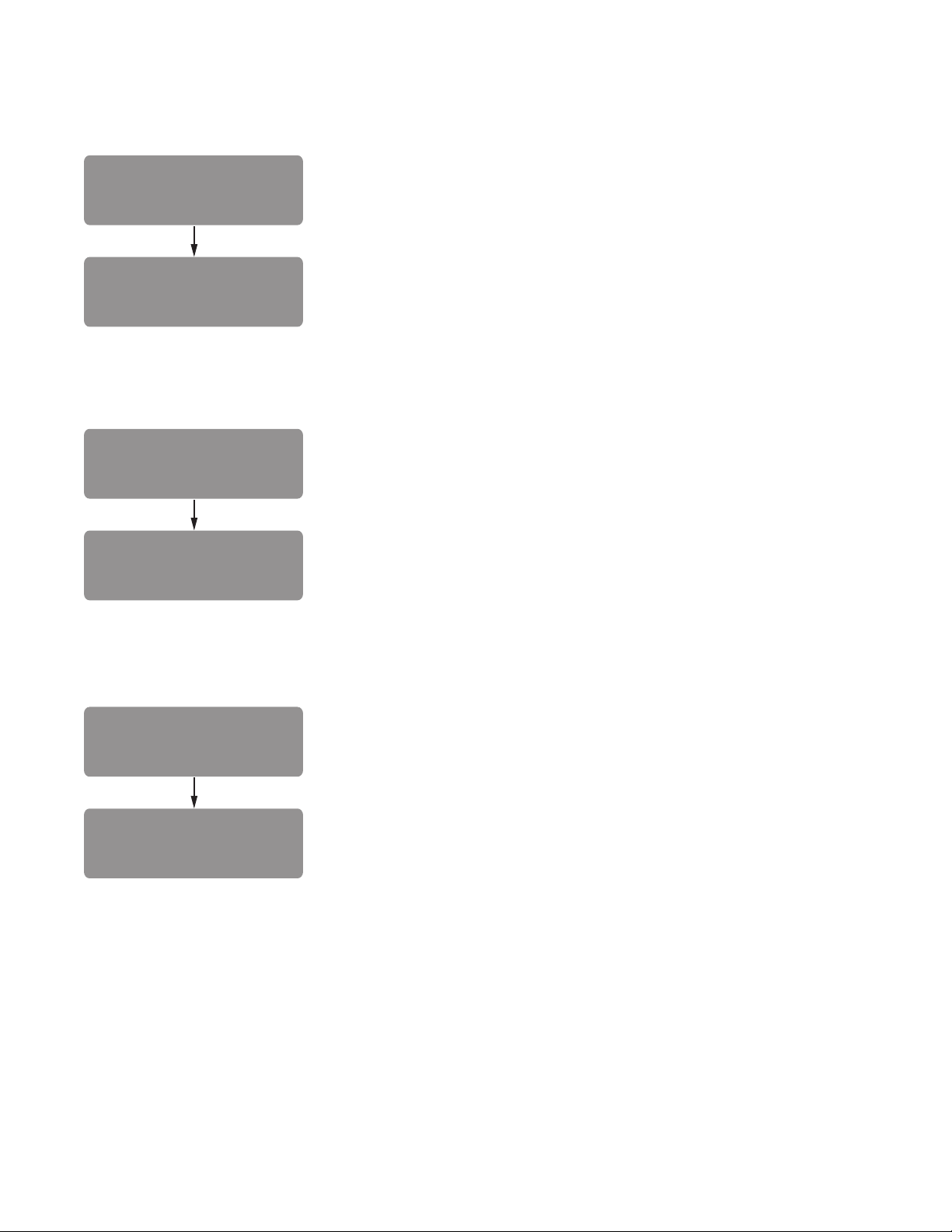

SERVICE TOOLS?

NO YES

EXIT TO

NEXT FUNCTION

SCREEN

TEST OUTPUTS?

NO YES

TEST SERVERS?

NO YES

TEST FREQUENCY?

NO YES

TEST SWITCHES?

NO YES

NOTHING PRESSED

SINGLE

BREWERS

SERVER REMOVED

DUAL

BREWERS

<- SERVER REMOVED

PRESS AND RELEASE

® SYMBOL

SINGLE

BREWERS

PRESS AND RELEASE

® SYMBO L

IN PLACE ->

SINGLE

BREWERS

BREW VALVE

ON NEXT OFF

BYPASS

ON NEXT OFF

FUNNEL LOCK

ON NEXT OFF

SERVER

ON NEXT OFF

REFILL VALVE

ON NEXT OFF

DUAL

BREWERS

LEFT BREW VALVE

ON NEXT OFF

LEFT BYPASS

ON NEXT OFF

LEFT FUNNEL LOCK

ON NEXT OFF

LEFT SERVER

ON NEXT OFF

RIGHT BREW VALVE

ON NEXT OFF

EXIT TO

NEXT FUNCTION

SCREEN

125.0 KHZ. 4

DUAL

BREWERS

<-<-<- 125.0 KHZ. 4

4 125.0 KHZ ->->->

PRESS AND RELEASE

® SYMBOL

Page 16

TANK HEATRS

ON NEXT OFF

HEATER CONTACTOR

ON NEXT OFF

RIGHT BYPASS

ON NEXT OFF

RIGHT FUNEL LOCK

ON NEXT OFF

RIGHT SERVER

ON NEXT OFF

41746 112008

Page 17

TROUBLESHOOTING (cont.)

SERVICE TOOLS (cont.)

NOTE: The tank heater will automatically turn off if

left on too long.

26. After testing the tank heater, press NEXT to advance

to the next test.

27. The HEATER CONTACTOR is used only on certain

models. Check the machine schematic to see if the

contactor is present. Connect a voltmeter across a

tank heater that is operated by the contactor and

press ON to check that correct voltage is present.

