Page 1

! WARNING HOT LI

QUIDS

! AVERTISSEMENT LIQUIDES CHAUDS

POW

ER

READY

PO

R

TIO

N

RINSE

REFIL

L

ST

O

P!

HO

T

WATER

RELEASED FOR PRODUCTION

LCR-2

LCR-2A

LCR-2 PC

LCR-2A PC

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

36026.0001B 11/14 ©2013 Bunn-O-Matic Corporation

DIR Num: 36026.0001 19, May 2015

POST OFFICE BOX 3227

Page 2

RELEASED FOR PRODUCTION

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCR/MCP/MCA single cup brewers, thermal servers and ThermoFresh® servers (mechanical and digital) 1 year parts and 1 year labor.

2) All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labor for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts and

labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured

by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation,

improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor water quality,

damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal use including but

not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the Buyer 1) giving BUNN

prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office Box

3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an authorized

BUNN service location; and 3) receiving prior authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make

modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such

individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the

applicable parts and labor warranty periods specified above) to repair the defective components, provided that this repair

is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for

the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of

use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities

or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with

the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design,

Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet

Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment

Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com,

Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality in

Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, TRIFECTA (sylized logo), Velocity Brew, Air Brew, Beverage

Bar Creator, Beverage Profit Calculator, Brew better, not bitter., Build-A-Drink, BUNNSource, Coffee At Its Best, Cyclonic

Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Picture

Prompted Cleaning, Pouring Profits, Signature Series, Sure Tamp, Tea At Its Best, The Horizontal Red Line, Ultra are either

trademarks or registered trademarks of Bunn-O-Matic Corporation. The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

2

36026.1 031314

DIR Num: 36026.0001 19, May 2015

Page 3

RELEASED FOR PRODUCTION

CONTENTS

Warranty .......................................................................... 2

Introduction ..................................................................... 3

User Notices .................................................................... 4

Electrical Requirements ................................................... 5

Plumbing Requirements .................................................. 6

CE Requirements ............................................................. 6

Initial Set-up .................................................................... 7

Electrical Hook-up ............................................................ 7

Plumbing Hook-up ........................................................... 7

Installing the Drip Tray and Flip Down Cup Tray ...............8

Operating Controls & Interface ........................................ 9

Selecting the Correct Pump Tubing ................................ 10

Setting Dispenser Flow Rate .......................................... 11

Adjusting Mix Ratios ...................................................... 12

FlavorGard™ Feature ...................................................... 13

Rinse Alarm Feature ....................................................... 13

BIB Empty Lockout Feature ............................................ 14

Brew Temperature Lockout Feature

Programming the Dispenser .......................................... 15

Initial Fill & Heat ............................................................. 21

Loading the Concentrate ................................................ 22

Priming the Concentrate Lines ....................................... 22

Operating the Pull & Hold Dispenser .............................. 23

Operating the Preset Portion Control Dispenser ............ 24

Filling Cambros or other large containers ...................... 24

Cleaning & Preventive Maintenance ............................... 25

Replacing the Pump Tubing ........................................... 26

Draining the Hot Water................................................... 27

Troubleshooting ............................................................. 28

Field Calibration of the Concentrate Pumps ................... 33

Dispenser Flow Rate Calibration .................................... 34

Field Calibrating the Hot Water Flow Rate ...................... 34

Field Calibrating the Empty BIB Warning ........................ 35

Schematic Wiring Diagrams ........................................... 36

................................ 14

INTRODUCTION

The Liquid Coffee Refrigerated Dispenser delivers two types of coffee made from liquid concentrate plus

hot water. The dispenser can be set up for continuous draw (by the cup) for self-serve applications, or portioncontrol to fill carafes and decanters for wait staff. Follow the Concentrate Manufacturer’s Storage and Shelf Life

recommendations. Product Flavor Profile is extended with refrigerated product storage cabinet featured in the

LCR-2 and LCR-2 PC.

This dispenser is designed to operate when ambient temperatures are from 32°F (0°C) minimum to 104°F

(40°C) maximum.

3

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 4

As directed in the International Plumbing Code of the

International Code Council and the Food Code

Manual of the Food and Drug Administration (FDA),

this equipment must be installed with adequate

backflow prevention to comply with federal, state

and local codes. For models installed outside the

U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

To reduce the risk of electric shock,

do not remove or open cover.

No user-serviceable parts inside.

Authorized service personnel only.

Disconnect power before servicing.

33461.0008A

RELEASED FOR PRODUCTION

USER NOTICES

Carefully read and follow all notices on the equipment and in this manual. They were written for your protec-

tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels.

00656.0001

00986.0002

37881.0000

11646.0002

Moving Parts.

Do not operate

unit with this

Risk Of Electrical Shock.

Disconnect power before

servicing unit.

panel removed.

27442.0000

CHARGE

Type R134A, Amount 4 oz (113.4 gm)

Design Pressures:

High 230 psi (15.9 bar) (1.59 MPa)

Low 88 psi (6 bar) (0.61 MPa)

33461.0008

WARNING CENTER LEG OF CUP TRAY MUST BE SUPPORTED BY THE DRIP TRAY!

00824.0002

DIR Num: 36026.0001 19, May 2015

47624.0000

4

36026.1 111714

Page 5

120V A.C.

120V A.C.

208 or

240V A.C.

HEATER RED

208 or

240V A.C.

120V A.C.

10A. FUSE - WHITE

HEATER RED

10A. FUSE - WHITE

10A. FUSE - BLACK

LIMIT SW. - BLACK

HEATER RED

10A. FUSE - WHITE

10A. FUSE - BLACK

LIMIT SW. - BLACK

10A. FUSE - BLACK

LIMIT SW. - BLACK

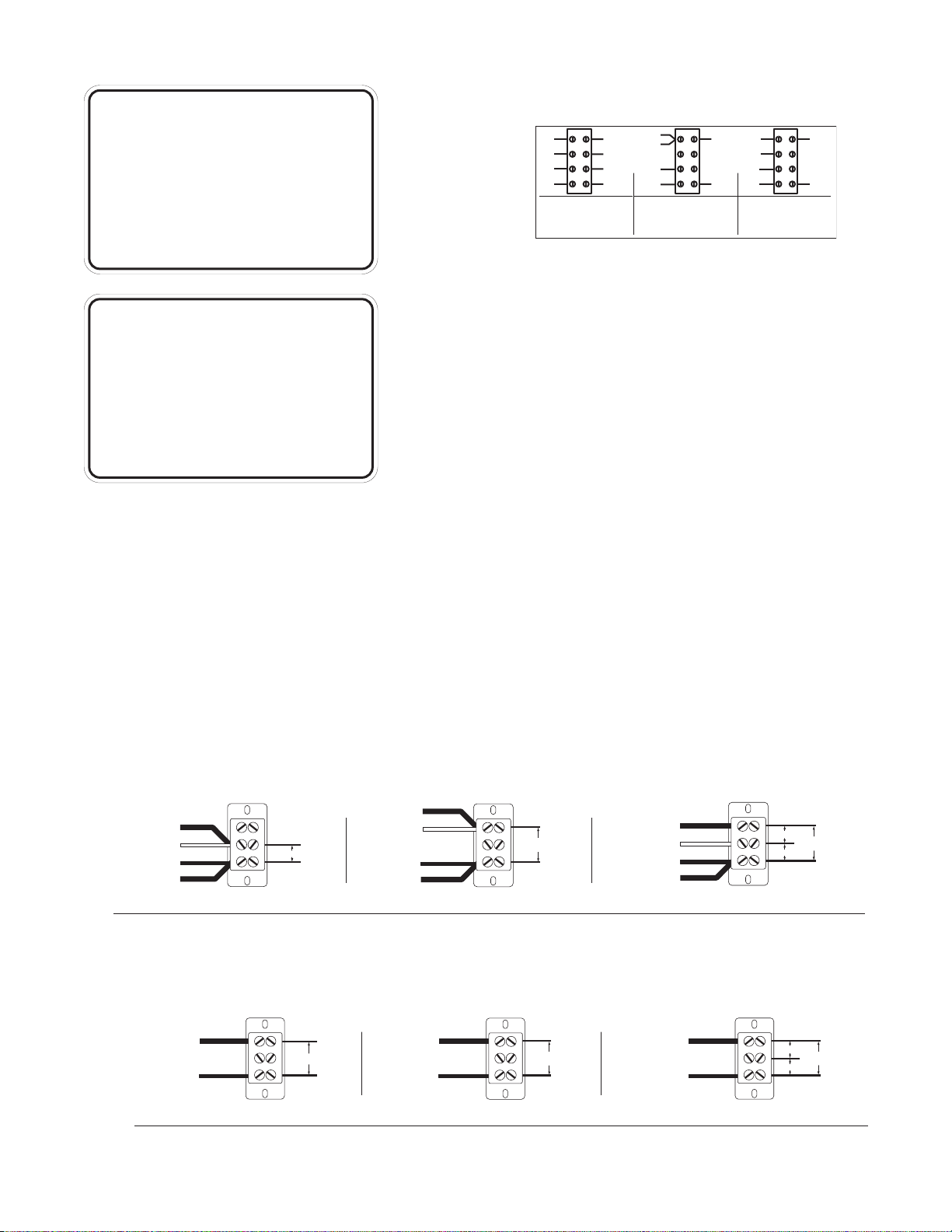

FIELD WIRING TERMINAL BLOCK DIAGRAM

For all 208 - 240 Volt Connections: Use No. 10 AWG Wires suitable for 90°C (194°F)

1. Unit shipped per Fig. 1, wired for 120V A.C./2-Wire.

2. For 208 - 240V A.C./2-Wire per Fig. 2: Move both the Red-Heater wire and the White-Fuse wire to the Top Red Terminal as shown.

3. For 120/208 - 240V A.C./3-Wire per Fig. 3: Move the Red Heater wire to the To p Red Terminal as shown.

Fig. 1 Fig. 2 Fig. 3

FIELD WIRING TERMINAL BLOCK DIAGRAM

3. For 120/208 - 240V A.C./3-Wire per Fig. 3.

RELEASED FOR PRODUCTION

USER NOTICES (Cont)

Optional Field Wiring

208-240 V, 25.8 A, 6200 W

1PH, 2-Wire + GND, 60HZ

or

120/208-240 V, 25.8 A, 6200 W

1PH, 3-Wire + GND, 60HZ

28181.0003

BRN

L1

L1L2L3N

BLK

L2

RED

L3

TO MACHINE

N

BLU

FOR 3-PHASE OPERATION

CONNECT INPUT WIRING TO

L1,L2,L3 & N AS SHOWN.

