Page 1

Gas Analysis

Sample gas probes

GAS 222.35 AMEX

Installation and Operation Instructions

Original instructions

BE460058

08/2019

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

E-Mail: analyse@buehler-technologies.com

Internet: www.buehler-technologies.com

Page 2

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

Internet: www.buehler-technologies.com

E-Mail: analyse@buehler-technologies.com

Read this instruction carefully prior to installation and/or use. Pay attention particularly to all advises and safety instructions to prevent injuries. Bühler Technologies can not be held responsible for misusing

the product or unreliable function due to unauthorised modifications.

All rights reserved. Bühler Technologies GmbH 2019

Document information

Document No......................................................... BE460058

Version.........................................................................08/2019

Page 3

GAS 222.35 AMEX

Table of Contents

1 Introduction..................................................................................................................................................................................................................... 2

1.1 Intended Use......................................................................................................................................................................................................... 2

1.2 Type Plate............................................................................................................................................................................................................... 2

1.3 Scope of Delivery.................................................................................................................................................................................................. 2

1.4 Ordering instructions ........................................................................................................................................................................................3

1.5 Product Description............................................................................................................................................................................................ 3

2 Safety instructions.........................................................................................................................................................................................................4

2.1 Important advice ................................................................................................................................................................................................. 4

2.2 General Hazard Warnings ................................................................................................................................................................................5

3 Transport and storage .................................................................................................................................................................................................. 7

4 Installation and connection........................................................................................................................................................................................8

4.1 Installation site requirements.........................................................................................................................................................................8

4.2 Installation ............................................................................................................................................................................................................8

4.3 Installing the Inlet Filter ....................................................................................................................................................................................8

4.4 Insulation...............................................................................................................................................................................................................8

4.5 Connecting the Gas Line....................................................................................................................................................................................9

4.5.1 Blowback Connection ......................................................................................................................................................................... 9

4.5.2 Connecting the Gas Line .................................................................................................................................................................... 9

4.5.3 Connecting the calibrating gas line (optional)..........................................................................................................................10

4.6 Connecting the Blowback and Pressure Vessel (Optional) ...................................................................................................................10

4.7 Electrical connections ......................................................................................................................................................................................10

4.7.1 Heated pressure vessel (optional) ..................................................................................................................................................11

5 Operation and Control.................................................................................................................................................................................................13

5.1 Before Start-Up ...................................................................................................................................................................................................13

6 Maintenance.................................................................................................................................................................................................................. 14

6.1 Maintaining the filter element ......................................................................................................................................................................15

6.1.1 Replacing the Inlet Filter .................................................................................................................................................................. 15

6.2 Blowback of the in-situ filter (within the process stream).................................................................................................................... 16

6.2.1 Manual Blowback (Without Blowback Control) ........................................................................................................................16

6.2.2 Automatic Blowback (External Blowback Control)...................................................................................................................16

6.3 Maintenance Schedule .....................................................................................................................................................................................17

7 Service and repair......................................................................................................................................................................................................... 18

7.1 Troubleshooting ................................................................................................................................................................................................ 18

7.2 Spare Parts and Accessories ...........................................................................................................................................................................19

8 Disposal...........................................................................................................................................................................................................................20

9 Appendices......................................................................................................................................................................................................................21

9.1 Technical Data .................................................................................................................................................................................................... 21

9.2 Connection Diagram ........................................................................................................................................................................................ 21

9.3 Connection diagram heated pressure vessel............................................................................................................................................22

9.4 Flow diagram......................................................................................................................................................................................................22

9.5 Dimensions ......................................................................................................................................................................................................... 23

9.6 List of chemical resistance..............................................................................................................................................................................24

9.7 User book (Please make copies) .................................................................................................................................................................... 25

10 Attached Documents...................................................................................................................................................................................................26

iBühler Technologies GmbHBE460058 ◦ 08/2019

Page 4

GAS 222.35 AMEX

GAS 222.35 AMEX

100105177 462223516633000999999 001

Cl. 1, Div. 2, Gps. B, C, D, T3

CSA Certificate: 1728394

Install per drawing 46/115-Z01-06-4

115-230 V; max. 360W @ 230V

at -20 up to 80 °C; max. 6 bar

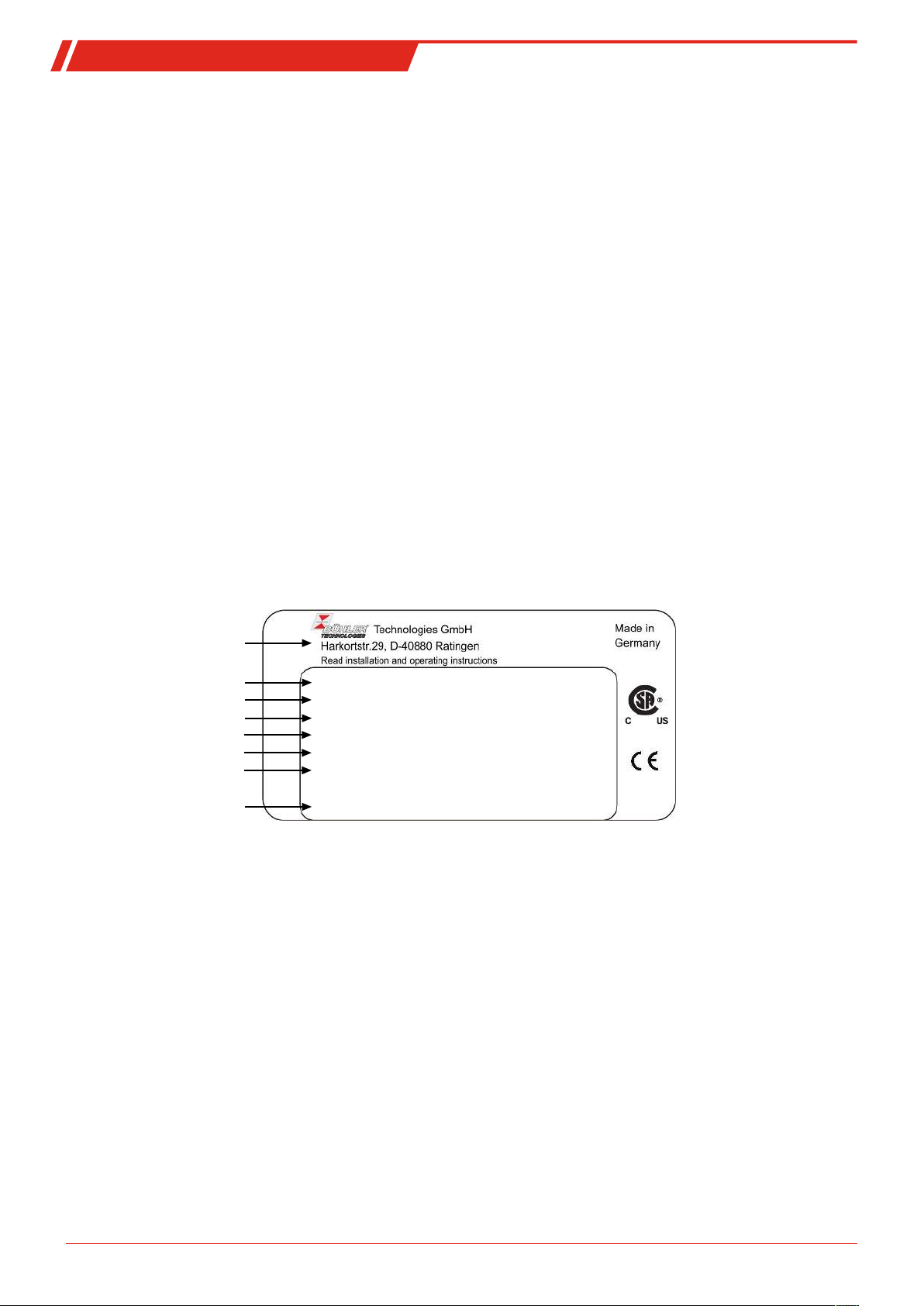

Manufacturer and address

Year: 2019

Type designation

Order no., Item no.

Blast protection marking

CSA certificate number

Drawing number

Item description

Year of manufacture

1 Introduction

1.1 Intended Use

The sample gas probe is intended for installation into gas analysis systems in commercial applications.

Sample gas probes are among the main components in a gas conditioning system.

– Therefore also note the related drawing in the data sheet in the appendix.

– Before installing the device, verify the listed technical data meet the application parameters.

– Further verify all contents are complete.

Please refer to the type plate to identify your model. In addition to the job number/ID number, this also contains the article

number and model designation.

Please note the specific values of the device when connecting, and the correct versions when ordering spare parts.

Passing through gases

Flammable gases above the UEL may only be blown back with inert gases. Flammable gases from 25% LEL and up to the UEG

may be blown back provided the operator ensures the blown back gas is not and cannot be explosive. For safety reasons we recommend only using inert gases in these cases as well.

Blowing back explosive atmospheres (range from UEG to OEG) with the probes is prohibited due to possible adiabatic compression (high blowback pressure against contaminated filter). The operator is responsible for compliance with these conditions taking into account his risk assessment.

