Bunn Liquid Autofill Kits Installation Instructions Manual

ULTRA-1 & 2

INSTRUCTIONS FOR INSTALLING

LIQUID AUTOFILL KITS

INTRODUCTION

These instructions are for installing the Liquid Autofill Kits on Autofill ready ULTRA-1 and ULTRA-2 cold drink dispensers.

KIT CONTENTS ULT-2 ULT-1

A. 37567.0000 1* - Circuit Board, ULTRA 2 Auto-Fill

B. 37962.0001 1* - Wire Harness, AF Kit

C. 36329.0000 2 2 Tie, Cable-Nylon BLK 4.04"

D. 43120.xxxx 2 1 Cover Assy, Motor LAF-BLK

E. 38055.0003 2* 1 Probe Assy, LAF

F. 34362.0003 4* 2 Bushing .156" ID x .490" OD x .12" Flg

G. 00973.0000 4* 2 Nut, KEPS #6-32

H. 43131.0000 2 1 Bracket, Motor Cover Support

I. 43145.0000 2 1 Bracket, Motor Cover Mounting

J. 00970.0000 8 4 Nut, KEPS #8-32

K. 02308.0000 4 2 Screw, Pan Head, Slotted w/serr. #8-32 x .38"

L. 38129.0017 4 2 Hose, Braided .25 ID x 11.0" Lg

M. 21275.0006 8 4 Clamp .406/.504" Dia.

N. 01317.0000 4 2 Screw, Truss Head, Slotted #8-32 x .50"

O. 44194.0000 - 1 Wire Harness (Not Auto-fill Ready)

P. 44195.0000 - 1 Wire Harness (Auto-fill Ready)

* Not included in all kits.

