Page 1

Page 2

Page 3

Finishing Mower

TABLE OF CONTENTS

DESCRIPTION PAGE

WARRANTY................................................................1

INTRODUCTION .........................................................2

SAFETY.......................................................................3

Safety.....................................................................3

General Safety .......................................................4

Start Up Safety.......................................................4

Operation Safety ....................................................4

Transport Safety.....................................................5

Service and Maintenance Safety............................5

Storage Safety........................................................5

Safety Signs...........................................................6

Safety Sign Installation...........................................6

ASSEMBLY.................................................................9

Hitch Assembly Instructions ...................................9

Wheel Assembly Instructions .................................9

START UP

Machine Break-In ...................................................9

OPERATION ...............................................................10

Operating Instructions ............................................10

Field Use Preparation.............................................11

Field Operation.......................................................11

Disconnecting from Tractor ....................................12

Rear Discharge Mower Chain Kit Assembly...........12

Quick Hitch ............................................................ 12

Theory of Operation................................................13

MAINTENANCE .......................................................... 15

Maintenance...........................................................15

Bolt Torque.............................................................17

Page 4

Finishing Mower

PARTS DRAWINGS....................................................18

Side Discharge Drawing.........................................18

Side Discharge Parts List.......................................19

4’ Rear Discharge Drawing.....................................22

4’ Rear Discharge Parts List...................................23

5’, 6’ & 7’ Rear Discharge Drawing......................... 25

5’, 6’ & 7’ Rear Discharge Parts List.......................26

Gearbox Drawing....................................................29

Gearbox Parts List..................................................30

Spindle Assembly Drawing.....................................31

Spindle Parts Lists..................................................32

PTO Shaft Drawing.................................................33

PTO Shaft Parts List...............................................34

Rear Discharge Chain Kit Drawing.........................35

Chain Kit Assembly Drawing..................................36

Quick Hitch Kit Drawing & Parts List.......................37

SHIPPING KIT AND BUNDLE NUMBERS .................38

Page 5

Finishing Mower

WARRANTY POLICY

Buhler Manufacturing products are warranted for a period of twelve (12) months (90 days for

commercial application) from original date of purchase, by original purchaser, to be free from

defects in material and workmanship under correct, normal agricultural use and proper

applications.

Buhler Manufacturing’s obligations under this warranty shall be limited to the repair or

exchange, at Buhler Manufacturing’s option, of any Buhler Manufacturing product or part which

proves to be defective as provided. Buhler Manufacturing reserves the right to either inspect

the product at the buyer’s location or have it returned to the factory for inspection.

The above warranty does not extend to goods damaged or subject to accident, abuse or misuse

after shipment from Buhler Manufacturing’s factory, nor to goods altered or repaired by anyone

other than an authorized Buhler Manufacturing representative.

Buhler Manufacturing makes no Express Warranties other than those which are specifically

described. Any description of goods, including any references and specifications in catalogues,

circulars and other written material published, is for the sole purpose of identifying goods and

shall conform to such descriptions. Any sample or model is for illustrative purposes only and

does not create an Express Warranty that the goods conform to sample or model shown.

The purchaser is solely responsible for determining suitability of goods sold. This warranty is

expressly in lieu of all other warranties expressed or implied. Buhler Manufacturing will in no

event be liable for any incidental or consequential damages whatsoever. Nor for any sum in

excess of the price received for the goods for which liability is claimed.

WARRANTY CLAIMS:

Warranty requests must be prepared on Buhler Manufacturing Warranty Claim Forms with all

requested information properly completed. Warranty Claims must be submitted within a thirty

(30) day period from date of failure repair.

WARRANTY LABOR:

Any labor subject to warranty must be authorized by Buhler Manufacturing. The labor rate for

replacing defective parts, where applicable, will be credited at 100% of the dealer’s posted shop

rate. Defective parts will receive an extra 10% discount to assist with freight or other incidental

costs.

GOVERNMENT LEGISLATION:

Warranty terms and conditions are subject to Provincial or State legislation.

IMPORTANT FACTS:

Buckets and Bucket Tines Carry No Warranty

Bent Spears Carry No Warranty

Snowblower Fan Shafts Carry No Warranty

Mower Blades Carry No Warranty

Portable Auger Parts Have Two (2) Year Warranty

Loader Parts Have Two (2) Year Warranty

IMPORTANT NOTE: This warranty does not apply to rentals

1

Page 6

Finishing Mower

INTRODUCTION

Buhler Farm King has been building top quality finishing mowers for 15 years and has

refined these mowers to be among the best in the industry. Manufactured with top

quality material, the edge of the mower deck features solid reinforcing rods. These

finishing mowers are Buhler Quick Hitch compatible and are available in widths ranging

from 48" to 84".

Each mower features three high-speed blades with one of the highest rated tip-speeds

in the industry. This creates powerful suction that lifts the grass for a crisp cut. A blade

overlap of 1 5/8" to 2 5/8" prevents stripping and ensures the lawn is mowed evenly.

Buhler Farm King Finishing Mowers are built to be durable and long lasting. Pneumatic

tires with puncture proof sealant are standard. Each wheel yoke assembly includes a

cutting height adjustment on the 1" wheel yoke shaft. Bushings in the wheel hubs

ensure long-term reliability without needing frequent lubrication. A slide adjustment is

located under the gearbox for easy belt tensioning.

Keep this manual handy for frequent reference. All new operators or owners must

review the manual before using the equipment and at least annually thereafter. Contact

your Buhler Dealer if you need assistance, information, or additional copies of the

manual. Visit our website at www.buhler.com for a complete list of dealers in your area.

The directions left, right, front and rear, as mentioned throughout this manual, are as

seen facing in the direction of travel of the implement.

2

Page 7

Finishing Mower

SAFETY INSTRUCTIONS

Remember, YOU are the key to safety. Good safety practices not only protect you, but

also the people around you. Make these practices a working part of your safety

program. Be certain that everyone operating this equipment is familiar with the

recommended operating and maintenance procedures and follows all the safety

precautions. Most accidents can be prevented. Do not risk injury or death by ignoring

good safety practices.

The alert symbol is used throughout this manual. It indicates attention is required and

identifies hazards. Follow the recommended precautions.

The safety alert symbol means…

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

CAUTION

The caution symbol indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

WARNING

The Warning Symbol indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against unsafe practices.

DANGER

The Danger Symbol indicates an imminently hazardous situation that, if not avoided will

result in death or serious injury. This signal word is to be limited to the most extreme

situations, typically for machine components that, for functional purposes, cannot be

guarded.

3

Page 8

Finishing Mower

GENERAL SAFETY INSTRUCTIONS

Have a first-aid kit available for use and know how to use it.

Have a fire extinguisher available, stored in a highly visible location, and know how to

use it.

Wear appropriate protective gear. This list may include but is not limited to:

- Hard hat

- Protective shoes with slip resistant soles

- Protective glasses or goggles

- Heavy gloves

- Wet weather gear

- Hearing protection

- Respirator or filter mask

Read and understand the Operator’s Manual and all safety signs before operating,

servicing, adjusting, repairing, or unplugging the equipment.

