Page 1

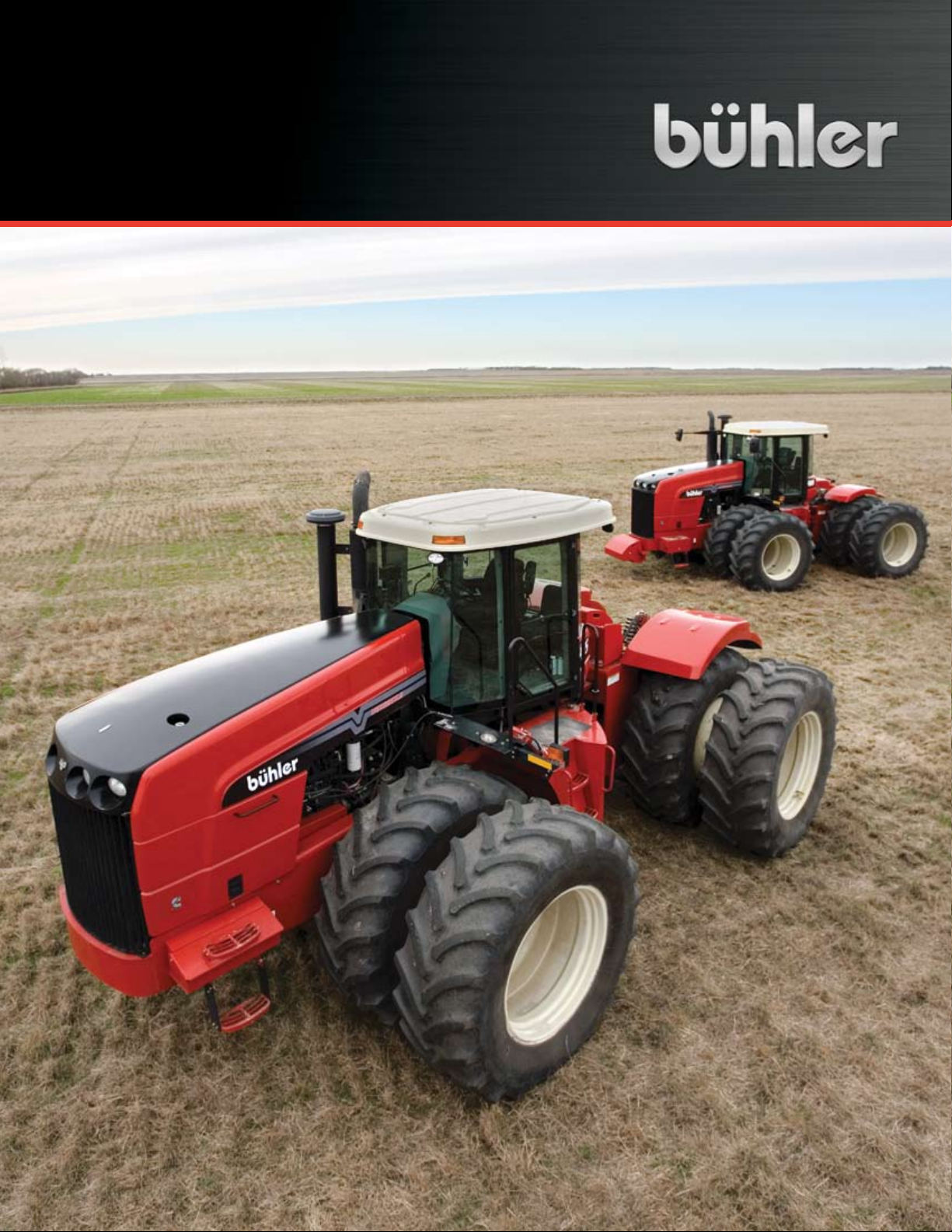

Four-Wheel Drive Tractors

305 to 535 hp

Page 2

PROVEN PERFORMERS

The 305, 340, 375 and 400 horsepower

models are all-new for 2008 and include

many of the same features as the successful

High Horsepower Tractor (HHT) Series.

2

Introduction

e Buhler Versatile line of four-wheel drives has been developed to enhance the protability of large-scale agricultural

operations. Using only proven components, Buhler tractors

focus on power, durability and reliability – because downtime

is not an option! Buhler Versatile four-wheel drive tractors

include the features most requested by farmers with additional

Page 3

History of Versatile 4-5

Engine 6-7

Transmission 8-9

Axles / Drawbar 10-11

Hydraulics 14-15

Cab / Interior 16-17

Service / Maintenance 18-19

options available to customize the tractor for the needs of

any farm. Engineered from the ground up using heavy-duty

components, the full line of Buhler Versatile four-wheel drive

tractors, from 305 to 535 horsepower, feature proven Cummins

engines, durable transmissions, spacious cab environments and

are ready to serve your farm for years to come.

Options 20-21

Specifications 22-23

Buhler Versatile four-wheel drive tractors

have a new decal scheme that features

the model number designation on the rear

of the cab. For many years, the model

designation on Versatile tractors appeared

on the cab and the new decal scheme

recognizes that tradition.

3Table of Contents

Page 4

A HISTORY OF SUCCESS

Versatile was the rst company to massproduce articulated four-wheel drive

tractors, starting in 1966 with the D100

and G100 four-wheel drives. ose

ground-breaking tractors were primitive

by modern standards, with a 6-cylinder

diesel or 8-cylinder gas engine producing 100 horsepower. 1966 models sold

for less than CA$10,000.

Four-wheel drive demand increased

signicantly, with Versatile becoming

one of the leaders in four-wheel drive

development and production. By the

late 1970’s the Versatile lineup included

tractors ranging from 220 to 330

horsepower. With the 1980’s came an

expanded line of four-wheel drive tractors that stretched to 470 horsepower

in the Versatile 1150.

In 1987, Versatile was acquired by

Ford New Holland and by 1989 the

four-wheel drive tractors assembled at

the Winnipeg factory were painted in

the Ford colors, blue, black and white,

and carried the Ford Versatile name.

Production of blue four-wheel drive

tractors under the New Holland name

continued until 2000.

