Buhler BA 4000 Inj. GV, BA 4000 Inj. KV, 55 11 399, 55 11 3991 Installation And Operation Instructions Manual

Analysentechnik

Installation and Operation Instructions

Original instructions

Portable Oxygen Analyser

BA 4000 Inj.

BE550004

07/2016-2

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

E-Mail: analyse@buehler-technologies.com

Internet: www.buehler-technologies.com

Bühler Technologies GmbH, Harkortstr. 29, D-40880 Ratingen

Tel. +49 (0) 21 02 / 49 89-0, Fax: +49 (0) 21 02 / 49 89-20

Internet: www.buehler-technologies.com

E-Mail: analyse@buehler-technologies.com

Read this instruction carefully prior to installation and/or use. Pay attention particularly to all advises and safety instructions to prevent injuries. Bühler Technologies can not be held responsible for misusing

the product or unreliable function due to unauthorised modifications.

All rights reserved. Bühler Technologies GmbH 2017

Document information

Document No..........................................................BE550004

Version......................................................................07/2016-2

BA 4000 Inj.

Contents

1 Introduction..................................................................................................................................................................................................................... 2

1.1 Intended Use......................................................................................................................................................................................................... 2

1.2 Design types.......................................................................................................................................................................................................... 2

1.3 Ordering instructions ........................................................................................................................................................................................ 2

1.4 Functional principle ...........................................................................................................................................................................................2

1.5 Scope of delivery ..................................................................................................................................................................................................2

2 Safety instructions......................................................................................................................................................................................................... 3

2.1 Important notices................................................................................................................................................................................................ 3

2.2 General hazard warnings .................................................................................................................................................................................4

3 Transport and storage .................................................................................................................................................................................................. 5

4 Installation and connection........................................................................................................................................................................................6

4.1 Installation site requirements.........................................................................................................................................................................6

4.2 Electrical connections ........................................................................................................................................................................................6

4.3 Sample gas supply ..............................................................................................................................................................................................6

4.4 Gas connections................................................................................................................................................................................................... 7

5 Operation and Control.................................................................................................................................................................................................. 8

5.1 Calibration............................................................................................................................................................................................................. 8

5.1.1 Test gases for calibration .................................................................................................................................................................. 9

5.1.2 Calibration for BA 4000 Inj. GV ....................................................................................................................................................... 9

5.1.3 Calibration for BA 4000 Inj. KV.......................................................................................................................................................10

5.1.4 Carrier gas influence (cross-sensitivity).......................................................................................................................................10

5.2 Notes on operating the BA 4000 Inj. KV/D with pressure gauge (optional) ................................................................................... 10

5.3 Performing the measurement ....................................................................................................................................................................... 11

6 Service...............................................................................................................................................................................................................................12

6.1 Replacing the rechargeable battery............................................................................................................................................................. 12

7 Service and repair..........................................................................................................................................................................................................13

7.1 Troubleshooting .................................................................................................................................................................................................13

7.2 Spare parts and accessories ............................................................................................................................................................................13

8 Disposal............................................................................................................................................................................................................................15

9 Appendix......................................................................................................................................................................................................................... 16

9.1 Technical Data ....................................................................................................................................................................................................16

9.2 Puncture devices ................................................................................................................................................................................................17

9.3 Flow charts ...........................................................................................................................................................................................................17

10 Attached documents................................................................................................................................................................................................... 18

iBühler Technologies GmbHBE550004 ◦ 07/2016-2

BA 4000 Inj.

1 Introduction

1.1 Intended Use

The portable BA 4000 Inj. Bühler O2 analyser is a special unit for determining oxygen in low gas volumes.

This analyser is a modification of the BA4000, primarily used in the food industry to analyse small residual amounts in modified atmosphere packaging, bottles or tins. The O2 content in insulating glass panes can also be determined. There are 2 versions.

The device

must not be used

– To analyse combustible, inflammable or explosive gas mixtures,

– In explosive areas and

– For applications where equipment failure or malfunction puts persons in immediate danger.

1.2 Design types

The

BA 4000 Inj. GV

is used for volumes > 35 ml. The duration of the internal sample gas pump can optionally be controlled us-

ing an adjustable timing relay.