Press OFF and confirm the voltage is zero.

28. Press NEXT to return to TEST OUTPUTS.

29. To exit SERVICE TOOLS, press and release the

ON/OFF switch (either on DUAL brewers) located

on the front switch panel. This will return to the

MAIN SCREEN.

Procedure to test switches:

This function allows the operator to test the opera-

tion of the individual switches on the front panel.

1. Place brew funnel(s) into rails on the brewer (both

sides on DUAL brewers).

2. Place server(s) beneath the brew funnel(s).

3. Press and hold the upper right hidden switch until

display reads UNITS. Release the switch. Continue

to press and release switch until SERVICE TOOLS

appears.

4. Press YES to run tests on various components

and outputs within the brewer. (Pressing NO will

exit this function and advance to the next function

screen.)

5. The display should read TEST OUTPUTS.

6. In TEST OUTPUTS screen, press NO. This advances

to TEST SWITCHES.

7. Pressing NO in this screen will advance to the

next function. Press YES in the TEST SWITCHES

screen to test the switches. The display will read

NOTHING PRESSED.

8. From this screen, press any of the switches on the

front of the brewer except the upper right hidden

switch. While the switch is pressed, the display

shows the name of that switch. If the name does

not appear, or if it remains after the switch has been

released, the switch is defective. Each switch can

be tested in this manner.

9. After all switches have been tested, press and release the right hidden switch (®). This will return

Page 17

to TEST SWITCHES?. Press and release switch

again to advance to TEST SERVERS?. Another

alternative is to press and release the ON/OFF

switch (either on DUAL brewers) located on the

front switch panel. This will exit TEST SWITCHES

and return to the MAIN SCREEN.

Procedures to test servers: (SH models only)

This function allows the operator to test the opera-

tion of the Soft Heat servers. It will also show if the

server is correctly placed on the brewer stand.

1. Place brew funnel(s) into rails on the brewer (both

sides on DUAL brewers).

2. Place a Soft Heat server(s) beneath the brew

funnel(s).

3. Press and hold the upper right hidden switch until

the display reads UNITS. Release the switch. Con-

tinue to press and release switch until SERVICE

TOOLS? appears.

4. Pressing NO will exit this function and advance to

the next function screen. Press YES to run tests

on various components and outputs within the

brewer.

5. The display should read TEST OUTPUTS?

6. In TEST OUTPUTS screen, press NO. This advances to TEST SWITCHES?. Press and release

NO once more. The display should now read TEST

SERVER(S)?

7. Press YES in the TEST SERVER(S) screen to show

if a server is in place. The display should read IN

PLACE (with arrows pointing to the left and right

on DUAL brewers).

8. Lift and pull both Soft Heat servers forward about

2 inches so that the two contacts on each server

do not touch the two contacts on the brewer.

9. The display should then read SERVER REMOVED

(with arrows pointing to the left and right on DUAL

brewers).

10. After the server(s) have been tested, press and release the ON/OFF switch (either on DUAL brewers)

located on the front switch panel. This will exit TEST

SERVERS and return to the MAIN SCREEN.

Procedures to test coil frequency:

1. Place brew funnel(s) into rails on the brewer (both

sides on DUAL brewers).

2. Place server(s) beneath the brew funnel(s).

41746 112008

Page 18

TROUBLESHOOTING (cont.)

SERVICE TOOLS (cont.)

3. Press and hold the upper right hidden switch until

the display reads UNITS. Release the switch.

Continue pressing and releasing the upper right

hidden switch until SERVICE TOOLS appears.

4. Pressing NO will exit this function and advance to

the next function screen. Press YES to run tests

on various components and outputs within the

brewer.

5. The display should read TEST OUTPUTS?.

6. In TEST OUTPUTS screen, press NO. Continue

to press and release NO until the display reads

TEST FREQUENCY?.

7. Press and release YES. The display will show the

frequency of the sensor coil circuits. This is for

diagnostic service use when troubleshooting this

circuit.

8. After the coils have been tested, press and release

the ON/OFF switch (either on DUAL brewers)

located on the front switch panel. This will exit

the TEST FREQUENCY function and return to the

MAIN SCREEN.

NOTE: If the operator wishes to test more than one

function in the SERVICE TOOLS section (outputs,

switches, servers, or coil frequency), it is not

necessary to exit the program. Use the flow chart

for SERVICE TOOLS to navigate to a particular

function.

Page 18

41746 112008

Page 19

COMPONENT ACCESS

This section provides procedures for testing and

replacing various major components used in this

brewer should service become necessary. Refer to

Troubleshooting for assistance in determining the

cause of any problem.

If no voltage is present, check wiring to the board.

If voltage is present, and brewer does not power on,

replace board.

WARNING - Inspection, testing, and repair of electri-

cal equipment should be performed only by qualified

service personnel. The brewer should be disconnected

from power source when servicing, except when

electrical tests are required and the test procedure

specifically states to plug in the brewer.

WARNING - Disconnect the brewer from the power

source before the removal of any panel or the replacement of any component.

All components are accessible by the removal of

the top cover, front access panel and platform cover.

Refer to wiring diagrams at the back of this manual

when reconnecting wires.

CONTROL BOARD

Control Board Mounting Nut

Removal and Replacement:

1. Disconnect brewer from power source.

2. Disconnect the funnel sensor(s) from connector

J9 on the control board.

3. Disconnect the main harness from connector J11

on the control board.

4. Disconnect the ribbon cable from connector J4 on

the control board.

5. Disconnect the level probe harness and server

detect harness for SH models from connector J2

on the control board.

6. Remove the two mounting nuts securing the top

of the control board to the hood.

7. Tilt the control board inward to clear the display

section and lift out of the control board mount.

