Page 1

Gas Analysis

Sample gas cooler

TC-Standard (+) X2

Installation and Operation Instructions

Original instructions

BE440023

10/2018

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

E-Mail: analyse@buehler-technologies.com

Internet: www.buehler-technologies.com

Page 2

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

Internet: www.buehler-technologies.com

E-Mail: analyse@buehler-technologies.com

Read this instruction carefully prior to installation and/or use. Pay attention particularly to all advises and safety instructions to prevent injuries. Bühler Technologies can not be held responsible for misusing

the product or unreliable function due to unauthorised modifications.

All rights reserved. Bühler Technologies GmbH 2019

Document information

Document No..........................................................BE440023

Version..........................................................................10/2018

Page 3

TC-Standard (+) X2

Contents

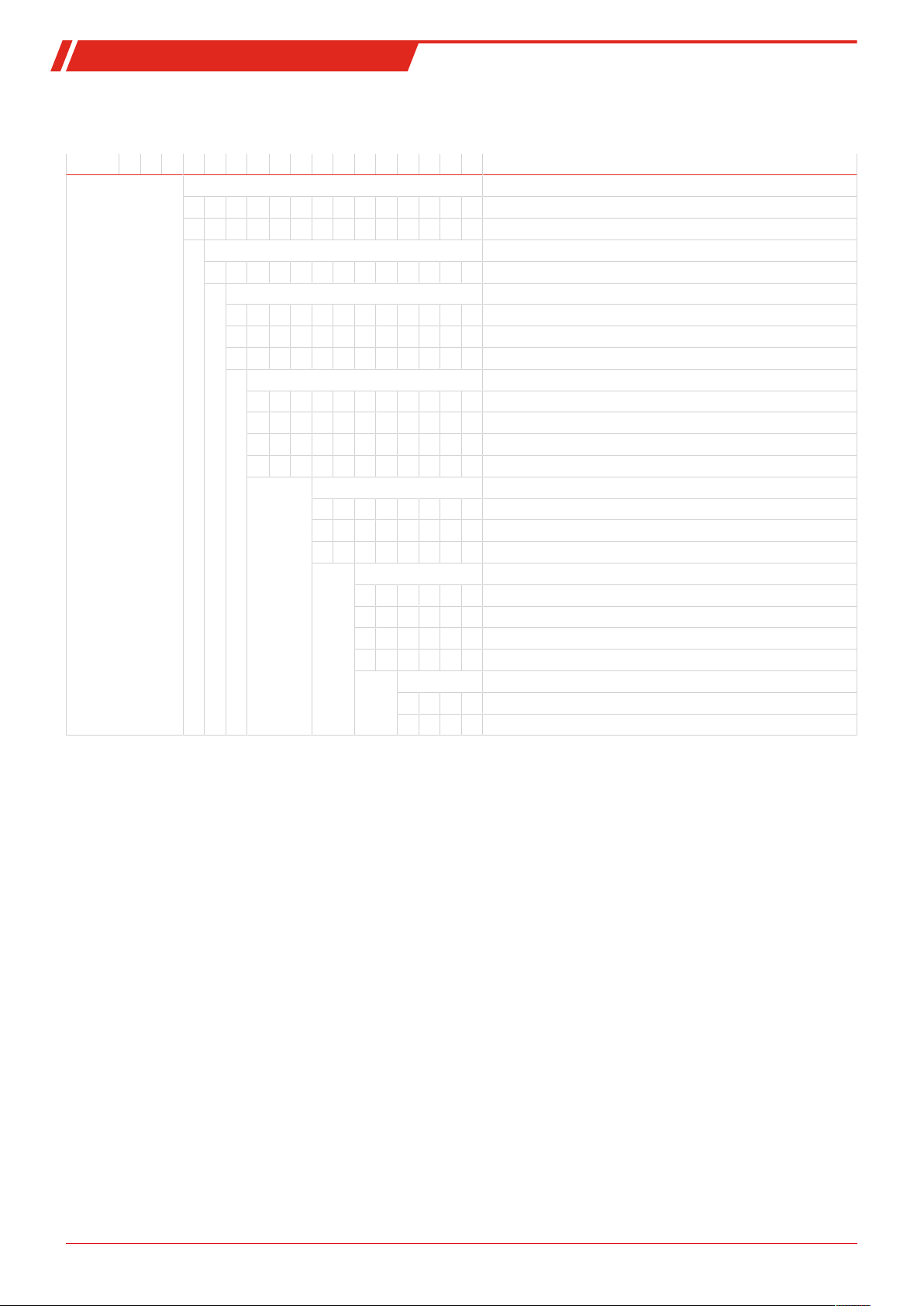

1 Introduction..................................................................................................................................................................................................................... 3

1.1 Intended use .........................................................................................................................................................................................................3

1.2 Overview ................................................................................................................................................................................................................3

1.3 Type plate ..............................................................................................................................................................................................................4

1.4 Scope of delivery.................................................................................................................................................................................................. 4

1.5 Ordering instructions ........................................................................................................................................................................................ 5

1.5.1 Gas cooler models with one heat exchanger ...............................................................................................................................5

1.5.2 Gas cooler models with two heat exchangers ............................................................................................................................ 6

1.5.3 Gas cooler model with two heat exchangers in series ..............................................................................................................7

2 Safety instructions.........................................................................................................................................................................................................8

2.1 Important notices................................................................................................................................................................................................8

2.2 General hazard warnings .................................................................................................................................................................................9

3 Transport and storage .................................................................................................................................................................................................11

4 Installation and connection.......................................................................................................................................................................................12

4.1 Installation site requirements....................................................................................................................................................................... 12

4.2 Installation .......................................................................................................................................................................................................... 12

4.2.1 Connecting the filter gas connections (optional) ..................................................................................................................... 12

4.2.2 Flow adapter connection (optional).............................................................................................................................................. 12

4.2.3 Connecting the moisture detector (option)................................................................................................................................12

4.2.4 Peristaltic pump connector (optional) ......................................................................................................................................... 13

4.2.5 Connecting the heat exchanger .....................................................................................................................................................13

4.3 Electrical connections ...................................................................................................................................................................................... 14

4.4 Signal outputs.....................................................................................................................................................................................................15

5 Operation and control .................................................................................................................................................................................................17

5.1 Description of functions...................................................................................................................................................................................17

5.2 Delta T control option .......................................................................................................................................................................................17

5.3 Use of menu functions .................................................................................................................................................................................... 18

5.3.1 Lock Menu.............................................................................................................................................................................................18

5.3.2 Menu navigation overview..............................................................................................................................................................19

5.4 Description of menu functions ..................................................................................................................................................................... 21

5.4.1 Main menu ...........................................................................................................................................................................................21

5.4.2 Submenu 1 ............................................................................................................................................................................................ 21

5.4.3 Submenu 1 (global settings)........................................................................................................................................................... 22

5.4.4 Set favourite menu ............................................................................................................................................................................25

6 Maintenance..................................................................................................................................................................................................................26

7 Service and repair......................................................................................................................................................................................................... 27

7.1 Troubleshooting ................................................................................................................................................................................................ 27

7.1.1 Error messages on the display....................................................................................................................................................... 28

7.2 Safety instructions ............................................................................................................................................................................................29

7.3 Cleaning and removal of the heat exchanger...........................................................................................................................................30

7.4 Replacing the hoses of the peristaltic pump (option) ............................................................................................................................30

7.5 Replacing the filter element (option)..........................................................................................................................................................30

7.6 Drying of the moisture detector (option)....................................................................................................................................................31

7.7 Calibration of the moisture detector (option)...........................................................................................................................................31

7.8 Spare parts and accessories ............................................................................................................................................................................31

7.8.1 Consumables and accessories ........................................................................................................................................................32

8 Disposal........................................................................................................................................................................................................................... 33

9 Appendices.....................................................................................................................................................................................................................34

9.1 Gas cooler technical data ................................................................................................................................................................................34

9.2 Technical Data - Options .................................................................................................................................................................................35

9.3 Flow diagrams....................................................................................................................................................................................................36

9.4 Performance curves.......................................................................................................................................................................................... 37

9.5 Heat exchanger ..................................................................................................................................................................................................38

iBühler Technologies GmbHBE440023 ◦ 10/2018

Page 4

TC-Standard (+) X2

9.5.1 Heat exchanger description ........................................................................................................................................................... 38

9.5.2 Heat exchanger overview................................................................................................................................................................ 39

9.6 Dimensions (mm)............................................................................................................................................................................................. 40

10 Attached documents................................................................................................................................................................................................... 41

ii Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 5

TC-Standard (+) X2

1 Introduction

1.1 Intended use

This unit is intended for industrial use in gas analysis systems. It's an essential component for conditioning the sample gas to

protect the analysis instrument from residual moisture in the sample gas.

This device may be operated in a zone 2, explosion class IIC (ATEX & IECEx), explosive gas atmosphere which is rarely and only

temporarily explosive and in Class I, Division 2 (US & Canada).

Optional mounting of various add-on units may limit the area of application of this device.

Cooler with certificate Canada and IECEx

The equipment shall be mounted within a tool-secured IP54 enclosure.

Cooler with certificate USA

The equipment shall be mounted within a tool-secured IP54 enclosure which is capable of accepting one or more of the

ClassIDivision2 wiring methods per the National Electric Code (ANSI/NFPA70).

Cooler with certificate ATEX

The equipment shall be mounted within a IP54 enclosure in accordance with EN60079-15, and in a tool-secured enclosure which

meets the requirements of EN60079-0 and EN60079-15.

Please note the specifications in the data sheet on the specific intended use, existing material combinations, as well as pressure

and temperature limits.

1.2 Overview

The TC-StandardX2 series was designed specifically for high cooling capacities and high ambient temperatures.

The TC-Standard+X2 series was designed specifically for the requirements in so-called automated measuring systems(AMS) according to EN15267-3. The series connection of the heat exchangers will cool in two cycles to minimise wash out effects.

The Peltier cooler is distinguished by two types according to cooling capacity or operation temperature. This classification is reflected in the type designation. The exact item number of the model defined by you is determined by the model code in the category ordering information.

Application Standard applications

Operation temperature 40 °C 50 °C

1 heat exchanger TC-Standard 6111 X2 TC-Standard 6112 X2 3rd digit=1

2 heat exchangers TC-Standard 6121 X2 TC-Standard 6122 X2 3rd digit=2

2 heat exchangers in series TC-Standard+ 6121 X2 TC-Standard+ 6122 X2 3rd digit=2

4th digit=1 4th digit=2

Additional components which every conditioning system should feature can optionally be integrated:

– Peristaltic pump for condensate separation,

– Filter,

– Moisture detector.

This allows for various configurations of cooler and options. Here the approach is to simplify creating a complete system in a

cost-efficient way through pre-installed components with hoses connected. We further paid attention to easy access to wear

parts and consumables.

3Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 6

TC-Standard (+) X2

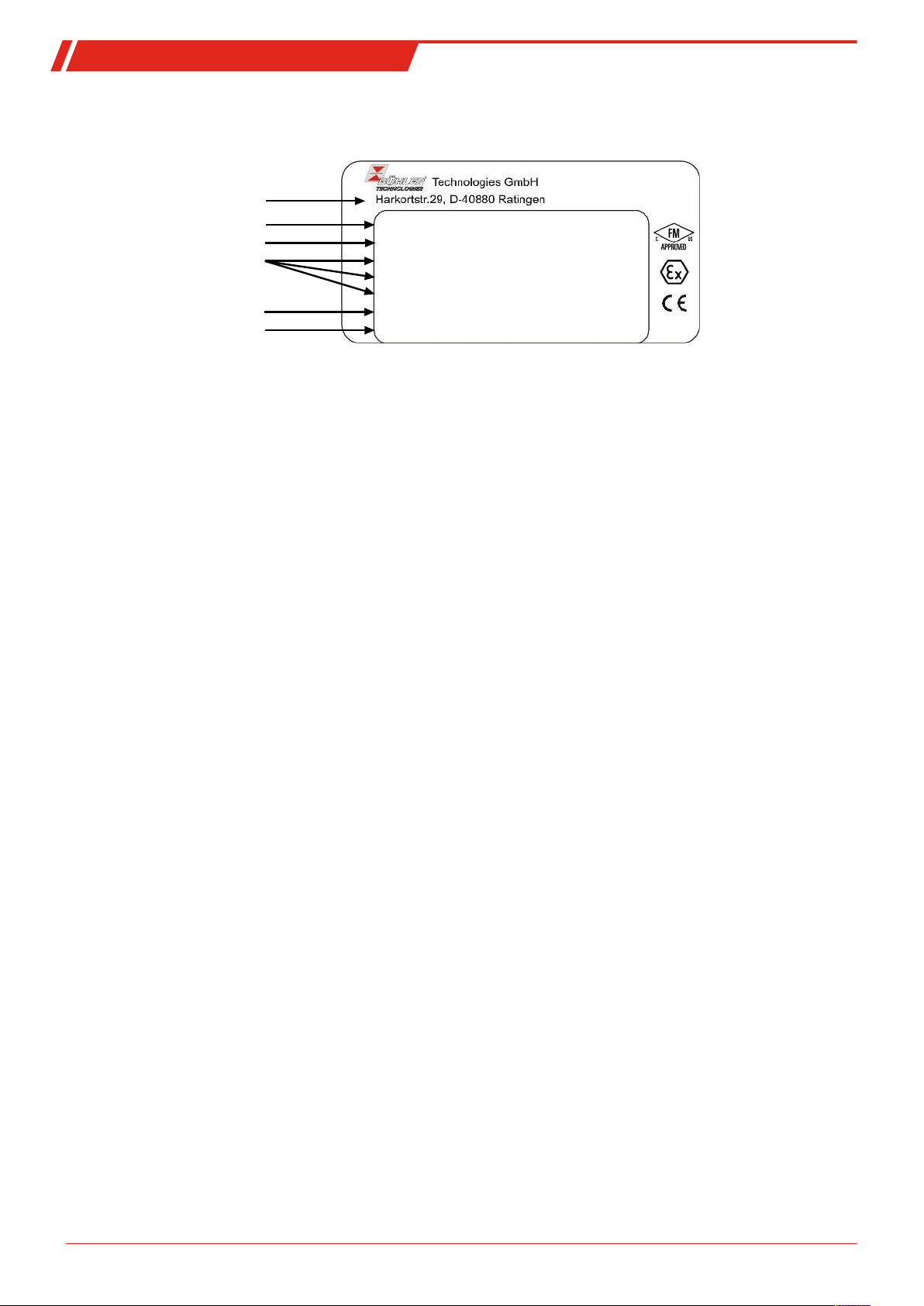

Manufacturer and address

Type designation and voltage

Serial no., Item no.

Blast protection markings

(Atex, IECex and US/Canada)

Description

Year of manufacture

TC-Standard 230 V, 50/60Hz, 130W

101001081115 449621112412510011010

FM18ATEX0012X II 3 G Ex ec nC IIC T4 Gc

IECEx FMG 18.0005X Ex ec nC IIC T4 Gc

USA/Canada: CL I DIV 2 GP ABCD

Tamb: 0°C to 50°C

Year: 2018 Manual doc.no.: BX440023

1.3 Type plate

Example:

1.4 Scope of delivery

– Cooler

– Product documentation

– Connection-/mounting accessories (optional)

4 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 7

TC-Standard (+) X2

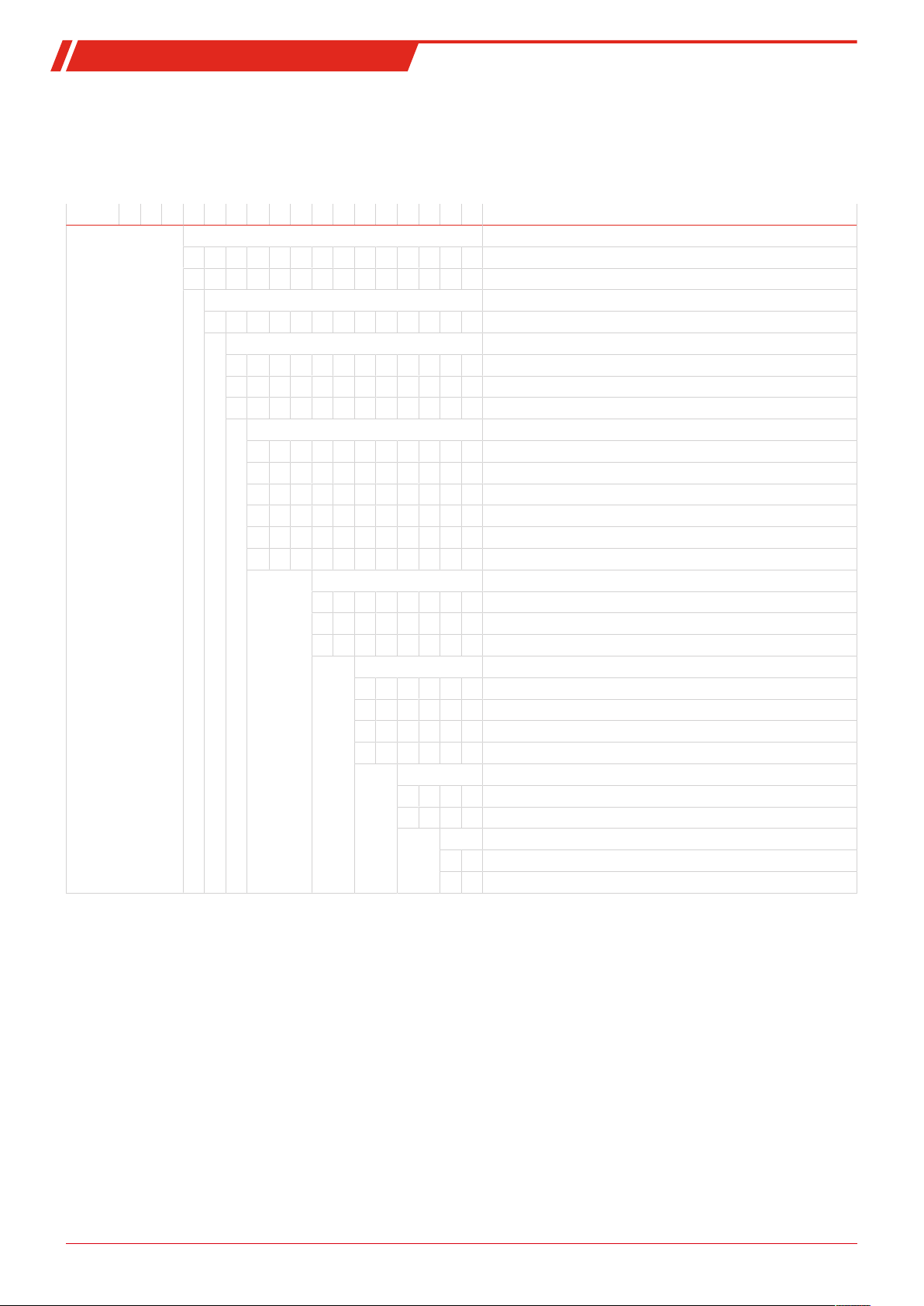

1.5 Ordering instructions

1.5.1 Gas cooler models with one heat exchanger

The item number is a code for the configuration of your unit. Please use the following model code:

4496 2 1 1 X 2 X 1 X X X 0 X X X 0 X 0 Product characteristic

Gas cooler models (with 1 heat exchanger)

1 TC-Standard 6111 X2: Ambient temperature 40 °C

2 TC-Standard 6112 X2: Ambient temperature 50 °C

Certifications

2 for explosive areas

Supply voltage

1 115 VAC, 50/60 Hz

2 230 V AC, 50/60 Hz

4 24 VDC

Heat exchanger

1 1 0 Stainless steel, PTS, metric

1 1 5 Stainless steel, PTS-I, US fitting

1 2 0 Duran glass, PTG, metric

1 2 5 Duran glass, PTG, US fitting

1 3 0 PVDF, PTV, metric

1 3 5 PVDF, PTV-I, US fitting

Peristaltic Pumps *

0 0 without peristaltic pump

1 0 CPsingle X2 with hose nipple, angled

3 0 CPsingle X2 with screw connection

Moisture detector / filter

0 0 without filter, without moisture detector

0 1 without filter, 1 moisture detector with adapter

1 0 1 filter, without moisture detector

1 1 1 filter with built-in moisture detector

Status Outputs

0 0 status output only

1 0 Analog output option, add-on

Delta T-control

0 0 without Delta T-control

1 0 Delta T-control option

* 24 V DC version not available

5Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 8

TC-Standard (+) X2

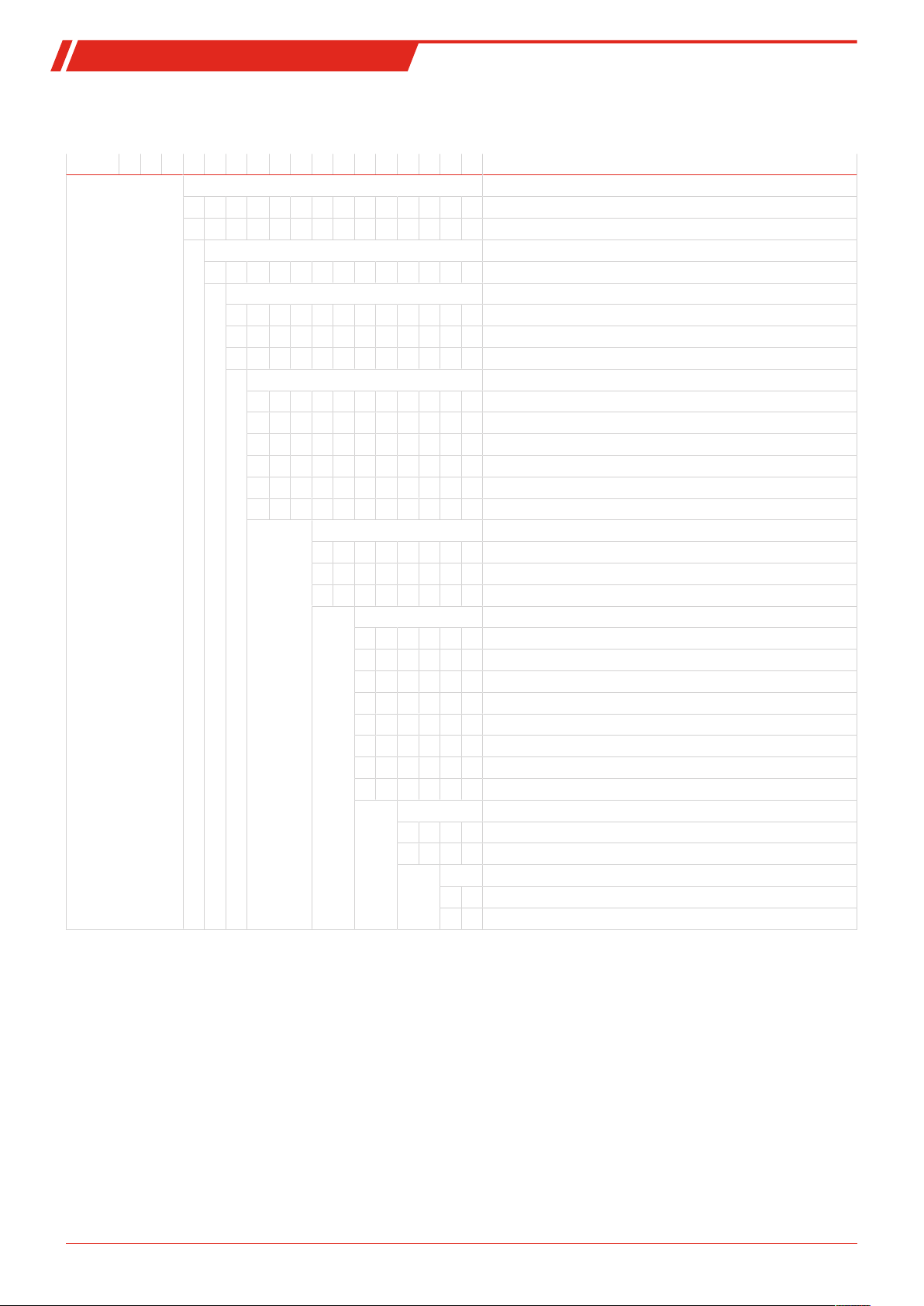

1.5.2 Gas cooler models with two heat exchangers

The item number is a code for the configuration of your unit. Please use the following model code:

4496 2 1 2 X 2 X 2 X X X 0 X X X 0 X 0 Product characteristic

Gas cooler models (with 2 heat exchangers)

1 TC-Standard 6121 X2: Ambient temperature 40 °C

2 TC-Standard 6122 X2: Ambient temperature 50 °C

Certifications

2 for explosive areas

Supply voltage

1 115 VAC, 50/60 Hz

2 230 V AC, 50/60 Hz

4 24 VDC

Heat exchanger

2 1 0 Stainless steel, 2 MTS, metric

2 1 5 Stainless steel, 2 MTS-I, US fitting

2 2 0 Duran glass, 2 MTG, metric

2 2 5 Duran glass, 2 MTG, US fitting

2 3 0 PVDF, 2 MTV, metric

2 3 5 PVDF, 2 MTV-I, US fitting

Peristaltic Pumps *

0 0 without peristaltic pump

2 0 CPdouble X2 with hose nipple, angled

4 0 CPdouble X2 with screw connection

Moisture detector / filter

0 0 without filter, without moisture detector

0 1 without filter, 1 moisture detector with adapter

0 2 without filter, 2 moisture detectors with adapter

1 0 1 filter, without moisture detector

1 1 1 filter with built-in moisture detector

2 0 2 filters, without moisture detector

2 1 2 filters, 1 moisture detector

2 2 2 filters, 2 moisture detectors

Status Outputs

0 0 status output only

1 0 Analog output option, add-on

Delta T-control

0 0 without Delta T-control

1 0 Delta T-control option

* 24 V DC version not available

6 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 9

TC-Standard (+) X2

1.5.3 Gas cooler model with two heat exchangers in series

The item number is a code for the configuration of your unit. Please use the following model key:

4496 2 1 2 X 2 X 2 X X X 0 X X X 0 X 0 Product characteristic

Gas cooler models (with 2 heat exchangers in series)

1 TC-Standard+ 6121 X2: Ambient temperature 40 °C

2 TC-Standard+ 6122 X2: Ambient temperature 50 °C

Certifications

2 for explosive areas

Supply voltage

1 115 V AC, 50/60 Hz

2 230 V AC, 50/60 Hz

4 24 V DC

Heat exchanger

2 2 2 Duran glass, 2x MTG-2, metric

2 2 7 Duran glass, 2x MTG-2, US fitting

2 3 2 PVDF, 2x MTV-2, metric

2 3 7 PVDF, 2x MTV-2-I, US fitting

Peristaltic Pumps

0 0 without peristaltic pump

2 0 CPdouble X2 with hose nipple, angled

4 0 CPdouble X2 with screw connection

Moisture detector / filter

0 0 without filter, without moisture detector

0 1 without filter, 1 moisture detector with adapter

1 0 1 filter, without moisture detector

1 1 1 filter with built-in moisture detector

Status outputs

0 0 status output only

1 0 Analog output option, add-on

*

* 24 V DC version not available

7Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 10

TC-Standard (+) X2

DANGER

WARNING

CAUTION

NOTICE

2 Safety instructions

2.1 Important notices

NOTICE

The device is suitable for hazardous areas.

This unit may only be used if:

– The product is being used under the conditions described in the operating- and installation instructions, used according to

the nameplate and for applications for which it is intended. Any unauthorized modifications to the unit will void the warranty provided by Bühler Technologies GmbH,

– The specifications and markings in the type plate must be observed,

– The threshold values in the data sheet and the instructions must be observed,

– Monitoring equipment / protection devices must be connected correctly,

– Service and repair work not described in these instructions are performed by Bühler Technologies GmbH,

– Genuine replacement parts must be used.

Erecting electrical systems in explosive areas requires compliance with the following national regulations:

– IEC/EN60079-14

– National electric code (NEC)

– Canadian electric code (CEC)

Additional national regulations pertaining to initial operation, operation, maintenance, repairs and disposal must be observed.

These operating instructions are a part of the equipment. The manufacturer reserves the right to change performance-, specification- or technical data without prior notice. Please keep these instructions for future reference.

Signal words for warnings

Signal word for an imminent danger with high risk, resulting in severe injuries or death if not avoided.

Signal word for a hazardous situation with medium risk, possibly resulting in severe injuries or death if not

avoided.

Signal word for a hazardous situation with low risk, resulting in damaged to the device or the property or

minor or medium injuries if not avoided.

Signal word for important information to the product.

8 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 11

TC-Standard (+) X2

Warning signs

These instructions use the following warning signs:

Warns of a general hazard General notice

Warns of voltage Unplug from mains

Warns not to inhale toxic gasses Wear respiratory equipment

Warns of corrosive liquids Wear a safety mask

Warns of explosive areas Wear gloves

Warns of hot surfaces

2.2 General hazard warnings

The equipment must be installed by a professional familiar with the safety requirements and risks.

Be sure to observe the safety regulations and generally applicable rules of technology relevant for the installation site. Prevent

malfunctions and avoid personal injuries and property damage.

The operator of the system must ensure:

– Safety notices and operating instructions are available and observed,

– The respective national accident prevention regulations are observed,

– The permissible data and operational conditions are maintained,

– Safety guards are used and mandatory maintenance is performed,

– Legal regulations are observed during disposal.

Maintenance, Repair

Please note during maintenance and repairs:

– Repairs to the unit must be performed by Bühler authorised personnel.

– Only perform conversion-, maintenance or installation work described in these operating and installation instructions.

– Always use genuine spare parts.

Always observe the applicable safety and operating regulations in the respective country of use when performing any type of

maintenance.

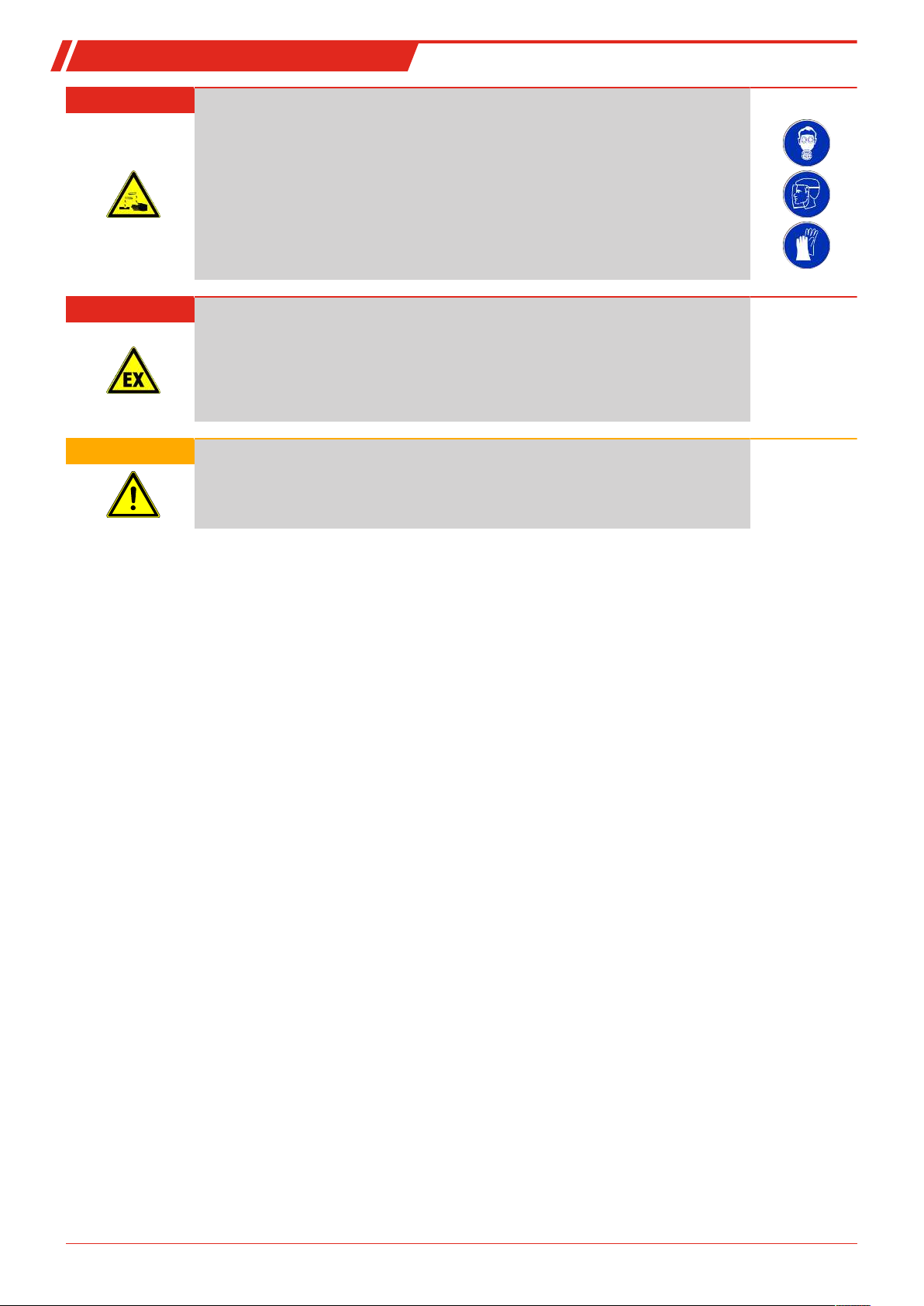

DANGER Electrical voltage

Electrocution hazard.

a) Disconnect the device from power supply.

b) Make sure that the equipment cannot be reconnected to mains unintentionally.

c) The device must be opened by trained staff only.

d) Regard correct mains voltage.

9Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 12

TC-Standard (+) X2

DANGER Toxic, corrosive gas/condensate

Sample gas/condensate may be hazardous to health.

a) If necessary, ensure a safe gas/condensate discharge.

b) Always disconnect the gas supply when performing maintenance or repairs.

c) Protect yourself from toxic/corrosive gasses/condensate when performing mainten-

ance. Wear appropriate protective equipment.

DANGER Explosion hazard

Life and explosion risk may result from gas leakage due to improper use.

a) Use the devices only as described in this manual.

b) Regard the process conditions.

c) Check tubes and hoses for leakage.

WARNING Risk of breakage

a) Protect the equipment against being hit.

b) Protect the device against falling objects.

10 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 13

TC-Standard (+) X2

3 Transport and storage

Only transport the product inside the original packaging or a suitable alternative.

The equipment must be protected from moisture and heat when not in use. It must be stored in a covered, dry and dust-free

room at a temperature of -20 °C to 60 °C (-4 °F to 140 °F).

11Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 14

TC-Standard (+) X2

4 Installation and connection

4.1 Installation site requirements

The unit is only intended for wall-mounted use in enclosed areas. Adequate protection from the weather must be provided

when used outdoors.

Install the unit leaving enough room below the cooler to discharge the condensate. Leave room above for the gas supply.