The

BA 4000 Inj. KV

is used for gas volumes < 35 ml. This analyser is operated by a vacuum pump. There are different puncturing

devices available, depending on the type of packaging.

An optional pressure gauge is available for use with vacuum packaging. This allows for comparing O2 concentrations at different package pressures. It further allows for zero point calibration without zero gas.

1.3 Ordering instructions

Device model

Item no. Description

55 11 399 BA 4000 Inj. GV

55 11 5991 BA 4000 Inj. KV

1.4 Functional principle

The measuring cell on the analyser uses the handle principle, utilising the paramagnetic properties of oxygen. In practice, the

quality of gas conditioning and the mechanical strain (impact, shock) limit the life of the measuring cell.

The

BA4000Inj.GV

is designed as a portable unit and can be used for monitoring changing locations.

1.5 Scope of delivery

– Analyser

– Product documentation

– Connection/mounting accessories (optional)

2 Bühler Technologies GmbH BE550004 ◦ 07/2016-2

BA 4000 Inj.

2 Safety instructions

2.1 Important notices

Operation of the device is only valid if:

– the product is used under the conditions described in the installation- and operation instruction, the intended application

according to the type plate and the intended use. In case of unauthorized modifications done by the user Bühler Technologies GmbH can not be held responsible for any damage,

– when complying with the specifications and markings on the nameplates.

– the performance limits given in the datasheets and in the installation- and operation instruction are obeyed,

– monitoring devices and safety devices are installed properly,

– service and repair is carried out by Bühler Technologies GmbH,

– only original spare parts are used.

This manual is part of the equipment. The manufacturer keeps the right to modify specifications without advanced notice. Keep

this manual for later use.

Please particularly note the following analyser instructions:

– Always transport the equipment diligently and carefully. Strong impact and shock may damage the measuring cells in the

analyser or shorten their life!

– Disconnect from the mains before opening the unit.

–

BA4000Inj.GV: This unit has a 12 V battery, which is always energised.

Signal words for warnings

DANGER

Signal word for an imminent danger with high risk, resulting in severe injuries or death if not avoided.

WARNING

Signal word for a hazardous situation with medium risk, possibly resulting in severe injuries or death if not

avoided.

CAUTION

Signal word for a hazardous situation with low risk, resulting in damaged to the device or the property or

minor or medium injuries if not avoided.

NOTICE

Signal word for important information to the product.