4

History of Versatile

Page 5

Buhler Industries, a Canadian-owned

farm equipment manufacturer, purchased the Winnipeg four-wheel drive

plant from New Holland and in 2001

the Versatile name returned. Buhler

Versatile continued to build the 2000

Series four-wheel drive (240 to 425

horsepower) and launched the High

Horsepower Tractor Series in 2004.

With 435, 485 and 535 horsepower it

was the highest-horsepower four-wheel

drive available in North America.

Buhler celebrated 40 Years of Versatile tractor production in 2006 and

commemorated 50,000 VersatileBuilt four-wheel drives in late 2007.

At the same time, Combine Factory

Rostselmash Ltd., a Russian combine

manufacturer, purchased Buhler Indus-

tries with plans of increasing the global

presence of Buhler Versatile four-wheel

drive tractors. e Versatile name

continues, known worldwide for reliability, durability and ease of service and

maintenance.

5History of Versatile

Page 6

ENGINES

::

THE POWER TO PERFORM

Proven Power

Versatile tractors have been powered

by Cummins engines for nearly 40

years. Cummins engines employ the

latest advancements in diesel engine

design and technology to provide

long-term reliability. ese engines

are turbocharged and aercooled for

clean-burning fuel eciency. e highpressure injection system with electronic

engine control quickly responds to load

conditions or throttle adjustments,

with a 35% torque rise at 1400 RPM

and a 7% power bulge at 1800 RPM to

meet the rigorous demands of modern

agricultural operations.

Biodiesel approved

e Cummins QSM and QSX

engines are Tier 3 compliant and

meet the stringent Tier 3 NOx emissions requirements by optimizing the

in-cylinder combustion system and

without the need for any additional

emissions subsystems. ese engines

have proven track records of excellent

fuel economy and are approved for B20

biodiesel in a continuing eort to support new fuel initiatives.

Bigger radiator, better cooling

e cooling system on Buhler fourwheel drive tractors uses a large grille

and radiator to provide better air ow.

e larger surface area reduces the

air velocity required for engine cooling, which results in more ecient fan

horsepower consumption. Some fourwheel drive tractors have smaller hoods,

compromising cooling surface areas,

meaning more air needs to be pumped

through the radiator, drawing valuable

engine horsepower to run the fan.

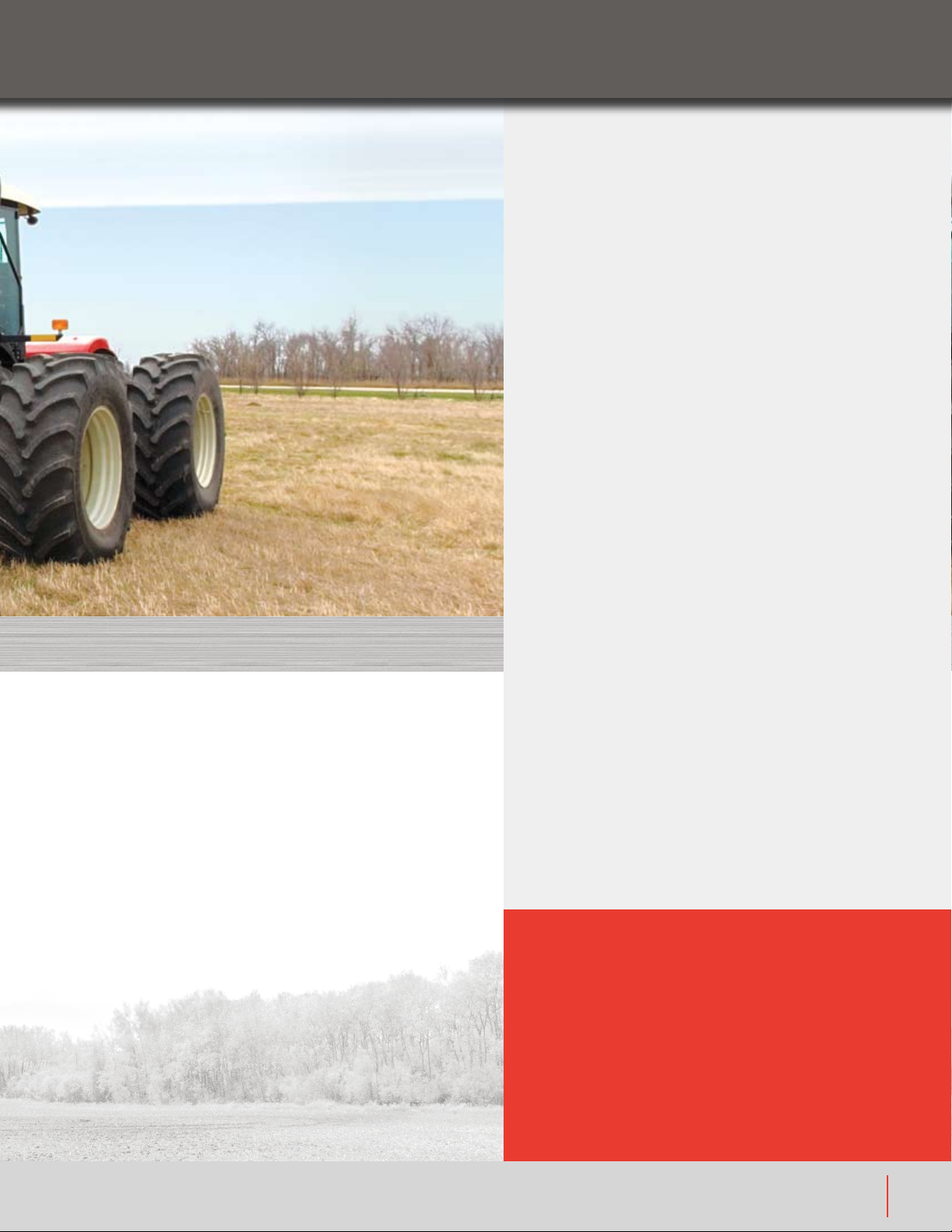

Cummins QSM11

e Cummins QSM11 powers the

305, 340, 375 and 400 models. e 11liter in-line six-cylinder turbocharged

engine delivers superior performance

using advanced combustion technology. e turbocharger is designed for

optimum boost to improve throttle

response across the operating range.