1.2 Type Plate

Example:

1.3 Scope of Delivery

– 1 x Sample gas probe

– 1 x Flange gasket and screws

– Product documentation

– Connection and mounting accessories (only optional)

2 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 5

GAS 222.35 AMEX

1.4 Ordering instructions

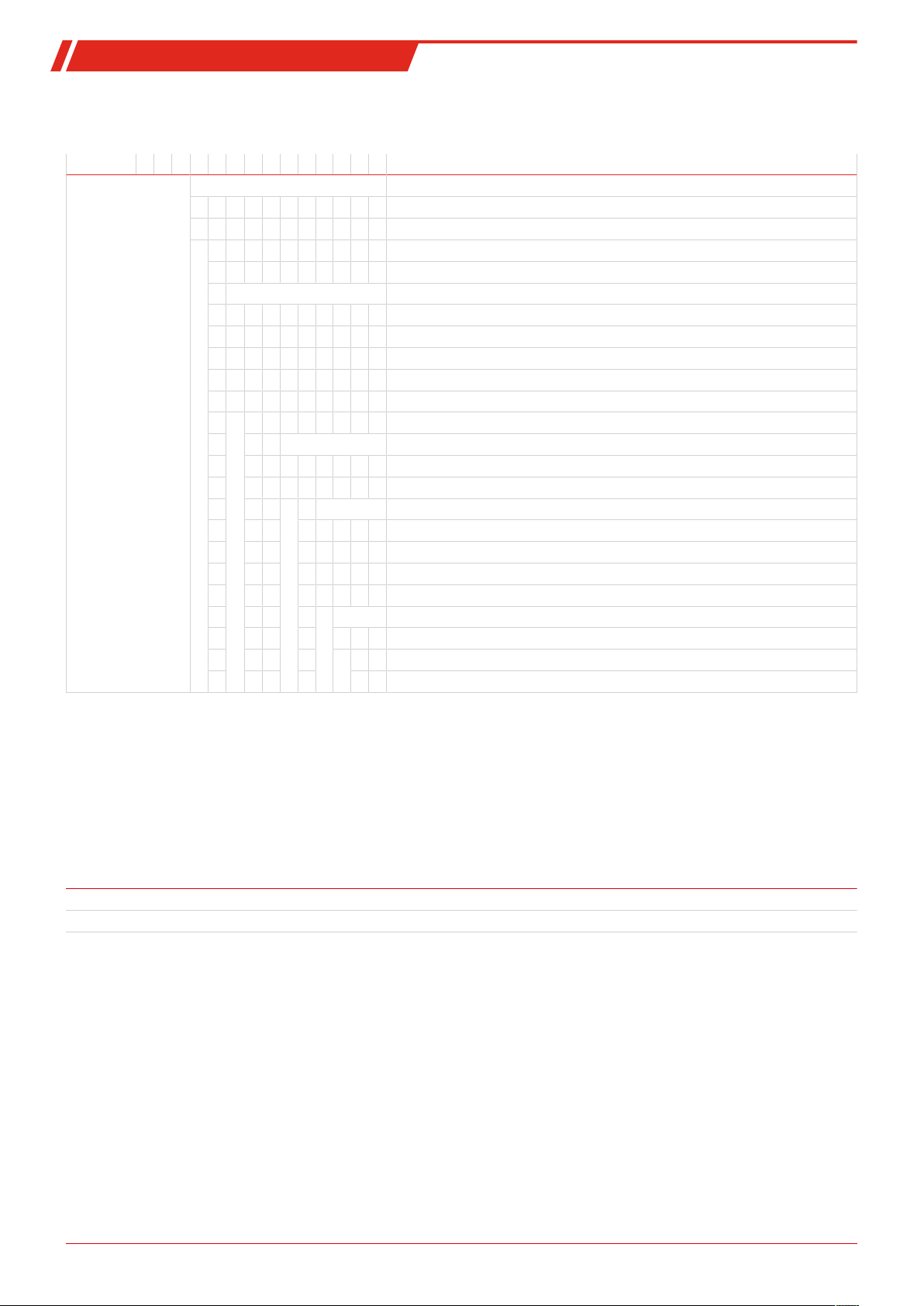

The item number is a code for the configuration of your unit. Please use the following model key:

4622235 1 6 6 X 3 X 0 0 X 9 X 9 9 9 Product Characteristics

1)

Ex temperature classes

3 T3

4 T4

Sample probe power supply

3 115 / 230 V

Calibration gas connection

0 No calibration gas connection

1 6 mm

2 6 mm + check valve

3 1/4"

4 1/4" + check valve

Blowback with air reservoir

2)

Air reservoir heating

1 Yes

9 No

Compressed air valve/valve voltage information

0 Manual

1 120 V 60 Hz

2 240 V 60 Hz

9 None (if no blowback requested)

Pneumatic drive for ball valve

9 N/A

Control valve for pneumatic drive

9 No control valve

1)

Please note, using certain accessories may limit gas probe use in Ex areas! Observe the respective operating manuals, accessory

compatibility charts, and data sheets to ensure proper technical product design!

2)

In the case of flammable gases, always use inert gas for blowback. Probe blowback prohibited when using explosive sample

gas!

1.5 Product Description

The probe is equipped with self-regulating PTC heating cartridges and a temperature contact.

Probe Description

GAS 222.35 AMEX Probe with retractable inlet filter and blowback connection

Accessories Please refer to the data sheet at the end of this manual for accessories for this probe

3Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 6

GAS 222.35 AMEX

DANGER

WARNING

CAUTION

NOTICE

2 Safety instructions

2.1 Important advice

This unit may only be used if:

– the product is being used under the conditions described in the operating- and installation instructions, used according to

the nameplate and for applications for which it is intended. any unauthorized modifications to the device will void the warranty provided by Bühler Technologies GmbH,

– the limits in the data sheet and the instructions must be observed,

– the temperature switch is being operated on an intrinsically-safe circuit,

– the controller itself is installed outside the explosive area,

– Monitoring equipment / protection devices must be connected correctly,

– service and repairs not described in these instructions is performed by Bühler Technologies GmbH,

– using genuine replacement parts.

– Regulation IEC/EN60079-14 must be observed when erecting electrical systems in explosive areas.

– Additional national regulations pertaining to initial operation, operation, maintenance, repairs and disposal must be ob-

served.

– These operating instructions are a part of the equipment. The manufacturer reserves the right to change performance-, spe-

cification- or technical data without prior notice. Please keep these instructions for future reference.

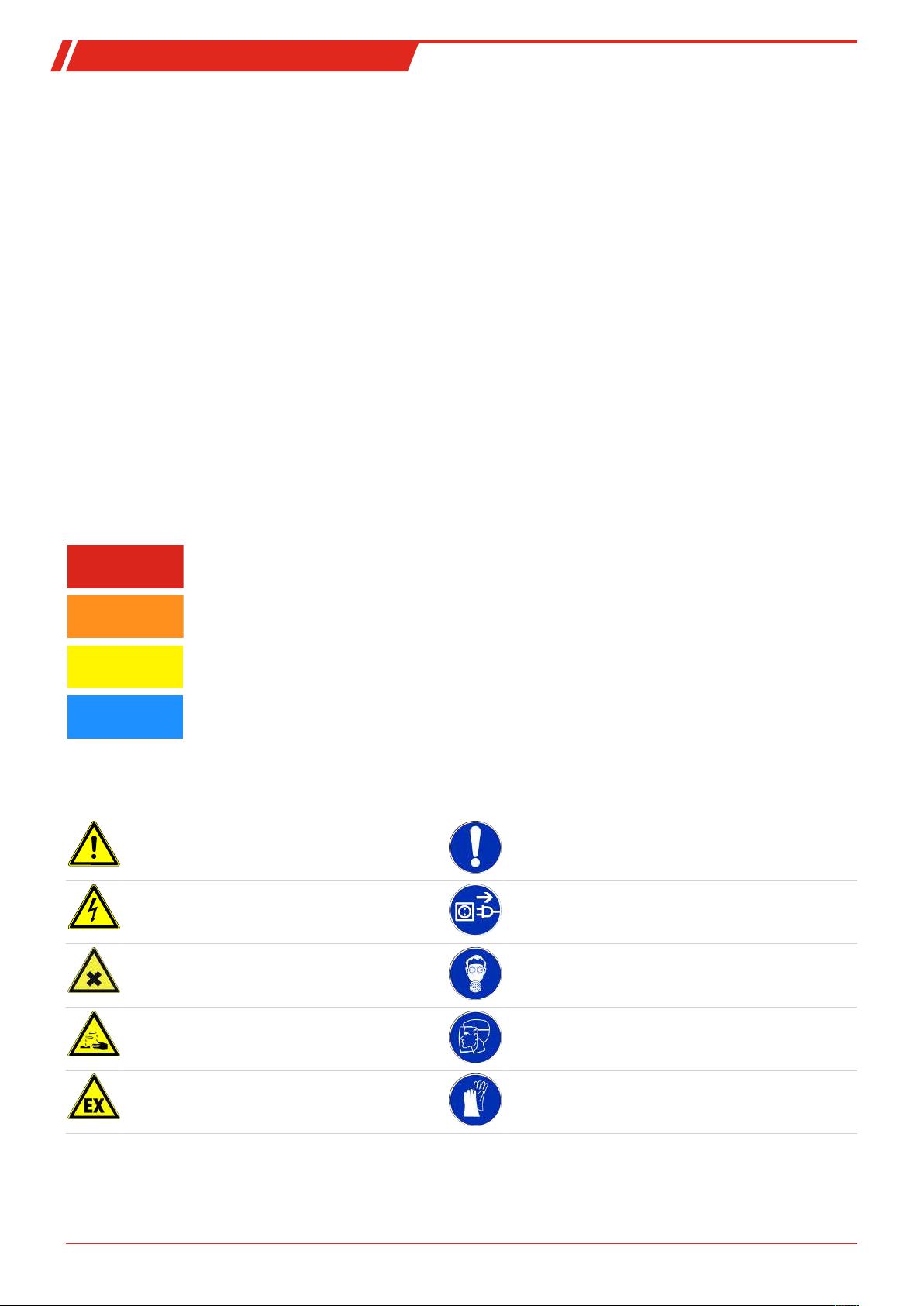

Signal words for warnings

Signal word for an imminent danger with high risk, resulting in severe injuries or death if not avoided.

