Page 1

Page 2

Page 3

Commercial Snowblower

TABLE OF CONTENTS

DESCRIPTION PAGE

WARRANTY................................................................ 1

INTRODUCTION ......................................................... 2

SAFETY....................................................................... 3

Safety................................................................ 3

General Safety .................................................. 4

Start Up Safety.................................................. 4

Operation Safety ............................................... 5

Transport Safety................................................ 5

Service & Maintenance Safety .......................... 5

Storage Safety .................................................. 6

Safety Signs...................................................... 6

Safety Sign Installation...................................... 6

ASSEMBLY

Assembly Instructions ....................................... 8

START UP................................................................... 11

OPERATION ............................................................... 12

Theory of Operation .......................................... 12

Operating Instructions ....................................... 13

Specifications .................................................... 15

Hydraulic Control Block Drawing & Parts List.... 16

MAINTENANCE ..........................................................17

Hydraulic Snowblower Wiring Schematic.......... 17

Troubleshooting ................................................ 18

Bolt Torque

PARTS LISTS

Hydraulic – 22” Housing Drawings .................... 20

Hydraulic – 22” Housing Parts List .................... 22

Hydraulic – 24” Housing Drawings .................... 25

Hydraulic – 24” Housing Parts List .................... 27

Snowblower Assembly Drawing ........................ 29

Snowblower Assembly Parts List ...................... 30

PTO Series – 24” Housing Drawings ................ 31

PTO Series – 24” Housing Parts List ................ 33

PTO Drive PTO Drawing & Parts List................ 35

Cylinder Drawings & Parts Lists ........................ 36

PTO Drive – Gearbox Drawing & Parts List ...... 37

SHIPPING KIT AND BUNDLE NUMBERS ................. 38

Page 4

Commercial Snowblower

WARRANTY POLICY

Buhler Manufacturing products are warranted for a period of twelve (12) months (90 days for

commercial application) from original date of purchase, by original purchaser, to be free from

defects in material and workmanship under correct, normal agricultural use and proper

applications.

Buhler Manufacturing’s obligations under this warranty shall be limited to the repair or

exchange, at Buhler Manufacturing’s option, of any Buhler Manufacturing product or part which

proves to be defective as provided. Buhler Manufacturing reserves the right to either inspect

the product at the buyer’s location or have it returned to the factory for inspection.

The above warranty does not extend to goods damaged or subject to accident, abuse or misuse

after shipment from Buhler Manufacturing’s factory, nor to goods altered or repaired by anyone

other than an authorized Buhler Manufacturing representative.

Buhler Manufacturing makes no Express Warranties other than those, which are specifically

described. Any description of goods, including any references and specifications in catalogues,

circulars and other written material published, is for the sole purpose of identifying goods and

shall conform to such descriptions. Any sample or model is for illustrative purposes only and

does not create an Express Warranty that the goods conform to sample or model shown.

The purchaser is solely responsible for determining suitability of goods sold. This warranty is

expressly in lieu of all other warranties expressed or implied. Buhler Manufacturing will in no

event be liable for any incidental or consequential damages whatsoever. Nor for any sum in

excess of the price received for the goods for which liability is claimed.

WARRANTY CLAIMS:

Warranty requests must be prepared on Buhler Manufacturing Warranty Claim Forms with all

requested information properly completed. Warranty Claims must be submitted within a thirty

(30) day period from date of failure repair.

WARRANTY LABOR:

Any labor subject to warranty must be authorized by Buhler Manufacturing. The labor rate for

replacing defective parts, where applicable, will be credited at 100% of the dealer’s posted shop

rate. Defective parts will receive an extra 10% discount to assist with freight or other incidental

costs.

GOVERNMENT LEGISLATION:

Warranty terms and conditions are subject to Provincial or State legislation.

IMPORTANT FACTS:

Buckets and Bucket Tines Carry No Warranty

Bent Spears Carry No Warranty

Snowblower Fan Shafts Carry No Warranty

Mower Blades Carry No Warranty

Portable Auger Parts Have Two (2) Year Warranty

Loader Parts Have Two (2) Year Warranty

IMPORTANT NOTE: This warranty does not apply to rentals

1

Page 5

Commercial Snowblower

INTRODUCTION

For more than a generation, Buhler has been building the most popular Snowblowers

used on farms, airports, and municipalities throughout the North American snow-belt.

Now, all that experience brings you the rugged commercial blowers to handle more

demanding snow clearing jobs.

These hydraulically driven blowers are offered in 60”, 66”, 74” and 84” sizes and four

series. Oil flow ranges from 13 to 32 gallon per minute, with 2000 P.S.I. to ensure there

is a model to match the horsepower of your machine. A hydraulic motor engages a

direct ring gear for smooth, positive rotation of the chute.

The Buhler Commercial Blower is totally operated by hydraulics – fan, auger, chute

rotator and deflector. The key to efficient snow blowing is the design of the fan and

housing. Four blades with tight clearance at the circumference and a replaceable

UHMW liner makes this an excellent design. The heart and soul of these hydraulic

Snowblower is the load sensing manifold which keeps all four functions operating

efficiently, even as the snow gets deeper and more packed. One set of remotes is all

you need. Adjustment ports allow you to fine tune the flow and route of oil to ensure

that the primary oil supply goes to the fan and auger, secondarily to the chute rotator

and deflector. A cushioning feature in the valve body softens the speed of the rotation

when it reaches the end of its rotating arc. The remote in-cab control allows the

operator to divert oil flow to the chute controls. This 3-point hitch, TO driven blower is

build with the same durable strength and features of the front mounted hydraulic models

shown here. Equipped with the same chute rotator as the hydraulically driven models, it

also features a telescopic hitch, replaceable cutting edge, adjustable skid shoes, 4

blade fan, and replaceable UHMW poly liner in the fan housing and spout.

Keep this manual handy for frequent reference. All new operators or owners must

review the manual before using the equipment and at least annually thereafter. Contact

your Buhler Dealer if you need assistance, information, or additional copies of the

manual. Visit our website at www.buhler.com for a complete list of dealers in your area.

The directions left, right, front and rear, as mentioned throughout this manual, are as

seen facing in the direction of travel of the implement.

2

Page 6

Commercial Snowblower

SAFETY

Remember, YOU are the key to safety. Good safety practices not only protect you, but

also the people around you. Make these practices a working part of your safety

program. Be certain that everyone operating this equipment is familiar with the

recommended operating and maintenance procedures and follows all the safety

precautions. Most accidents can be prevented. Do not risk injury or death by ignoring

good safety practices.

The alert symbol is used throughout this manual. It indicates attention is required and

identifies hazards. Follow the recommended precautions.

The safety alert symbol means…

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

CAUTION

The caution symbol indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

WARNING

The Warning Symbol indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against unsafe practices.

DANGER

The Danger Symbol indicates an imminently hazardous situation that, if not avoided will

result in death or serious injury. This signal word is to be limited to the most extreme

situations, typically for machine components that, for functional purposes, cannot be

guarded.

3

Page 7

Commercial Snowblower

GENERAL SAFETY INSTRUCTIONS

Have a first-aid kit available for use and know how to use it.

Have a fire extinguisher available, stored in a highly visible location, and know how to

use it.

Wear appropriate protective gear. This list may include but is not limited to:

- Hard hat

- Protective shoes with slip resistant soles

- Protective glasses or goggles

- Heavy gloves

- Wet weather gear

- Hearing protection

- Respirator or filter mask

Read and understand the Operator’s Manual and all safety signs before operating,

servicing, adjusting, repairing, or unplugging the equipment.

Do not attempt any unauthorized modifications to your Buhler product as this could

affect function or safety, and could affect the life of the equipment.

Never start or operate the Snowblower except from the operator’s station on the power

unit.

Inspect and clean the working area before operating.

Keep hands, feet, clothing, and hair away from moving parts.

Ensure bystanders are clear of the area before operating.

START UP SAFETY

Do not let inexperienced operators or children run this equipment.

Place all tractor and machine controls in neutral before starting.

Operate only with ROPS and seatbelt equipped tractors.

Do not operate inside a building unless there is adequate ventilation.

Ensure all shields are in place and in good condition before operating.

Stay clear of PTO shaft and machine when engaging PTO.

4

Page 8

Commercial Snowblower

OPERATION SAFETY

Do not permit riders.

Do not wear loose fitting clothing during operation.

Stay clear of Snowblower augers.

Stay clear of Snowblower discharge chute. Rocks or debris can be picked up and

thrown.

TRANSPORT SAFETY

Review Transport Safety instructions in tractor manual before moving.

Check with local authorities regarding transport on public roads. Obey all applicable

laws and regulations.

Make sure the SMV (Slow Moving Vehicle) emblem and all the lights and reflectors that

are required by the local highway and transport authorities are in place, are clean, and

can be seen clearly by all overtaking and oncoming traffic.

Never have the equipment in operation during transport.

Always travel at a safe speed.

SERVICE AND MAINTENANCE SAFETY

Stop engine, set brake, remove ignition key, and wait for all moving parts to stop before

servicing, adjusting, repairing, or unplugging.

Support the equipment with blocks or safety stands before working beneath it.

Follow good shop practices including

- Keep service area clean and dry

- Be sure electrical outlets and tools are properly grounded

- Use adequate light for the job

Use only tools, jacks, and hoists of sufficient capacity for the job.

Replace and secure all shields removed during servicing before operating.