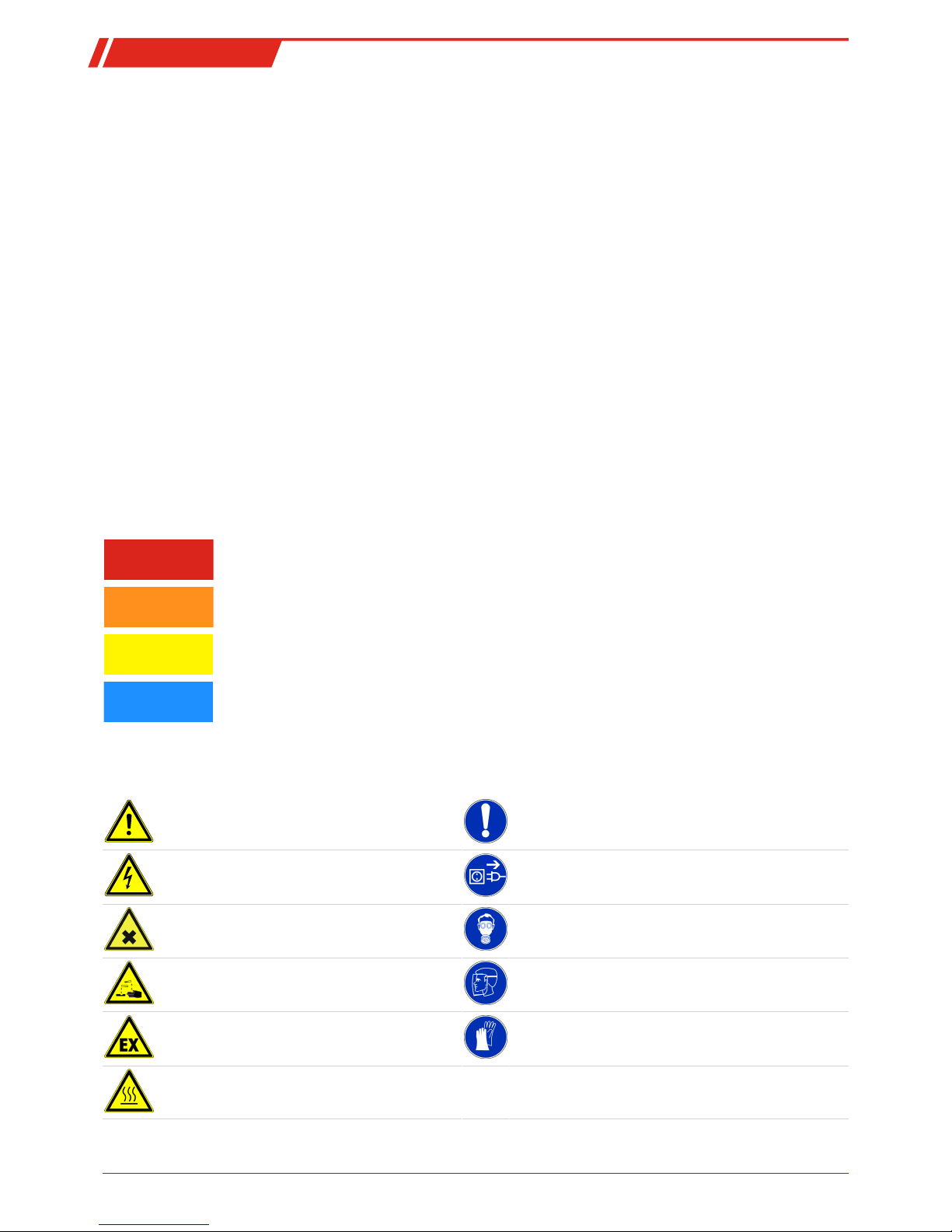

Warning signs

In this manual, the following warning signs are used:

Warning against hazardous situations General notice

Warning against electrical voltage Disconnect from mains

Warning against respiration of toxic gases Wear respirator

Warning against acid and corrosive substances Wear eye/face protection

Warning against potentially explosive atmospheres Wear protection gloves

Warning against hot surface

3Bühler Technologies GmbHBE550004 ◦ 07/2016-2

BA 4000 Inj.

2.2 General hazard warnings

Installation of the device shall be performed by trained staff only, familiar with the safety requirements and risks.

Check all relevant safety regulations and technical indications for the specific installation place. Prevent failures and protect

persons against injuries and the device against damage.

The operator of the system must secure that:

– safety and operation instructions are accessible and followed,

– local safety regulations and standards are obeyed,

– performance data and installation specifications are regarded,

– safety devices are installed and recommended maintenance is performed,

– national regulations for disposal of electrical equipment are obeyed.

Maintenance, Repair

Please note during maintenance and repairs:

– Repairs to the unit must be performed by Bühler authorised personnel.

– Only perform conversion-, maintenance or installation work described in these operating and installation instructions.

– Always use genuine spare parts.

Always observe the applicable safety and operating regulations in the respective country of use when performing any type of

maintenance.

