Page 1

Analysentechnik

Flow Meter

SM-6, SM-6-V, S-SM 3-1

Installation and Operation Instructions

Original instructions

BE400001

11/2016

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

E-Mail: analyse@buehler-technologies.com

Internet: www.buehler-technologies.com

Page 2

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

Internet: www.buehler-technologies.com

E-Mail: analyse@buehler-technologies.com

Read this instruction carefully prior to installation and/or use. Pay attention particularly to all advises and safety instructions to prevent injuries. Bühler Technologies can not be held responsible for misusing

the product or unreliable function due to unauthorised modifications.

All rights reserved. Bühler Technologies GmbH 2017

Document information

Document No......................................................... BE400001

Version...........................................................................11/2016

Page 3

SM-6, SM-6-V, SSM 3-1

Contents

1 Introduction..................................................................................................................................................................................................................... 2

1.1 Intended use .........................................................................................................................................................................................................2

1.2 Contents................................................................................................................................................................................................................. 2

1.3 Ordering instructions ........................................................................................................................................................................................ 3

2 Safety instructions.........................................................................................................................................................................................................4

2.1 Important advice ................................................................................................................................................................................................. 4

2.2 General hazard warnings .................................................................................................................................................................................4

3 Transport and storage ..................................................................................................................................................................................................6

4 Installation and connection........................................................................................................................................................................................ 7

4.1 Mounting a flow sensor with brackets (type SM-6 / SM-6-V only)....................................................................................................... 7

5 Operation and control ..................................................................................................................................................................................................8

5.1 Read the flow value ............................................................................................................................................................................................8

5.2 Adjusting the needle valve ...............................................................................................................................................................................8

6 Maintenance....................................................................................................................................................................................................................9

6.1 Replacing the flow sensor with brackets (type SM-6 / SM-6-V only) ...................................................................................................9

6.2 Replacing the metering tube (type SM-6 / SM-6V only)......................................................................................................................... 11

6.2.1 Without flow sensor ...........................................................................................................................................................................11

6.2.2 With flow sensor..................................................................................................................................................................................11

6.3 Replacing the metering tube - Safety flow meters S-SM........................................................................................................................ 11

7 Service and repair..........................................................................................................................................................................................................12

7.1 Troubleshooting ................................................................................................................................................................................................ 12

7.2 Spare parts and accessories ........................................................................................................................................................................... 12

7.2.1 Spare parts and accessories - S-SM ...............................................................................................................................................12

7.2.2 Spare parts and accessories - switch amplifier..........................................................................................................................12

8 Disposal............................................................................................................................................................................................................................13

9 Appendices..................................................................................................................................................................................................................... 14

9.1 Technical Data ....................................................................................................................................................................................................14

9.2 Dimensions ..........................................................................................................................................................................................................15

9.3 Measuring ranges .............................................................................................................................................................................................16

10 Attached documents................................................................................................................................................................................................... 18

iBühler Technologies GmbHBE400001 ◦ 11/2016

Page 4

SM-6, SM-6-V, SSM 3-1

1 Introduction

1.1 Intended use

The flow meter can be used to display flow volumes of sample gasses or liquid mediums. Please refer to the nameplate to

identify your model. In addition to the job number it also contains the item number and model designation. Any special features applicable to a flow meter model are described separately in the operating manual. When connecting, please note the specific values of the flow meter, and the correct version when ordering spare parts.

SM-6/SM-6-V series flow meters can also be equipped with a bistable limit switch. On the SM-6-V the flow volume can be adjusted with the needle valve.

On S-SM series safety flow meters the actual metering glass is protected by a second, thick-walled glass cylinder. If the metering

glass bursts, the outer glass cylinder resumes protecting so medium cannot leak. A stainless steel tube further protects this

outer glass cylinder from mechanical damage. Please refer to the data sheet for the various S-SM models.

NOTICE When used in explosive areas

Model SM-6, SM6-V and S-SM 3-1 flow meters meet the fundamental safety requirements of Directive 2014/34/EU and are therefore suitable for use in Ex areas (

plosion Group IIC

SM-6-V)

sionally be explosive during normal operation may be conveyed through the needle

valves (

ums have no own ignition sources and therefore do not fall under Directive 2014/34/EU.

or IIC

Zone 1

, hazard notes must be observed).

