Bunn Coffee Maker DUAL TF Installation Manual

DUAL TF BREWING INSTRUCTIONS

1. Insert a BUNN® filter into the

funnel.

5. Slide funnel into funnel rails

of the brewer. The brewer will

read the size ground through the

chip in the funnel handle and will

automatically select the correct

size to brew.

2. If a grinder is not used to obtain

the coffee grounds, pour in fresh

coffee.

6. Place empty servers beneath

the funnel.

3. If a G9-2T DBC or MHG grinder

is used with a compatible Smart

Funnel®, select the desired batch

size on the grinder. Grind the

selected amount of fresh coffee

into the funnel.

7. If a compatible DBC grinder

was not used, select the desired

batch size.

4. Shake funnel gently to level

grounds.

8. The ON/OFF switch must be in

the “ON” position.

10. There may be some situations

in which the brew cycle will not

begin when the BREW switch is

pressed.

a) ON/OFF must be ON.

b) BREW TEMPERATURE TOO

LOW - wait until heated or

cancel BREW LOCKOUT option.

9. Momentarily press and release

the BREW switch. If the brewer

has the funnel lock option and it

is activated, the funnel is locked

in place.

39482.0000A 10/06 ©2006 Bunn-O-Matic Corporation

c) FUNNEL NOT IN PLACE (or

using a standard brew funnel)

- cancel FUNNEL DETECT.

d) CHECK FUNNEL - remove fun-

nel, empty previously brewed

grounds and grind a new

batch into the funnel.

11. If none of the previous messages are displayed, the display

will read NOW BREWING and

the time remaining in the brew

cycle.

12. Following the BREW will be

a countdown of DRIPPING time

which shows the time remaining

until the funnel lock will release.

Discard the grounds and filter

only after visible dripping stops.

DUAL TF CLEANING INSTRUCTIONS

1. Clean and sanitize funnels.

5. Use the pointed end of sprayhead cleaning tool to remove any

mineral deposits from the sprayhead holes. The sprayhead holes

must always remain open.

NOTE: Any buildup on the sprayhead and fitting may restrict water

flow, and impact your coffee

brewing. For consistently great

coffee, clean sprayheads and

fittings weekly with sprayhead

cleaning tool (#38227.0000).

Upon visual inspection it may appear that light passes through all

holes in the sprayhead plate, but a

thin film of residue can pass light

and still impede water flow.

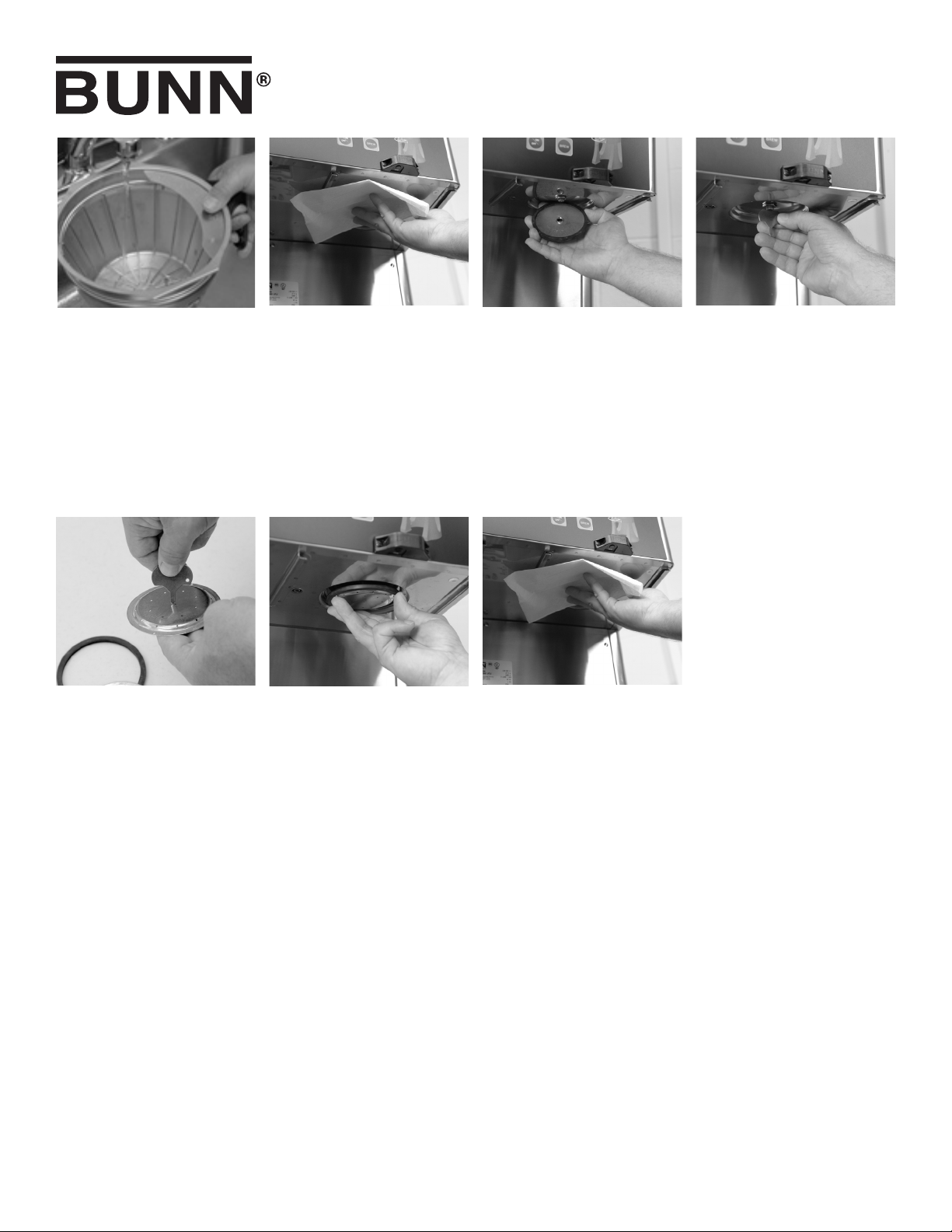

2. Use a clean damp cloth rinsed

in mild, non-abrasive detergent to

clean both sides of the sprayhead

panel.

6. Reassemble sprayheads and

reattach. Sprayheads only need

to be hand tightened.

See installation and operating

manual for calibration routine

to verify sprayhead flow rate

matches programmed flow rate.

Machine may need to be recalibrated due to lime build up

or the use of alternate designed

sprayheads. If machine is cleaned

and build up removed, machine

must be re-calibrated to achieve

desired volumes.

3. Remove sprayheads from

brewer. Disassemble by removing the seal.

7. The use of a damp cloth rinsed

in any mild, nonabrasive, liquid

detergent is recommended for

cleaning all surfaces on Bunn-OMatic equipment. Do NOT clean

this equipment with a water jet

device.

4. Insert the long end of sprayhead

cleaning tool into the sprayhead

fittings, and rotate several times

to remove any mineral deposits

from the fitting.

39482 101206

Loading...

Loading...