AFPO-2

F

L

AV

O

R

IN

P

U

T

1

2

W

A

T

E

R

IN

P

U

T

RE

FI

LL

M

AI

N

PO

W

E

R

2 1

1

2

3

3

3

FLA

V

O

R

OU

T

P

U

T

F

LA

VO

R

O

U

T

PU

T

WA

T

E

R

OU

T

PU

T

FL

A

V

O

R

O

U

T

P

U

T

W

A

T

ER

O

U

T

P

U

T

W

AT

ER

O

U

T

PU

T

F

LA

VO

R

IN

P

UT

1

2

W

A

T

E

R

IN

P

U

T

FL

A

V

OR

O

U

T

P

U

T

FL

A

V

O

R

OU

T

PU

T

W

A

T

E

R

O

U

T

P

U

T

W

A

T

E

R

OU

T

PU

T

RE

F

I

LL

MA

I

N

PO

W

ER

2 1

1

2

AFPO-2 SL

AFPO-3

AFPO-3 SL

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

PHONE: (217) 529-6601 FAX: (217) 529-6644

SPRINGFIELD, ILLINOIS 62708-3227

POST OFFICE BOX 3227

41093.0000A 04/08 ©2008 Bunn-O-Matic Corporation

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis:

parts and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by

it will be commercially free of defects in material and workmanship existing at the time of manufacture and

appearing within the applicable warranty period. This warranty does not apply to any equipment, component or

part that was not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect,

alteration, improper installation or operation, improper maintenance or repair, damage or casualty. This warranty is

conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone

at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by

BUNN, shipping the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior

authorization from BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN

are not authorized to make modifications to this warranty or to make additional warranties that are binding on

BUNN. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts

and/or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

BrewWISE, BUNN Gourmet Ice, BUNN Pour-O-Matic, BUNN, Bunn-OMatic, Bunn-O-Matic, BUNNlink, BUNNserve, BUNN

Espress, DBC, Dr. Brew, Dual, EasyClear, EasyGard, Easy Pour, FlavorGard, Gourmet Ice, Gourmet Juice, High Intensity,

IMIX, Infusion Series, Legendary for Quality, The Mark of Quality in Beverage Equipment Worldwide, My Café, PowerLogic, Safety-Fresh, Scale-Pro, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, System III,

ThermoFresh, 392, AXIOM, Beverage Profit Calculator, Beverage Bar Creator, BrewLOGIC, BrewMETER, BrewWIZARD,

BUNNSERVE, BUNNsource, Coffee At Its Best, Cool Froth, Digital Brewer Control, Intellisteam, Nothing Brews Like a

BUNN, Pouring Profits, Pulse Wave, Quality Beverage Equipment Worldwide, , Signature Series, Silver Series, Smart Heat,

Tea At Its Best, The Horizontal Red Line, Titan, Ultra, are either trademarks or registered trademarks of Bunn-O-Matic

Corporation.

2

41093 041108

CONTENTS

User Notices ..............................................................................................................................3

Preventive Maintenance

Cleaning ..................................................................................................................................... 4

Adjustments ...............................................................................................................................4

Operating Controls .....................................................................................................................6

Troubleshooting .........................................................................................................................7

Service ......................................................................................................................................9

Circuit Board ............................................................................................................................ 10

Fuse & Fuse Holder .................................................................................................................. 11

Main ON/OFF Switch ................................................................................................................ 12

Probe LOW/OFF/HIGH Switches ............................................................................................... 13

Pump (Flavor) Start Switches .................................................................................................. 14

Refill ON/OFF Switches ........................................................................................................... 15

Solenoid ................................................................................................................................... 16

Solenoid (Water) Start Switches .............................................................................................. 17

Test/Operate Switch ................................................................................................................. 18

Vacuum/Supply Pump Assembly ............................................................................................. 19

Vacuum Switches .................................................................................................................... 21

Piping Diagram ........................................................................................................................ 22

Wiring Diagrams ...................................................................................................................... 23

USER NOTICES

All notices on the equipment are written for your protection. All notices are to be kept in good condition. Replace

any unreadable or damaged labels.

3

41093 040408

CLEANING

RECOMMENDED WEEKLY CLEANING:

This should be done in conjunction with the recommended weekly cleaning of your machine. The Hoppers must

be empty before starting.

1. Prepare a 1 gallon cleaning solution consisting of 1 gallon of hot water and a sanitizing cleaner which contains

3-5% chlorine based sanitizer. Mix per manufacturers instructions

2. Remove connectors from each concentrate container and place them directly into the cleaning solution.

3. Energize each refill station and allow the cleaning solution to pump through the system into the hoppers. The

cleaning procedure should remove the color stains from the tubing. If not, prepare another gallon of cleaning

solution and repeat.

4. After the cleaning solution has been pumped into the hoppers, rinse the cleaning solution container with hot

water.

5. Fill the cleaning solution container with hot water. Energize each refill station and rinse thoroughly. The amount

of clean hot rinse water should equal the amount of cleaning solution pumped through the system.

6. Empty the hoppers of your machine and follow the recommended cleaning instructions.

NOTE: The hoses should be checked monthly for deterioration, cracks and possible discoloration from some

concentrates. Replace the tubing when necessary.

MIX RATIO ADJUSTMENTS

1. Remove the top access panel.

2. Connect the test hose to the “WATER OUTPUT” to be adjusted.

3. Connect the provided hose (or other suitable water hose) to the “WATER INPUT”.

4. Ensure water regulator is set at 20 psi(137.9 kPa). Press the “TEST OUTPUT” switch and while water is

flowing from the test hose, check that the gauge reads 20.

5. Place a one-cup container under the test hose. Press the “TEST OUTPUT” switch, and carefully measure and

note the elapsed time from when water first flows form the test hose to when one cup of water has been

dispensed. Hoses and tubing should be primed and free of substantial air spaces and/or bubbles prior to

calibration.

6. Compare results with chart or formula below.

7. If the time observed is too short or long, turn the needle valve clockwise or counterclockwise, respectively,

a little at a time. Repeat from the preceding step until correct.

4

41093 040408

1

2

2 1

1

2

3

3

3

MIX RATIO ADJUSTMENTS(cont.)

Mix ratio (water/flavor) Time for FLAVOR OUTPUT (1/2 cup) Time for WATER OUTPUT (1 cup)

1+1 assume 20 sec. or obtain time per note below 40 sec. or 2 times flavor output time

2+1 assume 20 sec. or obtain time per note below 20 sec. or equal to flavor output time

3+1 assume 20 sec. or obtain time per note below 13.3 sec. or 0.67 times flavor output time

4+1(see below) assume 20 sec. or obtain time per note below 10 sec. or 0.5 times flavor output time

5+1 assume 20 sec. or obtain time per note below 8 sec. or 0.4 times flavor output time

6+1 assume 20 sec. or obtain time per note below 6.7 sec. or 0.33 times flavor output time

NOTE: For a typical adjustment, the time for flavor output in the center column above is assumed to be 20

seconds. A more specific flavor pump output time may be obtained prior to adjustment of the needle valve.