(model S-SM 3-1) non-flammable and flammable gasses which may occa-

). The type plate on the flow meters has no Ex classification, as the medi-

Explosion group IIB

Zone 1, Ex-

(model SM-6 and

1.2 Contents

– 1 x Flow meter

– 1 x Product documentation

– 1 x Bracket (Model SM-6 / SM-6-V only)

2 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 5

SM-6, SM-6-V, SSM 3-1

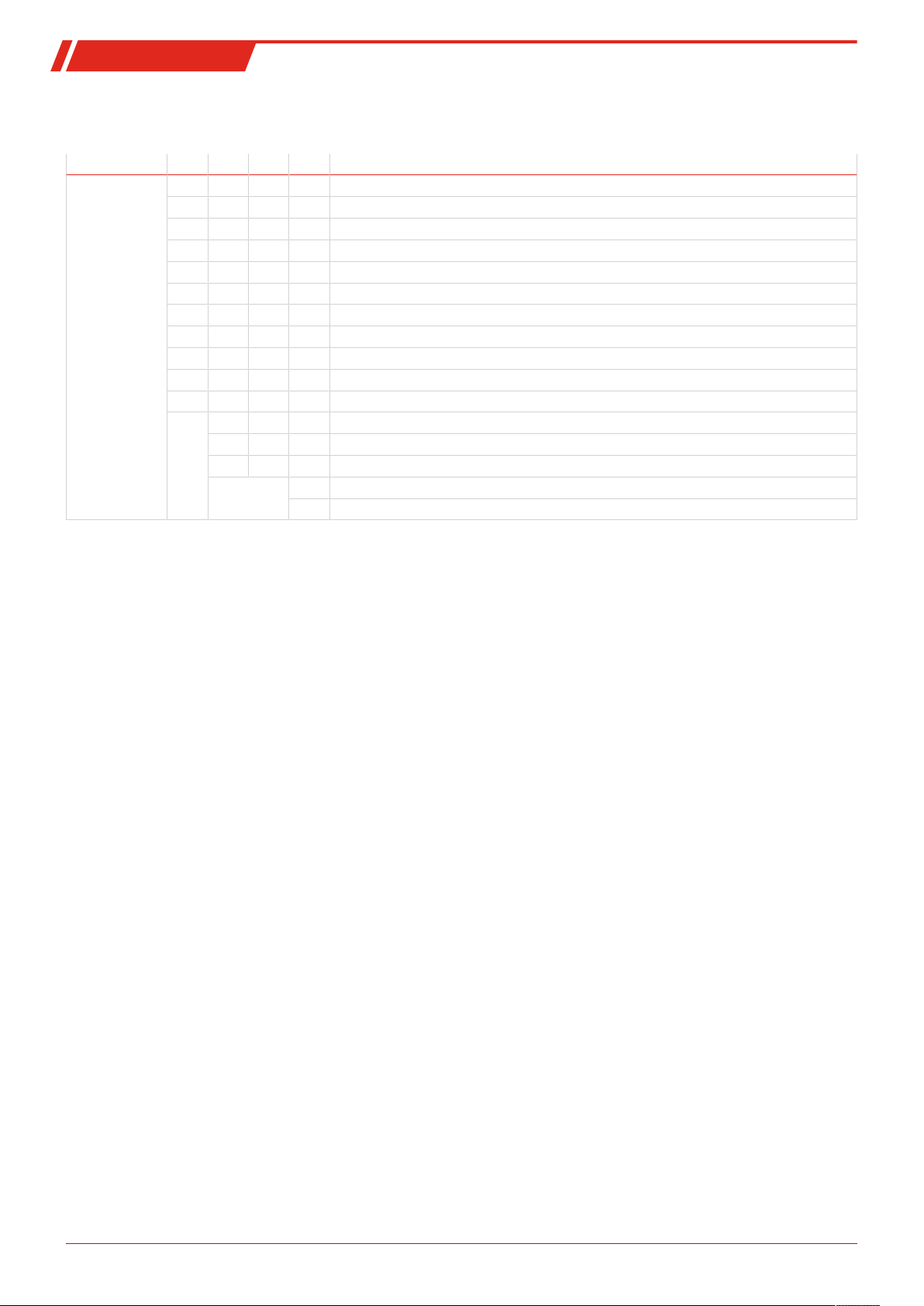

1.3 Ordering instructions

The item number is a code for the configuration of your unit. Please use the following model key:

4056 X X X 99 X Measuring range*

0 0 Air 6 - 60 Nl/h

0 1 Air 10 - 100 Nl/h

0 2 Air 25 - 250 Nl/h

0 3 Air 50 - 500 Nl/h

0 4 Air 80 - 800 Nl/h

0 5 Water 0.5 - 5 L/h

0 6 Water 1.2 - 12 L/h

0 7 Water 2.5 - 25 L/h

0 8 Water 4 - 40 L/h

0 9 Water 6 - 60 L/h

1 0 Special range

0 without needle valve

1 Valve PVDF / Viton

2 Valve PCTFE / perfluorelastomer

S Limit switch with mounting bracket

- without limit switch

* Standard measuring tubes; air 20 °C 1.2 bar abs; water 20 °C

Ordering information for limit switch:

the "S" marking the flow meter has no limit switch. We offer various switch amplifiers for controlling the limit switch (see data

sheet no. 400003).

A limit switch is factory installed if the last character of the item number is "S". Without

3Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 6

SM-6, SM-6-V, S-

DANGER

WARNING

CAUTION

NOTICE

SM 3-1

2 Safety instructions

2.1 Important advice

Operation of the device is only valid if:

– the product is used under the conditions described in the installation- and operation instruction, the intended application

according to the type plate and the intended use. In case of unauthorized modifications done by the user Bühler Technologies GmbH can not be held responsible for any damage,

– when complying with the specifications and markings on the nameplates.

– the performance limits given in the datasheets and in the installation- and operation instruction are obeyed,

– monitoring devices and safety devices are installed properly,

– service and repair is carried out by Bühler Technologies GmbH,

– only original spare parts are used.

This manual is part of the equipment. The manufacturer keeps the right to modify specifications without advanced notice. Keep

this manual for later use.

Signal words for warnings

Signal word for an imminent danger with high risk, resulting in severe injuries or death if not avoided.

Signal word for a hazardous situation with medium risk, possibly resulting in severe injuries or death if not

avoided.

Signal word for a hazardous situation with low risk, resulting in damaged to the device or the property or

minor or medium injuries if not avoided.

Signal word for important information to the product.

Warning signs

These instructions use the following warning signs:

Warns of a general hazard Wear respiratory equipment

Warns not to inhale toxic gasses Wear a safety mask

Warns of corrosive liquids Wear gloves

Warns of explosive areas

2.2 General hazard warnings

The equipment must be installed by a professional familiar with the safety requirements and risks.

Be sure to observe the safety regulations and generally applicable rules of technology relevant for the installation site. Prevent

malfunctions and avoid personal injuries and property damage.

4 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 7

SM-6, SM-6-V, SSM 3-1

The operator of the system must ensure:

– Safety notices and operating instructions are available and observed,

– Inspections prior to initial operation and routine inspections according to the Ordinance on Industrial Safety and Health (Be-

trSichV) are performed,

– The respective national accident prevention regulations are observed,

– The permissible data and operational conditions are maintained,

– Safety guards are used and mandatory maintenance is performed,

– Legal regulations are observed during disposal.

Maintenance, Repair

Please note during maintenance and repairs:

– Repairs to the unit must be performed by Bühler authorised personnel.

– Only perform conversion-, maintenance or installation work described in these operating and installation instructions.

– Always use genuine spare parts.

Always observe the applicable safety and operating regulations in the respective country of use when performing any type of

maintenance.

DANGER Toxic, acidic gasses

Sample gas can be harmful.

a) Switch off the gas supply before performing maintenance and, if necessary, flush the

gas lines with air.

b) If necessary, ensure a safe gas discharge.

c) Protect yourself from toxic / acidic gasses when performing maintenance. Wear ap-

propriate protective equipment.