TERMINAL

BLOCK

FROM POWER SOURCE

FOR 1-PHASE/30 AMP. OPERAT ION

MOVE BLACK WIRE INTO

TERMINAL BLOCK WITH BROWN

WIRE, CONNECT INPUT WIRING

TO L1 & N AS SHOWN.

39762.0000

BRN

BLK

RED

TO MACHINE

BLU

L1L2L3N

L1

N

FROM POWER SOURCE

BRN

L1

L1L2L3N

BLK

RED

TO MACHINE

FOR 1-PHASE/15 AMP. OPERAT ION

CONNECT INPUT WIRING TO

BLU

L1 & N AS SHOWN.

N

FROM POWER SOURCE

Optional Field Wiring

230 V, 26 A, 6000 W

1PH, 2-Wire + GND, 50/60HZ

or

230 V, 13 A, 3000W

1PH, 2-Wire + GND, 50/60HZ

ELECTRICAL REQUIREMENTS

29710.0014

CAUTION: The dispenser must remain disconnected from power source until specified in Electrical Hook-Up.

The LCR-2 dispenser is supplied with a 120-volt / 15 Amp cord set and require a 2-wire, grounded, individual branch

circuit rated for 120 volts AC, 15 amp, single phase, 60Hz. The mating connector must be a NEMA 5-15R.

The LCR-2C dispenser is supplied with a 120-volt / 20 Amp cord set and require a 2-wire, grounded, individual branch

circuit rated for 120 volts AC, 20 amp, single phase, 60Hz. The mating connector must be a NEMA 5-20R.

These dispensers can be Field Wired for 208 or 240 volt applications. This requires a 2 or 3-wire, grounded, individual

branch circuit rated for 208/240 volts AC, 30 amp, single phase, 60 Hz.

NOTE: The internal terminal block must be rewired for 208/240 applications, (see Optional Field Wiring Diagram).

FIELD WIRING TERMINAL BLOCK DIAGRAM

Models without Master ON/OFF Switch

FIELD WIRING TERMINAL BLOCK DIAGRAM

Models with Master ON/OFF Switch

RED

TO MASTER

ON/OFF

SWITCH

BLACK

1. Unit shipped per Fig. 1, wired for 120V A.C./2-Wire.

2. For 208 - 240V A.C./2-Wire per Fig. 2.

120V A.C.

Fig. 1 Fig. 2

For all 208 - 240 Volt Connections: Use No. 10 AWG Wires suitable for 90°C (194°F)

DIR Num: 36026.0001 19, May 2015

TO MASTER

ON/OFF

SWITCH

RED

BLACK

208 or

240V A.C.

5

TO MASTER

ON/OFF

SWITCH

RED

BLACK

120V A.C.

120V A.C.

Fig. 3

208 or

240V A.C.

36026.1 010313

Page 6

200, 230 or

RELEASED FOR PRODUCTION

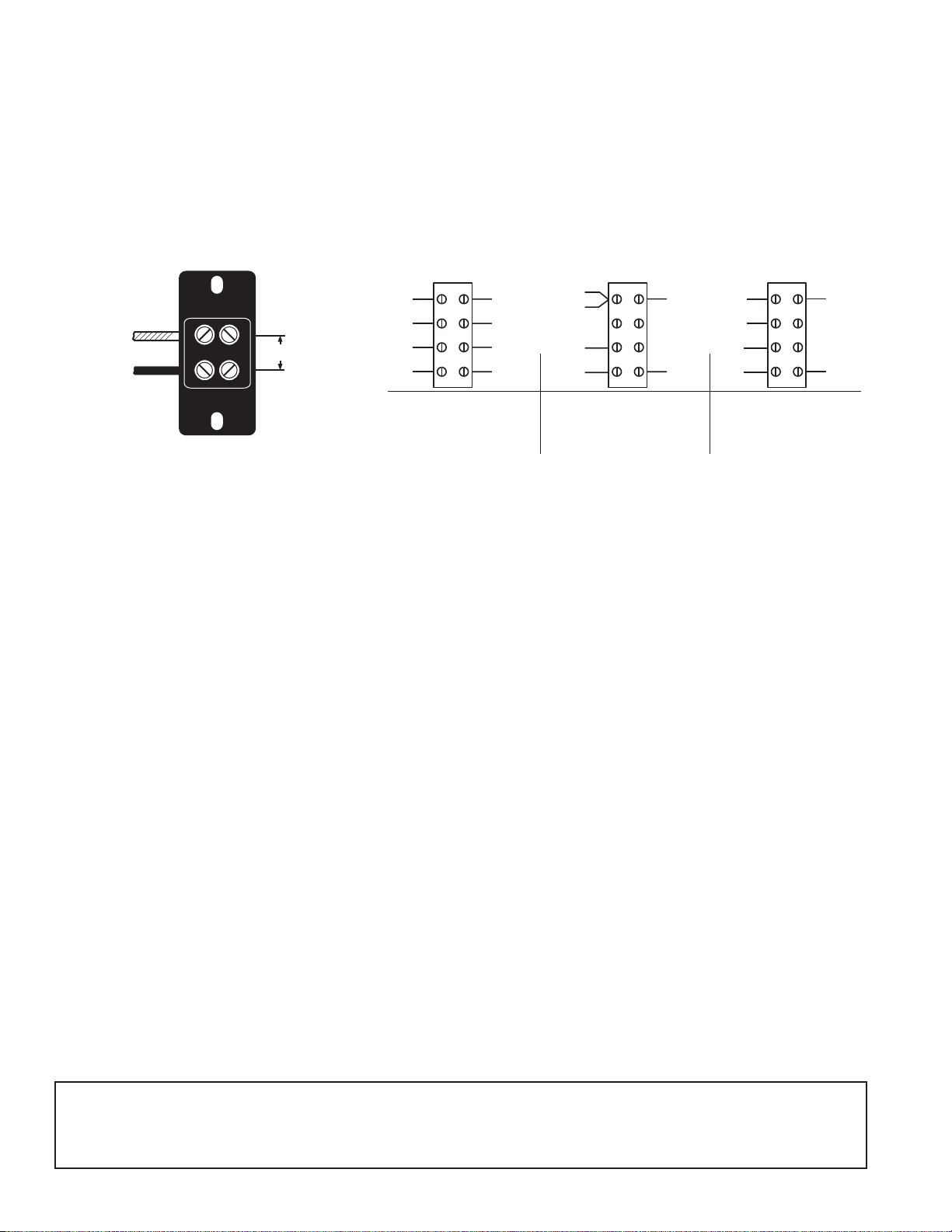

ELECTRICAL REQUIREMENTS (Cont.)

CAUTION: The dispenser must remain disconnected from power source until specified in Electrical Hook-Up.

The LCR-2A 3 Phase dispenser is internally wired from the factory for 400 Volts AC Phase to Phase, 220-240 Volts AC

Phase to Neutral, 3 Phase 50/60 Hz. It requires a 4-wire, grounded, individual branch circuit rated for 400 Volts AC, Three

Phase, 50/60 Hz. At Three Phase operation, each Phase will have approximately 13.5-14.0 Amps flow through it.

The LCR-2A 3 Phase dispenser can be Field Wired for 220-240 Volts AC, Single Phase applications. This requires a

2-wire, grounded, individual branch circuit rated for 220-240 volts AC, Single Phase, 50/60 Hz. At Single Phase operation,

the machine will have approximately 27.5 Amps flow through it.

NOTE: The internal terminal block must be rewired for 220-240 Volts AC, Single Phase applications, (see Optional Field

Wiring Diagram).

BRN

BLK

RED

TO MACHINE

BLU

FOR 1-PHASE/30 AMP. OPERATION

MOVE BLACK WIRE INTO

TERMINAL BLOCK WITH BROWN

WIRE, CONNECT INPUT WIRING

TO L1 & N AS SHOWN.

L1

L1L2L3N

N

BRN

BLK

RED

TO MACHINE

FROM POWER SOURCE

BLU

FOR 1-PHASE/15 AMP. OPERATION

CONNECT INPUT WIRING TO

L1 & N AS SHOWN.

L1

L1L2L3N

N

FROM POWER SOURCE

L2 RED

230V A.C.

L1 BLACK

240V A.C.

The LCR-2A dispenser is internally wired from the

BRN

BLK

RED

TO MACHINE

BLU

FOR 3-PHASE OPERATION

CONNECT INPUT WIRING TO

L1,L2,L3 & N AS SHOWN.

L1

L1L2L3N

L2

L3

N

FROM POWER SOURCE

TERMINAL

BLOCK

factory for 220-240 Volts AC Single Phase 50/60

Hz. It requires a 2-wire, grounded, individual

branch circuit rated for 220-240 Volts AC.

CE REQUIREMENTS

• This appliance must be installed in locations where it can be overseen by trained personnel.

• For proper operation, this appliance must be installed where the temperature is between 5°C to 35°C.

• Appliance shall not be tilted more than 10° for safe operation.

• An electrician must provide electrical service as specified in conformance with all local and national codes.

• This appliance must not be cleaned by water jet.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given instructions concerning use of this appliance by

a person responsible for its safety.

• Children should be supervised to ensure they do not play with the appliance.

• If the power cord is ever damaged, it must be replaced by the manufacturer or authorized service personnel with a special

cord available from the manufacturer or its authorized service personnel in order to avoid a hazard.

• Machine must not be immersed for cleaning.

PLUMBING REQUIREMENTS

The dispenser may be connected to a cold or hot water system (140°F Max.) with operating pressure between 20 and 90 psi

(0.138 and 0.620 MPa) from a 1/2” or larger supply line. A shut-off valve should be installed in the line before the dispenser.

Install a regulator in the line when pressure is greater than 90 psi (0.620 MPa) to reduce it to 50 psi (0.345 MPa). The water

inlet fitting is 3/8” flare. Dispensers set up to deliver to 1.8 Oz./sec. (53.2 ml/sec) per dispense tip, require a water supply

source that can deliver a minimum of 1.7 gpm (6.4 lpm) at the inlet fitting. Dispensers set up to deliver 2.6 Oz./sec. (76.9

lpm) per dispense tip, require a water supply source that can deliver a minimum of 2.4 gpm (9.2 lpm) at the inlet fitting.

NOTE: Bunn-O-Matic recommends 3/8” tubing from the 1/2” water supply line. At least 18 inches of FDA approved flexible

beverage tubing, such as reinforced braided polyethylene or silicone, before the dispenser will facilitate movement to clean

the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the dispenser. The size and shape

of the hole made in the supply line by this type of device may restrict water flow.

NOTE: Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed, and

maintained in accordance with federal, state, and local codes.