To do so, connect the flavor to be tested to the “FLAVOR INPUT”, and the test hose to the corresponding

“FLAVOR OUTPUT” (make no connection to the “WATER INPUT”). With a one-cup container under the

test hose press the corresponding “TEST OUTPUT” switch, and carefully measure and note the elapsed

time from when the product first flows from the test hose to when one-half cup of the product has been

dispensed. This value may then be used in the formula below. Following flavor pump output measurement,

disconnect the flavor line from the “FLAVOR INPUT” and purge remaining product from the line.

Formula for setting mix ratio: To obtain the time for dispensing 1 cup of water, divide the time it

takes to dispense one-half cup of product by the first number in the mix ratio and then multiply

the result by two.

Example: W=2(F/X) Where W is the time it should take to dispense one cup of water, it took F

seconds (20 here) to dispense 1/2 cup of flavor concentrate, we desire a mix ratio X of 4+1 (X

will be the first number in the mix ratio, 4).

Therefore: W = 2/(20/4)

W = 2/5

W = 10 seconds

So if it took 20 seconds to dispense one-half cup of flavor concentrate, and a mix ratio of 4 to 1

is required, the needle valve should be adjusted to dispense 1 cup of water in 10 seconds.

NOTE: Hoses and tubing should be primed and free of substantial air spaces and/or bubbles prior

to calibration.

NEEDLE VALVE

P1521

5

41093 040408

FLAVOR

INPUT

1

2

WATER

INPUT

REFILL

MAIN

POWER

1

1

2

3

FLAVOR

OPERATING CONTROLS

C

B

A

P1949

A. MAIN POWER ON/OFF

The main power ON/OFF switch is located on the right of the front panel just above the power cord.

B. REFILL CIRCUIT ON/OFF

The refill circuit ON/OFF switches are located on the right of the front panel just above the main power switch.

These allow each circuit to operate independently.

C. TEST/OPERATE

The TEST/OPERATE switch is located inside the auto-fill

box just below the top access cover. For setting flow

rates and mix ratios for flavors, place the TEST/OPERATE switch in the “TEST” position. This allows the op-

D

erator to run the water and flavor lines for each circuit

depending on the requirements for the flavor recipe.

D. PROBE CONTROL BOX LOW/OFF/HIGH

On models equipped with a dual level probe, there is a

LOW/OFF/HIGH switch located at the probe control box

on the hopper. The “OFF” position allows the operator

to disable the probe for that hopper only. THE “LOW”

and “HIGH” positions allow the operator to select the

level of product desired for that hopper.

P1951

6

41093 040408

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection,testing,andrepairofelectricalequipmentshouldbeperformedonlybyqualiedserviceperson-

nel.

• Allelectronic components have 120 volt ac andlowvoltagedcpotentialontheirterminals.Shortingof

terminals or the application of external voltages may result in board failure.

• Intermittentoperationofelectroniccircuitboardsisunlikely.Boardfailurewillnormallybepermanent.If

an intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Solenoidremovalrequiresinterruptingthewatersupplytothevalve.Damagemayresultifsolenoidsare

energized for more than ten minutes without a supply of water.

• Theuseoftwowrenchesisrecommendedwheneverplumbingttingsaretightenedorloosened.Thiswill

help to avoid twists and kinks in the tubing.

• Makecertainthatallplumbingconnectionsaresealedandelectricalconnectionstightandisolated.

• Keepawayfromcombustibles.

WARNING – • Exerciseextremecautionwhenservicingelectricalequipment.

• Unplugthedispenserwhenservicing,exceptwhenelectricaltestsarespecied.

• Followrecommendedserviceprocedures

• Replaceallprotectiveshieldsorsafetynotices

PROBLEM

Product will not dispense

PROBABLE CAUSE

1. No water

2. No power or incorrect voltage to

the dispenser

3. Signal cable unplugged

4. Hopper is full

5. Fuse and fuse holder

REMEDY

Water lines and valves to the dispenser must be open.

(A1) Check the outlet for 120 volts

on two wire 120 volt dispensers.

(A2) Check the outlet for 200 volts

or 240 volts ac for two wire 200 volt

or 240 volt dispensers.

(A3) Check the outlet for 230 volts

on two wire 230 volt dispensers.

(B) Check circuit breakers or fuses.

Signal cable must be plugged in.

Product must not be touching probes

to fill.

Refer to Service - Fuse and Fuse

Holder for test procedures. See

page 12

7

41093 040408

TROUBLESHOOTING (cont.)

PROBLEM

PROBABLE CAUSE

REMEDY

Product will not dispense (cont.)

6. Main ON/OFF switch

7. Probe box LOW/OFF/HIGH switches

8. Circuit board

9. Vacuum switch

10. Vacuum/Supply pump

11. Pump (flavor) start switches

Refer to Service - Main ON/OFF

Switch for testing procedure. See

page 13

Refer to Service - Probe system.

See page 14

Refer to Service - Circuit Board for

testing procedures. See page 11

Refer to Service - Vacuum switch for

testing procedures. See page 22

Refer to Service - Vacuum/Supply

pump for testing procedures. See

page 20

Refer to Service - Pump (flavor)

start switches for test procedures.

See page 15

Incorrect mix ratio

1. No water

Water lines and valves to the dispenser must be open.

2. Needle valve

Refer to Setup - Mix Ratio Adjustments for adjustment. See page 5

3. Solenoids

Refer to Service - Solenoids for test

procedures. See page 17

Motor thermal cutout (motor stops

running)

1. Motor overheat

The thermal switch will reset, but

requires up to 30 minutes of cooling

time. See NOTE below

NOTE: This refill unit should not be used to initially fill the hopper. Running the motor for extended periods will

trip the thermal switch. The thermal switch will reset, but requires up to 30 minutes of cooling time.

8

41093 040408

FL

A

V

O

R

INPU

T

1

2

WAT

ER

IN

PU

T

R

EF

IL

L

M

AI

N

PO

W

ER

2 1

1

2

3

3

3

F

LA

VOR

O

U

T

PUT

FL

A

V

OR

O

UT

PU

T

W

AT

E

R

O

UT

PU

T

FL

A

VO

R

OU

T

P

UT

WA

TER

OU

T

P

UT

W

AT

ER

O

UT

PU

T

SERVICE

This section provides procedures for testing

and replacing various major components used in this

dispenser should service become necessary. Refer

to Troubleshooting for assistance in determining the

cause of any problem.

WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified

service personnel. The dispenser should be unplugged

when servicing, except when electrical tests are required and the test procedure specifically states to

plug in the dispenser.

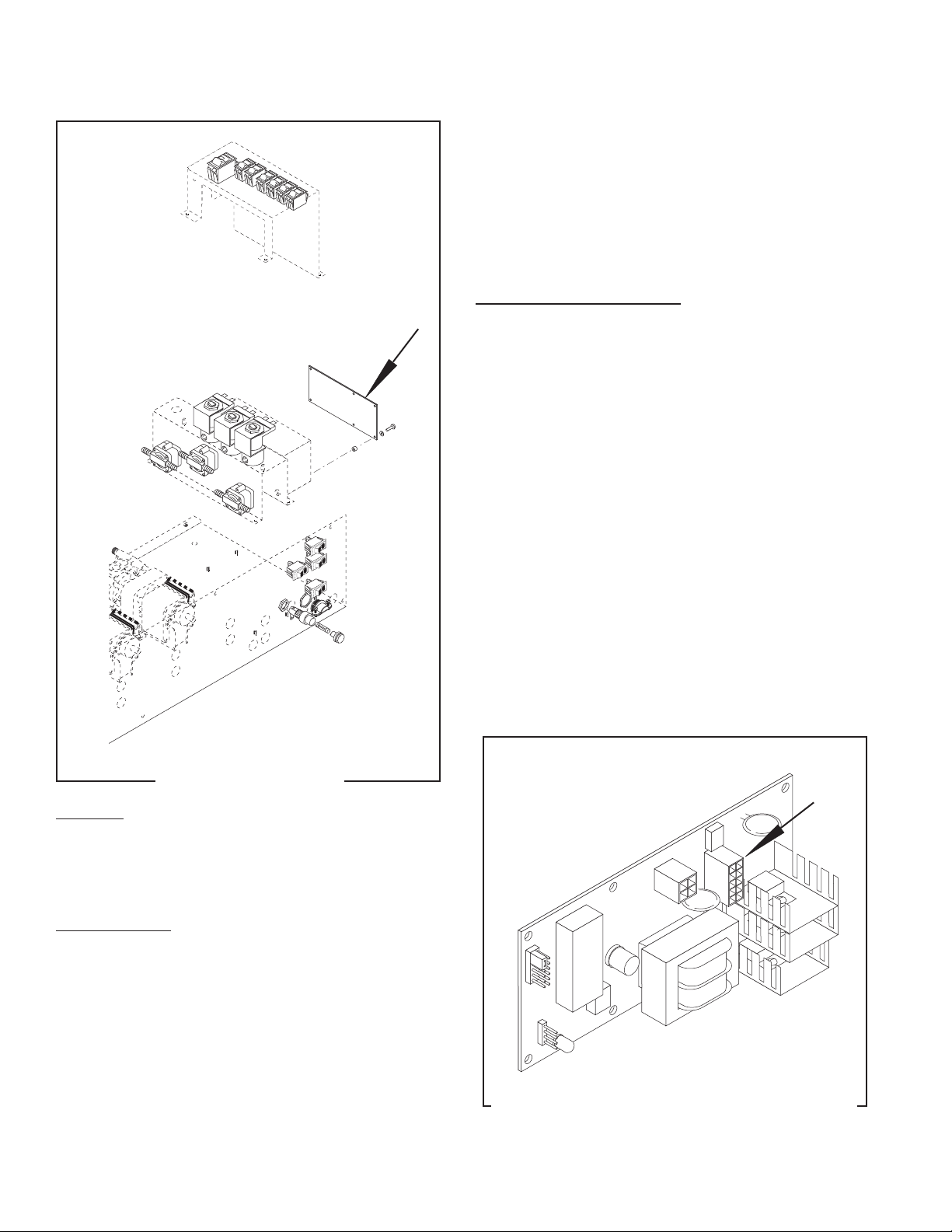

COMPONENT ACCESS

WARNING - Disconnect the dispenser from the power

source before the removal of any panel or the replacement of any component.

All components are accessible by removing the

eight #8-32 screws (five on the front and three on the

rear) securing the main housing to the main mounting

panel and the removal of the four #8-32 nuts securing the pump/solenoid switch panel to the solenoid

mounting bracket. Refer to Fig. 1

FIG. 1 COMPONENT ACCESS

P1521

9

41093 040408

J4

J1

J2

J3

SERVICE

CIRCUIT BOARD

c) 230 volts ac for two wire 230 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, replace the circuit

board.

If voltage is not present as described, refer to the

Wiring Diagrams and check main wiring harness.

Removal and Replacement:

1. Remove the four #8-32 keps nuts securing the

switch mounting bracket. Set aside with the wires

attached.

2. Remove the circuit board shield and set aside for

reassembly.

3. Disconnect the ten pin plug from the main wiring

harness to the circuit board.

4. Remove the six #4-40 screws and spacers securing

the circuit board to the solenoid mounting bracket.

Remove circuit board and discard.

5. Install new circuit board using #4-40 screws and

spacers to secure the circuit board to the solenoid

mounting bracket. The spacers must be between the

solenoid mounting bracket and the circuit board.

6. Place circuit board shield over the circuit board.

7. Install switch panel assembly and secure with four

#8-32 keps nuts.