Do not attempt any unauthorized modifications to your Buhler product as this could

affect function or safety, and could affect the life of the equipment.

Never start or operate the mower except from the operator’s station on the power unit.

Inspect and clean the working area before operating.

Keep hands, feet, clothing, and hair away from moving parts.

Ensure bystanders are clear of the area before operating.

START UP SAFETY

Do not let inexperienced operators or children run this equipment.

Place all tractor and machine controls in neutral before starting.

Operate only with ROPS and seatbelt equipped tractors.

Do not operate inside a building unless there is adequate ventilation.

Ensure all shields are in place and in good condition before operating.

Stay clear of PTO shaft and machine when engaging PTO.

OPERATION SAFETY

Do not permit riders.

Do not wear loose fitting clothing during operation.

Never operate over 540 PTO rpm speed.

Never operate the equipment in the raised position.

4

Page 9

Finishing Mower

TRANSPORT SAFETY

Review Transport Safety instructions in tractor manual before moving.

Check with local authorities regarding transport on public roads. Obey all applicable

laws and regulations.

Make sure the SMV (Slow Moving Vehicle) emblem and all the lights and reflectors that

are required by the local highway and transport authorities are in place, are clean, and

can be seen clearly by all overtaking and oncoming traffic.

Never have the equipment in operation during transport.

Always travel at a safe speed.

Inflate transport tires to recommended pressure.

SERVICE AND MAINTENANCE SAFETY

Stop engine, set brake, remove ignition key, and wait for all moving parts to stop before

servicing, adjusting, repairing, or unplugging.

Support the equipment with blocks or safety stands before working beneath it.

Follow good shop practices including:

- Keep service area clean and dry

- Be sure electrical outlets and tools are properly grounded

- Use adequate light for the job

Use only tools, jacks, and hoists of sufficient capacity for the job.

Replace and secure all shields removed during servicing before operating.

Use heavy leather gloves to handle sharp objects.

Failure to follow proper procedures when mounting a tire on a wheel or rim can produce

an explosion, which may result in serious injury or death.

STORAGE SAFETY

Store the unit in an area away from human activity.

Do not permit children to play on or around the stored machine.

Support the frame on stands and blocks to provide a secure base.

5

Page 10

Finishing Mower

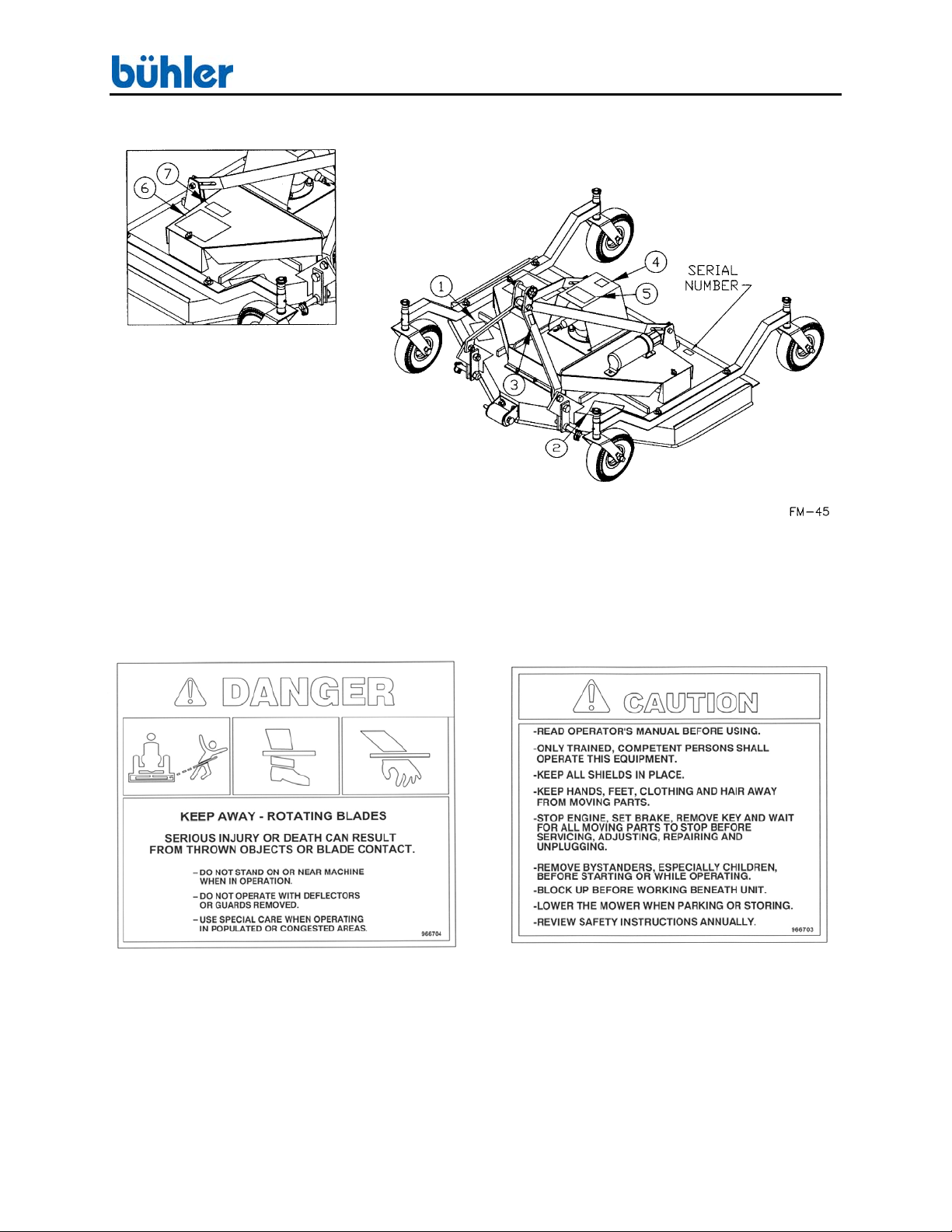

SAFETY SIGNS

The following illustration shows the approximate location and detail of safety signs.

Keep all safety signs clean and legible and replace any that are damaged or missing.

When original parts are replaced, any safety signs affixed to those parts should be

replaced as well. Replacement safety signs are available from your local dealer.

INSTALLATION OF SAFETY SIGNS

To install safety signs, ensure the installation area is clean and dry. Decide on the exact

position before you remove the backing paper. Remove the smallest portion of the split

backing paper and align over the specified area. Carefully press in place. Slowly peel

back the remaining paper and smooth the remaining portion in place. Small air pockets

can be pierced with a pin and smoothed out.

