Page 1

Operator’s and Parts Manual

Model 1500

Model 1500Model 1500

Model 1500

For serial number 08BM1500001 and later

Bale Carrier

inland

46912

04/08

Page 2

INLAND WARRANTY POLICY

Buhler Manufacturing products are warranted for a period of twelve (12) months (90 days for commercial

application) from original date of purchase, by original purchaser, to be free from defects in material and

workmanship under correct, normal agricultural use and proper applications.

Buhler Manufacturing’s obligations under this warranty shall be limited to the repair or exchange, at Buhler

Manufacturing’s option, of any Buhler Manufacturing product or part which proves to be defective as provided.

Buhler Manufacturing reserves the right to either inspect the product at the buyer’s location or have it returned to the

factory for inspection.

The above warranty does not extend to goods damaged or subject to accident, abuse or misuse after shipment from

Buhler Manufacturing’s factory, nor to goods altered or repaired by anyone other than an authorized Buhler

Manufacturing representative.

Buhler Manufacturing makes no Express Warranties other than those, which are specifically described. Any

description of goods, including any references and specifications in catalogues, circulars and other written material

published, is for the sole purpose of identifying goods and shall conform to such descriptions. Any sample or model

is for illustrative purposes only and does not create an Express Warranty that the goods conform to sample or model

shown.

The purchaser is solely responsible for determining suitability of goods sold. This warranty is expressly in lieu of

all other warranties expressed or implied. Buhler Manufacturing will in no event be liable for any incidental or

consequential damages whatsoever. Nor for any sum in excess of the price received for the goods for which liability

is claimed.

WARRANTY CLAIMS:

Warranty requests must be prepared on Buhler Manufacturing Warranty Claim Forms with all requested information

properly completed. Warranty Claims must be submitted within a thirty (30) day period from date of failure repair.

WARRANTY LABOR:

Any labor subject to warranty must be authorized by Buhler Manufacturing. The labor rate for replacing defective

parts, where applicable, will be credited at 100% of the dealers posted shop rate. Defective parts will receive an

extra 10% discount to assist with freight or other incidental costs.

GOVERNMENT LEGISLATION:

Warranty terms and conditions are subject to Provincial or State legislation.

IMPORTANT FACTS:

Buckets and Bucket Tines Carry No Warranty

Bent Spears Carry No Warranty

Snowblower Fan Shafts Carry No Warranty

Mower Blades Carry No Warranty

Portable Auger Parts Have Two (2) Year Warranty

Printed in U.S.A.

Page 3

bühler

1500 Bale Carrier

OPERATORS AND PARTS MANUAL

Table of Contents

Description Page

TERMINOLOGY AND DECAL LOCATIONS ILLUSTRATIONS……..………... 2

GENERAL SPECIFICATIONS…..………………………………………………… 3

INTRODUCTION……………………………………………………………………. 4

Serial Decal Location……………………………………………………………. 4

Warranty Registration……………………………………………………………. 4

SAFETY……………………………………………………………………………… 5

General Safety Notes……………………………………………………………. 5

Safety Decals…………………………………………………………………….. 7

Important Precautions…………………………………………………………… 8

PRE OPERATION CHECKLIST...………………………………………………… 9

OPERATION.……………………………………………………………………….. 10

Attaching Bale Carrier to Tractor……………………………………………….. 10

Attaching Bale Carrier Controls to Tractor…………………………………….. 10

Carrier Controls Operation……………………………………………………… 12

Loading Bales……………………………………………………………………..

Bale Pusher Operation…………………………………………………………... 14

Transporting 1500 Bale Carrier………………………………………………… 14

Unloading……..………………………………………………………………….. 15

LUBRICATION.……………………………………………………………………… 16

Pivot Points……………………………………………………………………….. 16

Roller Chain………………………………………………………………………. 16

Carrier Beams……………………………………………………………………. 16

MAINTENANCE……………………………………………………………………. 17

Fasteners…………………………………………………………………………. 17

Hydraulic System………………………………………………………………… 18

Hydraulic Fitting Torques……………………………………………………….. 18

Chain………………………………………………………………………………. 19

Wheels/Tires……………………………………………………………………… 19

Storage……………………………………………………………………………. 20

APPENDIX LIST…………………………………………………………………….. 21

APPENDIX A ASSEMBLY INSTRUCTIONS……………………………………. 22

APPENDIX B HYDRAULIC ASSEMBLY………………………………………... 30

APPENDIX C ELECTRICAL ASSEMBLY………………………………………... 55

APPENDIX D GENERAL ASSEMBLY…………………………………………... 59

CHECKLIST………………………………………………….……………………… 78

Predelivery………………………………………………………………………... 78

Customer Delivery……………………………………………………………….. 78

12

1

Page 4

bühler

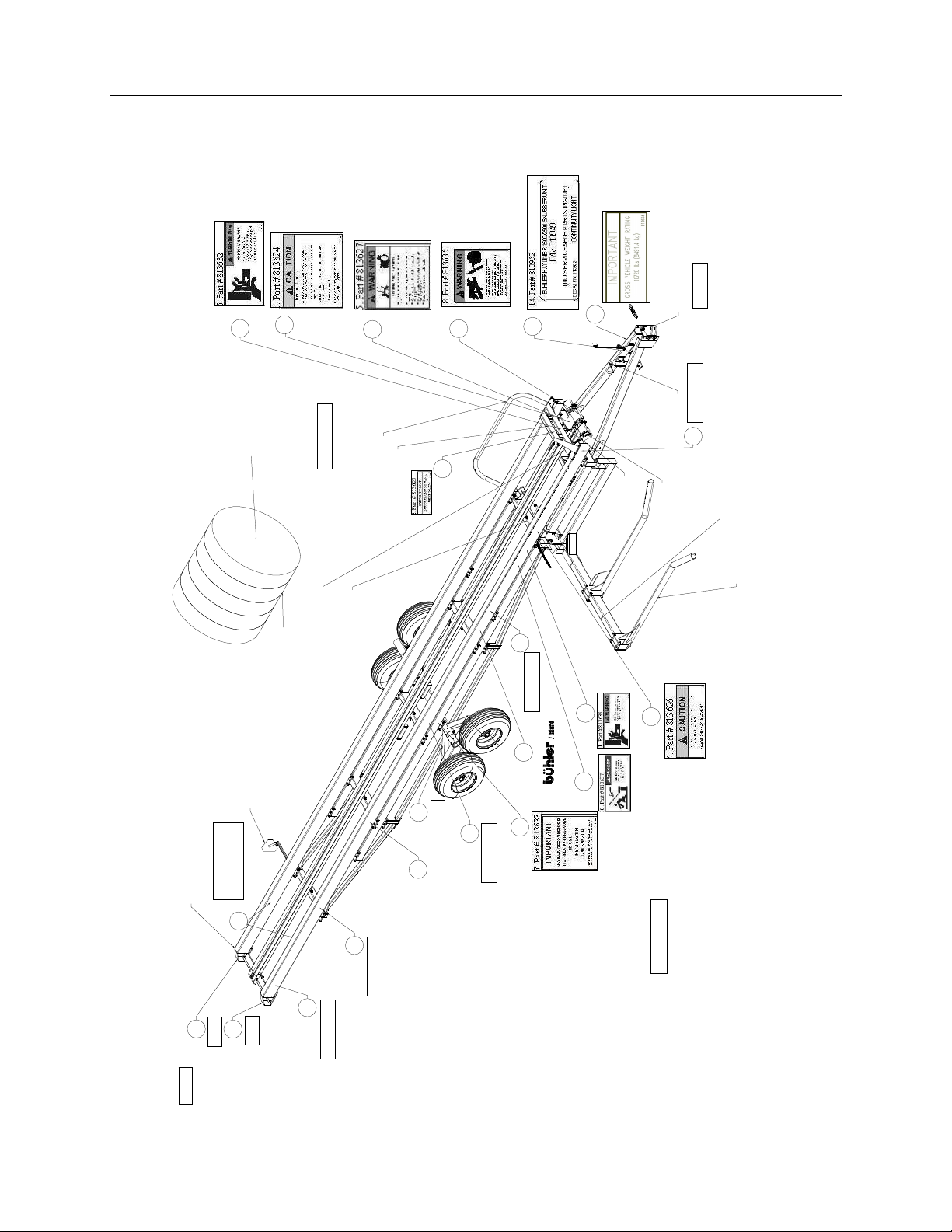

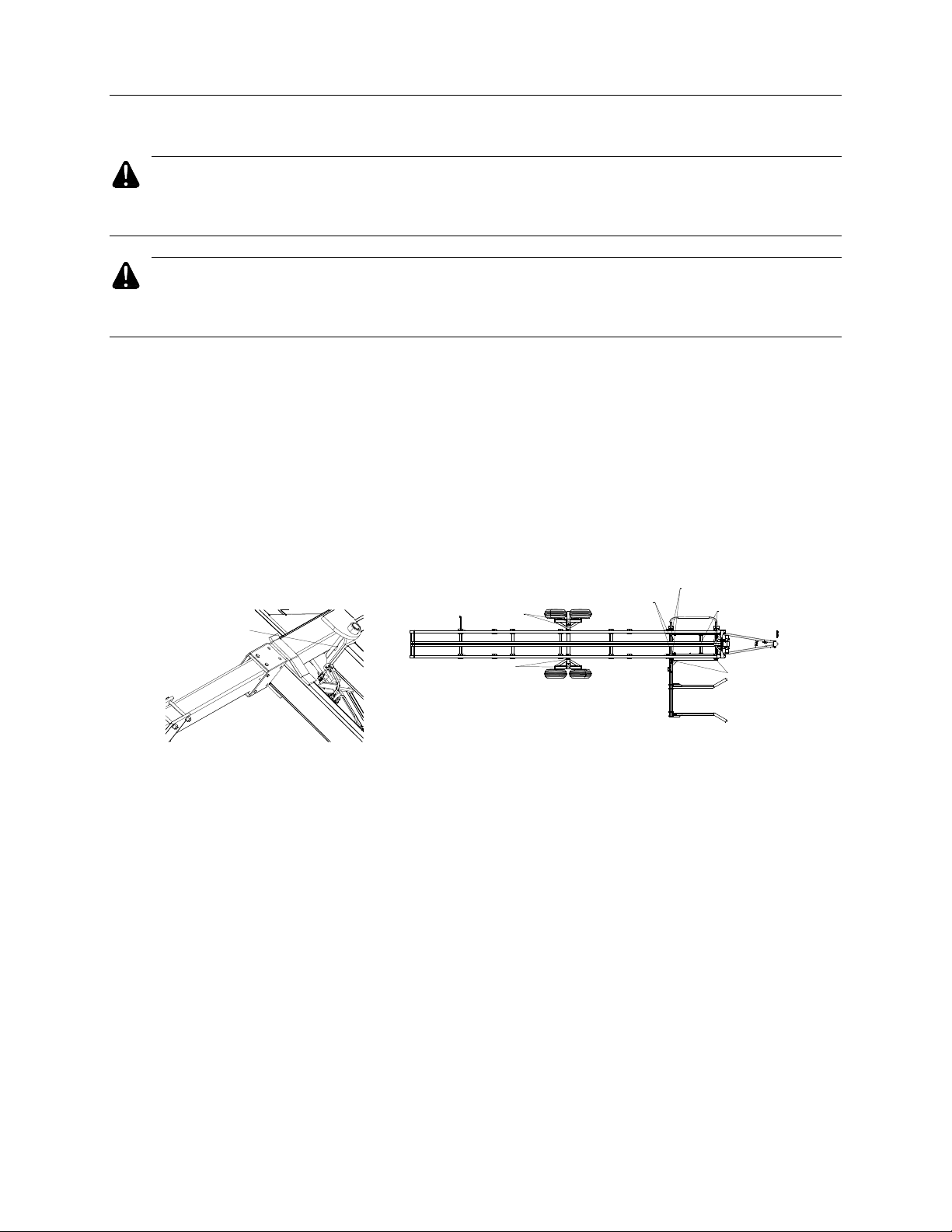

TERMINOLOGY AND DECAL LOCATIONS ILLUSTRATION

1500 Bale Carrier

9. Part # 813634

1

6

End

LEFT SIDE

Side

Front Crossmember

5

Pusher

Bale Stop

Second Crossmember

8

2

14

16

YELLOW

9

Front Stop

11

4

FRONT

Clevis

YELLOW

Jack

16

Bale Lift Arm

Valve Bank

Bale Fork

12

12. Part # 814490

Vehicle

Slow Moving

AMBER

REFLECTOR

Carrier Beam

18

15

15

RED

BACK

16

16

RED

YELLOW

15

RED

16

13

1500

13. Part # 814457

YELLOW

7

YELLOW

10

RIGHT SIDE

2) Awarness signs are shown on one

side only for clarification. Signs are

except for numbers 1, 2, 5, 6, 8, 9

information on safety decals.

Note: 1) Refer to page 7 for detailed

and14 which are only on the position

provided on both left and right sides

indicated.

2

Page 5

bühler

1500 Bale Carrier

GENERAL SPECIFICATIONS:

Dimensions:

- Length: 44’ (13.4 m)

- Deck Length: 37’ (11.3 m)

- Width: 8’6” (2.6 m)

- Weight (empty): 5495 LB (2498 kg)

- Drawbar Vertical Load (empty): 1365 LBF (6071 N)

- GVW: 18720 LB (8491 kg)

Capacity:

- Total bale payload: 13225 LB (6000 kg)

- Bales 6’ (1.8 m) diameter maximum to 4’ (1.2 m) diameter minimum

- Hay crop, small grains, and flax straw

- Eight 4’ (1.2 m) wide bales

- Seven 5’ (1.52 m) wide bales

Tires:

- 4-12.5L x 15 FI - 12 ply, Load Range F, Farm Hwy Service tire

- Six bolt heavy-duty hubs with twine guards

- Walking beam axle design

Control Handle:

- Power: 12v

- Fuse: 15 amp (surge protection provided on machine)

Hydraulics:

- Two remote tractor hydraulics circuits required for operation

- Closed-center hydraulic standard.

