Page 1

INSTRUCTIONS

AND

PARTS MANUAL

UNIVERSAL

BUG-O-MATIC

Please record your equipment identication information below for future reference. This information can be

found on your machine nameplate.

Model Number

Serial Number

Date of Purchase

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above.

LIT-BUG-O-MATIC-IPM-0415

Bug-O Systems is guided by honesty, integrity and

ethics in service to our customers and in all we do.

A DIVISION OF WELD TOOLING CORPORATION

280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA 15317-9564 USA

PHONE: 412-331-1776 http://www.bugo.com FAX: 412-331- 0383

Page 2

SAFETY

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH. KEEP

CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE

AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

MOVING PARTS can

ELECTRIC SHOCK CAN KILL.

cause serious injury.

1) The equipment is not waterproof. Using

the unit in a wet environment may result

in serious injury. Do not touch equipment

when wet or standing in a wet location.

2) The unused connectors have power on

them. Always keep the unused

connectors covered with the supplied

protective panels. Operation of the

machine without the protective panels

may result in injury.

3) Never open the equipment without rst

unplugging the power cord or serious

injury may result.

4) Verify the customer supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist, use

International Electric Code (IEC) 950.

5) Never remove or bypass the equipment

power cord ground. Verify the equipment

is grounded in accordance with all

applicable local and national electrical

safety codes. In none exist, use

International Electric Code (IEC) 950.

1) Never try to stop the pinion from

moving except by removing power or

by using the STOP control.

2) Do not remove any protective panels,

covers or guards and operate

equipment.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or

walk underneath equipment.

PLASMA CUTTING can

produce destructive High

Voltage at High Frequency.

1) If using plasma, see that the machine

as well as the plasma power source is

properly grounded.

READ INSTRUCTIONS.

Read the instruction manual before

installing and using the equipment.

2

2) Do not use older model plasma

machines meant for manual operation.

These can leak high frequency at high

voltages, which can cause dangerous

shock, as well as destroy control

circuits.

3) Read the instruction manual page on

plasma cutting carefully, and follow all

precautions.

Page 3

HIGH FREQUENCY WARNINGS

SPECIAL PRECAUTIONS ARE REQUIRED WHEN USING PLASMA,

TIG OR ANY WELDING PROCESS THAT USES HIGH FREQUENCY

TO STRIKE AN ARC.

WARNING: HIGH FREQUENCY CAN EFFECT MACHINE

OPERATION AND THEREFORE, WELD QUALITY.

Read the precautions below before installing and using the equipment.

PRECAUTIONS:

1) Some plasma or welding cables are strong sources of high frequency interference.

NEVER lay a plasma or welding cable across the controls of the machine.

2) Always physically separate the plasma or welding cable leads from the machine

cables. For example, the plasma or welding cable leads should NEVER be bundled

with a pendant cable or the machine power cord. Maximize the separation between

any machine cables and the plasma or welding cables.

3) Strictly follow the grounding procedures specied for the plasma or welding unit.

NOTE: Some plasma and welding units produce exceptionally large amounts of

high frequency noise. They may require a grounding rod be driven into the earth

within six feet (2 meters) of the plasma or welding unit to become compatible with

an automatic cutting or welding process.

4) If the high frequency is produced using a spark gap, adjust the points so the gap is

as small as possible. The larger the gap, the higher the voltage and the higher the

interference.

5) Some plasma or welding units will inject high frequency interference into the AC

power line. Use separate power line branches whenever possible to power the plasma

or welding source and the machine. Do not plug them into the same outlet box.

6) High frequency noise may enter the machine through the plasma or welding supply

remote contactor leads. Some plasma and welding sources can produce noise

spikes of up to several thousand volts. These sources are not compatible with

automated cutting and welding equipment. It is recommended that the remote

contactor leads on these plasma or welding sources not be connected to the machine.

An alternate solution is to purchase a separate remote contactor isolation box.

3

Page 4

UNIVERSAL BUG-O-MATIC

INSTRUCTIONS AND PARTS MANUAL

TABLE OF CONTENTS

PAGE

5 ..........Technical Data

6 ..........Pendant Control Functions

7 ..........Universal BUG-O-Matic BUG-5700 Parts List

8 ..........BUG-5710: Drive Box Assembly

9 ..........BUG-5720: Cover Assembly, 120 Vac

1 0 .........BUG-5715: Base Assembly

11 .........BUG-5725: Cross Drive Assembly

12 .........Drive Unit Wiring Diagram

13 .........Electrical Component Chart Drive Unit

14 .........Wiring Harness BUG-5726 Diagram

1 5 .........PCB-5700: Drive Unit Interconnect PC Board

16 .........PCB-5700: Wiring Diagram

17 .........BUG-5775: Control Pendant / Exploded View

18 .........BUG-5775: Control Pendant / Parts List

1 9 .........Control Pendant, BUG-5775 Wiring Diagram

2 0 .........BUG-5751 Pendant Cable Wiring Diagram

21 .........Rail Options

2 5 .........Carriage Options

28 .........Accessories

2 9 .........Service Procedure / Installing The Cross Rail (WPD-1150)

31 .........Warranty

4

Page 5

UNIVERSAL BUG-O-MATIC

TECHNICAL DATA

Power BUG-5700 120 VAC/50-60/1

Requirements: BUG-5702 240 VAC/50-60/1

BUG-5704 42 VAC/50-60/1

Linear Speed: 3-70 ipm (75-1750 mm/min)

Weave Speed: 4-100 ipm (100-2500 mm/min)

Dwell Time: 0-3 seconds, left and right

Weave Width: 0.1 to 2" (2.5-50 mm)

Steering: 2" (50 mm) left and right of center

4" (100 mm) total

Load Capacity: 30 lbs (14 kg)

Net Weight: 22 lbs (10 kg)

The machine can be mounted on MPD-1065 Releasable Carriage, MPD-1055 18" Carriage, FMD-1100

Carriage for Hi-Flex rail, or on BUG-5910 Tube Carriage. By simply changing the carriage, the machine

will run on any BUG-O rail - Aluminum Rigid, Semi-Flex, Bent Rigid, or Hi-Flex . The chart below shows

which types of rail are compatible with each carriage. See pages 21- 27 for details.