6

Page 11

Finishing Mower

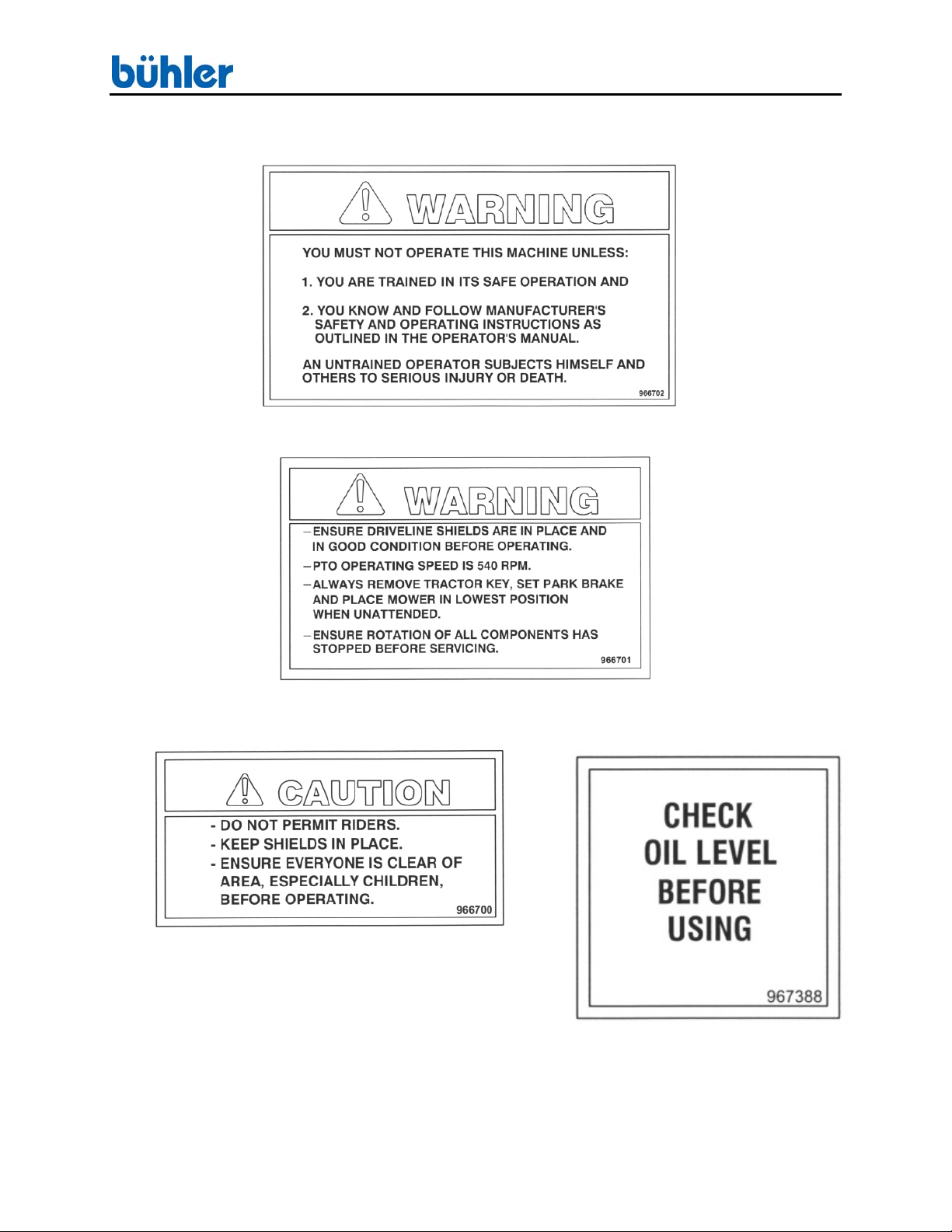

FINISHING MOWER SAFETY SIGNS

Replace safety signs immediately should they become damaged, torn or illegible.

Obtain replacements from your authorized dealer using the part numbers shown.

#1 #2

7

Page 12

Finishing Mower

FINISHING MOWER SAFETY SIGNS – cont’d.

#3

#5

#4

#6

8

Page 13

Finishing Mower

HITCH ASSEMBLY INSTRUCTIONS

1. The hitch is assembled except for the two pivot bars (#70). Bolt one end of each

pivot bar between the welded brackets at the back of the deck using the bolts

assembled in the mower.

2. Remove the 3/4” bolt (#64) at the top of the hitch weldment. Using the same

bolt, assemble with the pivot bars between the hitch weldment (#38).

WHEEL ASSEMBLY INSTRUCTIONS

1. The wheel and tire assemblies (Side FM - #65, Rear FM - #67) are shipped in a

separate carton. Remove the wheel bolts (Side FM - #52, Rear FM - #55) from

the four wheel yokes (Side FM - #47, Rear FM - #54). Assemble the wheels

using bolt and lock nut. Grease wheels and wheel yokes before using for the first

time.

START UP

MACHINE BREAK-IN

The following items should be checked when the implement is used for the first time:

Before operating:

Lubricate all grease points.

Remove plug in gearbox, and fill with oil to plug level.

After operating for 1/2 hour or after completing 1/2 acre (0.2 ha), stop the engine and

set the brake:

Check all nuts, bolts, and other fasteners. Tighten to their specified torque level

Check that the blades are in good condition and bolted securely to the spindle

Check that the PTO driveline shield turns freely.

Lubricate all grease points.

Check the oil level in the gearbox. Add as required.

After operating for 5 hours and after operating for 10 hours:

Repeat the items above

After these initial checks, refer to the Maintenance section of this manual for regular

maintenance intervals.

9

Page 14

Finishing Mower

OPERATING INSTRUCTIONS

The Finishing Mower is designed to be used on a tractor with a standard category 1

three-point hitch. See the specification sheet for horsepower requirements. Using

excessive power will shorten the life of the drive train components.

CONNECTING TO TRACTOR:

Park the mower and tractor on a level dry area free of debris and foreign objects.

1. Slowly back the tractor up to the machine.

2. Adjust the three-point arms to align with the mower lift pins.

3. Stop the tractor, set the parking brake and remove the ignition key before

dismounting.

4. Slide the three-point arms on the lift pins and lock in place with the clips

supplied.

5. With the tractor engine shut off, attach the PTO shaft. Both ends of the

PTO have a standard 6-spline end with a spring-loaded locking collar.

Turn the round collar at the ends of the PTO clockwise to slide onto the

splined shafts. The spring-loaded pin in the PTO yoke must lock into the

groove on the splined shaft on the gearbox and tractor. Always check to

see that both ends of the PTO shaft are securely attached every time the

mower is used. This should always be done with the tractor engine shut

off. Attach the safety chains supplied with the PTO shaft, allowing

sufficient slack for the driveline during turns and operation. Check booklet

attached to the PTO for instructions.

NOTE: At lease one third of the telescoping length of the PTO

should overlap when the mower is in operation.

6. Attach the top link on the tractor to the link pin assembled in the hitch

weldment (#45). Adjust the turnbuckle on the tractor top link so that the

upper lift bracket hangs straight down with the tractor and mower both on

level ground.

10

Page 15

Finishing Mower

FIELD USE PREPARATION

Read and understand the Operator’s Manual and all safety signs before operating.

The implement and tractor should be on a dry level area, clear of debris.

Lower the three point arms on the tractor so they line up with the mounting pins on the

implement.

Stop the engine and set the brake.

Mount the lower lift pins first and then adjust the implement angle using the turnbuckle

on the top link. Check that all the clips holding the three point pins are securely in place.

Start the engine, and raise the implement slightly.

Adjust the sway blocks or chains on the tractor so the mower is centered between the

rear wheels.