8. Refer to Fig. 3 for circuit board ten pin connector.

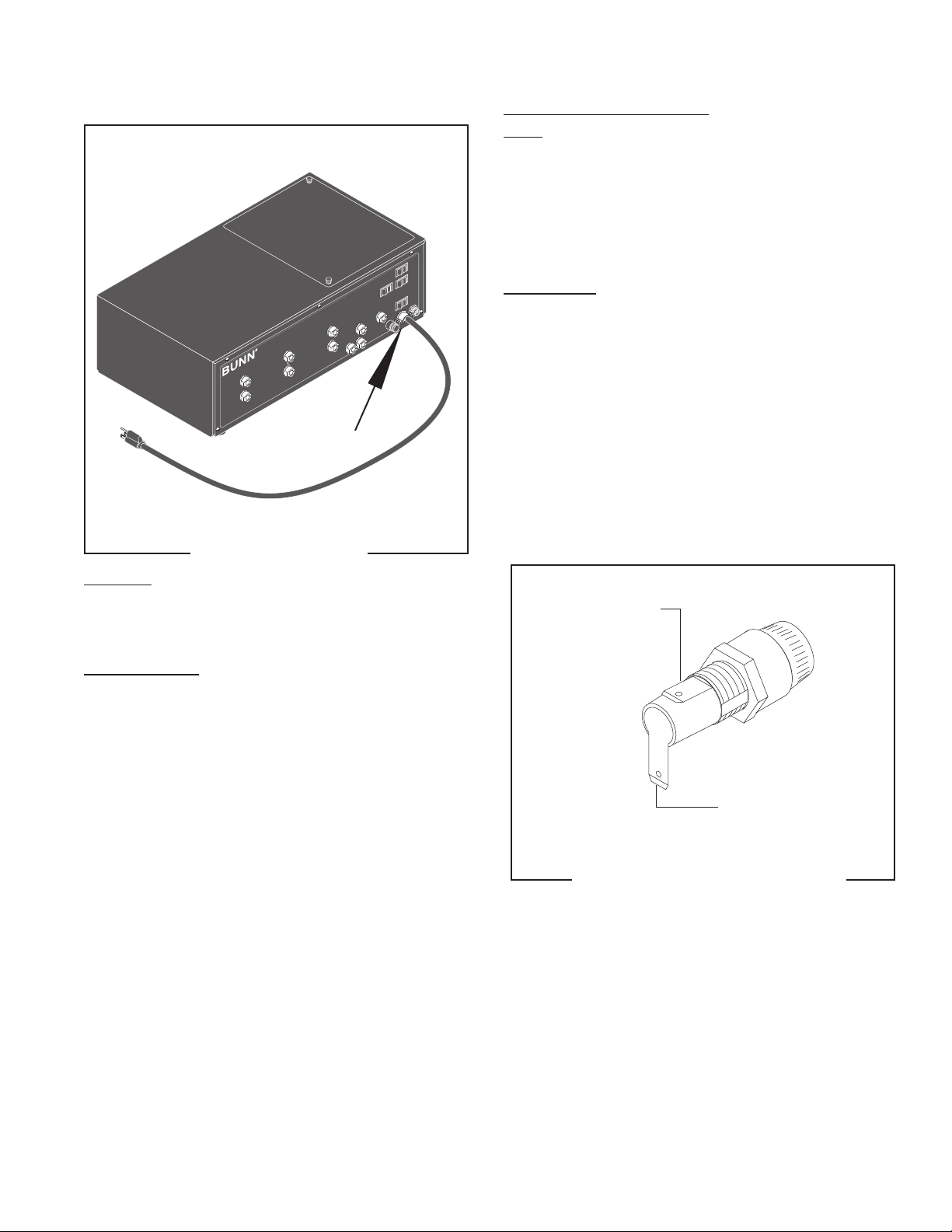

FIG. 2 CIRCUIT BOARD

P1520

Location:

The circuit board is located inside the autofill box,

mounted on the right side of the solenoid mounting

bracket under the switch panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the ten pin plug on the main wiring

harness from the connector on the circuit board.

3. Connect the dispenser to the power source. With

a voltmeter, check the voltage across the black

wire(#3) and the white wire (#6). The indication

must be:

a) 120 volts ac for two wire 120 volt models.

FIG. 3 CIRCUIT BOARD CONNECTOR LOCATION

P1528

b) 200 to 240 volts ac for two wire 200 or 240 volt

models.

10

41093 040408

FLAVOR

INPU

T

1

2

WATER

INPUT

REFILL

MAIN

POWER

2 1

1

2

3

3

3

FLAVOR

OUTPUT

FLAVOR

OUTPUT

W

ATER

OUTPUT

F

L

A

VOR

OUT

PUT

W

A

T

ER

OUT

PUT

WATER

OUTPUT

SERVICE

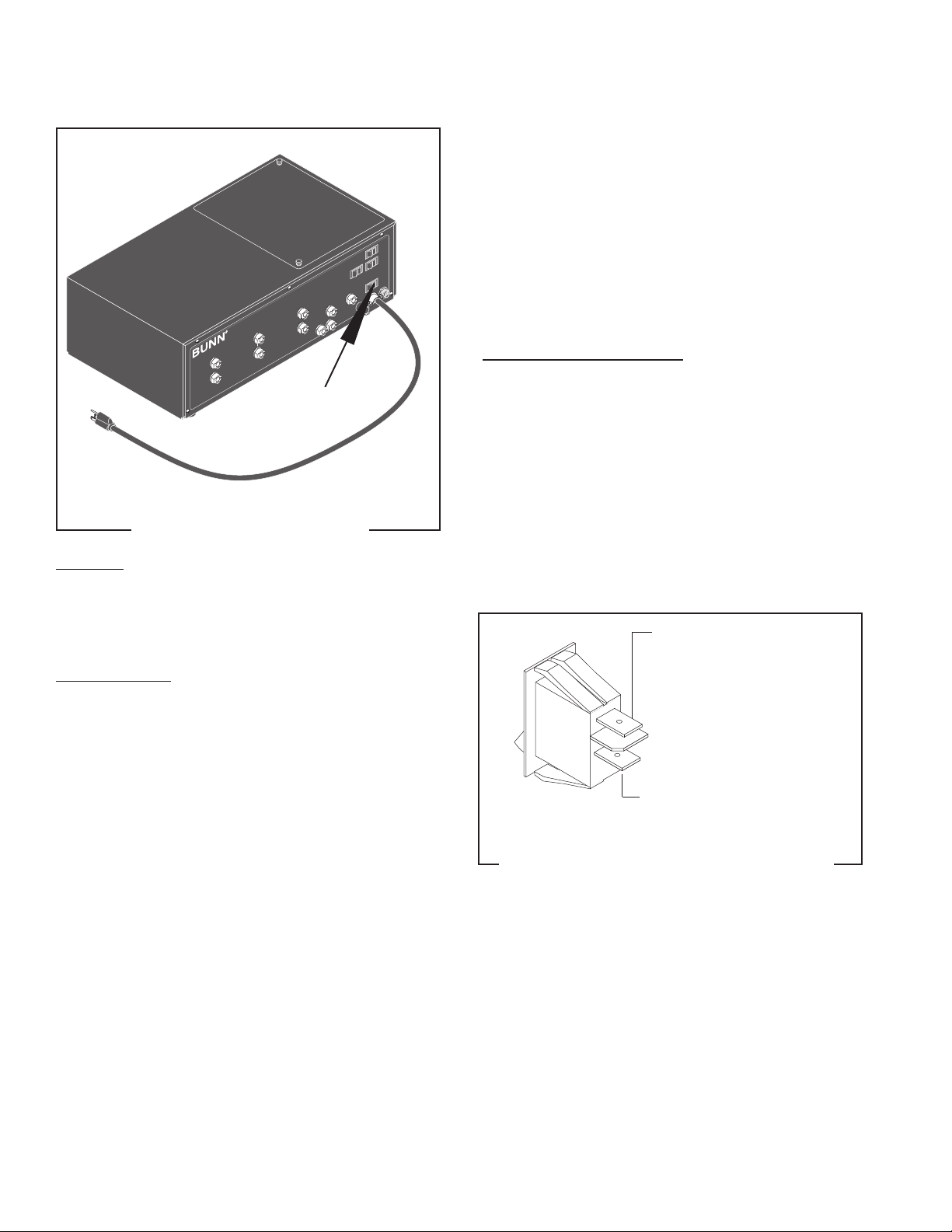

FUSE AND FUSE HOLDER

FIG. 4 FUSE HOLDER

P1516

Location:

The fuse holder is located on the lower right front

of the autofill box just to the left of the power cord.