As directed in the International Plumbing Code of the International Code Council and the Food Code Manual of the

Food and Drug Administration (FDA), this equipment must be installed with adequate backflow prevention to comply

with federal, state and local codes. For models installed outside the U.S.A., you must comply with the applicable

Plumbing /Sanitation Code for your area.

6

DIR Num: 36026.0001 19, May 2015

36026.1 111714

Page 7

1/16" to 1/8"

LEVEL

RELEASED FOR PRODUCTION

INITIAL SET-UP

NOTE: The LCR-2 dispenser weighs approximately 100 lbs. (45 kg). If necessary, use more than one person

when lifting or moving the dispenser.

1. Cut the two straps and remove the box and foam packing.

2. Locate and remove the information packets and tube kits from top of packaging and set aside.

3. Open the dispenser door and remove the drip tray and the lower splash guard panel.

4. Set dispenser on the counter where it is to be used. CAUTION: DO NOT LIFT ON THE DOOR.

5. Confirm the dispenser is level on the counter (See LEVELING THE DISPENSER).

ELECTRICAL HOOK-UP

CAUTION: Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specified in conformance with all local, state and federal

electrical codes.

2. Using a voltmeter, check the voltage and color-coding of each conductor at the electrical source.

3. Connect the dispenser to the power source.

4. If plumbing is to be hooked up later, be sure the dispenser is disconnected from the power source. If plumbing

has been hooked up, the dispenser is ready for Initial Fill & Heat.

PLUMBING HOOK-UP

1. Flush the water line to remove any debris or foreign material.

2. Securely attach the water line to the 3/8” flare fitting, on bottom right side of the dispenser.

3. Turn on the water supply and check for leaks.

LEVELING THE DISPENSER

Proper leveling of the dispenser is required to insure proper drainage of condensation from the refrigeration

unit.

1. Set the dispenser on a level counter top.

2. Use the adjustable legs to level the dispenser on all four corners.

3. Once the unit is level, adjust the front two legs out another 1/16” to create a slight tilt towards the rear of the

dispenser. (See Fig. 1)

7

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 8

RELEASED FOR PRODUCTION

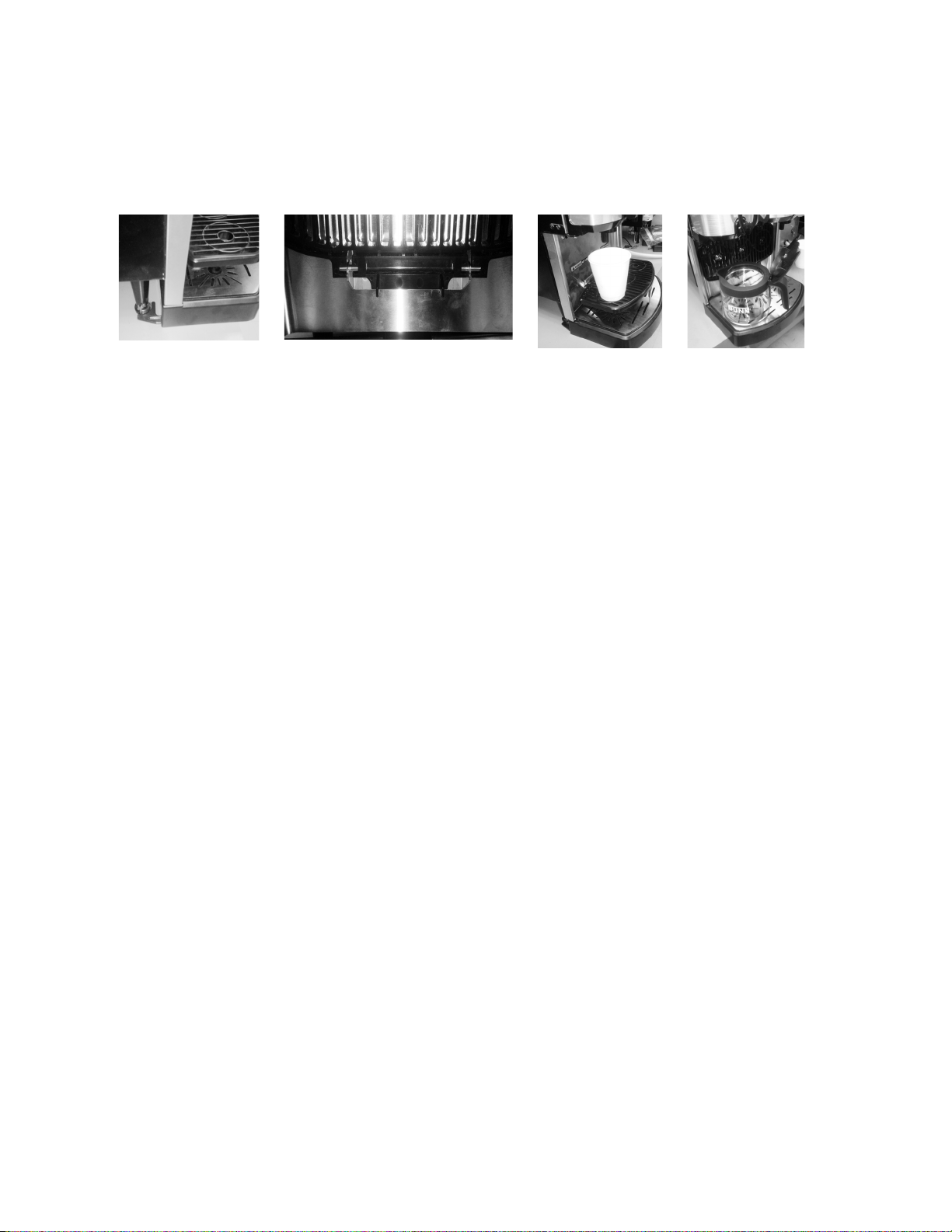

INSTALLING THE DRIP TRAY AND FLIP DOWN CUP TRAY

• Place the SST Cover in the recessed area of the Drip Pan.

• Slide the Drip Pan under the front of the LCR-2 and align the tabs with the legs.

• Insert the hinge pins of the Cup Tray into the notched bracket on the splash panel and rotate the Tray into

place.

• The Cup Tray should be down for serving individual cups of coffee.

• The Cup Tray can be flipped up out of the way for filling carafe’s and/or airpots.

WARNING: The center leg of Cup Tray must be supported by the Drip Tray during use. Do not use the Cup Tray

if the Dispenser legs have been extended and/or the Drip Tray has been removed. Failure to support the Cup Tray

during use can cause damage to the Cup Tray and/or spillage of HOT Liquids.

8

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 9

RELEASED FOR PRODUCTION

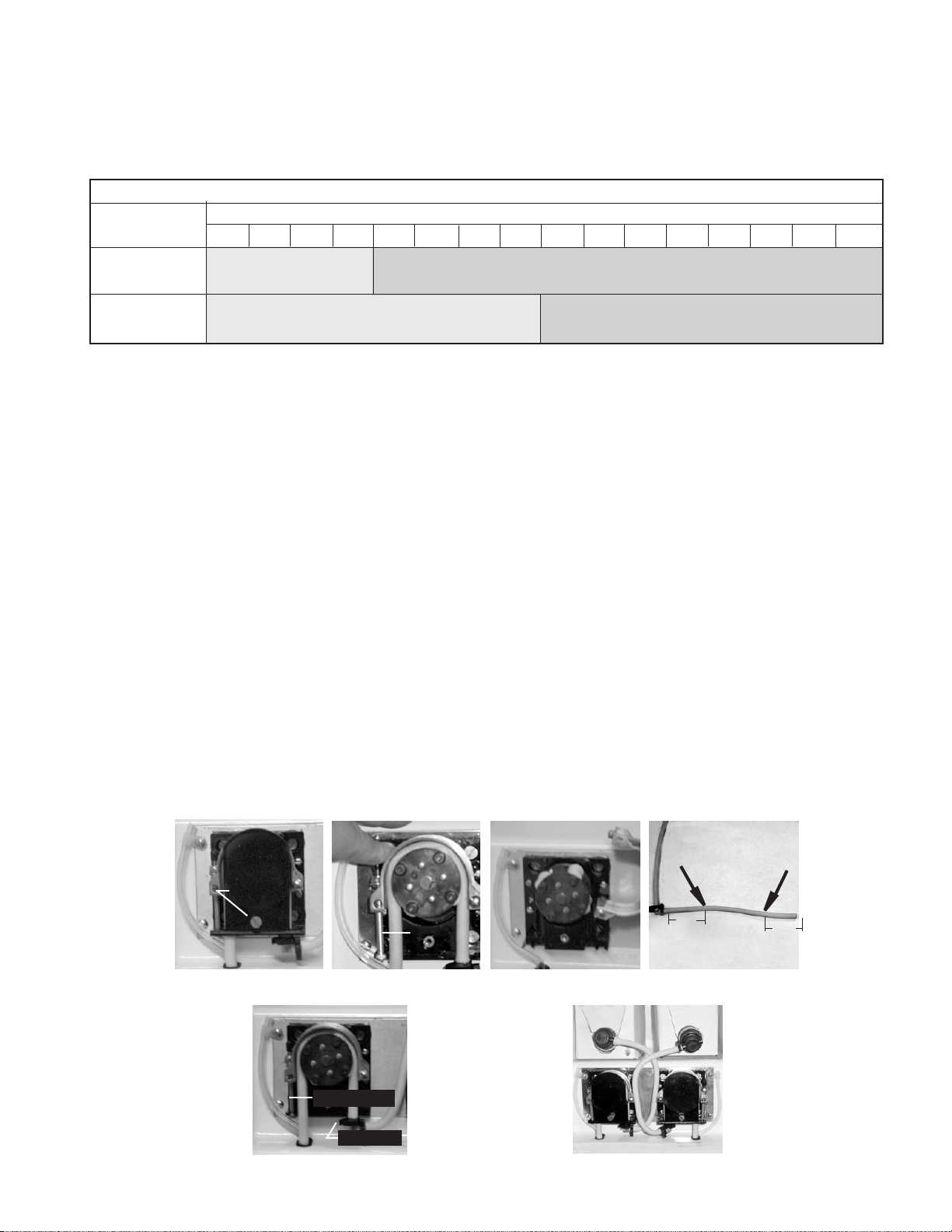

SELECTING THE CORRECT PUMP TUBING

There are two pump tube sizes available for use with this dispenser. To determine the correct tubing for your

application, first determine the dispenser flow rate you intend to use, refer to Setting Dispenser Flow Rate. Then

look up the recommended tube size for the mix ratio of your concentrate, refer to the Tube Selection Chart.