Adjust the three-point hitch arms to level the implement from side to side.

Adjust the turnbuckle on the top of the three-point hitch arms to level the implement

from front to back.

Adjust the cutting height using the wheel spacers on the wheel yokes. The spacers

should be set at the same height on all four wheels.

Check for proper air pressure in tires.

Check tightness of belts, bolts, and other hardware.

Check blades to see if they are damaged. Sharpen or replace blades if necessary.

Check that blade bolts are tight.

Clear the working area of foreign objects and check that all bystanders are standing

clear before starting.

Start the tractor with the mower resting on the ground on all four wheels.

Slowly engage the PTO and bring the speed up to 540 PTO rpm for cutting.

FIELD OPERATION

1. The mower works best on dry grass. Slower cutting speed and occasional

cleaning may be required on damp or wet grass.

2. The PTO must run at the full 540 PTO rpm for a good cut.

Slower speeds or double cutting could be required for very high grass.

3. Use a higher blade setting for rough areas to prevent scalping of the

surface.

4. Always cut counter-clockwise so grass clippings are thrown on the grass

already cut. This saves power and wear on the blades.

5. Sharpen blades if grass tears instead of cutting cleanly.

6. Slow down when cutting corners. Turning too sharply on corners can

leave a small strip of grass uncut.

11

Page 16

Finishing Mower

DISCONNECTING FROM TRACTOR

1. Park on a firm level area and clean the mower.

2. Lower the mower until the load is off the hitch arms.

3. Disconnect the hitch arms and the PTO shaft.

4. Cover the mower for storage to prevent rust.

REAR DISCHARGE MOWER CHAIN KIT ASSEMBLY

1. With the narrow lip of the chain guard plate (#2) turned up, push an end link of a

3-link chain up through the slot nearest the end of the guard plate. The chain rod

(#3) slides through the chain link along the top surface of the chain guard plate.

Slide through each chain in order along the entire guard plate. Slide a flat washer

on each end of the rod. Hold the assembly in place with a 1/8” x 1” cotter pin

(#8) at both ends of the rod.

2. A 5/8” long spacer (#6) fits between the guard plate and the rear lip on the deck.

These spacers must be centered on the holes in the guard plate and the rear lip

on the deck. With the spacers in place, position the chain guard assembly under

the lip on the deck. Clamp on assembly to hold in place. Bolt guard plate

assembly to the deck using 3/8” x 1 1/2” bolts, lock washers and hex nut.

QUICK HITCH KIT INSTRUCTIONS

SIDE & REAR DISCHARGE FINISHING MOWER

1. Remove the two sets of lift brackets with the lower lift pins from the mower

hitch arms (#4).

2. Bolt the adaptor plates (#13) to the outside of the hitch arms welded to the

deck. Turn the plates as shown in drawing. Use the 3/4” x 2 1/2” bolts and

bushings in the 1” holes. The 5/8” x 2” bolts holding on the a-frame weldment

are removed and replaced with 2 1/2” bolts (#3) which also fit through the

adaptor plates. The bushings already in the A-frame must remain in place.

3. Assemble the two quick hitch arms (#4) on the inside of the adaptor plates

using the lift pins with the swivel bushings from step one at the bottom. The

A-frame and the quick hitch arms are connected at the top using an adaptor

weldment (#11). With the welded bushings on the adaptor facing down, the

A-frame is attached using the top link pin (#9). The hitch arms (#4) are bolted

on using a 3/4” x 4 1/2” bolt (#1) which fits through a 2 3/8” spacer (#12).

12

Page 17

Finishing Mower

THEORY OF OPERATION

13

Page 18

Finishing Mower

14

Page 19

Finishing Mower

MAINTENANCE

1. GEARBOX: The gearbox should be filled with SAE 90 oil to the bottom of

level plug when shipped. Check the mower before using and at regular

intervals (approx. every 40 hours). See that this oil level is maintained.

2. GREASE: Grease wheel yokes, wheel bushing and PTO u-joints

approximately every 8 hours. Before using the mower for the first time,

grease wheel bushings until you can see the grease squeezed out at the

ends of the wheel hub. Lubricate the telescoping PTO tube and the quick

release collars on the ends of the shaft about every 20 hours. Clean all

grease fittings before injecting grease and immediately replace any

damaged or missing grease fittings. When using the safety chains

supplied with the PTO shaft, the shield bearings must be kept lubricated.

NOTE: There is no grease nipple on the spindles because they use

sealed bearings.

3. SHIELDING: Always keep all shielding in place and repair or replace if

damaged.

4. BLADES: When replacing or grinding blades, all three blades must be

replaced or reground at the same time to maintain the proper balance in

the cutting unit. Block up the mower securely before attempting to remove

the blades. Use heavy leather gloves to handle the blades. Be sure to

tighten center bolt and lock washer securely when replacing blades. Use

a torque wrench to re-tighten spindle bolts to 180 ft.-lbs. (244 N-m). The

bolts have a patch of thread lock material pre-approved which will hold for

up to five usages. Always replace the lock washer with the extra heavy

duty washer supplied with the spindle

15

Page 20

Finishing Mower

MAINTENANCE – Cont’d.

5. BELTS: Remove the belt guards to check belt tightness. The center of

the belt span should deflect about 1/2” with nominal pressure. If the belts

slip or are too loose, the bolts holding the gearbox must be loosened. Use

the threaded tightener rod on the gearbox mount to tighten the belts. Lock

the rod in place and re-tighten the gearbox bolts when the belts are

properly tightened. Replace belt guards. Changing belts follows the same

procedure as given in the preceding paragraph, except you will have to

loosen the belts further to remove them. The belt installation is shown in

the following drawing. NOTE: Belts should always be replaced in

matched sets.

7. TIRES: Maintain proper air pressure in tires.

50 psi (345 kPa) max. for 4’, 5’, & 6’ Finishing Mowers

40 psi (276 kPa) max. for 7’ Finishing Mowers

16

Page 21

Finishing Mower

BOLT TORQUE

CHECKING BOLT TORQUE

The tables shown below give correct torque values for various bolts and hex bolts.

Tighten all bolts to the torques specified in chart unless otherwise noted. Check

tightness of bolts periodically, using bolt torque chart as a guide. Replace hardware

with the same strength bolt.

NOTE: See page 15 for correct spindle torque. Do not use this chart for spindle

bolt only.

Torque figures indicated above are valid for non-greased or non-oiled threads and

heads unless otherwise specified. Therefore, do not grease or oil bolts or hex bolts

unless otherwise specified in this manual. When using locking elements, increase

torque values by 5%.

* Torque value for bolts and hex bolts are identified by their head markings.

17

Page 22

Finishing Mower

FINISHING MOWER (SIDE DISCHARGE)

18

Page 23

Finishing Mower

WHEN ORDERING PARTS

Always give your dealer the Model, Color and Serial Number of your machine to assist

him in ordering and obtaining the correct parts. Use the exploded view and tabular

listing of the area of interest to exactly identify the required part.