Use heavy leather gloves to handle sharp objects.

Check hydraulics regularly for leaks. Use cardboard to look for leaks, and use hand and

eye protection.

Relieve pressure on hydraulic system before repairing or adjusting.

Failure to follow proper procedures when mounting a tire on a wheel or rim can produce

an explosion, which may result in serious injury or death.

5

Page 9

Commercial Snowblower

STORAGE SAFETY

Store the unit in an area away from human activity.

Do not permit children to play on or around the stored machine.

Support the frame on stands and blocks to provide a secure base.

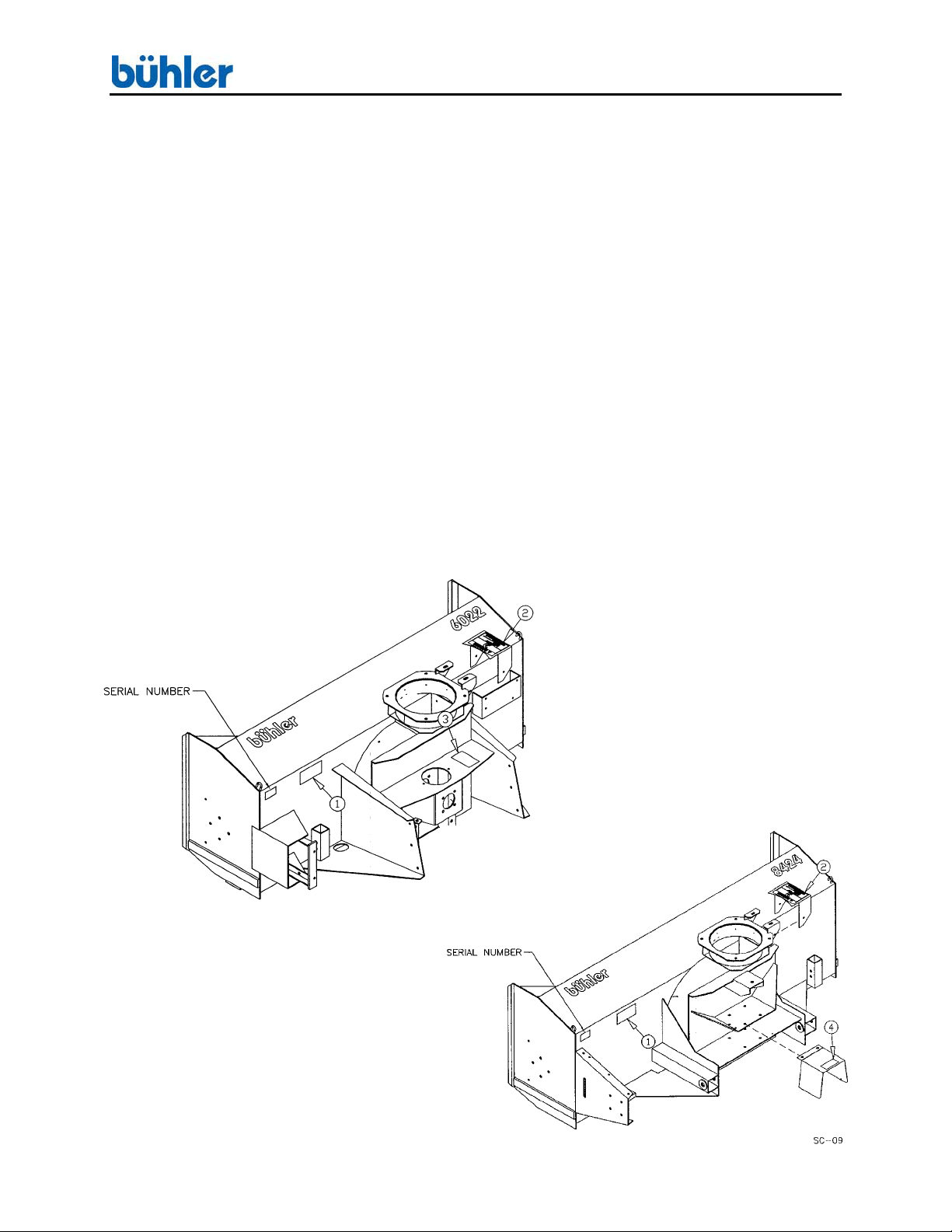

SAFETY SIGNS

The following illustration shows the approximate location and detail of safety signs.

Keep all safety signs clean and legible and replace any that are damaged or missing.

When original parts are replaced, any safety signs affixed to those parts should be

replaced as well. Replacement safety signs are available from your local dealer.

INSTALLATION

To install safety signs, ensure the installation area is clean and dry. Decide on the exact

position before you remove the backing paper. Remove the smallest portion of the split

backing paper and align over the specified area. Carefully press in place. Slowly peel

back the remaining paper and smooth the remaining portion in place. Small air pockets

can be pierced with a pin and smoothed out.

PTO Drive

Hydraulic Drive

6

Page 10

Commercial Snowblower

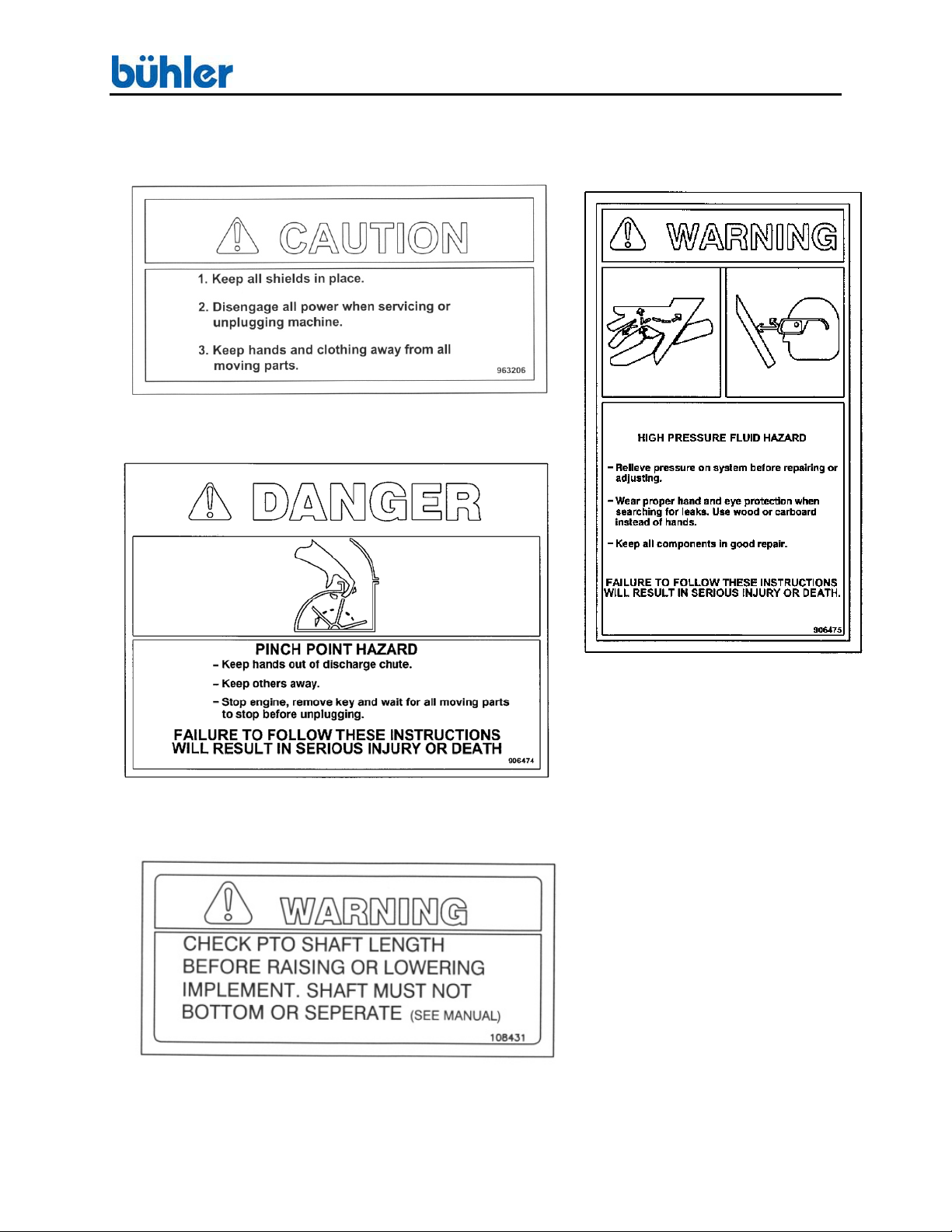

SAFETY SIGNS

#1

#3

#3

Replace safety signs

immediately should they

become damaged, torn or

illegible. Obtain replacements

from your authorized dealer

using the part numbers shown.

#4

7

Page 11

Commercial Snowblower

ASSEMBLY INSTRUCTIONS

1. SPOUT ASSEMBLY FOR ALL SNOWBLOWERS: Remove two of the

grooved spout rollers to mount the discharge spout. Replace the two rollers

to hold spout in place. Install the 2 ½” x 8” cylinder on the spout using the

pins supplied.