TUBE SELECTION CHART

Dispense Concentrate Ratios

Rate 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

1.8 Oz/sec. 3/16” I.D. TUBING 1/8” I.D. TUBING

(53 ml/sec.)

2.5 Oz/sec. 3/16” I.D. TUBING 1/8” I.D. TUBING

(74 ml/sec.)

Examples:

1. For a Dispenser Flow Rate of 2.5 Oz./sec (74 mL/sec) and a Mix Ratio of 35:1 – use 3/16” I.D. Tubing.

2. For a Dispenser Flow Rate of 1.8 Oz./sec (53 mL/sec) and a Mix Ratio of 60:1 – use 1/8” I.D. Tubing.

Tube kits can be purchased from BUNN-O-MATIC.

Part # 34727.1000 for 3/16” I.D. Tubing or #34728.1000 for 1/8” I.D. Tubing.

INSTALLING THE PUMP TUBING (Refer to the Tubing Installation Instructions in side the cabinet door for

details.)

1. Loosen the thumbscrew securing the tubing retainer plate to the pump housing. Set it and the retainer plate

aside.

2. Depress the tension screw and remove it from the notch in the pump body, releasing the spring tension on

the pump band.

3. Apply lubricant (BUNN-O-MATIC part number M2531.0001) to the new pump tubing.

4. Insert the tubing onto the mix chamber port and wrap the tubing around the pump rotor, making sure that

the elbow and clamps end up on the bottom side of the pump body.

5. Close the compression band reinsert the tension screw into the notch in the pump housing.

6. Replace the tubing retainer plate and tighten the thumbscrew.

7. Reconnect bag connector to the product box.

8. Repeat steps 1 through 7 for the other pump.

9. Prime the pumps. Refer to Priming the Concentrate Lines section.

Thumbscrew

Tension

Screw

2.0”

Lubricate between arrows

2.0”

Remove Retaining Plate Release Spring Tension Remove Tubing

Tension Screw

Tube Clamp

Install New Tubing Completed Installation

9

DIR Num: 36026.0001 19, May 2015

Lubricate New Tube

36026.1 010313

Page 10

BUNN ICED COFFEE

AMBIENT UNIT

RELEASED FOR PRODUCTION

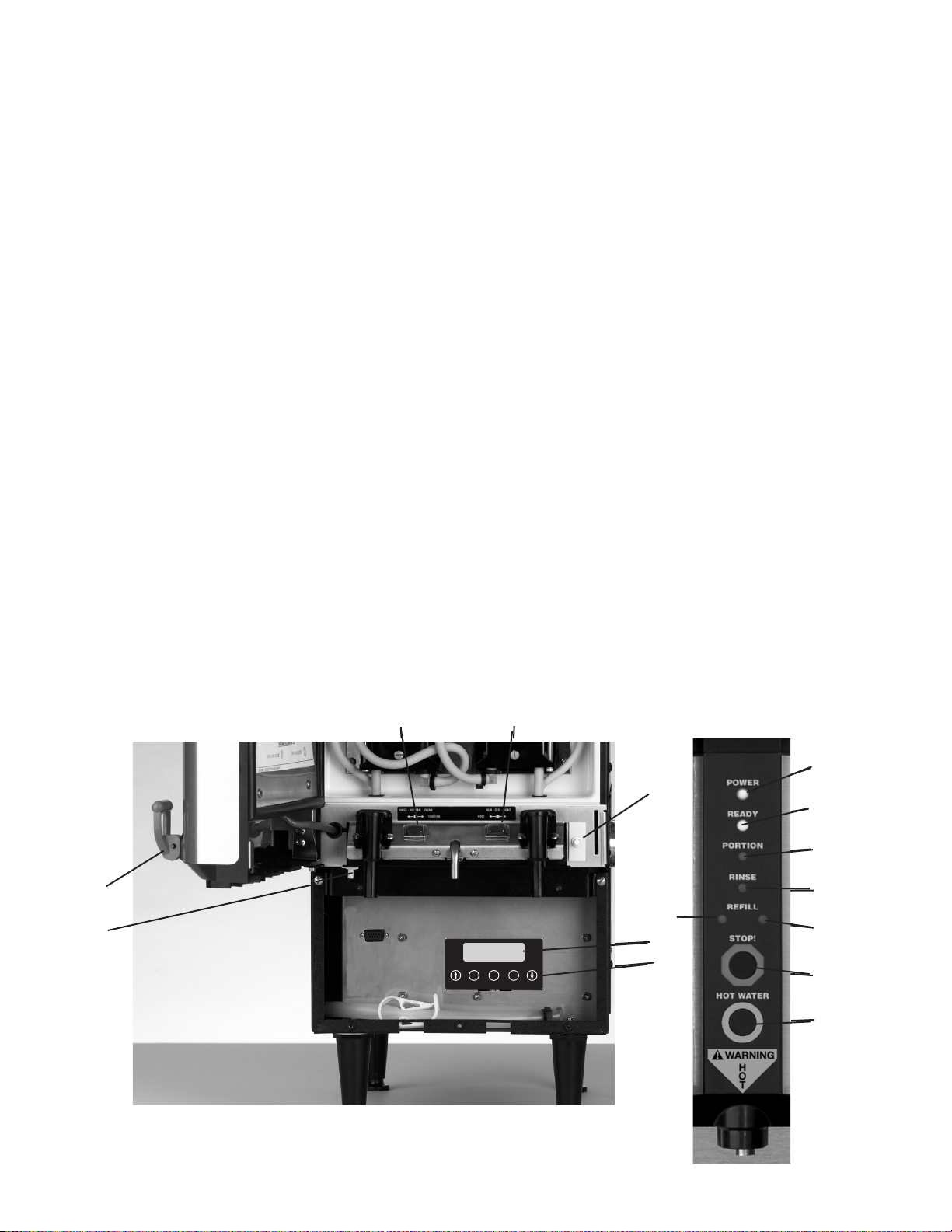

OPERATING CONTROLS AND INTERFACE

1a. Dispense Handles: Pull and Hold to dispense product.

1b. Dispense Switches: Push and Release to dispense product for Portion Control Models.

2. Stop Switch: Momentary switch stops all dispense functions.

3a. Hot Water Switch: Push and Hold switch to dispense hot water from the center dispense tip.

3b. Push and Release switch for Portion Control Models.

4. Alternate Portion Control Switch: Momentarily pushed to select the Alternate Portion Control Volume #2.

5. Function Selector Switch: Allows the user to set the dispenser into different dispensing modes.

a. Rinse: Dispenses hot water only- Flushes the mix chamber and dispense tip.

b. Prime: Dispenses concentrates only – Primes the concentrate pump.

c. Normal: Normal dispense mode - Dispenses mixed product (concentrate and water).

6. Mode Selector Switch: Allows the user to set the dispenser into different operating modes.

a. Run: Normal operating position.

b. Off: Turns off all functions including tank heater and chiller.

WARNING - The OFF Mode does not remove AC power from the dispenser. Disconnect power source before

servicing the dispenser

c. Night: Anti-pilfering mode that disables dispensing, but keeps the tank heater and chiller (if applicable)

operational.

7. Door Interlock Switch: Unit will not dispense product if the door is open.

8. Power LED: Red - illuminates when AC power is applied to dispenser.

9. Ready LED: Green - illuminates when the water is at the preset ready temperature.

10. Portion LED: Yellow - illuminates when the portion dispense option has been selected, (5 second delay).

11. Rinse LED: Yellow - illuminates when the optional preset rinse alarm time has elapsed.

12. Left Refill LED: Yellow - illuminates when the Left Concentrate BIB needs replaced.

13. Right Refill LED: Yellow - illuminates when the Right Concentrate BIB needs replaced.

14. Programming Keypad: Used in conjunction with the LCD display to program and calibrate the dispenser to

customer specific requirements. (Located behind the splash guard panel)

15. LCD Display: Displays programming menus and fault messages. (Located behind the splash guard panel)

5 6

8

7

9

10

1

11

12

4

15

13

14

2

3

10

36026.1 010313

DIR Num: 36026.0001 19, May 2015

Page 11

RELEASED FOR PRODUCTION

SETTING DISPENSER FLOW RATE

The dispenser comes from the factory with flow restrictors in the mix chambers. With the restrictors in place

the dispense rate is about 1.8 oz./sec (53.2 ml/sec) and is used primarily for cup at a time dispensing. The

flow restrictors can be removed to increase the dispense rate to about 2.5 oz./sec (74 ml/sec) for larger volume

dispensing (airpots, carafes, etc.).

NOTE: The hot water FlowRate is fixed at approximately 1.7 oz/sec. and can not be adjusted.

Removing the restrictors:

1. Disconnect the dispenser from the AC power source.

2. Open the Product Cabinet door.

3. Remove the concentrate tube, vent line and grommet from mix chamber ports in side the product cabinet.

4. Remove the two screws that fasten mix chamber to the control panel.

5. Gently pull mix chamber away from dispenser to expose water line connection, (you may have to rotate it

slightly).

6. Disconnect FlavorGard™ sensor wire and hot water tubing from the mix chamber.

7. Remove the flow restrictor from the inlet to the mix chamber.

8. Reconnect FlavorGard™ sensor wire and hot water tubing to the mix chamber.

9. Place mix chamber back into position in the dispenser, (you may have to rotate it slightly) and secure it with

the two screws

10. Reposition the grommet, vent line and pump tubing onto the mix chamber ports.

Caution: Failure to properly replace and secure any of the above components may result leaks and/or cause

damage to the dispenser.

If you changed the Dispenser Flow Rate, you will need to reprogram the dispenser to the new rate, see Programming

the Dispenser.

CAUTION: Failure to reprogram the Dispenser Flow Rates will result in inaccurate Mix Ratios.

Reprogramming the Dispenser Flow Rate:

1. Remove the lower splash guard panel and locate the Programming module.

2. Use the Down Arrow key to enter into the programming function and scroll through the menu’s to the “CAL

LEFT SIDE?” menu and select “YES”.

3. Scroll down to the “CAL LF WTR VOL” menu

4. Use the (+) & (-) keys to enter a volume of 50 Oz. (1478 mL). This will recalibrate the Left dispenser to the

new rate.

5. Scroll down to the “CAL RT WTR VOL” menu

6. Use the (+) & (-) keys to enter a volume of 50 Oz. (1478 mL). This will recalibrate the Right dispenser to the

new rate.

7. Select “Exit” to leave the programming menu.

Note: The default volume of 50 Oz (1478 mL), is the typical Cal Volume for a 2.5 Oz/sec Flow Rate Test, see Field

Calibration of the Concentrate Pumps / Dispenser Flow Rates.