SIDE DISCHARGE FINISHING MOWER

ITEM PART # DESCRIPTION

1 902663 4' Deck Weldment

902664 5' Deck Weldment

902665 6' Deck Weldment

2 912300158 Gearbox (Without Oil)

3 980004200 Gearbox Base Plate

4 906342 Gearbox Mount Plate (4')

906343 Gearbox Mount Plate (5' & 6')

5 966748 PTO Guard

6 966762 47" Axle Beam Weldment (4')

980008111 51" Axle Beam Weldment (5')

966763 53" Axle Beam Weldment (6')

7 906346 Right Hand Pulley Guard (4')

906353 Right Hand Pulley Guard (5')

906355 Right Hand Pulley Guard (6')

8 906347 Left Hand Pulley Guard (4')

906354 Left Hand Pulley Guard (5')

906356 Left Hand Pulley Guard (6')

9 966749 Discharge Shield (4')

966750 Discharge Shield (5')

966751 Discharge Shield (6')

10 966724 Roller Mount Bracket 10ga x 3 3/4" x 13 7/16" (4' & 5')

966182 Roller Mount Bracket 7ga x 4" x 16 3/16" (6')

11 966723 Lift Bracket

12 904250 B-61 Belt (4')

904251 B-70 Belt (5')

973506 B-78 Belt (6')

13 966722 12" Double Sheave complete with Set Screws

14 966601 Lift Pin Bushing 1 1/4" O.D. x 9/16" long

15 966727 Hitch Bushing 1" O.D. x 9/16" long

16 966823 Lift Pin complete with Nut & Washer (XL) (Cat. 1)

17 965911 7/16" Linch Pin (1493)

18 900929 Pulley Key 1/4" Square x 1 5/8" long

19 81570 5/16" B.S. Flat Washer (pl)

19

Page 24

Finishing Mower

20 86170 3/8" x 1" Hex Bolt (pl)

21 86182 3/8" x 1 1/4" Carriage Bolt (pl)

22 84000 3/8" B.S. Flat Washer (pl)

23 81593 3/8" Lock Washer (pl)

24 81592 3/8" Hex Nut (pl)

25 84217 3/8" Wing Nut (pl)

26 964001 1" x 7/16" I.D. x 10ga Flat Washer (pl)

27 81628 1/2" x 3 1/4" Hex Bolt (pl)

28 81637 1/2" Lock Washer (pl)

29 81636 1/2" Hex Nut (pl)

30 812769 1 1/2" O.D. x 9/16" I.D. x 10ga Washer (pl)

31 84270 5/8" x 1 3/4" Hex Bolt (pl)

32 81677 5/8" Lock Washer (pl)

33 81676 5/8" Hex Nut (pl)

34 84346 3/4" x 2 1/2" Hex Bolt (pl)

35 812365 3/4" Lock Nut (pl)

36 81700 3/4" Hex Nut (pl)

37 9812377 5/16" x 3/4" Square Head Set Screw (pl)

38 966758 Hitch Weldment

39 812364 1/2" Lock Nut (pl)

40 966810 Arm Spacer 1"OD x 1 13/16"

41 81678 5/8" BS Flat Washer Standard (pl)

42 965807 Top Link Pin (Category 1)

43 84277 1/2" x 1 1/2" Hex Bolt (pl)

44 900931 1/4" Square x 1.11" Key

45 81207 3/16" x 2" Cotter Pin

46 F0398 PTO Shaft (4')

F0399 PTO Shaft (5' & 6')

47 966855 Wheel Yoke

48 904244 3 3/4" Double Sheave complete with Set Screws (4')

904246 4 1/2" Double Sheave complete with Set Screws (5' & 6')

49 904243 3 3/4" Single Sheave complete with Set Screws (4')

904245 4 1/2" Single Sheave complete with Set Screws (5' & 6')

50 966731 1/2" long x 1 5/16" O.D. Bushing (pl)

51 966730 1" long x 1 5/16" O.D. Bushing (pl)

52 902614 3/4" x 6" Wheel Bolt (pl)

53 900930 1/4" Square x 1 1/2" Key

54 967164 Pound-in Grease Nipple (pl)

55 966729 3/16" Linch Pin (pl)

56 811792 3/8" x 1 1/2" Hex Bolt (pl)

57 966811 Sheave Spacer 1 1/4" O.D. x .70" long

20

Page 25

Finishing Mower

58 966190 5/8" Lock Washer (pl) Extra Heavy (Supplied with Spindle)

59 84299 5/8" x 2" Hex Bolt (pl)

60 81701 3/4" Lock Washer (pl)

61 9812433 3/16" x 1 1/2" Cotter Pin (pl)

62 966721 Nylon Ends (4' & 5')

966177 Nylon Ends (6')

63 966725 3" O.D. x 4" Roller Tube (4' & 5')

966179 4" O.D. x 5 3/8" Roller Tube (6')

64 811790 3/4" x 4 1/2" Hex Bolt (pl)

65 966852 4.10/3.50-4 Tire with Wheel (4 1/2" Hub)

66 966737 17 3/4" Standard Blade (4')

966719 21 3/4" Standard Blade (5')

966738 25 3/4" Standard Blade (6')

67 966726 5/8" x 5 17/32" Roller Pin (4' & 5')

966180 5/8" x 7 1/16" Roller Pin (6')

68 966189 5/8" x 1 1/4" Gr. 8 Hex Bolt Lock (Supplied with Spindle)

69 966188 2 1/2" O.D. x 21/32" I.D. Washer (Supplied with Spindle)

70 966759 Pivot Bar 1/4" x 2" x 37" long (4')

966760 Pivot Bar 1/4" x 2" x 40" long (5')

966761 Pivot Bar 1/4" x 2" x 46" long (6')

71 906339 Spindle with Hardware

72 912301558 1" Snap Ring

73 905247 1" Washer & Slotted Hex Nut Weldment Inc. with Gearbox

74 967140 Narrow Rim Washer 1" x 10ga (pl)

75 903488 Roller Holder 1/4" x 4 5/32" x 18 1/4"

76 903104 Roller Pin 3/4" Dia x 8 3/4" Long

77 903113 Roller Tube Assembly

78 9812434 1/4" x 1 1/2" Cotter Pin (pl)

79 9812436 1/4" x 2 1/2" Cotter Pin (pl)

80 81545 1/4" Lock Washer (pl)

81 81544 1/4" Hex Nut (pl)

82 81525 1/4" x 3/4" Hex Bolt (pl)

83 81549 5/16" x 3/4" Hex Bolt (pl)

84 81569 5/16" Lock Washer (pl)

85 81568 5/16" Hex Nut (pl)

86 909277 Manual Holder

21

Page 26

Finishing Mower

FINISHING MOWER (4’ REAR DISCHARGE)

22

Page 27

Finishing Mower

4' REAR DISCHARGE FINISHING MOWER

ITEM PART # DESCRIPTION

1 903815 Deck Weldment (4')

2 912300158 Gearbox (Without Oil)

3 980004200 Gearbox Base Plate

4 906342 Gearbox Mount Plate

5 966748 PTO Guard

6 903804 53" Axle Beam Weldment

7 906346 Right Hand Pulley Guard

8 906347 Left Hand Pulley Guard

9 966724 Roller Holder 10ga x 3 3/4" x 13 7/16"