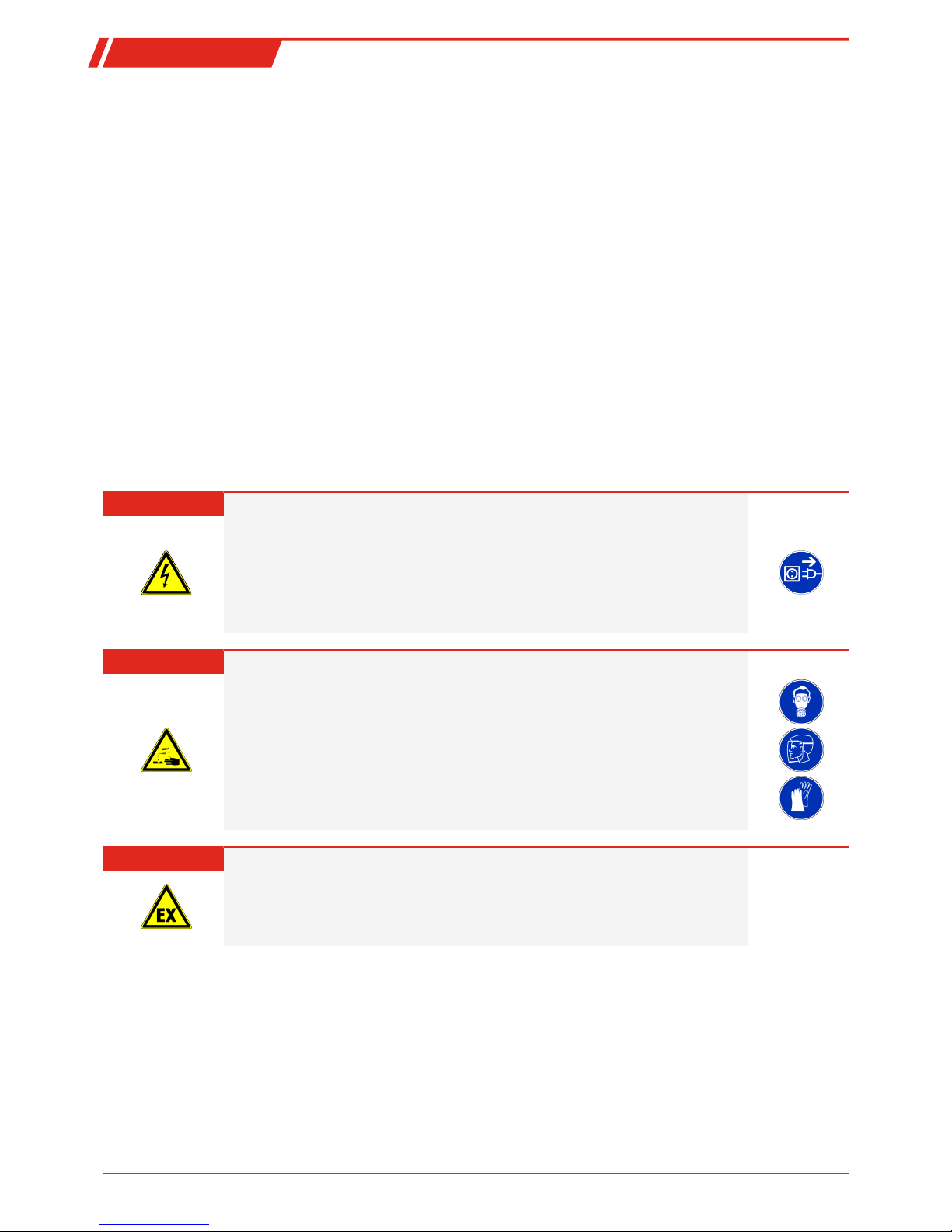

DANGER Electrical voltage

Electrocution hazard.

a) Disconnect the device from power supply.

b) Make sure that the equipment cannot be reconnected to mains unintentionally.

c) The device must be opened by trained staff only.

d) Regard correct mains voltage.

DANGER Toxic, acidic gasses

Sample gas / calibrating gas can be harmful.

a) If necessary, ensure a safe gas discharge.

b) Switch off the gas supply before performing maintenance and protect from opening

inadvertently.

c) Protect yourself from toxic / corrosive gasses when performing maintenance. Wear

appropriate protective equipment.

DANGER Potentially explosive atmosphere

Explosion hazard if used in hazardous areas.

The device is not suitable for operation in hazardous areas with potentially explosive atmospheres.

Do not expose the device to combustible or explosive gas mixtures.

4 Bühler Technologies GmbH BE550004 ◦ 07/2016-2

BA 4000 Inj.

3 Transport and storage

Transport

The unit is sensitive to shock and vibration. Therefore, where possible, transport in the original packaging or large, sturdy packaging at a minimum consisting of 3 layer carton, plastic or aluminium sheet. Line the inside of the packaging with padding at

least 10 cm thick on all sides.

The unit should be marked fragile for shipping.

Removal from service and storage

Purge the unit with dry nitrogen or dry air before removing from service for extended periods. Then close the gas inputs and

outputs to prevent dirt, dust and moisture from entering the unit.

Store the unit in a dry, ventilated, dust-free room. Cover the unit with suitable packaging to protect it from liquids and dirt.

Storage temperature: -20°C … +50°C

5Bühler Technologies GmbHBE550004 ◦ 07/2016-2

Loading...

Loading...