2. HYDRAULIC DRIVE: (Page 29 & 30) The 80” long hydraulic lines (#14) for

the spout deflector cylinder should be connected to the two ports on the

hydraulic block labeled C1 and C2 (see Page 16 for block drawing). The 30”

long lines (#15) from the spout control motor connect to the two ports labeled

M1 and M2 on the hydraulic block. The ¾” diam. x 84” main

lines (#21) connect to the implement. NOTE: The customer must supply the

appropriate tips to connect the main lines to the implement. A two-piece

wiring harness is supplied with all hydraulic snowblowers. The 45” part of the

harness (#6) is mounted on the snowblower. One end of this wire connects

to the control block. The plug end mounts on a bracket welded to the top

edge of the quick hitch. The 155” part (#1) of the harness with the switch is

connected to the plug on the harness mounted on the snowblower. A switch

mounted in the cab controls the spout and the deflector. The alligator clips

attach to the battery which acts as a power source. A schematic of the wiring

harness is included in this manual. (See page 17)

3. PTO DRIVE: (Page 31-34)

1. Slide the two hitch adaptor weldments (#17) into the sleeves on the body.

These tubes are adjustable to three different positions. The correct position

for each individual tractor will be determined when mounting the snowblower

on the tractor (see section on mounting blower on tractor). Start with the

tubes pulled out to the last hole. Connect to the snowblower using pins (#71)

and lynch pins (#73).

Mount the hitch Weldment (#7) to the body. The top arm of the hitch bolts on

top of the bracket on the body using a ¾” x 1 5/8” bolt, lock washer and hex

nut. The bottom of the hitch bolts to the outside of the two hitch adaptors

using 5/8” x 1 ¾” hex bolts, flat washers, lock washers and hex nuts.

2. Connect two 108” hoses (#76) to the hydraulic spout control motor and

two 108” hoses (#76) to the cylinder on the discharge spout. Connect these

hoses to the tractor after mounting the snowblower on the tractor.

3. Mounting blower on tractor:

a) The pins supplied with the snowblower are for a category 2 quick

hitch. The quick coupling hitch has two holes both at the top of the

hitch and at each lift arm. When using a quick coupler, the pins

must be in the inside set of holes. Use the outside set of holes

with a standard three-point hitch.

8

Page 12

Commercial Snowblower

ASSEMBLY INSTRUCTIONS – cont’d.

b) Using tape or a bright colored marking pen, mark on the outer

shields the position where the shaft is completely pushed together

and the position where you have a 4” overlap. Watch these marks

when moving the blower through all possible operating angles to

see that the PTO shaft stays within this range.

c) With the engine on the tractor shut off, attach the PTO shaft. The

tractor end has a standard 6-spline end with a spring loaded locking

collar. The snowblower end has a clamp-style yoke with a 3/8” key

way. Slide the yoke onto the gearbox shaft with the 3/8” key (#67)

supplied. Lock the yoke in place with the ½” x 3” bolt (#39) and

lock nut (#40) fitted through the groove in the gearbox shaft. After

tightening the bolt, insert and tighten the 3/8” socket set screw

(#74) supplied.

Caution: Always check to see that both ends of the PTO shaft are securely

attached every time the Snowblower is used. This should always

be done with the tractor engine off.

d) Check that the PTO shaft does not bottom or separate with the

blower in the extreme high and low positions. A longer optional

PTO shaft is available if the standard shaft is too short. Check for

free movement of all parts in various raised positions; particularly

the PTO shaft.

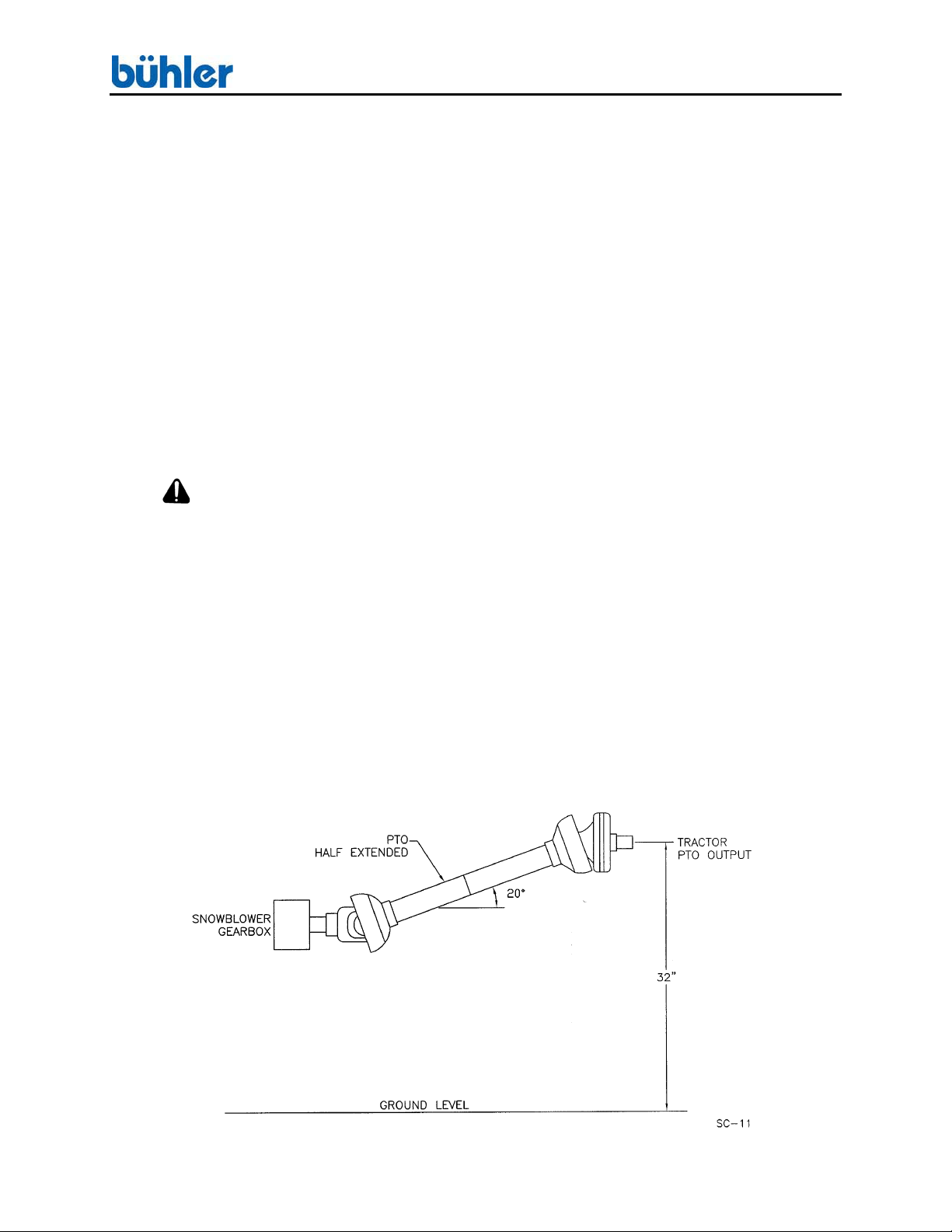

e) NOTE: Excessive U-joint wear and shear pin failure may result if

the tractor PTO angle exceeds 20º. The drawing below gives an

approximate way to check this angle. With the PTO half extended,

the tractor output should not be over 32 inches high. Use 34 inches

if the PTO is nearly compressed.

9

Page 13

Commercial Snowblower

ASSEMBLY INSTRUCTIONS – cont’d.

4. PTO SHIELD: All PTO snowblowers are supplied with a PTO shield

(#18). To install, remove the two rear bolts at the top of the gearbox

(#34). Bolt the PTO shield to the gearbox by the hinges using these same

bolts. A utility spring (#68) keeps the shield in place. Hook one end of the

spring in the hole in the shield and the other end to the hole in the brace

under the gearbox.

CAUTION: Do not run the snowblower without this shield in place.

REFILLING GEARBOX WITH OIL: If the gearbox requires refilling with oil

because of repairs to the gearbox, add oil to the level shown in drawing.

Check the level regularly using the plug in the lid. The correct level is

even with the bottom of the plug.

10

Page 14

Commercial Snowblower

START UP

HYDRAULIC CONTROL BLOCK

NON-STALLING-FAN FEATURE:

The Hydraulic Snowblower has a unique modulating element that keeps the blower fan

from stalling in an overloaded condition. This is accomplished by starving the hydraulic

flow to the front auger motor (which then stops feeding the fan) and diverts all of the

flow (and energy) to the main fan motor. As the fan clears itself, and the pressure

drops, the auger again begins feeding according to load. When the system is set up

properly the fan motor should not stall or plug up.

MODULATING ELEMENT SETUP:

For optimum performance the modulating element (#4) (page 16) must be adjusted to

match the system pressure of the tractor being used. The factory setting is for a 28003000 psi system. If your system is less, you should make adjustments accordingly. For

adjustment:

Loosen the LOCK NUT (on the MODULATING VALVE (#4) (page 16) and back

off the adjusting screw till the screw turns freely by hand, and then turn it in till

you feel the screw making contact with the pressure spring. One turn sets the

pressure up by about 600 psi.

For 2100 psi turn the screw in 3 ½ turns.

For 2400 psi, turn in 4 turns

For 2700 psi, turn in 4 ½ turns

For 3000 psi, turn in 5 turns.

If the fan stalls (in an over load condition), the (#4) (page 16) element is set too high. If

the Auger slows and stops too soon, it is set too low. Once it is set it should not need to

be adjusted any more.

Since there are a number of unknown variables that are unique to almost every

situation, it is difficult to give an exact setting for a particular model. The variables are:

hose size and length, type and size of quick couplers, etc.