10 904250 B-61 Belts

11 966723 Lift Bracket

12 966722 12" Double Sheave complete with Set Screws

13 966601 Lift Pin Bus hing (1 1/4" O.D. x 9/16" Long)

14 966727 Hitch Bushing (1" O.D. x 9/16" Long)

15 966823 Lift Pin complete with Nut & Washer (XL) (Cat. 1)

16 965911 7/16" Linch Pin (1493)

17 900929 Pulley Key (1/4" square x 1 5/8" Long)

18 86170 3/8" x 1" Hex Bolt (pl)

19 86182 3/8" x 1 1/4" Carriage Bolt (pl)

20 84000 3/8" B.S. Flat Washer (pl)

21 81593 3/8" Lock Washer (pl)

22 81592 3/8" Hex Nut (pl)

23 84217 3/8" Wing Nut (pl)

24 964001 1"O.D. x 7/16" I.D.x 10ga Flat Washer (pl)

25 81628 1/2" x 3 1/4" Hex Bolt (pl)

26 81637 1/2" Lock Washer (pl)

27 81636 1/2" Hex Nut (pl)

28 812769 1 1/2" O.D. x 9/16" I.D. x 10ga Washer (pl)

29 84270 5/8" x 1 3/4" Hex Bolt (pl)

30 81677 5/8" Lock Washer (pl)

31 81676 5/8" Hex Nut (pl)

32 84346 3/4" x 2 1/2" Hex Bolt (pl)

33 81701 3/4" Lock Washer (pl)

34 81700 3/4" Hex Nut (pl)

35 9812377 5/16" x 3/4" Square Head Set Screw (pl)

36 84277 1/2" x 1 1/2" Hex Bolt (pl)

37 812364 1/2" Lock Nut (pl)

38 966758 Hitch Weldment

39 905247 1"ID Washer & Slotted Hex Nut Weldment Included with Gearbox

40 966737 17 3/4" Standard Blade

23

Page 28

Finishing Mower

41 812365 3/4" Lock Nut (pl)

42 965807 Top Link Pin (Cat. 1)

43 966810 Arm Spacer 1"O.D. x 1 13/16"

44 F0398 PTO Shaft

45 904243 3 3/4" Single Sheave Assembly (machined end up)

46 966811 Sheave Spacer 1 1/4" O.D. x .70" Long

47 904244 3 3/4" Double Sheave complete with Set Screws

48 912301558 1" Snap Ring

49 906339 Spindle with Hardware

50 966731 1/2" long x 1 5/16" O.D. Bushing (pl)

51 966730 1" long x 1 5/16" O.D. Bushing (pl)

52 967164 Pound-in Grease Nipple

53 966729 3/16" Linch Pin (pl)

54 966855 Wheel Yoke

55 902614 3/4" x 6" Wheel Bolt (pl)

56 81207 3/16" x 2" Cotter Pin (br)

57 966726 5/8" x 5 17/32" Roller Pin

58 9812433 3/16" x 1 1/2" Cotter Pin (pl)

59 966721 Nylon End

60 966725 Roller Tube 3" O.D. x 4" Long

61 84299 5/8" x 2" Hex Bolt (pl)

62 966188 2 1/2" O.D. x 21/32" I.D. Washer (Supplied with Spindle)

63 900931 1/4" Square x 1.11" Key

64 811790 3/4" x 4 1/2" Hex Bolt (pl)

65 966189 5/8" x 1 1/4" Gr. 8 Hex Bolt Lock (Supplied with Spindle)

66 966190 5/8" Lock Washer (pl) Extra Heavy (Supplied with Spindle)

67 966852 4.10 x 3.50-4 Tire with Wheel

68 900930 1/4" x 1 1/2" Key

69 811792 3/8" x 1 1/2" Hex Bolt (pl)

70 966759 Pivot Bar 37" Long

71 967140 1" x 10ga Narrow Rim Washer (pl)

72 903488 Roller Holder 1/4" x 4 5/32" x 18 1/4" Long

73 903104 Roller Pin 3/4" Dia. X 8 3/4" Long

74 903113 Front Roller Assembly

75 9812436 1/4" x 2 1/2" Cotter Pin (pl)

76 81545 1/4" Lock Washer (pl)

77 81544 1/4" Hex Nut (pl)

78 81525 1/4" x 3/4" Hex Bolt (pl)

79 9812434 1/4" x 1 1/2" Cotter Pin (pl)

80 81678 5/8" BS Flat Washer Standard (pl)

81 81549 5/16" x 3/4" Hex Bolt (pl)

82 81569 5/16" Lock Washer (pl)

83 81568 5/16" Hex Nut (pl)

84 909277 Manual Holder

24

Page 29

Finishing Mower

FINISHING MOWER (5’, 6’ & 7’ REAR DISCHARGE)

25

Page 30

Finishing Mower

5', 6', & 7' REAR DISCHARGE FINISHING MOWER

ITEM PART # DESCRIPTION

1 902667 Deck Weldment (5')

902668 Deck Weldment (6')

902669 Deck Weldment (7')

2 912300158 Gearbox (Without Oil)

3 980004200 Gearbox Base Plate

4 906343 Gearbox Mount Plate

5 966748 PTO Guard

6 966283 56 1/2" Axle Beam Weldment (5')

966284 58 1/2" Axle Beam Weldment (6')

966857 70" Axle Beam Weldment (7')

7 906353 Right Hand Pulley Guard (5')

906355 Right Hand Pulley Guard (6')

902269 Right Hand Pulley Guard (7')

8 906354 Left Hand Pulley Guard (5')

906356 Left Hand Pulley Guard (6')

902268 Left Hand Pulley Guard (7')

9 966724 Roller Holder 10ga x 3 3/4" x 13 7/16" (5')

966182 Roller Holder 7ga x 4" x 16 3/16" (6' & 7')

10 904251 B-70 Belts (5')

973506 B-78 Belts (6')

973248 B-87 Belts (7')

11 966723 Lift Bracket

12 966722 12" Double Sheave complete with Set Screws

13 966601 Lift Pin Bushing (1 1/4" O.D. x 9/16" Long)

14 966727 Hitch Bushing (1" O.D. x 9/16" Long)

15 966823 Lift Pin complete with Nut & Washer (XL) (Cat. 1)

16 965911 7/16" Linch Pin (1493)

17 900929 Pulley Key (1/4" square x 1 5/8" Long)

18 86170 3/8" x 1" Hex Bolt (pl)

19 86182 3/8" x 1 1/4" Carriage Bolt (pl)

20 84000 3/8" B.S. Flat Washer (pl)

21 81593 3/8" Lock Washer (pl)

22 81592 3/8" Hex Nut (pl)

23 84217 3/8" Wing Nut (pl)

24 964001 1"O.D. x 7/16" I.D. x 10ga Flat Washer (pl)

25 81628 1/2" x 3 1/4" Hex Bolt (pl)

26 81637 1/2" Lock Washer (pl)

27 81636 1/2" Hex Nut (pl)

28 812769 1 1/2" O.D. x 9/16" I.D. x 10ga Washer (pl)

29 84270 5/8" x 1 3/4" Hex Bolt (pl)