- In-field configuration is required for open-center or load-sensing tractors

- One Lift cylinder with restrictor

- One Tilt cylinder with restrictor

- Two 22.2 cu. inch (363.79 cu cm) hydraulic motors

- See Appendix B for details on hydraulic components

Tractor:

- Size: 60 hp (45kW) recommended

- Weight: As per ASAE specification ASAE S365.4 the tractor must weight 12480 LB

(5660 kg) to adequately handle a GVW of 18720 LB (8491 kg)

- Maximum loaded towing speed 20 mph (32 km/h)

3

Page 6

bühler

INTRODUCTION

1500 Bale Carrier

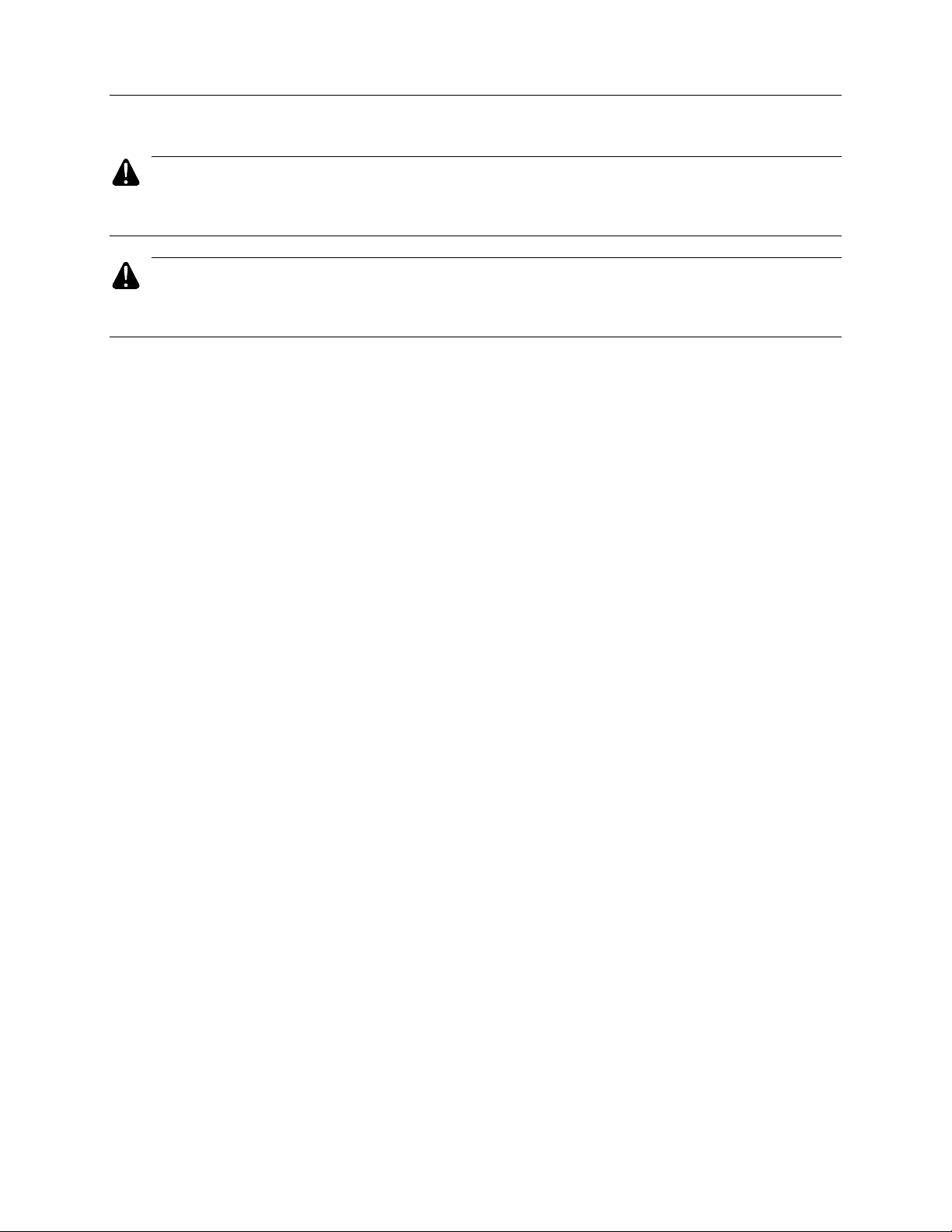

CAUTION:

Your 1500 Bale Carrier requires a recommended minimum 60 hp

(75kw) tractor. The maximum loaded transportation speed of 20 mph (32 km/h) and

18720 LB (8491 kg) must not be exceeded.

This manual has been provided as information regarding the specifications, safe

operation and maintenance of your agricultural 1500 Bale Carrier. Read and understand

this manual and the tractor manual prior to operating to obtain the best use of operating

your 1500 Bale Carrier. Keep this manual for reference and to forward to new operators

and owners. Contact your local Buhler Inland dealer if you require any assistance,

information or additional manuals.

Your new bale carrier is designed to retrieve, transport, and unload a wide range of

round bales. Sizes that can be accommodated range from 4’ (1.2 m) diameter to 6’ (1.8

m) diameter in a variety of hay crops as well as small grain and flax straw.

Serial Decal Location

The serial decal is located on the left side of the front crossmember. Please record the

serial number in the space provided for future reference. The serial decal will provide

the model and date of manufacture of the Bale Carrier and will be required to obtain

correct replacement parts and complete warranty claims.

For your records, record

Serial Number here: ________________________

B.I.I. FARGO INC.

FARGO NORTH DAKOTA

versatile

farm king

allied

inland

Warranty Registration

The warranty registration and delivery report MUST be completed within thirty (30) days

of delivery to validate the warranty.

4

Page 7

bühler

1500 Bale Carrier

SAFETY

Read and understand all the safety messages listed in this manual. For your safety and

the safety of others near the machine, learn how to control and operate your 1500 Bale

Carrier properly. It is your responsibility to inform subsequent operators and owners of

these precautions.

General Safety Notes

Keep young children away from machinery and bales at all times.

Be aware that accidents often happen when the operator is tired or in a hurry to get

finished. Take the time to consider the safest way. Never ignore warning signs of

fatigue.

Keep hands, feet, clothing and hair away from moving

parts. Never attempt to clear obstructions or objects

from a machine while the engine is running.

Keep all shields in place. Never alter or remove safety

equipment.

Do not attempt to clear any blockage or reach into the

1500 Bale Carrier with your arm or leg unless the tractor engine is stopped.

Do not load bales of sizes not out lined in the specifications section.

Use proper lighting and safety warnings when transporting equipment on public

roads and during darkness. The slow moving vehicle emblem must be visible. Check

with your local law enforcement agency for specific requirements.

Provide a first-aid kit for use in case of

emergencies.

The safety information in this manual does not

replace safety codes, insurance needs, or laws

governing your area. Be sure your machine

meets the standards set by these regulations.

Keep a fire extinguisher with the machine. Be

sure the extinguisher is properly maintained and

be familiar with its proper use.

Wear close-fitting clothing and cover long hair. Never wear

dangling items such as scarves or bracelets.

Remember that YOU are the key to safety. Good safety

practices protect you and the people around you.

Follow all safety messages in the manual and on safety

signs located on the machine.

It is your responsibility to read and understand this manual completely before

operating the bale carrier.

5

Page 8

bühler

1500 Bale Carrier

Never leave the tractor unattended while the 1500 Bale Carrier is hooked up, always

shut tractor off and remove key before leaving the tractor seat. A child or even a pet

could engage an idling machine.

Keep the 1500 Bale Carrier on solid ground; rocks and holes can be dangerous for

operation and movement.

Prior to use, check to ensure the attachment is properly hitched.

Improper use of the 1500 Bale Carrier and tractor can cause serious injury or death.

Never operate 1500 Bale Carrier with frayed or damaged hoses or leaking fittings. A

burst could cause one or more hydraulic components to behave erratically causing

serious injury or loss of life.

Operate 1500 Bale Carrier only while seated in the tractor seat.

Do not load bales improperly; always load according to the manual’s operation

procedures.

If for some reason you feel the tractor tipping immediately lower lift arms.

Do not raise lift arms to extreme heights while tractor is on an incline. Be alert for

terrain changes and adjust accordingly.

Allow for 1500 Bale Carrier and tractor length when turning.

Do not overload the GVW of 18720 LB (8491 kg) and when loaded keep the speed

below 20 mph (32 km/h).

Before allowing anyone to operate the machine, for however a short time or

distance, make sure they have been instructed in its safe and proper use.

Review the manual and all safety related items with all operators annually.

Correct other operators not using recommended procedures before an accident

occurs.

When assembling, operating and servicing machinery, wear all the protective

clothing and personal safety devices that could be necessary for the job at hand.

Never work beneath a raised lift arm unless it is securely supported. The control

handle can be moved or a hydraulic leak could cause the arm to drop resulting in

serious injury or death.

Use only service and repair parts made or approved by the equipment manufacturer.

Substituted parts may not meet strength, design, or safety requirements.

Do not modify the machine. Unauthorized modifications may impair the function

and/or safety and affect machine life.

Keep the area used for servicing machinery clean and dry. Wet

or oily floors are slippery. Wet spots can be dangerous when

working with electrical equipment. Be sure all electrical outlets

and tools are properly grounded.

Keep machinery clean. Straw and chaff on hot surfaces are a fire hazard. Do not

allow oil or grease to accumulate on service platforms, ladders or controls. Clean

machines before storage.

Never use gasoline, naphtha or any volatile material for cleaning purposes. These

materials may be toxic and/or flammable.

When storing machinery, cover sharp or extending components to prevent injury

from accidental contact.

6

Page 9

bühler

1. Part # 813624

2. Part # 8

13625

4. Part # 813626

5. Part # 813627

6. Part # 813632

11. Part # 813636

10. Part # 813637

3. Part # 21867

before repairing or adjusting or disc onnecting.

14. Part # 813952

RED RELFECTIVE

ORANGE FLOURESCENT

AMBER REFLECTIVE

1500 Bale Carrier

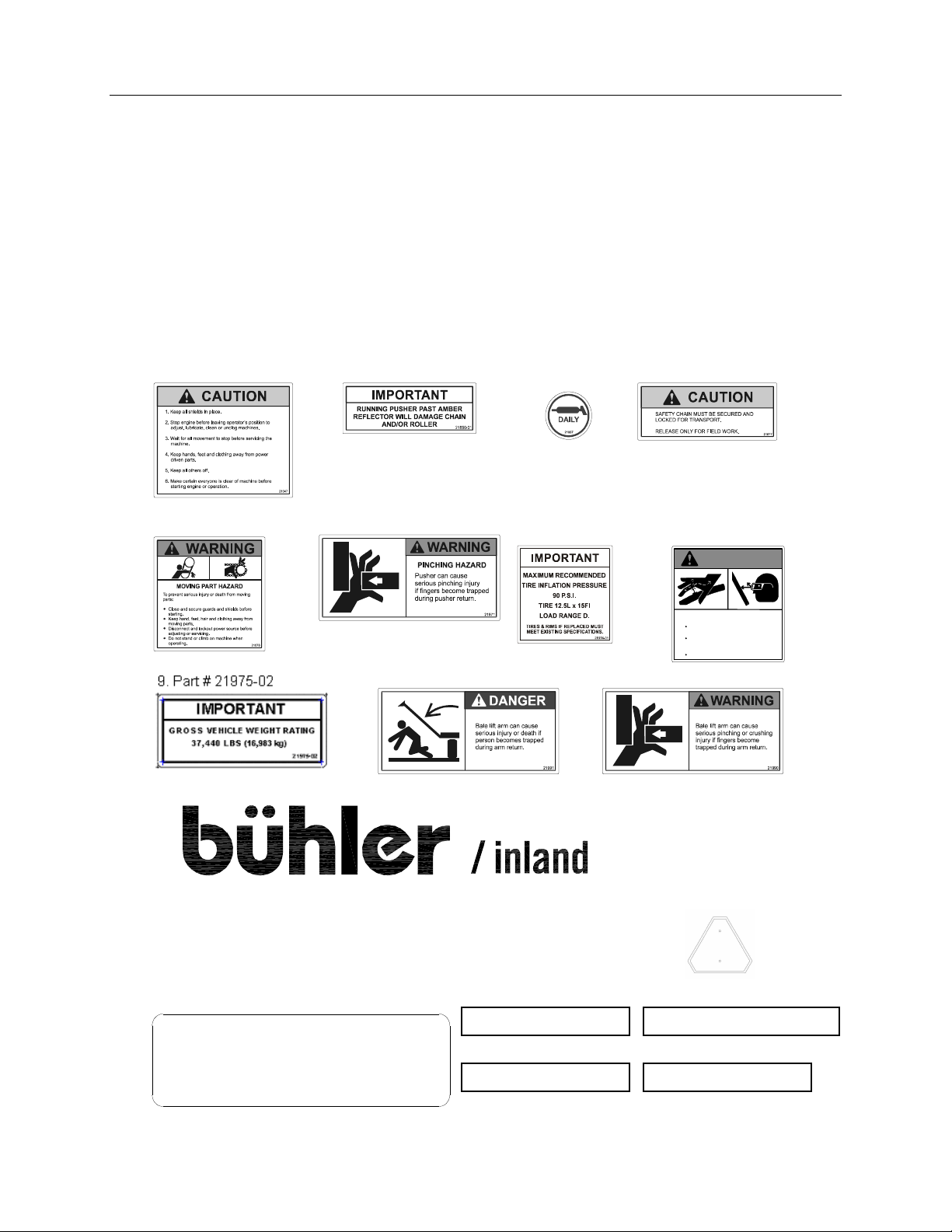

Safety Decals

The terminology and decal location illustration shows the approximate location and

detail of safety decals. To install safety decals ensure the installation area is clean and

dry. Decide on the exact position before you remove the backing paper. Remove the

smallest portion of the split backing paper and align over the specified area. Carefully

press in place. Slowly peel back the remaining paper and smooth the remaining portion

in place. Small air pockets can be pierced with a pin and smoothed out. Keep all decals

clean and replace any that are damaged or missing. Replacement decals are available

from you local dealer. The following pictorials indicate important precautions to be used

during the operation of the 1500 Bale Carrier.

8. Part # 813635

WARNING

HIGH-PRESSURE FLUID HAZARD

To prevent serious injury or death:

Relieve pressure on system

Wear proper hand and eye protection

when searching for leaks. Use wood or

cardboard instead of hands.

Keep all components in good repair.

SW700

12. Part # 814490

13. Part # 814457

1500

BUHLER BALE CARRIER 1500/2500 SNUBBER UNIT

P/N: 813949

(NO SERVICEABLE PARTS INSIDE)

DECAL PN: 813952

CONTINUITY LIGHT

YELLOW REFLECTIVE

7

Page 10

bühler

Important Precautions

The alert symbol is used throughout this manual. It indicates attention is required and

identifies hazards and alerts you that your safety is involved. Follow the recommended

precautions.

