Bulls Alpine Hawk EVO, Grinder EVO Carbon, Millennial EVO Carbon, Grinder EVO, WildFlow EVO RS Operating Instructions Manual

...

TRANSLATION OF THE ORIGINAL

OPERATING INSTRUCTIONS

EN

19-22-1001, 19-22-1002, 19-22-1003, 19-17-1033, 19-22-4001, 19-17-4003, 19-18-1061, 19-18-1062

034-03275 • 1.0 • 23 November 2018

Alpine Hawk EVO, Grinder EVO, Grinder EVO Carbon,

Harrier EVO, Millennial EVO, Millennial EVO Carbon,

WildFlow EVO RS, WildFlow EVO SL

E-BIKES

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_COVER.book Page 2 Friday, November 23, 2018 1:32 PM

Copyright

© ZEG Zweirad-Einkaufs-Genossenschaft eG

Distribution or reproduction of these operating instructions

and utilisation or communication of their content is prohibited

unless expressly approved. Any infringement will render the

offender liable for compensation. All rights reserved in the

event that a patent, utility model or industrial design is

registered.

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_COVER.book Page 3 Friday, November 23, 2018 1:32 PM

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 1 Friday, November 23, 2018 1:44 PM

Data sheet

Surname, first name of the purchaser:

Date of purchase:

Model:

Frame number:

Type number:

Unladen weight (kg):

Tyre size:

Recommended tyre pressure (bar)*: front: rear:

Wheel circumference (mm):

Company stamp and signature:

*After a tyre change, refer to the tyre markings for the permitted tyre

pressures and make sure that they are observed. The recommended tyre

pressure must not be exceeded.

034-03275_1.0_23.11.2018

1

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 2 Friday, November 23, 2018 1:44 PM

Table of contents

Table of contents

1 About these instructions 8

1.1 Manufacturer 8

1.2 Laws, standards and directives 9

1.3 Other valid documents 9

1.4 Subject to change 10

1.5 Language 10

1.6 For your safety 11

1.6.1 Instruction, training and customer service 11

1.6.2 Basic safety notes 12

1.6.3 Warnings 12

1.6.4 Safety markings 13

1.7 For your information 13

1.7.1 Instructions for actions 13

1.7.2 Information on the type plate 13

1.7.3 Language conventions 16

1.8 Type plate 17

1.9 Identifying 18

1.9.1 Operating instructions 18

1.9.2 Bicycle 18

2 Safety 19

2.1 Requirements for the rider 19

2.2 Hazards for vulnerable groups 19

2.3 Personal protective equipment 19

2.4 Proper use 19

2.4.1 City and trekking bicycle 20

2.4.2 Mountain bike 20

2.4.3 Racing bicycle 21

2.4.4 Improper use 22

2.4.5 City and trekking bicycle 22

2.4.6 Mountain bike 23

2.4.7 Racing bicycle 23

2.5 Duty of care 24

2.5.1 Operator 24

2.5.2 Rider 24

2

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 3 Friday, November 23, 2018 1:44 PM

Table of contents

3 Description 25

3.1 Overview 25

3.2 Handlebars 26

3.3 Wheel and fork 27

3.3.1 Valve 27

3.3.2 Suspension 29

3.3.3 Suspension fork structure 30

3.3.3.1 Rear frame damper structure 31

3.4 Brake system 32

3.4.1 Rim brake 32

3.4.2 Disc brake 34

3.4.3 Back-pedal brake 35

3.5 Electric drive system 36

3.5.1 Drive unit 38

3.5.2 Rechargeable battery 39

3.5.3 Control panel 41

3.5.3.1 Display bar 42

3.5.3.2 Level of assistance 43

3.6 Charger 44

4 Technical data 45

5 Transportation, storage and assembly 49

5.1 Transportation 49

5.1.1 Transporting the battery 51

5.1.2 Using the transport securing system 51

5.2 Storing 52

5.2.1 Break in operation 53

5.2.1.1 Preparing a break in operation 53

5.2.1.2 Taking out of operation 53

5.3 Assembly 54

5.3.1 Required tools 54

5.3.2 Unpacking 55

5.3.3 Scope of delivery 55

5.3.4 Commissioning 56

5.3.4.1 Checking the battery 58

5.3.5 Mounting the wheel in the Suntour fork 59

5.3.5.1 Mounting the wheel with screw-on axle (15 mm) 59

5.3.5.2 Mounting the wheel with screw-on axle (20 mm) 61

034-03275_1.0_23.11.2018

3

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 4 Friday, November 23, 2018 1:44 PM

Table of contents

5.3.5.3 Mounting the wheel with a quick release axle 62

5.3.6 Mounting the wheel with a quick release 66

5.3.7 Mounting the wheel in the FOX fork 69

5.3.7.1 Mounting the wheel with the quick release (15 mm) 69

5.3.7.2 Adjusting the FOX quick release 70

5.3.7.3 Mounting the wheel with Kabolt axles 72

5.3.7.4 Checking the stem and handlebars 73

5.3.8 Sale of the bicycle 74

6 Before the first ride 75

6.1 Adjusting the saddle 75

6.1.1 Adjusting the saddle tilt 75

6.1.2 Determining the seat height 76

6.1.3 Adjusting the seat height with quick release 77

6.1.4 Setting the height-adjustable seat post 79

6.1.4.1 Lowering the saddle 79

6.1.4.2 Raising the saddle 79

6.1.5 Adjusting the seat position 80

6.2 Adjusting the handlebars 81

6.2.1 Adjusting the height of the handlebars 82

6.2.2 Turning the handlebars to the side 83

6.2.2.1 Checking the clamping force of the quick releases 84

6.2.2.2 Adjusting the quick release clamping force 84

6.3 Adjusting the brake lever 85

6.3.1 Adjusting the pressure point on a Magura brake lever 85

6.3.2 Adjusting the grip distance 86

6.3.2.1 Adjusting the grip distance on a Magura brake lever 87

6.4 Adjusting the suspension of the Suntour fork 88

6.4.1 Adjusting the negative deflection 89

6.4.1.1 Adjusting the air suspension fork negative deflection 89

6.4.1.2 Adjusting the steel suspension fork negative deflection 91

6.4.2 Adjusting the rebound 92

6.5 Adjusting the suspension of the FOX fork 93

6.5.1 Adjusting the negative deflection 93

6.5.2 Adjusting the rebound 96

6.6 Adjusting the Suntour rear frame damper 97

6.6.1 Adjusting the negative deflection 97

6.6.2 Adjusting the rebound 98

6.6.3 Setting the compression 99

4

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 5 Friday, November 23, 2018 1:44 PM

Table of contents

6.7 Adjusting the FOX rear frame damper 100

6.7.1 Adjusting the negative deflection 100

6.7.2 Adjusting the rebound 102

6.8 Retracting brake linings 103

7 Operation 104

7.1 Before each ride 106

7.2 Check list before each ride 107

7.3 Charger 108

7.3.1 Connecting the charger to the mains 110

7.4 Rechargeable battery 111

7.4.1 Charging the battery 114

7.4.1.1 Charging the battery in the drive unit 116

7.4.1.2 Charging the battery on the bicycle 117

7.4.2 Inserting the battery into the drive unit 118

7.4.3 Removing the battery from the drive unit 119

7.5 Drive unit 119

7.5.1 Installing the drive unit on the bicycle 119

7.5.2 Removing the drive unit from the bicycle 121

7.6 Drive system 123

7.6.1 Switching on the drive system 123

7.6.2 Switching off the drive system 123

7.6.3 Shutting down the drive system 124

7.7 Control panel 125

7.7.1 Using the push assist system 125

7.7.2 Selecting the level of assistance 126

7.8 Gear shift 127

7.8.1 Using the derailleur gears 127

7.9 Brake 128

7.9.1 Using the brake lever 132

7.9.2 Using the back-pedal brake 132

7.10 Suspension and damping 133

7.10.1 Adjusting the compression of the Fox fork 133

7.10.2 Adjusting the compression of the Fox damper 134

8 Maintenance 136

8.1 Cleaning and servicing 138

8.1.1 After each ride 138

8.1.1.1 Cleaning the suspension fork 138

034-03275_1.0_23.11.2018

5

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 6 Friday, November 23, 2018 1:44 PM