NOTICE When used in explosive areas

Model SM-6, SM6-V and S-SM 3-1 flow meters meet the fundamental safety requirements of Directive 2014/34/EU and are therefore suitable for use in Ex areas (

plosion Group IIC

SM-6-V)

or IIC

, hazard notes must be observed).

(model S-SM 3-1) non-flammable and flammable gasses which may occa-

sionally be explosive during normal operation may be conveyed through the needle

Zone 1

valves (

). The type plate on the flow meters has no Ex classification, as the medi-

ums have no own ignition sources and therefore do not fall under Directive 2014/34/EU.

DANGER Application in explosive atmosphere

Combustible gases and dust may inflame or explode. Avoid the following hazardous

situations:

Electrostatic charge (spark formation)!

Clean plastic parts and labels with damp cloth only.

Connect metallic housings to ground!

Maximum surface temperature!

The maximum surface temperature T

temperature T

med

; T

surf

≤ T

med

.

Ignition temperature!

Regard the ignition temperature of the explosive gas-atmosphere as well as maximum

allowable surface temperatures (regard directive 94/9/ EC and harmonized standards).

Risk of breakage / emission of explosive or toxic gas possible.

Protect the equipment against being hit.

Gas leakage!

Life and explosion risk may result from gas leakage due to improper use or during maintenance.

Zone 1, Ex-

Explosion group IIB

of the equipment corresponds to the medium-

surf

(model SM-6 and

5Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 8

SM-6, SM-6-V, SSM 3-1

3 Transport and storage

The product should only be transported inside the original packaging or a suitable alternative.

When not in use, the equipment must be protected from moisture and heat. They must be stored in a covered, dry and dust-free

room at a temperature between -10 °C and 40 °C.

6 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 9

SM-6, SM-6-V, SSM 3-1

4 Installation and connection

The flow meters are equipped with the following threads:

Flow meter Thread

SM-6 / SM-6-V G 1/4

S-SM 3-1 NPT 1/4”

Please refer to chapter Dimensions [> page15] for the assembly drawing. The fittings must be screwed in tight, sealed with Teflon tape or sealant/flat gasket!

4.1 Mounting a flow sensor with brackets (type SM-6 / SM-6-V only)

DANGER Explosion hazard

Application in explosive atmosphere

Only use certificated flow sensors.

The limit switch is preinstalled.

– Prior to first use, loosen the plastic countersunk screws from the mounting plate and position the limit switch at the desired

height.

– The Plastic countersunk screws must be fastened again.

– Connect the cable to the power supply.

– Using the limit switch in Ex areas: Please note the wiring parameters! We recommend a selection of switch amplifiers, also

see data sheet no. 400003.

7Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 10

SM-6, SM-6-V, SSM 3-1

5 Operation and control

NOTICE

The device must not be operated beyond its specifications.

5.1 Read the flow value

The flow value can be read at the top of the float.

Please note: The values can only be correct, if the medium and pressure specified on the type plate match the sample.

5.2 Adjusting the needle valve

NOTICE!Please note: The needle valve is NOT a shut-off valve. Do not force the valve.

The valve is closed turning clockwise.

8 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 11

SM-6, SM-6-V, SSM 3-1

6 Maintenance

During maintenance, remember:

– The equipment must be maintained by a professional familiar with the safety requirements and risks.

– Only perform maintenance work described in these operating and installation instructions.

– When performing maintenance of any type, observe the respective safety and operation regulations.

DANGER Explosion hazard

Gas leakage

If explosive, toxic or corrosive gas (liquid) will lead through the flow meter, check the leak

tightness at regular intervals.

DANGER Toxic, corrosive gasses

Sample gas can be harmful.

a) Switch off the process (depressurise) before starting maintenance. To do so, close the

shut-off valve (if applicable).

b) Flush the flow meter with air before opening.

c) Protect yourself from toxic / corrosive gasses when performing maintenance. Wear

appropriate protective equipment.

CAUTION Gas leakage

Don’t use damaged parts again.

Only use original spare parts.