Removal and Replacement:

Fuse:

1. Remove the cap from the fuse holder.

2. Remove fuse from the fuse holder and inspect. If

blown, discard.

3. Install new 10 amp fuse in the fuse holder.

4. Reinstall fuse holder cap.

Fuse Holder:

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the rear of the fuse

holder.

3. Remove the nut securing the fuse holder to the

front of the main mounting panel.

4. Push the fuse holder through the hole in the

panel.

5. Install new fuse holder and fuse through the hole

in the panel.

6. Secure the fuse holder to the panel.

7. Refer to Fig. 5 and reconnect the wires.

BLKfromMain

Wiring Harness

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Remove cap and fuse from fuse holder.

3. Remove fuse from the cap.

4. Check for continuity through the fuse.

If continuity is present, reinstall the fuse, the fuse is

operating properly.

If continuity is not present, replace the fuse.

BLKtoMain

ON/OFF Switch

P1331

FIG. 5 FUSE HOLDER TERMINALS

11

41093 040408

FLAVOR

INPU

T

1

2

WATER

INPUT

REFILL

MAIN

POWER

2 1

1

2

3

3

3

FLAVOR

OUTPUT

FLAVOR

OUTPUT

W

ATER

OUTPUT

F

L

A

VOR

OUT

PUT

W

A

T

ER

OUT

PUT

WATER

OUTPUT

SERVICE (cont.)

MAIN ON/OFF SWITCH

5. Check for continuity across the switch terminals

with the switch in the “ON” position. Continuity

must not be present when the switch is in the

“OFF” position.

If continuity is present as described, reconnect the

wires to the switch terminals.

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Remove the wires from the switch terminals.

2. Compress the clips inside the autofill box and

gently push the switch through the opening

3. Push the new switch into the opening and spread

the clips to hold switch in the autofill box.

4. Refer to Fig. 7 when reconnecting the wires.

FIG. 6 MAIN ON/OFF SWITCH

P1516

Location:

The main ON/OFF switch is located on the lower

right front of the autofill box just above the power

cord.

Test Procedure:

1. Disconnect the dispenser from the power

source.

2. Disconnect the black wire from the fuse holder

and the white wire from pump #1.

3. Connect the dispenser to the power source. Check

for voltage across the black wire removed from

the switch and the white wire removed from pump

#1. The indication must be:

a) 120 volts ac for 2 wire 120 volt models.

b) 200 to 240 volts ac for two wire 200 or 240 volt

models.

c) 230 volts ac for two wire 230 volt models.

4. Disconnect the dispenser from the power

source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagrams and check the dispenser wiring harness.

BLKfromFuseHolder

BLKtoSolenoid(Water)

Switch #2 AFPO-2 & 3

FIG. 7 MAIN ON/OFF SWITCH TERMINALS

P1522

12

41093 040408

BU

N

N

SERVICE (cont.)

PROBE SYSTEM

P1523

FIG. 8 PROBE SWITCHES

Location

The probe switches are located on the rear of each

hopper, mounted in the probe housing cover.

Test Procedure

Probe System

1. Disconnect the dispenser from the power

source.

2. With the probe boxes connected to the signal cable,

remove connector from refill box.

3. Place the switch on the probe box in the “HIGH”

position.

Probe Boxes:

1. Disconnect the signal cable from the probe

boxes.

2. Remove probe box from CDS hopper.

3. Place the switch on the probe box in the “HIGH”

position.

4. Check the resistance across the box cable pins,

see Fig. 10.

AFPO-2 & 3

FIG. 10 PROBE BOX CABLE PINS

P1539

5. With the probe box switch in the “LOW” position

check the resistance across the pins, refer to Fig.

10.

6. If readings match the values indicated, the probe

system is functioning properly.

Switch Removal and Replacement:

1. Remove the #6 thread cutting screw securing the

probe housing cover to the probe housing.

2. Remove the wires from the switch terminals.

3. Compress the clips inside the probe box and gently

push the switch through the opening

4. Push the new switch into the opening and spread

the clips to hold switch in the autofill box.

5. Refer to Fig. 11 when reconnecting the wires.

AFPO-2 AFPO-3

P1538

FIG. 9 SIGNAL CABLE PINS

4. Check resistance across pins as shown in Fig. 9.

5. With the probe box switch in “LOW” position check

the resistance across the signal cable pins, see Fig.

9.

6. If readings match values indicated, the probe

system is functioning properly. If not, check the

probe boxes.

13

BLU (HIGH) from Probe

Box Cable

GRN (OFF) from Probe

Box Cable

TAN (LOW) from Probe Box

Cable

FIG. 11 PROBE LOW/OFF/HIGH SWITCH

TERMINALS

P1540

41093 040408

1

2

2 1

1

2

3

3

3

SERVICE (cont.)