RAILS

CARRIAGES

Aluminum Rigid Rail

Bent Rigid Rail

ARR-1080 & ARR-1085

Hi-Flex Rail

BRR-1180 & BRR-1210

Semi-Flex Rail

FMD-1050

AFR-3000

BUG-5910 Tube Carriage X X X

FMD-1100 Hi-Flex Carriage X

MPD-1055 18" Carriage X

MPD-1065 Releasable Carriage X X

The power Supply transformer is contained inside the unit. Pendant control of all functions is provided, including:

weave speed and amplitude, and centerline steering,

left and right dwell time,

tractor speed and direction,

weld contact on/off.

5

Page 6

PENDANT CONTROL FUNCTIONS

B

A

D

G

C

E

F

H

I

J

BUG-5775 Pendant Control

A. Weave Speed

B. Steering, 2" (50 mm) left or right from center

C. Amplitude, 0-2" (50 mm)

D. Dwell Left, 0-3 sec.

E. Dwell Right, 0-3 sec.

F. Weld Contact Switch

G. Mode Selector Switch

H. Digital Display, Tractor Speed

I. Forward / Off/ Reverse, Tractor Travel

J. Tractor Speed

6

Page 7

UNIVERSAL BUG-O-MATIC BUG-5700 PARTS LIST

8

9

2

6

1

4

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-2975 Cable Mounting Assembly

2 2 BUG-5462 Right Angle Clamp

3 1 BUG-5710 Drive Box 120 V

1 BUG-5712 Drive Box 240 V

1 BUG-5714 Drive Box 42 V

4 1 BUG-5751 Pendant Cable

5 1 BUG-5775 Pendant Control

6 1 BUG-9180-6 Rod, 6" (152 mm)

7 1 BUG-1853 Machined Rack, 7.5"

8 1 BUG-5455 Gun Mounting Group

9 1 BUG-5965 Handle Assembly

3

7

2

5

7

Page 8

BUG-5710: DRIVE BOX ASSEMBLY

6

6

6

7

7

4

7

7

1

7

7

7

7

7

7

2

6

6

6

7

7

5

3

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-5707 Left Side Panel

2 1 BUG-5708 Right Side Panel

3 1 BUG-5715 Base Assembly

4 1 BUG-5720 Cover Assembly 120 V

5 1 BUG-5725 Cross Drive Assembly

6 6 FAS-0114 Pan Hd Scr 6-32" x 3/8"

7 12 FAS-0124 Pan Hd Scr 8-32" x 3/8"

8

Page 9

BUG-5720: COVER ASSEMBLY, 120 VAC*

12

Included

w/item #6

14

17

20

13

8

5

11

9

4

1

15

2

10

13

16

16

15

Included

w/item #6

13

7

19

3

6

18

ITEM QTY PART NO. DESCRIPTION

1 1 ARM-2279 Toggle Switch

2 1 BUG-1393 Volt trap 120 VAC

3 1 BUG-1770-PW Motor control board

4 1 BUG-2923 Circuit Breaker 0.7 amps

5 1 BUG-2924 Reset Button Seal

6 1 BUG-5218 Transformer 117 VAC

7 1 BUG-5721 Cover panel anodized

N/S 1 BUG-5726 Wire harness

8 1 BUG-9445 Power Cord

9 1 BUG-9446 Cord Grip

10 1 BUG-9487 Cable connector 2-T

11 1 BUG-9884 On-Off switch plate

12 1 CAS-1770 Speed Control

13 8 FAS-0114 Pan Hd Scr 6-32 x 3/8"

14 1 FAS-0124 Pan Hd Scr 8-32 x 3/8"

15 8 FAS-0205 Rnd Hd Scr 4-40 x 1/2"

16 8 FAS-1305 Hex nut 4-40

17 1 FAS-1320 Hex nut 8-32

18 1 FAS-1330 Hex nut 10-24

19 1 PCB-5700 Interconnect board

20 1 WAS-0221 #8 INT Star lock washer

* For 240V and 42V machines, refer to Electical Component List on pg 13.