Table of contents

8.1.1.2 Cleaning the rear frame damper 138

8.1.1.3 Cleaning the pedals 138

8.1.2 Basic cleaning 139

8.1.2.1 Cleaning the frame 140

8.1.2.2 Cleaning the stem 140

8.1.2.3 Cleaning the rear frame damper 140

8.1.2.4 Cleaning the wheel 140

8.1.2.5 Cleaning the drive elements 141

8.1.2.6 Cleaning the chain 141

8.1.2.7 Cleaning battery 142

8.1.2.8 Cleaning the display 142

8.1.2.9 Cleaning the drive unit 143

8.1.2.10 Cleaning the brake 144

8.1.3 Servicing 145

8.1.3.1 Servicing the frame 145

8.1.3.2 Servicing the stem 145

8.1.3.3 Servicing the fork 145

8.1.3.4 Servicing the drive elements 145

8.1.3.5 Servicing the pedal 145

8.1.3.6 Servicing the chain 146

8.1.3.7 Servicing the drive elements 146

8.2 Maintenance 147

8.2.1 Wheel 147

8.2.2 Brake system 148

8.2.3 Electrical cables and brake cables 148

8.2.4 Gear shift 148

8.2.5 Stem 149

8.2.6 Checking the chain and belt tension 149

8.2.7 USB port 150

8.2.8 Suspension fork 150

8.3 Service 151

8.4 Adjusting and repairing 153

8.4.1 Use original parts and lubricants only 153

8.4.2 Axle with quick release 154

8.4.2.1 Checking the quick release 155

8.4.3 Adjusting the tyre pressure 156

8.4.3.1 Dunlop valve 156

8.4.3.2 Presta valve 157

6

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 7 Friday, November 23, 2018 1:44 PM

Table of contents

8.4.3.3 Schrader valve 158

8.4.4 Adjusting the gear shift 159

8.4.5 Cable-operated gear shift, single-cable 159

8.4.6 Cable-operated gear shift, dual-cable 160

8.4.7 Cable-operated twist grip, dual-cable 161

8.4.8 Offsetting the brake lining wear 162

8.4.9 Hydraulically operated rim brake 162

8.4.10 Hydraulically operated disc brake 163

8.4.11 Replacing the lighting 163

8.4.12 Setting the headlight 163

8.4.13 Repair by the specialist dealer 163

8.4.14 Repair by the specialist dealer 164

8.4.15 First aid 165

8.4.16 Drive system or control panel does not start up 167

8.5 Accessories 168

8.5.1 Child seat 168

8.5.2 Bicycle trailer 170

8.5.3 Pannier rack 171

9 Recycling and disposal 172

9.1 EC declaration of conformity 174

9.2 Table of figures 175

9.3 List of tables 178

9.4 Index 179

034-03275_1.0_23.11.2018

7

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 8 Friday, November 23, 2018 1:44 PM

About these instructions

1 About these instructions

Read these operating instructions before

commissioning the bicycle to ensure you use all the

functions correctly and safely. The operating

instructions are not a substitute for personal

instruction by the supplying specialist dealer. The

operating instructions are a component part of the

bicycle. Therefore, if it is re-sold at a later time, they

must be handed over to the subsequent owner.

These operating instructions are mainly intended for

the rider and operator of the bicycle, who tend to be

non-professionals

Text passages which are expressly intended for

specialist staff (e.g. bicycle mechanics) are clearly

marked with a tool symbol.

.

Staff at all specialist dealers have specialist training

and qualifications, and are therefore capable of

identifying risks and preventing hazards which may

arise during maintenance, servicing and repairs on the

bicycle. Information for specialist staff does not require

non-professionals to take any action.

1.1 Manufacturer

The manufacturer of the bicycle is:

ZEG Zweirad-Einkaufs-Genossenschaft eG

Longericher Straße 2

50739 Köln, Germany

Tel.: +49 221 17959 0

Fax: +49 221 17959 31

E-mail: info@zeg.de

Internet: www.zeg.de

8

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 9 Friday, November 23, 2018 1:44 PM

About these instructions

1.2 Laws, standards and directives

These operating instructions comply with the essential

requirements from:

• Machinery Directive 2006/42/EC,

• Electromagnetic Compatibility Directive 2014/30/EU,

• EN ISO 12100:2010 Safety of machinery – General

principles of design – Risk assessment and reduction,

• EN 15194:2015, Cycles – Electrically power assisted

cycles – EPAC bicycles,

• EN ISO 4210, Cycles – Safety requirements for

bicycles,

• EN 11243:2016, Cycles – Luggage carriers for

bicycles – Requirements and test methods,

• EN 82079-1:2012, Preparation of instructions for

use – Structuring, content and presentation – Part 1:

General principles and detailed requirements and

• EN ISO 17100:2016-05, Translation Services –

Requirements for translation service.

1.3 Other valid documents

These operating instructions are only complete in

conjunction with the other valid documents.

The following document applies for this product:

• Charger operating instructions.

No other information is also applicable.

The constantly updated lists of approved accessories

and parts are available to specialist dealers.

034-03275_1.0_23.11.2018

9

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 10 Friday, November 23, 2018 1:44 PM

About these instructions

1.4 Subject to change

The information contained in these operating

instructions are the approved technical specifications

at the time of printing. Any significant changes are

included in a new issue of the operating instructions.

You will find any modifications to these operating

instructions at:

www.bulls.de/service/downloads

1.5 Language

The original operating instructions are written in

German. A translation is not valid without the original

operating instructions.

10

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 11 Friday, November 23, 2018 1:44 PM

About these instructions

1.6 For your safety

The safety concept of the bicycle comprises four

elements:

• rider and/or operator instruction, and bicycle

maintenance and repair by the specialist dealer,

• the chapter on general safety,

• the warnings in these instructions and

• the safety marking on the type plates.

1.6.1 Instruction, training and customer service

The supplying specialist dealer will provide customer

service. Contact details can be found on the back page

of these operating instructions and in the data sheet. If

you are unable to contact this person, you will find

other specialist dealers at www zeg.de.

The specialist dealer authorised to perform repairs and

maintenance work receives regular training.

034-03275_1.0_23.11.2018

The rider or the operator of the bicycle will be

instructed in person on the bicycle functions when the

supplying specialist dealer hands over the bicycle, if

not before. This instruction particularly covers the

bicycle's electrical functions and correct use of the

charger.

Each rider to whom this bicycle is provided must

receive instruction on the bicycle's functions. The

operating instructions must be submitted to each rider

in printed form and must be acknowledged and

adhered to.

11

SIGNAL WORD

DANGER

!

WARNING

!

CAUTION

!

NOTICE

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 12 Friday, November 23, 2018 1:44 PM

About these instructions

1.6.2 Basic safety notes

These operating instructions have a chapter with

general safety notes [

distinguish this chapter as it has a grey background.

Chapter 2, page 19]. You can

1.6.3 Warnings

Hazardous situations and actions are marked with

warnings. The warnings in these operating instructions

are shown as follows:

Type and source of the danger

Description of the danger and the consequences.

Measures

The following pictograms and signal words are used in

the operating instructions for warnings and information

notices:

Will lead to serious or even fatal injuries if ignored.

High-risk hazard.

May lead to serious or even fatal injuries if ignored.

Medium-risk hazard.

May lead to minor or moderate injuries. Low-risk

hazard.

May lead to material damage if ignored.

Table 1: Meanings of the signal words

12

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 13 Friday, November 23, 2018 1:44 PM

About these instructions

1.6.4 Safety markings

The following safety markings are used on the

bicycle's type plates:

General warning

Adhere to the instructions for use

Table 2: Meaning of safety markings

1.7 For your information

1.7.1 Instructions for actions

Instructions for actions are structured in accordance

with the following pattern:

Requirements (optional)

Instruction for action

Result of the action (optional)

1.7.2 Information on the type plate

Alongside the warnings, the type plates of the

products also contain other important information on

the bicycle:

034-03275_1.0_23.11.2018

13

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 14 Friday, November 23, 2018 1:44 PM

About these instructions

Suitable for tarmacked and paved roads – no off-road

riding or jumps

Suitable for tarmacked roads, cycle paths and firm

gravel paths and roads, longer sections with

moderate slopes and jumps up to 15 cm.