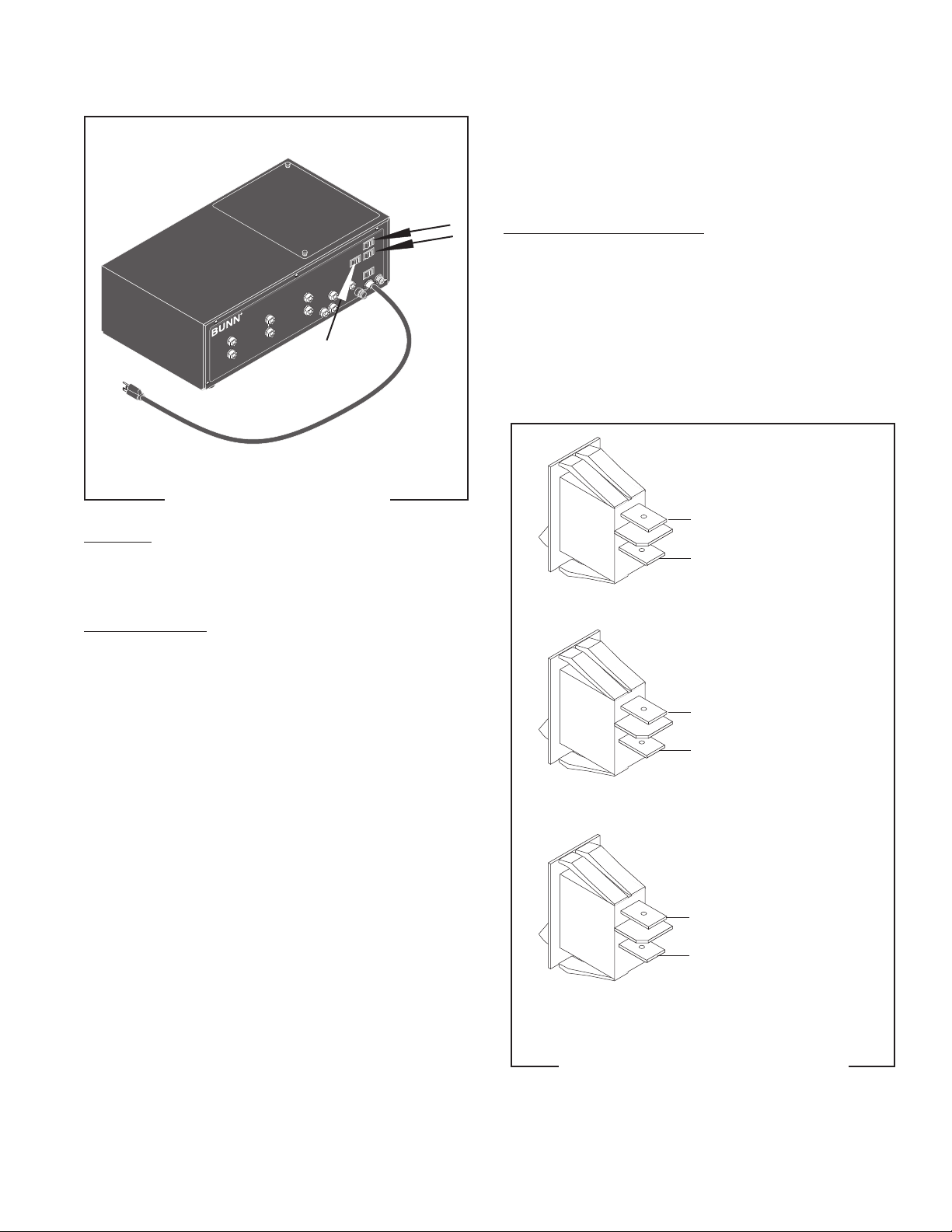

PUMP (FLAVOR) ON/OFF SWITCHES

FIG.12 PUMP (FLAVOR) START SWITCHES

Removal and Replacement:

1. Disconnect the dispenser from the power

source.

2. Remove the wires from the switch terminals.

3. Compress the clips inside the autofill box and

gently push the switch through the opening.

4. Push the new switch into the opening and spread

the clips to hold switch in the autofill box.

5. Refer to Fig. 13 when reconnecting the wires.

#1 AFPO-2 & 3

P1521

Location:

The pump (flavor) START switches are located on

the switch mounting plate inside the autofill box on

the right side.

Test Procedure:

1. Disconnect the dispenser from the power

source.

2. Disconnect the wires from the switch to be

tested.

3. Check for continuity across the terminals on the

switch when it is held in the on position. Continuity

must not be present across these terminals in the

released position.

If continuity is present as described, reconnect the

wires to the switch.

If continuity is not present as described, replace the

switch.

BLKfromSolenoidSwitch#1

BLKtoTest/OperateSwitch

RED/BLKtoTest/OperateSwitch

YEL to Pump #1

#2 AFPO-2 & 3

BLKfromSolenoidSwitch#1

BLKtoSolenoidSwitch#2

BRN/BLKtoTest/OperateSwitch

ORN to Pump #2

#3 AFPO-3 ONLY

BLKfromSolenoidSwitch#2

BLKtoSolenoidSwitch#3

WHI/RED to Test/Operate Switch

RED to Pump #3

P1524

14

FIG. 13 PUMP (FLAVOR) SWITCH TERMINALS

41093 040408

1

2

2 1

1

2

3

3

3

SERVICE (cont.)

REFILL SWITCHES

If continuity is present as described, reconnect the

wires to the switch terminals.

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Remove the wires from the switch terminals.

2. Compress the clips inside the autofill box and gently

push the switch through the opening in the front of

autofill box.

3. Push the new switch into the opening and spread

the clips to hold switch in the autofill box.

4. Refer to Fig. 15 when reconnecting the wires.

#1 AFPO-2 & 3

FIG. 14 REFILL SWITCHES

P1516

Location:

The refill switches are located on the upper right

front of the autofill box.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the two white/red, brown/black or

red/black wires from the switch terminals.

3. Connect the dispenser to the power source. Check

for voltage across the white/red, brown/black or

red black wires from the test/operate switch and

the white wire on solenoid #2 or #3. The indication

must be:

a) 120 volts ac for two wire 120 volt models

b) 200 to 240 volts ac for two wire 200 or 240 volt

models.

c) 230 volts ac for two wire 230 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagrams and check dispenser wiring harness.

5. Check for continuity across the switch terminals

with the switch in the “ON” position. Continuity

must not be present when the switch is in the “OFF”

position.

RED/BLKfromTest/

Operate Switch

RED/BLKtoVacuum

Switch #1

#2 AFPO-2 & 3

BRN/BLKfromTest/

Operate Switch

BRN/BLKtoVacuum

Switch #2

#3 AFPO-3 ONLY

WHI/RED from Test/

Operate Switch

WHI/RED to Vacuum

Switch #3

P1522

FIG. 15 REFILL SWITCH TERMINALS

15

41093 040408

1

2

2 1

1

2

3

3

3

SERVICE (cont.)

SOLENOIDS

FIG. 16 SOLENOIDS

Location:

The solenoids are located inside the autofill box.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the white/violet, violet or blue wire and

the white wire from the solenoid.

3. Connect the dispenser to the power source. Press

the solenoid (water) switch, and with a voltmeter,

check the voltage between the white wire, and either

the blue, violet, or white/violet wire. The indication

must be:

a) 120 volts ac for two wire 120 volt models.

b) 200 to 240 volts ac for two wire 200 or 240 volt

models.

c) 230 volts ac for two wire 230 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the Wiring

Diagrams and check dispenser wiring harness.

P1521

6. Check the solenoid valve for coil action. Connect the

dispenser to the power source. Press the solenoid

(water) switch and listen carefully in the vicinity of

the solenoid valve for a “clicking” sound as the

coil magnet attracts.

7. Disconnect the dispenser from the power source.

If the sound is heard as described and water will not

pass through the solenoid valve, there may be a blockage in the water inlet before the solenoid valve or, the

solenoid valve may require inspection for wear, and

removal of waterborne particles.

If the sound is not heard as described, rebuild or replace

the solenoid valve.

Solenoid Valve Repair:

1. Remove the wires from the solenoid valve to be

repaired.