1500 Bale Carrier

CAUTION

injury. It may also be used to alert against unsafe practices.

WARNING

situation, which could result in death or serious injury and includes hazards that are

exposed when guards are removed. It may also be used to alert against unsafe

practices.

DANGER

situation, which will result in death or serious injury. This signal word is limited to the

most extreme situations, typically for machine components, which for functional

purposes, cannot be guarded

Indicates a potentially hazardous situation, which may result in

The warning symbol indicates a potentially hazardous

The danger symbol indicates an imminently hazardous

8

Page 11

bühler

PRE-OPERATION CHECKLIST

1500 Bale Carrier

CAUTION

and a mass of 12480 LB (5660 kg). Make sure the drawbar is capable of supporting the

1500 Bale Carrier empty or loaded.

WARNING

Protection Structure (ROPS) and safety belts to help prevent personal injury or death

caused by tractor roll over.

To ensure safe and proper operation of the 1500 Bale Carrier, inspect the following

items prior to operation and daily thereafter. Refer to operation, lubrication and

maintenance sections for detailed instructions.

Prior to first use verify that the 1500 Bale Carrier has been properly assembled and

that the operator understands the safety, operating, and maintenance requirements.

Check for missing fasteners and replace if necessary. Refer to maintenance section

for details.

Check and maintain proper tire pressure of 90 psi (620 kpa).

Check for loose wheel bolts. Bolts must be torqued to 125 ft LB (170 Nm).

Clean 1500 Bale Carrier of any foreign material that may have accumulated from

previous run.

Lubricate all points requiring daily lubrication.

Check chain tension and adjust if necessary with front sprocket adjusting bolt

(approximately 6” (15 cm) of upward slack). This is verified by raising the chain by

hand.

Ensure top surface of bale carrier beams are properly coated with a graphite coating

to reduce bale friction while pushing bales back.

Ensure that the tractor used to pull the 1500 Bale Carrier is in working order

according to the tractor manual.

Verify the 1500 Bale Carrier is properly coupled to the tractor with the safety chain.

Inspect all safety reflective decals, slow moving vehicle decals and lights where

applicable.

Inspect the hydraulic system on the 1500 Bale Carrier and your tractor for leaks or

any other damage.

Ensure the control handle actions reflect the movements of the 1500 Bale Carrier.

Inspect all electrical connections to ensure proper function of the machine

Ensure transport safety chain is disengaged from bale lift arm and stored on chain

lug located on second cross member. Failure to do so may cause damage to lift arm.

.

Make sure the tractor has a 60 hp (45 kw) or greater rating

The tractor must be equipped with an approved Roll over

9

Page 12

bühler

OPERATION

1500 Bale Carrier

CAUTION

understands the safety requirements of the 1500 Bale Carrier. Ensure the pre-operation

checks have been completed prior to operation.

1. Attaching Bale Carrier To Tractor

CAUTION

working around 1500 Bale Carrier. Refer to tractor manual for tractor parking

procedures.

CAUTION

tractor. Ensure drawbar is capable of handling the 1500 Bale Carrier load. The tractor

must have a minimum mass of 12480 LB (5660 kg) and recommended 60 hp (45 kw).

Using the tongue jack, raise tongue to align with hitch pin, adjust clevis position

as necessary to level the carrier beams.

Position tractor and secure with locking type drawbar pin (not supplied). Use an

approved hitch pin with a mechanical retainer.

Route safety chain around the hitch clevis, around drawbar support and back

hook. Refer to tractor manual for further drawbar instructions.

Do not use intermediate support on drawbar as attaching point.

Store safety chain off the ground when not in use. If safety chain is damaged in

any way, contact your dealer for a replacement.

For serial number 08BM1500001 and later, open-center valve is a factory-

installed feature

Note: The bale carrier is factory-configured to operate with tractors

For tractors with OPEN-CENTER or LOAD-SENSING hydraulic systems,

refer to the configuration on pages 33, 50 and 51.

2. Attaching Bale Carrier Controls To Tractor

Bale lift and push functions are controlled by the 1500 Bale Carrier valve. Two

hoses complete with black hydraulic tip covers supply pressure and tank. The

retraction hose is designated with a check valve and ensures proper flow through

the valve. Connect the return hose to the retract circuit and the extend hose to

opposite extend port.

The tilt function is controlled by the tractor’s remote valve. Two hoses complete

with red hydraulic tip covers supply extension and retraction.

Connect control handle harness to the machine harness. Connection is made at

the snubber unit by matching the appropriate socket and plug.

Prior to operation ensure the operator has read and

Shut off tractor, engage parking brake and remove key before

Use only the drawbar to couple the 1500 Bale Carrier to the

having CLOSED-CENTER hydraulic systems (page 31).

10

Page 13

bühler

1500 Bale Carrier

The power required to operate the 1500 Bale Carrier is supplied by the tractors

12-volt electrical system. Connect the red wire to the tractor positive and green to

tractor ground. Connection may be made via tractor accessory plug or alternate

method. The 15-amp fuse must be used on the positive wire as supplied.

Verify 1500 Bale Carrier operation matches 1500 Bale Carrier control handle

decal.

11

Page 14

bühler

3. Carrier Control Operation

1500 Bale Carrier

To start 1500 Bale Carrier operation, engage the remote hydraulic valve in the

extension position. Lock valve in detent. Valve to remain constantly on during

operation.

The control handle is fitted with one rocker switch and two momentary contact

rocker switches. They function as follows:

o PUSHER SPEED: Select (HIGH) to operate

pusher motors in series at high speed or

(LOW) to operate in parallel at low speed. Torque

is increased at low speed and pushes bales with

more force.

o PUSHER: Depress and hold PUSHER FWD to

move forward. Depress and hold PUSHER BACK

to move pusher back.

o LIFT ARM: Depress and hold LIFT ARM UP to

raise lift-arm. Depress and hold LIFT ARM DN to

lower lift-arm.

To operate raise / lower tilt function engage the remote hydraulic valve in the

extension position to raise the tilt deck and engage the retract position to lower

the deck.

4. Loading Bales

CONTROL

HANDLE

WARNING

do so could result in injury or death.

Align the tractor and 1500 Bale Carrier as indicated in the pictoral for pick up

method used. Slowly approach the bale at 5 mph (8 km/h) while loading. When

bale is properly captured, begin to lift bale.

The 1500 Bale Carrier is designed to load bales with one of three options. Refer

to the appropriate section on the next page for your option loading instructions.

Instructions for the fork positions are provided in appendix A.

NOTE:

Before loading bale the pusher must be at the front of the carrier deck.

Make sure area is clear before lowering bale lift-arm. Failure to

12

Page 15

bühler

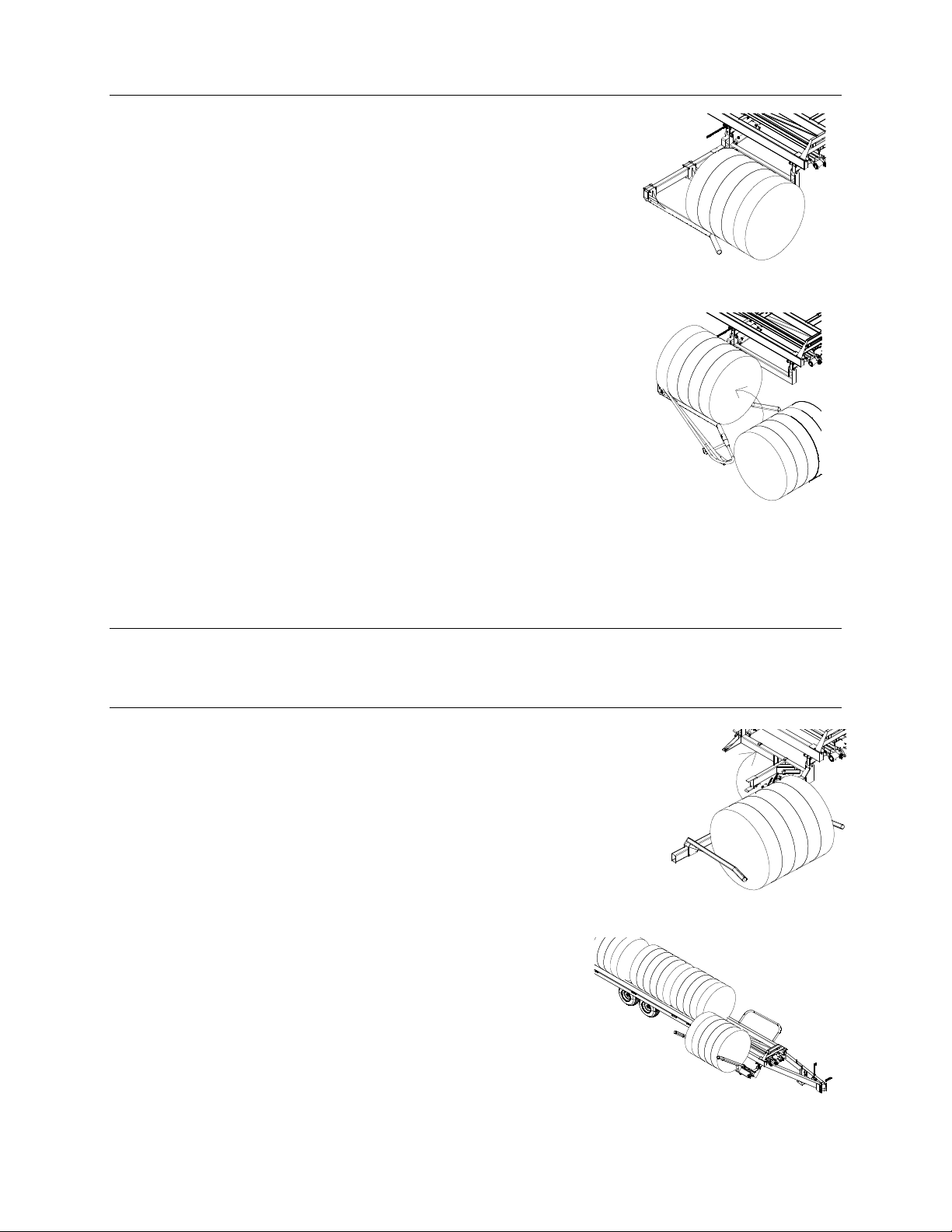

The Fixed Pick Up Arm requires the

The Bale Deflector attached to the fixed pick

operator to drive at 90° to the bale direction.

The bales are loaded “End On”. The bale is

loaded onto the carrier deck by depressing

and holding LIFT ARM UP until the bale rolls

off the pickup arm and onto the carrier

beams.

up arm allows the bales to be picked up from

either “End On” or “Side On.” The deflector

rotates the bale 90° before it is lifted up onto

the carrier. Forward travel is used to rotate

the bale. Approach the bale so that the outer

end of the bale rides up on the bale deflector

as the loading arm moves under the bale.

To pickup bales that are placed “End On,”

drive so the inner arm of the loading fork is

against the inner edge the bale. The bale will

then be loaded onto the carrier in the same

direction as it was picked up. Continue to

load using fixed arm instrucitons.

1500 Bale Carrier

FIXED PICK UP ARM

BALE DEFLECTOR

NOTE:

using the bale deflector. Contacting the bale further to the inside may result in damage

to the deflector, bale lift arm or bale.

The Rotating Pick Up Arm (RPU) loads

The bale should be contacted about 12” (30 cm) from its outer end when

bales “side on”. The lift arm starts in the

lowered position. Drive forward until the forks

are positioned around the ends of the bale

with the inside stationary fork as close as

possible to the bale. Depress and hold LIFT

ARM UP. The bale is then squeezed on end

until the pressure matches the sequence

valve setting that rotates and raises the bale.

When the bale is lifted above, the bale is

released by depressing LIFT ARM DN. This

releases the bale and returns the RPU to the

ready state for the next bale. Refer to the

assembly instructions for adjusting RPU’s

settings.

13

RPU LOADING BALE

RPU LIFTING BALE

Page 16

bühler

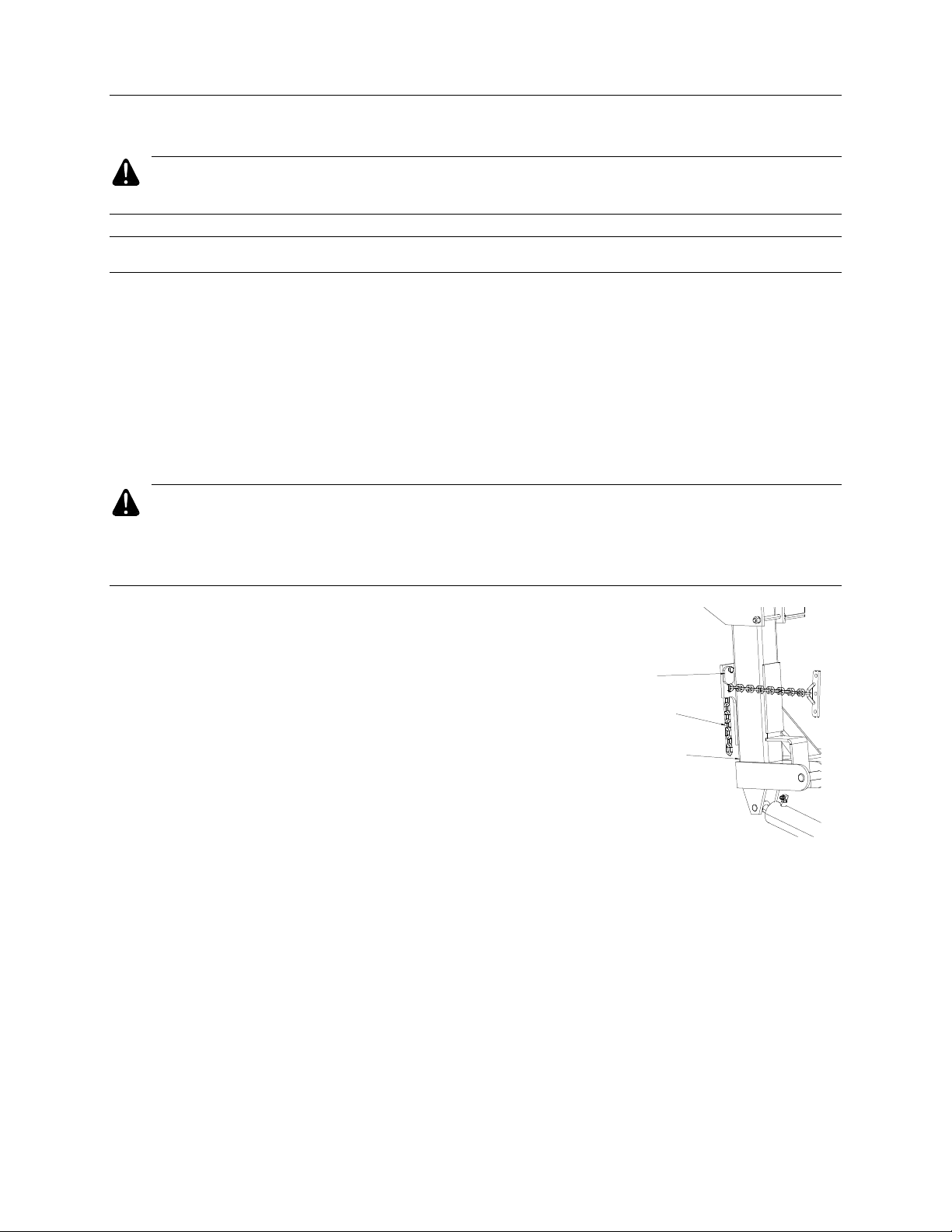

5. Bale Pusher Operation

1500 Bale Carrier

CAUTION

push back one bale length to prepare for the next bale.