Be sure to maintain the approved ambient temperature. Do not obstruct the convection of the cooler. The vents must have

enough room to the next obstacle. The distance must especially be a minimum of 10 cm on the air outlet side.

Ensure adequate ventilation when installing in enclosed housings, e.g. analyser cabinets. If the convection is inadequate, we recommend aerating the cabinet or installing a fan to lower the inside temperature.

4.2 Installation

Run the gas supply to the cooler with a downward slope. The gas inputs are marked in red and additionally labelled "IN".

If a large amount of condensate accumulates, we recommend using a condensate trap with automatic condensate drain. Our

condensate drains, 11LDV38, AK20, AK5.5 OR AK5.2, are suitable.

Glass vessels and automatic condensate drains are available for draining condensate for external mounting below the unit.

When using automatic condensate drains, the sample gas pump must be installed upstream of the cooler (pressure operation)

to ensure proper function of the condensate drain.

If the sample gas pump is located at the cooler outlet (suction operation), we recommend using glass condensate traps or peristaltic pumps.

Connecting the condensate drain

Depending on the material, build a connecting line with fittings and tubing or hose between the heat exchanger and condensate drain. For stainless steel the condensate drain can be hung directly from the connecting tube, for hoses the condensate drain

must be secured separately using a clamp.

The condensate drain can be mounted directly to the heat exchanger.

Condensate lines must always be installed with a slope and a minimum inside diameter of 6 mm (1/4").

The MTG heat exchanger (in coolers with 2 heat exchangers) can only be operated with peristaltic pumps.

4.2.1 Connecting the filter gas connections (optional)

The connection between the heat exchanger outlet and the filter inlet already has tubing. The connection G1/4 or NPT 1/4" (filter

head marked NPT) for the gas outlet must be carefully and properly connected using a suitable screw connection.

When ordering the cooler with the

The filter head is intended for a G1/4 internal screw thread which is plugged at the factory. To use it, unscrew the plug and screw

in a suitable screw connection. Pay attention to leaks.

NOTICE

Installing

Operating pressure ≤ 2 bar

option filter without Moisture detector

filters

limits the maximum approved

, a bypass may be connected to the filter head.

operating pressure

in the system!

4.2.2 Flow adapter connection (optional)

When ordering the cooler with the

The connection between the heat exchanger outlet and the flow adapter inlet does not have tubing included. The connection

G1/4 or NPT1/4" (flow adapter marked NPT) for the gas inlet/outlet must be carefully and properly connected using a suitable

screw connection. Here the direction of flow is not relevant.

option moisture detector without filter

, it will be factory installed inside a flow adapter.

4.2.3 Connecting the moisture detector (option)

When ordering the cooler with

installed and connected in the filter head.

12 Bühler Technologies GmbH BE440023 ◦ 10/2018

moisture detector option

, it will be factory installed inside a flow adapter, or for the

filter option

Page 15

TC-Standard (+) X2

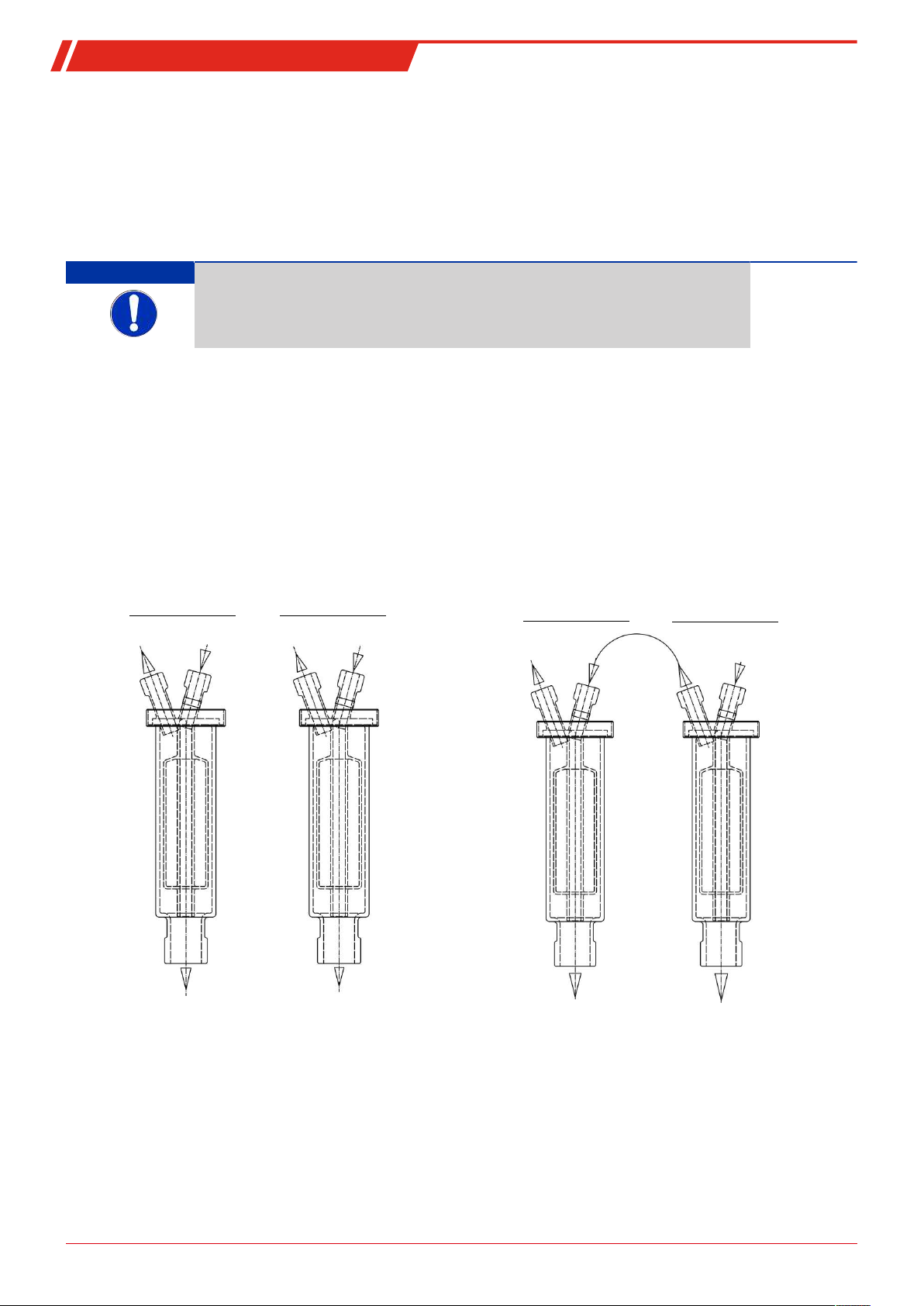

gas out

gas in

gas out

gas in

condensate out

condensate out

Heat exchanger 1

Heat exchanger 2

Gas cooler

(two single heat exchangers)

gas out

gas in

gas out

gas in

condensate out

condensate out

Heat exchanger 1

Heat exchanger 2

Gas cooler +

(two heat exchangers in series)

4.2.4 Peristaltic pump connector (optional)

Coolers ordered with attached peristaltic pump already have it installed and wired. Heat exchangers ordered at the same time

are already installed and connected to the peristaltic pump.

The ø6mm (0.24inch) hose nipple for the pump’s condensate outlet must be carefully and properly connected with a suitable

hose and hose clamp.

Versions with screw connections DN4/6 or 1/6”-1/4” are supplied with ferrule and knurled nut and must be carefully sealed

with appropriate hose.

NOTICE

Installing peristaltic

ating pressure

Operating pressure ≤ 1 bar

pumps

in the system!

CPsingle / CPdouble limits the maximum permissible

oper-

4.2.5 Connecting the heat exchanger

The picture on the left shows the schematics for connecting two separate heat exchangers.

To minimise gas wash out in the cooler, the two (identical) heat exchangers must be operated in series (right picture). This

should be done as follows:

1. Gas inlet line to red gas inlet on heat exchanger 2 (pre-cooling).

2. Connection between gas outlet on heat exchanger 2 and the red gas inlet on heat exchanger 1 (after-cooling).

3. Attaching the final gas output line to the gas outlet on heat exchanger 1.

The gas inputs are marked in red.

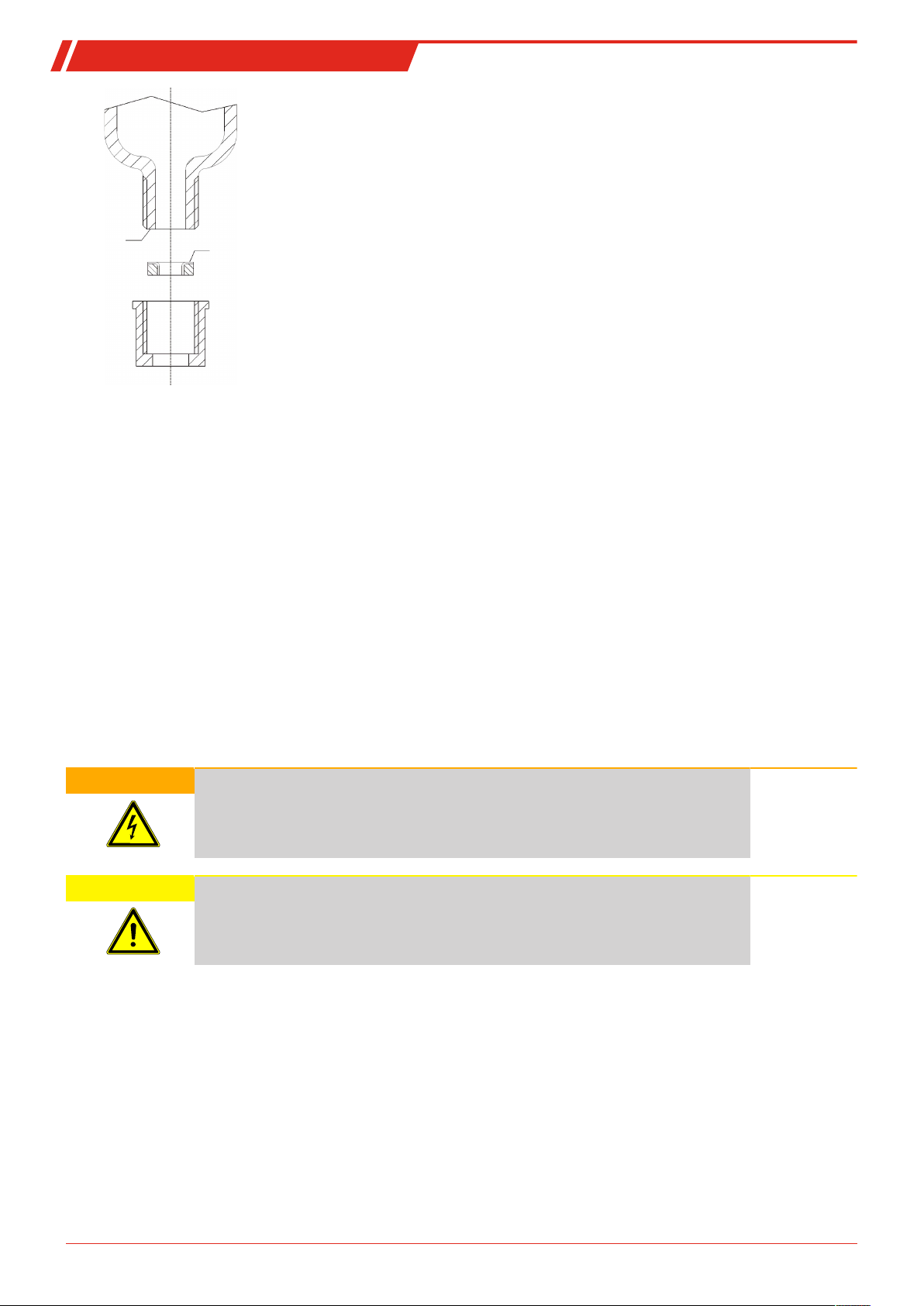

On glass heat exchangers the correct position of the seal is important when connecting the gas lines (see image). The seal consists of a silicone ring with a PTFE sleeve. The PTFE side must face the glass thread.

13Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 16

TC-Standard (+) X2

Glass

PTFE

4.3 Electrical connections

The operator must install an external separator for the device which is clearly assigned to this device.

This separator

– must be located near the device,

– must be easy for the operator to reach,

– must comply with IEC 60947-1 and IEC 60947-3,

– must separate all live conductors and the status output, and

– must not be attached to the power feed.

The mains supply of the device must be fused according to the specifications under technical data.

Potential equalization/static charge

Static charges can result in incendive sparking. Avoid static charges. Any conductive parts of the cooler must be grounded!

The housing has a connection for an earth/equipotential bonding conductor. Ensure the housing is adequately earthed (minimum conductor cross-section 4 mm2).

Particularly observe the requirements of EN 60079-14!

WARNING Hazardous electrical voltage

The device must be installed by trained staff only.

CAUTION Wrong mains voltage

Wrong mains voltage may damage the device.

Regard the correct mains voltage as given on the type plate.

14 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 17

TC-Standard (+) X2

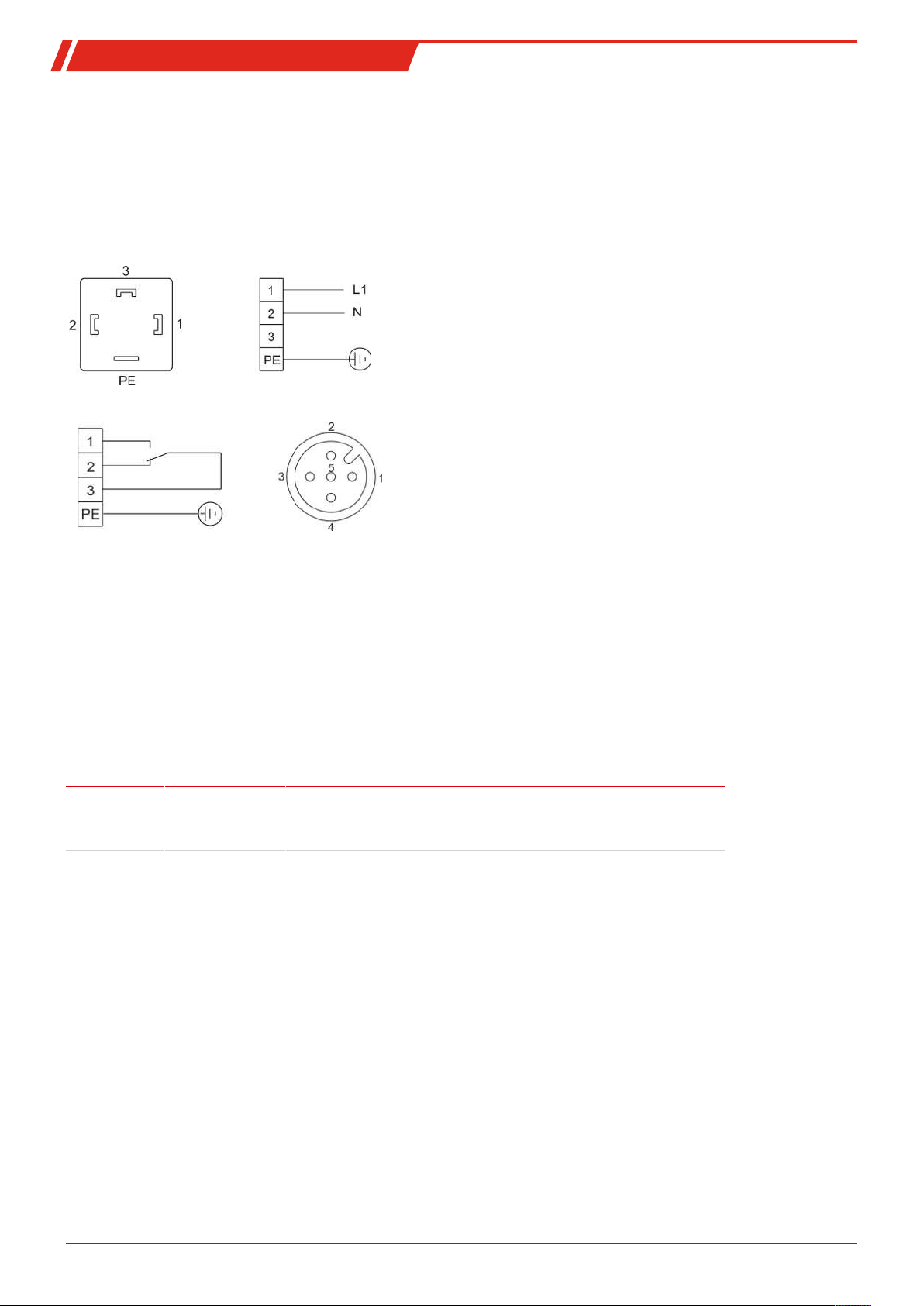

Plug numbering

Electric supply S1

115/230 V (24 V DC)

Alarm contact S2 *

Analogue output S3

1 - N/C

2 - N/C

3 - GND

4 - 4-20 mA out

5 - shield

(+24 V)

(-24 V)

*

Connection via plug

The device is equipped with connectors according to EN 175301-803 for mains and status output. If the cables are mounted properly, they cannot be interchanged. Please make sure that the connectors are remounted correctly after connecting the cable. The

following figures show the pin assignment with respect to the numbers printed on the connector.

The supply line cross-sections must be suitable for the rated current. Use a maximum line cross-section of 1.5mm² (AWG16) and

a cable diameter of 8-10mm (0.31-0.39 inch).

* When using an alarm contact connect to ≥33VAC or ≥70VDC PE voltage.

The clamping area has a diameter of 8-10mm (0.31–0.39 inch).

4.4 Signal outputs

The device provides different status signals. The maximum switching load of the alarm outputs is limited to 250VAC/150VDC,

2A, 50VA each.

An alarm is triggered by the alarm contact/status output (S2) if the temperature of the cooler is outside the specified limits. It

does not indicate if the alarm was triggered due to excess temperature or insufficient temperature.

The front film has three LEDs:

Colour Marking Function

Red S2 High/low temperature, device error

Yellow S1 --Green OP Normal operation

The LEDs OP and S2 indicate the device status similar to S2.

If the option “temperature signal” is built in, the unit has a signal output via the analogue output to indicate the actual cooler

temperature.

When the moisture detector (optional) is installed, an alarm is activated by the alarm contact/status output (S2) if the moisture

is still present in the prepared sample gas. Thereby, no distinction is made between the alarm/cable break triggered by moisture

detector 1 or 2. This information is displayed by an error message instead.

The temperature signal can be read via the panel plug (S3) using the M12x1 connector. This plug is located next to the moisture

detector connectors at the top of the cooler.

15Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 18

TC-Standard (+) X2

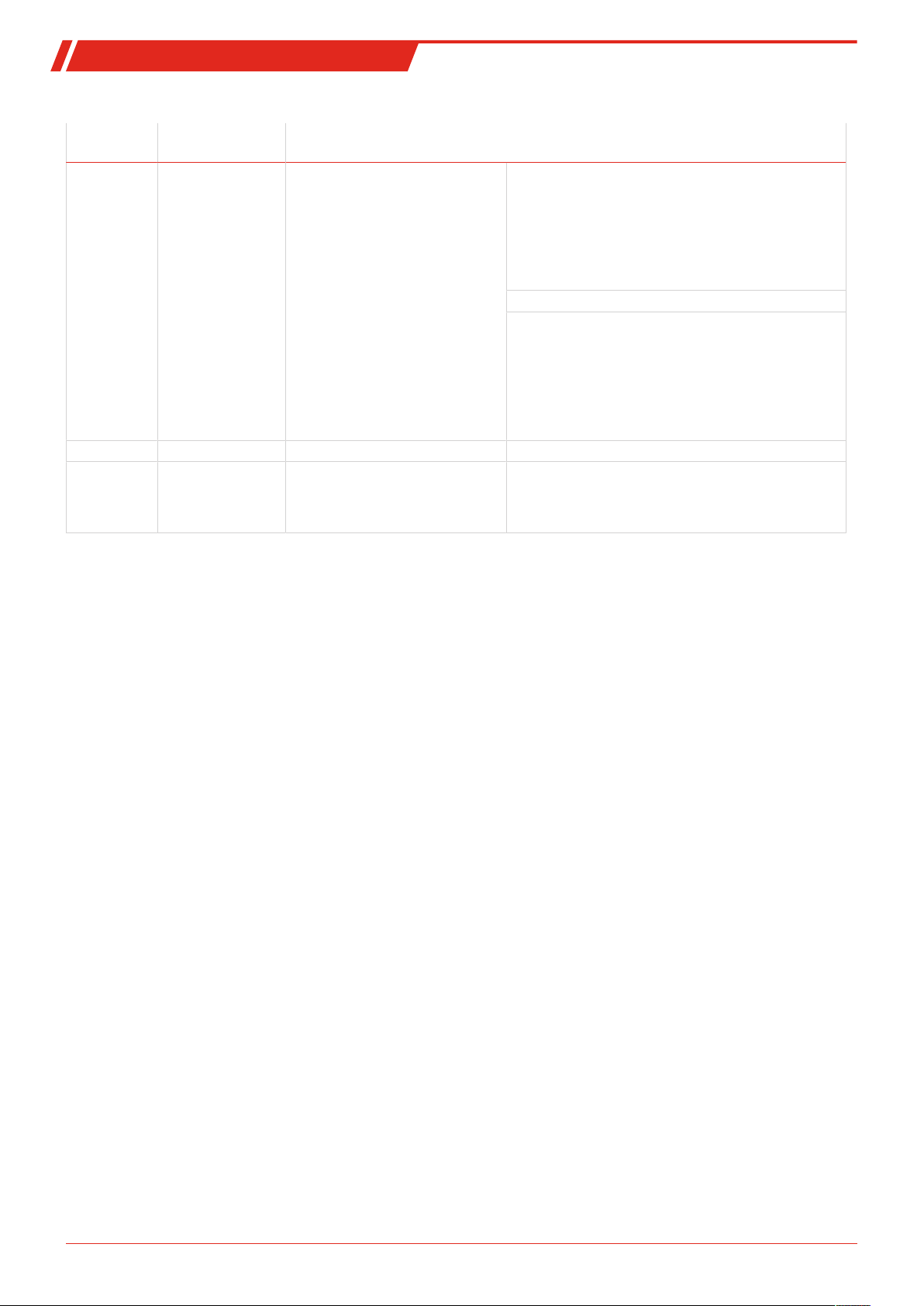

Description of signal outputs

Function / contact

type

Regarding S2) internal changeover

contact: max.

250VAC / 150VDC,

2A, 50VA

Regarding S3) 4-20mA analogue

output

(R

<500Ω)

Load

Description

the following device statuses can

be indicated via two switching

outputs:

Signalling of actual temperature

(please use shielded cables)

Contact between 3 and 2 closed (alarm)

– No mains voltage and/or actual temperature out-

side the alarm thresholds

Contact between 3 and 1 closed (ok)

– Mains voltage attached + actual temperature

within the alarm thresholds

With moisture detector option

Contact between 3 and 2 closed (alarm)

– The moisture detector registers residual humidity

in the sample gas or cable break: Error message

Contact between 1 and 3 closed (ok)

– no residual moisture in measuring gas / no cable

break

With temperature signal option

T

= -20°C ≙ (-4°F) -> 4mA/ 2 V

Cooler

T

= 5°C ≙ (41°F) -> 9mA/ 4,5 V

Cooler

T

= 60°C ≙ (140°F) -> 20mA/ 10 V

Cooler

16 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 19

TC-Standard (+) X2

5 Operation and control

NOTICE

The device must not be operated beyond its specifications.