9

Page 10

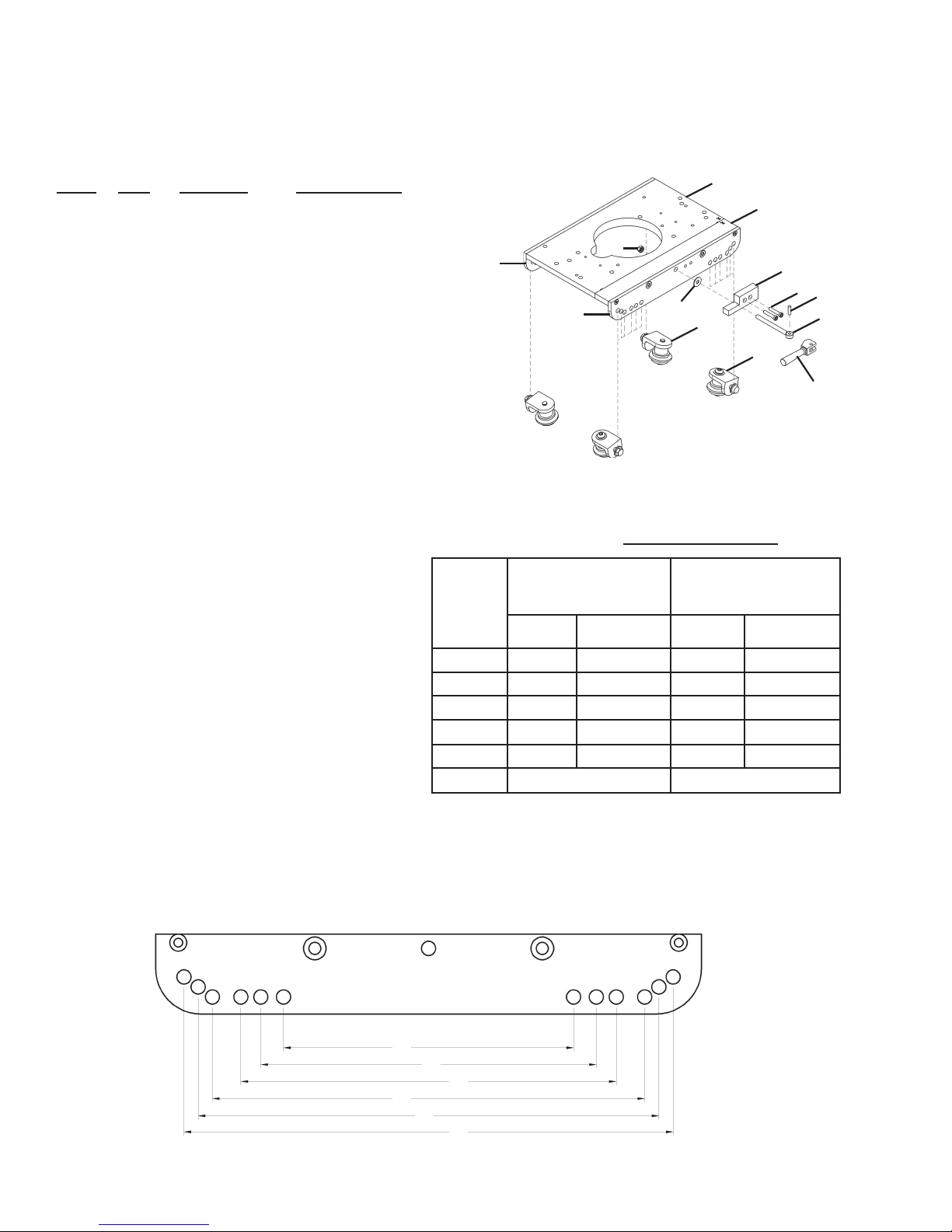

BUG-5715: BASE ASSEMBLY

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-5709 Base Plate

2 1 BUG-5716 Clutch Assembly

3 2 BUG-5723 Attachment Bar

4 4 FAS-0557 Soc Hd Cap Scr 1/4-20 x 3/4"

5 4 FAS-0825 Flt Hd Slot Scr 8-32 x 1/2"

6 8 FAS-0923 Flt Hd Soc Scr 8-32 x 5/16"

7 1 GOF-3014 Drive Pinion w/ Key & Set Scr

8 1 MPD-1015 Gear Motor (60:1)

9 1 WPD-1013 Rubber Ring Gasket

10 1 WPD-1045 Brake Assembly

10

9

8

2

6

1

7

3

5

6

4

10

Page 11

BUG-5725 CROSS DRIVE ASSEMBLY

1

3

8

6

14

5

10

11

12

13

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-5590 Gear motor

2 1 BUG-5591 Pinion

3 3 BUG-5592 Spacer

4 4 BUG-5594 Slt Pan Hd Scr 3mm x 18mm

5 1 BUG-5595 Pot/ Gear Assembly

6 2 BUG-5670 Adj. Leg & Wheel Assembly

7 2 BUG-5675 Fixed Leg & Wheel Assembly

8 1 BUG-5728-A Cross Drive Support

9 1 WPD-1164 Arm Stop

10 1 FAS-0539 Screw, 10-24 x 1"

11 1 WPD-1150 Cross Arm, 15.50"

12 2 WAS-0230 #10 SAE Flat Washer

13 2 FAS-0537 Screw, 10-24 x 3/4"