2. Turn off the water supply to the dispenser.

3. Remove the nut securing solenoid valve coil to the

base.

4. Remove guide, washer, o-ring, plunger/spring and

inspect for wear. Replace parts as required.

5. Install new o-ring in the solenoid valve base.

6. Install plunger/spring in the guide with spring to

the bottom of the guide.

7. Install guide with the plunger/spring into the solenoid

valve base.

8. Install washer on guide.

9. Install coil with retainer on guide and secure with

nut.

10. Refer to Fig. 17 and reconnect the wires.

WHI from Main Harness

WHI to Solenoid #2

BLU from Solenoid

Switch #1

WHI to Solenoid #1

WHI to Pump #1

VIO from Solenoid

Switch #2

WHI/VIO from

Solenoid Switch #3

5. Check for continuity across the solenoid valve coil

terminals.

If continuity is present as described, refer to Fig. 17

and reconnect the wires to the solenoid.

If continuity is not present as described, replace the

solenoid valve.

#1 AFPO-2

& 3

16

#2 AFPO-2

& 3

#3 AFPO-3

ONLY

FIG. 17 SOLENOID TERMINALS

WHI to Main

Harness

WHI to Pump #3

P1544

41093 040408

1

2

2 1

1

2

3

3

3

SERVICE (cont.)

SOLENOID (WATER) ON/OFF SWITCHES

P1521

FIG.18 SOLENOID (WATER) ON/OFF SWITCHES

Location:

The solenoid (water) ON/OFF switches are located

on the switch mounting plate inside the autofill box on

the right side.

Removal and Replacement:

1. Remove the wires from the switch terminals.

2. Compress the clips inside the autofill box and gently

push the switch through the opening.

3. Push the new switch into the opening and spread

the clips to hold switch in the autofill box.

4. Refer to Fig. 19 when reconnecting the wires.

#1 AFPO-2 & 3

BLKfromPumpSwitch#2

BLKtoPumpSwitch#1

BLU to Test/Operate Switch

BLU to to Solenoid #1

#2 AFPO-2 & 3

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the switch to be tested.

3. Check for continuity across the terminals on the

switch when it is held in the on position. Continuity

must not be present across these terminals in the

released position.

If continuity is present as described, refer to Fig. 19

and reconnect the wires to the switch.

If continuity is not present as described, replace the

switch.

BLKfromMainON/OFFSwitch

BLKtoPumpSwitch#2

VIO to Test/Operate Switch

VIO to Solenoid #2

#3 AFPO-3 ONLY

BLKfromPumpSwitch#3

WHI/VIO to Test/Operate Switch

WHI/VIO to Solenoid #3

P1524

FIG. 19 SOLENOID (WATER) SWITCH

TERMINALS

17

41093 040408

1

2

2 1

1

2

3

3

3

SERVICE (cont.)

TEST/OPERATE ON/OFF SWITCH

FIG. 20 TEST/OPERATE SWITCH

Location

The test/operate switch is located inside the autofill

box on the right side.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Remove the black wire from the top center switch

terminal.

3. Connect the dispenser to the power source. With a

voltmeter, check the voltage across the black wire

removed from the test/operate switch and the white

wire from one of the solenoids. The indication must

be:

a) 120 volts ac for two wire 120 volt models.

b) 200 to 240 volts ac for two wire 200 or 240 volt

models.

c) 230 volts ac for two wire 230 volt models.

P1521

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #6.

If voltage is not present as described, refer to the Wiring

Diagrams and check the wiring harness.

6. Disconnect the wires from the left and center

terminals.

7. Check for continuity across the left and center

terminals in rows one, two, three and four with the

switch in the “operate” position. Continuity should

not be present across the left and center terminals

with the switch in the “center” or “Test” position.

If continuity is present as described, replace the wires.

The switch is operating properly.

If continuity is not present as described, replace the

switch.

Removal and Replacement:

1. Disconnect the dispenser from the power source.

2. Remove the wires from the switch terminals.

3. Compress the clips inside on the back of the switch

panel and gently push the switch through the opening.

4. Push the new switch into the opening and spread

the clips to hold the switch in the switch panel.

5. Refer to FIG. 21 when reconnecting the wires.

BLKtoCircuit

Board J4-3

BLU from Solenoid Switch #1

VIO from Solenoid Switch #2

WHI/VIO from Solenoid Switch #3

FIG. 21 TEST/OPERATE SWITCH TERMINALS

18

BLKfromMain

ON/OFF Switch

RED/BLKfromPumpSwitch#1

RED/BLKtoRellSwitch#1

BRN/BLKfromPumpSwitch#2

BRN/BLKtoRellSwitch#2

WHI/RED from Pump Switch #3

WHI/RED to Refill Switch #3

P1525

41093 040408

1

2

2 1

1

2

3

3

3

SERVICE (cont.)

VACUUM/SUPPLY PUMP ASSEMBLY

P1521

FIG. 22 VACUUM/SUPPLY PUMP ASSEMBLY

Location:

The vacuum/supply pumps are located inside the

autofill box.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the white wire from the pump lead

and the yellow, orange or red wire from the other

lead.

3. Connect the dispenser to the power source. With a

voltmeter, check the voltage across the white wire

and yellow, orange or red wire. Push the pump

(flavor) switch for the pump to be tested. The

indication must be :

a) 120 volts ac for two wire 120 volt models.

b) 200 to 240 volts ac for two wire 200 or 240 volt

models.

c) 230 volts ac for two wire 230 volt models.

4. Disconnect dispenser from the power source.

If voltage is present as described, replace the pump.

If voltage is not present as described, refer to the Wiring

Diagrams and check main wiring harness.

Pump Motor Removal and Replacement:

NOTE: Do not disconnect or damage tubing. Tubing is

not replaced when pump is replaced.

1. Disconnect the pump motor leads.

2. Remove the four thumb screws securing the pump

head to the pump body.

3. Remove the two #8-32 keps nuts securing the pump

motor/bracket assembly to the refill unit.

4. Remove the two #6-32 screws securing the pump

motor to its mounting bracket.

5. Reattach this bracket to the new motor, and reinstall

the assembly in the refill unit.

6. Reattach the pump head to the rear of the pump

motor with the four thumbscrews.

7. Reconnect the pump motor leads. Refer to Fig. 23

to reconnect the wires.

Pump Removal and Replacement:

NOTE: Do not disconnect or damage tubing. Tubing is

not replaced when pump is replaced.

1. Remove the four thumb screws securing the pump

head to the pump body.

WHI from Solenoid #2

YEL from Pump Switch #1

WHI from Solenoid #3

WHI from Pump #1

ORN from Pump Switch #2

RED from Pump Switch #3

FIG. 23 VACUUM/SUPPLY PUMP TERMINALS

19

P1526

41093 040408

SERVICE (cont.)