11

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 12

RELEASED FOR PRODUCTION

ADJUSTING MIX RATIOS

The dispenser comes with the Mix Ratios preset to 35:1. The Left and Right ratios can be set for any ratios

between 20:1 and 100:1, (refer the concentrate package or the supplier for the recommended ratio). Once the

recommended ratio has been entered, the Ratios can be adjusted to suit local taste preferences (i.e. lighter or

darker).

Procedure for Adjusting the Mix Ratio to Taste:

1) Set the left and right dispense ratios to the recommended ratios for the concentrate to be used - refer to

“PROGRAMMING THE DISPENSER” section in this manual.

2) Load the concentrate in the cabinet – refer to “LOADING THE CONCENTRATE” section in this manual.

3) Allow the dispenser to fill with water and heat up to the Ready temp – refer to “INITIAL FILL AND HEAT”

section in this manual.

4) Prime both pumps – refer to “PRIMING THE CONCENTRATE LINES” section in this manual.

5) Dispense Product (left and right) for approx. 30 sec and discard. This will finish priming the lines and allow

the pumps time to adjust to the target RPM.

6) Dispense one full cup of coffee (8 oz minimum) from both sides and evaluate.

a) If the coffee is too weak – Decrease the Mix Ratio slightly.

b) If the coffee is too strong – Increase the Mix Ratio slightly.

7) Repeat steps 5 and 6 until the desired taste profile is achieved

Note: Bunn does not recommend adjusting the Mix Ratio more than 20% from the recommended ratio. Contact

your product supplier or service agent, if more than a 20 % adjustment is indicated, as there may be an error

with the set up of the dispenser.

12

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 13

RELEASED FOR PRODUCTION

FlavorGard™ Feature

FlavorGard™ is a patented feed back control loop that monitors the mixed product and adjusts the concentrate

delivery rate to maintain a consistent mix profile, i.e. Flavor Profile. The system consists of a conductance probe

mounted in the final stages of the mixing chamber, a metering pump with RPM sensor and a digital controller.

Once you have completed the installation of the dispenser, entered the desired mix ratio for your concentrate,

dispensed several cups of the mixed product, and are satisfied with the Flavor and Strength being delivered,

simply enable FlavorGard™, (refer to FlavorGard™ in Programming the Dispenser).

The dispenser will automatically calibrate the system to all the factors that make up your particular mix profile,

(e.g. water source, filtration system, Brand of concentrate and mix ratio selected, etc.).

NOTE: It is very important that you have dispensed enough product to insure that the dispenser is fully functional

and you are satisfied with the Flavor Profile of the mix product before enabling FlavorGard™.

Once FlavorGard™ is enabled, the dispenser will continuously monitor the mix product as it is being dispensed

and adjust the metering pump speed to maintain a consistent mixed product, thus eliminating factors such as

(settling of the concentrate, tube wear, viscosity changes, liming, etc.).

The system is designed to work with in the range of variations that can be caused by these factors. The factory

preset range is (+/- 10 %) and is adjustable to a Max of (+/- 15%). This insures that the FlavorGard™ system is

not responding to factors that cannot be corrected by minor adjustments to the speed of the metering pump,

(e.g. kinked hoses, low water pressure, severely worn tubes, empty BIB’s, etc).

NOTE: Changes to Concentrate Ratios or Dispenser Flow Rates will automatically disable FlavorGard™.

You will need to re-enable FlavorGard™, once you are satisfied with the new Flavor Profile.

Rinse Alarm Feature

Periodic rinsing of the mix chambers and dispense tips is essential for proper maintenance and optimum

performance of the dispenser. The automated Rinse Alarm feature has three levels of operation, Disabled, Warning

Only and Warning with Brew Lockout, see chart for details.

Alarm Level Selected Alarm Mode

Disabled None

Warning Only Rinse LED will come on 4 hrs prior to the selected time interval

and remain on until the Rinse procedure has been performed. The dispenser will

continue to serve product.

Warning w/ Brew Lockout Rinse LED will come on 4 hrs prior to the selected time interval and remain on

until the Rinse procedure has been performed. The dispenser will Lockout and

not continue to serve product once the selected time interval has elapsed.

NOTE: The time interval between Rinses is adjustable from 8 to 24 hrs.

The dispenser is shipped with the automated Rinse Alarm disabled, (No Alarm). It is up to the user to determine the

Rinse time interval and the level of warning required, based on their application and maintenance procedures.

To enable the automated Rinse Alarm feature, refer to RINSE ALARM ? in Programming the Dispenser.

13

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 14

RELEASED FOR PRODUCTION

Rinse Procedure:

1. Open the cabinet door and select Rinse on the Function Selector switch – close the door.

2. Place a 2 Liter (1/2 Gal) container under the Left dispense tip.

3. Activate the Left dispense until water flow stops automatically, approximately 20 sec.

4. Repeat Steps 2 & 3 for the Right dispense tip.

The Rinse LED will turn OFF, when the Rinse procedure has been satisfied for both sides.

5. Open the cabinet door and select Normal on the Function Selector switch – close the door.

1 5

BIB Empty Lockout Feature

The dispenser can be set to not dispense product when the concentrate BIB is empty. To enable this feature, first

calibrate the Empty BIB Threshold (refer to Field Calibrating the Empty BIB Warning). Then enable the BIB Empty

Lockout feature (refer to the BIB Empty Lockout menu in Programming the Dispenser). The dispenser will now

Lockout dispensing and flash the Right or Left “REFILL LED” corresponding to the empty BIB. Once the BIB has

been replaced, PRIME the concentrate line (refer to Priming the Concentrate Lines) and then dispense mixed

product until the “REFILL LED” goes out. NOTE: If the dispenser fails to clear the BIB Empty Lockout, repeat the

Priming operation a second time to insure the concentrate is flowing properly.

Brew Temperature Lockout Feature

The dispenser can be set to not dispense product if the hot water is not up to the preset READY temperature. To

enable this feature set the READY temperature to the minimum allowable dispense temperature. Then enable the

Brew Lockout feature, refer to READY TEMP and BREW LOCKOUT, in Programming the Dispenser.

14

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 15

RELEASED FOR PRODUCTION

PROGRAMMING THE DISPENSER

Remove the lower splash guard assembly to access the digital programming module with LCD display.

Press the Down Arrow key to inter the programming menu.

Use the Up and Down Arrow keys to scroll through the menu screens.

Select Exit to leave the programming function and return to normal operations.

NOTE 1: Flashing menu items indicate which selection is active.

NOTE 2: Values shown below are the factory default values for English units.

NOTE 3: Values in [X - X] are the Min. and Max. for that function.

MENU SCREEN ACTION DESCRIPTION

TANK TEMP XXX

CABINET TEMP XX

L DISPENSE RATIO

(-) 35:1 (+)

SET LF TUBE SIZE

1/8 EXIT 3/16

R DISPENSE RATIO

(-) 35:1 (+)

SET RT TUBE SIZE

1/8 EXIT 3/16

FLAVOR GUARD ?

NO EXIT YES

If NO - go to LF DISP VOLUME menu.

LF TASTE OK ?

NO EXIT YES

Use the Down Arrow Key

to enter Programming

Functions

Use the (+) or (-) buttons to

adjust the Mix Ratio

Select tube size.

Use the (+) or (-) buttons to

adjust the Mix Ratio

Select tube size.

Select (YES) to activate.

Select (NO) to deactivate.

Select (YES) or (NO)

Normal Display for LCR models.

Enter the desired Mix Ratio for the concentrate

used in the Left dispenser. [20:1 - 100:1]

Enter Pump Tube Size to be used in the Left

metering pump, (see Tube Selection Chart)

Enter the desired Mix Ratio for the concentrate

used in the Right dispenser. [20:1 - 100:1]

Enter Pump Tube Size to be used in the Right

metering pump, (see Tube Selection Chart)

Select Yes, if you are ready to calibrate the Flavor

Guard sensor. Select NO, if you do not wish to

use this feature, (see Flavor Guard)

Select YES, if you have dispensed several cups

and are satisfied with the Left dispenser flavor.

Select NO, if you have not run taste test.

FIND LF TARGET

PULL DISPENSE

RT TASTE OK ?

NO EXIT YES

FIND RT TARGET

PULL DISPENSE

Place a 16 Oz. (500 mL)

cup under the Left dispense

tip, then activate the Left

dispenser

Select (YES) or (NO)

Place a 16 Oz. (500 mL) cup

under the Right dispense

tip, then activate the Right

dispenser

15

Calibrates the Left FlavorGard™ sensor to the

current MixProfile. The dispenser will shut OFF

automatically when finished.

Select YES, if you have dispensed several cups

and are satisfied with the Right dispenser flavor.

Select NO, if you have not run taste test.

Calibrates the Right FlavorGard™ sensor to the

current MixProfile. The dispenser will shut OFF

automatically when finished.

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 16

RELEASED FOR PRODUCTION

MENU SCREEN ACTION DESCRIPTION

LOCK FLAVOR ?

EXIT YES

Select (YES) or (EXIT)

Select YES, to Lock In sensor calibration. NOTE:

Display will return to “Find LF Target” if sensor

calibration is out of range.

FLAVORS LOCKED

NONE

EXIT

Portion Control Settings for Pull & Hold Dispensers

For Portion Control Dispensers (LCR-2 PC, LCR-2C PC, and LCR-2A PC) go to Full Time Portion Control Settings

LF DISP VOLUME

(-) 4.0oz (+)

Use the (+) or (-) buttons to

adjust the volume

Confirms that sensor calibration was in range and

accepted. Scroll down to continue.