NOTE:

Depress and hold PUSHER BACK and move bales far enough to the rear to

Return pusher all the way to the front by depressing and holding PUSHER FWD.

Hi speed / Low torque mode is recommended for normal use.

Low speed / High torque mode is for heavier payloads or situations where bales

6. Transporting 1500 Bale Carrier

Lower loading arm before operating the pusher.

provide room to load the next bale.

are wet or resist sliding.

WARNING

flashing lights when transporting on public roadways. Obey local regulations regarding

road transport. Raise bale lift arm and use the safety chain when transporting. Ensure

the lift arm chain latch is used to prevent the safety chain from dislodging or loosening.

Do not transport if end bale is overhanging

beams. Beam should extend beyond last bale

for a minimum of 2’ (61 cm).

Raise lift arm prior to transport. Always

engage lift arm safety chains when

transporting on public roadways or when not

in field. Lock chain in position with latch

provided.

Monitor the condition and position of bales

that are being transported.

Slow speed when transporting over bumps or

rough terrain.

To avoid misbalanced loads the operator is only required to

Do not tow over 20 mph (32 km/h) when loaded. Turn on

LATCH

SAFETY CHAIN

LIFT ARM

LIFT ARM SAFETY CHAIN

ILLUSTRATION

14

Page 17

bühler

7. Unloading

1500 Bale Carrier

DANGER

could result in serious injury or death.

NOTE:

damage to chain and drive.

Extend tilt cylinder to raise carrier beam by engaging the tractor’s extension

Depress and hold the PUSHER BACK switch to push the bales off the carrier

Once the rear bale has been pushed off the carrier, slowly drive forward while

When amber reflector on inside of the carrier

Release PUSHER BACK and slowly drive

Do not run pusher all the way to the end, the resulting shock load may cause

hydraulics.

beam.

pushing the bales back (unloading) to keep all bale ends in contact.

beam becomes visible stop the pusher. The

reflector is approximately 26” (66cm) from the

end of the beam.

forward to unload the last bale. Retract the tilt

cylinder to lower the beam and begin the next

loading cycle.

Make sure area is clear before unloading. Failure to do so

AMBER REFLECTOR

LOCATION

15

Page 18

bühler

LUBRICATION

1500 Bale Carrier

CAUTION

Place all controls in neutral, stop engine, set parking brake

and remove ignition key before inspecting, servicing, adjusting or repairing the 1500

Bale Carrier.

CAUTION

Ensure the 1500 Bale Carrier tires and hitch are securely

blocked. Otherwise, verify the 1500 Bale Carrier is properly coupled to the drawbar on a

tractor with a minimum mass of 12480 LB (5660 kg).

Pivot Points

Lubricate 1500 Bale Carrier bushings and pivots every eight hours of average

operation with high-grade grease at all fitting locations. Select grease based on

the expected outside temperature range. Lithium, Molybdenum and synthetic

greases are preferred. Use the tractor hour meter as a guide. Increase lubrication

intervals for extreme use or adverse conditions. Each pivot should be lubricated

until grease is visible at pin. The fixed arm carrier has 12 lubrication points and

the RPU carrier has 13 points. Refer to the illustrations below for locations.

HYDRAULIC CYLINDER ENDS

HYDRAULIC CYLINDER

ENDS

RPU PIVOT LEFT

AND RIGHT SIDES

AXLE BEARING

HITCH BEAM

BUSHINGS

AXLE BEARING

RPU LUBRICATION LUBRICATION ILLUSTRATION

ILLUSTRATION

Roller Chain

Manually brush SAE lubricant while chain is stationary.

Lubricate the chain every time bolt torque maintenance is performed.

Carrier Beams

Apply a graphite coating such as Slip PlateTM to the carrier beams as required to

ensure a smooth push back operation.

Follow application instructions as provided by the coating manufacturer.

At the end of the season apply a coating to prevent rust on the carrier beams.

16

Page 19

bühler

MAINTENANCE

1500 Bale Carrier

CAUTION

Place all controls in neutral, stop engine, set parking brake,

remove ignition key and wait for all moving parts to stop before servicing, adjusting or

repairing the 1500 Bale Carrier.

CAUTION

Ensure the 1500 Bale Carrier tires and hitch are securely

blocked. Otherwise, verify the 1500 Bale Carrier is properly coupled to the drawbar on a

tractor with a minimum mass of 12480 LB (5660 kg).

NOTE:

Service intervals should be increased when operating in extreme or difficult

conditions.

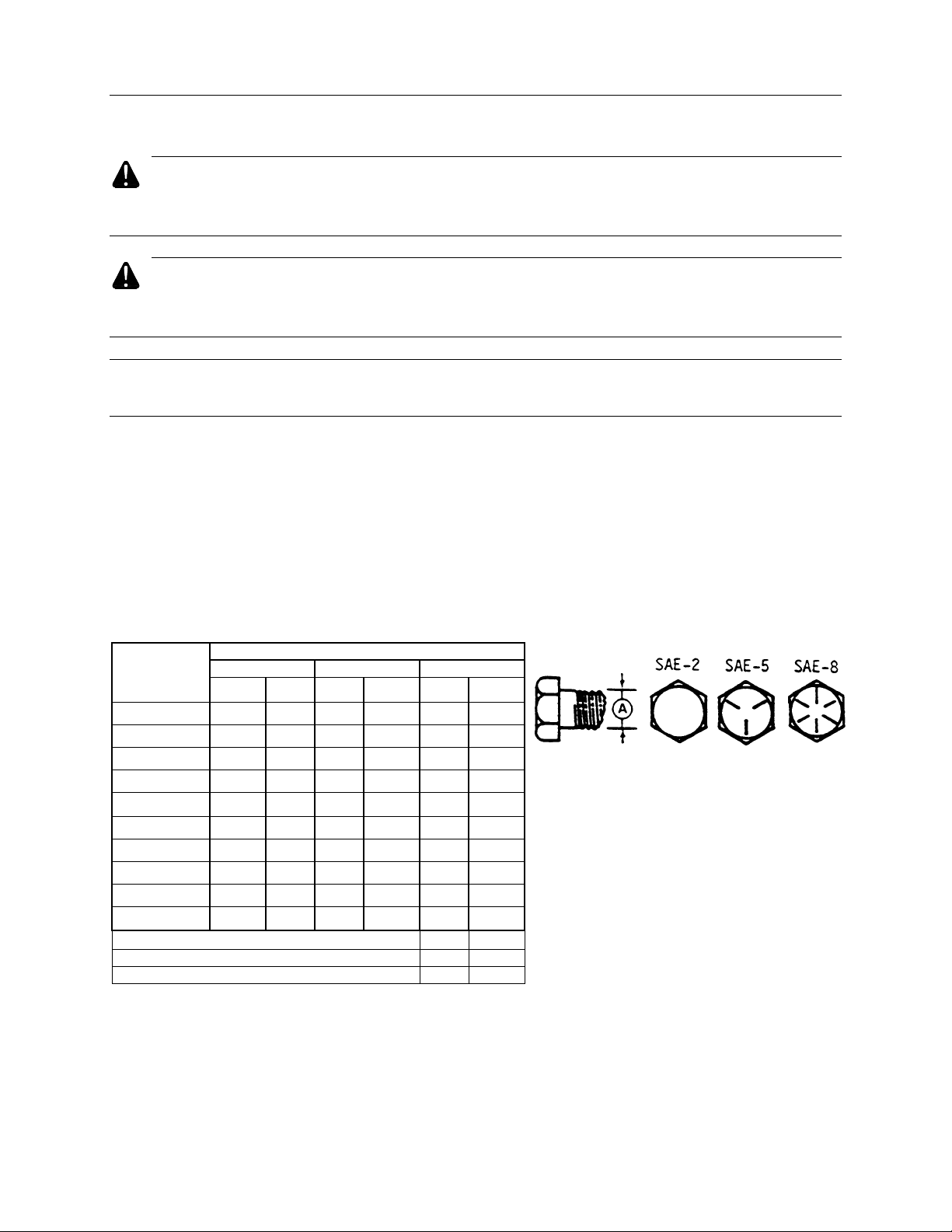

1. Fasteners

Inspect all bolt torques after first use and 50 hours thereafter.

Periodically inspect for broken or missing fasteners. Replace with fasteners of

similar size and equivalent grade.

The table below lists the correct torque values for various bolts and cap screws

used on the bale carrier. Tighten all bolts to specified values unless otherwise

noted.

BOLT

DIAMETER

"A"

1/4" 6 8 9 12 12 17

5/16" 10 13 19 25 27 36

3/8" 20 27 33 45 45 63

7/16" 30 41 53 72 75 100

1/2" 45 61 80 110 115 155

9/16" 70 95 115 155 165 220

5/8" 95 123 160 215 220 298

3/4" 155 225 290 390 400 540

7/8" 170 230 420 570 650 880

1" 225 305 630 850 970 1320

WHEEL HUB BOLTS 125 170

ALL CARRIAGE BOLTS 33 45

SAE 2 SAE 5 SAE 8

lb-ft N.m lb-ft N.m lb-ft N.m

LOCATION

BOLT TORQUE

lb-ft

N.m

17

Page 20

bühler

-04

7/16-20

14-16

20-22

10-11

13-15

-05

1/2-20

18-20

24-27

13-15

18-20

-06

9/16-18

24-26

33-35

17-19

23-26

-08

3/4-16

50-60

68-78

34-38

47-52

-10

7/8-14

72-80

98-110

50-56

69-76

-12

1-1/16-12

125-135

170-183

70-78

96-106

-14

1-3/16-12

160-180

215-245

80-90

110-122

-16

1-5/16-12

200-220

270-300

94-104

127-141

-20

1-5/8-12

210-280

285-380

124-138

169-188

-24

1-7/8-12

270-360

370-490

156-173

212-235

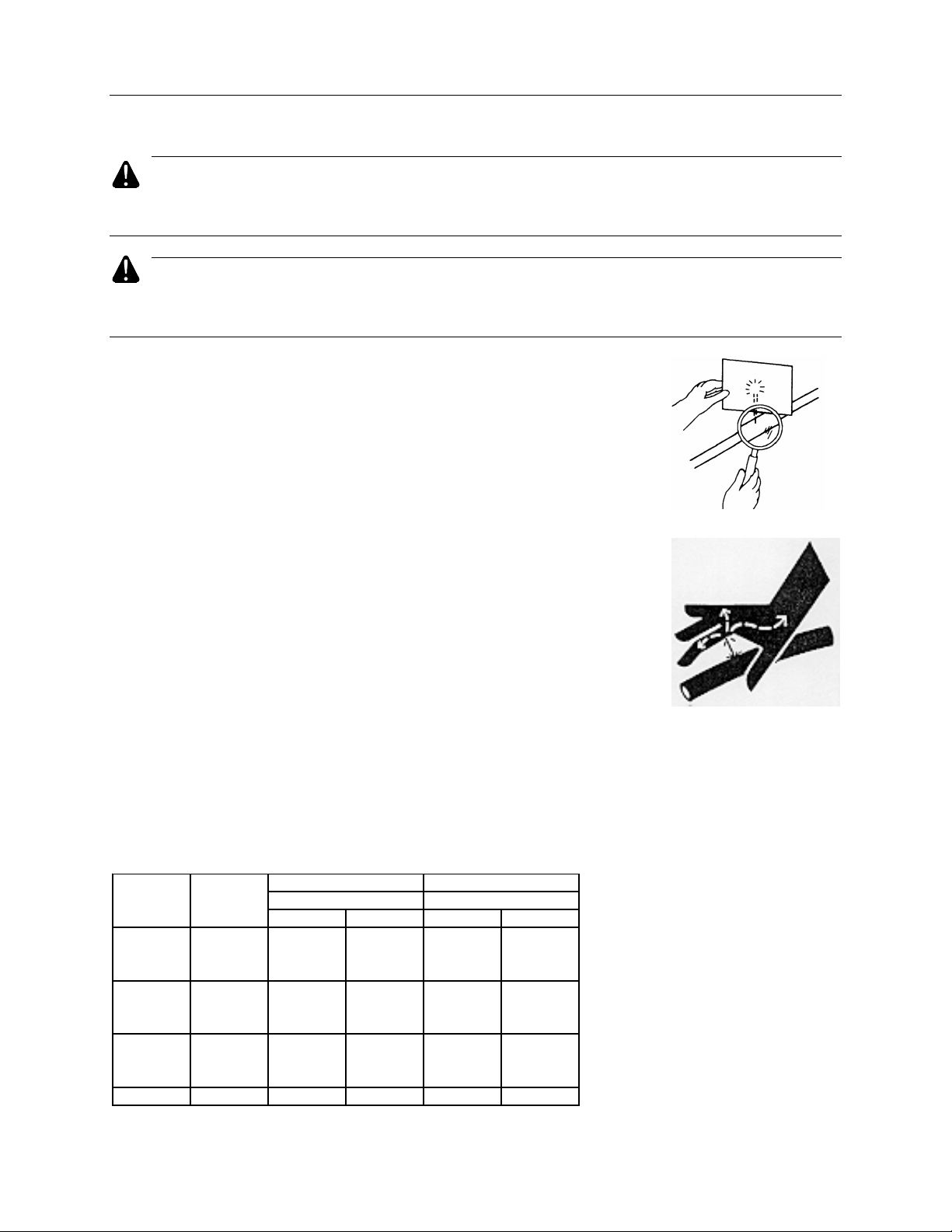

2. Hydraulic System

1500 Bale Carrier

WARNING

Escaping fluid under pressure can have sufficient force to

penetrate the skin, causing serious personal injury. Before repairing, adjusting, or

disconnecting lines, be sure to relieve all pressure.