Signal word for a hazardous situation with medium risk, possibly resulting in severe injuries or death if not

avoided.

Signal word for a hazardous situation with low risk, resulting in damaged to the device or the property or

minor or medium injuries if not avoided.

Signal word for important information to the product.

Warning signs

These instructions use the following warning signs:

Warns of a general hazard General notice

Warns of voltage Unplug from mains

Warns not to inhale toxic gasses Wear respiratory equipment

Warns of corrosive liquids Wear a safety mask

Warns of explosive areas Wear gloves

4 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 7

GAS 222.35 AMEX

2.2 General Hazard Warnings

The maximum surface temperature of the probes solely varies by operating conditions

temperature, ambient temperature, fluid flow rate). For use

ings.

The equipment must be installed by a professional familiar with the safety requirements and risks.

Be sure to observe the safety regulations and generally applicable rules of technology relevant for the installation site. Prevent

malfunctions and avoid personal injuries and property damage.

in explosive areas

please particularly note the related hazard warn-

(steam temperature, sample gas inlet

The operator of the system must ensure:

– Safety notices and operating instructions are available and observed,

– The respective national accident prevention regulations are observed,

– The permissible data and operational conditions are maintained,

– Safety guards are used and mandatory maintenance is performed,

– Legal regulations are observed during disposal,

– compliance with national installation regulations.

Maintenance, Repair

Please note during maintenance and repairs:

– Repairs to the unit must be performed by Bühler authorised personnel.

– Only perform conversion-, maintenance or installation work described in these operating and installation instructions.

– Always use genuine spare parts.

Always observe the applicable safety and operating regulations in the respective country of use when performing any type of

maintenance.

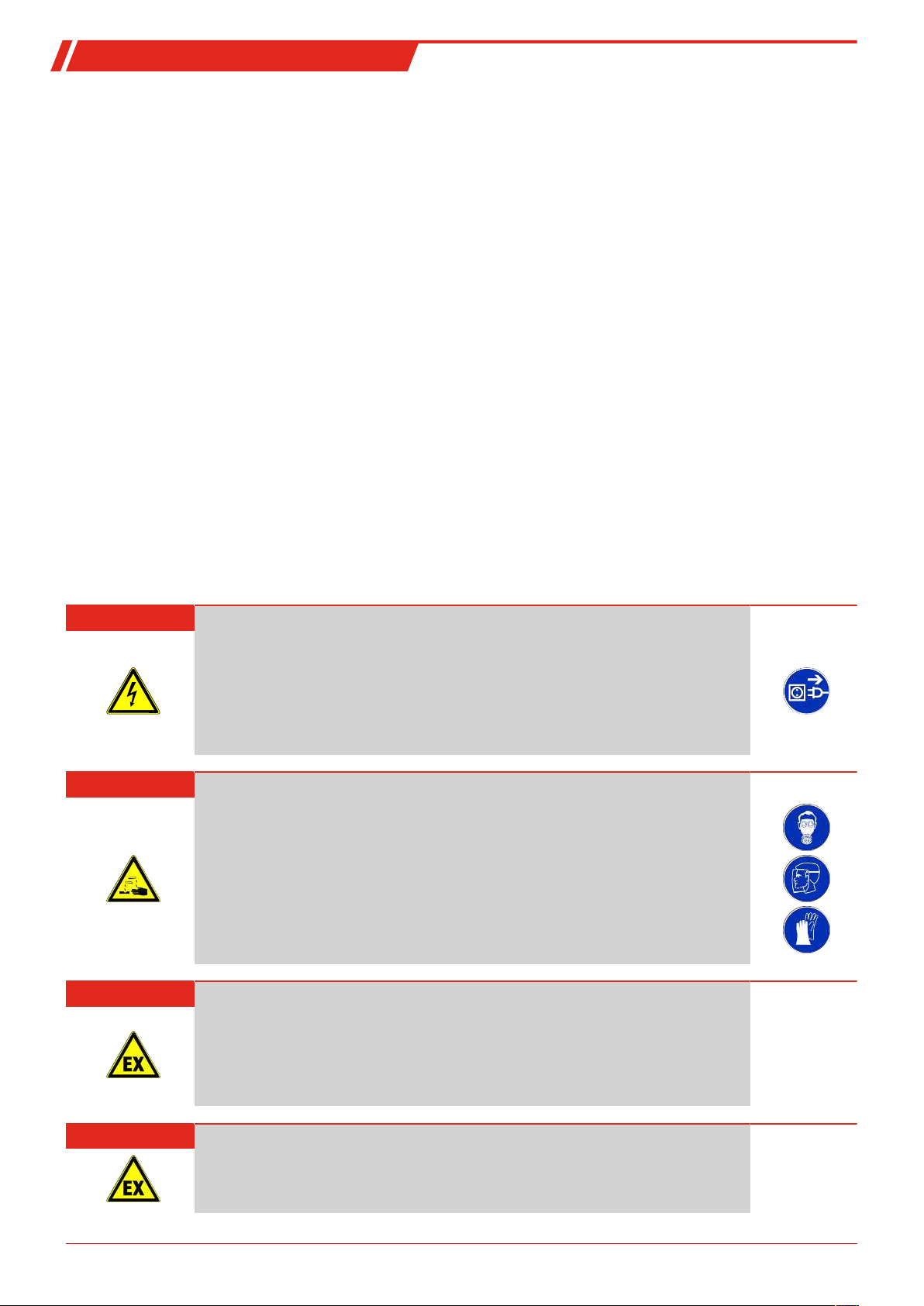

DANGER Electrical voltage

Electrocution hazard.

a) Disconnect the device from power supply.

b) Make sure that the equipment cannot be reconnected to mains unintentionally.

c) The device must be opened by trained staff only.

d) Regard correct mains voltage.

DANGER Toxic, corrosive gas/condensate

Sample gas/condensate may be hazardous to health.

a) If necessary, ensure a safe gas/condensate discharge.

b) Always disconnect the gas supply when performing maintenance or repairs.

c) Protect yourself from toxic/corrosive gasses/condensate when performing mainten-

ance. Wear appropriate protective equipment.

DANGER Explosion hazard

Life and explosion risk may result from gas leakage due to improper use.

a) Use the devices only as described in this manual.

b) Regard the process conditions.

c) Check tubes and hoses for leakage.

DANGER Danger to life and explosion during installation and maintenance

The unit must not be worked on (assembly, installation, maintenance) in explosive atmospheres.

5Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 8

GAS 222.35 AMEX

DANGER

Use in explosive areas

Flammable gasses and dust could ignite or explode. Avoid the following hazard sources:

Application area!

Never operate the gas probe outside the specifications. Extracting gases or gas mixtures

which are also explosive in the absence of air is prohibited.

Electrostatic charge (sparking)!

The equipment may only be used where normal operating conditions do not frequently

produce flammable, electrostatic discharge.

Always clean plastic housing parts and decals with a damp cloth.

Sparking!

Protect the equipment from external blows.

Flame propagation!

If the process holds a risk of flame propagation, install a flame arrestor.

Adiabatic compression (explosion hazard)

Adiabatic compression may cause high gas temperatures during blowback.

back if gases are explosive. Only use nitrogen (inert gas) to blowback

Dust:

If possible, take the electrical components which must be opened for repair to a dustfree room. If unable to do so, prevent dust from entering the housing.

Ignition of dust layers!

When using the device in a dusty environment, routinely clean dust from all components.

The ignition temperature resp. smouldering temperature of flammable dusts resp. dust

layers present must be considerably higher than the maximum surface temperature of

the probe (observe applicable standards and statutory regulations).

Never blow-

flammable

gas

.

6 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 9

GAS 222.35 AMEX

3 Transport and storage

Only transport the product inside the original packaging or a suitable alternative.

The equipment must be protected from moisture and heat when not in use. They must be stored in a covered, dry and dust-free

room at a temperature between -20°C to 50°C (-4°F to 122°F).

7Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 10

GAS 222.35 AMEX

4 Installation and connection

4.1 Installation site requirements

Sample gas probes are intended for flange mounting.

– Installation site and installation position are determined based on requirements specific to the application.

– If necessary, the connection piece should be slightly tilted toward the centre of the channel.

– The installation site should be protected from the weather.

– In addition, adequate and safe access for installation and future maintenance work should be provided. Particularly follow

the uninstalled size of the probe tube!

If the probe is transported to the installation site in pieces, it will first need to be assembled.