8. Place the bottom edge of the new control board

in the control board mount, tilt the board forward,

and secure with the two keps nuts.

9. Re-connect wires to the circuit board.

Ribbon Cable

Control Board Mount

FIG 1 CONTROL BOARD MOUNTING

Location:

The Control Board (Fig 1) is located under the top

cover behind the control panel.

Check for Power to board:

1. Insert one meter lead in J11-pin 12 and the other

lead in J11-pin 14.

2. With the power connected to brewer, the voltage

reading to the board should be the line voltage

rated for that model.

Page 19

41746 112008

Page 20

COMPONENT ACCESS (cont)

MEMBRANE SWITCH

Funnel Sensor

FIG 2 MEMBRANE SWITCH

Location:

The Membrane Switch (Fig 2) is located on the front

of the hood with a ribbon cable extending through the

hood and connected to the control board.

4. Remove any adhesive that remains on the hood.

5. Remove the adhesive backing from the new membrane switch. Insert the ribbon cable through the

slot in the hood and apply the membrane switch

to the front of the hood.

6. Reconnect the ribbon cable to the 20-pin connector on the control board making sure every pin on

the control board is inserted into the ribbon cable

connector.

Test Procedures:

There are two methods for testing the membrane

switch. The easiest method is to use the built in test

mode. Refer to the Trouble Shooting Section for Service

Tools/Test Switches. If for some reason you can't get

into the program modes, or brewer won't power up,

you can test it with an ohmmeter or continuity tester.

Refer to the schematic to trace the appropriate pins.

NOTE: Pin 1 is the static shield & will not provide a

reading to the other pins. There are three commons

in this circuit, pins #2, 11 & 12.

Disconnect brewer from power source before disconnecting ribbon cable from control board.

Removal and Replacement:

1. Disconnect the ribbon cable from 20-pin connector

on the control board.

2. Disconnect the wires from funnel sensor(s)and

remove sensor(s) from the front of the hood.

3. Gently peel the membrane switch from the

hood.

Page 20

41746 112008

Page 21

COMPONENT ACCESS (cont)

DISPENSE & BYPASS VALVES

FIG 3 DISPENSE & BYPASS VALVES

Location:

The dispense and bypass valve(s) (Fig 3) are located

inside the hood under the top cover.

Test Procedures:

1. Refer to the Trouble Shooting Section for Service

Tools/Test Outputs/Dispense/Bypass Valve.

2. Be sure brew funnel & server are in place before

activating valve.

3. Check the valve for coil action. Turn on the valve

with the test mode. Listen carefully in the vicinity

of the dispense/bypass valve for a click as the coil

pulls the plunger in.

If no sound is heard as described, proceed to

#4.

If the sound is heard as described, there may be a

blockage in the valve , hose, tank, or sprayhead. Disconnect the brewer from the power source. Remove

the valve and inspect for blockage, and de-lime all

related areas.

If the polarity of meter leads are reversed, reading

will indicate -170VDC. (Double these readings for

240 volt coils)

If voltage is present as described, but no coil action

is observed, valve is defective. Replace valve and test

again to verify repair.

If voltage is not present as described, refer to Wiring Diagrams and check the brewer wiring harness.

Also check the control board and switch for proper

operation.

Removal and Replacement:

1. Disconnect the brewer from the power source.

2. Disconnect wires from the valve.

3. Drain enough water from the tank so the water

level is below the outlet.

4. Remove tube(s) from the valve.

5. Dispense valve:

Remove the sprayhead and nut securing valve to

the sprayhead panel.

Bypass valve:

Remove the two #8-32 mounting nuts.

6. Install new valve using nut(s) removed in step 5.

Clean and install the sprayhead.

7. Reconnect tube(s) to the valve and secure in place

with clamp(s).

4. Connect the voltmeter leads to the coil terminals.

Turn on the valve with the test mode. NOTE: Due

to the internally rectified coil, the indication will

be 120VAC all the time. Set the meter to DC volts.

The indication should be 170VDC when activated.

Page 21

41746 112008

Page 22

COMPONENT ACCESS (cont)

REFILL VALVE

FIG 4 REFILL VALVE

(DUAL SH DBC Models)

FIG 5 REFILL VALVE

(SINGLE SH DBC Models)

FIG 6 REFILL VALVE

(DUAL TF DBC Early Models)

FIG 7 REFILL VALVE

(DUAL TF DBC Late Models)

Page 22

41746 112008

Page 23

COMPONENT ACCESS (cont)

REFILL VALVE (cont)

FIG 8 REFILL VALVE

(DUAL GPR DBC Models)

Location:

DUAL SH DBC models:

SINGLE TF DBC late models:

DUAL TF DBC late models:

The refill valve is located inside the front of the

brewer behind the front access panel.

If voltage is not present, refer to Wiring Diagrams

and check main wiring harness. If harness checks ok,

replace control board.

4. Check the refill valve for coil action. Briefly activate

the refill valve in the test mode and listen carefully

near the refill valve for a"clicking" sound as the

magnetic coil pulls the plunger in.

If the sound is heard as described and water will not

pass through the refill valve, there may be a blockage

in the water line before the refill valve or, the solenoid

valve may require inspection for wear, and removal of

waterborne particles.

If the sound is not heard as described, proceed to

# 5.

5. Disconnect the brewer from the power source.

6. Check for continuity across the refill valve coil

terminals.

If continuity is not present as described, replace

the refill valve.

If continuity is present as described, there could

be some debris in the valve.

SINGLE SH DBC models:

SINGLE GPR DBC models:

SINGLE TF DBC early models:

DUAL GPR DBC models:

DUAL TF DBC early models:

The refill valve is located inside the hood of the

brewer under the top cover.

Test Procedures:

1. Enter programming level 2, scroll to "Service Tools"

then scroll to "Refill Valve".