WARNING

Never operate the 1500 Bale Carrier with frayed or damaged

hoses or leaking fittings. A burst would cause the lift arm to drop suddenly and result in

serious injury or death and cause damage to the loader or tractor.

Before applying pressure to the system, be sure all

connections are tight and the lines, pipes, and hoses are

not damaged.

Wear proper hand and eye protection when searching for

leaks. Use a piece of wood or cardboard instead of hand

to check for leaks.

Maintain all components in good working order.

If injured by escaping fluid, see a doctor at once. Serious

infection or toxic reaction can develop if proper medical

treatment is not administered immediately.

Regularly check the fluid level in the tractor reservoir and

follow the maintenance procedures in the tractor

Operator’s Manual.

Regularly inspect cylinders, hoses and fittings for leaks,

crimps and abrasions or other signs of wear and tear or

impending failure.

Ensure hoses do not bind or stretch during operation.

Always keep hoses tied or supported to prevent rubbing against sharp areas or

being pinched. We suggest using tie wraps to support hoses.

Replacement hoses must have a working pressure of 3000 psi (20685 kpa) or

higher.

3. Hydraulic Fitting Torques

Jam Nut or Straight SAE 37° (JIC)

ORB Fitting Torque Swivel Nut Torque

(ft-lbs) (NM) (ft-lbs) (NM)

Dash Size

Thread

Size

18

Page 21

bühler

1500 Bale Carrier

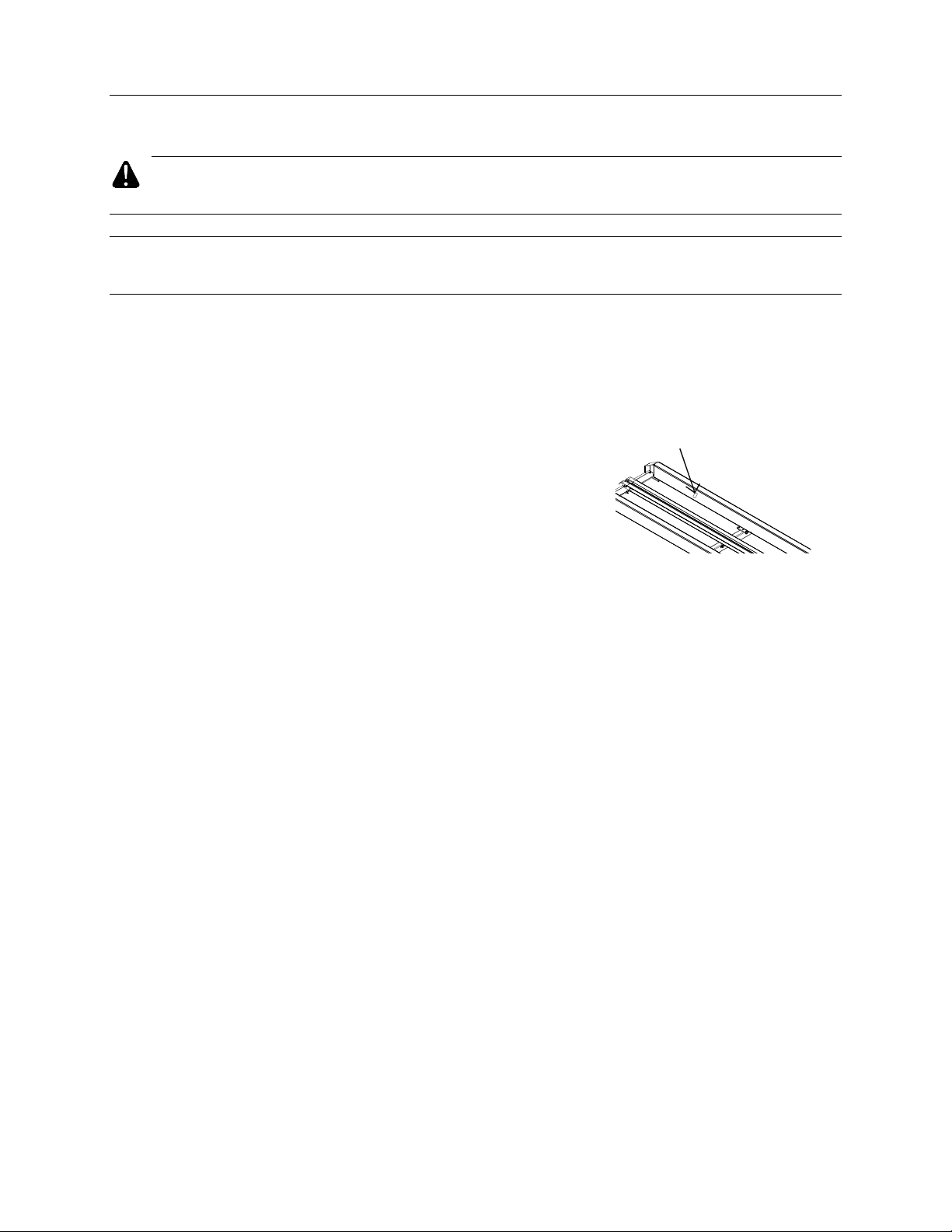

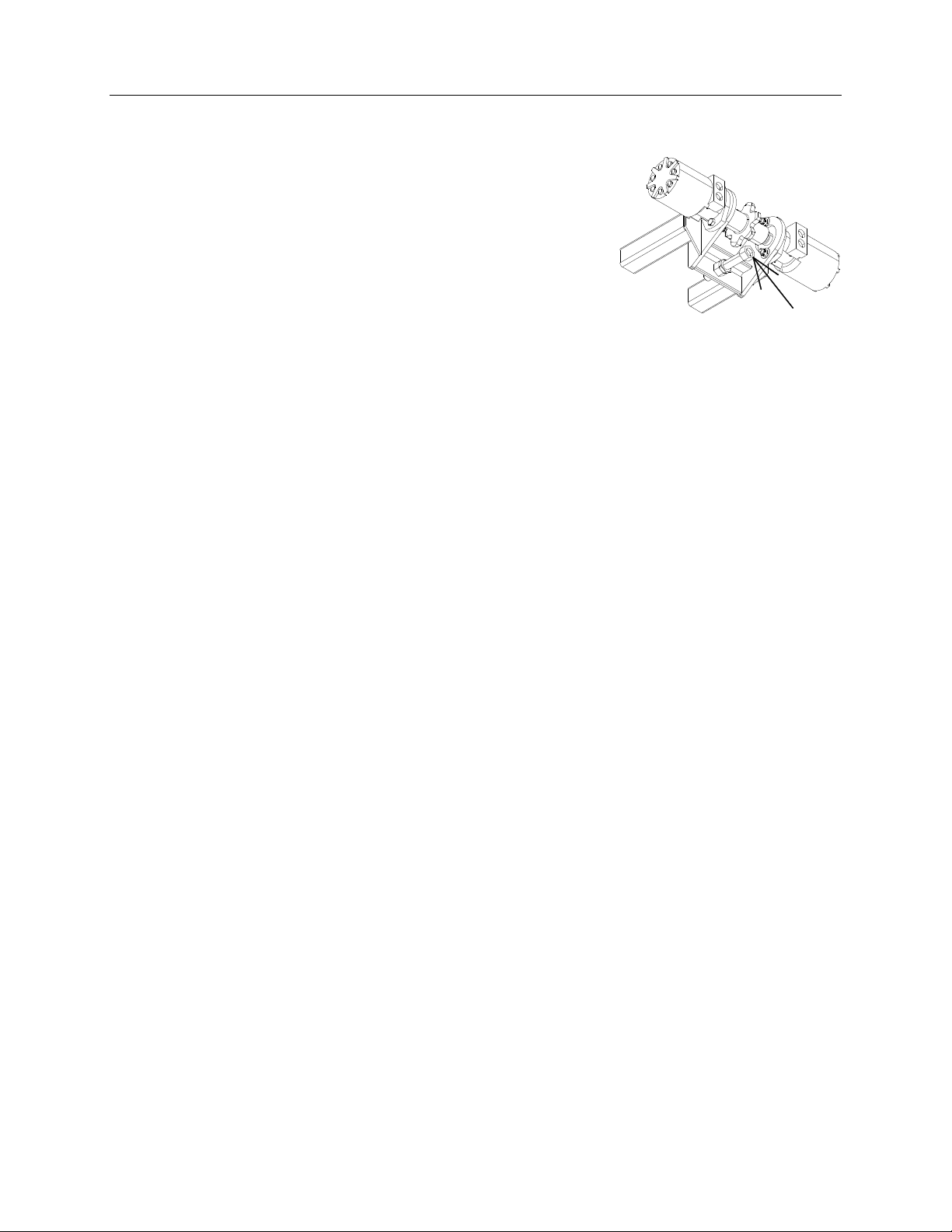

4. Chain

Check for proper chain tension and sprocket

alignment after first use and every 50 hours

thereafter.

Turn the front sprocket-adjusting bolt

clockwise until there is approximately 6” (15

cm) of upward slack in the chain at the center

of the track. Clockwise increases tension and

counter clockwise reduces tension.

Proper chain tension may be verified by

raising the chain by hand.

See lubrication section for further

FRONT ADJUSTING

BOLT

maintenance instructions.

5. Wheels / Tires

Inspect hub bolts after first use and 50 hrs thereafter. Hub bolts must be torqued to

125 ft-lb (170 Nm).

Thread-locking compound such as Locktite 242 is recommended for the hub bolts.

Ensure that dust caps are firmly in place.

Check tires pressure regularly: 90 psi (620 kpa).

The wheel bearings should be inspected and re-packed annually with SAE multi

purpose type grease. Grease every 500hrs if hub is supplied with grease fitting.

Air valve should face away from the hub.

19

Page 22

bühler

6. Storage

1500 Bale Carrier

CAUTION

remove ignition key before inspecting, servicing, adjusting or repairing the 1500 Bale

Carrier.

CAUTION

Otherwise, verify the 1500 Bale Carrier is properly coupled to the drawbar on a tractor with

a minimum of 12480 LB (5660 kg).

Start of Season

Clean and inspect the bale carrier when taking it out of storage. Ensuring that the

bale carrier is in optimum condition at the start of the season reduces the chances of

a costly breakdown during the season.

Clean and inspect chains and chain rollers for excessive wear or stiffness. Check for

proper adjustment and alignment.

Lubricate entire bale carrier. Ensure that all grease fittings are in place and taking

grease properly.

Operate the bale carrier for a short time. Check that all moving parts are operating

freely. Check for hydraulic leaks.

Inspect and repack wheel bearings with SAE multi purpose type grease.

Replace and secure safety shields. Review safety regulations.

Check all bolts for tightness. Replace lost or worn bolts.

Check that tires are properly inflated.

Review the Operator’s Manual.

During The Season

At the end of each day of operation park the bale carrier in a clean, dry, sheltered

area.

Lubricate areas requiring daily lubrication.

Remove any build up of hay or straw.

End Of Season

Replace worn or damaged parts and replace if necessary. To avoid costly delays

contact your dealer for replacement parts before the start of the next season.

Store the bale carrier in a clean, dry, sheltered area.

Replace all missing or broken bolts with bolts of similar size and grade.

Clean the baler carrier thoroughly. Dirt draws moisture that rusts metal.

Repaint chipped or worn areas. Paint is available from your dealer.

Clean chains and brush with SAE light machine oil (or equivalent) to prevent rust.

Repaint the top of the carrier beams with graphite paint such as Slip PlateTM to

prevent rust.

Place all controls in neutral, stop engine, set parking brake and

Ensure the 1500 Bale Carrier tires and hitch are securely blocked.

20

Page 23

bühler

1500 Bale Carrier

APPENDIX LIST

Description Appendix

Assembly Instructions…..…………………………………………………….

Hydraulic Assembly……………………………………………………………

Electrical Assembly………..…………………………………………………..

General Assembly….…………………………………….…………………...

A

B

C

D

21

Page 24

bühler

1500 Bale Carrier

APPENDIX A

Assembly Instructions

Table of Contents

Description Page

Carrier Bundled Assembly………………………………………………………. 23

Tandem Axle Assembly……………………………………………………… 23

Brace Weldment……………………………………………………………... 23

Taillight Assembly……………………………………………………………. 24

Bale Retainer Weldment…………………………………………………….. 24

Fixed Loading Arm………………………………………………………….. 24

Bale Deflector Arm Assembly……………………………………………... 25

RPU Assembly………………………………………………………………... 25

Carrier Bundled Assembly Drawing……………………………………………. 27

Carrier Bundled Assembly Parts List…………………………………………... 28

22

Page 25

bühler

1500 Bale Carrier

CAUTION

room for safe assembly. Do not work underneath raised assembly.

CAUTION

Otherwise, verify the carrier is properly coupled to the drawbar on a tractor with a minimum

of 12480 LB (5660 kg).

Carrier Bundled Assembly

Make sure area is clear of obstructions, well lit, and has sufficient

Ensure the carrier’s tires and hitch are securely blocked.

1. Tandem Axle Assembly Installation

Refer to Carrier Bundled Assembly drawing:

Raise the main assembly to a maximum of three feet to insert the tandem axle

assembly (A2400-14) on both sides. Make sure that the assembly is securely held in

place. Support assembly with the appropriate rated stands for the load.

Insert the tandem axle assembly on to the axle Beam (C2407-00).

Insert the tandem axle locator (C8005-00) between the tandem axle assembly

bushings, continue to insert the axle assembly.

Insert nut (984077) and set screw (813547) into the locator.

Install tires

Torque all fasteners to the torque specifications listed in the maintenance section of

this manual.

Lubricate axle and hubs; refer to lubrication section for details.

Recheck all bolt torques after first use.