30 81677 5/8" Lock Washer (pl)

26

Page 31

Finishing Mower

31 81676 5/8" Hex Nut (pl)

32 84346 3/4" x 2 1/2" Hex Bolt (pl)

33 81701 3/4" Lock Washer (pl)

34 81700 3/4" Hex Nut (pl)

35 9812377 5/16" x 3/4" Square Head Set Screw (pl)

36 84277 1/2" x 1 1/2" Hex Bolt (pl)

37 812364 1/2" Lock Nut (pl)

38 966758 Hitch Weldment

39 905247 1"I.D. Washer & Slotted Hex Nut Weldment Inc. with Gearbox

40 966719 21 3/4" Standard Blade (5')

966738 25 3/4" Standard Blade (6')

966167 29 3/4" Hard Surfaced Blade (7')

41 812365 3/4" Lock Nut (pl)

42 965807 Top Link Pin (Cat. 1)

43 966810 Arm Spacer 1"O.D. x 1 13/16" (5' & 6')

966287 Arm Spacer 1"O.D. x 1 9/16" (7')

44 F0399 PTO Shaft (5' & 6')

F0400 PTO Shaft (7')

45 904245 4 1/2" Single Sheave Assembly (machined end up) (5' & 6')

904247 5 1/4" Single Sheave Assembly (machined end up) (7')

46 966811 Sheave Spacer 1 1/4" O.D. x .70" Long

47 904246 4 1/2" Double Sheave complete with Set Screws (5' & 6')

904248 5 1/4" Double Sheave complete with Set Screws (7')

48 912301558 1" Snap Ring

49 906339 Spindle with Hardware (5' & 6')

966860 Spindle with Hardware (7')

50 966731 1/2" Long x 1 5/16" O.D. Bushing (pl)

51 966730 1" Long x 1 5/16" O.D. Bushing (pl)

52 967164 Pound-in Grease Nipple

53 966729 3/16" Linch Pin (pl)

54 966855 Wheel Yoke (5' & 6')

966856 Wheel Yoke (7')

55 902614 3/4" x 6" Wheel Bolt (pl) (5' & 6')

902615 3/4" x 7" Wheel Bolt (pl) (7')

56 81207 3/16" x 2" Cotter Pin (br)

57 966726 5/8" x 5 17/32" Roller Pin (5')

966180 5/8" x 7 1/16" Roller Pin (6' & 7')

58 9812433 3/16" x 1 1/2" Cotter Pin (pl)

59 966721 Nylon End (5')

966177 Nylon End (6' & 7')

60 966725 Roller Tube 3" O.D. x 4" Long (5')

966179 Roller Tube 4" O.D. x 5 3/8" Long (6' & 7')

61 84299 5/8" x 2" Hex Bolt (pl)

62 966188 2 1/2" O.D. x 21/32" I.D. Washer (Supplied with Spindle)

63 900931 1/4" Square x 1.11" Key

27

Page 32

Finishing Mower

64 811790 3/4" x 4 1/2" Hex Bolt (pl)

65 966189 5/8" x 1 1/4" Grade 8 Hex Bolt Lock (Supplied with Spindle)

66 966190 5/8" Lock Washer (pl) Extra Heavy (Supplied with Spindle)

67 966852 4.10 x 3.50-4 Tire with Wheel (5' & 6')

966851 13/500 x 6" Tire with Wheel (7')

68 900930 1/4" x 1 1/2" Key

69 811792 3/8" x 1 1/2" Hex Bolt (pl)

70 966760 Pivot Bar 40" Long (5')

966761 Pivot Bar 46" Long (6')

966282 Pivot Bar 51" Long (7')

71 967140 1" x 10ga Narrow Rim Washer (pl)

72 903488 Roller Holder 1/4" x 4 5/32" x 18 1/4" Long

73 903104 Roller Pin 3/4" Dia. X 8 3/4" Long

74 903113 Front Roller Assembly

75 9812436 1/4" x 2 1/2" Cotter Pin (pl)

76 81545 1/4" Lock Washer (pl)

77 81544 1/4" Hex Nut (pl)

78 81525 1/4" x 3/4" Hex Bolt (pl)

79 9812434 1/4" x 1 1/2" Cotter Pin (pl)

80 81678 5/8" BS Flat Washer Standard (pl)

81 81549 5/16" x 3/4" Hex Bolt (pl)

82 81569 5/16" Lock Washer (pl)

83 81568 5/16" Hex Nut (pl)

84 909277 Manual Holder

28

Page 33

Finishing Mower

FINISHING MOWER GEARBOX

29

Page 34

Finishing Mower

FINISHING MOWER GEARBOX PARTS LIST

Item # Part # Description

912300158 Gearbox Complete

1 966813 Housing

2 914015 Output Cap

3 966814 Blank Cap

4 966815 Input Gear, 29T

5 966816 Pinion Gear, 15T

6 966817 Input Shaft

7 966542 Ball Bearing, 6207

8 966555 Ball Bearing, 6208

9 966818 Input Seal

10 966819 Output Seal

11 914019 Output Gasket

12 914007 Input Gasket

13 914001 Spacer

14 966562 Cotter Pin

15 86171 3/8'' x 1 1/4'' Hex Bolt

16 905247 1'' NF Hex Nut W/Washer

18 81593 3/8'' Lock Washer

19 914016 1/8'' Sq. Hd. Solid Plug

20 966193 1/4'' Vented Plug

21 914008 Retaining Ring

22 914003 Retaining Ring

30

Page 35

Finishing Mower

FINISHING MOWER SPINDLE ASSEMBLY

31

Page 36

Finishing Mower

FINISHING MOWER SPINDLE PARTS LIST (4', 5' & 6' SIDE AND REAR)

Item # Part # Description

906339 Spindle Assembly Complete

(Includes Hardware)

1 966764 Spindle Housing

2 906399 Spindle Bearing, 6206-Z

3 912301558 Snap Ring

4 906394 Spindle Shaft

5 966769 Snap Ring

6 966820 Shield

7 966821 Blade Mount Base

FINISHING MOWER SPINDLE PARTS LIST (7' REAR)

(ALL SIZE HEAVY DUTY & TRIPLEX)

Item # Part # Description

966860 Spindle Assembly Complete

(Includes Hardware)

1 966862 Spindle Housing

2 966863 Spindle Bearing (63067)

3 912301558 Snap Ring

4 906394 Spindle Shaft

5 966769 Snap Ring

6 966865 Shield

7 966821 Blade Mount Base

32

Page 37

Finishing Mower

FINISHING MOWER PTO SHAFT (STANDARD & OPTIONAL HEAVY DUTY)

33

Page 38

Finishing Mower

FINISHING MOWER PTO SHAFT PARTS LIST

Item # Part # Description

F0398 Shaft Complete - 4'

F0399 Shaft Complete - 5' & 6'

F0400 Shaft Complete - 7'

F0401 Shaft Complete - Optional Heavy Duty for 5' & 6'

1 907288 Yoke - 4',5' & 6'

907290 Yoke - 7' & Heavy Duty

2 930-106 Repair Kit - 4',5' & 6'