2. Briefly activate the refill valve in the test mode.

With a voltmeter, check the voltage across the coil

wires.

3. The indication must be 120 volts ac for two wire

120 volt models, three wire 120/208, and 120/240

volt models or 230 volts ac for two wire 230 volt

models.

If voltage is present, proceed to # 4.

Removal and Replacement:

1. Shut off the water supply.

2. Remove both wires from the refill valve.

3. Disconnect both water lines at the valve.

4. Remove the two 1/4"-20 screws securing the valve

to the component mounting bracket.

5. Using the two 1/4"-20 screws, install the new valve

to the component mounting bracket.

6. Securely fasten the water lines to the valve.

7. Refer to wiring diagrams when reconnecting the

wires.

8. Install access panels and covers and refer to Initial

Set-up for refill and operation.

Page 23

41746 112008

Page 24

COMPONENT ACCESS (cont)

TANK HEATERS

Location:

The tank heaters (Fig 9) are located inside the tank,

secured to the tank lid.

Test Procedures:

1. With a voltmeter, check voltage across the white

wire (120V Models) or red wire (120/208 and

120/240V Models) and blue wire on the top of

the tank heaters. Connect brewer to the power

source. The indication must be 120 volts ac for

two wire 120 volt models, 208 volts ac for three

wire 120/208 volt models and 240 volts ac for

120/240 volt models (during a heating cycle).

2. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #3.

If voltage is not present as described, refer to the

Wiring Diagrams and check wiring harness. If harness

checks ok, replace control board.

3. Disconnect the wires from the tank heater terminals.

4. Check resistance value across tank heater terminals

and compare to chart.

If resistance is present as described, reconnect the

wires, the tank heater is ok.

If resistance is not present as described, replace the

tank heater.

Tank Heaters

FIG 9 TANK HEATERS

Removal and Replacement:

1. Remove the top cover from the brewer.

2. Disconnect the wires from tank heater terminals.

3. Remove the four #8-32 nuts securing the tank

heater(s) to the tank lid assembly.

4. Remove tank heater(s) with gasket(s) and discard.

5. Install new tank heater(s) with gasket(s) to the

tank lid assembly with the original nuts.

6. Reconnect the wires to the tank heater(s) terminals.

NOTE- If any resistance is read between sheath and

either terminal, remove and inspect heater for cracks

in the sheath.

HEATER RESISTANCE

1800W-120V 8.05

2200W-120V 6.54

2850W-208V 15.25

3300W-240V 18.81

4000W-208V 11.0

4000W-240V 14.47

5000W-240V 11.65

TERMINAL TO SHEATH - INFINITE (OPEN)

Page 24

41746 112008

Page 25

COMPONENT ACCESS (cont)

TEMPERATURE PROBE

Removal and Replacement:

1. Disconnect the brewer from the power source.

2. Refer to instructions included in Temperature Probe

Kit#29327.0000toreplaceTemperatureProbe.

LIMIT THERMOSTAT

Temperature Probe

FIG 10 TEMPERATURE PROBE

Location:

The temperature probe (Fig 10) is inserted into a

grommet in the tank lid assembly.

Test Procedures:

1. Disconnect the brewer from the power source.

2. With a DC voltmeter, check voltage across the

black and white wires at J2 on control board (Black

voltmeter probe to black wire, red voltmeter probe

to white wire). Connect the brewer to the power

source. The indication should be aproximately between 4vdc cool to 1vdc at ready temperature.

3. Disconnect the brewer from the power source.

If voltage is present as described, circuit is working

correctly, check limit thermostat (and TCO on 200V

and 230V models).

If voltage is not present as described, proceed to

#4.

4. Disconnect temperature probe from J2 on control

board. Check the resistance across the two terminals of the temperature probe. The indication

shouldbeaproximatelybetween10.5K

cool to

870 at ready temperature.

If resistance is to specification, replace the control

board.

If resistance is not to specification, replace the temperature probe.

Page 25

Limit Thermostats

FIG 11 LIMIT THERMOSTATS

Location:

The limit thermostats (Fig 11) are located under

the top cover on the tank lid assembly.

Test Procedures:

1. Disconnect the brewer from the power source.

2. Disconnect the wires from the limit thermostat.

3. With an ohmmeter, check for continuity across

the limit thermostat terminals.

If continuity is present as described, the limit thermostat

is operating properly.

If continuity is not present as described, replace the

limit thermostat.

Removal and Replacement:

1. Remove the wires from limit thermostat terminals.

2 Remove the two #8-32 nuts securing the limit

thermostat to the tank lid and lift limit thermostat

off the studs.

3. Install the new limit thermostat onto the studs on

the tank lid and secure with original nuts.

4. Connect the wires to the limit thermostat.

41746 112008

Page 26

COMPONENT ACCESS (cont)

WARMER ELEMENTS (GPR MODELS)

Removal and Replacement:

1. Remove the three #4-40 screws securing the

warmer assembly to the brewer.

2. Lift the warmer assembly from the brewer.

3. Disconnect the two wires from the warmer element

terminals.

4. Remove the two #8-32 nuts securing the warmer

element to the warmer plate.

5. Securely install new warmer element.

6. Reconnect the two wires to warmer element terminals.

7. Securely install warmer assembly on the brewer.

FIG 12 WARMER ELEMENTS

Location:

The warmer element(s) (FIG 12) is located under

the warmer plate(s).

Test Procedures:

1. Disconnect the brewer from the power source.

2. With a voltmeter, check voltage across the two

wires at the warmer element with the "ON/OFF"

switch in the "ON" position. Connect the brewer

to the power source. The indication must be 120

volts ac.

3. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #4.

If voltage is not present as described, refer to Wiring

Diagrams and check wiring harness.