After switching on the cooler the block temperature will be displayed. The display will flash until the block temperature has

reached the preset target value (± adjustable alarm range). The status contact is in the Alarm position.

Once the target temperature range has been reached, the temperature will continuously be displayed and the status contact

switches over.

If the display flashes during operation or an error message appears, please refer to bullet “Troubleshooting”.

Please refer to the data sheet for performance data and maximum ratings.

5.1 Description of functions

The cooler is controlled by a microprocessor. With the factory preset the control already incorporates the various characteristics

of the built-in heat exchangers.

The programmable display shows the block temperature in the selected display unit (°C/°F) (factory preset °C). Application-specific settings can easily be configured guided by the menu, using the 5 buttons. For one, this applies to the target outlet dew

point, which can be set from 2 to 20°C (36°F to 68°F) (factory preset 5°C/41°F).

And then the warning thresholds can be adjusted for low and excess temperature. These are set relative to the outlet dew point

τa setting.

For the low temperature the range is τa -1 to - 3K (at a minimum 1°C/ 34°F cooling block temperature), for the excess temperature the range is τa +1 to +7K. The factory presets for both values are 3K.

The flashing display and the status relays indicate the conditions are below or above the configured warning range (e.g. after

switching on).

The status output can e.g. be used to control the sample gas pump to allow for the gas flow to only be switched on once the permissible cooling range has been reached or shut off the pump in the event of a moisture detector alarm.

The separated condensate can be drained via connected peristaltic pumps or add-on automatic condensate drains.

Fine mesh filters can also be used, which in turn can be installed in optional moisture detectors.

The glass dome allows the dirt level of the filter element to easily be determined.

The moisture detector is easy to remove. This may be required if a condensate enters the cooler due to a malfunction and the

peristaltic pump or the automatic condensate drain is unable to remove it.

5.2 Delta T control option

Not all applications require an outlet dew point of 5°C (41°F). In some applications a higher dew point is sufficient. In other applications a stable outlet dew point doesn’t matter, it’s enough for the gas to be dry, so if the outlet dew point has an adequate

difference in temperature below the ambient temperature.

Here the electronics measure the ambient temperature and regulate the outlet dew point to an adjustable value below it. This

extends the potential cooling capacity to the limits of the heat exchanger. Here it’s important to note the outlet dew point fluctuates along with the ambient temperature and a stable dew point cannot be a prerequisite for the measurement.

The target temperature range is defined by the ambient temperature, the adjustable temperature difference and the alarm limits. If the block temperature is not within the target range with active Delta T-control, the status message "dt" will flash in the

display.

Example:

to an ambient temperature of approx. 35°C (95°F), and the safe drop is only preferred over the ambient temperature with ambient temperature peaks over 35°C (95°F). The cooling capacity specified in the cooling capacity graphs at 35°C (95°F) is then

available at above 35°C (95°F).

At a difference of 30°C (30 K/54 °F), at a set outlet dew point of 5°C (41°F) this means the dew point remains stable up

17Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 20

TC-Standard (+) X2

OK

ESC

F

Func

5.3 Use of menu functions

Brief description of the operating principle:

The unit is operated using 5 keys. Their functions are:

Button Section Functions

Display – Switches from the measurement display to the main menu

or

or

Menu – Selects the menu item displayed

Enter – Applies an edited value or a selection

Display – temporarily switches to the alternative measurement display (if option installed)

Menu – Back

Enter – Increase value or browse selection

– Note:

– Press button 1 x = changes parameter / value by one;

– Hold button = fast mode (numerical values only)

– Display flashes: modified parameter/value

– Steady display: original display/value

Display – temporarily switches to the alternative measurement display (if option installed)

Menu – Next

Enter – Reduce value or browse selection

Menu – Move one level up

Enter – Return to menu

Changes will not be saved!

– Sets a menu to favourite.

(Note: The favourite menu will also be activated with the menu locked!)

5.3.1 Lock Menu

Some menus can be locked to prevent inadvertently changing the settings of the unit. This requires setting a code. For information on setting up or disabling the menu lock please refer to "Global Settings" (toP) under menu item toP>Loc.

The menu lock is

With the menu locked, only the following menu items will be visible without entering the correct code:

Menu item Explanation

toP > unit Temperature unit selection (°C or °F).

F or Func. Accessing the Favourites menu

not

enabled at the time of delivery, all menu items can be accessed.

NOTICE!This menu may be one that is normally locked.

18 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 21

TC-Standard (+) X2

Top Settings

top

Globale Einstellungen

3

21

Eingabe

5'C

-20 . . . 60 'C

6

54

Auswahl

oP

op haLf Lo hi

9

87

10

5.3.2 Menu navigation overview

When pressing the OK button in normal mode, the display will show the prompt code if the menu is locked. Use the ▲ and ▼

buttons to enter the correct code and press OK.

If an incorrect code or no code is entered, the menu will not be unlocked and you will not be able to access all menu items.

If you forgot the password you can always enter master code 287 to access the menu; the menu will be unlocked.

The following image shows an overview of the menu structure.

Items with a dashed frame will only appear with the respective settings or with the respective status messages.

The factory defaults and settings ranges are specified in the overview as well as under the respective menu item. The factory defaults apply unless otherwise agreed.

You can cancel entries and menu selections without saving by pressing the

ESC

key.

Menu:

Parameter:

Optional menu

navigation:

1.

Menu designation

2.

Display

3.

Brief description

4.

Value input

5.

Factory preset

6.

Parameter range

7.

Selecting from the list of values

8.

Factory preset

9.

Parameter range/selection

10. dashed box = Optional

19Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 22

TC-Standard (+) X2

Login

Loc

Enable menu lock

Selection

noP

nop- haLf - Lo - hi

OK

OK

OK

OK

OK

OK

OK

Input

0

0. . . . 9999

OK

OK

Selection

unit

°C - °F

Reset

rSt

Factory settings

Exit

E

Close submenu

TC Standard

tcSt

Device designation

Display

ch1

Temperature CH1

Display

ch2

Ambient temperature CH2

Top Settings

top

Global settings

Analogue Out1

An1

Settings menu Analog 1

Settings menu

unit

Temperature unit

Temperature

tEmP

Target temp. Cooling block

Exit

E

Close submenu

Drop-down menu

cout

Functional test

Exit

E

Close submenu

OK

Display Main menu Submenu 1 Submenu 2 Parameter

Input

5°C

2 . . . 20 °C

OK

OK

Input

3°C

1 . . . 7 °C

Settings menu

A hi

Alarm hysteresis

Settings menu

A Lo

Alarm hysteresis

Drop-down menu

dt

DeltaT Temp. Mode

OK

OK

Drop-down menu

h2o

Drop-down menu

sen

Moisture detector 1 sensitivity

Drop-down menu

h2o.2

Drop-down menu

sen.2

OK

Input

-3°C

-1 . . . -3 °C

OK

Calibrate moisture detector 1

Calibrate moisture detector 2

Moisture detector 2 sensitivity

Drop-down menu

Modes

Deactivate DeltaT mode

OK

Selection

Abso

Abso - dt

Drop-down menu

out

Output signal

Selection

i

i- u

rst

OK

Input

non

non - hi - Lo

OK

rst

OK

Input

non

non - hi - Lo

OK

Confirm

rst

yes - no

OK

Exit

E

Close submenu

Drop-down menu

PuMP

Stop pumps

Input

-15°C

-30°C .. . .0°C K

Drop-down menu

noP

NoP - off

OK

Moisture detector 1

Moisture detector 2

Confirm

Confirm

Error

Err

Status message

Drop-down menu

hLtc

Humidity auto reset

Input

no

yes - no

OK

Drop-down menu

bLtc

Cable break auto reset

Input

YES

yes - no

OK

Restart

rESt

Restart device

Confirm

no

yes - no

OK

Drop-down menu

h.chn

Heat exchanger material selection

Drop-down menu

tS

tS

OK

t6

tU

(Steel)

(Glass)

(PVDF)

Fig.1: Menu Overview TC Standard

20 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 23

TC-Standard (+) X2

5.4 Description of menu functions

5.4.1 Main menu

Peltier Cooler TC-Standard (tc.St)

Display → tc.st

This will take you to the cooler target temperature and the tolerance range setting (alarm

threshold).

Global setting (ToP Settings)

Display → toP

This menu is used to configure the global cooler settings.

Peristaltic Pump

Display → PuMP

Switching the peristaltic pump on and off.

Parameter range: NoP , oFF

Factory setting: NoP

Note: Status switches, "PuMP" flashes.

Heat exchanger material selection

Display → h.chn

Heat exchanger material selection

Parameter range: tS (Steel), t6 (Glass), tU (PVDF)

Factory setting: tS (cooler without heat exchanger), or respective material per configuration

Exit main menu

Display → E

Selecting this will return you to display mode.

5.4.2 Submenu 1

Target temperature (Temperature)

Display → Cooler → temp

This setting determines the nominal temperature for the cooler temperature.

Parameter range: 2 °C to 20 °C (35.6 °F to 68 °F)

Factory setting: 5 °C (41 °F)

Note: If the temperature is changed the indicator may blink, until the new operating range has been

reached.

This menu item is hidden if the keylock is enabled.

21Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 24

TC-Standard (+) X2

upper alarm limit (alarm high)

Display → Cooler → A hi

Here you can set the upper threshold for the visual signal and the alarm relay. The alarm limit is set

based on the cooler temperature setting.

Parameter range: 1 °C to 7 °C (1.8 °F to 12.6 °F)

Factory setting: 3 °C (5.4 °F)

Note: This menu item is hidden if the keylock is enabled.

lower alarm limit (alarm low)

Display → Cooler → A Lo

Here you can set the lower threshold for the visual signal and the alarm relay. The alarm limit is set

based on the cooler temperature setting.

Parameter range: -1 °C to -3 °C (-1.8 °F to -5.4 °F)

Factory setting: -3 °C (-5.4 °F)

Note: This menu item is hidden if the keylock is enabled.

DeltaT (dt)

Display → Cooler → dt

Here you can set the nominal difference with respect to ambient temperature.

Parameter range: -30 K…0 K

Factory setting: -15 K

Note: This menu will be hidden if the menu is locked.

DeltaT mode (Modu)

Display → Cooler → Modu

Here you can activate or deactivate DeltaT-mode.

Parameter range: AbSo , dt

Factory setting: AbSo (normal operation mode)

Note: This menu will be hidden if the menu is locked.

Exit submenu 1

Display → Submenu → E

Selecting this will return you to the main menu.

5.4.3 Submenu 1 (global settings)

Temperature unit

Display → toP → unit

Used to select the temperature display unit.

Parameter range: °C, °F

Factory setting: °C

22 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 25

TC-Standard (+) X2

Analog output

Display → toP → An1

This submenu is used to specify the settings for analog output 1, see chapter Submenu 2 (Analog

Output 1)

Note: This menu will be hidden if the menu is locked.

Calibrate moisture detector

Display → toP → h2o (h2o)

If a moisture detector is installed, calibration can now be performed. To do so, the unit must be

flushed with dry gas.

Note: Calibration was performed at the factory using ambient air. After replacing the moisture detector a

calibration is again required.

Calibrating the moisture detector will set the menu sEn to hi.

This menu will be hidden if the menu is locked.

If the unit has multiple moisture detectors built in, they will be numbered in the menu. In this case, h2o indicates the first, h2o2

the second moisture detector. The same applies to setting the sensor sensitivity in menu SEn.

Moisture detector sensitivity

Display → toP → SEn

If moisture detectors are installed, the sensitivity can be reduced here.