2. Brace Weldment Installation

Refer to Carrier Bundled Assembly drawing:

The carrier has six braces that need to be installed on the undercarriage of the main

assembly.

All fasteners require a flat washer and a lock nut.

Loosely assemble and fasten all braces.

Torque all hardware to the required torque specifications listed on the maintenance

section of this manual.

23

Page 26

bühler

1500 Bale Carrier

3. Taillight Assembly

Refer to Carrier Bundled Assembly drawing:

Remove and inspect all required hardware from parts box.

Mount lights using fasteners supplied

Connect the taillight wiring harnesses to their appropriate connections.

Connect main lighting plug to tractor.

Test by verifying correct lamps illuminate when signalling and braking.

.

4. Bale Retainer Weldment

Remove the hardware from parts box and transfer on to bale retainer weldment.

Place the weldment on the matching bolt holes in the position shown in Carrier

Bundled Assembly drawing. Torque the provided hardware to the specifications

listed on the bolt chart.

5. Fixed Loading Arm

CAUTION

Stay clear of the arm when testing a finished assembly.

Ensure during assembly to keep your entire body out from underneath parts that are

being attached to the main frame.

Remove lift arm pivot pins that are installed

on the carrier.

Thoroughly lubricate all pins involved in the

assembly with SAE multi purpose grease.

36.0"

Align arm to pivots with open end of arm

facing forward and reinstall pins with

hardware provided and torque to

specifications called for in the bolt chart.

Remove the lift cylinder pin from the arm.

FIXED LIFT ARM

ATTACHMENT ASSEMBLY

LAYOUT

Align the lift cylinder rod and reinstall the pin.

Adjust the outside bale fork to be positioned at the end of the lift arm and the

inner bale fork about 36” (91 cm) from the end.

Recheck all hardware so that every bolted connection on the lift arm is torqued

according to the specifications of the bolt chart.

Approach the bale and inspect to ensure the spacing of the forks is accurate.

For first operation, cycle the lift arm slowly with a bale and inspect just before

lifting bale from ground.

Finish the cycle and observe how the bale transits from the forks to the carrier

beam. If transition is smooth with minimum bale binding, assembly is completed.

If not, adjust the forks to a different location and try until loading is smooth.

24

Page 27

bühler

ASSEMBLY LAYOUT

6. Bale Deflector Arm Assembly

Remove all hardware that is included with the

deflector assembly.

Remove the two top bolts from outer fork on

lift arm.

Maintain the spacing of the forks if already

preset. If not, set spacing as described in the

fixed pick up arm assembly section.

Insert the coned end of the deflector onto the

end of the outer fork.

Align the bolt holes from the removed bolts

on the outer fork and the end of the deflector

attachment.

Insert hardware supplied with the deflector

the same way the hardware was installed

before the attachment was added.

Torque all hardware according to the bolt

chart and tighten the set screws on the cone

also according to the chart.

During first bale lift, cycle slowly and watch

for excessive flexing or movement of the

deflector. If movement is detected, stop cycle

and retorque all hardware involved.

7. RPU Assembly

Remove lift cylinder and install Pilot Check

assembly (see Appendix B)

Reinstall cylinder at base end only.

Lubricate all pins involved in RPU attachment

with a SAE multi purpose grease.

Align arm to pivots with open end of arm

facing away from the carrier and reinstall pins

with hardware provided and torque to

specifications called for in the bolt chart.

Remove the lift cylinder pin from the RPU

arm.

1500 Bale Carrier

BALE DEFLECTOR

ATTACHMENT ASSEMBLY

LAYOUT

RPU ATTACHMENT

25

Page 28

bühler

ROTATING PICK UP ARM

ADJUSTABLE FORK

BALE WIDTH + 6” TO 8”

1500 Bale Carrier

Align the lift cylinder rod and reinstall the pin.

Adjust the outside bale fork to be positioned

at the end of the lift arm and the inner bale

fork 6” (15 cm) to 8” (20 cm) bigger than the

size of bale that is being loaded.

Install the hydraulics according to the way

the hydraulic assembly Appendix B calls for.

Recheck all hardware so that every bolted and

hydraulic connection on the lift arm is torqued according to the specifications of

the torque charts.

Depress LIFT ARM UP. The RPU cycle should begin with a squeeze action, then

lift and rotate. After rotation is complete the lift continues until the bale is above

the carrier beams.

Release LIFT ARM UP when bale is above the carrier beam. Depress LIFT ARM

DN to release the bale and return to ground level ready for the next bale.

For the first operation, cycle the lift arm slowly with the bale and observe the

RPU operation.

Approach the bale slowly; once the bale is captured in the forks press the lift

switch. The bale is squeezed until the pressure in the sequence valve, which is

preset at 1800 psi (12400 kpa), has been achieved

If bale is not held in between the forks increase the sequence valve pressure by

turning the setscrew clockwise. Refer to the RPU Rotate Cylinder drawing for

adjustment location of the setscrew. Verify that the fork spacing is accurate and

refer to the drawing on this page for fork adjustments.

The lift and rotate sequence won’t begin until the clamp pressure is met within

the sequence valve.

When the clamp pressure is met, the lifting action should start before the rotating

action to minimize bale damage from the moving ground.

To increase lift prior to rotate turn the restrictor knob clockwise. Refer to the RPU

Rotate Cylinder drawing for more information.

Continue to raise the bale until it is positioned above the carrier beam.

To release the bale, depress LIFT ARM DN.

Finish the cycle and observe how the bale transits from the forks to the carrier

beam. If transition is smooth with minimum bale binding, assembly is completed.

If not, adjust the forks to a different location and try until loading is smooth.

26

Page 29

bühler

Carrier Bundled Assembly

1500 Bale Carrier

19

15 16

25

19

12

24

21

YELLOW LENSE

4

TO MAIN WIRING HARNESS

10

AS VIEWED FROM B B

UNDERSIDE VIEW OF TAILLIGHTS / WIRING HARNESS

1

11

WHEEL

6 BOLTS PER

2

A

A

8

BRACES USE SAME HARDWARE AS AXLE

3

19

12

20

1713

18

23

20

17

13

7

6

BALE CARRIER ASSEMBLED

AS VIEWED FROM A A

REAR VIEW OF BALESTOP PLACEMENT

20

17

17

14

B

9

B

5

27

Page 30

bühler

Carrier Bundled Assembly

ITEM COMPONENT DESCRIPTION QTY

PART NUMBER

1 B2400-14 AXLE ASSEMBLY 2

2 B2700-03 TIRE ASSEMBLY 4

3 C2407-00 TANDEM AXLE LOCATOR 2

4 C2907-00 SMV BRACKET & TAIL LIGHT MOUNT 1

5 C7035-00 REAR BRACE WELD'T 2

6 C7036-00 CENTER BRACE 2

7 C8005-00 AXLE 1

8 C8006-00 FRONT BRACE WELD'T 2

9 C8009-00 BALE RETAINER WELD'T-YELLOW 1

10 INE7045-00 LIGHT MOUNT BRACKET 1

11 813653 BOLT 0.563 NF X 1.75 (WB12)/HUB 24

12 81527 BOLT HEX 0.25NC X 1.00 GR5 PL 10

13 967274 BOLT HEX 0.500NC X 1.50 GR8 PL 34

14 81629 BOLT HEX 0.500NC x 3.5 GR5 PL 4

15 81525 BOLT HEX 0.250NC X 0.75 UNC GR5 PL 2

16 812624 WASHER 0.250 FLAT BS PL 2

17 84048 WASHER 0.500 FLAT SAE BS PL 42

18 948077 NUT HEX JAM 0.500NC GR2PL 2

19 81922 NUT LOCK (NYLON) 0.25NC GR B PL 12

20 813663 NUT LOCK (STEEL) 0.500NC X 1.50 GRC PL 38

21 814196 LAMP-AG/DUAL/LH/4-WAY WP 1

22 814195 LAMP-AG/DUAL/RH/4-WAY WP 1

23 813547 SET SCREW SQHDCUP 0.500 NC 2

24 967075 SMV SPADE MOUNT 1

25 967066 SMV SIGN 1

1500 Bale Carrier

28

Page 31

bühler

NOTE PAGE

1500 Bale Carrier

29

Page 32

bühler

APPENDIX B

Hydraulic Assembly

1500 Bale Carrier

NOTE: 1)

left sides. Only one side of each component is shown in this manual.

2) Seal Kits and Service Parts are only listed in the parts lists and are not indicated on

the illustrations.

Table of Contents

Description Page

Carrier Hydraulic Assembly Schematic (Standard Configuration). …………… 31

Valve Bank Assembly………….….……………………………………….….... 33

FPS Directional Valve Bank Assembly……………………………………... 35

Series Parallel Valve (Low and High Speed)………………………………. 36

Hydraulic Return Line Assembly……………………………………………….. 37

Hydraulic Pressure Line Assembly…………………………………………... 38

Carrier Tilt Assembly…………………………………………………………….. 39

Carrier Tilt Cylinders Hydraulic 3/8 line………………………………………... 40

Fixed Pick Up Cylinder Assembly……………………………………………… 41

Pusher Motor Assembly…………………………………………………………. 42

Carrier Hydraulic Assembly Hardware………………………………………… 43

Fixed Pick Up Arm Hydraulic Assembly Schematic…………………………….. 44

RPU Hydraulic Assembly…………………………………………………………... 45

RPU Squeeze Cylinder………………………………………………………….. 46

RPU Lift Cylinder…………………………………………………………………. 47

Pilot Check Valve Assembly…………………………………………………. 48

RPU Rotate Cylinder…………………………………………………………….. 49

Open-Center Configuration Schematic…………………………………………… 50

Open-Center Valve………………….…………………………………………… 51

1500 Bale Carrier Hydraulic Schematic………………………………………….. 53

Hydraulic Assembly methods and layouts are common to the right and

30

Page 33

bühler

Carrier Hydraulic Assembly Schematic (Part # A8000-04)

Standard Configuration

TO TRACTOR COUPLER

(RETRACT)

TO TRACTOR COUPLER

(EXTEND)

1500 Bale Carrier

TO TRACTOR COUPLER

(EXTEND)

TO TRACTOR COUPLER

(RETRACT)

31

Page 34

bühler

Carrier Hydraulic Assembly (Part # A8000-04)

Standard Configuration

Item Component

Part #

1 A8002-01 1500 BALE CARRIER VALVE BANK ASSEMBLY 1

2 A7010-00 HYD ASSY 1/2 X 130 RETURN LINE 1

3 A7011-00 HYD ASSY 1/2 X 130 PRESSURE LINE 1

4 A8012-00 TILT CYLINDER ASSY 3 X 10 PIN EYED 1

5 A8013-00 TILT CYLI ASSY HYD 3/8 HOSE 2

6 A7013-00 TILT ASSY LIFT ARM CYLINDER 1

7 A8011-00 MOTOR MT ASSY 1500 BALE CARRIER 22.2 CU 1

8 115001 HOSE 1/2 X 24 3/4 SWFJIC X 7/8 4

9 812176 HOSE 3/8 X 96 9/16 SWF X JIC 2

10 29105 HOSE 1/2 X 28 3/4 SWFJIC 4

11 886704 ADAPTOR STR 3/4 MJIC 1

1500 Bale Carrier

Description Qty

32

Page 35

bühler

Valve Bank Assembly (Part # A8002-01)

(**) To be used only with OPEN-CENTER Configuration.

33

1500 Bale Carrier

**

Page 36

bühler

Item Component

10 812080 ADAPTOR STR 3/4 MORB X 3/4 MJIC 3

11 810582 BOLT HEX 0.313NC X 3.00 GR5PL 4

1500 Bale Carrier

Valve Bank Assembly (Part # A8002-01)

Description Qty

Part #

1 C8013-00 VALVE BANK MOUNT WELDMENT 1

2 B7010-00 SERIES/PARALLEL VALVE (2-SPEED) 2

3 B8008-00 VALVE ASSY FPS DIRECTIONAL 1

4 E2781-00 FLOW RESTRICTOR 1

5 81549 BOLT HEX 0.313NC X 0.75 GR5PL 4

6 812362 NUT LOCK (STEEL) 0.313NC GRBPL 8

7 813667 TEE RUN 1/2 MJIC X 3/4 MORB 3

8 811916 ELBOW 90 3/4 MORB X 9/16 MJIC 2

9 811414 ELBOW 90 3/4 MORB X 3/4 MJIC 4

34

Page 37

bühler

FPS Directional Valve Assembly (Part # B8008-00)

1

2450 PSI PLUG

FACING FORWARD

1500 Bale Carrier

5

2

4

NOTE: THE SECOND ITEM

4 IS NOT VISIBLE BUT IS

ON THE OPPOSITE SIDE IN

THE POSITION OF THE

OPEN HOLE IN THIS VIEW

3

B8008-00 FPS Valve Service Parts

Item Compone

nt

Part #

1 22208-01 MV4-17 SPOOL SECTION 2

2 22149 CROSS OVER RELIEF VALVE BALE CARRIER SET 2400 1

3 222083-03 C07-12TD COIL 4

4 812081 PLUG 3/4 MORB STL 2

5 22208-02 MV4-A LOCK VALVE 1

6 X2684 SEAL KIT VALVE BANK (ITEM NOT VISIBLE) 2

Description Qty

35

Page 38

bühler

Series/Parallel Valve Low and High Speed (Part # B7010-00)

2

1

1500 Bale Carrier

B7010-00 Parallel Valve Service Parts

Item Component

Part #

1 22083-03 C07-12TD COIL 1

2 22083-01 SERIES/PARALLEL VALVE (LOW &HIGH SPEED) 1

3 X2684 SEAL KIT VALVE BANK (ITEM NOT VISIBLE) 1

Description Qty

36

Page 39

bühler

Hydraulic Return Line Assembly (Part # A7010-00)

1

1500 Bale Carrier

3

5

2

4

Item Component

Part #

1 29170 HOSE 1/2 X 130 3/4 MORB X 3/4 1

2 812841 MALE TIP 0.5 BODY 0.75 ORB 1

3 813119 ADAPTOR STR 3/4 MORB X 3/4 MORB 1

4 813305 DUST CAP 0.5 BLACK 1

5 813666 VALVE CHECK 3/4 ORB LINE 1

Description Qty

37

Page 40

bühler

Hydraulic Pressure Line Assembly (Part # A7011-00)