4. Check the resistance across the two terminals on

warmer element. Resistance should be 144.0

terminal to sheath - infinite (open).

MASTER POWER SWITCH

FIG 13 MASTER POWER SWITCH

Location:

The main power switch (FIG 13) is located under the brewer in the base just behind the right front

,

leg on SH and GPR models and behind the front

support leg on TF models.

If resistance is to specification, reconnect the two

wires to the warmer element.

If resistance is not to specification, replace the warmer

element.

Page 26

Test Procedure:

1. Disconnect the brewer from the power source.

2. Disconnect the wires from the power switch. With

the switch in the ON position, check for continuity

between terminals opposite each other.

There should be continuity between the two terminals

on each side when the switch is in the ON position,

no continuity when in the OFF position.

41746 040210

Page 27

COMPONENT ACCESS (cont)

MASTER POWER SWITCH (cont)

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Disconnect the brewer from the power source.

2. Disconnect the wires from the power switch.

3. Remove the switch mounting screws from the

under the base.

4. Install new switch in trunk with the two 6-32 x ¼˝

mounting screws.

5. Connect wires to the switch terminals.

SH SERVER TIMER SETTING

Timer may be set to the OFF position as shown

on Tag (Fig 15) to prevent the LED on the front of

the server from flashing, or one of nine various settings to flash the LED after Timer has expired. For

instance, setting Timer on position 5 will flash the

LED after 120 minutes. Server must be docked on a

SH Brewer or SH Server Stand to engage Timer.

INSTRUCTIONS:

•Emptyallcontentsandturnserverupsidedown.

•Removetwoscrews(Fig14)securingbottom

cover to server, remove bottom cover from server.

•RefertotheTimerSettingTag(Fig15)todeter-

mine the desired timer setting number.

•Usingasmallatbladescrewdriver,settheTimer

to the corresponding number (Fig 16).

•Installthebottomcoveronserverandsecurewith

screws.

FIG 15 TIMER & TAG

FIG 16 SETTING TIMER

FIG 14 REMOVE BOTTOM COVER

Page 27

41746 040210

Page 28

LIMIT THERMOSTAT

TRIAC

TANK HEATER

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

WHI

WHI

WHI

MT 1 BLU -14

BLK-14 BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

+

–

AC

AC

RECTIFIER

4

AMP

24VDC

+

–

WHI

BLK

BLU/BLK

BLK

BLU/BLK

RED

120/208 OR 120/240

VOLT A.C. + GND

SINGLE PHASE

32043.0000D 01/07 © 2000 BUNN-O-MATIC CORPORATION

SCHEMATIC WIRING DIAGRAM

SINGLE® SH with SMART FUNNEL® (DBC)

MT2

SERVER

TRANSFORMER

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI

WHI/VIO

GRY

WHI/GRN

VIO

SWITCH UNIT ASSY

SHIELD

FUNNEL SENSOR

CONTROL PC BOARD

WATER LEVEL

PROBE

TEMP

PROBE

VIO

WHI/VIO

WHI

PNK

BLK

BLK

GRN

WHI/RED

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

GRN

RED-14

BLK-14

N

L1

BLK-14

RED-14

RED-14

BLK-14

MODELS WITH MAIN ON/OFF SWITCH ONLY

WHI

WHI

L2

RED

BLK

41746 112008

Page 28

Page 29

LIMIT THERMOSTAT

TRIAC

TANK HEATER

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

MT 1 BLU -14

BLK-14

BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

+

–

AC

AC

RECTIFIER

4

AMP

24VDC

+

–

BLK

BLU/BLK

BLK

BLU/BLK

RED

230 VOLT AC

2 WIRE

SINGLE PHASE

50HZ

MT2

SERVER

TRANSFORMER

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI/VIO

GRY

WHI/GRN

VIO

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

RED

RED

RED RED

RED

RESETTABLE

FUSE

BLK

SCHEMATIC WIRING DIAGRAM

SINGLE SH DBC (W/SMART FUNNEL)

L2

L1

RED

RED

EMI

FILTER

GRN/YEL

BLK

BLK

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

C1 D1 A1 B1 B2 A2 D2 D3 C2 C3

L3

L4 L1 L2

TOUCH SWITCH ASSMBLE

Page 29

41746 112008

Page 30

LIMIT THERMOSTAT

TRIAC

TANK HEATER

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

MT 1 BLU -14

BLK-14

BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

+

–

AC

AC

RECTIFIER

4

AMP

24VDC

+

–

BLK

BLU/BLK

BLK

BLU/BLK

RED

200 VOLT AC

2 WIRE

SINGLE PHASE

50/60HZ

MT2

SERVER

TRANSFORMER

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI/VIO

GRY

WHI/GRN

VIO

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

RED

RED

RED RED

RED

RESETTABLE

FUSE

BLK

SCHEMATIC WIRING DIAGRAM

SINGLE SH DBC (W/SMART FUNNEL)

L2

L1

RED

RED

EMI

FILTER

GRN/YEL

BLK

BLK

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

C1 D1 A1 B1 B2 A2 D2 D3 C2 C3

L3

L4 L1 L2

TOUCH SWITCH ASSMBLE

Page 30

41746 112008

Page 31

LIMIT THERMOSTAT

TRIAC

TANK HEATER

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI-14

WHI

WHI

WHI

WHI

W

H

I

L1

N

MT 1 BLU -14

BLK-14 BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

+

–

AC

AC

RECTIFIER

4

AMP

24VDC

+

–

WHI

BLK

BLU/BLK

BLK

BLU/BLK

RED

120 VOLT A.C.

2 - WIRE

SINGLE PHASE

SCHEMATIC WIRING DIAGRAM

SINGLE® SH with SMART FUNNEL® (DBC)