Parameter range: hi: high sensitivity

Lo: low sensitivity

non: no moisture detector

Factory setting: hi

Note: This menu will be hidden if the menu is locked.

Moisture detector: automatic reset following moisture ingress

Display → toP → hLtc

(hLtc = humidity latch). The setting applies to all connected moisture detectors.

Specifies whether the moisture ingress message must be reset manually or will automatically be re-

set after the sensor dries.

Parameter range: YES: The status will be indicated until the user restarts the device and the pumps will be disabled.

no: The status message will automatically be cleared/the pumps will be released again once mois-

ture is no longer detected.

Factory setting: no

Note: This menu will be hidden if the menu is locked.

23Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 26

TC-Standard (+) X2

Moisture detector: error cleared automatically after cable break

Display → toP → bLtc

(bLtc = broken wire latch). The setting applies to all connected moisture detectors.

Determines whether the cable break alarm must be reset manually or will automatically clear on

valid measuring signal.

Parameter range: YES: The status will be indicated until the user restarts the device/clears the error, and the pumps

will be disabled.

no: The error message will extinguish/the pumps will be released again once the moisture detector

is recognised again.

Factory setting: YES

Note: This menu will be hidden if the menu is locked.

Lock Menu

To protect the menu from unauthorised use, enter a value for the lock code. Menu items can then only be accessed after entering the correct code.

Display → toP → Loc

This setting will cancel/enable the menu lock.

Parameter range: 0 to 9999

Factory setting: 0 (keylock cancelled)

Note: This menu will be hidden if the menu is locked.

Restart

Display → toP → rESt

(rESt = restart)

The device will restart, all settings are saved. All error messages will be reset.

The moisture detector will be reset, irrespective of the settings in menus h.Itc and h.Moi.

Parameter range: YES: Restart. The display will show the software version for the device and returns to measurement

display.

no: Exit menu without restarting.

Note: The user settings will be saved.

Factory settings

Display → toP → rst

This setting restores the factory settings.

Parameter range: Yes: factory settings restored.

No: Exit menu without making changes.

Factory setting: No

Note: This menu will be hidden if the menu is locked.

Exit submenu 1

Display → Submenu → E

Selecting this will return you to the main menu.

24 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 27

TC-Standard (+) X2

5.4.3.1 Submenu 2 (Analog Output 1)

The analog output will display the actual cooler temperature.

Signal behaviour

In normal mode (noP) the measuring point will output the actual temperature. For testing purposes you can generate constant

values hi, Lo or hALF. The analogue output will output a constant signal with a value as specified in the table.

Constant Current output

4 – 20 mA

hi 20 mA 10 V

Mi 12 mA 6 V

Lo 4 mA 2 V

noP 4 – 20 mA 2 – 10 V

After testing, the signal behaviour must be changed back to normal mode (noP).

Display → toP → An1 → cout

This setting determines how the analogue output will behave.

Parameter range: noP = Operation (normal mode), hi, Lo, hALF

Factory setting: noP

Note: This menu will be hidden if the menu is locked.

Voltage output

2 – 10 V

Selection -> Output Signal

Display → toP → An1 → out

Select the type of output signal.

Parameter range: i Status output 4… 20mA

u Status output 2…10V

Factory setting: i

Note: Disconnect meter before switching!

This menu item is hidden if the keylock is enabled.

Exit Submenu 2

Display → toP → An1 → E

Selecting this will return you to submenu 1.

5.4.4 Set favourite menu

Use the F or

– Open the menu you wish to set as the favourite. This menu can also be a lockable menu.

– Press the function key for more than 3 sec.

The current menu has been set as the favourite. The display will briefly show the message Func.

– Press

To now access the favourite menu, press the F or

NOTICE!The favourite menu can also be accessed if the menu is locked.

Func

(function) key to set a favourite menu to later open it with just the push of a button.

ESC

or E (Exit) to return to the display.

Func

key.

25Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 28

TC-Standard (+) X2

6 Maintenance

If the cooler is delivered in basic configuration, no special maintenance is necessary.

Nevertheless, depending on the configuration different options or accessories may be installed. In this case, follow the maintenance schedule in regular intervals.

Option peristaltic pump:

–

Option filter:

–

Option moisture detector:

–

During maintenance, remember:

– The equipment must be maintained by a professional familiar with the safety requirements and risks.

– Only perform maintenance work described in these operating and installation instructions.

– When performing maintenance of any type, observe the respective safety and operation regulations.

DANGER Electrical voltage

Checking the filter element

Checking the hoses

Calibrating the moisture detector

Electrocution hazard.

a) Disconnect the device from power supply.

b) Make sure that the equipment cannot be reconnected to mains unintentionally.

c) The device must be opened by trained staff only.

d) Regard correct mains voltage.

DANGER Toxic, corrosive gas/condensate

Sample gas/condensate may be hazardous to health.

a) If necessary, ensure a safe gas/condensate discharge.

b) Always disconnect the gas supply when performing maintenance or repairs.

c) Protect yourself from toxic/corrosive gasses/condensate when performing mainten-

ance. Wear appropriate protective equipment.

26 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 29

TC-Standard (+) X2

7 Service and repair

This chapter contains information on troubleshooting and correction should an error occur during operation.

Repairs to the unit must be performed by Bühler authorised personnel.

Please contact our Service Department with any questions:

Tel.: +49-(0)2102-498955

If the equipment is not functioning properly after correcting any malfunctions and switching on the power, it must be inspected

by the manufacturer. Please send the equipment inside suitable packaging to:

Bühler Technologies GmbH

- Reparatur/Service -

Harkortstraße 29

40880 Ratingen

Germany

Please also attach the completed and signed RMA decontamination statement to the packaging. We will otherwise be unable to

process your repair order.

You will find the form in the appendix of these instructions, or simply request it by e-mail:

service@buehler-technologies.com

or your agent

.

7.1 Troubleshooting

Problem / Malfunction Possible cause Action

Condensate inside the gas

outlet

Reduced gas flow rate – Gas circuit clogged – Uninstall and clean heat exchanger

Excess temperature – Operating point not yet reached – Wait (max. 20 min)

Insufficient temperature – Faulty control – Send in cooler

– Condensate trap full – Empty condensate trap

– Valve inside the automatic condensate

drain may be stuck

– Cooler overloaded – Maintain limits

– Condensate outlet iced over – Send in unit

– Cooling outlet too long despite the cooler

running

– Flow rate / dew point / gas temperature too

high

– Installed fan stopped – Check and replace if necessary

– Flush in both directions

– if necessary, replace filter element

– Be sure the vents are not covered (heat

buildup)

– Maintain limits / install pre-separator

27Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 30

TC-Standard (+) X2

7.1.1 Error messages on the display

If an error occurs, the display will read "Err". Press the " " button to show the error number(s).

Error messages will appear until the unit has been restarted or the error is cleared using the "Func" button. It can only be cleared

if the cause for the error has been corrected.

Causes / Action: The following is a list of the most common causes and actions for the respective error. If the actions listed do

not resolve the problem, please contact Service.

Problem / Malfunction Possible cause Action

No display – No voltage

– Loose connecting cable

– Display defective

D1.02 (The software version for the display will ap-

(permanent)

Error – An error has occurred – Read the error number as described above

Error 01 – Controller malfunction – Clear error (temporary fault)

Error 03 – Microcontroller Fault / MCP2 – Contact service

pear).

– Not communicating with the controller

– Check the supply cable

– Check fuse

– Check connections

– Check connections

– Disconnect from power for approx. 5 s

– Contact service

Error 04 – EEPROM error – Contact service

Error 22 – Moisture detector 1 cable break – Check moisture detector line

– Check moisture detector

Error 32 – Moisture detector 2 cable break – Check moisture detector line

– Check moisture detector

Error 40 – General error temperature sensor 1 – Sensor possibly defective

Error 41 – Low temperature / short-circuit temperat-

ure sensor 1

Error 42 – Excess temperature / short-circuit temper-

ature sensor 1

Error 43 – Measurement fluctuation temperature

sensor 1

Error 50 – General error temperature sensor 2 – Sensor possibly defective

Error 51 – Low temperature / short-circuit temperat-

ure sensor 2

Error 52 – Excess temperature / short-circuit temper-

ature sensor 2

Error 53 – Measurement fluctuation temperature

sensor 2

– Check temperature sensor connection

– Check temperature sensor connection

– Check temperature sensor connection

– Check temperature sensor connection

– Check temperature sensor connection

– Check temperature sensor connection

28 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 31

TC-Standard (+) X2

Status text Possible cause Action

H2o.1 – Moisture alarm moisture detector 1 – Dry

– Check condensate trap

H2o.2 – Moisture alarm moisture detector 2 – Dry

– Check condensate trap

init – Initialisation phase – Wait

PuMP – Pumps deactivated – Reactive pumps via menu

dt Active Delta T control only: The block temperat-

ure is outside the defined temperature range.

– Cooler is still in the "break-in phase"

– Fluctuating ambient temperature

– Insufficient cooling capacity

– Excess/low temperature – see chapter “Troubleshooting”

(Flashing)

– Wait to see if the target temperature will be

– Check the ambient temperature / power sup-

– Process-related: Adjust alarm limits

7.2 Safety instructions

– The device must be operated within its specifications.

– All repairs must be carried out by Bühler authorised personnel only.

– Only perform modifications, servicing or mounting described in this manual.

– Only use original spare parts.

DANGER Electrical voltage

Electrocution hazard.

a) Disconnect the device from power supply.

b) Make sure that the equipment cannot be reconnected to mains unintentionally.

c) The device must be opened by trained staff only.

d) Regard correct mains voltage.

reached

plied

DANGER Toxic, corrosive gas/condensate

Sample gas/condensate may be hazardous to health.

a) If necessary, ensure a safe gas/condensate discharge.

b) Always disconnect the gas supply when performing maintenance or repairs.

c) Protect yourself from toxic/corrosive gasses/condensate when performing mainten-

ance. Wear appropriate protective equipment.

CAUTION Health hazard if the heat exchanger leaks

The heat exchanger is charged with glycol-based coolant.

In the event of a heat exchanger leak:

a) Avoid contact with the skin and eyes.

b) In the event of a leak, do not restart the cooler under any circumstances The cooler

must be repaired by the manufacturer.

29Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 32

TC-Standard (+) X2

7.3 Cleaning and removal of the heat exchanger

Heat exchangers only need to be replaced or maintained if clogged or damaged. If they are clogged, we recommend checking if

using a filter will avoid future occurrences.

– Close gas supply.

– Switch off device and disconnect all plugs (e.g. connector plug alarm output, supply input, etc.).

– Disconnect gas connections and condensate drain.

– Pull the heat exchanger up and out.

– Clean the heat exchanger hole (hole inside the cooler block), as the heat exchangers are installed with silicone grease.

– Flush the heat exchanger until all contaminants have been removed.

– Grease the cooled outside surface external surface with silicone grease.

– Reinsert the heat exchanger into the cooling nest with a rotating movement.

– Reconnect the gas supply and condensate drain. The gas inlet is marked red.

– Restore power/gas supply and wait for unit to be ready for operation.

– Open gas supply.

7.4 Replacing the hoses of the peristaltic pump (option)

– Turn off gas supply.

– Switch the device off and disconnect power supply.

– Remove the supplying and draining hoses from the pump (

– Loosen the centre knurled screw but do not remove it. Push the screw downwards.

– Pull off the cover.

– Pull the connections sidewards and remove the hose.

– Replace the hose and remount the pump in reverse order.

– Reconnect power supply.

Take care of the safety instructions!

).

7.5 Replacing the filter element (option)

CAUTION Gas leakage

The filter should not be dismantled under pressure.

Don’t use damaged parts again.

– Close the gas supply.

– Switch off and unplug the device.

– Pull the bracket, holding on to the filter glass.

– Whilst holding the filter head, move the glass back and forth and carefully remove downward.