1

1500 Bale Carrier

2

3

Item Component

Part #

1 29170 HOSE 1/2 X 130 3/4 MORB X 3/4 1

2 812841 MALE TIP 0.5 BODY 0.75 ORB 1

3 813305 DUST CAP 0.5 BLACK 1

Description Qty

38

Page 41

bühler

Carrier Tilt Cylinder Assembly (Part # A8012-00)

1

1500 Bale Carrier

2

Item Component

Part #

1 813640 ELBOW 90 9/16 MORB ADJ 9/16 MJIC 2

2 24895 CYLINDER 3.0 DIA X 10 PIN EYED W / RESTRICTOR 1

24895 Cylinder 3.0 Diameter Service Parts

Component

Part #

812655 LOCKNUT 0.875 NF 1

X2353 SEAL KIT FOR ITEM 24895 1

24899 TUBE WELDMENT 3.0 DIA 1

115288 SHAFT WELDMENT 1.25 X 16.75 LG 1

24897 HEADPLATE 3.0 X 1.250 ROD 1

Description Qty

Description Qty

39

Page 42

bühler

Carrier Tilt Cylinders Hydraulic 3/8 Line (Part # A8013-00)

1

1500 Bale Carrier

3

2

Item Component

Part #

1 29174 HOSE 3/8 X 168 9/16 SWFJIC X 3/4RB 1

2 812841 MALE TIP 0.5 BODY 0.75 ORB 1

3 813303 DUST CAP 0.5 RED 1

Description Qty

40

Page 43

bühler

Fixed Pick Up Cylinder Assembly (Part # A7013-00)

TO LIFT PORT ON MAIN VALVE BANK (FRONT PORT)

USE 3/8 X 96" HOSE SUPPLIED WITH MAIN FRAME

TO LIFT PORT ON VALVE BANK (REAR PORT)

USE 3/8 X 96" HOSE SUPPLIED WITH MAIN FRAME

3

1500 Bale Carrier

1

Item Component

Part #

1 813640 ELBOW 90 9/16 MORB ADJ 9/16 MJIC 1

2 22510 CYLINDER 3.0 DIA X 16 INLAND 1

3 E2872-00 ELBOW RESTRICTOR MALE 90° 1

22510 Cylinder 3.0 Diameter Service Parts

Component

Part #

813407 LOCKNUT 1.00 NF 1

X2504 SEAL KIT FOR ITEM 22510 1

24957 TUBE WELDMENT 3.0 DIA 1

115519 SHAFT WELDMENT 1.50 X 22.63 1

24598 HEAD PLATE 3.0 X 1.50 1

2

Description Qty

Description Qty

41

Page 44

bühler

Pusher Motor Assembly (Part # A8011-00)

6

7

1500 Bale Carrier

4

1

8

2

Item Component

Part #

1 C7031-00 SPROCKET DRIVE WELDMENT 1

2 C7030-00 MOTOR 22.2 CU MT WELDT 1

3 C2768-00 SPROCKET ADJUSTING BOLT FRONT 1NC 1

4 967275 BOLT HEX 0.500 NC X 2.00 GR8PL 4

5 84051 NUT HEX JAM 1.00 NC GR2 1

6 84048 WASHER 0.500 FLAT SAE BS PL 4

7 813663 NUT LOCK (STEEL) 0.500 NC GRCPL 4

8 B2799-00 MOTOR 22.2 CU PAINT YELLOW 2

B2799-00 Motor Service Parts

Component

Part #

X2725 SEAL KIT FOR B2799-00 1

5

Description Qty

Description Qty

3

42

Page 45

bühler

Carrier Hydraulic Assembly Hardware (Part # A8000-04)

5

1

1

3

2

1

1500 Bale Carrier

3

4

3

3

Note: Open-Center Valve is not shown

Item Component

Part #

1 811795 BOLT HEX 0.375 NC X 2.00 GR5PL 3

2 E2345-00 CYL PIN 1 DIA X 4.5 1

3 812363 NUT LOCK (STEEL) 0.375 NC GRBPL 7

4 84072 BOLT HEX 0.375 NC X 0.75 GR5PL 4

5 E1932-00 CYL PIN 1 DIA X 5 9/16 C1045 2

5

Description Qty

43

Page 46

bühler

SCHEMATIC THAT ARE MARKED WITH A "*"

1500 Bale Carrier

Fixed Pick Up Arm Hydraulic Assembly Schematic (Part # A2300-87)

A2300-87

FRONT OF

CARRIER

*812176

*812176

*A7013-00

Note: Open-Center Valve is not shown

*A8002-01

NOTES: 1) ALL ITEMS IN THE HYDRAULIC

ARE SUPPLIED ON THE MAIN FRAME

ASSEMBLY.

2) LOOP ALL HOSES THROUGH

APPROPRIATE HOSE HOLSTERS AND TIE

WRAP.

3) DURING FIRST USE CHECK FOR

CLEARANCE AND BINDING.

44

Page 47

bühler

Hydraulic RPU Assembly Schematic (Part # A2400-32) (Optional)

R3

R6

1500 Bale Carrier

R1 (*812176)

DETAIL A

R5

R2

R3 (IN29074)

(812176)

R2 (*812176)

R6

R4

A

B

R4 (IN29067)

R5 (29150)

CARRIER

FRONT OF

R1

R5

R6

DETAIL B

ARE SUPPLIED ON THE MAIN FRAME.

2) LOOP ALL HOSES THROUGH APPROPRIATE

SCHEMATIC CORRESPOND WITH THE PORTS

NOTES: 1) THE LABELLED LINES IN THE

REPRESENT THE PART NUMBER.

IN DETAIL VIEWS A AND B. BRACKETS

4) ALL ITEMS THAT ARE MARKED WITH A "*"

3) CHECK FOR HOSE CLEARANCE AND

BINDING DURING FIRST USE.

HOSE HOLSTERS AND TIE WRAP.

Note: Open-Center Valve is not shown

45

Page 48

bühler

RPU Squeeze Cylinder (Part # A2400-35)

1500 Bale Carrier

5

TO ROTATE CYLINDER ROD END

9/16 TEE OPEN END THAT POINTS IN

THE DIRECTION OF CYLINDER EXTENSION

2

1

TO ROTATE CYLINDER BASE END

9/16 TEE OPEN END

Item Component

Part #

1 IN29074 HOSE 3/8 X 60 9/16 SWFJIC 1

2 813640 ELBOW 90 9/16 MORB ADJ X 3/8 1

3 IN29067 HOSE 3/8 X 68 9/16 SWFJIC 1

4 24367 CYLINDER 2.0 X 18.0 INLAND 1

5 813640 ELBOW 90° 9/16 MORB ADJ X 3/8 2

24367 Cylinder 2.0 Diameter Service Parts

Component

Part #

811843 NOT GREASE NIPPLE 90 DEGREES 1

X1348 SEAL KIT FOR 24367 2.0 DIA CYLINDER 1

83224 BACKUP WASHER 1.75 ID X 2.00 OD 1

812655 0.875 UNF LOCKNUT 1

114521 2.00 DIA PISTON HALF (NARROW) 1

114520 2.00 DIA PISTON HALF (WIDE) 1

24366 2.00 DIA TUBE WELDMENT 1

115042 SHAFT WELDMENT 1.25 DIA X 24.125 LG 1

24516 2.00 DIA HEAD PLATE 1

3

4

Description Qty

Description Qty

46

Page 49

bühler

1500 Bale Carrier

RPU Lift Cylinder (Part # A2400-37 Assembled To Existing 22510 Cylinder)

3

2

1

TO SEQUENCE VALVE (PORT #2)

USE EXISTING 3/8 X 108 HOSE SUPPLIED

WITH ROTATE CYLINDER ASSEMBLY

TO ROTATE CYLINDER BASE END

USE 3/8 X 96 HOSE SUPPLIED WITH

ROTATE CYLINDER ASSEMBLY

Item Component

Part #

1 22510 CYLINDER 3.0 DIA X 16 INLAND 1

2 E2872-00 RESTRICTOR ELBOW MALE 90° 1

3 A2400-37 PILOT CHECK VALVE ASSEMBLY 1

22510 Cylinder 3.0 Diameter Service Parts

Component

Part #

813407 LOCKNUT 1.00 NF 1

X2504 SEAL KIT FOR ITEM 22510 1

24957 TUBE WELDMENT 3.0 DIA 1

115519 SHAFT WELDMENT 1.50 X 22.63 1

24598 HEAD PLATE 3.0 X 1.50 1

SIDE PUMP

PORT (FREE

FLOW IN)

Description Qty

CYLINDER PORT

(CHECKED FLOW IN)

PILOT PORT

TO LIFT LOWER PORT ON MAIN VALVE

(FRONT PORT) USE EXISTING 3/8 X 96

HOSE SUPPLIED WITH MAIN FRAME

Description Qty

47

Page 50

bühler

Pilot Check Valve Assembly (Part # A2400-37)

1

1500 Bale Carrier

3

2

6

Item Component

Part #

1 IN29098 HOSE 3/8 X 14 3/8 FNPT X 9/16 SWFJIC 1

2 29043 ADAPTOR STR 9/16 MJIC X 3/8 MNPT 1

3 22203 PILOT CHECK VALVE PC-37 1

4 29020 CONNECTOR 9/16 MJIC X 1/4 MNPT 1

5 29023 TEE 1/4 FNPT RUN X 1/4 MNPT 1

6 29039 ADAPTOR STR 1/4 MNPT X 9/16 FJIC 1

7 29015 TEE 9/16 MJIC RUN X 9/16 MORB 1

Description Qty

4

5

7

48

Page 51

bühler

COUNTER CLOCKWISE ADJUSTMENT

RPU Rotate Cylinder (Part # A2400-36)

NOTES: 1) REMOVE TIE ROD

SUPPLIED BY MANUFACTURER AND

REPLACE WITH MANUFACTURED TIE

ROD (ITEM 16). USE NEW ROD TO

MOUNT SEQUENCE VALVE HOLDER

(ITEM 15).

TO LIFT CYLINDER PILOT

CHECK VALVE "SIDE"

PUMP PORT

1

2

1500 Bale Carrier

3

4

8

2

3

1

FLOW CONTROL

CLOCKWISE ADJUSTMENT

-INCREASES LIFT

-DECREASES ROTATE

5

6

-INCREASES ROTATE

-DECREASES LIFT

TO SQUEEZE CYLINDER ROD END

USE 3/8 X 68 HOSE SUPPLIED WITH

SQUEEZE CYLINDER ASSEMBLY

7

13

12

15

TO LIFT CYLINDER ROD END USE

9/16 MJIC TEE FOR CONNECTION

16

"BOTTOM ISOMETRIC VIEW"

14

TO SQUEEZE CYLINDER BASE END

USE 3/8 X 60 HOSE SUPPLIED WITH

SQUEEZE CYLINDER ASSEMBLY

10

Item Component

Part #

1 29150 HOSE 3/8 X 108 9/16 SWFJIC X 3 1

2 29149 RESTRICTOR ONE WAY ADJ PARKER 1

3 22060 3 X 8 TIE ROD CYLINDER 1

4 29016 ELBOW 90 1/4 MNPT X 9/16 MJIC 1

5 20877 PRESSURE LINE / SEQUENCE TUBE 1

6 811631 BOLT HEX JAM 0.500 NC GR2PL 2

7 29015 TEE 9/16 MJIC RUN X 9/16 MJIC 3

8 29022 ELBOW 90 1/4 MNPT X 9/16 MORB 1

9 22075 SUN SEQUENCE VALVE SET 1800 psi 1

10 984077 NUT HEX JAM 0.500 NC GR2PL 1

11 29047 ELBOW 90 9/16 MORB X 3/8 MJIC LG 1

12 813691 SEQUENCE VALVE VENT TUBE 1

13 887572 TEE 9/16 MJIC X 9/16 SWFJIC 1

14 E2430-00 SEQUENCE VALVE HOLDER 1

15 812176 HOSE 3/8 X 96 9/16 SWFJIC X 3 1

16 E2478-00 HYDRAULIC CYLINDER TIE ROD 1

22060 Cylinder 3.0 Diameter Service Parts

Component

Part #

22060-02 SEAL KIT FOR 22060 CYLINDER 1

11

SEQUENCE VALVE

THAT CONTROLS

THE LIFT AND

ROTATION ACTION.

TO LIFT RAISE PORT ON MAIN VALVE

9

(REAR PORT) USE BASE END LIFT CYLINDER

3/8 X 96 HOSE SUPPLIED WITH MAIN FRAME

ASSEMBLY

Description Qty

Description Qty

49

Page 52

bühler

Open-Center Configuration Schematic

TO TRACTOR

TO TRACTOR

COUPLER (RETURN)

COUPLER (EXTEND)

1500 Bale Carrier

A7011-00

A7010-00

29105

813667

29105

A8002-00

50

Page 53

bühler

Open-Center Valve (Part # A7016-00)

Open-Center Configuration

1500 Bale Carrier

51

Page 54

bühler

Open-Center Valve (Part # A7016-00)

Open-Center Configuration

Item Component

Part #

1 B7010 SERIES/PARALLEL VALVE 1

2 812081 PLUG 3/4 MORB STL 721-FS0-08 3

3 812080 ADAPTOR STR 3/4 MORB X 3/4 MJIC 1

4 811414 ELBOW 90 3/4 MORB X 3/4 MJIC 1

5 813667 TEE RUN 3/4 MJIC X 3/4 MORB 1

6 29105 HOSE 1/2 X 28 - 3/4 SWFJIC 2

B7010-00 Parallel Valve Service Parts

Component

Part #

22083-03 C07-12TD COIL 1

22083-01 SERIES PARALLEL VALVE (LOW &HIGH SPEED) 1

X2684 SEAL KIT VALVE BANK 1

1500 Bale Carrier

Description Qty

Description Qty

52

Page 55

bühler

1500 Bale Carrier Hydraulic Schematic

1500 Bale Carrier

53

Page 56

bühler

NOTES PAGE

1500 Bale Carrier

54

Page 57

bühler

APPENDIX C

Electrical Assembly

1500 Bale Carrier

WARNING

Bale Carrier operator manual. Shut off all power to unit before inspecting, servicing,

adjusting or repairing the 1500 Bale Carrier.

WARNING

to the RED power wire from the control handle. Ensure that there is a 15-amp fuse in

place to protect this circuit. Verify prior to installing Snubber. Incorrect wiring will result

in electrical failure.