Suitable for tarmacked roads, cycle paths and easy to

demanding off-road riding, sections with moderate

slopes and jumps up to 61 cm.

Suitable for tarmacked roads, cycle paths and easy to

demanding off-road riding, limited downhill use up to

25 km and jumps up to 122 cm.

Suitable for tarmacked roads, cycle paths and easy to

extremely difficult off-road riding, unlimited downhill

use and any jumps

Table 3: Relevance of area of use

City and trekking bicycle

Child's bicycle / bicycle for young adults

Mountain bike

Racing bicycle

Carrier bicycle

Folding bicycle

Table 4: Relevance of bicycle type

14

034-03275_1.0_23.11.2018

max. 50°C

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 15 Friday, November 23, 2018 1:44 PM

About these instructions

Read the instructions

Separate collection of electrical and electronic

devices

Separate collection of ordinary and rechargeable

batteries

Must not be thrown into fire (burning prohibited)

It is forbidden to open any type of battery

Device of protection class II

Only suitable for use indoors

Fuse (device fuse)

EU conformity

Recyclable material

Protect from temperatures above 50 °C and direct

sunlight

Table 5: Relevance of safety instructions

034-03275_1.0_23.11.2018

15

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 16 Friday, November 23, 2018 1:44 PM

About these instructions

1.7.3 Language conventions

The bicycle described in these operating instructions

may be equipped with alternative components. The

equipment of the bicycle is defined by the respective

type number. Where applicable, the word Alternative

beneath the heading indicates alternatively used

components. The following terms are used for better

legibility:

Term Meaning

Operating

instructions

Bicycle Electric motor driven cycle

Motor Drive motor

The following conventions are used in these operating

instructions:

Original operating instructions

or translation of the original

operating instructions

16

Convention Use

Italics Entry in the index

SPACED Indicators on the display

screen

[

Example, page

Cross references

numbering]

• Bulleted lists

034-03275_1.0_23.11.2018

ZEG Zweirad-Einkaufs-

Genossenschaft eG

Longericher Str. 2

50739 Köln, Germany

Typ:

19-16-0001

EN 15194

0,25 kW / 25 km/h

zGG 180 kg

EPAC 25 kg

BJ 2018 / MJ 2019

nach

EPAC

2

3

1

4

5

6

7

8

9

12

13

10

11

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 17 Friday, November 23, 2018 1:44 PM

About these instructions

1.8 Type plate

The type plate is situated on the frame. The type plate

features the following information:

Figure 1: Type plate, example

1 CE marking

2 Manufacturer

3 Type number

4 Nominal continuous power

5 Permitted total weight

034-03275_1.0_23.11.2018

6 Year of manufacture

7 Bicycle type

8 Safety instructions

9 Disposal instruction

10 Area of use

11 Model year

12 Weight of the ready-to-ride bicycle

13 Shut-off speed

17

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 18 Friday, November 23, 2018 1:44 PM

About these instructions

1.9 Identifying

1.9.1 Operating instructions

The identification number of these operating

instructions is made up of the document number, the

version number and the release date. It can be found

on the cover page and in the footer.

Identification number 034-03275_1.0_23.11.2018

Table 6: Identification number of the operating instructions

1.9.2 Bicycle

These BULLS operating instructions refer to the model

year 2019. The production period is from August 2018

to July 2019. They are issued in August 2018.

The operating instructions are a component part of the

following bicycles:

18

Type

number

19-22-1001 Harrier EVO Racing bicycle

19-22-1002 Grinder EVO Racing bicycle

19-22-1003 Grinder EVO Carbon Racing bicycle

19-17-1033 Millennial EVO City and trekking bicycle

19-22-4001 Alpine Hawk EVO Racing bicycle

19-17-4003 Millennial EVO Carbon City and trekking bicycle

19-18-1061 WildFlow EVO RS Mountain bike

19-18-1062 WildFlow EVO SL Mountain bike

Model Bicycle type

034-03275_1.0_23.11.2018

!

!

!

!

!

!

!

! ! !

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 19 Friday, November 23, 2018 1:44 PM

2 Safety

2.1 Requirements for the rider

The physical and mental abilities of the rider must be

sufficient for riding on public roads.

2.2 Hazards for vulnerable groups

Legal guardians hold sole responsibility for

determining whether minors are capable of using the

bicycle.

2.3 Personal protective equipment

We recommend that you wear a suitable safety

helmet. We also recommend that you wear typical,

long, close-fitting cycling clothing and sturdy footwear.

Safety

2.4 Proper use

034-03275_1.0_23.11.2018

The bicycle may only be used in a perfect, fully

functional condition. National requirements may apply

to the bicycle which differ from the standard

equipment. For riding on public roads, some special

regulations apply in relation to the driving light,

reflectors and other components.

The general laws and the regulations for the

prevention of accidents and environmental protection

in the respective country of use must be adhered to.

Proper use also includes all instructions for actions

and check lists in these operating instructions.

Approved accessories can be installed by specialist

staff. The drive system is only intended for use during

a bicycle journey and must not be used for other

purposes.

Each bicycle is categorised [

bicycle type, which determines its designated use.

Table 4, page 14] as a

19

!

! !

!

!

!

!

! ! !

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 20 Friday, November 23, 2018 1:44 PM

Safety

2.4.1 City and trekking bicycle

City and trekking bicycles are designed for daily,

comfortable use. They are suitable for riding on public

roads.

Area of use

Suitable for tarmacked and paved roads.

Suitable for tarmacked roads, cycle paths and firm

gravel paths and roads, and longer sections with

2.4.2 Mountain bike

moderate slopes and jumps up to 15 cm.

The mountain bike is designed for sporting use. The

design characteristics include a short wheelbase, a

sitting position with the rider inclined towards the front,

and a brake requiring low actuation force.

A mountain bike is a piece of sporting equipment. It

requires an adaptation period as well as physical

fitness. Use requires the appropriate training; in

particular riding in bends and braking should be

practised.

The strain on the rider, in particular the hands and

wrists, arms, shoulders, neck and back, is accordingly

high. Inexperienced riders tend to brake excessively

and lose control as a result.

Area of use

:

:

Suitable for tarmacked roads, cycle paths and easy to

demanding off-road riding, sections with moderate

slopes and jumps up to 61 cm.

Suitable for tarmacked roads, cycle paths and easy to

demanding off-road riding, limited downhill use and

jumps up to 122 cm.

20

034-03275_1.0_23.11.2018

!

!

!

!

!

!

!

! ! !

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 21 Friday, November 23, 2018 1:44 PM

Suitable for tarmacked roads, cycle paths and easy to

extremely difficult off-road riding, unlimited downhill

use and any jumps

2.4.3 Racing bicycle

A racing bicycle is designed for fast rides on roads and

paths with a good, undamaged road surface.

A racing bicycle is a piece of sporting equipment and

not a means of transport. A racing bicycle is

characterised by its lightweight structure and a design

which is stripped to the minimum parts required for

riding.

The frame geometry and the layout of the operating

elements are designed in such a way that the bicycle

can be ridden at high speeds. The frame design

requires practice to ensure the ride is able to ride

slowly, apply the brakes and get on and off the bike

safely.

The sitting position is athletic. The strain on the rider,

in particular the hands and wrists, arms, shoulders,

neck and back, is accordingly high. The sitting position

therefore requires physical fitness.

Safety

Area of use

Suitable for tarmacked and paved roads.

Suitable for tarmacked roads, cycle paths and firm

gravel paths and roads, and longer sections with

moderate slopes and jumps up to 15 cm.

034-03275_1.0_23.11.2018

:

21

!

! !

!