Set the volume to be dispensed during a Left

Portion controlled dispense to:

[0 - 640 Oz.] or [0 - 18.93L]

RT DISP VOLUME

(-) 4.0oz (+)

Use the (+) or (-) buttons to

adjust the volume

Set the volume to be dispensed during a Right

Portion controlled dispense to:

[0 - 640 Oz.] or [0 - 18.93L]

Full Time Portion Control Settings

LF DISP VOLUME 1

(-) 4.0oz (+)

Use the (+) or (-) buttons

to adjust the Normal Left

volume

Set the desired portion control volume to be

dispensed during a Normal Left dispense to:

[0 - 640 Oz.] or [0 - 18.93L]

LF DISP VOLUME 2

(-) 0.0oz (+)

RT DISP VOLUME 1

(-) 4.0oz (+)

RT DISP VOLUME 2

(-) 0.0oz (+)

WATER DISP VOL 1

(-) 0.0oz (+)

WATER DISP VOL 2

(-) 0.0oz (+)

Use the (+) or (-) buttons

to adjust the Alternate Left

volume

Use the (+) or (-) buttons

to adjust the Normal Right

volume

Use the (+) or (-) buttons to

adjust the Alternate Right

volume

Use the (+) or (-) buttons to

adjust the Normal Hot Water

volume

Use the (+) or (-) buttons to

adjust the Alternate Hot Water

volume

Set the desired portion control volume to be

dispensed during a Alternate Left dispense to:

[0 - 640 Oz.] or [0 - 18.93L]

Set the desired portion control volume to be

dispensed during a Normal Right dispense to:

[0 - 640 Oz.] or [0 - 18.93L]

Set the desired portion control volume to be

dispensed during a Alternate Right dispense to:

[0 - 640 Oz.] or [0 - 18.93L]

Set the desired portion control volume to

be dispensed during a Normal Hot Water

dispense:

[0 - 640 Oz.] or [0 - 18.93L]

Set the desired portion control volume to

be dispensed during a Alternate Hot Water

dispense:

[0 - 640 Oz.] or [0 - 18.93L]

16

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 17

RELEASED FOR PRODUCTION

MENU SCREEN ACTION DESCRIPTION

TANK TEMP 180

(-) EXIT (+)

READY TEMP 175

(-) EXIT (+)

CABINET TEMP 38

(-) EXIT (+)

LF PRODUCT DISP

.0GAL RESET?

LF PRODUCT DISP

.0GAL

RT PRODUCT DISP

.0GAL RESET?

Use the (+) or (-) buttons to

adjust the target Temp.

Use the (+) or (-) buttons to

adjust the target Temp.

Use the (+) or (-) buttons to

adjust the target Temp.

Select (RESET) to clear total

NONE

Select (RESET) to clear total

Sets the water Tank temperature [120 - 200°F]

or [49 - 93°C]

Sets the hot water Ready temperature. Typically

set to the minimum desired dispense temp.

Sets the Chilled Cabinet target temperature [38

- 50°F] or [3 - 10°C]

Selecting Reset will clear the Current accumulated

volume of concentrate dispensed through the Left

dispenser. Gal (Liters)

Displays the Total accumulated volume of

concentrate dispensed through the Left dispenser.

Not Re-settable. Gal (Liters)

Selecting Reset will clear the Current accumulated

volume of concentrate dispensed through the

Right dispenser. Gal (Liters)

RT PRODUCT DISP

.0GAL

NONE

Displays the Total accumulated volume of

concentrate dispensed through the Right

dispenser. Not Re-Settable. Gal (Liters)

The following functions can be Password Protected. If you wish to prevent others from accessing these

functions, enter a 4 digit code of your choice. Record your password code [_ _ _ _], as you will need it

to access these functions in the future.

ENTER PASSWORD

(-) 0 (+)

SET PASSWORD ?

(-) 0 (+)

SELECT UNITS

ENG EXIT METRIC

CHILLED UNIT ?

NO EXIT YES

Use the (+) or (-) buttons to

enter password.

Use the (+) or (-) buttons to

change the password.

Select the preferred units

Select (YES) or (NO)

Enter the access Code to view the remaining

functions. Factory Default = 0.

Enter your own Code to prevent access to the

remaining functions. [0 to 9999]

Used to select the preferred units of measurement.

(Oz., Gal, deg F) or (mL, L, deg C)

LCR Models default to (YES)

Select (NO) to turn the refrigeration system

OFF.

RINSE ALARM ?

NO EXIT YES

Select (YES) or (NO)

Selecting Yes will enable the Rinse Alarm function,

(see Rinse Alarm)

If NO - go to BIB EMPTY LOCKOUT menu.

DIR Num: 36026.0001 19, May 2015

17

36026.1 010313

Page 18

RELEASED FOR PRODUCTION

MENU SCREEN ACTION DESCRIPTION

RINSE TIME ?

(-) 12 Hrs (+)

RINSE LOCKOUT ?

NO EXIT YES

BIB EMPTY LOCKOUT

NO EXIT YES

Use the (+) or (-) buttons to

adjust Rinse Alarm delay

Select (YES) to enable

Select (YES) to enable

Enter the desired time between required Rinse

Cycles in hours, [8 - 24 hrs.]

Select YES to Lockout dispensing until the Rinse

Alarm has been cleared. Default is NO

Select YES to Lockout dispensing until the

Concentrate BIB has been replaced. Default is

NO

BREW LOCKOUT ?

NO EXIT YES

Select (YES) to enable

Select YES to Lockout dispensing until the hot

water tank is at READY Temp. Default is NO

DLY REPEAT DISP

(-) 0 SEC (+)

Use the (+) or (-) buttons to

adjust the Delay Time

Enter the desired time delay before allowing the

next dispense to take place, [0 - 10 sec.]

The following functions are for diagnostic and troubleshooting purposes and typically do not have to be

adjusted. Contact your local service agent for assistance before making changes to these functions.

CAL LEFT SIDE ?

EXIT YES

Select (YES) to enable

Selecting Yes will enable the Left Dispenser

Calibration routine, (see Field Calibration before

attempting to calibrate the dispenser).

If NO - go to CAL RIGHT SIDE menu.

CAL LEFT PUMP ?

PULL DISPENSE

Place a 50 mL (#34843.1000)

graduated cylinder under the

Left dispense tip, then activate

the Left Dispenser

CAL LF PUMP VOL

(-) 43mL (+)

CAL LF WTR FLOW ?

PULL DISPENSER

Use the (+) or (-) buttons to

enter volume collected

Place a 64 Oz. (2000 mL)

container under the Left

dispense tip, then activate the

Left Dispenser

CAL LF WTR VOL

(-) 36.0OZ (+)

Use the (+) or (-) buttons to

enter volume collected

CAL LEFT SIDE ?

EXIT YES

NONE

The Left Pump will dispense concentrate for 20

seconds, then shut off automatically. Collect and

measure the concentrate dispensed.

Enter the volume of concentrate measured from

the Left Pump in mL, (not Oz.) regardless of

Preferred Units selected.

The Left Dispenser will dispense hot water for 20

seconds, then shut off automatically. Collect and

measure the water dispensed.

Enter the volume of the water measured from the

Left dispenser in Oz. (mL).

Scroll down to bypass this screen.

CAL RIGHT SIDE ?

EXIT YES

Select (YES) to enable

Calibration routine.

Selecting Yes will enable the Right Dispenser

Calibration routine, (see Pump Calibration) prior

to calibrating the dispenser.

18

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 19

RELEASED FOR PRODUCTION

MENU SCREEN ACTION DESCRIPTION

If NO - skip to next menu.

CAL RIGHT PUMP ?

PULL DISPENSER

Place a 50 mL (#34843.1000)

graduated cylinder under

the Right dispense tip, then

The Right Pump will dispense concentrate for

20 seconds, then shut off automatically. Collect

and measure the concentrate dispensed.

activate the Right Dispenser

CAL RT PUMP VOL

(-) 43mL (+)

Use the (+) or (-) buttons to

enter volume collected

Enter the volume of concentrate measured from

the Right Pump in mL(not Oz.) regardless of

Preferred Units selected.

CAL RT WTR FLOW

PULL DISPENSER

Place a 64 Oz. (2000 mL)

container under the Right

dispense tip, then activate the

The Right Dispenser will dispense hot water for

20 seconds, then shut off automatically. Collect

and measure the water dispensed.

Right Dispenser

CAL RT WTR VOL

(-) 36.0OZ (+)

CAL RIGHT SIDE ?

Use the (+) or (-) buttons to

enter volume collected

NONE

Enter the volume of the water measured from the

Right dispenser in Oz. (mL)

Scroll down to bypass this screen.

EXIT YES

For Portion Control Dispensers (LCR-2 PC, LCR-2C PC, LCR-2A PC) only

CAL HOT WTR FLO ?

PULL DISPENSE

CAL HOT WTR VOL

(-) 34.0OZ (+)

XXX CAL -> XXX

(-) TankTemp (+)

FlvrGrdRange 10%

(-) EXIT (+)

LfFlvrGrdTargets

RPM XXX-CON XXX

RtFlvrGrdTargets

RPM XXX-CON XXX

Place a 64 Oz. (2000 mL)

container under the Hot Water

dispense tip, then activate the

Hot Water Dispenser

Use the (+) or (-) buttons to

enter volume collected

Use the (+) or (-) buttons to

adjust temperature reading

Use the (+) or (-) buttons to

adjust % value

NONE

NONE

The Hot Water Dispenser will dispense for 20

seconds, then shut off automatically. Collect and

measure the water dispensed.

Enter the volume of the water measured from the

Hot Water Dispenser in Oz. (mL)

Adjust the display reading to match a calibrated

probe inserted next to the Tank Sensor, °F (°C).

Used to set the maximum adjustment the Flavor

Guard feature is allowed to make, [3 - 15%].

Displays the Left Dispenser target RPM and

Conductance Reading, (Diagnostics Only)

Displays the Right Dispenser target RPM and

Conductance Reading, (Diagnostics Only)

19

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 20

RELEASED FOR PRODUCTION

MENU SCREEN ACTION DESCRIPTION

BIB EMPTY -> 500

(-) EXIT (+)

XX REFILL -> 155

(-) EXIT (+)

WTR START DELAY

(-) .15SEC (+)

WTR STOP DELAY

(-) .15SEC (+)

TEST LED’S ?

NO EXIT YES

TEST SWITCHES ?

UseSwitchToTest

TEST REFILL ?

EXIT YES

Use the (+) or (-) buttons to

adjust empty BIB threshold

Use the (+) or (-) buttons to

adjust Refill threshold

Use the (+) or (-) buttons to

adjust delay time

Use the (+) or (-) buttons to

adjust delay time

Select (YES) or (NO)

NONE

Momentarily depress (YES)

Used to set the Conductance Threshold for the

Empty BIB warning. Default is 500

Used to set the Conductance Threshold for the

Tank Refill Probe.

Dispense Valve ON Delay. Eliminates weak mix

at the beginning of a dispense.

Dispense Valve OFF Delay. Flushes the mix

chamber at the end of a dispense.

LED diagnostics. Selecting YES will light all Front

Door LED’s.

Switch Diagnostic: Activate switches separately to

test. Display will indicate which Switch has been

activated. NOTE: Door Interlock switch must be

held closed.

Refill Valve Diagnostic: Press YES to momentarily

energize the Solenoid. CAUTION: Inlet Valve will

open and water will flow, if connected and turned

ON.

TEST HEATER ?

EXIT YES

ENTER ASSET #

(-) 000000 (+)

SERIAL #

LCR 0000000

VIEW FAULTS?