920-002 Repair Kit - 7' & Heavy Duty

3 930-105 Outer Tube Yoke - 4', 5' & 6'

920-004 Outer Tube Yoke - 7' & Heavy Duty

4 930-109 Flexible Pin - 4', 5' & 6'

936351 Flexible Pin - 7' & Heavy Duty

5 936298 Outer Cardan Tube - 4'

930-108 Outer Cardan Tube - 5' & 6'

936403 Outer Cardan Tube - 7'

936404 Outer Cardan Tube - Heavy Duty

6 936299 Inner Cardan Tube - 4'

930-107 Inner Cardan Tube - 5' & 6'

936405 Inner Cardan Tube - 7'

936406 Inner Cardan Tube - Heavy Duty

7 930-104 Flexible Pin - 4'

930-109 Flexible Pin - 7' & Heavy Duty

8 930-115 Inner Tube Yoke - 4', 5' & 6'

920-003 Inner Tube Yoke - 7' & Heavy Duty

9 930-110 Outer Shield Retainer - 4', 5', & 6'

920-013 Outer Bearing - 7' & Heavy Duty

10 936300 Outer Cone Set - 4', 5' & 6'

11 936301 Outer Shield - 4'

936302 Outer Shield - 5' & 6'

936407 Outer Safety Tube - 7'

936408 Outer Safety Tube - Heavy Duty

12 936303 Inner Shield - 4'

936304 Inner Shield - 5' & 6'

936409 Inner Safety Tube - 7'

936410 Inner Safety Tube - Heavy Duty

13 936305 Inner Cone Set - 4', 5', 6', 7' & Heavy Duty

14 930-113 Inner Shield Collar - 4', 5' & 6'

920-015 Inner Shield Bearing - 7' & Heavy Duty

15 936402 Safety Chain - All

16 908244 Ball Collar Kit - All

34

Page 39

Finishing Mower

Rear Discharge Finishing Mower Chain Kit

Item # Part # Description

1 903815 4' Deck Weldment

902667 5' Deck Weldment

902668 6' Deck Weldment

902669 7' Deck Weldment

2 905166 50 1/4'' Chain Guard Plate (4')

902820 62 1/4'' Chain Guard Plate (5')

902823 74 1/4'' Chain Guard Plate (6')

902825 86 1/4'' Chain Guard Plate (7')

3 905167 50 3/8'' Long Chain Kit Rod (4')

902827 62 3/8'' Long Chain Kit Rod (5')

902828 74 3/8'' Long Chain Kit Rod (6')

902829 86 3/8'' Long Chain Kit Rod (7')

4 967907 1/4'' X 3 Link Chain (pl)

5 811792 3/8'' X 1 1/2'' Hex Bolt (pl)

6 902821 Spacer 5/8'' O.D. X 12Ga X 5/8'' Long

7 81592 3/8'' Hex Nut (pl)

8 9812430 1/8'' X 1'' Cotter Pin (pl)

9 84039 3/8'' SAE Washer (pl)

10 81593 3/8" Lock Washer (pl)

35

Page 40

Finishing Mower

MOWER CHAIN KIT ASSEMBLY

36

Page 41

Finishing Mower

QUICK HITCH KIT DRAWING AND PARTS LIST

37

Page 42

Finishing Mower

SHIPPING KIT AND BUNDLE NUMBERS

The following is a list of Kit Numbers for this product and the Bundle Numbers,

Descriptions, and Quantities for each Kit.

QUANTITY BUNDLE NO. DESCRIPTION

Y450S 48” SIDE DISCHARGE FINISHING MOWER

1 F0681 Mower

1 F6568 Carton w/tires

Y550S 60” SIDE DISCHARGE FINISHING MOWER

1 F0683 Mower

1 F6568 Carton w/tires

Y650S 72” SIDE DISCHARGE FINISHING MOWER

1 F0685 Mower

1 F6568 Carton w/tires

Y450R 48” REAR DISCHARGE FINISHING MOWER

1 F0682 Mower

1 F6568 Carton w/tires

Y550R 60” REAR DISCHARGE FINISHING MOWER

1 F0684 Mower

1 F6568 Carton w/tires

Y650R 72” REAR DISCHARGE FINISHING MOWER

1 F0686 Mower

1 F6568 Carton w/tires

Y750R 84” REAR DISCHARGE FINISHING MOWER

1 F0687 Mower

1 F6569 Carton w/tires

38

Page 43

Finishing Mower

OPTIONAL BUNDLE NUMBERS

The following is a list of options available for the Kits listed above.

F0401 Heavy Duty PTO Shaft (5’ & 6’)

903798 Hard Surfaced Blade (4’)

966273 Hard Surfaced Blade (5’)

966274 Hard Surfaced Blade (6’)

F6589 Solid Rubber Tires (4’, 5’ & 6’)

F9459 UHMW High Density Poly Roller Assembly

Y410 Chain Kit (4’)

Y510 Chain Kit (5’)

Y610 Chain Kit (6’)

Y710 Chain Kit (7’)

Y730 Quick Hitch Adaptor Kit (all sizes)

F0840 Solid Rubber Tires (set of 4)

39

Page 44

NOTES

Page 45

NOTES

Page 46

NOTES

Page 47

Page 48

Farm King Division

301 Mountain Street S.

Morden, MB R6M 1X7

Ph.: (204) 822-4467

Fax: (204) 822-6348

Allied/Inland Division

1260 Clarence Avenue

Winnipeg, MB R3T 1T2

Ph.: (204) 284-6100

Fax: (204) 477-2325

B.I.I. Division

1330 43

rd

Street N.W.

Fargo, ND 58102

Ph: (701) 282-7014

Fax: (701) 282-5865

B.C., Abbotsford

(604) 864-2665

AB, Edmonton

(780) 962-6991

SK, Regina

(306) 781-2300

ON, Woodstock

(519) 539-0435

QC, Dorion

(450) 455-4840

AR, West Memphis

(870) 732-3132

GA, Stone Mountain

(770) 908-9439

ID, Meridian

(208) 887-6006

IN, Clarksville

(812) 284-3376

KS, Wichita

(316) 265-9577

MN, Lakeville

(952) 469-5267

MT, Billings

(406) 248-7771

ND, Bismarck

(701) 223-1886

Burando Hill

Katanning

W. Australia

011-618-98-214422

011-52-158-90306

Chihuahua, Mexico

ND, Fargo

(701) 282-7003

NE, Blair

(402) 426-8211

OH, Youngstown

(330) 793-0862

OR, Beaverton

(503) 641-1865

SD, Huron

(605) 352-8616

TX, Houston

(713) 928-2632

UT, Salt Lake City

(801) 972-4321

WI, Portage

(608) 742-1370

John Kerr Equipment Ltd.

Wilcoxholm Farm

Linlithgow, W. Lothian

Scotland

011-441-506-842280

Skovde, Sweden

011-46-500-452651

Naestved, Denmark

011-45-557-29511

Buhler Manufacturing

301 Mountain Street S.

Morden MB.

R6M 1X7

Ph.: (204) 822-4467

Fax: (204) 822-6348

www.buhler.com

Printed in Canada

Loading...

Loading...