14 1 WPD-1177 Post

9

7

4

4

2

5

11

Page 12

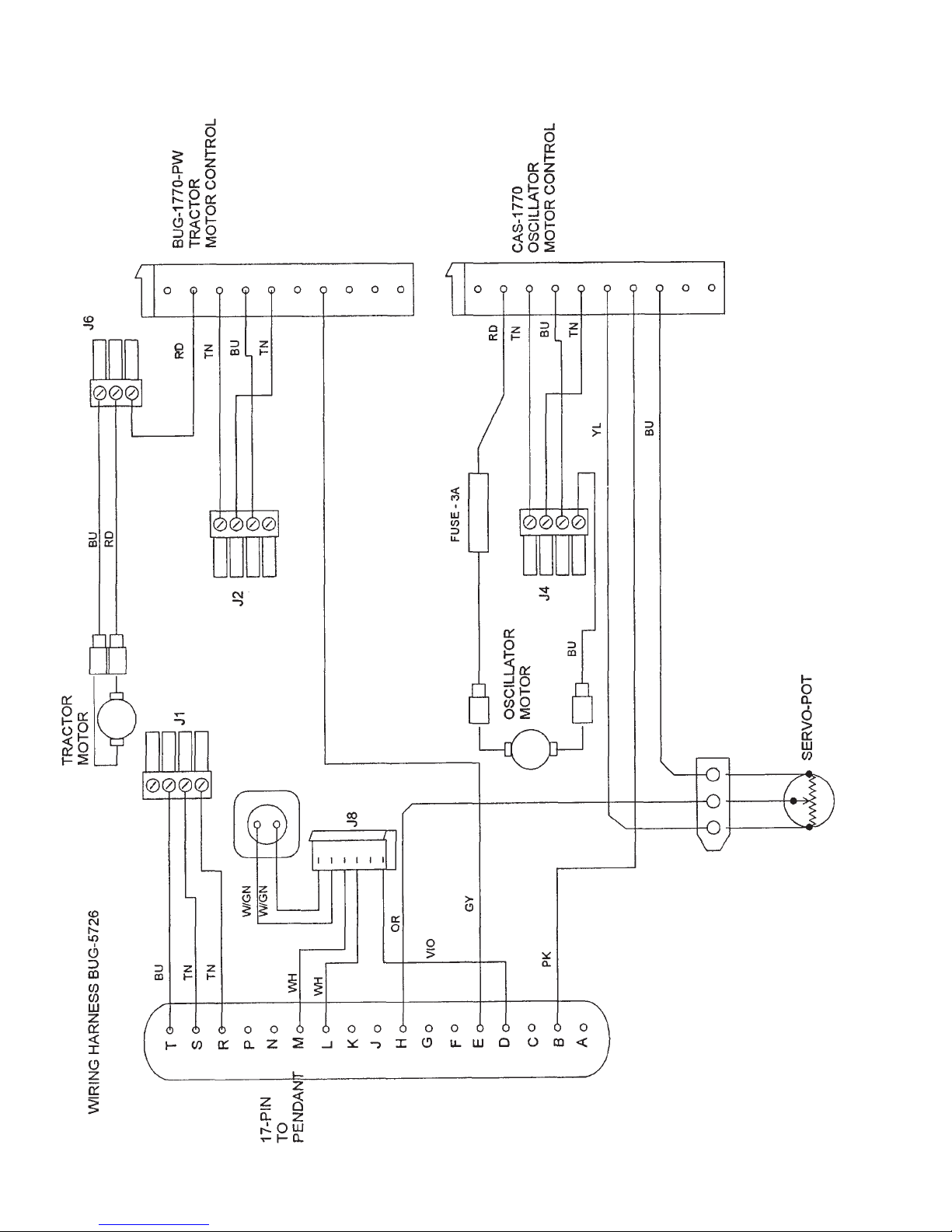

BUG-655X DRIVE UNIT / WIRING DIAGRAM

12

Page 13

BUG-655X DRIVE UNIT / ELECTRICAL COMPONENT CHART

ITEM DESCRIPTION

BUG-5990

120 VAC

BUG-5992

240 VAC

BUG-5994

42 VAC

PC Power Cord BUG-9445 GOF-3115 BUG-9442

CB Circuit Breaker BUG-2923 BUG-2952 BUG-2933

TR Transformer BUG-5218 BUG-5231 BUG-5232

SW Toggle Switch ARM-2279

IB Interconnect Board PCB-5700

CN1 Connector, to Pendant BUG-5527

CN2 Connector, to Weld Contact BUG-1034

MT Tractor Motor MPD-1015

BR Brake WPD-1045

MW Weave Motor BUG-5590

MC1 Motor Control, Tractor BUG-1770-UB

MC2 Motor Control, Weave CAS-1770

SVP Servo-Pot BUG-5240

13

Page 14

BUG-5726 WIRING HARNESS / WIRING DIAGRAM

14

Page 15

PCB-5700 DRIVE UNIT INTERCONNECT PC BOARD

15

Page 16

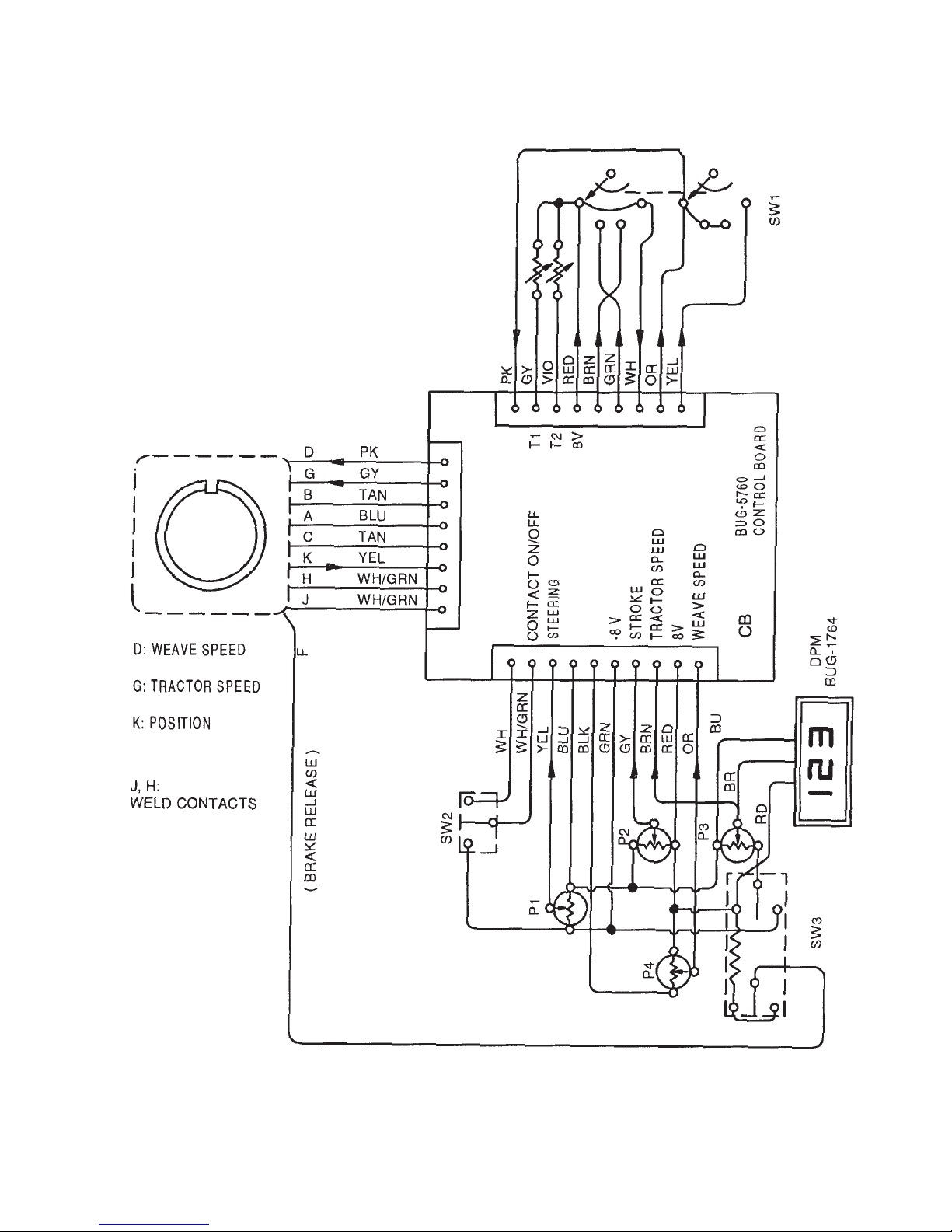

PCB-5700 / WIRING DIAGRAM

16

Page 17

BUG-5775 CONTROL PENDANT / WIRING DIAGRAM

17

Page 18

BUG-5775 CONTROL PENDANT / EXPLODED VIEW

11,16,17

6,11,16

1,9,11

2,19,23

1,11,16

21,22,25

6,11,16

18

20

8

11,16,17

10

11

13

7

4,10

15

12

18

20

14

20

24

3

5

Page 19

BUG-5775 CONTROL PENDANT / PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 2 BUG-1562 Potentiometer, 10k, 3 turn