4.2 Installation

DANGER Danger to life and explosion during installation and maintenance

The unit must not be worked on (assembly, installation, maintenance) in explosive atmospheres.

DANGER Explosion hazard

When used in explosive areas

Flammable gasses and dust could ignite or explode.

Never operate the gas probe outside the specifications. Extracting gases or gas mixtures

which are also explosive in the absence of air is prohibited.

DANGER Explosion hazard due to ignition of dust

When using the device in a dusty environment, routinely clean dust from all components.

The ignition temperature resp. smouldering temperature of flammable dusts resp. dust

layers present must be considerably higher than the maximum surface temperature of

the device (observe applicable standards and statutory regulations).

If possible, take the electrical components which must be opened for repair to a dustfree room. If unable to do so, prevent dust from entering the housing.

DANGER Explosion hazard due to flame propagation

Severe injuries and damage to the system

If the process holds a risk of flame propagation, install a flame arrestor.

4.3 Installing the Inlet Filter

The inlet filter, if necessary with matching extension, must be screwed in. The probe is then attached to the mating flange using

the included seals and screws.

4.4 Insulation

On heated probes completely insulate any exposed flange areas and, if applicable, the connection piece to absolutely prevent

thermal bridges. The insulating material must meet the application requirements and be weatherproof.

8 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 11

GAS 222.35 AMEX

4.5 Connecting the Gas Line

The sample gas line must be carefully and properly connected using a suitable fitting.

This table provides an overview of the sample gas probe connections:

Probe

GAS 222

Reservoir

PAV01

Ball valve

pneumatic drive

Control valve

3/2-way solenoid

valve

Connecting flange

1)

DN65/PN6/

DN3“-150

2)

Sample gas inlet G3/4

Sample gas outlet NPT 1/4

Blowback connection G3/8

Test gas connection

1)

Tube Ø6 mm

Tube Ø1/4

2)

Filling port NPT 1/4

Condensate G1/2

Bypass NPT 1/4

Control air G1/8 G1/4

NPT 1/4

Tab.1: Gas Probe Connections (Varies by Model)

1)

Varies by version.

2)

Only GAS 222.xx ANSI and GAS 222.xx AMEX

WARNING Gas emanation

Sample gas can be harmful to the health!

Check the lines for leaks.

4.5.1 Blowback Connection

If the probe has a G3/8 blowback connection, without factory installed blowback device it will be open. The blowback connection

must be sealed gas-tight prior to start-up.

DANGER Toxic, corrosive gasses

Explosive or toxic gases can develop due to a leaking or open blowback connection.

4.5.2 Connecting the Gas Line

Please note the following items when connecting the sample gas line (NPT 1/4") on heated probes to prevent thermal bridges:

– Choose the shortest possible screw connection.

– Shorten the connection pipe for the sample gas line as much as possible. To do so, remove the insulation around the sample

gas line. This is done by loosening the fixing bolts.

CAUTION Fragile

The insulation is fragile. Handle with care, do not drop.

After connecting the sample gas line it must be braced and secured with the clamp.

Long sample gas lines may require additional support clamps along the way to the analysis system! Once all lines have been

connected and checked for leaks, carefully reinstall and secure the insulation.

9Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 12

GAS 222.35 AMEX

WARNING Gas emanation

Sample gas can be harmful to the health!

Check the lines for leaks.

4.5.3 Connecting the calibrating gas line (optional)

Connecting the calibrating gas line requires a Ø6 mm or Ø1/4” pipe fitting.

If the calibrating gas connection was ordered with check valve, a Ø6 mm or Ø1/4” pipe can be connected directly to the check

valve.

4.6 Connecting the Blowback and Pressure Vessel (Optional)

The air lines must be connected carefully and properly, using suitable fittings.

If the probe is equipped with pressure vessel for efficient blowback (optional), a manual shut-off valve (ball valve) must be installed in the air supply, immediately upstream from the pressure vessel.

On probes used to sample flammable gas, nitrogen (inert gas) must be used for blowback. Blowback of explosive gases is prohibited.

NOTICE

The operating pressure of the compressed air (inert gas) required for blowback must always be higher than the process pressure.

Required pressure differential min. 3 bar (44 psi).

DANGER Broken pressure vessel

Gas leak, danger due to flying parts.

Maximum operating pressure of the pressure vessel 10 bar (145 psi)!

The operating pressure reduces based on the operating voltage (see solenoid valve type

plate).

DANGER Adiabatic compression during gas blowback (explosion hazard)!

Adiabatic compression may cause high gas temperatures and must be checked by the

user.

Gas blowback may result in high gas temperatures due to adiabatic compression. This

can cause flammable gases to ignite spontaneously.

a) Blowback of explosive atmosphere / gases is prohibited.

b) Flammable atmosphere / gases (non-explosive) may only be blown back with nitro-

gen (inert gas).

4.7 Electrical connections

WARNING Hazardous electrical voltage

The device must be installed by trained staff only.

CAUTION Wrong mains voltage

Wrong mains voltage may damage the device.

Regard the correct mains voltage as given on the type plate.

10 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 13

GAS 222.35 AMEX

CAUTION Equipment damage

Cables damaged

Do not damage the cable during installation. Install a strain relief for the cable connection. Secure the cable against twisting and loosening. Please note the temperature resistance of the cables (> 100°C/212°F).

The probe includes two cubic plugs per EN 175301-803 (ex DIN43650) and a junction box. The plugs are prewired to the junction

box. For safety reasons this connection must not be modified. The electrical connections must only be run to the terminals of the

junction box.

The power supply for the two heating cartridges (mains supply 115/230V, 50/60 Hz) and the connection for the thermal alarm

contact are provided via the terminal strip in the junction box. Per EN 60079-14 and -15, connection for the alarm output must

be connected energy-limited (U

– Only use cables with a temperature resistance of >100°C to connect to power.

– Make sure the connecting cable has sufficient strain relief (match cable diameter to the seal on the cubic plug).

– Please note, the heating system briefly has high starting currents (max. 6A). Use a suitable fuse (8A). When connecting,

please also observe the applicable Ex protection regulations.

NOTICE

The thermal alarm contact must be connected energy-limited!

(U

= 30 V, I

max

= 30 V, I

max

max

= 100 mA). Please see the enclosed terminal diagram for the connection.

max

= 100 mA)

WARNING High voltage

Damage to the device in case of insulation testing

Do not proceed insulation tests with high voltage

to the device as a whole!

Electric strength test

The necessary tests of all assemblies required to be tested were carried out at the factory (test voltage 1 kV or 1.5 kV depending

on component).

To check the electric strength again yourself, only do so on the respective individual components.

– Now perform the electric strength test against earth.

4.7.1 Heated pressure vessel (optional)

A heated blowback vessel may optionally be used for blowback. Heated via self-regulating PTC heating cartridge to protect

against frost.

The electrical (mains connection 115/230 V AC) connects via the junction box per the enclosed terminal diagram at the end.

– Only use cables with a temperature resistance of >100°C to connect to power.

– Make sure the connecting cable has sufficient strain relief (match cable diameter to the seal on the junction box).

– When connecting, also observe the applicable Ex protection regulations and general warnings in these operating instruc-

tions.

CAUTION Equipment damage

Cables damaged

Do not damage the cable during installation. Install a strain relief for the cable connection. Secure the cable against twisting and loosening. Please note the temperature resistance of the cables (> 100°C/212°F).

11Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 14

GAS 222.35 AMEX

DANGER Adiabatic compression during gas blowback (explosion hazard)!

Adiabatic compression may cause high gas temperatures and must be checked by the

user.

Gas blowback may result in high gas temperatures due to adiabatic compression. This

can cause flammable gases to ignite spontaneously.

a) Blowback of explosive atmosphere / gases is prohibited.

b) Flammable atmosphere / gases (non-explosive) may only be blown back with nitro-

gen (inert gas).

12 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 15

GAS 222.35 AMEX

5 Operation and Control

NOTICE

The device must not be operated beyond its specifications.

NOTICE

The weather hood must be closed during operation!

WARNING Housing or component damage

Never exceed the maximum working pressure and temperature range of the drive.

DANGER Explosion hazard due to electrostatic discharge

Equipment may only be used where normal operating conditions do not produce frequent flammable, electrostatic discharge.

5.1 Before Start-Up

Before starting the device, verify:

– The hose and electrical connections and the heating tape are not damaged and installed correctly.

– No parts of the sample gas probe have been removed.

– The protection and monitoring devices are installed and functional (e.g. flame arrester).

– The gas inlet and outlet on the gas probe are open.

– Ambient parameters are met.

– Probe parts are resistant to media to be conveyed and in the surrounding area.

– The performance specifications in the type plate are met.

– The voltage and frequency of the heating tape match the mains values.

– The temperature has an energy-limited connection (U

– The electrical connections are tight.

– The monitoring equipment is connected and set as specified.

– All connection cables are installed without strain.

– Precautions have been taken; earthing.

– The junction box cover is closed and the cable gland is properly sealed.

= 30V, I

max

= 100 mA).

max

13Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 16

GAS 222.35 AMEX

6 Maintenance

– Damaged parts must be replaced immediately.

– Regularly check the function of the electrical protection.

During maintenance, remember:

– The equipment must be maintained by a professional familiar with the safety requirements and risks.

– Only perform maintenance work described in these operating and installation instructions.