(-) EXIT (+)

LATEST FAULT

NO FAULTS

FACTORY DEFAULTS

NO YES

Momentarily depress (YES)

Use the (+) or (-) buttons to

adjust the ASSET NUMBER

NONE

Select (+) to view Fault

Conditions

Use (+) or (-) to scroll through

the Faults

Select (YES) or (NO)

Tank Heater Diagnostic: Press YES to momentarily

energize the Tank Heater Circuit.

CAUTION: AC power will be applied to the Tank

Heater Circuit.

Allows the user the option of entering an Asset

Number. Default is 000000

Displays the manufacture’s Serial Number (should

be identical to the Serial Number on the machine

Data Plate)

This unit stores the last 3 Fault Conditions in

memory for diagnostic purposes.

Displays up to 3 FAULT Conditions or NO FAULTS,

if nothing has failed since the last “Reset Factory

Defaults”.

CAUTION: Selecting YES will RESET all

Programming Functions to the Factory Default

settings.

20

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 21

RELEASED FOR PRODUCTION

INITIAL FILL & HEAT

1. Select Normal on the Function Selector Switch and Run on the Mode Selector Switch.

2. Confirm the water supply is on.

3. Connect the dispenser to the power source. The Red POWER LED will illuminate and water will begin flowing

into the tank. The dispenser will automatically stop filling when the tank is full. The dispenser will not begin

heating the water until after the tank is filled. Dispenser models with product chillers will begin to cool the

cabinet at this time.

4. The Green READY LED will illuminate when the tank temperature reaches the preset ready temperature.

Note: The time required to heat the water initially will vary depending on the AC Power supplied to the

dispenser.

While the tank is heating, the dispenser may be readied for use as described in Programming Functions & Basic

Operations.

1 1

3

4

21

36026.1 010313

DIR Num: 36026.0001 19, May 2015

Page 22

RELEASED FOR PRODUCTION

LOADING THE CONCENTRATE

1. Thoroughly mix concentrate by vigorously shaking the product Bag-In-Box (BIB).

2. Pull the BIB connector through the hole provided in the box and place it on the drip tray with the connector

facing up. (See Fig. 1)

3. Open the dispenser door and locate the appropriate left or right BIB Adapter fitting.

4. Pull the Adapter fitting down and connect it to the BIB. (See Fig. 2)

5. Place the BIB upright in the machine, rotating it into position with the connector facing forward.

6. Rotate the BIB Adapter to avoid sharp bends in the tubing and allow it to be routed between the two

pumps.

Refer to the Tube Installation Decal on the door for proper routing. (See Fig. 3)

7. Close the cabinet door.

Fig. 1

Fig. 2 Fig. 3

PRIMING THE CONCENTRATE LINES

1. Open the dispenser door.

2. Load concentrate per instructions in the section titled Loading the Concentrate.

3. Select Prime on the Function Selector Switch and Run on the Mode Selector Switch.

4. Close the dispenser door.

5. Place a container under the appropriate dispense tip.

6. Activate the appropriate dispenser until concentrate flows from the dispense nozzle. Priming may take 5 to

10 seconds.

7. Open the dispenser door, select Normal on the Function Selector Switch, and then close door.

Note: Concentrate may continue to drip out of dispense tip. The user may wish to run a Rinse Cycle (refer to

Rinsing) after Priming the dispenser to clean out the remaining concentrate.

7 3 3

22

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 23

RELEASED FOR PRODUCTION

OPERATING THE PULL & HOLD DISPENSER

(Models LCR-2, LCR-2C, LCR-2A)

Set the Function Selector Switch to Normal and the Mode Selector Switch to Run.

1. Pull and Hold Dispense Mode (Cup at a time)

a. Place cup on the cup tray beneath the desired dispensing tip. For a large container, flip the cup tray up

and place the container on top of the drip tray.

b. Pull and Hold the corresponding dispense handle until the cup or other container is full.

c. Remove cup or container.

2. Portion Dispense Mode (Preset volume dispensing) Refer to Programming Functions on how to set this

volume.

a. Place the appropriate size container beneath the desired dispensing tip. For large containers, flip the cup

tray up and place the container on top of the drip tray.

b. Momentarily press the Portion Switch. The Portion LED will illuminate for 5 seconds after the Portion

Switch is pressed.

c. Momentarily pull the corresponding dispense handle, then release. If the user waits longer than 5 seconds

to pull the handle, the dispenser will default back to the Pull & Hold Mode. Portion Dispense Mode can

be disabled at any time during the portion dispense by either momentarily pulling the Dispense Handle

again or pressing the Stop button.

d. Wait for container to fill and the dispenser to quit dispensing, then remove container.

3. Hot Water Dispense

a. Place container under the hot water dispenser (center of machine). For large containers, flip the cup tray

up and place the container on top of the drip tray.

b. Push and hold the Hot Water Switch until the water reaches the desired level, then release.

c. Remove container.

Filling Cambros or other large containers:

The dispenser is designed primarily for cups or other small containers that will fit under the dispense tips.

However, it may be used to fill larger containers (up to 2 Gal) by use of an extension hose on the dispense tip.

Removing the Flow Restrictors will increase the dispenser flow rate to 2.5 Oz/sec. (74 mL/sec.) and reduce the

time to fill larger containers, (see Setting Dispenser Flow Rate.)

Care must be taken to insure that the mixed product flows freely from the dispense tip into the container.

1. Use a 5/8” I.D. or larger, NSF (National Sanitation Foundation) approved hose.

2. Use as short a hose as possible with no loops, bends or kinks in it.

3. Insure that the outlet of the hose is below the dispense tip and that the mixed product flows freely into the

container

A properly sized and positioned hose will not run full or back up into the dispense tip. Failure to follow these

directions can alter the mix ratio and/or cause flooding of the vent tube.

NOTE: The temperature of the product being dispensed will start to drop after ~2 gal. continuous draw. Recovery

time will be dependent on the temperature of the supply water and the voltage at which the heater coil is being

operated.

23

36026.1 010313

DIR Num: 36026.0001 19, May 2015

Page 24

RELEASED FOR PRODUCTION

OPERATING THE PRESET PORTION CONTROL DISPENSER

(Models LCR-2 PC, LCR-2C PC, LCR-2A PC)

Set the Function Selector Switch to Normal and the Mode Selector Switch to Run.

Dispensing Preset Portions of Coffee or Hot Water

1. Primary Volume Portion Dispense Mode. (Volume 1) Refer to Programming Functions on how to set this

amount.

a. Place cup on the cup tray beneath the desired dispensing tip. For a large container, flip the cup tray up

and place the container on top of the drip tray.

b. Momentarily press the appropriate dispense switch. The dispenser will automatically dispense the beverage

at the preset amount. Allow the mix chamber to drain at the end of the cycle.

c. Remove cup or container.

2. Alternate Volume Portion Dispense Mode. (Volume 2) Refer to Programming Functions on how to set this

volume.

a. Place the appropriate size container beneath the desired dispensing tip. For large containers, flip the cup

tray up and place the container on top of the drip tray.

b. Momentarily press the Portion Switch. The Portion LED will illuminate for 5 seconds after the Portion

Switch is pressed.

c. Momentarily press the corresponding Dispense Switch. If the user waits longer than 5 seconds to push

the switch, the dispenser will default back to the Primary Volume preset amount. Alternate Portion

Dispense Mode can be disabled at any time during the portion dispense by either momentarily pushing

the Dispense Switch again or pressing the Stop button.

d. Wait for the container to fill and the dispenser to quit dispensing, then remove the container.

Push and Hold Dispensing of Coffee or Hot Water

Push and Hold Dispense Mode. See Programming Functions on how to set the Preset Volume to Zero.

a. Place cup on the cup tray beneath the desired dispensing tip. For a large container, flip the cup tray up

and place the container on top of the drip tray.

b. Push and hold the corresponding dispense switch until the container is full.

c. Remove cup or container.

Filling Cambros or other large containers:

The dispenser is designed primarily for cups or other small containers that will fit under the dispense tips.

However, it may be used to fill larger containers (up to 5 Gal) by use of an extension hose on the dispense tip.

Removing the Flow Restrictors will increase the dispenser flow rate to 2.5 Oz/sec. (74 mL/sec.) and reduce the

time to fill larger containers, (see Setting Dispenser Flow Rate.)

Care must be taken to insure that the mixed product flows freely from the dispense tip into the container.

1. Use a 5/8” I.D. or larger, NSF (National Sanitation Foundation) approved hose.

2. Use as short a hose as possible with no loops, bends or kinks in it.

3. Insure that the outlet of the hose is below the dispense tip and that the mixed product flows freely into the

container

A properly sized and positioned hose will not run full or back up into the dispense tip. Failure to follow these

directions can alter the mix ratio and/or cause flooding of the vent tube.

NOTE: The temperature of the product being dispensed will start to drop after ~2 gal. continuous draw. Recovery

time will be dependent on the temperature of the supply water and the voltage at which the heater coil is being

operated.

24

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 25

RELEASED FOR PRODUCTION

CLEANING & PREVENTATIVE MAINTENANCE

General Cleaning and Sanitizing Procedures

Note: The BUNN

®

Liquid Coffee Dispenser incorporates a “user selectable” rinse reminder feature, which lights

the Rinse LED on the front panel and disables dispensing when it is time to rinse. See Programming Functions

to activate this feature.

Daily: RINSING

1. Open the dispenser door.

2. Select Rinse on the Function Selector Switch and Run on the Mode Selector Switch.

3. Close the dispenser door.

4. Place a 1/2 gal (2 liter) container under the appropriate dispense nozzle or nozzles.

5. Activate the dispenser on the appropriate side or sides for approximately twenty seconds or until the hot

water is clear or has no concentrate coloring in it.

6. Open the dispenser door, select Normal on the Function Selector Switch, and then close door.

Note: To clear the “Rinse” alarm, activate the dispenser until the flow stops automatically (approx. 20 seconds

for each tip). The “Rinse” alarm LED will turn off when the Rinse Procedure has been satisfied for both sides.

Daily: PARTS WASHING

1. Remove and wash the drip tray, drip tray cover, and cup tray in a mild detergent solution. Rinse

thoroughly.

2. Wipe splash panel, area around dispense nozzles, door, and cabinet with a clean damp cloth.

Weekly: SANITIZING

1. Open the dispenser door.

2. Select Prime on the Function Selector Switch and Run on the Mode Selector Switch.

3. Remove the bag connector from the product box and disassemble or prop open the internal valve to allow

free flow of product through the connector. NOTE: Cutting the mating fittings from an empty bag makes an

excellent “free flowing” connector for this purpose.

4. Place the bag connector into a one-gallon (3.8 liter) container of warm soapy tap water 140°F (60°C).

5. Place an empty container under dispense tip and activate the corresponding dispenser until the clean soapy

water is dispensed from the dispense tip.

