Page 1

Page 2

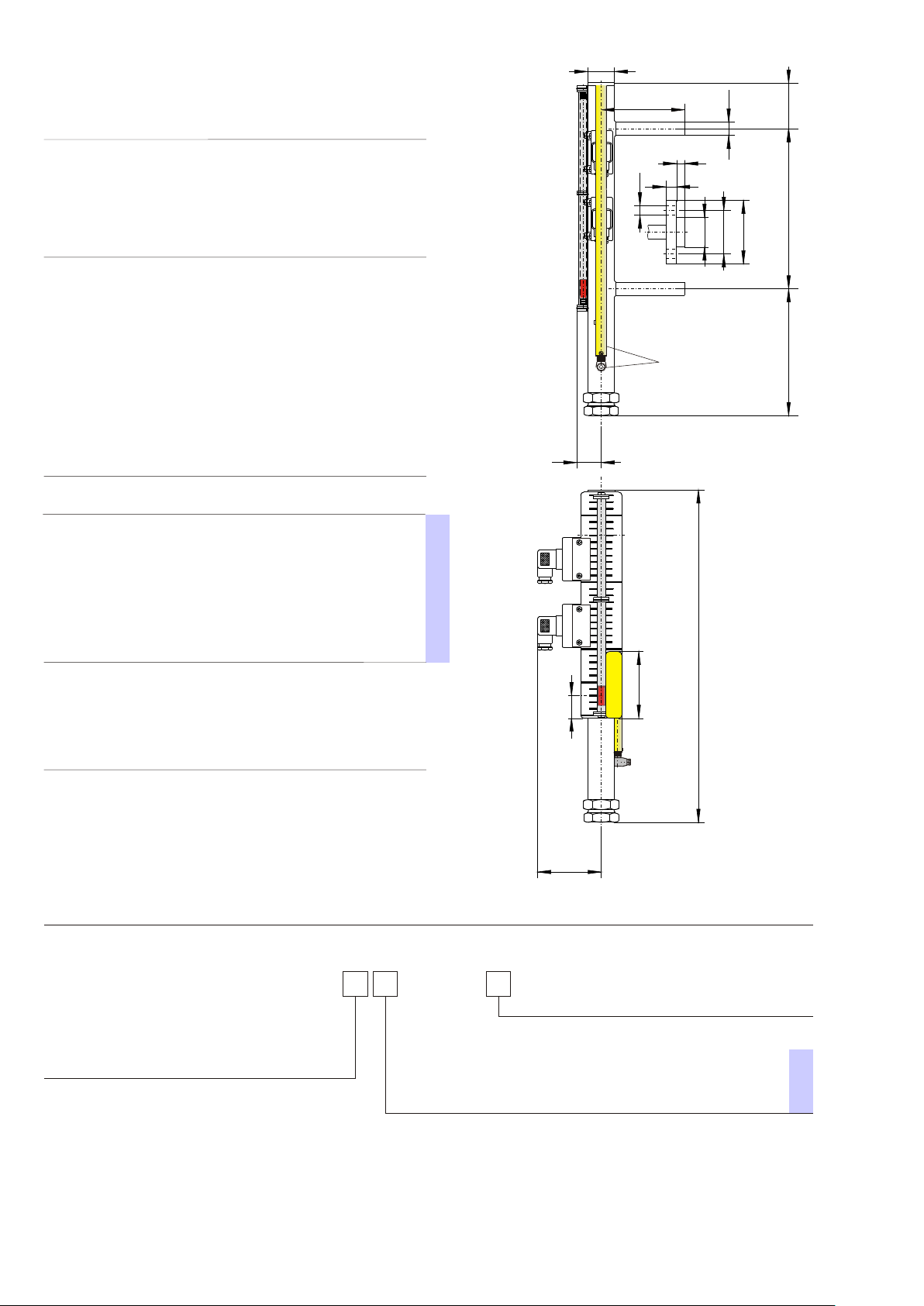

Technical data NS 10 ..-AM

Basic unit

max. operating pressure 10 bar

max. operating temperature 100 °C

min. spec. density of fluid 0.75 kg/dm³

Material

float SK166 NBR

standpipe 1.4571

flange steel galvanized

sight glass PC

sealing cap 1.4571

Design 0-AM 15-AM 25-AM

connector pipe flange flange

flange DIN 2656 DN15 DN25

øD 20 95 115

øk 65 85

ød 14 14

b 16 18

øA 45 68

h 12 14

weight at L1=500 mm, approx. 7.5 kg 8 kg 8.75 kg

weight L1 + 100 mm, approx. 0.2 kg 0.2 kg 0.2 kg

Other designs on request

appropriate level contacts see on page 4

Ø40

125

Ø D

65

h

b

Ød

ØA

ØD

Øk

F00000075X

optional transducer

tube with continuous

output signal

37

L1 = max. 2700

190

Option

transducer tube -K continuous level

measurement principle reed contact

resolution 5 or 10 mm

operating voltage (U ) 10 - 30 V DC

B

output 4 - 20 mA

(nominal voltage 24 V DC)

load W max. = (U - 7.5 V) / 0.02 A

B

O

P

T

I

O

N

Accessories:

Part No.

22 51 000 flange gasket 45/22x2 mm (DN15)

22 52 000 flange gasket 68/27x2 mm (DN25)

22 71 999 mounting bolts 8 x M12x65

Notes on the Pressure Equipment Directive:

The level switches were designed, manufactured and tested in

accordance with the Pressure Equipment Directive 91/23/EU and the

AD 2000 Code.