!

!

!

! ! !

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 22 Friday, November 23, 2018 1:44 PM

Safety

2.4.4 Improper use

Failure to adhere to the proper use poses a risk of

personal injury and material damage. The bicycle is

not suitable for the following uses:

• riding with a damaged or incomplete bicycle

• riding over steps

• riding through deep water

• lending the bicycle to untrained riders

• carrying other people

• riding with excessive luggage

• riding with no hands

2.4.5 City and trekking bicycle

• riding on ice and snow

• improper servicing

• improper repair

• tough areas of use, such as professional competitions

• stunt riding or acrobatics.

City and trekking bicycles are not sports bicycles. If

used for sports, the rider can expect reduced riding

stability and diminished comfort.

Forbidden areas of use

Never drive off-road or perform jumps.

Never drive off-road or perform jumps over 15 cm.

22

:

034-03275_1.0_23.11.2018

!

!

!

!

!

!

!

! ! !

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 23 Friday, November 23, 2018 1:44 PM

2.4.6 Mountain bike

A mountain bike must be retrofitted with lighting, a

guard etc. according to the applicable national laws

and regulations before it can be used in public street

traffic.

Safety

Forbidden areas of use

Never ride downhill or perform jumps over 61 cm.

Never traverse extremely difficult off-road terrain or

2.4.7 Racing bicycle

perform jumps over 122 cm.

Never exceed your personal limits.

Racing bikes must be retrofitted with lighting, a guard

and other fittings as specified by national laws and

regulations before they are used on public roads.

Forbidden areas of use

Never drive off-road or perform jumps.

Never drive off-road or perform jumps over 15 cm.

:

:

034-03275_1.0_23.11.2018

23

!

! !

!

!

!

!

! ! !

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 24 Friday, November 23, 2018 1:44 PM

Safety

2.5 Duty of care

The safety of the bicycle can only be assured if all the

necessary measures are taken.

2.5.1 Operator

The operator has the duty of care and responsibility for

scheduling these measures and checking that they are

implemented.

The operator:

2.5.2 Rider

• makes these operating instructions available to the

rider for the duration of use of the bicycle. If

necessary, they translate the operating instructions

into a language which the rider understands.

• familiarises the rider with the functions of the bicycle

before the first ride. Only riders who have received

instruction may be allowed to ride.

• instructs the rider on proper use and the wearing of

personal protective equipment.

• only employs specialist staff for maintenance and

repair of the bicycle.

The rider:

• receives instruction before the first ride. They can

clarify any questions relating to the operating

instructions with the operator or specialist dealer

• wears personal protective equipment.

• assumes all the obligations of the operator in case

the bicycle changes hands.

24

034-03275_1.0_23.11.2018

1

2

3

4

5

6

7

8

910

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 25 Friday, November 23, 2018 1:44 PM

Description

3 Description

3.1 Overview

Figure 2: Bicycle viewed from the right, Alpine Hawk EVO used as example

1 Front wheel

2 Fork

3 Handlebars

4 Stem

5 Frame

6 Seat post

7 Saddle

8 Rear wheel

9Chain

10 Rechargeable battery, frame number and type

plate

034-03275_1.0_23.11.2018

25

1

2

34

5

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 26 Friday, November 23, 2018 1:44 PM

Description

3.2 Handlebars

Figure 3: Detailed view of bicycle from rider position, example

1 Rear brake lever

2 Front brake lever

3 Control panel

4 Fork lock on suspension fork head

5 Shifter

26

034-03275_1.0_23.11.2018

1

2

4

5

8

7

3

9

6

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 27 Friday, November 23, 2018 1:44 PM

3.3 Wheel and fork

Figure 4: Components of the wheel – example showing front wheel

1 Tyre

2Rim

3 Suspension fork head with setting wheel

4Fork

5 Spoke

6 Quick release

7Hub

8 Valve

9 Fork end of the suspension fork

Description

3.3.1 Valve

Each wheel has a valve. It is used to fill the tyre with

air. There is a valve cap on each valve. The screw-on

valve cap keeps out dust and dirt.

The bicycle either has a classical Dunlop valve, a

Presta valve or a Schrader valve.

034-03275_1.0_23.11.2018

27

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 28 Friday, November 23, 2018 1:44 PM

Description

Dunlop valve

The rider can easily exchange the

valve and quickly release the air. The

air pressure cannot be measured with

this valve.

Presta valve

The Presta valve requires a smaller

hole in the rim, which is why it is

especially suitable for the narrow rims

of racing bicycles. The air pressure

can be measured with this valve.

28

Schrader valve

The rider can fill the Schrader valve

very easily at a petrol station. The air

pressure can be measured with this

valve.

034-03275_1.0_23.11.2018

1

2

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 29 Friday, November 23, 2018 1:44 PM

3.3.2 Suspension

Both forks and suspension forks are fitted in this model

series. A suspension fork is based either on a steel

spring or air suspension. Unlike a rigid fork, a

suspension fork has two functions which improve floor

contact and comfort: suspension and damping.

Description

Figure 5: Bicycle without suspension (1) and with suspension (2) when

riding over an obstacle

The suspension prevents an impact, such as one

caused by a stone lying in the bike's path, from being

channelled directly into the rider's body via the fork.

The impact is absorbed by the suspension system

instead. This causes the suspension fork to compress.

The compression can be disabled so that a

suspension fork reacts like a rigid fork. The switch to

disable the fork is called a remote lockout.

After compressing, the suspension fork returns to its

original position. If there is a damper, it decelerates

movement, preventing the suspension system from

springing back in an uncontrolled manner and

stopping the fork from vibrating up and down.

034-03275_1.0_23.11.2018

29

1

2

3

4

5

6

8

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 30 Friday, November 23, 2018 1:44 PM

Description

Dampers which dampen compressive deflection

movements, i.e. a compression load, are called

compression dampers or compression dashpots.

Dampers which dampen rebound deflection

movements, i.e. a rebound load, are called rebound

dampers or dashpots.

3.3.3 Suspension fork structure

Figure 6: Example showing FOX fork

The stem and handlebars are fastened to the fork

shaft (3). The wheel is fastened to the quick release

axle (7). Other elements: Stanchion (1) and spring setting

wheel (2), compression setting (4), crown (5), dust

30

seal (6) and quick release lever (7)

034-03275_1.0_23.11.2018

25-30%

1

2

4

3

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 31 Friday, November 23, 2018 1:44 PM