2 1 BUG-1764 Digital Meter

3 1 BUG-2034 Teon Washer

4 1 BUG-2255 Toggle Switch, DPDT, On-Off-On

5 1 BUG-2436 Knob Screw

6 2 BUG-5054 Potentiometer, 500 K

7 1 BUG-5363 Rotary Switch, 3-P, 4-position

8 1 BUG-5687 Panel Connector, 10-T, F

9 1 BUG-5757 Knob, Large

10 2 BUG-5758 Toggle Switch Seal

11 7 BUG-5759 Pot Shaft Seal

12 1 BUG-5760 Control Board

13 1 BUG-5761 Toggle Switch, SPDT, On-On

14 1 BUG-5772 Rear Panel

15 1 BUG-5773 Front Panel

16 5 BUG-9621 Knob

17 2 BUG-9677 Potentiometer, 10 K

18 1 BUG-9694 Knob (Pointer)

19 4 FAS-0104 Pan Hd Scr, 4-40 x 3/8 L

20 8 FAS-0114 Pan Hd Scr, 6-32 x 3/8 L

21 4 FAS-0205 Rnd Hd Scr, 4-40 x 1/2 L

22 4 FAS-1305 4-40 Hex Nut

23 1 MDS-1011 Display Bezel

24 1 PAN-1033 Rod Clamp

25 4 WAS-0201 Star Washer #4

19

Page 20

BUG-5751 PENDANT CABLE / WIRING DIAGRAM

A __________________ T Common

B __________________ S

C __________________ R

D __________________ B Osc. Speed

E __________________ P (Osc. Dir)

F __________________ D Brake Release

G __________________ E Tractor Speed

H __________________ L Weld Contact

J ___________________ M Weld Contact

K __________________ H Gear Pot.

20

Page 21

RAIL OPTIONS

With a simple carriage change, the Universal Bug-O-Matic with AHC can be made compatible with

any BUG-O rail. A brief description of each BUG-O rail type is provided below. Contact your BUG-O

representative for more information about these rails and the mounting options available.

ARR-1080 ALUMINUM RIGID RAIL / CROSS SECTION / EXPLODED VIEW /

PARTS LIST

ALUMINUM RIGID RAIL is a rigid channel section made of high quality alloy to machine tool tolerance

as in the section view below. A machined gear rack is mounted on the rail, with which the drive pinion

of the carriage meshes. The wheels of the carriage travel in opposed grooves at either side of the rail,

locking the carriage to the rail.

Heavy duty [H.D] aluminum four-legged rigid rail is supplied in two lengths:

ARR-1080 [93-1/2" (2.37 m)] called 8' (2.37 m) rail

ARR-1085 [46-1/2 (1.18 m)] called 4' (1.18 m) rail.

Extra Heavy Duty aluminum four-legged rigid rail is also

available:

ARR-1250 [93-1/2" (1.18 m)] called 8' (2.37 m) rail

ARR-1200 [46-1/2" (1.18 m)] called 4" (1.18 m) rail.

5

ARR CROSS SECTION VIEW

A

C

D

B

A 2.75" (70 mm)

B 4.0" (102 mm)

C 0.375" (9.5 mm)

D 0.875" (22 mm)

3

4

1

2

6

PARTS LIST

ITEM PART NO. DESCRIPTION

1 ARR-1006 Rack

2 ARR-1027 Splicer Bar

3 ARR-1028 Carriage Bolt

4 ARR-1081 Rail Extrusion

5 FAS-0375 Screw, Hex Hd Cap 5/16-18

6 FAS-1370 Hex Nut 5/16-18

RAIL FOR LONGER SPANS:

When unsupported rail paths longer than nominal 8' (2.37 m) rail are required, multiple sections of standard rail are mounted on plate, I beam, channel or box sections.

21

Page 22

BRR-1180 BENT RIGID RAIL / CROSS SECTION / APPLICATION VIEW /

PARTS LIST

BENT RIGID RAIL (BRR) is a rigid section of high quality alloy bent for circumferential applications. A

machined gear rack is mounted on the rail, with which the pinion of the drive unit meshes, providing

positive drive in all directions. The wheels of the carriage travel in opposed grooves at either side of the

rail, securing the carriage to the rail.

The rail can be ordered as a complete ring (BRR1210-__) or as individual sections (BRR-1180). When

ordering, specify the work diameter (inside or outside),

method of mounting and if a complete ring is required.

On larger diameters, rail can be “leapfrogged” around

the vessel to reduce the quantity needed. Maximum

section length is 80" (2 m).

PARTS LIST

PART NO. QTY DESCRIPTION

ARR-1002 1 Rack

ARR-1027 2 Splicer Bar

ARR-1028 2 Carriage Bolt

ARR-1044-E 1 Rail Extrusion

FAS-0375 2 Screw, Hex Hd Cap 5/16-18

FAS-1370 2 Hex Nut 5/16-18

Note: Adjustable magnet support legs (ARM-2480),

shown above, are sold separately.

BRR CROSS SECTION VIEW

A

C

D

B

A 2.75" (70 mm)

B 4.0" (102 mm)

C 0.375" (9.5 mm)

D 0.875" (22 mm)

22

Page 23

AFR-3000 SEMI-FLEX RAIL / CROSS SECTION / EXPLODED VIEW / PARTS LIST

SEMI-FLEX RAIL (AFR) can be bent inside or outside to a minimum radius of 15' (5 m) without

permanent deformation. A splice plate is mounted at one end of each ex-rail section for connecting

multiple sections of rail. A rack adjusting tool is supplied with every two (2) rails, for moving the rack on

the rail. Available in 8' ( 2.37 m) lengths. Use at least four (4) attachments - vacuum cups or magnets on each section of Semi-Flex Rail.