6.1 Replacing the flow sensor with brackets (type SM-6 / SM-6-V only)

DANGER Explosion hazard

Application in explosive atmosphere

Only use certificated flow sensors.

Remove the plastic countersunk screws (1) from the limit switch mounting plate (see Fig. 1). This will also loosen the clamping

plate at the back of the flow meter.

Loosen both swivel nuts on the measuring tube. Slide the measuring tube into the upper end piece, applying light pressure. You

can now swing out the measuring tube (see Fig. 2). Remove the gasket (2), die swivel nut (3) and limit switch (4) at the bottom

end of the measuring tube. The measuring tube may be cleaned if necessary.

Measuring tubes with limit switch are assembled in the reverse order. Please be sure the chamfer on the gasket faces the respective end piece.

9Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 12

SM-6, SM-6-V, S-

1

2

3

4

6

7

8

5

SM 3-1

Fig. 1 Fig. 2

Fig. 4

1 Plastic countersunk screws 3 Swivel nut

2 Gasket 4 Limit switch with mounting plate

5 Limit switch 7 Machined mounting plate

6 M3 square nuts 8 Cross-head screws

Loosen both cross-head screws (8) on the mounting plate for the limit switch (see Fig. 4). Remove the mounting plate (7). Be careful not to lose the two square nuts (6) in the slots on the limit switch! Replace the limit switch (5) and fasten the mounting plate.

The machined chamfer on the mounting plate (7) must face the top left.

You can now slide the limit switch onto the measuring tube again. When doing so, please note the direction of flow, i.e. the

markings must be visible, the mounting plate for the limit switch must be positioned with the screw holes over the slot and the

cable is fed out the bottom.

Finally, slide the swivel nut and the gasket (with the sealing cone toward the bracket) onto the measuring tube. Reinstall the

measuring tube and tighten the swivel nut by hand.

Now insert the plastic countersunk screws through the slot in the base plate of the flow meter to fasten and adjust the mounting plate to the clamping plate inside the back of the base plate.

Fig. 5

Fig. 3

10 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 13

SM-6, SM-6-V, SSM 3-1

6.2 Replacing the metering tube (type SM-6 / SM-6V only)

6.2.1 Without flow sensor

Loosen the two swivel nuts for the measuring tube. Slide the metering tube into the upper end piece, applying light pressure.

You can now move the gaskets under the swivel nuts onto the tapered end of the metering tube. You can now swing out the

measuring tube.

You can now remove the swivel nuts and gaskets from the measuring tube and, if necessary, move them onto the new measuring tube. The metering tube is assembled in the reverse order. Please be sure the chamfer on the gasket faces the respective end

piece.

6.2.2 With flow sensor

Loosen the top plastic countersunk screw (1) from the mounting plate for the limit switch (see Fig. I) and loosen the bottom

plastic countersunk screw (1) so the limit switch can be moved. Removing it completely from the mounting plate is not required.

Loosen the two swivel nuts (3) for the measuring tube. Slide the metering tube into the upper end piece, applying light pressure.

Turn the limit switch to the side (see Fig. 6) when pulling the metering tube out of the limit switch as well as the swivel nut. If

necessary, move the limit switch in the process. Remove the gasket (2) and the swivel nut (3) at the bottom of the metering tube.

Leave the limit switch on the mounting plate (see Fig. 7).

Assemble the measuring tube in the reverse order. Please be sure the chamfer on the gasket faces the respective end piece.

Fig. 6 Fig. 7

6.3 Replacing the metering tube - Safety flow meters S-SM

NOTICE!This procedure has to be carried out very carefully. You should only do it yourself, if you are sure, you are able to cope

with it. We recommend sending the flow meter back to the manufacturer.

Screw one of the end pieces out of the flow meter while holding the flow meter in a direction preventing the metering tube from

slipping out. The metering tube can now be taken out.

When mounting the new metering tube the metering and the protection glass has to fit correctly into the O-rings and end

pieces.

11Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 14

SM-6, SM-6-V, SSM 3-1

7 Service and repair

This chapter contains information on troubleshooting and correction should an error occur during operation.

Repairs to the unit must be performed by Bühler authorised personnel.