– When performing maintenance of any type, observe the respective safety and operation regulations.

DANGER Danger to life and explosion during installation and maintenance

The unit must not be worked on (assembly, installation, maintenance) in explosive atmospheres.

DANGER Electrical voltage

Electrocution hazard.

a) Disconnect the device from power supply.

b) Make sure that the equipment cannot be reconnected to mains unintentionally.

c) The device must be opened by trained staff only.

d) Regard correct mains voltage.

DANGER Toxic, corrosive gases

The measuring gas led through the equipment can be hazardous when breathing or

touching it.

a) Check tightness of the measuring system before putting it into operation.

b) Take care that harmful gases are exhausted to a save place.

c) Before maintenance turn off the gas supply and make sure that it cannot be turned

on unintentionally.

d) Protect yourself during maintenance against toxic / corrosive gases. Use suitable pro-

tective equipment.

CAUTION Hot surface

Risk of burns

Depending on the operating parameters, the housing temperature may reach over 100

°C during operation.

Allow the unit to cool down before performing maintenance.

CAUTION Excess pressure

The unit mustn’t be pressurised or energised when opened.

If necessary, close the gas supply and ensure a safe pressure on the process end before

opening.

DANGER Dangerous electrostatic charge (explosion hazard)

Incendive electrostatic charges may occur when cleaning plastic housing parts and

decals (e.g. with a dry cloth or compressed air). The sparks this produces could ignite

flammable, explosive atmospheres.

Always clean plastic housing parts and decals

14 Bühler Technologies GmbH BE460058 ◦ 08/2019

with a damp cloth

!

Page 17

GAS 222.35 AMEX

DANGER Explosion hazard due to ignition of dust

When using the device in a dusty environment, routinely clean dust from all components.

The ignition temperature resp. smouldering temperature of flammable dusts resp. dust

layers present must be considerably higher than the maximum surface temperature of

the device (observe applicable standards and statutory regulations).

If possible, take the electrical components which must be opened for repair to a dustfree room. If unable to do so, prevent dust from entering the housing.

6.1 Maintaining the filter element

The probes feature a particle filter which needs to be changed as it becomes dirty.

To do so, disconnect the voltage supply and if applicable close the shut-off valve to the process or switch off the process.

CAUTION!Do not damage the rear filter seat.

NOTICE

Ceramic filter elements

fall.

Filter elements made out of sintered stainless steel

and be used several times as long as both seals are still in proper conditions.

are very brittle by nature. Handle them with care, don’t let them

can be cleaned in an ultrasonic bath

6.1.1 Replacing the Inlet Filter

The probes are equipped with an inlet filter which is always inside the process stream. The filter is suitable for blowback with

compressed air (inert gas), i.e. blowing air (inert gas) through the filter from the inside to the outside to remove adhering

particles. When sampling flammable gases, nitrogen (inert gas) must be used for blowback. Blowback of explosive gases is prohibited.

The effectiveness of cleaning a filter within a process is directly influenced by the available airflow (amount of gas). We therefore recommend using a pressure vessel directly on the probe.

With sufficient inlet filter blowback (within the process stream) the probes are maintenance-free. However, due to process conditions the filter may clog over time. In this case the filter element will need to be replaced.

Proceed as follows:

– Slightly push in the handle at the back of the probe and turn 90° (handle must then be horizontal) and remove.

– Screw the dirty filter element out of the handle.

– Check the sealing faces on the handle, replace O-rings, then install the filter element and new seal. (The spare filter includes

O-rings and seals).

– Then insert the handle with the new or cleaned filter, push in slightly and turn 90° (handle must then be vertical). Pull on the

handle to verify the filter element is firmly seated.

NOTICE

The weather hood can only be closed again when the handle is completely vertical. In order to do so, loosen the hood from the locking supports by lifting slightly and then fold

down. Ensure that the hood lock clicks into place correctly.

Condensate inside the pressure vessel

Depending on the installation site and application conditions a small amount of condensate may form inside the blowback air

pressure vessel. Open the drain screw at the bottom of the vessel and drain the condensate at least once a year.

If the probe needs to be serviced more frequently due to operating conditions, we recommend also draining the condensate at

these intervals.

CAUTION High pressure

Pressure vessel under pressure.

Before opening the condensate drain, close the air supply to the blowback control and

drain the vessel by manual blowback.

Pressing the main switch for the blowback control to interrupt the voltage supply.

15Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 18

GAS 222.35 AMEX

6.2 Blowback of the in-situ filter (within the process stream)

DANGER Adiabatic compression during gas blowback (explosion hazard)!

Adiabatic compression may cause high gas temperatures and must be checked by the

user.

Gas blowback may result in high gas temperatures due to adiabatic compression. This

can cause flammable gases to ignite spontaneously.

a) Blowback of explosive atmosphere / gases is prohibited.

b) Flammable atmosphere / gases (non-explosive) may only be blown back with nitro-

gen (inert gas).

Be sure to use filtered air with a minimum rating of PNEUROP / ISO Class 4 for blowback:

Class Particles / m

Particle size:

(1 to 5) µm

4

to 1000

(no particles ≥ 15 µm)

3

Pressure dew point

[°C]

≤ 3 ≤ 5

Residual oil content

[mg / m3]

6.2.1 Manual Blowback (Without Blowback Control)

The shut-off valve in the air supply (inert gas supply) to the pressure vessel must be open. The optional pressure gauge on the

pressure vessel shows the current operating pressure.

Abruptly

–

gauge has dropped to the lowest reading.

open the ball valve in the connecting line from the pressure vessel to the probe until the display on the pressure

6.2.2 Automatic Blowback (External Blowback Control)

Automatic blowback requires a shut-off valve downstream from the probe. The control unit for the system is designed for sequential valve control, i.e.:

1. Closing the shut-off valve downstream from the probe with a controller.

2. Open the solenoid valve between the pressure vessel and probe for approx. 10 seconds.

3. Open the shut-off valve downstream from the probe again.

Blowback can also be set as a closed process at intervals ranging from several minutes to hours or even days based on requirements.

16 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 19

GAS 222.35 AMEX

6.3 Maintenance Schedule

NOTICE

When using the probe in explosive areas the maintenance schedule must be observed!

Maintenance schedule for normal ambient conditions:

Component Interval in operating

hours

Entire probe every 8000 h – Check gas connections

– Check safety devices and controllers

– Check electrical protective measures

– Proper function, dirt, visual inspection for dirt / dam-

age.

If damaged, replace or have repaired by Bühler.

Ball valves every 8000 h – Check ball valve function and check for leaks. Operator

Filter every 8,000 h – Check dirt level of filter. Operator

Seals every 8,000 h – Replace O-rings.

– Replace seals after every filter change.

Pressure vessel every 8,000 h – Drain condensate Operator

Entire probe

With respect to the

ball valve and solenoid

valves

after 20,000 h or

3years

– Inspection by Bühler Service technician /

Work to be performed To be performed by

Operator

Operator

Bühler

17Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 20

GAS 222.35 AMEX

7 Service and repair

This chapter contains information on troubleshooting and correction should an error occur during operation.

Repairs to the unit must be performed by Bühler authorised personnel.

Please contact our Service Department with any questions:

Tel.: +49-(0)2102-498955

If the equipment is not functioning properly after correcting any malfunctions and switching on the power, it must be inspected

by the manufacturer. Please send the equipment inside suitable packaging to:

Bühler Technologies GmbH

- Reparatur/Service -

Harkortstraße 29

40880 Ratingen

Germany

Please also attach the completed and signed RMA decontamination statement to the packaging. We will otherwise be unable to

process your repair order.

You will find the form in the appendix of these instructions, or simply request it by e-mail:

service@buehler-technologies.com

or your agent

.

7.1 Troubleshooting

CAUTION Risk due to defective device

Personal injury or damage to property

a) Switch off the device and disconnect it from the mains.

b) Repair the fault immediately. The device should not be turned on again before elim-

ination of the failure.

Problem / malfunction Possible cause Action

No or reduced gas flow – Filter element clogged – Clean or replace filter element

– Gas circuit clogged – Clean sampling tube

– Ball valve closed – Open ball valve

– Blowback (optional) not responding – Check compressed air supply

– Check solenoid valve, check pneumatic con-

trol

No heat output – No/incorrect power supply – Check power supply

Condensation forming – Heater defective – Send in probe for repair

– Thermal bridges at the sampling point – Insulate to eliminate thermal bridges

18 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 21

GAS 222.35 AMEX

7.2 Spare Parts and Accessories

Please also specify the model and serial number when ordering parts.

Upgrade and expansion parts can be found in our catalog.

Available spare parts:

Item no. Description

90 091 05 Measuring outlet seal

90 090 79 Flange seal DN65 PN6

46 222 351 5 O-ring kit for filter element and probe, material: Viton/Cu *

Please see the accessories data sheet in the appendix for filter elements

*Lowest ambient temperature: -20 °C (-4 °F)

The temperature limits of the seals in the low temperature range are particularly important and must be observed for unheated

probes. On heated probes the seals will have higher temperatures during normal operation, so the limits specified for the low

temperatures typically do not apply. When changing the seals in low temperatures the temperature limits must particularly be

observed, as the filter element and handle may have these low temperatures outside the probe.

19Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 22

GAS 222.35 AMEX

8 Disposal

Dispose of parts so as not to endanger the health or environment. Follow the laws in the country of use for disposing of electronic components and devices during disposal.

20 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 23

GAS 222.35 AMEX

M16 x 1.5 mm

4.5 - 10 mm

Customer power supply

Customer alarm output

Probe

power

supply

Heater

power

supply

PAV 01

Alarm

output

M16 x 1.5 mm

4.5 - 10 mm

M16 x 1.5

M16 x 1.5

9 Appendices

9.1 Technical Data

Gas Probe Technical Data

Self-regulating temperature: 125 °C (T3)/70 °C (T4)

Ambient temperature: -20 to +80 °C

Ambient temperature with accessories:

Low temperature alarm: Contact open at operating temperature, closes at < 95 °C (T3) resp. < 50 °C (T4);

Electrical data: 115 V-230 V, 50/60 Hz

Max. operating pressure: 6 bar

Parts in contact with media: 1.4571

Explosion protection: Class 1, Div 2, Gps B, C, D

9.2 Connection Diagram

Component Ambient temperature range

Compressed air valve: -10 °C < T

U

=30 VDC, I

max

Seals: PTFE/Graphit/1.4404 and see filters

=100 mA, Ci/Li~0

max

< +55 °C

amb

21Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 24

GAS 222.35 AMEX

Heater

Operating voltage

115-230 V AC 200 W

9.3 Connection diagram heated pressure vessel

9.4 Flow diagram

22 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 25

GAS 222.35 AMEX

9.5 Dimensions

23Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 26

GAS 222.35 AMEX

9.6 List of chemical resistance

Materials of your device in contact with media are printed on the type plate.

Formula Medium Concentration Teflon®

PTFE

CH3COCH

C6H

6

CI

2

CI

2

C2H

6

3

Acetone 1/1 1/1 4/4 1/1

Benzol 1/1 1/1 3/3 1/1

Chlorine 10 % wet 1/1 1/1 3/0 4/4

Chlorine 97 % 1/0 1/0 1/1 1/1

Ethane 1/0 1/0 1/0 2/0

FFKM Viton®

FPM

V4A

C2H5OH Ethanol 50 % 1/1 1/1 2/2 1/0

C2H

4

C2H

2

C6H5C2H

5

Ethylene 1/0 1/0 1/0 1/0

Ethyne 1/0 1/0 2/0 1/0

Ethylbenzene 1/0 1/0 2/0 1/0

HF Hydrofluoric acid 1/0 2/0 4/0 3/4

CO

2

Carbon dioxide 1/1 1/0 1/1 1/1

CO Carbon monoxide 1/0 1/0 1/0 1/1

CH

4

Methane technically pure 1/1 1/0 1/1 1/1

CH3OH Methanol 1/1 1/1 3/4 1/1

CH3CI

H3PO

H3PO

C3H

2

4

4

8

Methylene chloride 1/0 1/0 3/0 1/1

Phosphoric acid 1-5 % 1/1 1/1 1/1 1/1

Phosphoric acid 30 % 1/1 1/1 1/1 1/1

Propane gaseous 1/1 1/0 1/0 1/0

C3H6O Propylene oxide 1/0 2/0 4/0 1/0

HNO

HNO

3

3

Nitric acid 1-10 % 1/1 1/0 1/1 1/1

Nitric acid 50 % 1/1 1/0 1/0 1/2

HCI Hydrochloric acid 1-5 % 1/1 1/1 1/1 2/4

HCI Hydrochloric acid 35 % 1/1 1/1 1/2 2/4

O

2

SF

6

H2SO

4

Oxygen 1/1 1/1 1/2 1/1

Sulphur hexafluoride 1/0 1/0 2/0 0/0

Sulfuric acid 1-6 % 1/1 1/1 1/1 1/2

H2S Hydrogen sulphide 1/1 1/1 4/4 1/1

N

2

C6H5C2H

C6H5CH

3

3

Nitrogen 1/1 1/0 1/1 1/0

Styrene 1/1 1/0 3/0 1/0

Toluol (methylbenzene) 1/1 1/1 3/3 1/1

H2O Water 1/1 1/1 1/1 1/1

H

2

Hydrogen 1/0 1/0 1/0 1/0

0 - no information available

1 - durability/suitability very good

2 - durability/suitability good

3 - limited suitability

4 - not suitable

Two values are specified per medium. Left number = value at 20 °C, right number = value at 50 °C.

Important information

The tables were listed based on specifications from various raw material manufacturers. The values solely refer to laboratory

tests using raw materials. Components made from these are often subject to impacts which cannot be determined in laboratory

testing (temperature, pressure, material strain, impacts of chemical agents, design features, etc.). The values specified can

therefore only serve as a guideline. When in doubt, we recommend performing a test. These specifications do not infer a legal

claim, we exclude any warranty and liability. The chemical and mechanical durability alone do not suffice to determine the usage property of a product, particularly e.g. the regulations for liquid fuels (Ex-protection) must be observed.

Durability to other mediums available upon request.

24 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 27

GAS 222.35 AMEX

9.7 User book (Please make copies)

Maintained on Unit no. Operating hours Remarks Signature

25Bühler Technologies GmbHBE460058 ◦ 08/2019

Page 28

GAS 222.35 AMEX

10 Attached Documents

– Certificate of Compliance: CSA 1728394

– Accessories Data Sheet 461099

– RMA - Decontamination Statement

26 Bühler Technologies GmbH BE460058 ◦ 08/2019

Page 29

Certificate of Compliance

Certificate:

Project:

Issued to: Bühler Technologies GmbH

1728394

2361506

Harkortstr. 29

Ratingen, D-40880

Germany

Attention: Christopher Sungergeld

The products listed below are eligible to bear the CSA

Mark shown with adjacent indicators 'C' and 'US' for

Canada and US or with adjacent indicator 'US' for

US only or without either indicator for Canada only.

PRODUCTS

CLASS 2252 81

CLASS 2252 01

- PROCESS CONTROL EQUIPMENT - Certified to US Standards

- PROCESS CONTROL EQUIPMENT

Issued by:

Master Contract:

Date Issued:

Joe da Silva

Joe da Silva, C.E.T.

231516

November 18, 2010

- Series GAS222.XX sample gas probes, Models GAS222.11ANSI/CSA, GAS222.30ANSI/CSA,

GAS222.35UANSI/CSA, GAS222.15ANSI/CSA, GAS222.17ANSI/CSA, GAS222.20ANSI/CSA,

GAS222.21ANSI/CSA, GAS222.31ANSI/CSA and GAS222.35ANSI/CSA, rated 115/230Vac, 50/60Hz, 440W,

max. Ambient 70°C max.

- Series AHF 22 heated sample gas filters, models AHF- 22-S-K and AHF-22-yyy-R-K, where yyy means the

mains voltage, 115 or 230V.

CLASS 2258 02 - PROCESS CONTROL EQUIPMENT - For Hazardous Locations

CLASS 2258 82 - PROCESS CONTROL EQUIPMENT - For Hazardous Locations - CERTIFIED TO U.S.

STANDARDS

Class I, Div 2, Groups B, C and D:

- Series GAS222.XX sample gas probes, Models GAS222.20 AMEX, GAS222.21 AMEX, GAS222.31AMEX,

GAS222.35 AMEX, GAS222.11ANSI/CSA, GAS222.30ANSI/CSA, GAS222.35UANSI/CSA, rated

115V/230V, 50/60Hz, 360W max, Ambient 80°C max., Temp code T3 or T4.

DQD 507 Rev. 2009-09-01 Page: 1

Page 30

Certificate:

1728394

Master Contract:

231516

Project:

2361506

Date Issued:

November 18, 2010

APPLICABLE REQUIREMENTS

CAN/CSA C22.2 No. 0-M91 (R2001) - General Requirements - Canadian Electrical Code, Part II

CSA Std C22.2 No. 142-M1987 - Process Control Equipment

CSA Std C22.2 No. 213-M1987 - Non-Incendive Electrical Equipment for Use in Class I, Division 2

Hazardous Locations

UL Std No. 1604, Third Ed.1994 - Electrical Equipment for Use in Class I and II, Division 2; Class III

Hazardous (Classified) Locations

UL Std No.916, Fourth Ed. 2007 - Energy Management Equipment

DQD 507 Rev. 2009-09-01 Page: 2

Page 31

Accessories for

Sample Gas Probe GAS 222

§ Sample tubes

§ In-situ filters

§ Extensions

For general information, see data sheet “Sample gas probes GAS 222” DE461000.