AFR CROSS SECTION VIEW

A

Minimum Radius

15' (5 m)

8'

(2.37 m)

8'

(2.37 m)

B

A 2.75" (70 mm)

B 4.0" (102 mm)

C 0.33" (8.5 mm)

D 0.500" (12.7 mm)

C

D

2

4

1

5

8

7

6

3

PARTS LIST

ITEM PART NO. DESCRIPTION

1 AFR-1015 Spacer Washer

2 AFR-2001 Rack Adjuster Tool

3 AFR-3002 Splice Plate

4 AFR-3006 Rack

5 AFR-3009 Extrusion, Punched

6 FAS-0955 Screw, Flt Hd Soc 1/4-20

7 FAS-1446-HW S.T. Slt. Hx. 10-32

8 WAS-0230 #10 Washer

23

Page 24

FMD-1050 HI-FLEX RAIL / CROSS SECTION / ASSEMBLED VIEW / PARTS LIST

HI-FLEX RAIL is made from heavy duty, wear resistent stainless steel with steel rack. The rail comes

in 57.7" (1.47 m) lengths and can be held in place with vacuum cups or magnets. This rail can be used

in straight applications or for bends down to 40" (1 m) radius, in or out. Hi-Flex rail can be used on

compound curvatures and can be twisted 10

o

per 24" (600 mm) of length.

Minimum

Radius

40" (1 m)

Minimum

Radius

40" (1 m)

FMD CROSS SECTION VIEW

A

B

C

A 3.995" 102 mm

B 0.080" 2 mm

C 0.250" 6.4 mm

3,5

1

4

6

24

2,7

PARTS LIST

ITEM PART NO. DESCRIPTION

1 FAS-0376 Screw, Hex Hd Cap 5/16-18

2 FAS-1370 Hex Nut 5/16-18

3 FAS-1444 Screw, Phil Pan Hd 10-32

4 FMD-1051 Track

5 FMD-1052 Rack Section, 3 Teeth

6 FMD-1053 Flex-Rail Splice Plate

7 WAS-0250 Washer, SAE 5/16

Page 25

CARRIAGE OPTIONS

The Universal Bug-O-Matic with AHC can be used with many BUG-O carriages, allowing it to be used

on any BUG-O rail. Each carriage is made of high-strength, lightweight aluminum alloy, with wheels

that ride in or along the rail to provide smooth, accurate travel. On each carriage, one set of wheels is

adjustable. All wheels contain permanently lubricated, sealed bearings and their steel components are

plated to resist corrosion.

MDP-1065 RELEASABLE CARRIAGE / EXPLODED VIEW / PART LIST

The MPD-1065 Releasable 12" Carriage has a carrying capacity of 100 lb (45 kg) and can be

placed anywhere on the rail by using the knob located on the side of the carriage, which engages or

disengages the wheels from the rail. Use with BUG-O Aluminum Rigid or Semi-Flex Rails.

6

5

4

ITEM QTY PART NO. DESCRIPTION

1 2 BUG-1984 External Adj. Leg & Wheel Assembly

2 2 FAS-0545 Screw, Soc Hd Cap 10-32 x 1/2

3 2 MPD-1045 Fixed Leg & Wheel Assembly

4 1 MPD-1049 Handle, Black

5 1 MPD-1059 Knob Screw (Included w/carriage)

6 1 MPD-1066 Carriage

2

3

MPD-1055 CARRIAGE 18" / EXPLODED VIEW / PART LIST

The 18" Carriage provides an extended deck for mounting accessories, wire feeder, etc. and has a

carrying capacity of 150 lb. (67.5 kg). Use with BUG-O Aluminum Rigid Rail.

5

1

ITEM QTY PART NO. DESCRIPTION

1 3 BUG-1984 External Adj. Leg & Wheel Assembly

2 3 BUG-2956 Fixed Leg & Wheel Assembly

3 4 FAS-0545 Screw, Soc Hd Cap 10-32 x 1/2

4 2 MPD-1049 Handle, Black

5 1 MPD-1055-PNT Carriage 18"

4

1

3

2

25

Page 26

BUG-5960 TUBE CARRIAGE / EXPLODED VIEW / PARTS LIST

The Tube Carriage features a split carriage body for quick and easy placement on the rail. It has a carrying

capacity of 100 lb (45 kg). The carriage also offers six (6) wheel positions for circumferential applications

over a wide range of diameters. Use with BUG-O Aluminum Rigid, Semi-Flex or Bent Rigid Rails.

ITEM QTY PART NO DESCRIPTION

1 1 BUG-5908A Plate Assembly (Incl. Spring x2

& Dowel Pin x2, not shown)

2 1 BUG-5907 Skirt, Right

3 1 BUG-5964 Skirt, Left

4 2 BUG-5918 Fixed Wheel Assembly

5 2 BUG-5920 Adj. Wheel Assembly

6 1 BUG-5961 Modied Cam Handle

7 1 BUG-5962 Cam Stop Block

8 1 BUG-5963 Swing Eye Bolt

9 1 BUG-5916 Dowel Pin

10 1 ARM-2316 Thrust Race

11 1 FAS-1353 Hex Nut, 1/4-20

12 2 FAS-0537 Screw, Soc Hd Cap 10-24 x 3/4

2

11

3

10

1

1

7

12

9

4

5

8

6

INSTALLING THE BUG-5960 DRIVE CARRIAGE

1. Select the correct pair of holes on each side of the carriage for the rail diameter being used (see

chart). If the wheels are not attached to the correct set of holes, remove them and bolt the wheel

brackets in selected holes. Tighten the bolts until the brackets are snug, but still free to rotate.

2. Open the cam handle to separate the

carriage. On the drive unit, loosen and turn

the clutch knob counterclockwise to declutch

the drive pinion.

3. Place the carriage on the rail with the wheels

in the rail grooves. Close the cam handle

and move the carriage back and forth a

few inches. The wheels on their mounting

brackets will align themselves correctly in

the rail grooves.

4. Verify that wheels are properly aligned, then

tighten the wheel mounting bolts

to lock them in position. Rotate the clutch

knob clockwise to engage the drive pinion

with the rack.

5. Verify that pinion is properly engaged in the rack. The correct wheel position will provide a minimum

of 1/8" engagement (approx. 3 mm) between the drive pinion and the gear rack. Note: For some rail

or pipe sizes, the pinion height may need to be adjusted.