INSTRUCTIONS

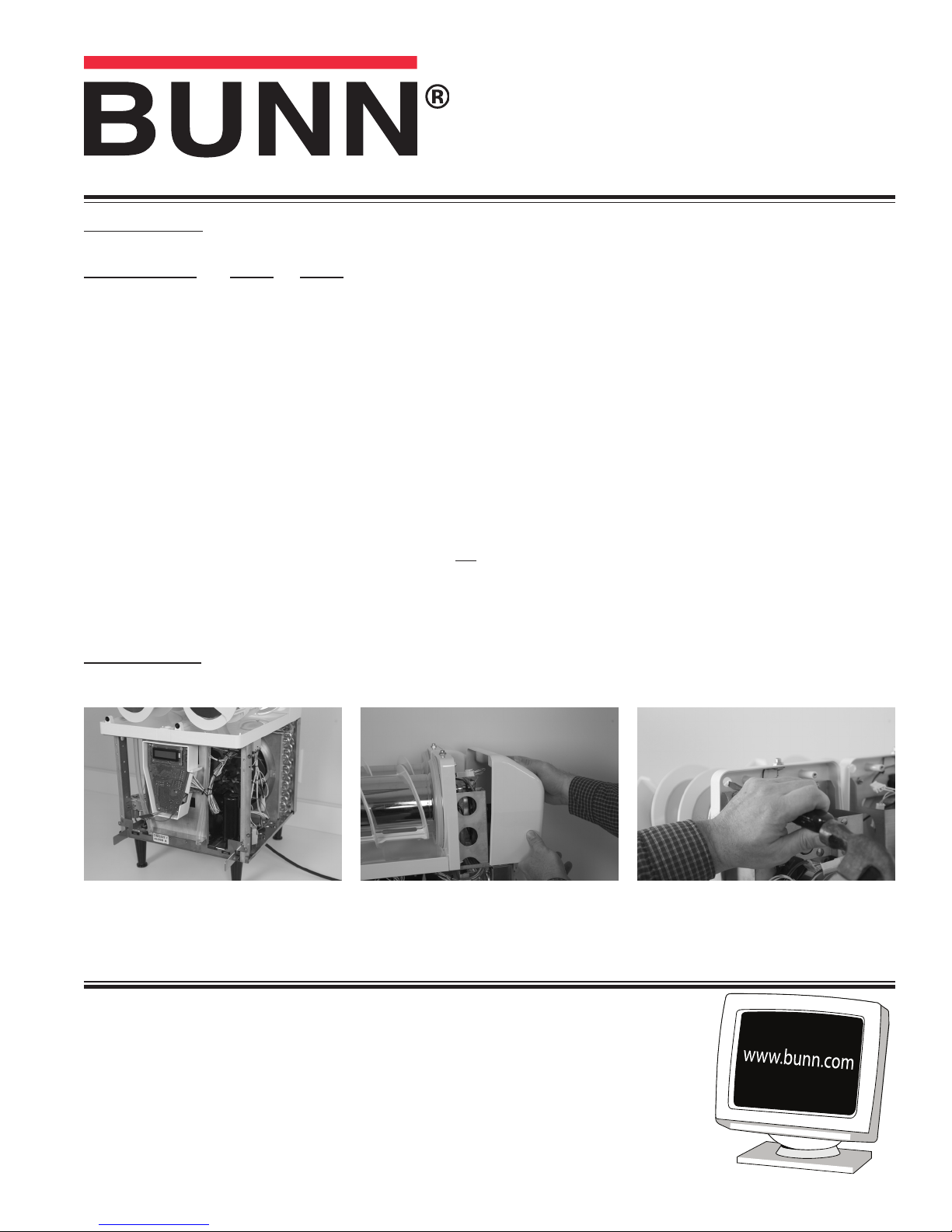

1. Unplug machine from power source before removing any panels.

2. Drain both hoppers and clean the machine if needed before proceeding.

3. Remove hoppers, drip tray, both side

panels and front panel.

4. Remove both motor covers and locate

.50" round knock out in top right area

of plastic drum mount. Discard screws.

(Continued)

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

5. With a standard screwdriver and a

hammer, punch out the hole needed

for the level probe. Repeat this step

for all barrels.

37570.0002A 08/11 ©2011 Bunn-O-Matic Corporation

INSTRUCTIONS (Continued)