NOTE:

The snubber minimizes coil voltage discharge during the de-energizing of the valve

solenoid coils. There are no serviceable parts within the unit. Ensure that all electrical

connections are clean and dry. Test the 1500 Bale Carrier and view to see if the

hydraulic system is operating correctly. If any wires are damaged or cut, the schematic

on the next page will assist in repair and maintenance. All wire is 18 gage.

Table of Contents

Description Page

Electrical Schematic………………………………………………………………... 56

Electrical Assembly ………………………………………………………………… 57

The snubber unit is designed to protect the momentary control switches.

Read and understand the safety messages listed in the 1500

For proper operation of the Snubber, power must be supplied

55

Page 58

bühler

Electrical Schematic

NOTE: VALVE HARNESS (1) TERMINATES

WITH THE FEMALE SPADE CONNECTORS

TO MATCH THE SOLENOID COIL.

1500 Bale Carrier

2

PUSHER BACK 7 - BROWN

4

ARM UP 2 - TAN

PUSHER FWD. 6-BLUE

ARM DN. 4-PINK

5

LOW SPEED 1 - BLACK

OPEN CENTER 5-ORANGE

GROUND 12- GREEN

LOW SPEED 1-BLACK

PUSHER FWD. 6-BLUE

PUSHER BACK 7-BROWN

ARM DN. 4-PINK

ARM UP 2-TAN

POWER 3-RED

OPEN CENTER 5-ORANGE

15 AMP FUSE

POWER 3-RED

GROUND 12- GREEN

1

3

END VIEW CONNECTOR

POWER 3-RED

GROUND 12- GREEN

FRONT OF HAYLINER

2b

2

2a

2b22a

1

1b

1a

1b 1

1a

25

24

11

12

Item Component

Part #

1 A8018-02 MACHINE HARNESS 1500 BALE CARRIER 1

2 813949 SNUBBER UNIT 1

3 I20024 CONTROL HANDLE HARNESS ASSY 1500 1

4 A8002-01 VALVE BANK ASSEMBLY 1500 BALE CARRIER 1

5 A7016-00 OPTIONAL OPEN CENTER KIT 1

56

Description Qty

Page 59

bühler

Control Handle Assembly (Part # I20024)

1500 Bale Carrier

Item Component

Part #

1 INE22105-01 WIRE CLAMP PLATE 1

2 22105 CONTROL HANDLE 1

3 813539 8-32 X 3/8 TRUSS HEAD MACHINE SCREW 4

4 813540 8-32 X 1/2 ROUND HEAD MACHINE SCREW 2

5 814445 ROCKER SWITCH ON/OFF/ON MOMENTARY 2

6 813779 ROCKER SWITCH ON / OFF 1

7 I100016 SWITCH COVER PLATE - 1500 1

8 814448 DECAL BUHLER 1500 1

57

Description Qty

Page 60

bühler

NOTES PAGE

1500 Bale Carrier

58

Page 61

bühler

1500 Bale Carrier

APPENDIX D

General Assembly

Table of Contents

Description Page

Carrier Final Assembly…………………..…………………………………………. 60

Carrier Initial Assembly……………………………………………………….……. 62

Tandem Axle Assembly…………………………………………………………. 64

Tandem Axle / 1500………………………………………………………….. 65

Tire Assembly………………………………………………………………. 66

Tandem Axle Assembly…………………………………………………… 67

Hub Assembly……..……………………………………………………. 68

Pusher Assembly………………………………………………………………… 69

Bale Stop Bundle………………………………………………………………… 70

Roller / Chain Guide Assembly…………………………………………………. 71

Fixed Pick Up Arm Assembly……………………………………………………… 72

Bale Deflector Assembly.……………………….……………………….……….. 74

RPU Assembly……………………………….……………………………………. 76

59

Page 62

bühler

Carrier Final Assembly (Part # A8000-04)

2

28

5

24

A-A

DETAIL AA

1500 Bale Carrier

19

29

4

37

32

36

3533 34

22 26

3122 27

1

7

15

16

13

9

23

12

6

18

AMBER LAMP TO

THE OUTSIDE

TO THE INSIDE

RED LAMP

AMBER LAMP TO

THE OUTSIDE

25

20

30

17

10

3

MAIN ELECTRICAL HARNESS

11

14

8

AS VIEWED FROM BACK OF TRAILER

60

Page 63

bühler

Carrier Final Assembly (Part # A8000-04)

Item Component

Part #

1 A7006-00 PUSHER ASSEMBLY 1

2 A7008-00 CHAIN GUIDE ROLLER ASSEMBLY 1

3 A8011-00 MOTOR MOUNT ASSEMBLY 1

4 B2363-00 HOSE HOLDER 1

5 E2345-00 CYL PIN / 1.0" X 4 1/4" 1

6 E2413-00 ARM CUSHION 1

7 E2937-00 PLATE 1500/2500 LIGHTING KIT 1

8 E7038-00 MOUNTING BRACKET / SHIELD 1

9 E7040-00 CUSHION / PUSHER STOP 1

10 INE7039-00 SHIELD / CHAIN DRIVE 1

11 813949 SNUBBER UNIT 1500/2500 BALE CARRIER 1

12 813643 C2080H CONNECTOR LINK HD 2

13 52955-456 C2080H ROLLER CHAIN 76’

14 81620 CAPSCREW 0.500NC X 1.250 GR 5 ZPL 1

15 814193 ENHANCED AG LIGHTING MODULE 1

16 814199 EXTENSION HARNESS 27” LONG 1

17 814198 MAIN HARNESS 48 FT LONG 7 PIN PLUG 1

18 813602 RIVET 1/4" X 3/4" FLHD 2

19 814434 SAFETY CHAIN 20M GVW 1

20 813958 SCREW MACH #8-32X 0.75 6

21 99053 SLIP PLATE BEAM COATING (ITEM NOT VISBLE) 1 QT.

22 81549 BOLT HEX 0.313NC X 0.75GR5 PL 6

23 81552 BOLT HEX 0.313NC X 1.25GR5 PL 2

24 811795 BOLT HEX 0.375NC X 2.00GR5 PL 1

25 812537 NUT LOCK (NYLOCK) #8-32 STEEL 6

26 84541 NUT LOCK (NYLON) 0.313NC GR8PL 4

27 812362 NUT LOCK (STEEL) 0.313NC GR8PL 4

28 812363 NUT LOCK (STEEL) 0.375NC GR8PL 1

29 812364 NUT LOCK (STEEL) 1/2" NC GR. 8 ZPL. 1

30 813581 WASHER FLAT 0.5X0.531X0.25 PL 1

31 81570 WASHER FLAT STD 0.375 HS PL 4

32 81546 WASHER 0.313 FLAT STD HS PL 1

33 909277 MANUAL HOLDER 1

34 46912 OPERATOR’S & PARTS MANUAL 1

35 814433 WARRANTY REGISTRATION SHEET 1

36 814449 GOODYEAR TIRE WORKMANSHIP WARRANTY

(700-862-905-128)

37 814450 GOODYEAR TIRE STUBBLE WARRANTY

(700-862-905-129)

1500 Bale Carrier

Description Qty

1

1

61

Page 64

bühler

Carrier Initial Assembly (Part # A8000-04)

1500 Bale Carrier

25 24

25

7

14

2

23

26

18

11

19

18

21

16

18

19

13

13

10

18

9

20

1

8

13

18

18

3

18

4

22

26

17

19

18

5

23

26

18

19

18

6

22

26

17

12

23

15

62

Page 65

bühler

Carrier Initial Assembly (Part # A8000-04)

Item Component

PART #

1 C2369-00 HITCH 1

2 C7055-00 OUTER CARRIER BEAM 2

3 C7057-01 CHAIN GUIDE WELDMENT 1

4 C8003-01 SUBFRAME 1

5 C8004-01 REAR CROSSMEMBER 1

6 C8010-00 SAFETY CHAIN WELD'T 1

7 C8014-00 L.H. HITCH BEAM 1

8 C8015-00 R.H. HITCH BEAM 1

9 C8016-00 HITCH CROSSMEMBER WELDT 1

10 C8017-01 FRONT CROSSMEMBER 1

11 E2445-00 LIFT ARM PIN 2

12 INE7003-01 REAR CHAIN CROSSMEMBER 1

13 813646 GREASE FITTING 0.250NF DRIVEN 4

14 813647 SCREW JACK 3.50 TON 1

15 812288 BOLT CARR 0.500NC X 1.25GR5 ZPL 4

16 81581 BOLT HEX 0.375NC X 2.50GR5 PL 2

17 81620 BOLT HEX 0.500NC X 1.25GR5 PL 16

18 967274 BOLT HEX 0.500NC X 1.50GR8 PL 78

19 967275 BOLT HEX 0.500NC X 2.00GR8 ZPL. 16

20 813515 BOLT HEX 0.750NC X 2.50GR8 PL 4

21 812363 NUT LOCK (STEEL) 0.375NC GR8 PL 4

22 812364 NUT LOCK (STEEL) 0.500NC GR8 PL 16

23 813663 NUT LOCK (STEEL) 0.500NC GR8 PL 98

24 813648 NUT LOCK (STEEL) 0.750NC GR8 PL 4

25 813590 WASHER FLAT 1.25X0.781X0.25 PL 8

26 84048 WASHER FLAT SAE 0.500 BS PL 110

1500 Bale Carrier

Description Qty

63

Page 66

bühler

Complete Tandem Axle Assembly

1

1500 Bale Carrier

3

2

4

5

Item Component

Part #

1 C8005-00 AXLE BEAM WELDMENT 1

2 984077 NUT HEX JAM 0.500NC GR2 PL 2

3 813547 SETSCREW SQHDCUP 0.500 NC 2

4 C2407-00 TANDEM AXLE / 1500 LOCATOR WELDMENT 2

5 B2400-14 AXLE ASSEMBLY 2

Description Qty

64

Page 67

bühler

Tandem Axle / 1500 (A2400-14)

1500 Bale Carrier

1

2

Item Component

Part #

1 B2700-03 TIRE ASSEMBLY 1500 / 2500 BALE CARRIER 2

2 B2400-14 TANDEM AXLE 1500 / HUB ASSEMBLY 1

Description Qty

65

Page 68

bühler

Tire Assembly (Part # B2700-03)

1

1500 Bale Carrier

3

2

Item Component

Part #

1 813655 15 X 10lb X 6 BOLT P65 RIM 4

2 813656 TR-416-MS VALVE STEM WITH CAP 4

3 813657 TIRE 12.5 X 15FI 12 PLY RANGE F FARM HWY TIRE 4

Description Qty

66

Page 69

bühler

Tandem Axle Assembly (Part # B2400-14)

7

1500 Bale Carrier

7

1

3

2

4

8

6

5

Item Component

Part #

1 C2406-00 TANDEM AXLE 1500 WELDMENT 1

2 C2339-00 HUB ASSEMBLY 2

3 813649 DUST SHIELD 2

4 81206 3/16" X 1-1/2 " COTTER PIN BLACK 2

5 813673 NUT CASTLE 1.00 NF 2

6 813650 DUST CAP 2

7 813646 GREASE FITTING 1/4 DRIVEN 4

8 813651 WASHER FLAT 1-1/32" X 2" X .188" BLK. 2

Description Qty

67

Page 70

bühler

Hub Assembly (Part # C2339-00)

1500 Bale Carrier

2

5

1

3

Item Component

Part #

1 813652 6 BOLT WHEEL HUB 1

2 967205 BEARING CONE OUTER 1

3 967208 BEARING CONE INNER 1

4 967204 OIL SEAL SAE-30 1

5 813653 9/16" HUB BOLT 6

Description Qty

4

68

Page 71

bühler

Pusher Assembly (Part # A7006-00)

1500 Bale Carrier

1

4

3

2

7

5

3

4

4

5

2

NOTE: USE LOCKTITE ON ALL

BRASS SCREWS

6

4

Item Component

Description Qty

Part #

1 C7027-00 PUSHER 1

2 E2749-00 TOP SLIDER 2

3 E2750-00 SIDE SLIDER 2

4 813558 SCREW MACH M8 X 20 FLHD BRASS 16

5 813561 NUT HEX M8 BRASS 16

6 E7032-00 CENTER SLIDER 1

7 813644 SCREW MACH 0.313NC X 1.25 RDHD 4

69

Page 72

bühler

Bale Stop Bundle (Part # A8003-00)

1500 Bale Carrier

3

1

3

2

4

Item Component

Description Qty

Part #

1 C8009-00 BALE RETAINER WELDT 1

2 84048 WASHER 0.500 FLAT SAE BS PL 2

3 84277 BOLT HEX 0.500 NC X 1.50 GR5 PL 2

4 812364 NUT LOCK (STEEL) 0.500 NC GRBPL 2

70

Page 73

bühler

Roller / Chain Guide Assembly (Part # A7008-00)

1

2

1500 Bale Carrier

1

Item Component

Part #

1 813645 BEARING / 6205LLU/25.4/3E 2

2 INE7037-00 ROLLER / CHAIN GUIDE 1

Description Qty

71

Page 74

bühler

Fixed Pick Up Arm Assembly RH Side (Part # A2300-87)

7

2

5

7

7

1500 Bale Carrier

5

7

8

6

14

1

11

10

ITEM 3 NOT VISIBLE

2

13

6

9

4

13

12

3

72

Page 75

bühler

Fixed Pick Up Arm Assembly RH Side (Part # A2300-87)

Item Component

Part #

1 811795 BOLT HEX 0.375 NC X 2.00 GR5 PL 1

2 812087 BOLT HEX 0.625 NC X 6.00 GR8 PL 4

3 812363 NUT LOCK (STEEL) 0.375 NC GR8 PL 3

4 812364 NUT LOCK (STEEL) 0.500 NC GR5 PL 1

5 813509 NUT HEX 0.625 NC GR5 PL 4

6 81581 BOLT HEX 0.375 NC X 2.50 GR5 PL 2

7 81677 WASHER LOCK 0.625 PL 4

8 84277 BOLT HEX 0.500 NC X 1.50 GR5 PL 1

9 C2316-00 LIFT ARM RIGHT BALE 1

10 C2329-00 FORK BALE LEFT ASSEMBLY 1

11 C2330-00 FORK BALE RIGHT ASSEMBLY 1

12 E2345-00 PIN CYLINDER 1.0 DIA X 4.5 1

13 E2445-00 PIN LIFT ARM 1.25 DIA C1045 CR 2

14 INE2485-00 CHAIN LATCH LIFT ARM 1

Description Qty

1500 Bale Carrier

73

Page 76

bühler