MT2

SERVER

TRANSFORMER

B

L

K

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI

WHI/VIO

GRY

WHI/GRN

VIO

SWITCH UNIT ASSY

SHIELD

FUNNEL SENSOR

CONTROL PC BOARD

WATER LEVEL

PROBE

TEMP

PROBE

VIO

WHI/VIO

WHI

PNK

BLK

BLK

GRN

WHI/RED

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

Page 31

41746 112008

Page 32

LIMIT THERMOSTAT

TRIAC

TANK HEATER

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

WHI

WHI

WHI

MT 1 BLU -14

BLK-14 BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

+

–

AC

AC

RECTIFIER

4

AMP

24VDC

+

–

WHI

BLK

BLU/BLK

BLK

BLU/BLK

RED

SCHEMATIC WIRING DIAGRAM

SINGLE SH DBC with SMART FUNNEL

(With Audible Alarm)

MT2

SERVER

TRANSFORMER

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI

WHI/VIO

GRY

WHI/GRN

VIO

SWITCH UNIT ASSY

SHIELD

FUNNEL SENSOR

CONTROL PC BOARD

WATER LEVEL

PROBE

TEMP

PROBE

VIO

WHI/VIO

WHI

PNK

BLK

BLK

GRN

WHI/RED

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

WHI

BLK

AUDIBLE

ALARM

(FRESHNESS)

120/208 VOLT A.C. OR

120/240 VOLT A.C.

3 WIRE + GND

SINGLE PHASE

GRN

RED-14

BLK-14

N

L1

BLK-14

RED-14

RED-14

BLK-14

MODELS WITH MAIN ON/OFF SWITCH ONLY

WHI

WHI

L2

RED

BLK

Page 32

41746 112008

Page 33

LIMIT THERMOSTAT

TRIAC

TANK HEATER

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

MT 1 BLU -14

BLK-14

BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

+

–

AC

AC

RECTIFIER

4

AMP

24VDC

+

–

BLK

BLU/BLK

BLK

BLU/BLK

RED

200 VOLT AC

2 WIRE + GND

SINGLE PHASE

50/60HZ

MT2

SERVER

TRANSFORMER

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI/VIO

GRY

WHI/GRN

VIO

RED

RED

RED RED

RED

BLK

SCHEMATIC WIRING DIAGRAM

SINGLE SH DBC (W/SMART FUNNEL)

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

C1 D1 A1 B1 B2 A2 D2 D3 C2 C3

L3

L4 L1 L2

TOUCH SWITCH ASSMBLE

GRN

L1

BLK-14

RED-14

RED-14 RED-14

BLK-14

MAIN ON/OFF SWITCH ONLY

(Late Models only)

L2

RED

BLK

BLK-14

Page 33

41746 112008

Page 34

29876.0000D 01/07 © 2001 BUNN-O-MATIC CORPORATION

120/208 OR 120/240

VOLT A.C. + GND

SINGLE PHASE

GRN

N

L1

BLK-14

RED-14

RED-14

RED-14

RED-14

RED-14

BLK-14BLK-14

MODELS WITH MAIN ON/OFF SWITCH ONLY

WHI

WHI

L2

RED

BLK

SCHEMATIC WIRING DIAGRAM

DUAL SH with SMART FUNNEL (DBC)

Page 34

41746 112008

Page 35

RED

RED

RED

RED

29876.0001A 08/02 © 2002 BUNN-O-MATIC CORPORATION

230 VOLTS AC

2 WIRE

SINGLE PHASE

50HZ

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

RED

RED

RESETTABLE

FUSE

SCHEMATIC WIRING DIAGRAM

DUAL SH DBC (W/SMART FUNNEL)

RIGHT

TANK HEATER

LEFT

TANK HEATER

TRIAC

TRIAC

TEMP

PROBE

BLK

BLK

BLU/BLK

BLU/BLK

BLK

BLU/BLK

BLK

BLU/BLK

BRN/BLK

BRN/WHI

BLK

BLU

BLK-14

BLK-14

BLK-14

BLK-14

BLK

BLK

BLK

RED/BLK

RED

RED

WHI/RED

RED

RED

WHI/RED

WHI/ORA

ORA

WHI/GRN

VIO

WHI/VIO

GRY

TAN

TAN

YEL

SOL

SOL

SOL

SOL

SOL

SOL

L. FUNNEL LOCK

SOL

R. FUNNEL LOCK

L. BREW

R. BREW

L. BYPASS

R. BYPASS

REFILL

N.C.

OVERFLOW

PROTECTION SWITCH

WHI

WHI

WHI

WHI

MT2

MT2

MT1

BLU-14

MT1

BLU-14

L2

LIMIT THERMOSTAT

L1

PNK

WHI

GRN

WATER LEVEL

PROBE

AC

AC

4

AMP

RESETTABLE

FUSE

24VDC

LEFT

SERVER

TRANSFORMER

RIGHT

SERVER

TRANSFORMER

RECTIFIER

AC

AC

4

AMP

RECTIFIER

24VDC

CONTROL PC BOARD

RIGHT

FUNNEL SENSOR

LEFT

FUNNEL SENSOR

VIO

WHI/VIO

WHI/YEL

YEL

J9-1

J9-5

J2-1

J2-5

J2-10

J11-1

J11-10

J11-18

J11-5

J4-1

J4-10

J4-19

J4-5

J4-15

Touch Switch Assembly Codes

A1 Left Brew

A2 Left On/Off

A3 Right On/Off

A4 Right Brew

B1 "Hidden" Left

B2 "Hidden" Right

C1 Left Large Batch

C2 Left Medium Batch

C3 Left Small Batch

C4 Right Large Batch

C5 Right Medium Batch

C6 Right Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Left Large Batch LED