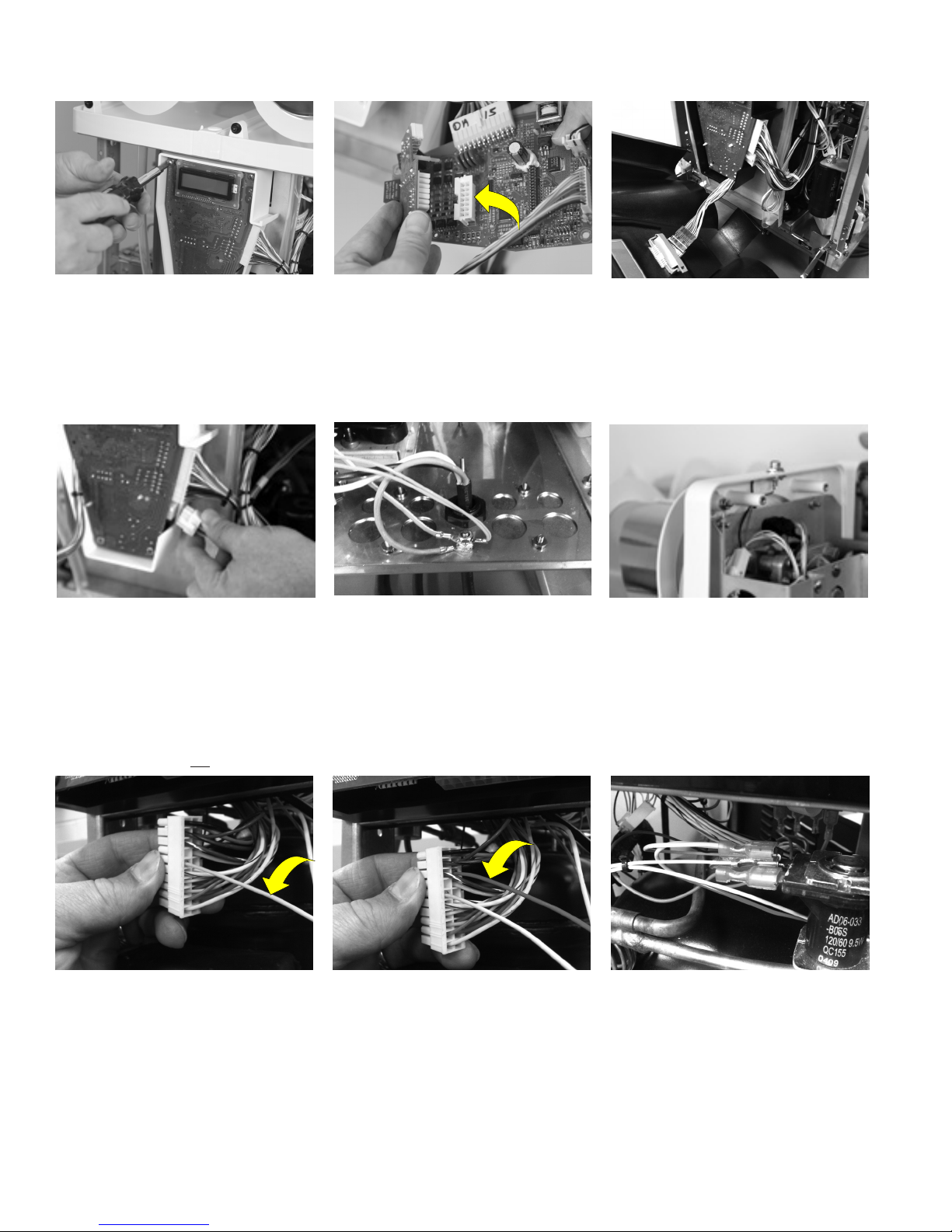

6. Remove 4 screws holding in the main

circuit board.

On ULTRA-1 Models, proceed to Step 12.

9. Plug wire harness (B) into Auto Fill

board connector and route wires in

front of drain tube and back into the

machine.

7. Connect Auto Fill board to J-12 on the

main board. Be sure to snap the plastic

stand off’s completely into the main

board.

10. Remove top nut off of grounding stud

in the base of the machine, add on the

green grounding wire from the new harness and reinstall the nut onto the stud.

Make sure that all the other grounding

wires remain on the ground stud.

8. Reinstall the main board into the

machine using the original mounting

screws.

11. Route Pink and Tan wires up to level

probes. To ease wire harness installation, remove both auger motors.

Note: valve connection wire colors –

right is red and white, left is blue and

white.

For ULTRA-1 Models not Auto-fill ready:

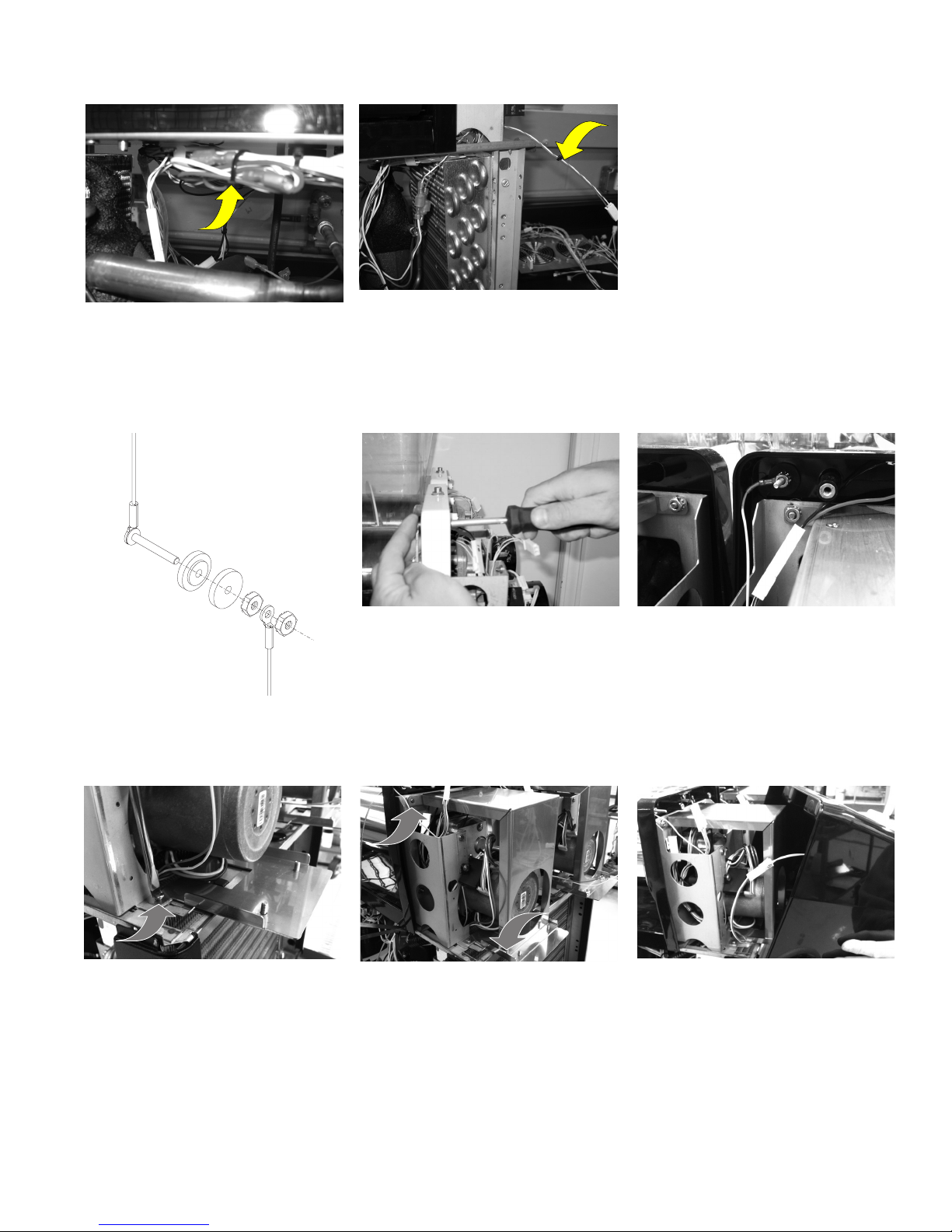

12. Disconnect main wiring harness from

circuit board. Insert pink wire from

Harness (Q) into terminal #6.

13. Insert red wire from Harness (Q) into

terminal #18.

NOTE: The pin terminal must be oriented

correctly to be inserted fully. After inserting

these connections, pull lightly on the wires

to insure they do not come out.

• Route new harness back into machine

along with the main harness.

(Continued)

2

14. Locate white wire on new harness with

piggy-back style spade connection.

Remove white wire from refrigerant

valve and connect piggy-back connector from new harness onto refrigerant

valve. Reconnect white wire from

main harness onto the new piggy-back

connector. Route remaining portion of

new harness toward the back of the

machine.

37570.2 081811

INSTRUCTIONS (Continued)

For ULTRA-1 Models that are Auto-fill ready:

15. Locate unused white and red auto-fill

valve wire connections tied in a bundle

on the main wiring harness. Carefully

cut wire tie to free the bundle.

16. Connect white and red wires from the

new harness (R) to white and red wires

repectively on the main harness. Route

the new harness toward the back of the

machine.

17. Install level probe assembly into hole

and secure with nuts provided (G).

18. Position wire and connector away from

metal bracket as shown. Attach using

nuts provided. Pink is the right probe

and Tan is the left probe. Reinstall motors using original screws.

19. Remove the two lower motor bracket

screws and align new bracket in place.

Attach with new screws (K ) provided.

20. Install larger metal bracket as shown.

Route light connection wires above

plastic boss to keep from being pinched

under the new mounting bracket. Route

torque sensor wires away to keep from

being pinched under metal mounting

bracket Secure with 4 nuts (J ) provided.

(Continued)

3

21. Connect harness to each new motor

cover assembly with Auto Fill, then

mount motor cover to machine with

new screws (N ) provided.

Hint: Align the motor cover in at the

top, then snap the bottom in place.

37570.2 081811

Loading...

Loading...