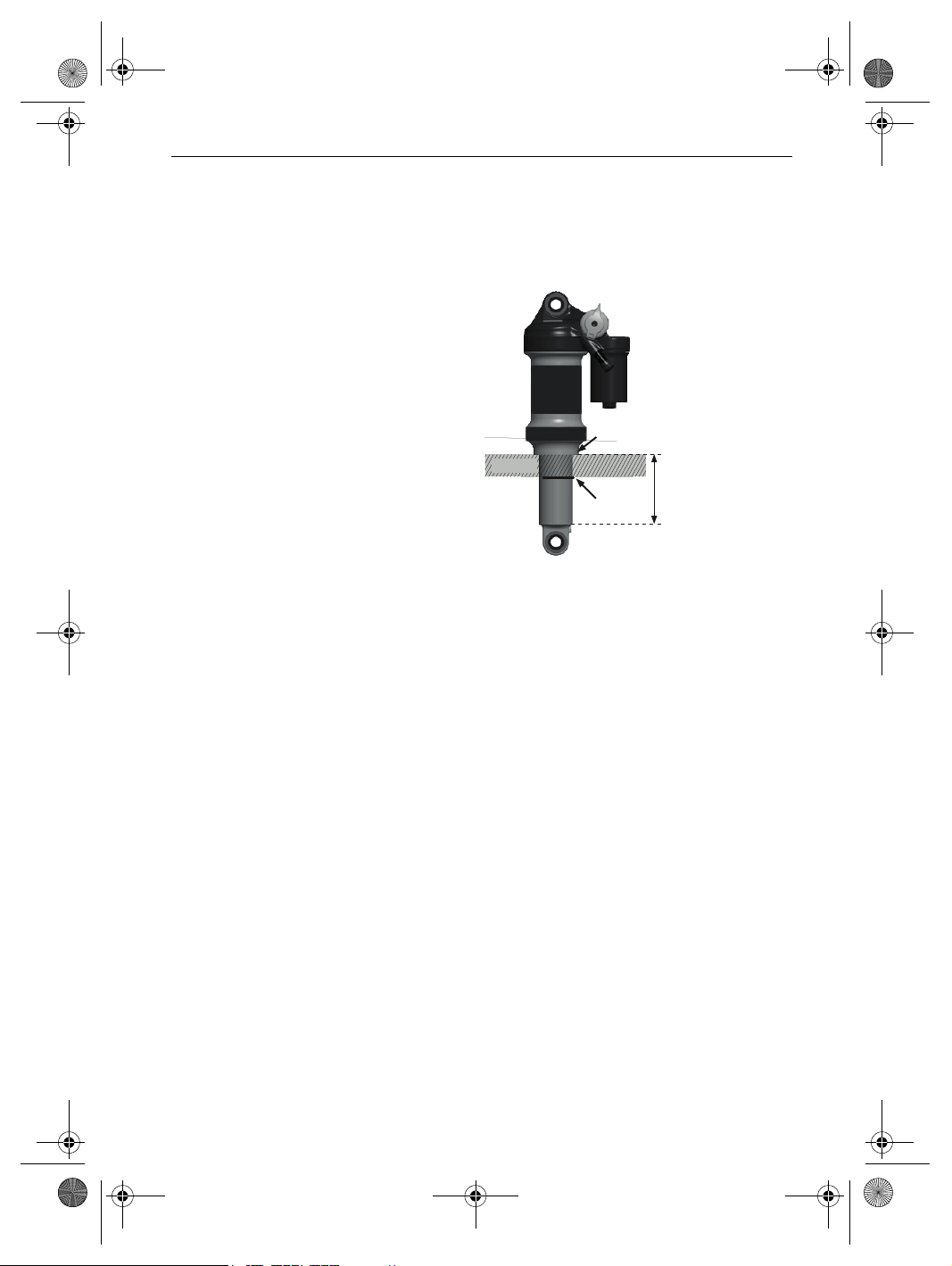

3.3.3.1 Rear frame damper structure

The rear frame damper features air suspension, a

compression damper and a rebound damper.

Figure 7: Example showing FOX rear frame damper

Description

034-03275_1.0_23.11.2018

1 Guide rod eye

2Air valve

3 Setting wheel

4 Lever

5 Air chamber

6O-ring

31

1

2

3

4

5

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 32 Friday, November 23, 2018 1:44 PM

Description

3.4 Brake system

The bicycle's brake system comprises either a

hydraulic:

• rim brake on the front and rear wheels,

• disc brake on the front and rear wheels or

• a rim brake on the front and rear wheels and an

additional back-pedal brake.

3.4.1 Rim brake

Alternative

Figure 8: Rim brake components with details; Magura HS22 used as an

example

1 Rear wheel rim brake

2 Brake booster

3 Brake lining

4 Handlebars with brake levers

5 Front wheel rim brake

The rim brake stops the wheel moving when the rider

pulls the brake lever, causing two brake linings,

positioned opposite one another, to be pressed onto

the rims.

32

034-03275_1.0_23.11.2018

21

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 33 Friday, November 23, 2018 1:44 PM

The hydraulic rim brake features a locking lever

Figure 9: Rim brake locking lever, closed (1) and open (2)

The rim brake locking lever is not marked with any

lettering. Only a specialist dealer may set the rim brake

locking lever.

Description

034-03275_1.0_23.11.2018

33

1

3

4

5

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 34 Friday, November 23, 2018 1:44 PM

Description

3.4.2 Disc brake

Alternative

Figure 10: Bicycle brake system with a disc brake, example

1Brake disc

2 Brake calliper with brake linings

3 Handlebars with brake levers

4 Front wheel brake disc

5 Rear wheel brake disc

2

On a bicycle with a disc brake, the brake disc is

screwed permanently to the hub of the wheel.

The brake lever is pulled to increase brake pressure.

The brake fluid is used to transfer pressure through

the brake lines to the cylinders in the brake calliper.

The braking force is boosted by a speed reduction and

applied to the brake linings. These apply the brake

disc mechanically. If the brake lever is pulled, the

brake linings are pressed against the brake disc, and

the movement of the wheel is decelerated until it

comes to a stop.

34

034-03275_1.0_23.11.2018

2

3

4

1

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 35 Friday, November 23, 2018 1:44 PM

3.4.3 Back-pedal brake

Alternative

Figure 11: Brake system with a back-pedal brake, example

1 Rear wheel rim brake

2 Handlebars with brake levers

3 Front wheel rim brake

4 Pedal

5 Back-pedal brake

Description

5

The back-pedal brake stops the movement of the rear

wheel when the rider pedals in the opposite direction

to the direction of travel.

034-03275_1.0_23.11.2018

35

2

3

4

1

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 36 Friday, November 23, 2018 1:44 PM

Description

3.5 Electric drive system

The bicycle is driven by muscle power via the chain

drive. The force which is applied by pedalling in the

direction of travel, drives the front chain wheel. The

chain transmits the force onto the rear chain wheel and

then onto the rear wheel.

Figure 12: Diagram of mechanical drive system

1 Direction of travel

2 Chain

3 Rear chain wheel

4 Front chain wheel

5 Pedal

The bicycle also has an integrated, electric drive

system.

36

5

034-03275_1.0_23.11.2018

1

234

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 37 Friday, November 23, 2018 1:44 PM

The electric drive system is made up of 5 components:

Figure 13: Diagram of electric drive system

1 Control panel

2 Bottom-bracket gears

3 Drive unit

4 Rechargeable battery

5 A charger which is designed for the battery.

Description

034-03275_1.0_23.11.2018

37

1

2

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 38 Friday, November 23, 2018 1:44 PM

Description

3.5.1 Drive unit

Figure 14: Drive unit

As soon as the required muscle power from the rider

pedalling passes a certain level, the motor is activated

gently and assists the pedalling motion of the rider.

The motor force is determined by the set level of

assistance. The system performance is determined

using the pedal assistance settings on the control

panel.

38

The bicycle does not have a separate emergency stop

or emergency shut-off button. The motor switches off

automatically as soon as the rider no longer pedals,

the temperature is outside the permitted range, there

is an overload or the shut-off speed of 25 km/h has

been reached.

When you step on the pedals again and the speed

drops below 25 km/h, the system starts again

A push assist system can be activated. The speed

depends on the selected gear. The rider brakes the

bicycle by holding the bicycle while pushing.

034-03275_1.0_23.11.2018

1

2

3

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 39 Friday, November 23, 2018 1:44 PM

3.5.2 Rechargeable battery

Figure 15: Rechargeable battery, view of charging port side

1 Charging port

2 On-Off button

3 Charge status indicator (battery)

Description

034-03275_1.0_23.11.2018

The lithium ion battery has an internal electronic

protection circuit. This is matched to the charger and

bicycle motor. The battery temperature is monitored at

all times. The battery is protected against deep

discharge, overcharging, overheating and short

circuit. In the event of a hazard, a protective circuit

switches the battery off automatically. If the bicycle

has not been moved for 10 hours and no button has

been pressed on the control panel or the charge status

of the battery falls below 30%, the bicycle has not

been moved for 3 hours and no button has been

pressed on the control panel, the electric drive system

and the battery automatically switch off to save

energy.

39

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 40 Friday, November 23, 2018 1:44 PM

Description

The battery's service life can be extended if it is well

maintained and, above all, stored at the correct

temperatures. The battery charge status will decrease

with age, even if the battery is maintained properly. If

the operating time is severely shortened after

charging, this is a sign that battery has reached the

end of its useful life.