L2 Left Medium Batch LED

L3 Left Small Batch LED

L4 Left On/Off LED

L5 Right On/Off LED

L6 Right Large Batch LED

L7 Right Medium Batch LED

L8 Right Small Batch LED

LED's

20

SHEILD

1

L1

L4 L5 L6 L7 L8 L3

L2

RED

RED

EMI

FILTER

GRN/YEL

BLK

BLK

C1 A1 B1 B2 A2 A3 A4 D1 D2 D3 C2 C3 C4 C5 C6

TOUCH SWITCH ASSEMBLY

Page 35

41746 112008

Page 36

RED

RED

RED

RED

29876.0003A 06/04 © 2004 BUNN-O-MATIC CORPORATION

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

THERMAL

SAFETY FUSE

RED

RED

RESETTABLE

FUSE

SCHEMATIC WIRING DIAGRAM

DUAL SH DBC (W/SMART FUNNEL)

RIGHT

TANK HEATER

LEFT

TANK HEATER

TRIAC

TRIAC

TEMP

PROBE

BLK

BLK

BLU/BLK

BLU/BLK

BLK

BLU/BLK

BLK

BLU/BLK

BRN/BLK

BRN/WHI

BLK

BLU

BLK-14

BLK-14

BLK-14

BLK-14

BLK

BLK

BLK

RED/BLK

RED

RED

WHI/RED

RED

RED

WHI/RED

WHI/ORA

ORA

WHI/GRN

VIO

WHI/VIO

GRY

TAN

TAN

YEL

SOL

SOL

SOL

SOL

SOL

SOL

L. FUNNEL LOCK

SOL

R. FUNNEL LOCK

L. BREW

R. BREW

L. BYPASS

R. BYPASS

REFILL

N.C.

OVERFLOW

PROTECTION SWITCH

WHI

WHI

WHI

WHI

MT2

MT2

MT1

BLU-14

MT1

BLU-14

L2

LIMIT THERMOSTAT

L1

PNK

WHI

GRN

WATER LEVEL

PROBE

AC

AC

4

AMP

RESETTABLE

FUSE

24VDC

LEFT

SERVER

TRANSFORMER

RIGHT

SERVER

TRANSFORMER

RECTIFIER

AC

AC

4

AMP

RECTIFIER

24VDC

CONTROL PC BOARD

RIGHT

FUNNEL SENSOR

LEFT

FUNNEL SENSOR

VIO

WHI/VIO

WHI/YEL

YEL

J9-1

J9-5

J2-1

J2-5

J2-10

J11-1

J11-10

J11-18

J11-5

J4-1

J4-10

J4-19

J4-5

J4-15

Touch Switch Assembly Codes

A1 Left Brew

A2 Left On/Off

A3 Right On/Off

A4 Right Brew

B1 "Hidden" Left

B2 "Hidden" Right

C1 Left Large Batch

C2 Left Medium Batch

C3 Left Small Batch

C4 Right Large Batch

C5 Right Medium Batch

C6 Right Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Left Large Batch LED

L2 Left Medium Batch LED

L3 Left Small Batch LED

L4 Left On/Off LED

L5 Right On/Off LED

L6 Right Large Batch LED

L7 Right Medium Batch LED

L8 Right Small Batch LED

LED's

20

SHEILD

1

L1

L4 L5 L6 L7 L8 L3

L2

RED

RED

EMI

FILTER

GRN/YEL

BLK

BLK

C1 A1 B1 B2 A2 A3 A4 D1 D2 D3 C2 C3 C4 C5 C6

TOUCH SWITCH ASSEMBLY

Page 36

41746 112008

Page 37

LIMIT THERMOSTAT

TRIAC

TANK HEATER #1

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

WHI

WHI

MT 1 BLU -14

BLK-14 BLK-14

RED

N.C.

RED

OVERFLOW

PROTECTION SWITCH

FUNNEL LOCK

(OPTIONAL)

120 VOLT A.C. + GND OR

120/208-240 VOLT A.C. + GND

SINGLE PHASE

32043.0003C 01/07 © 2004 BUNN-O-MATIC CORPORATION

SCHEMATIC WIRING DIAGRAM

SINGLE GPR DBC-DV with SMART FUNNEL

MT2

BRN/BLK

BRN/WHI

BLK

YEL

TAN

WHI

WHI/VIO

GRY

WHI/GRN

VIO

SWITCH UNIT ASSY

SHIELD

FUNNEL SENSOR

TANK LID ASSEMBLY

CONTROL PC BOARD

WATER LEVEL

PROBE

TEMP

PROBE

VIO

WHI/VIO

WHI

PNK

BLK

GRN

WHI/VIO

WARMER

WHI

WHI

BLK

WHI/VIO

RED-14

TANK HEATER #2

VOLTAGE SELECTOR SWITCH

120V Only

120V-208/240V

120V 3235W

20922-0004

20922-0001

120V 1650W

HEATER #1

LIMIT

HEATER #2

Touch Switch Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

LED's

GRN

RED-14

BLK-14

N

L1

BLK-14

RED-14

RED-14

BLK-14

MODELS WITH MAIN ON/OFF SWITCH ONLY

WHI

WHI

L2

RED

BLK

Page 37

41746 112008

Page 38

SCHEMATIC WIRING DIAGRAM

DUAL GPR with SMART FUNNEL (DBC)

GRN

BLK

PNK

WHI

TEMP PROBE

J2-1

J9-1

J11-1

J11-5

J11-10

J11-18

J9-5

J2-10

J2-5

CONTROL PC BOARD

J4-1

J4-5

J4-10

J4-15

J4-19

29876.0004B 01/07 © 2004 BUNN-O-MATIC CORPORATION

120/208 OR 120/240

VOLT A.C. + GND

SINGLE PHASE

WHI/VIO

WHI/RED

RT WARMER

LT WARMER

WHI

WHI

WHI

WHI

WHI

WHI

WHI

WHI

R.FUNNELLOCK

L.FUNNELLOCK

OPTIONAL

SOL

SOL

SOL

SOL

SOL

SOL

SOL

GRN

N

L1

BLK-14

RED-14

RED-14

RED-14

RED-14

RED-14

BLK-14BLK-14

MODELS WITH MAIN ON/OFF SWITCH ONLY

WHI

WHI

L2

RED

BLK

Page 38

41746 112008

Page 39

35726.0000B 02/07 © 2003 Bunn-O-Matic Corporation

120/208 OR 120/240 VOLT A.C.