11

Page 15

Commercial Snowblower

THEORY OF OPERATION

12

Page 16

Commercial Snowblower

OPERATING INSTRUCTIONS

1. HYDRAULIC DRIVE: All snowblower hydraulic blocks are set at the factory for a

2800 - 3000 psi system. Refer to the section on the hydraulic control block if

| your system does not fall into this range.

2. ALL: Depth of the cut can be partially controlled by tilting the Snowblower

forward or backward.

66” ONLY: Depth of cut can be controlled by bolting the skid shoe in one of the

following positions.

3. PTO DRIVE: Adjust the top link of the tractor hitch so the snowblower is just

slightly tilted back when resting on the ground. CAUTION: Excessive

backward tilt may cause the “U” joints to flutter resulting in PTO shear bolt failure.

4. PTO DRIVE: The inside holes on the hitch are spaced to fit a category 2 quick

hitch using the pins supplied. The hitch will also fit category 2 three point arms or

category 3 if you add bushings.

5. PTO DRIVE: Adjust the lower link sway chains or blocks on the tractor to restrict

movement of the blower when operating.

6. ALL: All snowblowers have a hydraulic control spout and spout deflector. Refer

to the hydraulic control block section. The pressure to the chute control is

regulated by the two torque limit controls (#13b and #13c). Each controls the

hydraulic pressure in one direction. They are set at the factory to about 2 ½

turns. If the pressure is too low, the chute won’t turn. If the pressure is too high

you could damage the teeth on the spout control ring. To adjust the pressure,

you loosen the lock nut on the modulating valve and back off the adjusting screw

till the screw turns freely by hand. Turn the screw in till you feel it making contact

and turn in 2 ½ turns. Start with this setting to do any fine adjustment if

necessary. Pressure should not go over 1000 psi.

The deflector cylinder pressure is regulated by no-load control (#13a). It is set at

the factory to about 2 turns. If pressure is too low it will not operate. Excess heat

will be generated if it is set too high. Adjust if necessary as per previous

paragraph. Operating pressure should be about 700 psi.

13

Page 17

Commercial Snowblower

OPERATING INSTRUCTIONS – cont’d.

7. ALL: Run the snowblower at low rpm to check operation before blowing snow.

8. PTO DRIVE: The blower has three shear bolts to protect the tractor and blower

in case a large object enters the blower. PTO shear bolt – two 5/16” x 1”

(grade 8); auger shear bolt – 5/16” x 1 ¼” (grade 5). Shear bolts should be

fastened with a lock nut or two jam nuts. These bolts must be tight to prevent

wear of the bolts and bolt holes.

9. PTO DRIVE: Never run PTO at over 600 rpm.

10. ALL: Chain tension on auger chain should be set at 3/8” to 1/2” slack.

11. LUBRICATION:

a) ALL: The gear teeth on the chute control should be periodically

lubricated with gun grease.

b) PTO DRIVE: PTO shaft universal joints and square shaft slide

should be periodically lubricated with a grease gun.

c) ALL: Regularly oiling the chain will significantly increase the life

of the chain.

d) PTO DRIVE: Use any 80-90 gear oil or multigrade with 80 minimum

in the gearbox up to the level plug height.

12. ALL: Periodically check all bolts for tightness. The bolt holding on the fan

and the bearing bolts are of particular importance.

13. HYDRAULIC DRIVE: Always use goggles and gloves when checking for

hydraulic leaks. Use a piece of cardboard instead of your hands to look

for leaks.

14. ALL: Always shut off snowblower for servicing or unplugging.

Disengage hydraulics or PTO shaft.

15. PTO DRIVE: Check the shear sprocket at the beginning of every season

to make sure it will spin freely. Clean to loosen if necessary.

16. ALL: When replacing bearings or tightening a loose bearing collar, always

tighten collar in the

similar tool.

17. HYDRAULIC DRIVE: WARNING: The locking pins must extend through

the holes in the attachment when mounting the snowblower to an implement.

Levers must be fully down and locked. Failure to secure pins can allow

attachment to come off and cause injury or death.

direction of shaft rotation

using a center punch or a

14

Page 18

Commercial Snowblower

SPECIFICATIONS

B7422HSB-1

B6022HSB-1

MODEL

Cutting Width 60" 66” 74" 74" 84" 84"

Cutting Height 28” 30” 30” 30” 30” 30”

Fan Housing

Fan 4-Blade 4-Blade 4-Blade 4-Blade 4-Blade 4-Blade

Fan Diameter 21.5” 21.5” 21.5” 23.5” 23.5” 23.5”

Fan Depth 7.5” 7.5” 7.5” 7.5” 7.5” 7.5”

Auger Diameter 20” 20” 20” 20” 20” 20”

Auger Center

Diameter 3”od x .250 wall 3”od x .250 wall 3”od x .250 wall 3”od x .250 wall 3”od x .250 wall 3”od x .250 wall

Auger Thickness 3/8” 3/8” 3/8” " 3/8” 3/8” 3/8”

Drive Fan

Drive Auger

B6022HSB-2

B6022HSB-3

Replaceable

UHMW Liner

Hyd w/#80

Chain

Hyd w/#60H

Chain

B6622HSB-1

B6622HSB-2

B6622HSB-3

Replaceable

UHMW Liner

Hyd w/#80

Chain

Hyd w/#60H

Chain

B7422HSB-2

B7422HSB-3

B7422HSB-4

Replaceable

UHMW Liner

Hyd w/#80

Chain

Hyd w/#60H

Chain

B7424HSB-3

B7424HSB-4

Replaceable

UHMW Liner

Hyd w/#80

Chain

Hyd w/#60H

Chain

B8424HSB-2

B8424HSB-3

Replaceable

UHMW Liner

Hyd w/#80

Chain

Hyd w/#60H

Chain #60H Chain

B84SB

(PTO Drive)

Replaceable

UHMW Liner

PTO

Gearbox

Body Housing 10ga 7ga 10ga 10ga 7ga 7ga

Hitch Type Skid Steer-fixed Ski Steer fixed Skid Steer-fixed Skid Steer-fixed Skid Steer-fixed Cat. 3 –3 pt.

Hitch Adjustment No No No No No 3 position

Chute Rotator Hydraulic-230 Hydraulic-230 Hydraulic-230 Hydraulic-230 Hydraulic-230 Hydraulic-230

Chute Deflector Hyd. Hyd. Hyd. Hyd. Hyd. Hyd.

½” x 4” Beveled

Cutting Edge

Skid Shoes

Truckloading

Spout

System Controls &

Drive

Hyd.

Requirements

Approx. Weight 1070 lbs. 1260 lbs. 1178 lbs. 1193 lbs. 1209 lbs 1307 lbs.

replaceable

Cup Type –

adjustable

Opt. Opt. Opt. Opt. Opt. Opt.

Hyd. Load

Sensing Block

flow adjustable

13-26 gpm

2000 psi Min.

½” x 4” Beveled

replaceable

Side mount

Fixed

Hyd. Load

Sensing Block

flow adjustable

13-26 gpm

2000 psi Min.

½” x 4” Beveled

replaceable

Cup Type –

adjustable

Hyd. Load

Sensing Block

flow adjustable

13-32 gpm

2000 psi Min.

½” x 4” Beveled

replaceable

Cup Type –

adjustable

Hyd. Load

Sensing Block

flow adjustable

20-32 gpm

2000 psi Min.

½” x 4” Beveled

replaceable

Cup Type –

adjustable

Hyd. Load

Sensing Block

flow adjustable

20-32 gpm

2000 psi Min.

½” x 4” Beveled

replaceable

Cup Type –

adjustable

PTO

w/shear pin

10 gpm

1000 psi Min.

Hydraulic Snowblower Fan RPM to GPM Rating

Series I 13 – 17 gpm 2000 psi min. (6.2 cu.in./rev)

Series II 16 – 22 gpm 2000 psi min. (8 cu.in./rev)

Series III 20 – 26 gpm 2000 psi min. (9.6 cu.in./rev)

Series IV 24 – 32 gpm 2000 psi min (11.9 cu.in./rev)

gpm x psi = hp

1714

15

Page 19

Commercial Snowblower

HYDRAULIC CONTROL BLOCK DRAWING AND PARTS LIST

HYD MANIFOLD ASSEMBLY

Item # Part # Description

1 905669 Main Block

2 813922 Logic Element

3 X2732 Element Seal Kit

4 813923 Control Valve

5 X2733 Seal Kit

6 813924 No-Load Valve

7 X2734 Seal Kit

8ab 813925 Chute Cont. Valves

9 X2735 Seal Kit

10a 813926 No-Load Press. Coil

10bc 813926 Chute Up Down Coil

10ef 813926 Chute Left Right Coil

11 813929 Check Valve

12 X2736 Seal Kit

13a 813930 No-Load Control

13bc 813930 Torque Limit Control

14 X2737 Seal Kit

15 813931 Check Valve

16 X2745 Seal Kit

16

Page 20

Commercial Snowblower

MAINTENANCE

HYDRAULIC SNOWBLOWER WIRING SCHEMATIC X2572

HYDRAULIC SNOWBLOWER MOTOR REQUIREMENT CHART

Category Motor GPM Motor HP @ HP @ Shaft Type Eaton Motor Buhler

Cu/in/rev RPM 2000 3000 psi Flange Mtg. Part #'s Part #

Group #1 6.2

Group #2 8

Group #3 9.6

Group #4 11.9

12 447 12 18 1.25" Straight 1 1/16-12 ORB

16 596 16 24 2 bolt 104-1062

17 491 17 25 1.25 Straight 1/16/=12 ORB

20 578 20 29 2 bolt 104-1063

20 481 20 29 1.25 Straight 1 16/-12 ORB

24 578 24 35 2 bolt 104-1064

21 408 21 31 1.25 Straight 1 116-12 ORB

28 544 28 41 1.25 Straight 104 - 1065

motor 146-1028-002 905625

spout

17

905623

905694

905695

905624

Page 21

Commercial Snowblower

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

D1 Nothing Works Hydraulic Circuit Not Complete

1. Hydraulic Valve not engaged 1. Engage valve to full detent

2. 1 or more quick couplers not 2. Fully engage all couplers

completely engaged.