Transportation temperature 5°C–25°C

Ideal transportation temperature 10 °C–15 °C

Storage temperature 5°C–25°C

Ideal storage temperature 10 °C–15 °C

Charging ambient temperature 10 °C–30 °C

Table 7: Rechargeable battery technical data

When the battery is switched on, the charge status

indicator shows the start animation. The LEDs then

briefly indicate the charge status of the battery.

40

If the battery is switched on, the charge status can be

queried by briefly pressing the On-Off button.

The five green LEDs on the charge status indicator

show the battery charge status when the battery is

switched on. Each LED represents 20% of the charge

status.

When the battery is discharged, the last LED lights up

intermittently. The charge status of the battery is also

shown on the display.

034-03275_1.0_23.11.2018

2

3

4

5

7

6

6

6

6

6

6

6

6

6

6

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 41 Friday, November 23, 2018 1:44 PM

3.5.3 Control panel

1

Figure 16: Overview of the structure and operating elements

Designation

1 Display bar

2 Top button

3 Middle button

4 Bottom button

5 Extension cable

6 Charge status indicator or pedal assistance

7 Status screen

Table 8: Operating element overview

Description

The control panel controls the drive system via three

buttons and displays either the charge status of the

battery or the pedal assistance selected.

The bicycle's battery supplies the control panel with

energy when a sufficiently charged battery is inserted

into the bicycle, and the drive system is switched on.

034-03275_1.0_23.11.2018

41

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 42 Friday, November 23, 2018 1:44 PM

Description

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Protection rating

(with USB cover closed)

Weight about 0.075 kg

Table 9: Display technical data

3.5.3.1 Display bar

The control panel display bar consists of 11 LEDs.

The uppermost LED serves as a status display to

provide information on the status of your e-bike. The

remaining 10 LEDs serve as an indicator for the

charge status and pedal assistance.

Status screen

The status screen indicates a status change or an

existing fault. The status indicator does not light up if

no fault is detected.

The different colours of the status screen have the

following meaning:

Colour Meaning

The status screen briefly flashes green after the

green

Yellow

Red

Table 10: Meaning of status screen colours

drive pack has been successfully installed in the

bicycle. This gives you a visual signal that the

system can now be switched on.

The status screen briefly turns yellow when a "soft

fault" is detected. This means that there is a

temporary or non-critical disturbance, which in most

cases leads to a loss of performance. In the event

of a "soft fault", you can still ride your bicycle.

However, this is not recommended.

The status screen briefly turns red when a "hard

fault" is detected. In the event of a "hard fault", the

bicycle cannot be operated and must be serviced.

IP54

42

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 43 Friday, November 23, 2018 1:44 PM

3.5.3.2 Level of assistance

You can adjust the desired level of assistance using

the control panel. The pedal assistance can be

changed at any time.

The higher the level of assistance, the more the drive

system assists the rider when pedalling. The following

levels of assistance are available.

The following levels of assistance are possible:

Level of assistance Use

NONE

BREEZE

RIVER

ROCKET

Table 11: Overview of levels of assistance

Motor assistance is deactivated. The

bicycle can be used as a normal

bicycle.

Low but effective support for

maximum range.

Reliable assistance for most usage

situations.

Maximum assistance for very

demanding excursions.

Description

034-03275_1.0_23.11.2018

Level of

assistance

NONE WHITE 0% 0 W

BREEZE GREEN 75% 125 W

RI V E R B L U E 150% 250 W

RO C K E T PINK 240% 400 W

Colour

Max.

assistance

factor

Max. output

Remaining range

Precise information about the range of your system is

not possible before or during an excursion. Several

factors can influence the range of the bicycle, such as

level of assistance, speed, gear switching habits, tyre

type and pressure, route and weather conditions,

weight of rider and bicycle or the condition or age of

the battery.

43

2

3

1

4

5

1

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 44 Friday, November 23, 2018 1:44 PM

Description

3.6 Charger

The lithium ion battery has an internal electronic

protection circuit. It is matched to the charger. The

bicycle may therefore only be charged using the

charger provided.

Nominal input voltage 100 ... 240 V AC

Frequency 50 ... 60 Hz

Output voltage 42 V DC

Charging current 2 A

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Protection class IP 54

Weight about 0.6 kg

Table 12: Charger technical data

Figure 17: Charger detail

1 Mains plug

2 LED display charger

3Mains plug

4 Connecting cable

5 Power jack

44

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 45 Friday, November 23, 2018 1:44 PM

Technical data

4 Technical data

Bicycle

Transportation temperature -20 ... +60 °C

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Discharging temperature -20 ... +60 °C

Charging temperature 0 ... +45 °C

Power output/system 250 W (0.25 kW)

Shut-off speed 25 km/h

Weight of the ready-to-ride bicycle See type plate

Table 13: Bicycle technical data

Drive unit

Continuous power rating 250 W

Max. output 400 W

Torque on chain, max. 60 Nm

Nominal voltage 36 V

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Protection class IP 54

Weight about 2kg

Table 14: Drive unit technical data

034-03275_1.0_23.11.2018

45

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 46 Friday, November 23, 2018 1:44 PM

Technical data

Rechargeable battery

Type Lithium ion battery

Nominal voltage 36 V

Nominal capacity 7Ah

Power 252 Wh

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Discharging temperature -20 ... +60 °C

Charging temperature 0 ... +45 °C

Protection class IP 54

Weight, approx. 1.4 kg

Table 15: Rechargeable battery technical data

Control panel

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Protection rating

(with USB cover closed)

Weight about 0.075 kg

Table 16: Display technical data

46

IP54

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 47 Friday, November 23, 2018 1:44 PM

Technical data

Bottom-bracket gears

Assistance torque, max. 60 Nm

Q factor, min. 135 (without crank

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

Protection class IP 54

Chainline 49, 52 mm

Weight about 1.3 kg

Table 17: Bottom-bracket gears technical data

Charger

Nominal input voltage 100 ... 240 V AC

Frequency 50 ... 60 Hz

Output voltage 42 V DC

Charging current 2 A

Operating temperature -20 ... +60 °C

Storage temperature -20 ... +60 °C

arm)

Protection class IP 54

Weight about 0.6 kg

Table 18: Charger technical data

034-03275_1.0_23.11.2018

47

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 48 Friday, November 23, 2018 1:44 PM

Technical data

Emissions

A-weighted emission sound pressure level < 70 dB(A)

Total vibration level for the hands and

arms

Highest effective value of weighted

acceleration for the entire body

Table 19: Emissions from the bicycle*

*The safety requirements as per Electromagnetic Compatibility

Directive 2014/30/EU have been met. The bicycle and the

charger can be used in residential areas without restriction.

Tightening torque

Axle nut tightening torque 35 Nm - 40 Nm

Handlebars clamping screw maximum

tightening torque*

Table 20: Tightening torque values*

*if there is no other data on the component

<2.5m/s²

<0.5m/s²

5Nm - 7Nm

48

034-03275_1.0_23.11.2018

CAUTION

!

CAUTION

!

CAUTION

!

NOTICE

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 49 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5 Transportation, storage and

assembly

5.1 Transportation

Crash caused by unintentional activation

There is a risk of injury if the drive system is activated

unintentionally.

Remove the battery before the bicycle is

transported.

Risk of fire and explosion due to high

temperatures

Excessively high temperatures will damage the

battery. Batteries may self-ignite and explode.

Never expose batteries to sustained direct sunlight.

Oil leak if no transport securing device

034-03275_1.0_23.11.2018

The brake securing device prevents the brakes from

being applied accidentally during transport. This could

cause irreparable damage to the brake system or an oil

leak, which will harm the environment.

Never pull the brake lever when the wheel has been

dismounted.

Always use the transport securing system when

transporting dismounted wheels.

If the bicycle is lying flat, oil and grease may leak from

the bicycle.

If the shipping box with a bicycle is lying flat or on one

end, it does not provide the frame and the wheels with

adequate protection from damage.

Only transport the bicycle in an upright position.

49

NOTICE

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 50 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Bicycle rack systems which secure the bicycle

standing on its head by the handlebars or frame,

generate inadmissible forces on the components

during transportation. This can cause the supporting

parts to break.