Please contact our Service Department with any questions:

Tel.: +49-(0)2102-498955

If the equipment is not functioning properly after correcting any malfunctions and switching on the power, it must be inspected

by the manufacturer. Please send the equipment inside suitable packaging to:

Bühler Technologies GmbH

- Reparatur/Service -

Harkortstraße 29

40880 Ratingen

Germany

Please also attached the completed and signed RMA decontamination statement to the packaging. We will otherwise be unable

to process your repair order.

You will find the form in the appendix of these instructions, or simply request it by e-mail:

7.1 Troubleshooting

or your agent

service@buehler-technologies.com

.

Problem / Failure Possible cause Solution

Float doesn’t rise – Needle valve closed – Open needle valve

– Pollution by liquid or particles – Clean metering tube

Tab.1: Troubleshooting

7.2 Spare parts and accessories

Please also specify the model and serial number when ordering parts.

Upgrade and expansion parts can be found in our catalog.

Available spare parts:

Item no. Description

40 15 89 97 Gasket for Ø 10 mm tube diameter

40 55 05 0 Gasket for Ø 15 mm tube diameter

7.2.1 Spare parts and accessories - S-SM

Item no. Description

40 22 999 Flow Meter S-SM 3-1 End sections stainless steel 1.4571

40 23 999 Flow Meter S-SM 3-1 End sections titanium

7.2.2 Spare parts and accessories - switch amplifier

Item no. Description

91 000 700 04 Switch amplifier, KFD2-SR2-Ex 1.W, 24 V DC

91 000 700 05 Switch amplifier, KFA5-SR2-Ex 1.W, 115 V AC

91 000 700 06 Switch amplifier, KFA6-SR2-Ex 1.W, 230 V AC

91 000 700 07 Switch amplifier, KCD2-E2L, 24 V DC

49 490 21 Limit switch with mounting bracket Ø10

49 490 19 Limit switch with mounting bracket Ø15

12 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 15

SM-6, SM-6-V, SSM 3-1

8 Disposal

Dispose of parts so as not to endanger the health or environment. Follow the laws in the country of use for disposing of electronic components and devices during disposal.

13Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 16

SM-6, SM-6-V, S-

10

** Max. operating pressure [bar] = 10 -

Max. operating temperature [°C] - 20

SM 3-1

9 Appendices

9.1 Technical Data

Flow meter SM-6, SM-6-V

Ambient temperature: -20 °C to +80 °C *

Medium temperature: ≤ 150 °C, for special ranges max. 80 °C

Operating pressure max. 4 bar

Material

Heads: PTFE

Seal: PTFE

Adjusting spindle: PVDF / Viton or PCTFE / perfluoroelastomer

Measuring tube: Borosilicate glass

Float: Hastelloy C 4 or optional

PEEK with soft iron core

Swivel nut: PPS fibreglass reinforced

Base plate: PA

* Please note the ambient temperature for the configuration with limit switch!

Limit switch Ø10 Ø15

Protection class: IP 67 IP 67

Ambient temperature: -20 °C to +100 °C -20 °C to +70 °C

Housing material: PBT PBT

Operation: bi-stable bi-stable

Cord length: 2 m 2 m

Approval: PTB 99 ATEX 2128X

II 2 G Ex ia II C T6…T1 Gb

Safety Flow Meter S-SM 3-1

Ambient temperature: -20 °C to 80 °C *

Operating pressure: 10 bar (at max. 20 °C) **

Operating temperature: 100 °C (at max. 2 bar) **

Measuring range: see table

Weight: 0.9 kg

Float: glass, Hastelloy, stainless steel or PTFE

End sections: PTFE, stainless steel or titanium

Mounting: via included pipe clamps

* specify in order, select mounting.

PTB 99 ATEX 2128X

II 2 G Ex ia II C T6…T1 Gb

14 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 17

SM-6, SM-6-V, S-

SM-6 SM-6-V

max.