DE 461099

05/2016

Page 1/9

§ Downstream filters

§ Cal gas connections

§ Adapter flanges

Bühler Technologies GmbH

D - 40880 Ratingen, Harkortstr. 29

Tel.: + 49 (0) 2102 / 49 89-0 Fax: + 49 (0) 2102 / 49 89-20

Internet: www.buehler-technologies.com

e-mail: analyse@buehler-technologies.com

§ Capacitive vessel

§ Pneumatic actuators

§ 3/2-way-solenoid valves

§ Blowback controllers

Page 5 - 7Page 8Page 2 - 4

Page 32

DE 461099

05/2016

Page 2/9

Sample tubes, in-situ filters and extensions

§ Various materials

§ Various dimensions

§ Heated or nonheated extensions

Sample tube

Material

1.4571

01

1.4571

01

1.4571

01

1.4571

01

1.4571

01

02

Ceramics / 1.4571

02

Ceramics / 1.4571

02

Ceramics / 1.4571

06

Hastelloy / 1.4571

06

Hastelloy / 1.4571

06

Hastelloy / 1.4571

06

Hastelloy / 1.4571

Inconel / 1.4571

08

Inconel / 1.4571

08

Inconel / 1.4571

08

Inconel / 1.4571

08

Inconel / 1.4571

08

1.4571

12

1.4571

12

1.4571

12

1.4571

12

13

Kanthal / 1.4571

Sample tube with demister PVDF/ETFE

Demister ETFE / as spare part

Sample tube with demister / 1.4571

Sample tube with demister / 1.4571

Sample tube with demister / 1.4571

Demister 1.4571 / as spare part

T max.

600°C

600°C

600°C

600°C

600°C

1600°C

1600°C

1600°C

400°C

400°C

400°C

400°C

1050°C

1050°C

1050°C

1050°C

1050°C

600°C

600°C

600°C

600°C

1400°C

120°C

120°C

400°C

400°C

400°C

400°C

Length

300 mm

500 mm

1000 mm

1500 mm

2000 mm

0.5 m

1.0 m

1.5 m

500 mm

1000 mm

1500 mm

2000 mm

500 mm

1000 mm

1500 mm

2000 mm

2500 mm

500 mm

1000 mm

1500 mm

2000 mm

up to 1 m

800 mm

300 mm

500 mm

1000 mm

Part No.:

462220010300

462220010500

462220011000

462220011500

462220012000

4622200205

4622200210

4622200215

462220060500

462220061000

462220061500

462220062000

462220040500

462220041000

462220041500

462220042000

462220042500

462220160500

462220161000

462220161500

462220162000

46222017

46222040

462220402

4622204203

4622204205

4622204210

4611004

222.10

222.11

222.30

222.35-U

222.15

222.17

222.20

222.21

222.31

222.35

222.20 DH

222.20 Atex

222.21 Atex

222.31 Atex

222.35 Atex

222.20 Atex2

222.21 Atex2

222.31 Atex2

222.35 Atex2

222.10 ANSI

222.11 ANSI/ CSA

222.30 ANSI/ CSA

222.35-U ANSI/ CSA

222.15 ANSI/ CSA

222.17 ANSI/ CSA

222.20 ANSI/ CSA

222.21 ANSI/ CSA

222.31 ANSI/ CSA

222.35 ANSI/ CSA

222.20 DH ANSI/ CSA

222.20 AMEX

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X

X

X

X

X

X

X

X X

X

X

X

X

X

X

X X

X X

XXX

X

X X

X

X X

X X

X

X

X

X

X

X

X X

X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X

X X

X

X

X

X

X X

X

X

X

X

X X

X

X

X

X

X

X

X X

X X

X

X

X

X

X

222.21 AMEX

222.31 AMEX

222.35 AMEX

Type GAS

Page 33

DE 461099

05/2016

Page 3/9

Sample tubes, in-situ filters and extensions

§ Various materials

§ Various dimensions

§ Heated or nonheated extensions

In-situ filter

03

03F

03H

03HF

031

031F

031H

031HF

04

04F

04H

04HF

041

041F

041H

041HF

07

07F

07 ANSI

35

35F

Material

stainless steel

stainless steel

Hastelloy

Hastelloy

stainless steel, with volume displacer

stainless steel, with volume displacer

Hastelloy, with volume displacer

Hastelloy, with volume displacer

stainless steel

stainless steel

Hastelloy

Hastelloy

stainless steel, with volume displacer

stainless steel, with volume displacer

Hastelloy, with volume displacer

Hastelloy, with volume displacer

Ceramics / 1.4571

Ceramics / 1.4571

Ceramics / 1.4571

stainless steel

stainless steel

T max.

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

600°C

1000°C

1000°C

1000°C

600°C

600°C

1)

1)

1)

Length

237 mm

237 mm

237 mm

237 mm

237 mm

237 mm

237 mm

237 mm

538 mm

538 mm

538 mm

538 mm

538 mm

538 mm

538 mm

538 mm

478 mm

478 mm

478 mm

229 mm

229 mm

Pore size

5 µm

0.5 µm

5 µm

0.5 µm

5 µm

0.5 µm

5 µm

0.5µm

5 µm

0.5 µm

5 µm

0.5 µm

5 µm

0.5 µm

5 µm

0.5 µm

2 µm

0.3 µm

2 µm

5 µm

0.5 µm

Part No.:

46222303

46222303F*

46222303H*

46222303HF*

462223031

462223031F*

462223031H*

462223031HF*

46222304

46222304F*

46222304H*

46222304HF*

462223041

462223041F*

462223041H*

462223041HF*

46222307

46222307F*

46222307C

46222359

46222359F*

222.10

222.11

222.30

222.35-U

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X

222.15

222.17

222.20

222.21

222.31

222.35

222.20 DH

222.20 Atex

222.21 Atex

222.31 Atex

222.35 Atex

222.20 Atex2

222.21 Atex2

222.31 Atex2

222.35 Atex2

222.10 ANSI

222.11 ANSI/ CSA

222.30 ANSI/ CSA

222.35-U ANSI/ CSA

222.15 ANSI/ CSA

222.17 ANSI/ CSA

222.20 ANSI/ CSA

222.21 ANSI/ CSA

X X X X X X X X X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X X X X

X

X

X

X

X

X

X

X

X

X XX X

X

X

X

X

X

X

X

X

X X X X

X X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X

X X X X X

X X X X XX X

222.31 ANSI/ CSA

222.35 ANSI/ CSA

X

X

X

X

X

X

X

X

X

X

X

X

222.20 DH ANSI/ CSA

222.20 AMEX

222.21 AMEX

X

X

X

X

X

X

X

X

X

X

X

X

222.31 AMEX

X

X

X

X

X

X

X

X

X

X

X

X

222.35 AMEX

Type GAS

1) Hot gas filtration, oxidizing atmosphere max. 750 °C

Hot gas filtration, reductive atmosphere max. 600 °C

* Prices and delivery time on request

Page 34

DE 461099

05/2016

Page 4/9

Sample tubes, in-situ filters and extensions

§ Various materials

§ Various dimensions

§ Heated or nonheated extensions

Protection shield

for in-situ filter 03

for in-situ filter 04

Extensions

Typ

G3/4

nonheated

nonheated

G3/4

nonheated

G3/4

nonheated

G3/4

nonheated

G3/4

nonheated

G3/4

nonheated

G3/4

nonheated

G3/4

nonheated

G1/2

nonheated

G1/2

nonheated

G1/2

nonheated

G1/2

GF

heated*

heated*

GF

ANSI / CSA,heated*

GF

GF

ANSI / CSA,heated*

Material

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

1.4571

Mains voltage

230V

230V

115V

115V

Length

0.2 m

0.4 m

0.5 m

0.7 m

1 m

1,2 m

1,5 m

2 m

0,25 m

0,5 m

0,7 m

1,5 m

0.5 m

1 m

0.5 m

1 m

Part No.:

462223034

462223044

4622230320200

4622230320400

4622230320500

4622230320700

4622230321000

4622230321200

4622230321500

4622230322000

4622235910250

4622235910500

4622235910700

4622235911500

462223036

462223033

462223036C1

462223033C1

222.10

222.11

222.30

222.35-U

222.15

222.17

222.20

X X X

X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X X X X X

X X X

X X X

222.21

222.31

222.35

222.20 DH

222.20 Atex

222.21 Atex

222.31 Atex

222.35 Atex

222.20 Atex2

222.21 Atex2

222.31 Atex2

222.35 Atex2

222.10 ANSI

222.11 ANSI/ CSA

222.30 ANSI/ CSA

222.35-U ANSI/ CSA

222.15 ANSI/ CSA

222.17 ANSI/ CSA

222.20 ANSI/ CSA

222.21 ANSI/ CSA

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X X

X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X X X X X X X X X X X X X X X X X

X X X

X X X

222.31 ANSI/ CSA

222.35 ANSI/ CSA

222.20 DH ANSI/ CSA

222.20 AMEX

222.21 AMEX

222.31 AMEX

222.35 AMEX

Type GAS

Controller for heated extension integrated into probe controller

* M ounting is only possible at a plain flange without G3/4 thread. Therefore a G has to be added to the part number, e.g. 4622220G.

It is not possible to add a heated extension after delivery.