Carriage

Wheel

Hole Set

A 20 - 25 500 - 635 9 - 21 230 - 530

B 23 - 35 585 - 890 12 - 31 300 - 790

C 30 - 44 760 - 1120 18 - 40 455 - 1015

D 41 - 60 1040 - 1525 29 - 54 735 - 1375

E 75 - 174 1905 - 4420 64 - 170 1625 - 4320

F at rail at rail

Note: Chart values are for reference only

BRR-1210

Pipe OD

Rail ID

in mm in mm

26

A

B

C

D

E

F

Page 27

FMD-1100 HI-FLEX CARRIAGE / EXPLODED VIEW / PARTS LIST

The Hi-Flex Carriage can be placed anywhere along the track using the quick release knob on the

side of the carriage to engage/disengage the wheels from the track. Use with BUG-O Hi-Flex Rails.

3

4

2

5

1

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-2708 Clamp

2 1 FMD-1060 FMD Clamp Block

3 1 FMD-1062 Carriage (Includes Items 4, 5 & 6)

4 1 FMD-1068 Fixed Wheel Mounting Block

5 1 FMD-1069 Adj. Wheel Mounting Block

6 1 FMD-1072 Knob

6

27

Page 28

ACCESSORIES

BUG-6553 RETROFIT CAS HALL EFFECT FOR BUG-5700 TO BUG-5704

AUTOMATED HEIGHT CONTROL

The BUG-6553 Retrot allows your Universal Bug-O-Matic to have Automated Height Control (AHC)

features. The AHC controls the welding tip to work distance and maintains a constant weld current, or

uniform weld penetration. AHC senses the actual weld current, compares this value to the setpoint, and

raises or lowers the welding gun accordingly. Controls for the AHC are self contained and its drives are

independent from those of the drive unit. AHC features a built-in time delay after the arc is struck, and

automatically shuts off when current drops too low (generally below 60 amp). The operator can temporarily override AHC using the manual jog switch while welding. AHC resumes as soon as the jog switch

is released. To disable the automated height control, move the Auto/Manual switch on the CAS Electronics Box (CAS-1555) to MANUAL.

NOTE: AHC is designed to work with the welding gun above the work piece. Contact Bug-O Systems

for other congurations.

28

Page 29

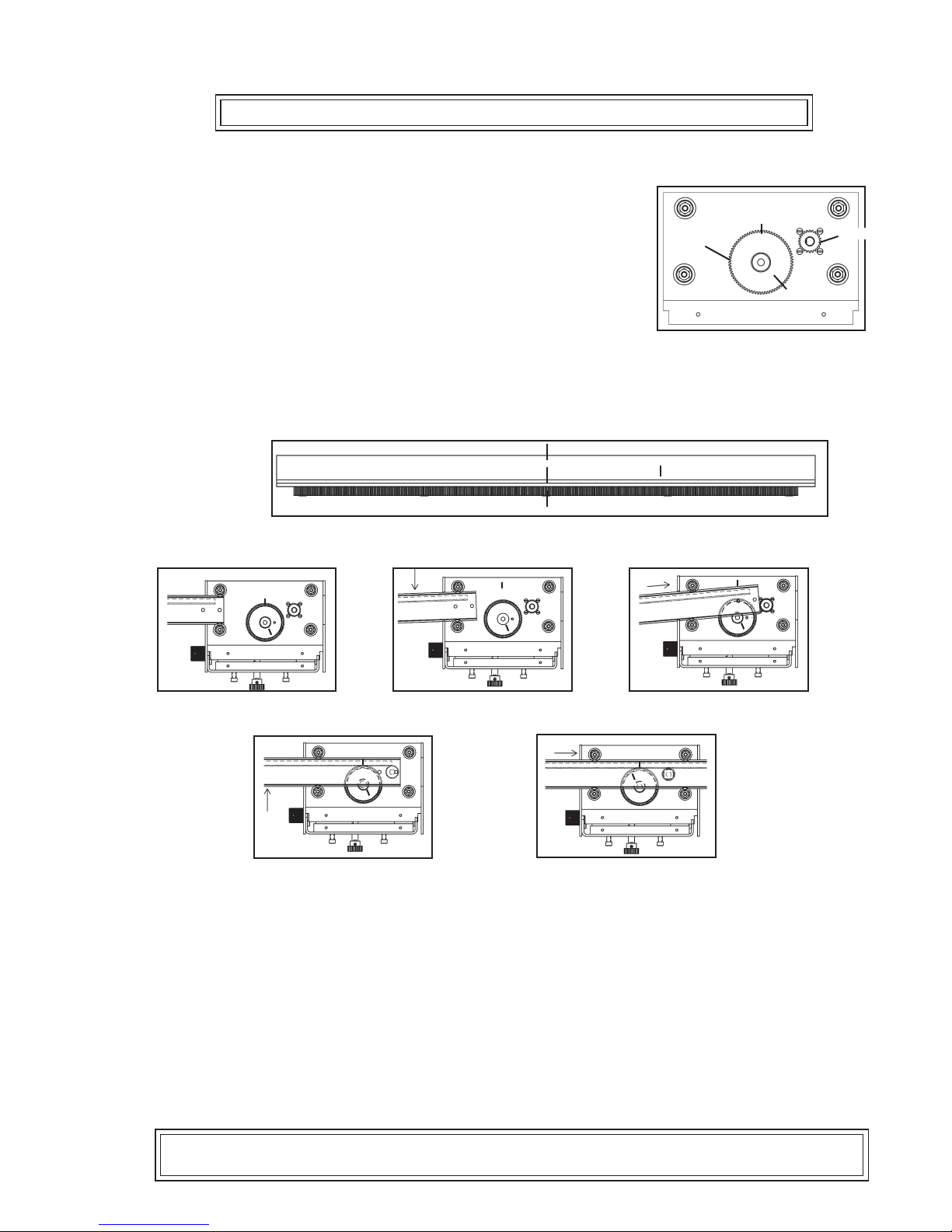

SERVICE PROCEDURE: INSTALLING THE CROSS ARM (WPD-1150)

OPTION 1 - In the Field

NOTE: Read and understand whole procedure before attempting.

Tools required - ash light or well lighted area, marking pen, tape measure or other measuring device.

1. Place machine on blocks to protect the drive pinion (underneath).

2. Turn machine OFF and disconnect from power supply.

3. Remove the Arm Stop (WPD-1164) and the Height Slide Assembly (CAS-1500).

Encoder

Gear

4. Remove the existing Cross Arm (WPD-1150). Manually

push/pull the Cross Arm from the machine

5. Looking from the clutch side of the drive unit, locate the reference mark on the mounting plate (“A” in Figure 1) and the

reference mark on the face of the brass encoder gear (“B” in

Figure 1).