Electronically controlled unit injectors

with cam-driven rate shaping optimize

both emissions and eciency. e

6

Engine

Page 7

mix of proven eld performance and

900

1100

1200

1400

1000

1300

1500

180017001600150014001200 1300

Torque (lb-ft)

Engine RPM

Power (hp)

300

350

400

325

375

425

450

Cummins QSM (305:: 340:: 375:: 400)

1300

1500

1600

1800

1400

1700

1900

180017001600150014001200 1300

Torque (lb-ft)

Engine RPM

Power (hp)

425

475

525

450

500

550

575

Cummins QSX (435:: 485:: 535)

advanced technology is designed to be

powerful, durable and reliable.

Cummins QSX15

e HHT Series (435, 585 and 535 hp)

is powered by the dependable Cummins

QSX 15-liter six-cylinder turbocharged

engine. Buhler selected the Cummins

QSX15 during the development of

the HHT Series to optimize the performance of the tractor, shaping power

curves and ratings to align with work

environment, load factors and operating modes. e result is an ecient and

reliable high horsepower tractor that

will work hard for years to come.

Built-in Cummins

®

reliability

35% torque rise at 1400 RPM

7% power bulge at 1800 RPM

7Engine

Page 8

TRANSMISSIONS

::

GET IN GEAR

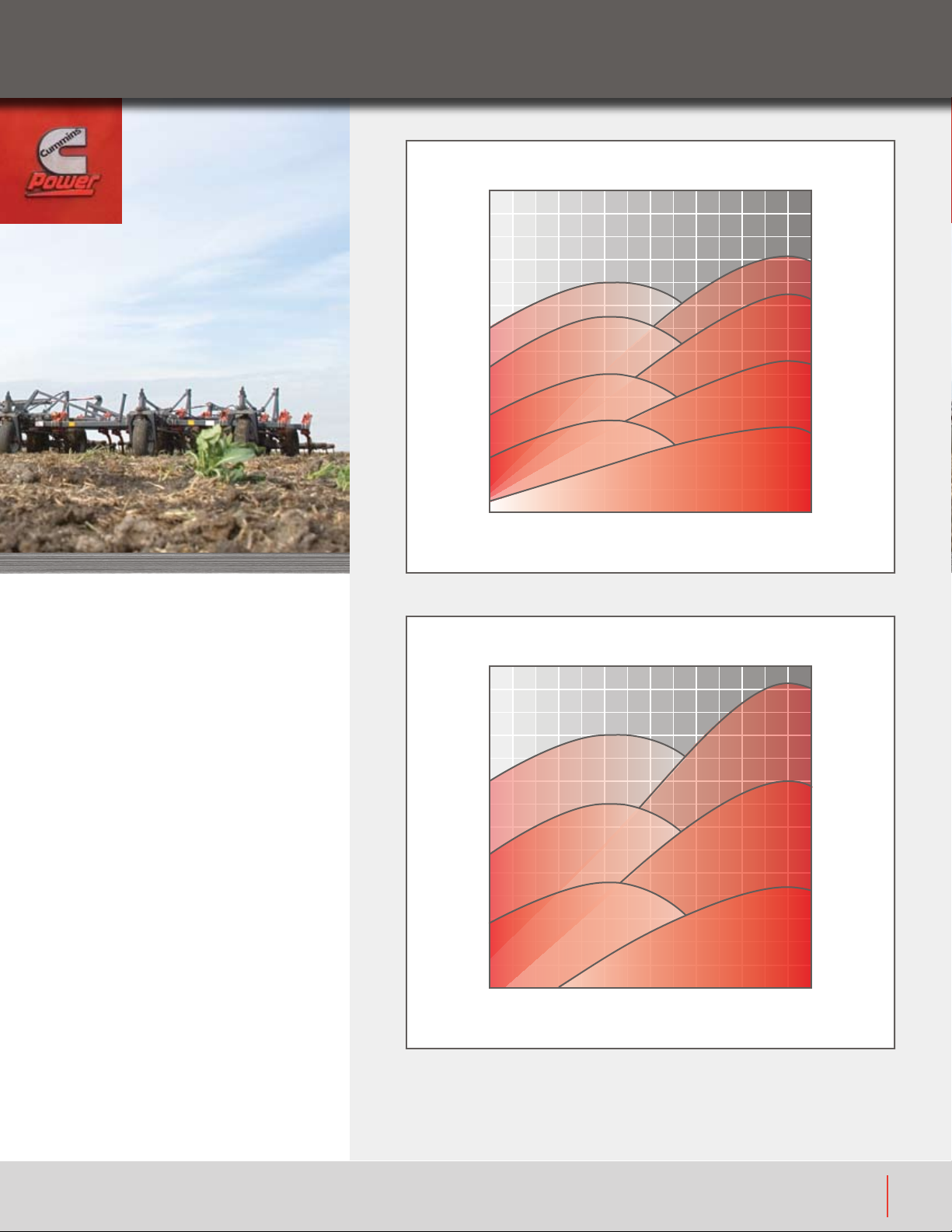

Transmission choices

Each farm has specic operating conditions and implement demands and

Buhler Versatile four-wheel drive tractors oer the choice of manual or

powershi transmissions, each developed to eciently manage eld demands

and engine horsepower. Choose the best

transmission for convenience, performance and operating conditions.

Manual transmission

e mechanical 12 x 4 transmission

features four synchronized sequential

smooth-shiing gears in each of its three

ranges. ese gears have closely matched

speed increments in the critical band

from 3 to 8 mph to provide exibility

for every farming application.

Powershift transmission

Available in the 305, 340, 375 and 400

models is the 12 x 2 Powershi transmission while the 435, 485 and 535 feature

a CAT® TA22 Powershi transmission

with 16 forward speeds and 4 reverse

speeds, with eight gears in the heart of

the critical eld working range. Single

lever control provides clutchless shiing from forward to neutral to reverse

for all speeds. Powershi gear selection

POWERSHIFT FEATURE DESCRIPTION

Automatic speed matching Provides automatic gear selection to match engine and ground speed.

Sequential shift Provides smooth continuous upshifts or downshifts by holding the lever left or right.

Pulse shift Allows upshifting or downshifting one gear at a time, by tapping the lever left or right.

Pre-select (305, 340, 375, 400) Pre-select any gear up to 7th while in neutral. The tractor will start in 3rd and automatically

upshift to the pre-selected gear.