6. Repeat steps 4 and 5 with warm tap water 140°F (60°C) to rinse the soapy water from the pump tubing.

Continue dispensing until the water is clear, and no soapy water is being dispensed.

7. Prepare 2.5 gallons (9.46L) of sanitizing solution by dissolving 1 packet of Kay 5 sanitizer into 2.5 gallons

(9.46L) of 120°F (48.9°C) water to ensure 100 ppm of available chlorine.

8. Again, repeat steps 4 and 5 with the sanitizing solution. Once sanitizing solution is visible, continue to dispense

for 1 minute. Release handle and allow solution to sit for 5 minutes.

9. After soaking for 5 minutes, activate the dispense switch a second time, this time for 2 minutes. After 2

minutes, release the dispense switch.

10. Repeat step 6 to flush out the sanitizing solution from the pump tubing.

11. Remove the mating connector from the bag connector.

12. Reattach the bag connector to product box.

13. Select Normal on the Function Selector Switch and Run on the Mode Selector Switch.

14. Activate the dispenser until concentrate/water mixture appears. Then dispense one 12 ounce (354.9 ml)

glass of concentrate/water mixture and discard.

15. Repeat steps 1 through 14 for other dispense head.

16. Wipe internal and external surfaces with a clean, damp cloth.

Weekly: REFRIGERATION AIR FILTER

1. Remove the screen filter from the back of the dispenser.

2. Wash the screen in a mild detergent solution.

3. Use a soft bristled brush to remove all dust and grease.

4. Reinstall the screen on the back of the dispenser.

25

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 26

RELEASED FOR PRODUCTION

PREVENTIVE MAINTENANCE

Bunn-O-Matic® Corporation recommends that preventive maintenance be performed at regular intervals. Maintenance

should be performed by a qualified service technician. For Technical Service, contact Bunn-O-Matic® Corporation at

1-800-286-6070.

NOTE: Replacement parts or service caused by failure to perform required maintenance is not covered by warranty.

Replace pump hoses every 6-Months or as needed.

REPLACING THE PUMP TUBING

The pumps and tubing used in the dispenser are designed to give maximum performance and long life. However,

the tubes are a wear item and must be replaced periodically. How long the tubes last is dependent on usage and

properties of the concentrate. Excessive wear will reduce the output of the pumps resulting in a weak mixed

beverage. Bunn-O-Matic recommends replacing the Pump Tubing a minimum of once every 6 months or

sooner if warranted.

Refer to the Tube Replacement Instruction on the Cabinet door for details.

1. Rinse the pump tubing with warm tap water (Refer to steps 1 - 5 of the Weekly Sanitizing instructions) prior

to removing the tubes to avoid concentrate spills.

2. Loosen the thumbscrew securing the tubing retainer plate to the pump housing. Set it and the retainer plate

aside.

3. Depress the tension screw and remove it from the notch in the pump housing, releasing the spring tension

on the pump band.

4. Open the compression band and gently pull the pump tube from around the pump’s rotor.

5. Inspect the pump bands for signs of wear. Replace if necessary.

6. Apply lubricant (BUNN-O-MATIC part number M2531.0001) to the new pump tubing’s rotor side.

7. Insert the tube onto the mix chamber port, then wrap the new tubing around the pump rotor, making sure

that the elbow and clamps end up on the bottom side of the pump housing.

8. Depress the tension screw and insert it in the notch in the pump body, reapplying spring tension on the pump

band.

9. Replace the tubing retainer plate and tighten the thumbscrew.

10. Repeat steps 1 through 9 for the other pump.

Note: Replacement Tube/Adapter Kits can be purchased from BUNN-O-MATIC.

Thumbscrew

Tension

Screw

Remove Retaining Plate Release Spring Tension Remove Tubing

Tension Screw

Tube Clamp

Install New Tubing Completed Installation

26

DIR Num: 36026.0001 19, May 2015

2.0”

Lubricate between arrows

Lubricate New Tube

2.0”

36026.1 010313

Page 27

RELEASED FOR PRODUCTION

DRAINING THE HOT WATER TANK

CAUTION: The dispenser must be disconnected from the power source throughout these steps.

1. Disconnect the dispenser from the power source.

2. Shut off and disconnect the incoming water supply.

3. Remove the front splash panel.

4. Pull out drain tube to empty into a sink or a container with a minimum of five-gallon capacity.

5. Make sure drain clamp is closed. Then, remove drain plug.

6. Direct tube into sink or container and open drain clamp. Continue draining tank until ALL of the water is out.

Be very careful with the draining water because it can be very hot.

7. Close drain clamp, insert drain plug, place drain tube back into machine, and replace splash panel.

Note: The dispenser must be refilled using the Initial Fill & Heat steps before reconnecting the power source.

27

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 28

RELEASED FOR PRODUCTION

Troubleshooting

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Only qualified service personnel should perform inspection, testing, and repair of electrical equipment.

• Shorting the terminals or the application of external voltages to electronic components may result in component

or circuit board failure.

• Intermittent operation of electronic circuit boards is unlikely. board failure will normally be permanent. If an

intermittent condition is encountered, the cause will likely be a switch contact or a loose wire connection at

a terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will

help avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and all electrical connections are tight and isolated.

• This dispenser is heated at all times. Keep away from combustibles.

WARNING:

• Exercise extreme caution when servicing electrical equipment.

• Disconnect the brewer from the power source when servicing, except when electrical tests are specified. The

red “Power LED” on the door indicates that the unit is connected to AC Power.

• Follow recommended service procedures.

• Replace all protective shields or safety notices.

Front Panel LED Display Messages

Power LED “OFF”

No AC Power

Ready LED “OFF”

Water Temp. Too Low

Rinse LED “ON”

Rinse Timer

Rinse LED “FLASHING”

Rinse Lockout Enabled

Portion LED “ON”

Portion Dispense

Enabled

Dispenser Not plugged in.

AC Circuit Breaker OFF

Usage has exceeded the

capacity of the Tank Heater

Rinse Cycle Required

Alternate Portion Dispenser

Volume #2 has been selected

Check Power Cord

Check the AC Power Circuit Breaker

Service Required

Check Tank Temp Setting

Check Ready Temp. Setting

Service Required: Change the Supply Voltage,

see Optional Field Wiring

Rinse Dispenser, see Rinse ProcedureRinse Cycle Required

Rinse Dispenser, see Rinse ProcedureDispenser Locked Out

Activate the Dispenser within 5 sec. to

dispense the pre-selected volume.

28

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 29

RELEASED FOR PRODUCTION

Troubleshooting (Continued)

Left Refill LED “ON”

Left BIB Empty

Right Refill LED “ON”

Right BIB Empty

Left Refill LED

“FLASHING”

Empty BIB Lockout

Enabled

Right Refill LED

“FLASHING”

Empty BIB Lockout

Enabled

Concentrate BIB is Empty.

BIB Not properly connected

Tubing kinked or blocked

Empty BIB warning set too high

Concentrate BIB is Empty.

BIB Not properly connected

Tubing kinked or blocked

Empty BIB Warning set too high

Replace BIB, see Loading the Concentrate

Check BIB Connector Fittings

Check Tubing Installation

Check Threshold, see Field Calibrating the

Emoty BIB Warning

Replace BIB, see Loading the Concentrate

Check BIB Connector Fittings

Check Tubing Installation

Check Threshold, see Field Calibrating the

Empty BIB Warning

Replace BIB, see loading the ConcentrateLeft Dispenser will not operate

Replace BIB, see loading the ConcentrateRight Dispenser will not operate

All LED’s “FLASHING”

Fauly Detected

The Dispenser has detected an

Internal Fault

Remove the Lower Splash Guard to view the

Fault Message, see Diagnostics. After the

fault has been repaired or corrected, hold

the “STOP” button for 10 seconds to clear

the message.

29

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 30

RELEASED FOR PRODUCTION

Troubleshooting (Continued)

Dispenser Diagnostics-LCD Display

Screen Displayed Possible Cause Troubleshooting Procedures

LF TARGET RPM

TOO HIGH !!

TUBE TOO SMALL

CHECK DISP RATIO

RT TARGET RPM

TOO HIGH !!

TUBE TOO SMALL

CHECK DISP RATIO

LF TARGET RPM

TOO LOW !!

TUBE TOO LARGE

CHECK DISP RATIO

1. The Tube Size selected for the Left

Hand Dispenser is too small for the

application.

2. The Ratio selected for the Left Hand

Dispenser is not correct for the

application.

1. The Tube Size selected for the Right

Hand Dispenser is too small for the

application.

2. The Ratio selected for the Right

Hand Dispenser is not correct for the

application.

1. The Tube Size selected for the Left

Hand Dispenser is too large for the

application.

2. The Ratio selected for the Left Hand

Dispenser is not correct for the

application.

Refer to “Selecting the Correct Pump

Tubing” section of the manual.

Refer to recommended Dispense Ratio

on the product label.

Refer to “Selecting the Correct Pump

Tubing” section of the manual.

Refer to recommended Dispense Ratio

on the product label.

Refer to “Selecting the Correct Pump

Tubing” section of the manual.

Refer to recommended Dispense Ratio

on the product label.

RT TARGET RPM

TOO LOW !!

TUBE TOO LARGE

CHECK DISP RATIO

LEFT PUMP FAULT!

CHK PUMP WIRING

CHK RPM SENSOR

CHK TUBING AREA

RT PUMP FAULT!

CHK PUMP WIRING

CHK RPM SENSOR

CHK TUBING AREA

1. The Tube Size selected for the Right

Hand Dispenser is too large for the

application.

2. The Ratio selected for the Right

Hand Dispenser is not correct for the

application.

1. Motor failure

2. RPM Sensor failure

1. Motor failure

2. RPM Sensor failure

Refer to “Selecting the Correct Pump

Tubing” section of the manual.

Refer to recommended Dispense Ratio

on the product label.

Service Required

Service Required

Service Required

Service Required

30

DIR Num: 36026.0001 19, May 2015

36026.1 010313

Page 31

RELEASED FOR PRODUCTION

Troubleshooting (Continued)

Screen Displayed Possible Cause Troubleshooting Procedures

LEFT BIB EMPTY!

REPLACE PRODUCT

CHECK THRESHOLD

RIGHT BIB EMPTY!

REPLACE PRODUCT

CHECK THRESHOLD

OVERFLOW CUP

FULL. EMPTY CUP

1. Concentrate BIB is Empty.

2. BIB Not properly connected.

3. Tubing kinked or blocked.

4. Empty BIB Warning set too high.

1. Concentrate BIB is Empty.

2. BIB Not properly connected.

3. Tubing kinked or blocked.