Never use bicycle rack systems which secure the

bicycle standing on its head by the handlebars or

frame.

Take into account the ready-to-use bicycle's weight

when transporting it.

Remove the display and the batteries before

transporting the bicycle.

Protect the electrical components and connections

on the bicycle from the elements with suitable

protective covers.

50

Remove accessories, for example drinking bottles,

before transportation of the bicycle.

When transporting by car, you must use a suitable

bicycle rack system.

The specialist dealer will advise you on how to select

a suitable rack system properly and how to use it

safely.

Transport the bicycle in a dry, clean place where it

is protected from direct sunlight.

When shipping the bicycle, we recommend that you

have the bicycle partially dismantled in the proper

manner and packaged by the specialist dealer.

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 51 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.1.1 Transporting the battery

Batteries are subject to hazardous goods regulations.

Undamaged batteries may be transported by private

persons in road traffic. Commercial transport requires

compliance with regulations concerning packaging,

labelling and the transportation of hazardous goods.

Open contacts must be covered and the battery

securely packaged. The parcel service must be made

aware of the presence of hazardous goods in the

packaging.

5.1.2 Using the transport securing system

Insert the transport securing devices between the

brake linings.

The transport securing device is squeezed between

the two linings.

Figure 18: Fastening the transport securing device

Transportation temperature -20 ... +60 °C

Table 21: Bicycle transport temperature

034-03275_1.0_23.11.2018

51

CAUTION

!

NOTICE

NOTICE

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 52 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.2 Storing

Risk of fire and explosion due to high

temperatures

Excessively high temperatures will damage batteries.

Batteries may self-ignite and explode.

Protect batteries against heat.

Never expose batteries to sustained direct sunlight.

If the bicycle is lying flat, oil and grease may leak from

the bicycle.

If the shipping box with a bicycle is lying flat or on one

end, it does not provide the frame and the wheels with

adequate protection from damage.

Only store the bicycle in an upright position.

The battery discharges when not in use. Storing a

discharged battery for longer periods can cause

serious damage to your battery or significantly reduce

its capacity.

I f the bicyc l e features a hydrauli c seat post, f ix only

the lower seat post or the frame into a fitting stand

to prevent damage to the upper seat post and the

seat post lever.

Never place a bicycle with a hydraulic seat post

upside down on the floor; otherwise you, will

damage the seat post lever.

Store the bicycle, battery and charger in a dry,

clean location.

Storage temperature -20 ... +60 °C

Table 22: Bicycle storage temperature

52

034-03275_1.0_23.11.2018

NOTICE

NOTICE

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 53 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.2.1 Break in operation

The battery discharges when not in use. Storing a

discharged battery for longer periods can cause

serious damage to your battery or significantly reduce

its capacity.

The battery may become damaged if it is connected

permanently to the charger.

Never connect the battery to the charger

permanently.

If the bicycle is to be removed from service for longer

than four weeks, e.g. in winter, a break in operation

has to be prepared. It is recommended to store the

battery and the drive unit.

5.2.1.1 Preparing a break in operation

Remove the battery and drive unit from the bicycle.

Charge the battery to 60% (three LEDs of the charge

status indicator light up).

The bicycle has to be cleaned with a damp cloth and

preserved with wax spray. Never wax the friction

surfaces of the brake.

Before longer periods without use, it is

recommendable to have your specialist dealer carry

out servicing and basic cleaning and apply

preservative agent.

5.2.1.2 Taking out of operation

Check the battery after 6 months. With a charge

status of 20% or less, charge the battery to 60%

again.

1 month -20 to +60 °C

3 months -20 to +45 °C

1 year -20 to +25 °C

Table 23: Storage time with 60% charge

034-03275_1.0_23.11.2018

53

CAUTION

!

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 54 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3 Assembly

Crushing caused by unintentional activation

There is a risk of injury if the drive system is activated

unintentionally.

Remove the battery if it is not absolutely necessary

for assembly.

Assemble the bicycle in a clean and dry environment.

The working environment temperature should be

between 15 °C and 25 °C.

Working environment temperature 15 °C–25 °C

Table 24: Working environment temperature

If a fitting stand is used, it must be approved for a

maximum weight of 30 kg.

To reduce the weight, we recommend that you always

disconnect the battery from the bicycle when using the

fitting stand.

5.3.1 Required tools

The following tools are required to assemble the

bicycle:

•Knife

• Hexagon socket spanner 2 (2.5 mm, 3, mm 4 mm,

5 mm, 6 mm and 8 mm)

• Torque wrench with working range between 5 and

40 Nm

• Twelve-point square socket T-25

• Ring spanner (8 mm, 9 mm, 10 mm, 13 mm, 14 mm

and 15 mm) and

• Cross, flat head and ordinary screwdriver.

54

034-03275_1.0_23.11.2018

CAUTION

!

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 55 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.2 Unpacking

Hand injuries caused by cardboard packaging

The shipping carton is closed with metal staples. There

is a risk of puncture wounds and cuts when unpacking

and crushing the packaging.

Wear suitable hand protection.

Remove the metal staples with pliers before the

shipping carton is opened.

The packaging material consists mainly of cardboard

and plastic film.

The packaging has to be disposed of in accordance

with the regulations of the authorities.

5.3.3 Scope of delivery

The bicycle was completely assembled in the factory

for test purposes and then dismantled for

transportation.

034-03275_1.0_23.11.2018

The bicycle is 95–98% pre-assembled. The scope of

delivery includes:

• the pre-assembled bicycle

• the front wheel

• the pedals

• quick release (optional)

• the charger

• the operating instructions.

The battery is supplied separately from the bicycle.

55

CAUTION

!

CAUTION

!

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 56 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.4 Commissioning

Fire and explosion caused by incorrect charger

Batteries which are recharged with an unsuitable

charger may become damaged internally. This may

result in fire or an explosion.

Only ever use the battery with the supplied charger.

Mark the supplied charger and these operating

instructions clearly to prevent mix-ups – with the

bicycle frame number or type number, for example .

Burns from hot drive

The drive cooler can become extremely hot during use.

Contact may cause burns.

Leave the drive unit to cool before cleaning.

Since initial commissioning of the bicycle requires

special tools and specialist knowledge, only trained

specialist staff may perform initial commissioning.

56

Experience has shown that a bicycle which has not yet

been sold, is spontaneously handed to consumers as

soon as it appears ready to ride.

For this reason, every bicycle must be prepared, so

that it is fully ready for use immediately after being

assembled.

Staff should work through the initial commissioning

check list to prepare the bicycle, so that it is ready

to ride.

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 57 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Initial commissioning check list

Check battery.

The battery is partially charged when delivered. Fully charge the

battery to ensure full power.

Mount the wheels, quick release and pedals.

Re-adjust the quick release clamping force if necessary.

Thoroughly degrease the brake discs in disc brakes or the brake

sides and linings in rim brakes with brake cleaner or spirit.

Place handlebars, stem and saddle in the functional position

and check they are firmly in place.

Check all the components to make sure that they are firmly in

place. Check all the settings and the tightening torque on the

axle nuts.

Check the entire cable harness to make sure that it is routed

properly:

• You must prevent the cable harness from coming into

contact with moving parts.

• The cable routes must be smooth and free from sharp edges.

• Moving parts must not apply any pressure or tension to the

cable harness.

034-03275_1.0_23.11.2018

Check the drive system, the light equipment and the brakes to

make sure that they are fully functional and effective.

Adjust the headlight.

Set the drive system has to the national language and the

appropriate system of measurement.

Check the software version of the drive system and update it as

necessary.

Take a test drive to check the brake system, gear shift and the

electric drive system.

57

WARNING

!

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 58 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.4.1 Checking the battery

Fire and explosion due to defective battery

The safety electronics on damaged or faulty batteries

may fail. The residual voltage can cause a short

circuit. The battery may self-ignite and explode.

Never charge a defective battery.

The battery must be checked before it is charged for

the first time.

Press the On-Off button (battery).

If none of the LEDs on the charge status indicator

light up, the battery may be damaged.