Pre-select (435, 485, 535) Pre-select any gear up to 10th while in neutral. The tractor will start in the pre-selected gear.

Straight line shuttle shift Shift from forward to reverse without clutching.

features are designed for simple gear

selection, smooth operation and in-eld

convenience.

Cruise control

Engine and ground speed consistency

is very important for maximizing the

eciency of modern implements such

as air seeders. Cruise control is included

on all Buhler four-wheel drive tractors

to maintain ground velocity or maintain

8

Transmission

Page 9

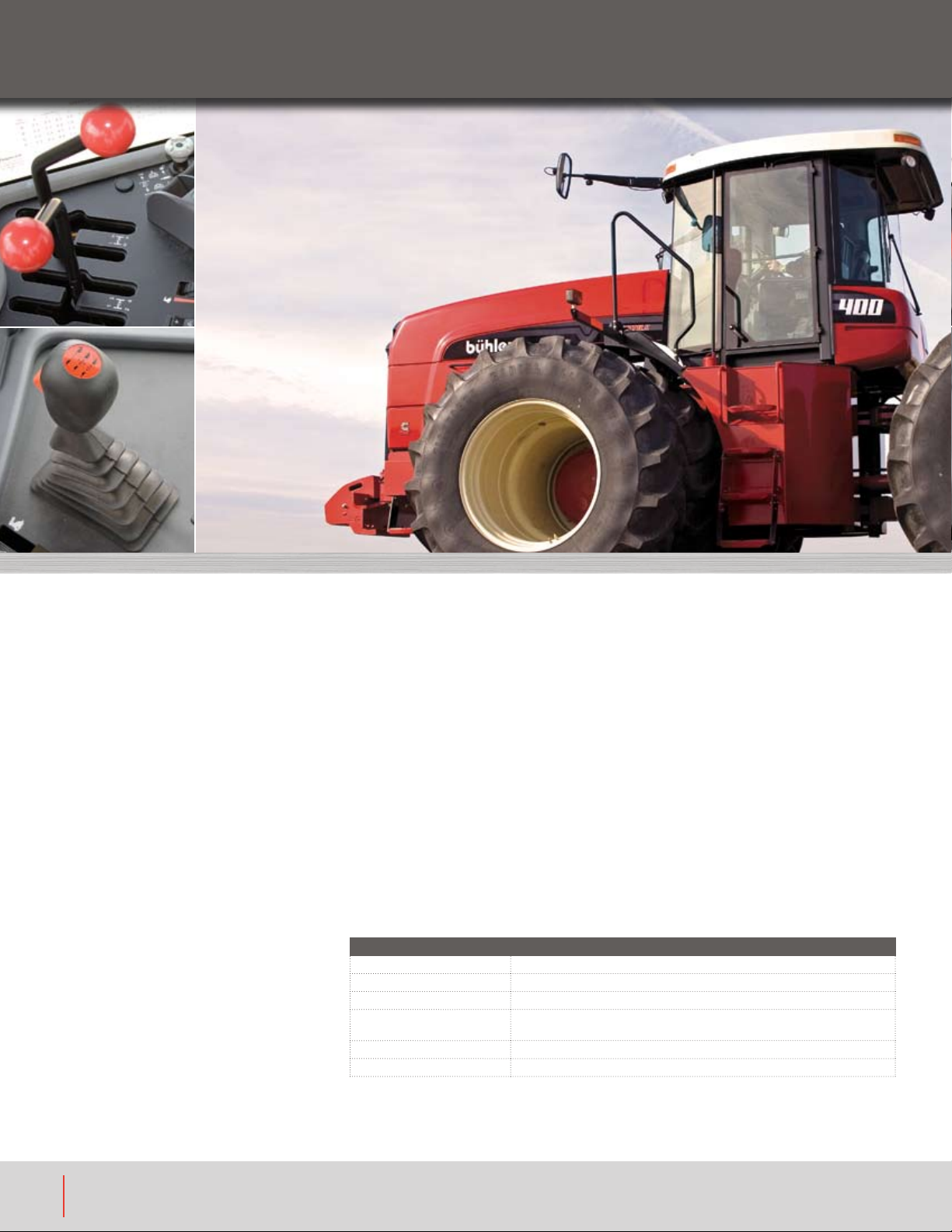

engine speed for peak horsepower and

4

8

10

12

14

16

2

6

18

20

22

24

MPH

LOW RANGE MEDIUM RANGE HIGH RANGE

1211108 97654321

GEAR

4

8

10

12

14

16

2

6

18

20

22

24

MPH

LOW RANGE MEDIUM RANGE HIGH RANGE

1211108 97654321

GEAR

4

8

10

12

14

16

2

6

18

20

22

24

MPH

LOW RANGE MEDIUM RANGE HIGH RANGE

12 13 14 15 1611108 97654321

GEAR

torque, or for constant PTO operation.

The next field

Farms have expanded and moving to the

next eld is no longer as simple as crossing the road. With that in mind, Buhler

Versatile four-wheel drive tractors now

have road speeds of up to 22 MPH so

moving equipment to the next eld

takes less time.

Quadshift gear ranges - All Models

Powershift gear ranges - Models 305, 340, 375, 400

Powershift gear ranges - Models 435, 485, 535

Helical cut gears generate

more tooth contact for more

reliable power transfer,

smoother shifts, and reduced

transmission noise.

9 Transmission

Page 10

BUILT TO PULL

::

FRAME, AXLE, DRAWBAR

Frame construction

e frame is manufactured from thick

high-grade steel plate to ensure structural integrity even under extreme

conditions. e main bearing at the

articulation point is larger than prior

models to enhance reliability. e

drawbar pull point on Buhler Versatile

four-wheel drives is immediately behind

the articulation point for maximum

pulling power and weight distribution.