The category actually achieved by the level sensor is printed on the

type plate. Depending on this category, comprehensive quality

assurance is performed according to Module H and/or H1 standard.

Product code for NS 10

L=(L1+258)

100

No contacts here

Pas de contacts ici

Hier keine Kontakte

34

96

-SK166/NS 10/

Design

Length

L1 = ...mm

0-AM with stub pipe

15-AM flange DN 15

25-AM flange DN 25

Option transducer tube

-K5 continuous resolution 5 mm

-K10 continuous resolution 10 mm

Example for order

You need: Level switch for the external mounting, operating pressure max. 10 bar, with flange connection DN15,

distance of stub L1 = 1500 mm, with 2 change over contacts MKS - 1/W

You order: NS 10/15-AM-SK166 / 1500

2 x Part No. 288 99 99 contact MKS 1/W

DE 20 0201

02/2012

Page 2/4

we reserve the right to amend specifications

O

P

T.

Page 3

Technical data NS 25 ..-AM

Basic unit

max. operating pressure 25 bar

max. operating temperature 120 °C

min. spec. density of fluid SK 661 SK 662

0.85 kg/dm³ 0.70 kg/dm³

Material

float 1.4571

standpipe 1.4571

flange galvanized steel

sight glass PC

Design 15-AM 25-AM

connector flange flange

flange DIN 2656 DN15 DN25

øD 95 115

øk 65 85

ød 14 14

b 16 18

øA 45 68

h 12 14

S with float SK 661 205 205

SK 662 390 390

weight at L1 = 500 mm, approx 9.5 kg 10.5 kg

weight L1+100 mm, approx. 0.4 kg 0.4 kg

other designs on request

125

b

d

ø

5X

2

01

0

F0

h

k

ø

øD

øA

optional transducer

tube with continuous

output signal

86

appropriate level contacts see on page 4

Option

transducer tube -K continuous level

measurement principle reed contact

resolution 5 or 10 mm

operating voltage(U ) 10 - 30 V DC

B

output 4 - 20 mA

(nominal voltage 24 V DC)

load W max. = (U - 7.5 V) / 0.02 A

B

O

P

T

I

O

N

L1

8

6

+

+S

1

L

L=

Accessories

Part No. Description

22 51 000 flange gasket 45/22x2mm (DN15)

22 52 000 flange gasket 68/27x2mm (DN25)

22 71 999 mounting bolts 8 x M12x65

Notes on the Pressure Equipment Directive:

S

The level switches were designed, manufactured and tested in accordance

with the Pressure Equipment Directive 91/23/EU and the AD 2000 Code.

The category actually achieved by the level sensor is printed on the type plate.

Depending on this category, comprehensive quality assurance is performed

according to Module H and/or H1 standard.

ø115

Product code for NS 25

NS 25/

Design

15-AM flange DN 15

25-AM flange DN 25

O

Option transducer tube

-K5 continuous resolution 5 mm

P

-K10 continuous resolution 10 mm

T.

Example for order

You need: Level switch for external mounting, operating pressure max. 25 bar, with flange connector DN25,

You order: NS 25/25-AM-K10-SK661 / 1500

DE 20 0201

02/2012

Page 3/4

spec. density of fluid 0.89 kg/dm³ stub distance L1 = 1500mm, continuous level output, resolution 10 mm and

with 2 change over contacts MKS - 1/W (see on page 4)

2 x Part No. 288 99 99 contact MKS - 1/W

/

Length

L1 = ...mm

float type

-SK661 min. spec. density of fluid 0.85 kg/dm³

-SK662 min. spec. density of fluid 0.70 kg/dm³

We reserve the right to amend specifications

Page 4

Contacts for NS ..-AM

Type MKS-1/K

function NC / NO

max. voltage 230 V AC/DC

max. current 1 A

max. load of contact 50 VA

connector DIN EN 175301-803 (M3)

3 pol. + PE

protection system IP 65

Part No. 28 88 999

Pin assignment (contact position empty reservoir)

mounting left mounting right

1

2

3

PE

1

2

3

PE

Type MKS-2/K

function 2 x NC / NO

max. voltage 230 V AC/DC

max. current 1 A

max. load of contact 50 VA

connector S6

6 pol. + PE

protection system IP 65

Part No. 28 91 999

Type MKS-1/W

function change over

max. voltage 230 V AC/DC

max. current 1 A

max. load of contact 50 VA

connector DIN EN 175301-803 (M3)

3 pol. + PE

protection system IP 65

Part No. 28 89 999

Type MKS-1/W-L 24 V

function change over with LED

max. voltage 24 V DC

max. current 1 A

max. load of contact 25 VA

connector S6

6 pol. + PE

protection system IP 65

Part No. 28 90 999

1

2

3

4

5

6

PE

1

2

3

PE

1 +24V

2

3

4 GND

LED red LED red

5

6

PE

1

2

3

4

5

6

PE

1

2

3

PE

1 +24V

2

3

4 GND

5

6

PE

other contacts on request

For operations in areas with strong vibrations we

suggest to use contacts MKS-1/K and MKS-2K.

Pin assignment for AM-K with connector S3

MKS 1/K

MKS 1/W

65

79

3

4

65

3

4

MKS 2/K

81

4-20

mA

1 +24V DC

level out

2

When mounting a

transducer tube

with continuous output

signals you have to

keep in mind that the

mounting of contacts

is possible only

on the left side.

MKS 1/W-L24V

56

81

34

DE 20 0201

02/2012

Page 4/4

We reserve the right to amend specifications

Loading...

Loading...