3 WIRE + GND

SINGLE PHASE

SCHEMATIC WIRING DIAGRAM

SINGLE TF DBC

FUNNELLOCK

SOL

BREW

BYPASS

REFILL

WHI

WHI

WHI

VIO

GRY

WHI/GRN

BRN/WHI

BRN/BLK

TAN

YEL

BLK

WHI

TANKHEATER

TRIAC

MT 1 BLU-14BLK-14BLK-14

MT2

LIMIT THERMOSTAT

FUNNEL SENSOR

WHI/VIO

VIO

WHI

PNK

BLK

GRN

TEMP PROBE

WATER LEVEL

PROBE

RED RED

N.C.

OVERFLOW

PROTECTION SWITCH

CONTROL PC BOARD

SWITCH UNIT ASSEMBLY

Switch Unit Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

LED's

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

GRN

RED-14

BLK-14

N

L1

BLK-14

RED-14

RED-14

BLK-14

MODELS WITH MAIN ON/OFF SWITCH ONLY

WHI

WHI

L2

RED

BLK

SOL

SOL

SOL

Page 39

41746 112008

Page 40

36883.0000A 05/04 © 2004 Bunn-O-Matic Corporation

230 OR 200

VOLT A.C.

SINGLE PHASE

SCHEMATIC WIRING DIAGRAM

SINGLE TF DBC

FUNNELLOCK

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

RED

RED

RED

VIO

GRY

WHI/GRN

BRN/WHI

BRN/BLK

TAN

YEL

BLK

RED

L2

TANKHEATER

TRIAC

MT 1 BLU-14 RED-14BLK-14BLK-14

RED-14BLK-14

RED-14BLK-14

MT2

L1

LIMIT THERMOSTAT

FUNNEL SENSOR

WHI/VIO

VIO

WHI

PNK

BLK

GRN

TEMP PROBE

WATER LEVEL

PROBE

RED RED

N.C.

OVERFLOW

PROTECTION SWITCH

CONTROL PC BOARD

SWITCH UNIT ASSEMBLY

Switch Unit Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

LED's

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

GRN

Page 40

41746 112008

Page 41

36883.0002A 11/04 © 2004 Bunn-O-Matic Corporation

120 VOLT A.C.

2 WIRE SINGLE PHASE

60HZ

SCHEMATIC WIRING DIAGRAM

SINGLE TF DBC

FUNNEL LOCK

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

WHI

WHI

WHI

VIO

GRY

WHI/GRN

BRN/WHI

BRN/BLK

TAN

YEL

BLK

WHI

N

TANK HEATER

TRIAC

MT 1 BLU-14 WHI-14BLK-14BLK-14

MT2

L1

LIMIT THERMOSTAT

FUNNEL SENSOR

WHI/VIO

VIO

WHI

PNK

BLK

GRN

TEMP PROBE

WATER LEVEL

PROBE

RED RED

N.C.

OVERFLOW

PROTECTION SWITCH

CONTROL PC BOARD

SWITCH UNIT ASSEMBLY

Switch Unit Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

LED's

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

Page 41

41746 112008

Page 42

36883.0001B 02/07 © 2004 Bunn-O-Matic Corporation

200,208 or 240 VOLT A.C.

2 WIRE + GND

SINGLE PHASE 50/60HZ

SCHEMATIC WIRING DIAGRAM

SINGLE TF DBC

FUNNELLOCK

SOL

BREW

BYPASS

REFILL

RED

RED

RED

VIO

GRY

WHI/GRN

BRN/WHI

BRN/BLK

TAN

YEL

BLK

RED

TANKHEATER

TRIAC

MT 1 BLU-14 RED-14BLK-14BLK-14

MT2

LIMIT THERMOSTAT

FUNNEL SENSOR

WHI/VIO

VIO

WHI

PNK

BLK

GRN

TEMP PROBE

WATER LEVEL

PROBE

RED RED

N.C.

OVERFLOW

PROTECTION SWITCH

CONTROL PC BOARD

SWITCH UNIT ASSEMBLY

Switch Unit Assembly Codes

A1 Brew

A2 On/Off

B1 "Hidden" Left

B2 "Hidden" Right

C1 Large Batch

C2 Medium Batch

C3 Small Batch

D1 "Digital" Left Hidden Button

D2 "Brewer" Center Hidden Button

D3 "Control" Right Hidden Button

LED's

L1 Large Batch LED

L2 Medium Batch LED

L3 Small Batch LED

L4 On/Off LED

GRN

L1

BLK-14

RED-14

RED-14 RED-14

BLK-14

MAIN ON/OFF SWITCH

(Late Models only)

L2

RED

BLK

BLK-14

SOL

SOL

SOL

Page 42

41746 112008

Page 43

36883.0003A 02/07 © 2007 Bunn-O-Matic Corporation

FUNNELLOCK

SOL

SOL

SOL

SOL

BREW

BYPASS

REFILL

RED

RED

RED

VIO

RED/BLK

GRY

WHI/GRN

BRN/WHI

BRN/BLK

YEL

BLK

RED

FUNNEL SENSOR

WHI/VIO

VIO

WHI

PNK

BLK

GRN

TEMP PROBE

WATER LEVEL

PROBE

RED RED

N.C.

OVERFLOW