Outboard Planetary Axles

In the 1970’s Versatile engineers developed the outboard single reduction

planetary axle, known in the industry for its strength, simplicity, ease of

service and wheel mounting. e tradition of building the most reliable

planetary combination in the industry

starts with placing the planetary and

sun gears towards the outside of the

axle. Outboard planetary axles deliver

The drawbar pull point on Buhler Versatile four-wheel drives is

immediately behind the articulation point, which now features a largediameter pivot pin for maximum strength and durability. Models 305,

340, 375 and 400 feature a 2.36" (60 mm) pivot pin while the High

Horsepower Tractor Series have a 3.15" (80 mm) pivot pin.

all available horsepower through a

large, precision machined oating sun

gear. e planetary hubs are suspended

on large diameter bearings mounted

directly to the axle tubes. e load is

supported by the axle assembly and

not by the drive train components. All

Buhler Versatile four-wheel drive tractors feature reliable heavy-duty nal

drives that deliver horsepower where it

counts: at the drawbar.

10

Frame :: Axle :: Drawbar

Page 11

e planetary axles remain on the

tractor during routine maintenance,

limiting downtime. Daily inspections

are easy with a quick visual check of the

axle oil level indicators. e gears can

also be reversed to extend the wear life.

Fuel capacity and weight distribution

Two fuel tanks provide a total capacity of 250 U.S. gallons in the 305, 340,

375 and 400, while models 435, 485

and 535 have a capacity of 350 U.S. gallons. e two fuel tanks are connected

with a crossover tube for convenient

refueling on either side of the tractor.

e tanks are located at the optimum

position near the center of the tractor

to maintain the front-to-rear weight

distribution. As the fuel level drops, the

front-to-rear weight ratio remains the

same so balance and ballast levels are

not aected, regardless of fuel level.

A large auxiliary fuel filter is standard equipment. With a larger capacity,

the fuel filter ensures that fuel is thoroughly filtered to ensure harmful

debris is removed before entering the engine, which is particularly

important when using biofuels. This filter is visible from the ground or

from the entry platform for easy inspection.

11Frame :: Axle :: Drawbar

Page 12

Page 13

Page 14

HYDRAULICS

::

MEETING THE DEMANDS OF MODERN EQUIPMENT

Modern implements require more

hydraulic capacity to operate eciently

and the hydraulic system on Buhler

four-wheel drive tractors has been

developed to meet those demands.

e closed center load sensing hydraulic system provides ample capacity for

implements that demand high hydraulic ow by providing pressure and ow

on demand. When no hydraulic power

is required, the system goes into lowpressure standby to conserve energy,

providing more power at the drawbar.

Mechanical hydraulic levers, positioned for easy reach, manage a variety

of applications and have the exibility

to do multiple functions simultaneously. Using lever locks, the mechanical

hydraulic levers can be locked in neutral,

kept out of the oat position, or held

between oat and retract for hydraulic

motor operation. Easily adjustable ow

control knobs for four hydraulic circuits

are conveniently located on the side

console. Rotate the knobs to increase or

decrease ow to each of the hydraulic

circuits. ese rotary controls make it

easy to adjust ow from the comfort of

your seat.

Electro-hydraulics are available

and feature fingertip controls to

manage the raise, lower, float

and neutral functions. Each

remote has a convenient thumb

wheel for precise flow settings

and programmable timed selfcentering detents.

14

Hydraulics

Page 15

Optional electro-hydraulics are ergonomically designed for both comfort

and convenience. Finger-tip controls

manage the hydraulic functions and

hydraulic ow is increased or decreased

by rotary thumb wheels.

e total hydraulic ow in the models 305, 340, 375 and 400 is 50 GPM

(190 L/min) and an optional high ow

hydraulic system increases that to 75

GPM (290 L/min). Models 435, 485

and 535 have a total hydraulic ow of

55 GPM (208 L/min), or 80 GPM

(303 L/min) with the optional high

ow hydraulic system. Four remote

valves are standard and the optional

high ow hydraulic system is available

with six remote valves, and eight remote

valves are available on the HHT Series.

[2]

[3]

[1]

[1] The hydraulic remote couplers at the

rear of the tractor are mounted on the left

side for better drawbar visibility and unobstructed access to attach implement lines.

The outlets are color-coded to match the

hydraulic controls inside the cab.

[2] Located in a comfortable ergonomic

position on the right side console, the four

hydraulic control levers are color-coded with

the couplers. Below each control lever is

a 3-position lever lock that allows for easy

setting.

[3] Continuously variable rotary control

knobs allow smooth and precise setting of

the hydraulic flow.

15Hydraulics

Page 16

CAB INTERIOR

::

COMFORT, CONVENIENCE, CUSTOMIZATION

A mounting bracket and

power center is available

near the B-pillar for

implement monitors, cell

phones or GPS equipment.

16

Cab :: Interior

e cab has been designed to meet the

demands of evolving farming trends.

e access steps are recessed in the fuel

tank and handrails and door handle

are functional and easy to reach. e

wider cab oers excellent 360º visibility for eldwork and maneuvering large

modern implements, and there is a clear

sightline to the drawbar when attaching equipment. e high-resolution

electronic display is easy to read and

provides operating data at a glance, and

the side console features a convenient

ngertip-control throttle.

An AM/FM/WB/CD stereo with

two speakers is optional. e upgraded

package adds two speakers and XM™ or

Sirius™ Satellite Radio.*

e standard cab can be customized

with many comfort and convenience

options while the Deluxe Cab creates

the ultimate in-cab environment. e

Deluxe Cab features a heated, semiactive air-ride suspension seat as well

as a secondary training seat. Front and

rear sun visors are included and electronic automatic climate control will

maintain the desired cab temperature.

Page 17

CAB FEATURES Standard Deluxe

Next generation cab with new right swing door and 8" wider interior • •

Air-ride suspension swivel seat with full control • N/A

Heated, semi-active suspension seat N/A •

Training seat Opt •

Manual climate control • N/A

Electronic automatic climate control N/A •

Monitor mounting bracket with power Opt •

Cruise control • •

Front windshield wiper and washer • •

Rear windshield wiper and washer • •

Storage compartment • •

Tilt and telescoping steering wheel • •

AM/FM/CD stereo w/ 2 speakers Opt Opt

AM/FM/CD/Satellite-ready* stereo w/ 4 speakers Opt Opt

12V power outlets (2 one pin and 2 multi-pin) • •

Cigarette lighter • •

Dual dome lights • •

Vents (6 driver-facing roof mounted, 1 floor mounted, 1 windshield) • •

Foot rest N/A •

Built-in trouble light with retractable cord N/A •

Cargo net N/A •

External mirrors • N/A

Power / heated external mirrors N/A •

Front / rear sun visor N/A •

Note: the Deluxe Cab is a bundled package. Some Deluxe Cab features can be ordered as options in the Standard Cab.