SM 3-1

Switch amplifier KFD2-SR2-Ex 1.W KFA5-SR2-Ex 1.W KFA6-SR2-Ex 1.W KCD2-E2L

Supply voltage: 20 - 30 V DC 103.5 - 126 V AC

45 - 65 Hz

Inherently safe per: EN 60079-11 EN 60079-11 EN 60079-11 no

Line monitor: yes yes yes yes

Approvals:

(FM, UL, CSA, IECEx in accordance

with the operating instructions)

Output (not inherently safe): Change-over contact Change-over contact Change-over contact NO contact

Switching current output: 230 V AC, 2 A

Ambient temperature: -20 °C ...+60 °C -20 °C ...+60 °C -20 °C ...+60 °C -25 °C ...+70 °C

Protection class: IP 20 IP 20 IP 20 IP 20

Dimensions: 20x119x115 mm

PTB 00 ATEX 2080

II(1)G [Ex ia Ga] IIC

cos φ > 0.7

40 V DC, 2 A

ohmic load

(WxHxD)

PTB 00 ATEX 2081

230 V AC, 2 A

cos φ > 0.7

40 V DC, 2 A

ohmic load

20x119x115 mm

(WxHxD)

II(1)G [Ex ia Ga] IIC

207 - 253 V AC

45 - 65 Hz

PTB 00 ATEX 2081

230 V AC, 2 A

cos φ > 0.7

40 V DC, 2 A

ohmic load

20x119x115 mm

(WxHxD)

10 - 30 V DC

II(1)G [Ex ia Ga] IIC

PNP transistor

200 mA DC

20x63x44 mm

(WxHxD)

9.2 Dimensions

SM6 / SM6-V flow meter:

15Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 18

SM-6, SM-6-V, S-

Locking screw

Limit switch

Locking screw

Switching point

7

34

20

SM 3-1

Limit switch:

S-SM safety flow meter:

9.3 Measuring ranges

Medium: Air Water

Pressure: + 1.2 bar abs.

Temperature: + 20 °C + 20 °C

16 Bühler Technologies GmbH BE400001 ◦ 11/2016

SM-6 flow meter

6 … 60 Nl/h 0.5 … 5 L/h

10 … 100 Nl/h 1.2 … 12 L/h

25 … 250 Nl/h 2.5 … 25 L/h

50 … 500 Nl/h 4 … 40 L/h

80 … 800 Nl/h 6 … 60 L/h

Page 19

SM-6, SM-6-V, SSM 3-1

Flow Meter S-SM 3-1

Medium: Air Water

Pressure: + 1.2 bar abs.

Temperature: + 20 °C + 20 °C

1.6 – 16 Nl/h 0.25 - 2.5 l/h

4 – 40 Nl/h 0.5 - 5 l/h

6 - 60 Nl/h 1.2 - 12 l/h

10 – 100 Nl/h 2.5 - 25 l/h

25 – 250 Nl/h 4 - 40 l/h

50 – 500 Nl/h 6 - 60 l/h

80 – 800 Nl/h 10 - 100 l/h

17Bühler Technologies GmbHBE400001 ◦ 11/2016

Page 20

SM-6, SM-6-V, SSM 3-1

10 Attached documents

– Manufacturer Declaration HX 40 0001

– RMA - Decontamination Statement

18 Bühler Technologies GmbH BE400001 ◦ 11/2016

Page 21

Page 22

RMA - Dekontaminierungserklärung

DE/EN

Gültig ab / valid since:

2014/11/01

Revision / Revision

1

ersetzt Rev. / replaces Rev.

0

Seite

1 / 2

Bühler Technologies GmbH

D - 40880 Ratingen, Harkortstr. 29

Tel.: + 49 (0) 2102 / 4989-0 Fax: + 49 (0) 2102 / 4989-20

e-mail: service@buehler-technologies.com

Internet: www.buehler-technologies.com

Page

Um eine schnelle und reibungslose Bearbeitung Ihres Anliegens zu erreichen, füllen Sie bitte diesen Rücksendeschein

aus. Eine genaue Fehlerbeschreibung ist für die Ursachenanalyse nötig und hilft bei der schnellen Bearbeitung des

Vorgangs. Die Aussage „Defekt“ hilft bei der Fehlersuche

leider nicht.

Please complete this return form to ensure your claim is

processed quickly and efficiently. An accurate description of

the problem is necessary for cause analysis and will help

processing the claim quickly. Unfortunately, stating

“defective” will not help us troubleshoot the issue.