46222292

X

X

X

X X

X

Page 35

DE 461099

05/2016

Page 5/9

Entnahmerohre / tubes

Typ L ø A SW

01 var. 12 G3/4 36

06 var. 12 G3/4 36

08 var. 21,3 G3/4 36

12 var. 20 G3/4 36

13 var. 15 G3/4 36

14 var. 18 G3/4 36

Typ L ø A SW

02-0,5 500 24 G3/4 36

02-1,0 1000 2 4 G3/4 36

02-1,5 1500 2 4 G3/4 36

Eintritssfilter / in-situ filter

Typ L ø A SW

03 237 51 G3/4 36

031 237 51 G3/4 36

04 538 60 G3/4 36

041 538 60 G3/4 36

35 229 29 G1/2 27

Verlängerungen / extensions

Unbeheizt / unheated

Тyp L A SW

G3/4 0,2-2 m G3/4 36

G1/2 0,25-1,5m G1/ 2 27

Beheizt / heated

Тyp L ø A B

GF 500 40 DN65 PN6 M12

GF 1000 40 DN65 PN6 M12

GF ANSI/CSA 500 40 DN3"- 150 M16

GF ANSI/CSA 1000 40 DN3"-150 M16

Abweisblech / protection shield

Eintrittsfilter / in-situ filter 03

Eintrittsfilter / in-situ filter 04

Typ L ø A B

07 500 60 DN65 PN6 M12

07 ANSI 500 60 DN3"-150 M16

Page 36

DE 461099

05/2016

Page 6/9

Blowback

§ With ball valve or solenoid valve

§ Heated or nonheated

§ Manuell or automatic control

Capacitive vessel

PAV 01

Accessories for capacitive vessel

ball valve

2/2-way-MV 24VDC*

2/2-way-MV 110V 50Hz

2/2-way-MV 220-230V 50/60Hz

2/2-way-MV 24VUC Atex II 2G/D EEx m II T4 IP65

2/2-way-MV 110VUC Atex II 2G/D EEx m II T4 IP65

2/2-way-MV 230VUC Atex II 2G/D EEx m II T4 IP65

2/2- way- AMEX 24 V/ 60 Hz Cl. I Div 2

2/2- way- AMEX 120 V/ 60 Hz Cl. I Div 2

2/2- way- AMEX 240 V/ 60 Hz Cl. I Div 2

self regulated heating system 115/230V 50/60Hz

self regulated heating system 115-230V 50/60Hz Atex 2

II 3G Ex nA IIC T3 Gc X

self regulated heating system 115-230V 50/60Hz Atex 2

II 3G Ex nA IIC T4 Gc X

self regulated heating system AMEX,115-230V,50/60 Hz, Cl. I Div 2 B,C,D,T3

self regulated heating system AMEX,115-230V,50/60 Hz, Cl. I Div 2 B,C,D,T4

support of pressurised vessel

Bourdon tube pressure gauge 0-10 bar

Pneumatic actuators

spring return, opened unpressurised

spring return, closed unpressurised

double action

limit switch

limit switch Atex II 2G/3D IIC T6 IP65

limit switch Atex II 2G/2D IIC T6 IP65

3/2-way-SV for controlling of pneumatic actuator

24 VDC

110 V 50 Hz

230 V 50 Hz

ATEX 24 V UC II 2G/D EEx m II T4

ATEX 110 V UC II 2G/D EEx m II T4

ATEX 230 V UC II 2G/D EEx m II T4

AMEX 24 V 60 Hz, NPT1/4", Cl. I Div 2

AMEX 120 V 60 Hz, NPT1/4", Cl. I Div 2

AMEX 240 V 60 Hz, NPT1/4", Cl. I Div 2

5/2-way-SV for controlling of pneumatic actuator

Blowback controller

RSS 24 VDC, IP65

RSS 115/230 VAC, IP65

RSS-MC integrated into probe controller cabinet

*max. pressure 6 bar

Ambient

temperature

-10 ... +55°C

-10 ... +55°C

-10 ... +55°C

-10 ... +60°C

-10 ... +60°C

-10 ... +60°C

-10 ... +55°C

-10 ... +55°C

-10 ... +55°C

-10 ... +55°C

-10 ... +55°C

-10 ... +55°C

-10 ... +60°C

-10 ... +60°C

-10 ... +60°C

-10 ... +55°C

-10 ... +55°C

-10 ... +55°C

-10 ... +70°C

Part No.:

46222PAV

46222PAVKH

46222PAVMV1

46222PAVMV2

46222PAVMV3

46222PAVMV4

46222PAVMV5

46222PAVMV6

46222PAVMV14

46222PAVMV8

46222PAVMV9

46222PAVHZ1

46222PAVHZ2

46222PAVHZ3

46222PAVHZ4

46222PAVHZ6

462223502

46222PAVMA

46222008

46222030

46222009

9008928

9008930

9027002

46222075

46222076

46222077

46222078

46222079

46222080

46222116

46222050

46222056

9148000117

46222199

46222299

46222392

222.10

222.11

222.30

222.35-U

222.15

222.17

222.20

222.21

222.31

222.35

222.20 DH

222.20 Atex

222.21 Atex

222.31 Atex

222.35 Atex

222.20 Atex2

222.21 Atex2

222.31 Atex2

222.35 Atex2

222.10 ANSI

222.11 ANSI/ CSA

222.30 ANSI/ CSA

222.35-U ANSI/ CSA

222.15 ANSI/ CSA

222.17 ANSI/ CSA

222.20 ANSI/ CSA

222.21 ANSI/ CSA

222.31 ANSI/ CSA

222.35 ANSI/ CSA

222.20 DH ANSI/ CSA

222.20 AMEX

222.21 AMEX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X X X X X X X X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X X X X X X

X

X

X

X X X X X X X X X

X

X

X

X

X

X

X

X

X X X X X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

222.31 AMEX

X X

X X

X X

XXX

X

X

X

X

222.35 AMEX

X

Type GAS

Page 37

Details:

Sample Gas Probe G AS 222.xx Atex

Model

with Accessories

resuting restircted

area;

marking

21 Atex, 31 Atex,

35 Atex

Pressure vessel PAV 01

(Part-No. 46222PAV with accessories)

II 1D / 2GD

21 Atex, 31 Atex, In situ filter*, ceramics

(Art.-Nr.:46222307 + 46222307F)

II 1D 3G / 2GD

20 Atex , 21 Atex, Downstream filter*, ceramic

(Part-No. 46222026 + 46222026P)

II 1D 3G / 2GD

20 Atex, 21 Atex, Sample tube

(Part-No. 46222001, 462220011,

46222006, 46222004, 46222016)

II 1G / 2GD

20 Atex, 21 Atex, Sample tube**, ceramics

(Part-No. 4622200205, 4622200210,

4622200215)

II 3G / 2GD

21 Atex, 31 Atex, Pneumatic cylinder with end switch Atex

(Part-No. 46222019)

II 1GD / 2G3D

* Accessory not suitable for sampling dust with extremely low ignition energy < 3mJ.

** When gases are sampled from Zone 2, ceramic sample tube must be used only if application related or process

related electrostatic charging is eliminated.

A) Blowback

Ordering note for capacitive vessel:

For attachment to GAS 222.11 / 30 / 35-U, a support is required.

Ordering note for pneumatic actuator:

If a blowback controller is required, only actuator P/N 46222030 is possible.

We advise the installation of a position indicator switch to control the pneumatic actuator.

Integrated blowback controller in the probe controller

In addition to the stand-alone blowback controller (RRS), an integrated blowback controller is optionally

available

Blowback cycle time and actual blowback time can be adjusted via the keys and menu of the controller.

The blowback and manual operation will be shown on the display. The blowback controller can be

programmed via the keys – manual or automatic operation is possible. Besides the status output of the

controller, a blowback status signal is provided. Blowback will be usually initiated by signals coming from

the main controls.

If the position indicator switch is installed, the controller will use this input for the process logic.

B) Hazardous Areas

Please note that installed accessories may change the approved category of the probe.

Follow strictly the advices given in the installation- and operation manual and regard the marking on

the type plate.

DE 461099

05/2016

Page 7/9

Page 38

DE 461099

05/2016

Page 8/9

Page 39

DE 461099

05/2016

Page 9/9

Downstream filter elements and further options

Downstream filter

Material

Ceramics

Ceramics

Sintered stainless steel

Sintered stainless steel

Sintered stainless steel

Sintered stainless steel

Pleated stainless steel

Pleated stainless steel

Handle for downstream filter with micro glass fibre element

Micro glass fiber with silicate binder

Micro glass fiber with silicate binder

Closing handle with filter tube and filter wool

Closing handle with filter tube and filter wool

Filter wool

Set of O-rings Viton incl. grease

Set of O-rings Perfluorelastomer incl. grease

Further options

Adapter flange ANSI 3“-150lbs

Cal gas connection ø6mm

Cal gas connection ø6mm with check valve

Cal gas connection ø1/4"

Cal gas connection ø1/4" with check vavle

Fitting for sample gas port ø6mm

Fitting for sample gas port ø8mm

Fitting for back wash port ø12mm

Ffitting for sample gas port ø1/4"

Fitting for sample gas port ø3/8"

Fitting for back wash port ø1/2"

Locking screw G3/8 for backflush connection

Sealing ring for sealing the backflush connection with a locking screw

Mounting bracket with clamp ring for DN65 PN6

Mounting bracket with clamp ring for ANSI 3”-150 lbs

O-Rings

Viton

Perfluorelastomer

Viton

Perfluorelastomer

Viton

Perfluorelastomer

Viton

Perfluorelastomer

Viton

Perfluorelastomer

Viton

Perfluorelastomer

Pore size

3 µm

3 µm

5 µm

5 µm

0,5 µm

0,5 µm

10 µm

10 µm

222.10

222.11

222.30

222.35-U

222.15

Part no.:

46222026

46222026P

46222010

46222010P

46222010F*

46222010FP*

46222011

46222011P

46222067

462220671

462220671P

46222163

46222163P

46222167

46222012

46222024

46222014

46222309

46222311

46222336

46222337

9008173

9008174

9008369

9008584