– Remove the filter element and insert a new one.

– Check for leaks and replace, if necessary.

– Whilst holding the filter head, move the glass back and forth and carefully reattach the filter head, attach the bracket, and

ensure it is seated securely.

– Restore the power and gas supply.

NOTICE!Please observe legal regulations when disposing of filter elements.

30 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 33

TC-Standard (+) X2

7.6 Drying of the moisture detector (option)

The moisture detector must be dried if moisture enters.

– Close the gas supply.

– Switch off and unplug the device.

– Loosen the swivel nut for the moisture detector connection line and disconnect the line.

– Unscrew the moisture detector counter-clockwise and remove.

– Dry moisture detector.

– Reinsert the moisture detector and carefully tighten the screw connection.

– Connect the connection line and tighten the swivel nut.

– Restore the power and gas supply.

7.7 Calibration of the moisture detector (option)

– When replacing the moisture detectors, they must be recalibrated.

– Be sure dry gas flows through the cooler.

– Select cooler menu and confirm.

or

– Select menu item moisture detector.

– The display shows (Reset).

– Confirm the display to calibrate the moisture detectors.

For a detailed overview of menu navigation, refer to chapter "Operation and Control".

7.8 Spare parts and accessories

Please also specify the model and serial number when ordering parts.

Upgrade and expansion parts can be found in our catalog.

Available spare parts:

Item no. Description

91 00 10 00 07 Display module MCD400

91 44 05 00 80 Connecting cable controller board display module

91 00 11 01 80 Microcontroller board LPP MCP2

40 11 00 0 Flow adapter type G, PVDF G1/4

40 11 00 0I Flow adapter type NPT, PVDF NPT 1/4"

41 11 10 0 Moisture detector FF-3-N, without cable

91 44 05 00 81 Moisture detector connection cable, 300 mm

91 44 05 00 82 Moisture detector connection cable, 450 mm

41 50 29 99 Filter AGF-PV-30-F2, G1/4

41 50 29 99 I Filter AGF-PV-30-F2, NPT 1/4"

44 65 90 00 5 Fan, 12 V DC

91 00 01 01 98 Power board

91 00 01 11 98 Power board, 24 V DC

91 00 01 11 87 Controller board

see data sheet 450022 Peristaltic Pumps CPsingle, CPdouble X2

31Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 34

TC-Standard (+) X2

7.8.1 Consumables and accessories

TC-Standard

Item no. Description

45 10 008 Automatic condensate drain AK 5.2

45 10 028 Automatic condensate drain AK 5.5

44 10 004 Automatic condensate drain AK 20

44 10 001 Automatic condensate drain 11 LD V 38

41 03 00 50 Replacement filter element F2; Unit 5 count

91 44 05 00 38 Cable for cooler temperature analog output 4 m

44 10 005 Condensate trap GL1, 0.4 L

44 92 00 35 012 Norprene replacement hose with angled connections for peristaltic pump 0.3 L/h

44 92 00 35 014 Norprene replacement hose with one angled connection and one screw connection (metric) for

peristaltic pump 0.3 L/h

44 92 00 35 015

43 81 045 Screw connection G1/4 – DN 8/12 for passive condensate connection MTS and MTV

43 81 048 Screw connection NPT 1/4" for passive condensate connection MTS-I and MTV-I

TC-Standard+

Norprene replacement hose with one angled connection and one screw connection (US) for peristaltic

pump 0.3 L/h

Item no. Description

45 10 008 Automatic condensate drain AK 5.2

45 10 028 Automatic condensate drain AK 5.5

44 10 004 Automatic condensate drain AK 20

44 10 001 Automatic condensate drain 11 LD V 38

41 03 00 50 Replacement filter element F2; Unit 5 count

91 44 05 00 38 Cable for cooler temperature analog output 4 m

44 10 005 Condensate trap GL1, 0.4 L

44 92 00 35 012 Norprene replacement hose with angled connections for peristaltic pump 0.3 L/h

44 92 00 35 014 Norprene replacement hose with one angled connection and one screw connection (metric) for

peristaltic pump 0.3 L/h

44 92 00 35 015 Norprene replacement hose with one angled connection and one screw connection (US) for peristaltic

pump 0.3 L/h

43 81 045 Screw connection G1/4 – DN 8/12 for passive condensate connection MTV-2

43 81 048 Screw connection NPT 1/4" for passive condensate connection MTV-2-I

32 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 35

TC-Standard (+) X2

8 Disposal

The heat exchanger is charged with glycol-based coolant.

Dispose of parts so as not to endanger the health or environment. Follow the laws in the country of use for disposing of electronic components and devices as well as hazardous materials during disposal.

33Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 36

TC-Standard (+) X2

9 Appendices

9.1 Gas cooler technical data

TC-Standard X2

Gas Cooler Technical Data

Ready for operation after max. 10 minutes

Ambient temperature 5 °C to 50 °C

Gas outlet dew temperature

preset:

adjustable:

Protection class IP 20

Mechanical load Tested to DNVGL-CG-0339, Table 6

Housing Stainless steel, brushed

Packaging dimensions approx. 355 x 220 x 205 mm

Weight incl. heat exchanger approx. 7.5 kg

Electrical data Unit without add-on Unit with add-on

Recommended fuse

(characteristic: delayed action)

Status output switching capacity max. 250 V AC, 150 V DC

Electrical connections Plug per EN 175301-803

Gas connections and condensate outlet Heat exchanger see table "Heat Exchanger Overview"

Parts in contact with mediums

Filter:

Moisture detector:

Heat exchanger:

Peristaltic pump:

Tubing:

Markings: FM18ATEX0012X: II 3 G Ex ec nC IIC T4 Gc

5 °C

2 °C…20 °C or Delta T-control

2 Hz-13.2 Hz Amplitude ± 1.0 mm

13.2 Hz -100 Hz acceleration

approx. 6 kg (for 24 V DC)

approx. 9 kg fully upgraded

(1 peristaltic pump)

24 V DC 230 V AC 115 V AC 24 V DC 230 V AC 115 V AC

5 A 0.6 A 1.2 A 5.5 A 0.7 A 1.4 A

120 W 110 W / 140 VA 130 W 130 W / 160 VA

6,3 A 1,25 A 2,5 A 6,3 A 1,25 A 2,5 A

2 A, 50 VA, potential-free

Filter, moisture detector adapter G1/4 or NPT 1/4"

see "Technical Data - Options"

see "Technical Data - Options"

see table "Heat Exchanger Overview"

see "Technical Data - Options"

PTFE/Viton

IECEx FMG 18.0005X: Ex ec nC IIC T4 Gc

FM18US0021X/FM18CA0010X: CL I DIV 2 GP ABCD

34 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 37

TC-Standard (+) X2

TC-Standard+ X2

Gas Cooler Technical Data

Ready for operation after max. 10 minutes

Ambient temperature 5 °C to 50 °C

Gas outlet dew temperature

preset:

adjustable:

Protection class IP 20

Mechanical load Tested to DNVGL-CG-0339, Table 6

Housing Stainless steel, brushed

Packaging dimensions approx. 355 x 220 x 205 mm

Weight incl. heat exchanger approx. 7.5 kg

Electrical data Unit without add-on Unit with add-on

Recommended fuse

(characteristic: delayed action)

Status output switching capacity max. 250 V AC, 150 V DC

Electrical connections Plug per EN 175301-803

Gas connections and condensate outlet Heat exchanger see table "Heat Exchanger Overview"

Parts in contact with mediums

Filter:

Moisture detector:

Heat exchanger:

Peristaltic pump:

Tubing:

Markings: FM18ATEX0012X: II 3 G Ex ec nC IIC T4 Gc

5 °C

2 °C…20°C

2 Hz-13.2 Hz Amplitude ± 1.0 mm

13.2 Hz -100 Hz acceleration

approx. 6 kg (for 24 V DC)

approx. 9 kg fully upgraded

(1 peristaltic pump)

24 V DC 230 V AC 115 V AC 24 V DC 230 V AC 115 V AC

5 A 0.6 A 1.2 A 5.5 A 0.7 A 1.4 A

120 W 110 W / 140 VA 130 W 130 W / 160 VA

6, 3 A 1,25 A 2,5 A 6,3 A 1,25 A 2,5 A

2 A, 50 VA, potential-free

Filter, moisture detector adapter G1/4 or NPT 1/4"

see "Technical Data - Options"

see "Technical Data - Options"

see table "Heat Exchanger Overview"

see "Technical Data - Options"

PTFE/Viton

IECEx FMG 18.0005X: Ex ec nC IIC T4 Gc

FM18US0021X/FM18CA0010X: CL I DIV 2 GP ABCD

9.2 Technical Data - Options

Analogue Output Cooler Temperature Technical Data

Signal 4-20mA or 2-10V

corresponds to -20°C to +60°C cooler temperature

Connection M12x1 plug, DIN EN 61076-2-101

Technical Data FF-3-N Moisture Detector

Ambient temperature 3 °C to 50 °C

max. operating pressure with FF-3-N 2 bar

Material PVDF, PTFE, epoxy resin, stainless steel 1.4571, 1.4576

35Bühler Technologies GmbHBE440023 ◦ 10/2018

Page 38

TC-Standard (+) X2

Technical Data peristaltic pumps CPsingle X2 / CPdouble X2

Ambient temperature 0°C to 50 °C

Flow rate 0.3 L/h (50 Hz) / 0.36 L/h (60 Hz) with standard hose

Vacuum inlet max. 0.8 bar

Pressure inlet max. 1 bar

Outlet pressure 1 bar

Hose 4 x 1.6 mm

Condensate outlet Hose nipple Ø6 mm

Screw connection 4/6 (metric), 1/6”-1/4” (US)

Protection class IP 44

Materials

Hose:

Connections:

AGF-PV-30-F2 Filter Technical Data

Ambient temperature 3 °C to 100 °C

max. operating pressure with filter 2 bar

Filter surface 60 cm

Filter mesh 2 µm

Dead volume 57 ml

Materials

Filter:

Seal:

Filter element:

Norprene (Standard), Marprene, Fluran

PVDF

2

PVDF, Duran glass (parts in contact with mediums)

Viton

sintered PTFE

9.3 Flow diagrams

TC-Standard

1 gas path:

1 Cooler 2 Moisture detector (option)

3 Filter (optional) 4 Condensate pump (optional)

TC-Standard+

1 in-line gas path:

1 Cooler 2 Moisture detector (option)

3 Filter (optional) 4 Condensate pump (optional)

36 Bühler Technologies GmbH BE440023 ◦ 10/2018

Page 39

TC-Standard (+) X2

TC-Standard

with PTS

Limit for

PTG, PTV

Ambient temperature

Cooling capacity

TC-Standard

with 2xMTS

Limit for

2xMTG

Ambient temperature

Cooling capacity

Limit for

2xMTV

TC-Standard

with PTS

Limit for

PTG, PTV

Ambient temperature

Cooling capacity

TC-Standard

with 2xMTS

Limit for

2xMTG

Ambient temperature

Cooling capacity

Limit for

2xMTV

9.4 Performance curves

TC-Standard

One heat exchanger Two heat exchangers

Model TC-Standard 6111 (X2) Model TC-Standard 6121 (X2)

Rated cooling capacity (at 25 °C) 100 kJ/h Rated cooling capacity (at 25 °C) 100 kJ/h

Max. Ambient temperature 40 °C Max. Ambient temperature 40 °C

Dew point fluctuations

static

in the entire specification range

± 0.1 K

± 1.5 K

Dew point fluctuations

static

in the entire specification range

Temperature difference between heat exchangers

± 0.1 K

± 1.5 K

< 0.5 K

Model TC-Standard 6112 (X2) Model TC-Standard 6122 (X2)

Rated cooling capacity (at 25 °C) 90 kJ/h Rated cooling capacity (at 25 °C) 90 kJ/h