3. Defective quick coupler 3. Replace defective quick couplers

4. Hydraulic pump low on fluid 4. Top up fluid level

D2 Auger Rotates Hydraulic Circuit Reversed

backwards, and

fan does not

rotate

D3 Fan turns too

slow

D4 Fan motor stalls

D5 Auger motor

slows or stalls

too quickly

D6 Fan & Auger work Electrical Problem

but chute controls

do not work

properly

D7 Chute controls do

not work properly

in no-load

conditions.

D8 Chute Rotation

seems to lack

power to turn.

1. Main valve is in reverse 1. Reverse valve direction or

2. Quick couplers are connected 2. Switch hose connections to

backwards. the machine.

1. Inadequate hydraulic flow for 1. Check the gpm of your

this motor size. system.

2. Wrong motor for your system. 2. Contact your dealer.

Valve #4 (Fig. 1) set too high See MODULATING

ELEMENT SET UP

Valve #4 (Fig. 1) set too low See MODULATING

ELEMENT SET UP

1. Electrical connections to battery 1. Ensure that the clamps are

making proper connection.

2. Breaker is tripped. 2. Reset breaker.

3. Connector from Sw to block not 3. Ensure the connector is

contacting. fully engaged. Check for

broken wires.

4. Connection to No-Load Valve #6 4. Check all items in D6

(Fig. #1) is not making

5. Diodes in switchbox are defective. 5. Check for voltage through diodes

6. Solenoid Valve Spool is stuck 6. Replace #8a or 8b solenoid

cartridge.

1. The No-Load pressurizing valve 1. Back of the adjuster-screw

#14a (Fig. #1) set too low. till it rotates freely by hand. Then

turn in till you feel it contacting the

spring. Then turn in 2 turns.

2. Electrical: Switch, harness, 2. Check the No-Load Circuit

connectors, coil 10a, diodes #5 in Fig. #2

3. Polarity of the system is reversed. 3. Red Alligator clip must be

on the Positive Terminal

4. Diodes in switchbox defective. 4. Replace defective diodes.

5. Defective Coil #10a (Fig. #1) 5. Replace Coil.

6. Defective Valve #6 (Fig. #1) 6. Replace Valve.

1. See D7-1 1. Same as D7-1.

2. Valve #14b or #14c set too low. 2. Back of the adjuster-screw

till it rotates freely by hand

then turn in till you feel it

contacting the spring. Then

turn in 2 turns.

18

Page 22

Commercial Snowblower

19

Page 23

Commercial Snowblower

HYDRAULIC COMMERCIAL SERIES SNOWBLOWER – 22” HOUSING

20

Page 24

Commercial Snowblower

21

Page 25

Commercial Snowblower

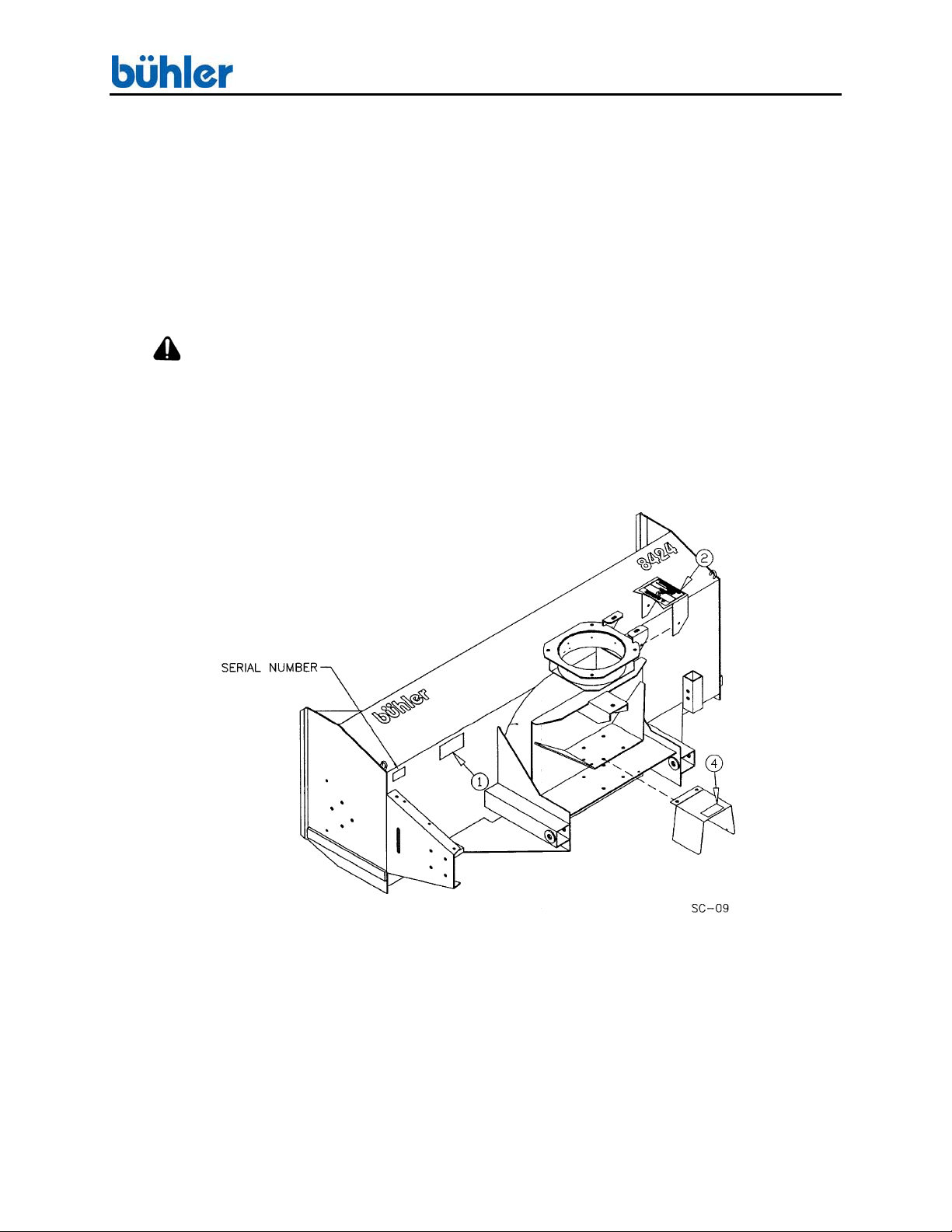

WHEN ORDERING PARTS

Always give your dealer the Model, Color and Serial Number of your machine to assist

him in ordering and obtaining the correct parts. Use the exploded view and tabular

listing of the area of interest to exactly identify the required part.

Hyd Commercial Series Snowblower - 22'' Housing

Item # Part # Description

1 909863 Main Body Weldment - 74''

909590 Main Body Weldment - 66''

909853 Main Body Weldment - 60''

2 905226 Fan Weldment - 22''

3 905206 Auger Weldment - 74''

909606 Auger Weldment - 66''

905210 Auger Weldment - 60''

4 905550 Spout Weldment

5 909608 48 Tooth Sprocket #60, 1 3/8'' Bore

6 909887 Cutting Edge (74'')

909592 Cutting Edge (66'')

909856 Cutting Edge (60'')

7 905291 Adaptor

8 909678 Roller Chain (#60H x 76 Links w/ Connector)

9 965426 1 3/8'' Housing W/ Bearing

965430 1 3/8'' Bearing W/ Stainless Steel Lock

10 906322 Auger Sprocket 15T #60 (1 1/4'' Bore) (Ser 1 - 3)

906323 Auger Sprocket 15T #60 (1 1/2'' Bore) (Ser 4)

11 906332 Spout Liner

12 905623 Fan Motor - 2 Hole (Ser 1)

905694 Fan Motor - 2 Hole (Ser 2)

905695 Fan Motor - 2 Hole (Ser 3)

905624 Fan Motor - 4 Hole (Ser 4)

13 906335 Spout Motor

14 967440 Pop Rivet SD68BSLF

15 905241 Spout Gear Weldment

16 968627 1 1/2'' Bearing w/ Collar

17 967260 1 1/2'' Bearing Flange (Set)

18 902869 Fan Motor Mount Plate (Ser 1-3)

905289 Fan Motor Mount Plate (Ser 4)

19 905362 Roller Chain (#80H x 30 Links w/ Connector)

20 905299 Auger Motor Mount Plate (Ser 1-3)

905528 Auger Motor Mount Plate (Ser 4)

21 906311 Hydraulic Box Shield Weldment

22 905224 Fan Shaft 1 1/2'' x 15 1/4''