Die RMA-Nummer bekommen Sie von Ihrem

Ansprechpartner im Vertrieb oder Service.

You may obtain the RMA number from your sales or

service representative.

Zu diesem Rücksendeschein gehört eine Dekontaminierungserklärung. Die gesetzlichen Vorschriften schreiben vor, dass

Sie uns diese Dekontaminierungserklärung ausgefüllt und

unterschrieben zurücksenden müssen. Bitte füllen Sie auch

diese im Sinne der Gesundheit unserer Mitarbeiter

vollständig aus.

This return form includes a decontamination statement. The

law requires you to submit this completed and signed

decontamination statement to us. Please complete the entire

form, also in the interest of our employees’ health.

Bringen Sie den Rücksendeschein mit der

Dekontaminierungserklärung bitte zusammen mit den

Versandpapieren in einer Klarsichthülle außen an der

Verpackung an. Ansonsten ist eine Bearbeitung Ihres

Reparaturauftrages nicht möglich!

Attach the return form including decontamination

statement along with the shipping documentation to the

outside of the package, inside a clear pouch. Otherwise

we are unable to process your repair order!

Angaben zum Absender:

Sender information:

Firma / Company

Ansprechpartner /

Contact person

Anschrift / Address

Abteilung /

Department

E-Mai / E-Mail:

Tel. / Phone

Fax / Fax:

Artikelnummer /

Item number

RMA-Nr. /

RMA no.

Auftragsnummer /

Order number

Anzahl / Quantity

Rücksendegrund /

Return reason

Reparatur / Repair

Vorgangsnummer des Kunden /

Customer transaction number::

Garantie / Warranty

Zur Prüfung / For inspection

Rückgabe / Return

Fehlerbeschreibung / Description of the problem:

Ort, Datum /

Place, Date

Unterschrift / Stempel /

Signature / Stamp:

RMA - Decontamination Statement

Page 23

RMA - Dekontaminierungserklärung

DE/EN

Gültig ab / valid since:

2014/11/01

Revision / Revision

1

ersetzt Rev. / replaces Rev.

0

Seite

2 / 2

Bühler Technologies GmbH

D - 40880 Ratingen, Harkortstr. 29

Tel.: + 49 (0) 2102 / 4989-0 Fax: + 49 (0) 2102 / 4989-20

e-mail: service@buehler-technologies.com

Internet: www.buehler-technologies.com

Page

Bitte füllen Sie diese Dekontaminierungserklärung für jedes

einzelne Gerät aus.

Please complete this decontamination statement for each

individual item

Gerät / Device

RMA-Nr /

RMA no:

Serien-Nr. / Serial no.

[ ]

Ich bestätige hiermit, dass das oben spezifizierte

Gerät ordnungsgemäß gereinigt und dekontaminiert

wurde und keinerlei Gefahren im Umgang mit dem

Produkt bestehen.

I herewith declare that the device as specified above has been

properly cleaned and decontaminated and that there are no

risks present when dealing with the device.

Ansonsten ist die mögliche Gefährdung genauer zu

beschreiben:

In other cases, please describe the hazards in detail:

Aggregatzustand (bitte ankreuzen):

Aggregate state (please check):

Flüssig / Liquid

Fest / Solid

Pulvrig / Powdery

Gasförmig / Gaseous

Folgende Warnhinweise sind zu beachten

(bitte ankreuzen):

Please note the following warnings (please check):

Explosiv

Explosive

Giftig / Tödlich

Toxic / lethal

Entzündliche Stoffe

Flammable substances

Brandfördernd

Oxidizing

Komprimierte Gase

Compressed gasses

Gesundheitsgefährdend

Hazardous to health

Gesundheitsschädlich

Harmful to health

Umweltgefährdend

Harmful to the environment

Bitte legen Sie ein aktuelles Datenblatt des

Gefahrenstoffes bei!

Please include an updated data sheet of the hazardous

substance!

Ort, Datum /

Place, Date:

Unterschrift / Stempel

Signature / Stamp:

RMA - Decontamination Statement

Loading...

Loading...