The battery can be charged if at least one, but not

all, of the LEDs on the charge status indicator is lit

up. Fully charge the battery before initial

commissioning in order to ensure that the full

capacity of the battery is available.

58

After initial commissioning and before every further

use, the battery is switched on using the On-Off

button.

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 59 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.5 Mounting the wheel in the Suntour fork

Alternative

5.3.5.1 Mounting the wheel with screw-on axle (15 mm)

Alternative

Insert the axle completely on the drive side.

Figure 19: Fully inserting the axle

Tighten the axle with a 5 mm hexagon socket

spanner to 8–10 Nm.

Figure 20: Tightening the axle

034-03275_1.0_23.11.2018

59

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 60 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Insert the securing screw on the non-drive side.

Figure 21: Pushing the quick release lever into the axle

Tighten the securing screw with a 5 mm hexagon

socket spanner to 5–6 Nm.

The lever is mounted.

Figure 22: Tightening the securing screw

60

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 61 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.5.2 Mounting the wheel with screw-on axle (20 mm)

Alternative

Insert the axle completely on the drive side.

Figure 23: Tightening the inserted axle

Tighten the securing clip with a 4 mm hexagon

socket spanner to 7 Nm.

Figure 24: Tightening the axle

034-03275_1.0_23.11.2018

61

CAUTION

!

CAUTION

!

CAUTION

!

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 62 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.5.3 Mounting the wheel with a quick release axle

Alternative

Crash caused by loose quick release axle

A faulty or incorrectly installed quick release axle may

become caught in the brake disc and block the wheel.

This will cause a crash.

Never fit a defective quick release axle.

Crash caused by faulty or incorrectly installed

quick release axle

The brake disc becomes very hot during operation.

Parts of the quick release axle may become damaged

as a result. The quick release axle becomes loose.

This will result in a crash and injuries.

The quick release axle and the brake disc must be

opposite one another.

Crash caused by incorrectly set quick release axle

62

Insufficient clamping force will cause a detrimental

transmission of force. The suspension fork or the quick

release axle may break. This will result in a crash and

injuries.

Never fasten a quick release axle with a tool, such

as a hammer or pliers.

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 63 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Insert the axle into the hub on the drive side.

Clamping version II.

Figure 25: Pushing the axle into the hub

Tighten the axle with the red handle.

Figure 26: Tightening the axle

034-03275_1.0_23.11.2018

63

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 64 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Push the quick release lever into the axle.

Figure 27: Pushing the quick release lever into the axle

Reverse the quick release lever.

The lever is secured.

Figure 28: Securing the lever

64

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 65 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Check the position and clamping force of the quick

release lever. The quick release lever must be flush

with the lower housing. You must be able to see a

slight impression on the palm of your hand when

you close the quick release lever.

Figure 29: Perfect position for the clamping lever

Use a 4 mm hexagon socket spanner to adjust the

clamping lever clamping force if required.

Afterwards, check the quick release lever position

and clamping force.

Figure 30: Adjusting the quick release clamping force

034-03275_1.0_23.11.2018

65

CAUTION

!

CAUTION

!

CAUTION

!

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 66 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.6 Mounting the wheel with a quick release

Alternative

Crash caused by unfastened quick release

A faulty or incorrectly installed quick release may

become caught in the brake disc and block the wheel.

This will cause a crash.

Never fit a defective quick release.

Crash caused by faulty or incorrectly installed

quick release

The brake disc becomes very hot during operation.

Parts of the quick release may become damaged as a

result. The quick release comes loose. This will result

in a crash and injuries.

The front wheel quick release lever and the brake

disc must be situated on opposite sides.

Crash caused by incorrectly set clamping force

66

Excessively high clamping force will damage the quick

release and cause it to lose its function.

Insufficient clamping force will cause a detrimental

transmission of force. The suspension fork or the quick

release may break. This will result in a crash and

injuries.

Never fasten a quick release using a tool (e.g.

hammer or pliers).

Only use the clamping lever with the specified set

clamping force.

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 67 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Before mounting, ensure that the quick release

flange is extended. Open the lever completely.

Figure 31: Open and closed flange

Push in the quick release until you hear a clicking

sound. Make sure that the flange is extended.

Figure 32: Pushing the quick release in

034-03275_1.0_23.11.2018

67

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 68 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Adjust the clamping with a half-open clamping lever

until the flange reaches the fork end.

Figure 33: Adjusting the clamping

Fully close the quick release. Check the quick

release to ensure it is firmly in place and adjust on

the flange if necessary.

The lever is secured.

Figure 34: Closing the quick release

68

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 69 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.7 Mounting the wheel in the FOX fork

Alternative

5.3.7.1 Mounting the wheel with the quick release (15 mm)

Alternative

The procedure for installing the 15 x 100 mm and

15 x 110 mm quick releases is the same.

Place the front wheel in the fork ends of the fork.

Push the axle through the fork end on the non-drive

side and hub.

Figure 35: Pushing the quick release in

Open the axle lever.

Turn the axle five to six complete revolutions

clockwise into the axle nut.

Close the quick release. The lever must be

tensioned to the point that it leaves a mark on your

hand.

034-03275_1.0_23.11.2018

69

1-20 mm

1

2

3

4

5

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 70 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

The lever must be 1 to 20 mm ahead of the fork leg

in the closed position.

Figure 36: Spacing between lever and fork leg

If the lever is tensioned too little or too much when

closed in the recommended position (1 to 20 mm

ahead of the fork), the quick release must be

adjusted.

5.3.7.2 Adjusting the FOX quick release

Figure 37: Structure of quick release from rear with (1) axle nut lock, (2) axle

nut securing screw, (3) directional arrow, (4) axle setting value

and (5) axle nut

70

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 71 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Record the axle setting value (4) indicated by the

directional arrow (3).

Loosen the axle nut securing screw (2) with a

2.5 mm hex key by approx. four revolutions, but do

not remove the screw completely.

Turn the quick release lever to the open position

and loosen the axle by approx. four revolutions.

Press the axle inward from the side of the open

lever. This pushes out the axle nut securing screw

so that you can turn it out of the way.

Push the axle further forward and turn the axle nut

clockwise to increase the lever tension or anticlockwise to reduce the lever tension.

Reinsert the axle nut lock and tighten the screw to

0.9 Nm (8 in-lb).

034-03275_1.0_23.11.2018

Repeat the steps for installing the axle to check

proper installation and correct adjustment.

71

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 72 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.7.3 Mounting the wheel with Kabolt axles

Alternative

The procedure for installing the 15 x 100 mm and

15 x 110 mm Kabolt axles is the same.

Place the front wheel in the fork ends of the fork.

Push the Kabolt axle through the fork end on the

non-drive side and hub.

Figure 38: Pushing the Kabolt axle in

Tighten the Kabolt axle screw to 17 Nm (150 in-lb)

with a 6 mm hex key.

72

034-03275_1.0_23.11.2018

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 73 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

5.3.7.4 Checking the stem and handlebars

Checking connections

Stand in front of the bicycle to check whether the

handlebars, stem and fork shaft are firmly attached

to one another. Clamp the front wheel between

your legs. Grasp the handlebar grips. Try to twist

the handlebars towards the front wheel.

The stem must not move or twist.

Firm hold

Place your entire body weight on the handlebars

with the quick release lever closed to check that the

stem is firmly in place.

The handlebars shaft must not move downwards in

the fork shaft.

034-03275_1.0_23.11.2018

If the handlebars shaft should move in the fork

shaft, increase the quick release lever tensioning.

To do so, turn the knurled nut slightly in a clockwise

direction with the quick release lever open.

Close the lever and check the stem is firmly in

position.

73

EN_034-03275_1.0_0.01_09.18_BULLS FAZUA_Inhalt.book Page 74 Friday, November 23, 2018 1:44 PM

Transportation, storage and assembly

Checking the headset backlash

To check the handlebar headset backlash, close

the quick release lever on the stem. Place the

fingers of one hand on the upper headset cup, pull

the front wheel brake with the other hand and try to

push the bicycle backwards and forwards.

The headset cup halves must not move towards