23 909593 Chain Cover

22

Page 26

Commercial Snowblower

24 909594 Skid Plate Weldment Left Hand

909610 Skid Plate Weldment Right Hand

25 103753 Cylinder Clevis Pin 1'' x 4''

26 12779 Hair Pin Clip #9 Western Wire

27 960719 Sprocket 15T, #80, 1 1/2'' Bore

28 905309 Sprocket 15T, #80, 1 1/4'' Bore (Ser 1-3)

960719 Sprocket 15T, #80, 1 1/2'' Bore (Ser 4)

29 909430 Spout Roller

30 905181 Spout Link 22''

31 24981 Cylinder 2 1/2'' Dia x 8''

32 905554 Spout Sprocket Cover

33 906660 1/2'' x 2'' Sq Hd Set Screw

34 81620 1/2'' x 1 1/4'' Hex Bolt

35 84277 1/2'' x 1 1/2'' Hex Bolt

36 909821 1/2'' x 2'' Flat Head Bolt

37 87553 1/2'' x 1 3/4'' Hex Bolt

38 87553 1/2'' x 1 3/4'' Hex Bolt (pl) (Series #1-3)

81624 1/2'' x 2 1/4'' Hex Bolt (pl) (Series #4)

40 812364 1/2'' Lock Nut

41 81638 1/2'' BS Flat Washer Std

42 81637 1/2'' Lock Washer

43 81636 1/2'' Hex Nut

44 86170 3/8'' x 1'' Hex Bolt

45 86171 3/8'' x 1 1/4'' Hex Bolt

46 811792 3/8'' x 1 1/2'' Hex Bolt

47 967431 3/8'' x 1'' Flat Bolt (skt)

48 81593 3/8'' Lock Washer

49 812363 3/8'' Lock Nut

50 81592 3/8'' Hex Nut

51 905543 3/8'' x 4'' Auger Chain Bolt Weldment

52 905648 Spout Liner Middle

53 905647 Spout Liner Bottom

54 81568 5/16'' Hex Nut

55 906393 5/16'' x 3/4'' Fl Hd Bolt (skt)

56 81569 5/16'' Lock Washer

57 81549 5/16'' x 3/4'' Hex Bolt

58 988999 3/8'' x 3/8'' Socket Set Screw

59 902874 Spout Motor Mount Plate

60 84268 5/8'' x 1 1/2'' Hex Bolt

61 81677 5/8'' Lock Washer

62 81678 5/8'' BS Flat Washer Standard

63 965821 3/8'' x 1 3/4'' Key

64 905310 3/8'' x 4 1/2'' Key

23

Page 27

Commercial Snowblower

67 905278 Cover Plate

68 905336 Fan Housing Liner 68''

69 906348 Motor Washer 13/32'' hole x 2'' OD

70 906574 Bronze Bushing 7/8'' OD x 1''

71 812026 5/16'' x 1'' Hex Bolt (pl)

72 907590 Spout Hose Holder

73 908966 Spout Liner Bottom (truckloader)

74 907689 Spout Weldment (truckloader)

75 909277 Manual Holder

24

Page 28

Commercial Snowblower

HYDRAULIC COMMERCIAL SERIES SNOWBLOWER – 24” HOUSING

25

Page 29

Commercial Snowblower

26

Page 30

Commercial Snowblower

Hyd Commercial Series Snowblower - 24'' Housing

Item # Part # Description

1 909891 Main Body Weldment - 84''

909865 Main Body Weldment - 74''

2 905225 Fan Weldt - 24''

3 905202 Auger Weldment - 84''

905206 Auger Weldment - 74''

4 905550 Spout Weldment

5 909608 48 Tooth Sprocket #60, 1 3/8'' Bore

6 909893 Cutting Edge (84'')

909887 Cutting Edge (74'')

7 905291 Adaptor

8 909678 Roller Chain (#60H x 76 Links w/ Connector)

9 965426 1 3/8'' Housing W/ Bearing

965430 1 3/8'' Bearing W/ Stainless Steel Lock

10 906322 Auger Sprocket 15T #60 (1 1/4'' Bore) (Ser 3)

906323 Auger Sprocket 15T #60 (1 1/2'' Bore) (Ser 4)

11 906332 Spout Liner

12 905695 Fan Motor - 2 Hole (Ser #3)

905624 Fan Motor - 4 Hole (Ser #4)

13 906335 Spout Motor

14 967440 Pop Rivet SD68BSLF

15 905241 Spout Gear Weldt

16 968627 1 1/2'' Bearing w/ Collar

17 967260 1 1/2'' Bearing Flange (Set)

18 902869 Fan Motor Mount Plate (Ser 3)

905289 Fan Motor Mount Plate (Ser 4)

19 905362 Roller Chain (#80H x 30 Links w/ Connector)

20 905299 Auger Motor Mount Plate (Ser 3)

905528 Auger Motor Mount Plate (Ser 4)

21 906311 Hyd Box Shield Weldment

22 905224 Fan Shaft 1 1/2'' x 15 1/4''

23 909593 Chain Cover

24 909594 Skid Plate Weldment L.H

909610 Skid Plate Weldment R.H

25 103753 Cylinder Clevis Pin 1'' x 4''

26 12779 Hair Pin Clip #9 Western Wire

27 960719 Sprocket 15T, #80, 1 1/2'' Bore

28 905309 Sprocket 15T, #80, 1 1/4'' Bore (Ser 3)

960719 Sprocket 15T, #80, 1 1/2'' Bore (Ser 4)

29 909430 Spout Roller

30 905181 Spout Link 22''

31 24981 Cylinder 2 1/2'' Dia x 8''

27

Page 31

Commercial Snowblower

32 905554 Spout Sprocket Cover

33 905246 3/8'' x 3'' Fan Bolt Weldment

34 81620 1/2'' x 1 1/4'' Hex Bolt

35 84277 1/2'' x 1 1/2'' Hex Bolt

36 909821 1/2'' x 2'' Fl Hd Bolt (skt)

37 87553 1/2'' x 1 3/4'' Hex Bolt

38 87553 1/2'' x 1 3/4'' Hex Bolt (Series #3)

81624 1/2'' x 2 1/4'' Hex Bolt (Series #4)

39 81624 1/2'' x 2 1/4'' Hex Bolt

40 812364 1/2'' Lock Nut

41 81638 1/2'' BS Flat Washer Standard

42 81637 1/2'' Lock Washer

43 81636 1/2'' Hex Nut

44 86170 3/8'' x 1'' Hex Bolt

45 86171 3/8'' x 1 1/4'' Hex Bolt

46 811792 3/8'' x 1 1/2'' Hex Bolt

47 967431 3/8'' x 1'' Flat Bolt (skt)

48 81593 3/8'' Lock Washer

49 812363 3/8'' Lock Nut

50 81592 3/8'' Hex Nut

51 905543 3/8'' x 4'' Auger Chain Bolt Weldment

52 905648 Spout Liner Middle

53 905647 Spout Liner Bottom

54 81568 5/16'' Hex Nut

55 906393 5/16'' x 3/4'' Fl Hd Bolt (skt)

56 81569 5/16'' Lock Washer

57 81549 5/16'' x 3/4'' Hex Bolt

58 988999 3/8'' x 3/8'' Socket Set Screw

59 902874 Spout Motor Mount Plate

60 84268 5/8'' x 1 1/2'' Hex Bolt

61 81677 5/8'' Lock Washer

62 81678 5/8'' BS Flat Washer Standard

63 965821 3/8'' x 1 3/4'' Key

64 905310 3/8'' x 4 1/2'' Key

67 905278 Cover Plate

68 905337 Fan Housing Liner 73 1/2''

69 906348 Motor Washer 13/32'' hole x 2'' OD

70 906574 Bronze Bushing 7/8'' OD x 1''

71 812026 5/16'' x 1'' Hex Bolt

72 907590 Spout Hose Holder

73 908966 Spout Liner Bottom (truckloader)

74 907689 Spout Weldment (truckloader)

75 909277 Manual Holder

28

Page 32

Commercial Snowblower

SNOWBLOWER ASSEMBLY

29

Page 33

Commercial Snowblower

HYD COMMERCIAL SERIES SNOWBLOWER ASSEMBLY

Item # Part # Description

1 907412 Wiring Harness - Tractor Half

2 890082 1 1/16 SWFJIC x 1 1/16 MJIC Elbow 90

3 JDF19M7866 HFL Bolt M8 x 20 (10.9) (pl)

4 905669 Hyd Manifold Assembly

5 905623 Series #1 Motor - 2 Holes (Already Assembled)

905694 Series #2 Motor - 2 Holes (Already Assembled)

905695 Series #3 Motor - 2 Holes (Already Assembled)

905624 Series #4 Motor - 4 Holes (Already Assembled)

6 906589 1 5/16 MORB x 1 1/16 MJIC Adaptor Straight

7 811918 9/16 MJIC x 9/16 SWMORB Elbow 90

8 812647 1 1/16 MJIC x 1 1/16 MORB Elbow 90

9 812661 1 1/16 MORB x 1 1/16 MJIC Adaptor Straight

10 812086 9/16 MORB x 9/16 MJIC Adaptor Straight

11 812838 7/16 MORB x 9/16 MJIC Adaptor Straight

12 813756 1 1/16 MJIC x 1 5/16 MORB Elbow 90

13 887575 1 1/16 SWFJIC X 1 1/16 MJIC x 1 1/16 MJIC Tee

14 IN29068 3/8'' x 80'' Hose 9/16 SWFJIC x 9/16 SWFJIC

15 115796 3/8'' x 30'' Hose 9/16 SWFJIC x 9/16 MORB

16 115618 3/8'' x 45'' Hose 9/16 SWFJIC x 9/16 SWFJIC - 84''