*XM™ or Sirius™ Satellite Radio. Monthly subscription fees may apply.

Power-adjustable heated external mirrors, front and rear wipers and washers

and a monitor-mounting bracket with

available power complete the Deluxe

Cab package.

Large controls for the heat and air conditioning are conveniently located to

easily manage the cab environment.

Plenty of storage space is provided

behind and beside the seat for lunch

coolers and toolboxes. e result is

enhanced comfort to make the long day

seem short.

17Cab :: Interior

Page 18

SERVICE AND MAINTENANCE

::

YOUR PARTNERS

ere are never enough hours in the day

and every minute counts. at’s why all

Buhler Versatile tractors are designed

with easy serviceability in mind. Routine service can extend the life of your

tractor, minimize downtime and lower

your operating costs.

Daily maintenance is made eortless

with side shields that open up and out

of the way to allow access to ll points

and dipsticks. Fluid checks are easy with

conveniently located sight gauges. A

swing-out assembly on the front grille

and radiator expose the hydraulic and

transmission oil coolers, air conditioning condenser, fuel cooler and charge

air cooler for fast cleaning.

e Versatile outboard planetary axle

system is known for its ease of service.

Planetary axle covers can be removed

from the tractor without removing the

axles and tires, limiting the amount of

time needed for routine maintenance.

Daily inspections are easy with a quick

visual check of the axle oil level sight

gauges.

Major components such as the engine,

transmission and axles can be removed

and repaired without splitting the tractor, reducing downtime and expense.

18

[1] [2] [3] [4]

Service :: Maintenance

Page 19

[1] A side-rail mounted toolbox is available

on all models.

[2] The fuse panel, with clearly labeled protected circuits, is located at eye level inside

the cab on the C-pillar.

[3] The heavy-duty pivot-joint is accessible

for easy inspection and service.

[4] The front grille swings out to provide

easy access to hydraulic and transmission

oil coolers, air conditioning condenser, fuel

cooler and charge air cooler.

[5] The gull wing side engine shields swing

up and out of the way.

[6] The batteries on the 305, 340, 375 and

400 are conveniently located on the lower

front area of the tractor, while batteries on

the 435, 485 and 535 models are located

on the right side of the tractor. The batteries are protected from the elements by an

enclosure equipped with a gas-assisted strut

that lifts and holds the shield out of the way

for inspection or servicing.

[7] Sight gauges are conveniently located for

quick checks of hydraulic, differential, and

transmission fluid levels.

[8] Diagnostic connectors and power points

are conveniently located behind the seat.

The diagnostic connectors allow for fast

system checks by trained technicians.

[5] [6] [7] [8]

19Service :: Maintenance

Page 20

OPTIONS

::

EVEN MORE FOR YOUR MACHINE

Buhler Versatile tractors are wellequipped with the standard features

most-requested by farmers. Additional

options are available to customize

the tractor for the requirements of

your farm.

3-Point Hitch

Models 305, 340, 375 and 400 are

available with a Category III/IVN

3-point hitch. e hitch, capable of

liing 13,000 lbs (5,897 kgs), is also

available with an optional quick hitch.

High-intensity discharge (HID) lighting

HID lights have proven themselves to

be very useful in agriculture operations.

ere’s never enough hours of daylight

and HID lighting provides up to ten

times more light than conventional

headlights. Known for a blue hue, two

HID light kits are available – frontonly and front-and rear.

Auto-Steer Ready

GPS technology saves time, fuel and

money when partnered with an autosteer system that prevents overlap and

maintains the eld heading. Buhler is

pleased to oer an optional factoryinstalled auto-steer-ready kit that is

compatible with most auto-steer packages on the market. Buhler has also

partnered with Outback Guidance and

Accutrak Systems Ltd. to oer factoryinstalled kits to match their specic

hardware. You can incorporate the

auto-steer kit that is best suited to your

agriculture operation, installed at the

factory or at your local dealership.

Scraper Hitch

Buhler engineers have worked with several scraper manufacturers to develop

and test scraper hitches. Scraper hitches

for most Buhler Versatile tractors are

available for some of the best-selling

commercial scrapers including Miskin,

K-Tek and Reynolds.

Power take-off

Certain equipment requires the use of

a power take-o, which is available on

most Buhler Versatile tractors.

20

Options

Page 21

Six hydraulic remotes are optional on models 305, 340, 375

and 400. The HHT Series is available with six or eight hydraulic

remotes. All four-wheel drives

are available with a high-flow

hydraulics for increased flow

to meet the demands of modern

implements.

OPTIONS 305, 340, 375, 400 435, 485, 535

PTO, 1000 RPM multi-disc wet clutch, electro-hydraulic Opt Opt

3-point hitch, 13,000 lbs (5,897 kg) SAE lift capacity Opt N/A

Quick hitch attachment Opt N/A

Implement status switch kit, (TPM only)* Opt N/A

Implement status switch harness extension kit (TPM only) Opt N/A

¾" coupler kit with ½" return line Opt Opt

Motorized flow control (1 section) Opt Opt

Performance monitor with radar Opt Opt

Front / rear differential lock Opt N/A

Front weight packages Opt Opt

Rear weight package (not compatible with PTO or 3-point hitch) Opt Opt

Rear mid-mounted weight package Opt Opt

Rotating magnetic roof mounted beacon Opt Opt

1 ½" hitch pin and bushing kit Opt Opt

French decal kit Opt Opt

Auxiliary 3-pin connector kit N/A Opt

Radio, CD with weatherband, XM, Sirius Opt Opt

Debris / mud kit Opt N/A

HID light package Opt Opt

Electro-hydraulics Opt Opt

Tow cable Opt Opt

Heavy-duty drawbar support kit Opt Opt

Canbus engine monitor Opt Opt

Rear toolbox† Opt Opt

*One switch kit included with each tractor equipped with a 3-point hitch at the factory.

†Not available with rear weight package.