Figure 1: Proper positioning of reference

marks A and B before the V-guide is inserted.

6. As shown in Figure 1, position reference “B” at approximately the 5 o’clock position.

7. Make a mark on the cross arm 3 5/8" right of center (“C” in Figure 2). This will serve as a reference

line for centering the cross arm.

A

Pinion

B

C

L

Figure 2: Placement of reference mark C on the V-guide.

C

8. Inserting from the brass gear side, install the Cross Arm, as shown in gures 3-7.

A

B

Figure 3: Insert Cross

Arm into guide wheels.

Figure 6: When arm is ready to

mesh with pinion, push up on arm.

Figure 4: Push down on

arm to tilt V-guide up.

A

B

A

B

Figure 5: Push cross arm into

machine. Avoid brass gear.

A

B

Figure 7: Push cross arm

in until it is centered.

A

B

Be careful not to bump or mesh brass gear and V-guide rack until V-guide is ready to engage pinion

also. Run the Cross Arm until it is centered (align reference mark “C” with face of side plate). Make

sure the brass gear teeth and the V-guide teeth do not skip.

9. If necessary, connect the Pendant Control (BUG-5755) to the Drive Unit (BUG-5980) using the Pendant Control Cable (BUG-5551-10).

10. On the control pendant, center steering control (1 1/2 turns from either extreme).

11. Connect the machine to a power supply of the proper voltage and turn machine ON to verify that

Cross Arm is centered. The centered V-Guide should stick out of the machine by about 4.25 in (110

mm) on each side.

12. If satised with position of Cross Arm, install Arm Stop and Height Slide Assembly; else repeat steps

4-11.

Note: Reference mark B will no longer apply if the potentiometer was changed in service or

the cross arm was previously centered using the electrical method on page 31.

29

Page 30

SERVICE PROCEDURE: INSTALLING THE CROSS ARM (WPD-1150)

OPTION 2 - The Electrical Way

Tools required: Ohm meter rated to at least 5k Ohm, at screw driver, 3/32" hex key, tape measure or

other measuring device.

1. Place the machine on blocks to protect the pinion (underneath).

2. Remove Right Side Panel (BUG-5708) from the clutch-side of the Drive Box (BUG-5710).

3. If necessary, install the Cross Arm (WPD-1150). Insert from the brass gear side. Make sure the

brass gear teeth and the V-guide teeth do not skip.

4. Center the cross arm. The cross arm will stick out of the machine by 4.25 in (110 mm) on side

when centered.

5. Loosen only the set screw on the gear side of the coupling between the potentiometer and the

brass gear. Refer to gure 8.

6. Unplug wire harness leading from Potentiometer.

7. Using Ohmmeter, measure resistance across Node 1 and Node 3 (refer to gure 9). This should

measure approximately 5000 ohms.

8. Rotate potentiometer until resistance across Node 1 and Node 2 is equal to resistance across

Node 2 and Node 3. This should be approximately 2500 ohms. The potentiometer is now centered.

9. While being careful not to move the potentiometer, secure the coupling to the gear shaft.

10. Plug wire harness from potentiometer into proper terminal on the speed control board (CAS-1770).

11. Connect to power supply of appropriate voltage, turn machine ON and verify that Cross Arm is

centered.

12. Install Right Side Panel.

13. If necessary, install the Arm Stop (WPD-1164) and gun mounting hardware to the ends of the

cross arm.

Brass

(Encoder)

Gear

2

3

1

Potentiometer

Figure 8: Simplied side view of machine with right cover

30

Coupling

(BUG-5708) removed.

Figure 9: Potentiometer

nodes used in Steps 7 & 8.

Page 31

WARRANTY

Model _____________________________

Limited 3-Year Warranty

For a period ending one (1) year from the date of invoice, Manufacturer warrants that any new machine or

part is free from defects in materials and workmanship and Manufacturer agrees to repair or replace at its

option, any defective part or machine. HOWEVER, if the invoiced customer registers the Product Warranty

by returning the Warranty Registration Card supplied with the product within 90 days of the invoice date, or

by registering on-line at www.bugo.com, Manufacturer will extend the warranty period an additional two (2)

years which will provide three (3) total years from the date of original invoice to customer. This warranty does

not apply to machines which, after Manufacture’s inspection are determined by Manufacturer to have been

damaged due to neglect, abuse, overloading, accident or improper usage. All shipping and handling charges

will be paid by the customer.

The foregoing express warranty is exclusive and Manufacturer makes no representation or warranty (either

express or implied) other than as set forth expressly in the preceding sentence. Specifically, Manufacturer

makes no express or implied warranty of merchantability or fitness for any particular purpose with respect to

any goods. Manufacturer shall not be subject to any other obligations or liabilities whatsoever with respect to

machines or parts furnished by Manufacturer.

Manufacturer shall not in any event be liable to Distributor or any customer for any loss of profits, incidental or

consequential damages or special damages of any kind. Distributor’s or customer’s sole and exclusive remedy

against Manufacturer for any breach of warranty, negligence, strict liability or any other claim relating to goods

delivered pursuant hereto shall be for repair or replacement (at Manufacturer’s option) of the machines or parts

affected by such breach.

Serial No. __________________________

Date Purchased: ____________________

Where Purchased:___________________

Distributor’s Warranty:

In no event shall Manufacturer be liable to Distributor or to any customer thereof for any warranties,

representations or promises, express or implied, extended by Distributor without the advance written consent

of Manufacturer, including but not limited to any and all warranties of merchantability or fitness for a particular

purpose and all warranties, representations or promises which exceed or are different from the express limited

warranty set forth above. Distributor agrees to indemnify and hold Manufacturer harmless from any claim

by a customer based upon any express or implied warranty by Distributor which exceeds or differs from

Manufacturer’s express limited warranty set forth above.

HOW TO OBTAIN SERVICE:

If you think this machine is not operating properly, re-read the instruction manual carefully, then call

your Authorized BUG-O dealer/distributor. If they cannot give you the necessary service, write or phone

us to tell us exactly what difculty you have experienced. BE SURE to mention the MODEL and SERIAL

numbers.

31

Loading...

Loading...