VACUUM/SUPPLY PUMP TUBE INSTALLATION

2. Separate the two halves of the pump and carefully

remove the tubing from within.

3. Hold the new pump head as shown in Fig. 24, with

rollers in the 2, 6, and 10 o’clock positions.

4. Reinstall tubing in the new pump head by wrapping the tubing around the rollers as shown in Fig.

24.

5. Insert the slot of the tubing key (supplied), as

shown in Fig. 24, on the rotor so the bottom edge

of the key is pressing the tubing into the pump

head cavity as shown in Fig. 25.

6. Hold the tubing and rotor in the pump head and

remove key carefully.

7. Squeeze the pump body and pump heads together

simultaneously until pump body and pump head

are touching on all sides. Be careful not to pinch

the tubing between the pump body and the pump

head.

8. Place the new pump body on the rotor shaft.

9. Replace the four thumbscrews to secure the pump

to the motor assembly. Finger-tighten only.

ROLLERS

EXIT

PORT

FIG. 24 TUBING START POSITION

ROTOR

PUMP

HEAD

TUBING

KEY

ENTRY

PORT

P1542

ROTOR

SHAFT

FIG. 25 TUBING LOADED

P1541

20

41093 040408

SERVICE (cont.)

1

2

2 1

1

2

3

3

3

VACUUM SWITCHES

FIG. 26 VACUUM SWITCHES

Location:

The vacuum switches are located inside autofill

box, mounted on the left side of the solenoid mounting

bracket just below the needle valves.

Test Procedure:

1. Disconnect the dispenser from the power

source.

2. Disconnect flavor input lines.

3. Disconnect white/red, red/black or the brown/black

wires on the vacuum switch.

4. Check for continuity across the switch leads.

P1521

If continuity is not present as described, the vacuum

switch is operating properly.

If continuity is present as described, without a vacuum

generated by an empty product concentrate, replace

the vacuum switch.

Removal and Replacement:

1. Disconnect dispenser from the power source.

2. Removal of the two #8-32 keps nuts securing

the pump/motor assembly nearest the vacuum

switches is required to access the lower vacuum

switch.

3. Disconnect the input tubes from the vacuum switch

to be replaced.

4. Disconnect the wires on the vacuum switch to be

removed.

5. Remove the two #4-40 screws securing the vacuum

switch to the solenoid bracket. Remove and discard

switch.

6. Using two #4-40 screws secure the new vacuum

switch to the solenoid bracket.

7. Refer to Fig. 27 and reconnect the wires.

8. Connect the input tubes to the new vacuum

switch.

9. Restore the pump/motor assembly to its normal

mounting position using the two #8-32 keps

nuts.

#3

WHI/RED from Refill ON/OFF Switch #3

WHI/RED to Circuit Board J4-2

RED/BLKfromRellON/OFFSwitch#1

RED/BLKtoCircuitBoardJ4-5

#1

BRN/BLKfromRellON/OFFSwitch#2

BRN/BLKtoCircuitBoardJ4-4

#2

FIG. 27 VACUUM SWITCH TERMINALS

21

P1527

41093 040408

PIPING DIAGRAM (AFPO-2)

The only difference between the AFPO-2/3 and AFPO-2/3 SL is the SL models have a water output line and

a flavor output line for each product. This allows the water and flavor to be mixed in the hoppers. Refer to the

illustration below when connecting the lines.

22

41093 040408

GRN

SOL

#1

SOL

#2

PUMP

#1

PUMP

#2

10

AMP

MAIN ON/OFF

SWITCH

REFILL ON/OFF

SWITCH #1

REFILL ON/OFF

SWITCH #2

J4-1

2

3

4

5

6

7

8

9

J4-10

C

I

R

C

U

I

T

B

O

A

R

D

L1 N

BLK

BLK

BLK

B

L

K

B

L

K

B

L

K

SOLENOID

SWITCH #2

PUMP

SW ITCH #2

PUMP

SW ITCH #1

T

E

S

T

/

O

P

E

R

A

T

E

S

W

I

T

C

H

BRN/BLK

BRN/BLK

BRN/BLK

VIO

VIO

BLK

ORN

BLU

BLU

YEL

RED/BLK

RED/BLK

RED/BLK

RED/BLK

BLK

ORN

VACUUM

SWITCH #2

VACUUM

SWITCH #1

BRN/BLK

WHI

WHI

WHI

WHI

W

H

I

W

H

I

VIO

YEL

SCHEMATIC WIRING DIAGRAM

AFPO-2

1

423

1

4

2

3

GRN

RED

BLK

BLK

1

2

1

2

1

2

1

2

LH LH

PROBE

CONTROL

1

PROBE

CONTROL

2

120 VOLT AC 2 WIRE

SINGLE PHASE

28814.0000D 6/98 ©1998 BUNN-O-MATIC CORPORATION

SOLENOID

SWITCH #2

SW1A

SW1B

SW1C

SW1D

GRN GRN

BLK

BLK

T

A

N

T

A

N

BLU

BLU

23

41093 040408

24

41093 040408

GRN

SOL

#1

SOL

#2

PUMP

#1

PUMP

#2

10

AMP

MAIN ON/OFF

SWITCH

REFILL ON/OFF

SWITCH #1

REFILL ON/OFF

SWITCH #2

J4-1

2

3

4

5

6

7

8

9

J4-10

C

I

R

C

U

I

T

B

O

A

R

D

L1 L2

BLK

BLK

BLK

B

L

K

B

L

K

B

L

K

SOLENOID

SWITCH #2

PUMP

SW ITCH #2

PUMP

SW ITCH #1

T

E

S

T

/

O

P

E

R

A

T

E

S

W

I

T

C

H

BRN/BLK

BRN/BLK

BRN/BLK

VIO

VIO

BLK

ORN

BLU

BLU

YEL

RED/BLK

RED/BLK

RED/BLK

RED/BLK

BLK

ORN

VACUUM

SWITCH #2

VACUUM

SWITCH #1

BRN/BLK

WHI

WHI

WHI

WHI

W

H

I

W

H

I

VIO

YEL

SCHEMATIC WIRING DIAGRAM

AFPOA-2

1

423

1

4

2

3

GRN

RED

BLK

BLK

1

2

1

2

1

2

1

2

LH LH

PROBE

CONTROL

1

PROBE

CONTROL

2

230 VOLT AC 2 WIRE

SINGLE PHASE

28814.0004A 11/99 ©1999 BUNN-O-MATIC CORPORATION

SOLENOID

SWITCH #2

SW1A

SW1B

SW1C

SW1D

GRN GRN

BLK

BLK

T

A

N

T

A

N

BLU

BLU

25

41093 040408

Loading...

Loading...