21Options

Page 22

SPECIFICATIONS

MODEL 305 340 375 400

Engine

Type of engine

Aspiration

Displacement

Horsepower

Power bulge

Peak horsepower

Torque rise

Peak torque

Fuel system

Capacity

Filter

Filler neck

Transmission

Quadshift transmission

Powershift transmission

Maximum speed

Axles

Versatile Outboard Planetary Axles

Differential Lock

Brakes

Hydraulic Trailer Brakes

Hydraulics

Type of system

Standard Flow

HydraFlow

Hydraulic remotes

(mechanical or electro-hydraulic)

Maximum system pressure

Electrical System

Alternator

Batteries

Lighting

Drawbar / 3-Point hitch / PTO

Vertical load rating

- with heavy-duty drawbar support

Hitch pin diameter (with auto drop)

3-point hitch (Category III/IVN)

Quick Hitch

3-point hitch lift capactiy

PTO (1 ¾" dia., 20 spline, 1000 RPM)

Dimensions

Wheelbase

Height to top of exhaust

Height to top of cab

Overall length, no ballast weights

Ground clearance, at drawbar

Turning radius (with base tires)

Base tractor weight*

Maximum operating weight

Capacities

Fuel tank

Engine crankcase with filter

Cooling system

Hydraulic system

Planetary axle, each (standard)

Planetary axle, each (heavy duty)

Windshield washer reservoir

*A base tractor is considered to have a mechanical transmission, with 520/85R42 drum-style duals , a standard drawbar, no fuel, no operator, no special added equipment, and no ballast.

Cummins QSM11

Turbocharged & air-to-air aftercooled

11-liter

305 hp (224 kw)

7% at 1800 RPM

330 hp (246 kw)

35% at 1400 RPM

1050 lb-ft

250 U.S. gal (946 L)

Engine mounted with water separator

Rock screen

Mechanical 12 x 4: 12 forward speeds, 4 reverse speeds, 4 synchronized gears in each of the 3 forward ranges

Powershift 12 x 2: 12 forward speeds, 2 reverse speeds, electronic valve clutch pack actuation

Quadshift: 22 mph (35 kph) / Powershift: 17 mph (27 kph)

Standard

Optional

Dry caliper

N/A

Closed Center Load Sensing System

50 GPM (190 L/min)

75 GPM (290 L/min)

4 standard, 6 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted

worklights, 2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

6,000 lbs (2,722 kg)

9,000 lbs (4,082 kg)

2" (51 mm)

Optional

Optional

13,000 lbs (5,897 kg)

Optional

142" (3597 mm)

146" (3720 mm)

143" (3627 mm)

265" (6750 mm)

16.9" (430 mm)

191.5" (4860 mm)

25,000 lbs (11,690 kg)

30,500 lbs (13,835 kg)

250 U.S. gal (946 L)

9.7 U.S. gal (36.7 L)

14.5 U.S. gal (55 L)

20 U.S. gal (75.7 L)

11.1 U.S. gal (42 L)

N/A

3.5 qt (3.3 L)

::

305, 340, 375, 400

Cummins QSM11

Turbocharged & air-to-air aftercooled

11-liter

340 hp (254 kw)

7% at 1800 RPM

370 hp (276 kw)

35% at 1400 RPM

1150 lb-ft

250 U.S. gal (946 L)

Engine mounted with water separator

Rock screen

Standard or heavy-duty

Optional

Dry caliper

N/A

Closed Center Load Sensing System

50 GPM (190 L/min)

75 GPM (290 L/min)

4 standard, 6 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted

worklights, 2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

6,000 lbs (2,722 kg)

9,000 lbs (4,082 kg)

2" (51 mm)

Optional

Optional

13,000 lbs (5,897 kg)

Optional

142" (3597 mm)

146" (3720 mm)

143" (3627 mm)

265" (6750 mm)

16.9" (430 mm)

191.5" (4860 mm)

25,000 lbs (11,690 kg)

34,000 lbs (15,422 kg)

250 U.S. gal (946 L)

9.7 U.S. gal (36.7 L)

14.5 U.S. gal (55 L)

20 U.S. gal (75.7 L)

11.1 U.S. gal (42 L)

13.5 U.S. gal (51 L)

3.5 qt (3.3 L)

Cummins QSM11

Turbocharged & air-to-air aftercooled

11-liter

375 hp (280 kw)

7% at 1800 RPM

405 hp (302 kw)

35% at 1400 RPM

1275 lb-ft

250 U.S. gal (946 L)

Engine mounted with water separator

Rock screen

Heavy-duty

Optional

Dry caliper

N/A

Closed Center Load Sensing System

50 GPM (190 L/min)

75 GPM (290 L/min)

4 standard, 6 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted

worklights, 2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

6,000 lbs (2,722 kg)

9,000 lbs (4,082 kg)

2" (51 mm)

Optional

Optional

13,000 lbs (5,897 kg)

Optional

142" (3597 mm)

146" (3720 mm)

143" (3627 mm)

265" (6750 mm)

16.9" (430 mm)

191.5" (4860 mm)

25,000 lbs (11,690 kg)

37,500 lbs (17,010 kg)

250 U.S. gal (946 L)

9.7 U.S. gal (36.7 L)

14.5 U.S. gal (55 L)

20 U.S. gal (75.7 L)

N/A

13.5 U.S. gal (51 L)

3.5 qt (3.3 L)

Cummins QSM11

Turbocharged & air-to-air aftercooled

11-liter

400 hp (298 kw)

7% at 1800 RPM

430 hp (321 kw)

35% at 1400 RPM

1350 lb-ft

250 U.S. gal (946 L)

Engine mounted with water separator

Rock screen

Heavy-duty

Optional

Dual dry caliper

N/A

Closed Center Load Sensing System

50 GPM (190 L/min)

75 GPM (290 L/min)

4 standard, 6 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted

worklights, 2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

6,000 lbs (2,722 kg)

9,000 lbs (4,082 kg)

2" (51 mm)

Optional

Optional

13,000 lbs (5,897 kg)

Optional

142" (3597 mm)

146" (3720 mm)

143" (3627 mm)

265" (6750 mm)

16.9" (430 mm)

191.5" (4860 mm)

25,000 lbs (11,690 kg)

40,000 lbs (18,144 kg)