115619 3/8'' x 40'' Hose 9/16 SWFJIC x 9/16 SWFJIC-74''&60''

17 115611 3/4'' x 52'' Hose 1 1/16 SWFJIC x 1 1/16 SWFJIC-84''

115612 3/4'' x 42'' Hose 1 1/16SWFJICxSWFJIC-60''&(74'' Ser #4)

115614 3/4'' x 48'' Hose 1 1/16 SWFJIC x SWFJIC-74'' Ser #1-3

18 115614 3/4'' x 48'' Hose 1 1/16 SWFJIC x 1 1/16 SWFJIC - 84''

115616 3/4'' x 40'' Hose 1 1/16 SWFJIC x SWFJIC - 74'' Ser #1-3

115615 3/4'' x 36'' Hose 1 1/16 SWFJICxSWFJIC-60''&(74'' Ser #4)

19 115612 3/4'' x 42'' Hose 1 1/16 SWFJIC x 1 1/16 SWFJIC - 84''

115616 3/4'' x 40'' Hose 1 1/16 SWFJIC x SWFJIC - 74'' Ser #1-3

115615 3/4'' x 36'' Hose 1 1/16 SWFJICxSWFJIC-60''&(74'' Ser#4)

20 115608 3/4'' x 86'' Hose 1 1/16 SWFJIC x 1 1/16 SWFJIC - 84''

115609 3/4'' x 74'' Hose 1 1/16 SWFJIC x 1 1/16 SWFJIC - 74''

115610 3/4'' x 68'' Hose 1 1/16 SWFJIC x 1 1/16 SWFJIC - 60''

21 115617 3/4'' x 84'' Hose 1 1/16 SWFJIC x 1 1/16 MORB

22 811922 9/16'' ORB Steel Plug

23 81525 1/4'' x 3/4'' Hex Bolt

24 81545 1/4'' Lock Washer

25 81544 1/4'' Hex Nut

26 907411 Sb Wiring Harness - Sb Half

27 116699 3/8'' x 166'' Hose 9/16 SWFJIC x 9/16 SWFJIC

30

Page 34

Commercial Snowblower

PTO COMMERCIAL SERIES SNOWBLOWER – 24 “ HOUSING

31

Page 35

Commercial Snowblower

32

Page 36

Commercial Snowblower

PTO Commercial Series Snowblower - 24'' Housing

Item # Part # Description

1 909894 Main Body Weldment

2 905225 Fan Weldment - 24''

3 905202 Auger Weldment

4 905550 Spout Weldment

5 909608 48 Tooth Sprocket #60, 1 3/8'' Bore

6 909893 Cutting Edge

7 F0328 Hitch

8 905196 Drive Shaft

9 965426 1 3/8'' Housing W/ Bearing

965430 1 3/8'' Bearing W/ Stainless Steel Lock

10 965433 1 1/4'' Housing W/ Bearing (UCF207-20)

961676 1 1/4'' Brg W/ Collar

11 909895 Roller Chain (#60H x 96 Links W/ Connector)

12 965914 13T Sprocket, #60 1 1/4'' Bore

13 906335 Spout Motor

14 84072 3/8'' x 3/4'' Hex Bolt

15 905241 Spout Gear Weldment

16 902874 Spout Motor Mount Plate

17 905214 Hitch Adaptor Weldment

18 908715 PTO Shield

19 BU50505 Gearbox without Oil

20 F0585 PTO Shaft

21 905227 Idler Shield

22 905199 Drive Shaft Guard

23 909593 Chain Cover

25 103753 Cylinder Clevis Pin 1'' x 4''

26 12779 Hair Pin Clip #9 Western Wire

27 905554 Spout Sprocket Cover

28 905337 Fan Housing Liner 73 1/2''

29 909430 Spout Roller

30 905181 Spout Link 22''

31 24981 Cylinder 2 1/2'' Dia X 8''

32 965969 Idler Spacer

33 965962 Idler Sprocket, 13T, #60, 5/8'' Bore

34 81619 1/2'' x 1'' Hex Bolt

35 81620 1/2'' x 1 1/4'' Hex Bolt

36 84277 1/2'' x 1 1/2'' Hex Bolt

37 909821 1/2'' x 2'' Fl Hd Bolt (skt)

38 81624 1/2'' x 2 1/4'' Hex Bolt

39 81627 1/2'' x 3'' Hex Bolt

40 812364 1/2'' Lock Nut

33

Page 37

Commercial Snowblower

41 81637 1/2'' Lock Washer

42 81636 1/2'' Hex Nut

43 812086 9/16 MORB x 9/16 MJIC Adaptor Str

44 81638 1/2'' BS Flat Washer

45 86170 3/8'' x 1'' Hex Bolt

46 906332 Spout Liner

47 86171 3/8" x 1 1/4" Hex Bolt

48 81593 3/8'' Lock Washer

49 81592 3/8'' Hex Nut

50 81549 5/16'' x 3/4'' Hex Bolt

51 906393 5/16'' x 3/4'' Fl Hd Bolt (skt)

52 906574 Bronze Bushing 7/8''OD x 1''

53 81552 5/16'' x 1 1/4'' Hex Bolt

54 81569 5/16'' Lock Washer

55 812362 5/16'' Lock Nut

56 81568 5/16'' Hex Nut

57 84268 5/8'' x 1 1/2'' Hex Bolt

58 84270 5/8'' x 1 3/4'' Hex Bolt

59 81671 5/8'' x 4'' Hex Bolt

60 81677 5/8'' Lock Washer

61 81678 5/8'' BS Flat Washer Std

62 81676 5/8'' Hex Nut

63 967437 3/4'' x 1 5/8'' Hex Bolt

64 81701 3/4'' Lock Washer

65 81700 3/4'' Hex Nut

66 902377 3/8'' x 3/8'' x 4 3/4'' Key

67 968807 3/8''x 3/8'' x 2'' Key

68 960135 Spring

69 909594 Skid Plate Weldment Left Hand

70 909610 Skid Plate Weldment Right Hand

71 965910 Top Link Pin (Category 2)

72 965966 Quick Hitch Lift Pin (Category 2)

73 965911 Linch Pin 7/16''

74 988999 3/8'' Dia x 3/8'' Socket Set Screw

75 811918 9/16 MJIC x 9/16 SWMORB Elbow 90

76 115370 3/8'' x 114'' Hose 9/16 SWFJIC x 1/2 MNPT

77 905648 Spout Liner Middle

78 905647 Spout Liner Bottom

79 967440 Pop Rivet SD68BSLF

80 812026 5/16'' x 1'' Hex Bolt

81 907590 Spout Hose Holder

82 908966 Spout Liner Bottom (truckloader)

83 907689 Spout Weldment (truckloader)

84 116699 3/8" x 166" Hose 9/16" SWFJIC x 9/16" SWFJIC

85 812320 1/2" MNPT x 9/16" MJIC Straight

86 909277 Manual Holder

34

Page 38

Commercial Snowblower

PTO DRIVE COMMERCIAL SNOWBLOWER – PTO

PTO DRIVE COMMERCIAL SNOWBLOWER PTO

Item # Part # Description

F0585 Shaft Complete

907987 Tractor Half of PTO (Shear)

907988 Implement Half of PTO (Clamp Yoke)

1 907989 Shear Assembly

2 936199 Safety Slide Lock Repair Kit

(Collar, Spring, Ret. Ring, 2-Pawls)

3 936249 Shear Assembly Repair Kit

(3/8" x 1/2" Bolt, Lube, Blank, 31-1/4" Balls)

4 903297 Shear Bolt - 5/16" x 1" (Grade 8) (Pack of 10)

5 936197 Repair Kit (Option)

906548 Extended Life Repair Kit (Std.)

6 907994 Yoke & Tube

7 907991 Nylon Bearing

8 907993 Inner Shield

9 907992 Outer Shield

10 907990 Yoke & Shaft

11 907995 Clamp Yoke

12 81627 1/2" x 3" Hex Bolt (pl)

13 812364 1/2" Lock Nut (pl)

14 908002 Shear Yoke

15 936411 6 Spl. Shear Hub

35

Page 39

Commercial Snowblower

2 ½” x 8” CYLINDER ASSEMBLY

2 1/2'' x 8'' CYLINDER ASSEMBLY

Item # Part # Description

1 24982 Tube Weldment

2 108655 Shaft 1.25 dia x 15.54 Lg

3 23156 2.50 Dia Headplate

4 13109 2.50 Dia Piston

5 13090 Piston Rod Clevis (Cast)

6 82330 2.50 OD x e Sect O-Ring

7 83330 2.50 OD x o Sect Backup Washer

8 82018 0.88 OD x 0.06 O-Ring

9 812200 1.50 OD x 1.25 ID x o Sect Seal

10 81901 1.50 OD x 1.25 ID Dust Seal

11 811922 0.56 MORB Plug

12 81578 3/8'' x 1 3/4'' Hex Bolt (pl)

13 81592 3/8'' Hex Nut

14 104314 7/8'' Jam Lock Nut (Steel) (pl)

15 103753 Clevis Pin 1'' x 4''