250 U.S. gal (946 L)

9.7 U.S. gal (36.7 L)

14.5 U.S. gal (55 L)

20 U.S. gal (75.7 L)

N/A

13.5 U.S. gal (51 L)

3.5 qt (3.3 L)

22

Specifications

Page 23

SPECIFICATIONS

MODEL 435 485 535

Engine

Type of engine

Aspiration

Displacement

Horsepower

Power bulge

Peak horsepower

Torque rise

Peak torque

Fuel system

Capacity

Filter

Filler neck

Transmission

Quadshift transmission

Powershift transmission

Maximum speed

Axles

Versatile Outboard Planetary Axles

Differential Lock

Brakes

Hydraulic Trailer Brakes

Hydraulics

Type of system

Standard flow

High flow hydraulic system

Hydraulic remotes

- mechanical

- electro-hydraulic

Maximum system pressure

Electrical System

Alternator

Batteries

Lighting

Drawbar / 3-Point hitch / PTO

Vertical load rating

- with heavy-duty drawbar support

Hitch pin diameter (with auto drop)

3-point hitch (Category III/IVN)

3-point hitch lift capactiy

PTO (1 ¾" dia., 20 spline, 1000 RPM)

Dimensions

Wheelbase

Height to top of exhaust

Height to top of cab

Overall length, no ballast weights

Ground clearance, at drawbar

Turning radius (with base tires)

Base tractor weight*

Maximum operating weight

Capacities

Fuel tank

Engine crankcase with filter

Cooling system

Hydraulic system

Planetary axle, each

Windshield washer reservoir

*A base tractor is considered to have a mechanical transmission, with 710/70R42 drum-style duals , a standard drawbar, no fuel, no operator, no special added equipment, and no ballast.

Cummins QSX15

Turbocharged & air-to-air aftercooled

15-liter

435 hp (324 kw)

7% at 1800 RPM

470 hp (345 kw)

35% at 1400 RPM

1475 lb-ft

350 U.S. gal (1325 L)

Engine mounted with water separator

Rock screen

Mechanical 12 x 4: 12 forward speeds, 4 reverse speeds, 4 synchronized gears in each of the 3 forward ranges

Caterpillar Powershift 16 x 4: 16 forward speeds, 4 reverse speeds, electro-hydraulic, fully modulated, oil-cooled, multidisc

Quadshift: 22 mph (35 kph) / Powershift: 22 mph (35 kph)

Standard or heavy-duty

Optional

Dual dry caliper

Optional

Closed Center Load Sensing System

55 GPM (208 L/min)

80 GPM (303 L/min)

4 standard, 6 optional

4 standard, 6 or 8 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted worklights,

2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

9,000 lbs (4,082 kg)

12,000 lbs (5,443 kg)

2" (51 mm)

N/A

N/A

Optional

154" (3930 mm)

155" (3940 mm)

11.9' (3450 mm)

299" (7630 mm)

21.9" (556 mm)

191.5" (4860 mm)

42,000 lbs (19,050 kg)

43,500 lbs (19,731 kg)

350 U.S. gal (1325 L)

11.6 U.S. gal (44 L)

22 U.S. gal (83 L)

30 U.S. gal (113.6 L)

15.1 U.S. gal (57 L)

4 qt (3.8 L)

Cummins QSX15

Turbocharged & air-to-air aftercooled

15-liter

485 hp (362 kw)

7% at 1800 RPM

525 hp (392 kw)

35% at 1400 RPM

1650 lb-ft

350 U.S. gal (1325 L)

Engine mounted with water separator

Rock screen

Standard or heavy-duty

Optional

Dual dry caliper

Optional

Closed Center Load Sensing System

55 GPM (208 L/min)

80 GPM (303 L/min)

4 standard, 6 optional

4 standard, 6 or 8 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted worklights,

2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

9,000 lbs (4,082 kg)

12,000 lbs (5,443 kg)

2" (51 mm)

N/A

N/A

Optional

154" (3930 mm)

155" (3940 mm)

11.9' (3450 mm)

299" (7630 mm)

21.9" (556 mm)

191.5" (4860 mm)

42,000 lbs (19,050 kg)

48,500 lbs (21,999 kg)

350 U.S. gal (1325 L)

11.6 U.S. gal (44 L)

22 U.S. gal (83 L)

30 U.S. gal (113.6 L)

15.1 U.S. gal (57 L)

4 qt (3.8 L)

::

435, 485, 535

Cummins QSX15

Turbocharged & air-to-air aftercooled

15-liter

535 hp (399 kw)

7% at 1800 RPM

580 hp (427 kw)

35% at 1400 RPM

1800 lb-ft

350 U.S. gal (1325 L)

Engine mounted with water separator

Rock screen

Standard or heavy-duty

Optional

Dual dry caliper

Optional

Closed Center Load Sensing System

55 GPM (208 L/min)

80 GPM (303 L/min)

4 standard, 6 optional

4 standard, 6 or 8 optional

2900 PSI (197 bar)

12V - 160 amps

3-12V low maintenance, 950 CCA ea.

2 headlights, 2 grille-mounted worklights,

2 front fender worklights,

4 rear fender worklights,

4 cab mounted worklights

9,000 lbs (4,082 kg)

12,000 lbs (5,443 kg)

2" (51 mm)

N/A

N/A

Optional

154" (3930 mm)

155" (3940 mm)

11.9' (3450 mm)

299" (7630 mm)

21.9" (556 mm)

191.5" (4860 mm)

42,000 lbs (19,050 kg)

53,500 lbs (24,267 kg)

350 U.S. gal (1325 L)

11.6 U.S. gal (44 L)

22 U.S. gal (83 L)

30 U.S. gal (113.6 L)

15.1 U.S. gal (57 L)

4 qt (3.8 L)

23Specifications

Page 24

1260 Clarence Avenue

Winnipeg, Manitoba

Tel.: 204.661.8711 :: Fax: 204.654.2503

Toll free: 888.524.1003

E-mail: info@buhler.com

www.buhler.com

TSX:BUI

Equipment shown is subject to change without notice.

©2008 Buhler Versatile Inc. Printed in Canada.

Ref: 012008-5000-PG P/N: 89999945

::

Canada R3T 1T2

Loading...

Loading...