16 12779 Hair Pin Clip

17 22370 Hyd Cyl Decal

36

Page 40

Commercial Snowblower

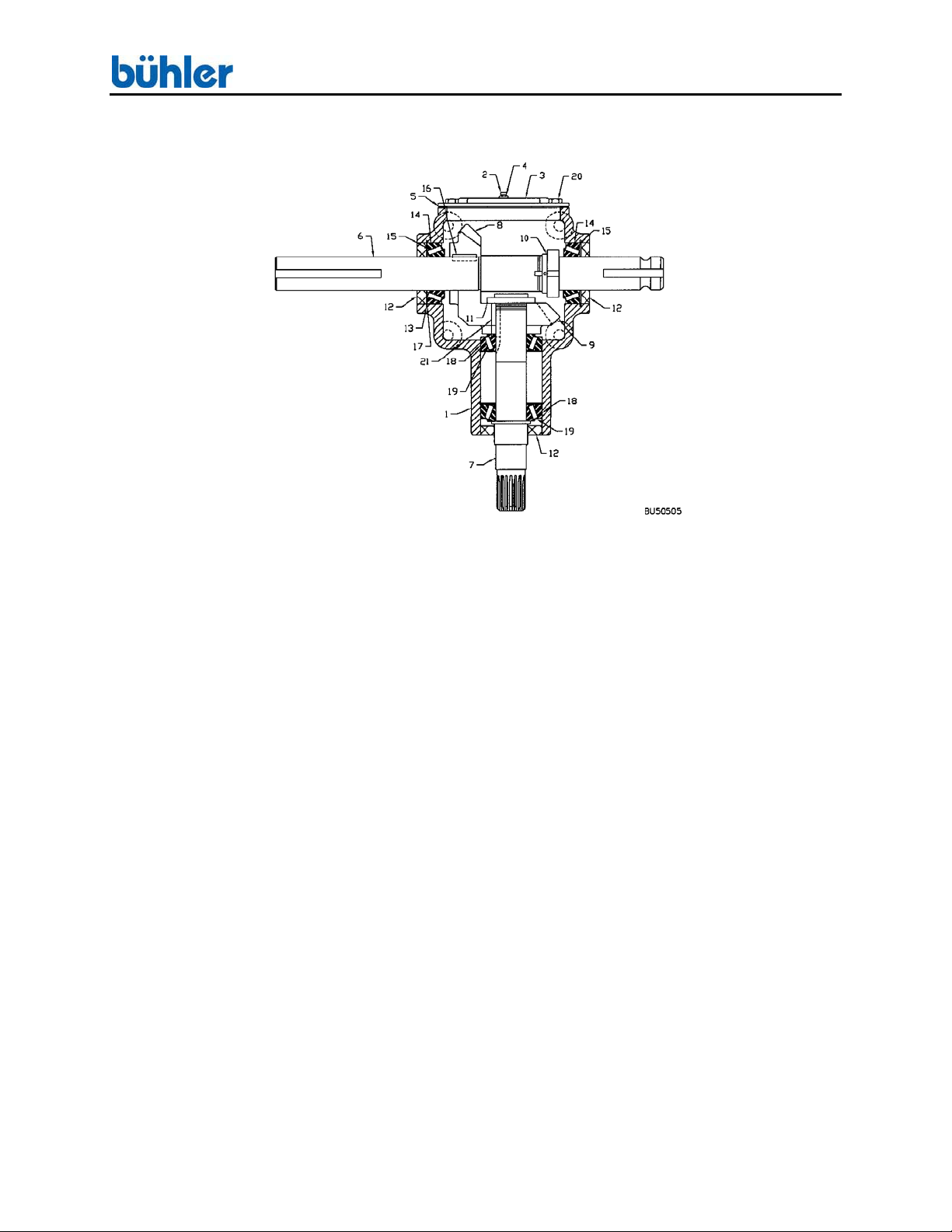

PTO DRIVE GEARBOX

PTO DRIVE GEARBOX

Item # Part # Description

BU50505 Gearbox Complete

1 BU50310 Gearbox Casting Only

2 BU500089-3 Pipe Plug

3 BU50457 Gearbox Cover

4 BU500167-1 Relief Valve

5 BU50458 Gearbox Gasket

6 BU50507 Cross Shaft

7 BU50502 Pinion Shaft

8 BU50329 Bevel Gear - 1 1/2" Bore

9 BU50331 Bevel Gear - 1 3/8" Bore

10 BU50428 Staking Lock Nut

11 BU50444 Staking Lock Nut

12 BU50422-1 Oil Seal (3 used)

13 BU50415 Retainer Ring (4 used)

14 BU575902 Bearing Cup (2 used)

15 BU575901 Bearing Cone (2 used)

16 BU50429 Key

17 BU50210X Shim Set

18 BU575907 Bearing Cup (2 used)

19 BU575906 Bearing Cone (2 used)

20 BU500397-6 Hex Bolt 5/16'' NC x 5/8'' GR5 (pl)

21 BU50417-1 Key

37

Page 41

Commercial Snowblower

SHIPPING KIT AND BUNDLE NUMBERS

The following is a list of Kit Numbers for this product and the Bundle Numbers,

Descriptions, and Quantities for each Kit.

QUANTITY BUNDLE NO. DESCRIPTION

B6022HSB-1 60” HYDRAULIC DRIVE W/22” FAN SERIES 1

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0887 Snowblower

B6022HSB-2 60” HYDRAULIC DRIVE W/22” FAN SERIES 2

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0888 Snowblower

B6022HSB-3 60” HYDRAULIC DRIVE W/22” FAN SERIES 3

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0889 Snowblower

B6022HSB-3 60” HYDRAULIC DRIVE W/22” FAN SERIES 3

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0889 Snowblower

B6622HSB-1 66” HYDRAULIC DRIVE W/22” FAN SERIES 1

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0842 Snowblower

B6622HSB-2 66” HYDRAULIC DRIVE W/22” FAN SERIES 2

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0798 Snowblower

B6622HSB-3 66” HYDRAULIC DRIVE W/22” FAN SERIES 3

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0843 Snowblower

B7422HSB-2 74” HYDRAULIC DRIVE W/22” FAN SERIES 2

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0872 Snowblower

38

Page 42

Commercial Snowblower

SHIPPING KIT AND BUNDLE NUMBERS – cont’d.

B7422HSB-3 74” HYDRAULIC DRIVE W/22” FAN SERIES 3

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0873 Snowblower

B7422HSB-4 74” HYDRAULIC DRIVE W/22” FAN SERIES 4

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0874 Snowblower

B7424HSB-3 74” HYDRAULIC DRIVE W/24” FAN SERIES 3

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0892 Snowblower

B7424HSB-4 74” HYDRAULIC DRIVE W/24” FAN SERIES 4

1 F0324 Spout Assembly

1 F0325 Snowblower

1 F0893 Snowblower

B8424HSB-3 84” HYDRAULIC DRIVE W/24” FAN SERIES 3

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0894 Snowblower

B8424HSB-4 84” HYDRAULIC DRIVE W/24” FAN SERIES 4

1 F0324 Spout Assembly

1 F0325 Crate of Parts

1 F0895 Snowblower

B84SB 84” PTO Drive W/24” FAN

1 F0324 Spout Assembly

1 F0626 Crate of Parts

1 F0328 Hitch

1 F0896 Snowblower

1 F0585 PTO

OPTIONAL BUNDLE NUMBERS

The following is a list of options available for the Kits listed above.

F4119 Truckloading Spout

39

Page 43

Page 44

Farm King Division

301 Mountain Street S.

Morden, MB R6M 1X7

Ph.: (204) 822-4467

Fax: (204) 822-6348

Allied/Inland Division

1260 Clarence Avenue

Winnipeg, MB R3T 1T2

Ph.: (204) 284-6100

Fax: (204) 477-2325

B.I.I. Division

1330 43

rd

Street N.W.

Fargo, ND 58102

Ph: (701) 282-7014

Fax: (701) 282-5865

B.C., Abbotsford

(604) 864-2665

AR, West Memphis

(870) 732-3132

GA, Stone Mountain

(770) 908-9439

ID, Meridian

(208) 887-6006

IN, Clarksville

(812) 284-3376

KS, Wichita

(316) 265-9577

MN, Lakeville

(952) 469-5267

MT, Billings

(406) 248-7771

ND, Bismarck

(701) 223-1886

ND, Fargo

(701) 282-7003

NE, Blair

(402) 426-8211

OH, Youngstown

(330) 793-0862

OR, Beaverton

(503) 641-1865

SD, Huron

(605) 352-8616

TX, Houston

(713) 928-2632

UT, Salt Lake City

(801) 972-4321

WI, Portage

(608) 742-1370

AB, Edmonton

(780) 962-6991

SK, Regina

(306) 781-2300

ON, Woodstock

(519) 539-0435

QC, Dorion

(450) 455-4840

Buhler Manufacturing

301 Mountain Street S.

Morden MB.

R6M 1X7

Ph.: (204) 822-4467

Fax: (204) 822-6348

www.buhler.com

Burando Hill

Katanning

W. Australia

011-618-98-214422

Chihuahua, Mexico

011-52-158-90306

John Kerr Equipment Ltd.

Wilcoxholm Farm

Linlithgow, W. Lothian

Scotland

011-441-506-842280

Skovde, Sweden

011-46-500-452651

Naestved, Denmark

011-45-557-29511

Printed in Canada

Loading...

Loading...