Page 1

MMIG125

Flux-cored 125 Amp Welder

Assembly & Operating Instructions

READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT.

This manual provides important information on proper operation & maintenance. Every effort has been

made to ensure the accuracy of this manual. These instructions are not meant to cover every possible

condition and situation that may occur. We reserve the right to change this product at any time

without prior notice.

IF THERE IS ANY QUESTION ABOUT A CONDITION BEING SAFE OR UNSAFE, DO

NOT OPERATE THIS PRODUCT!

HAVE QUESTIONS OR PROBLEMS? DO NOT RETURN THIS PRODUCT TO THE

RETAILER - CONTACT CUSTOMER SERVICE.

If you experience a problem or need parts for this product, visit our website http://www.buffalotools.com

or call our customer help line at 1-888-287-6981, Monday-Friday, 8 AM - 4 PM Central Time. A copy of

the sales receipt is required.

FOR CONSUMER USE ONLY – NOT FOR PROFESSIONAL USE.

KEEP THIS MANUAL, SALES RECEIPT & APPLICABLE WARRANTY FOR FUTURE

REFERENCE.

Page 2

GENERAL PRODUCT SPECIFICATIONS

SPECIFICATIONS

• Thermal Overload Protection

• Output: 80A (rated current)@18V-20%, 125A (peak current)

• Input: 120V, 60Hz, 20A, 1Ph

• Duty Cycle 20%@80 AMPS

• Wire Size: .030 - .035 Inch

• Heat Settings: Two

• MAX Metal Thickness: 18 Gauge / 3/16"

FEATURES:

• Includes Ground Cable With Clamp, Welding Gun, Face Shield & Brush H a mmer

KEEP THIS MANUAL, SALES RECEIPT & APPLICA BLE WARRANTY FOR FUTURE

REFERENCE.

READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT.

When unpacking, check to make sure all parts listed are included. If any parts are missing or broken,

please call Customer Service at 1-888-287-6981.

FOR CONSUMER USE ONLY – NOT FOR PROFESSIONAL USE

2

Page 3

TABLE OF CONTENTS

The warnings, cautions and instructions discussed in this instruction manual cannot

cover all possible conditions or situations that

could occur. It must be understood by the

operator that common sense and caution are

factors which cannot be built into this product, but must be supplied by the operator.

Reading this operator’s manual before using

the welder will enable you to do a better,

safer job. Learn the welder’s applications and

limitations as well as the specific potential

hazards peculiar to welding.

SAFETY SUMMARY

IMPORTANT SAFETY INFORMATION

The following safety information is provided

as guidelines to help you operate your new

welder under the safest possible conditions.

Any equipment that uses electrical power

can be potentially dangerous to use when

safety or safe handling instructions are not

known or not followed. The following safety

information is provided to give the user the

information necessary for safe use and operation.

A procedure step preceded by a WARNING

is an indication that the next step contains a

procedure that might be injurious to a person

if proper safety precautions are not heeded.

A procedure preceded by a CAUTION is an

indication that the next step contains a procedure that might damage the equipment

being used.

A NOTE may be used before or after a procedure step to highlight or explain something

in that step.

READ ALL SAFETY INSTRUCTIONS

CAREFULLY before attempting to install,

operate, or service this welder. Failure to

comply with these instructions could result in

personal injury and/or property damage.

RETAIN THESE INSTRUCTIONS FOR

FUTURE REFERENCE.

Note:

• The following safety alert symbols

identify important safety messages in this

manual.

• When you see one of the symbols shown

here, be alert to the possibility of personal injury and carefully read the message

that follows.

This symbol indicates that the

possibility of electric shock hazard

exists during the operation of the

step(s) that follow.

This symbol indicates that the

possibility of fire hazard exists

during the operation of the step(s)

that follow.

This symbol indicates that the

helmet must be worn during the

step(s) that follow to protect

against eye damage and burns

due to flash hazard.

This symbol indicates that the

possibility of toxic gas hazard

exists during operation of the

step(s) that follow.

This symbol indicates that the

possibility of being burned by hot

slag exists during operation of the

step(s) that follow.

This symbol indicates that the

eye protection should be worn to

protect against flying debris in the

following step(s).

• Published standards on safety are

available. They are listed in ADDITIONAL

SAFETY INFORMATION at the end of

this SAFETY SUMMARY.

The National Electrical Code, Occupation

Safety and Health Act regulations, local

industrial codes and local inspection requirements also provide a basis for equipment

installation, use, and service.

3

Page 4

SHOCK HAZARDS

WARNING

ELECTRIC SHOCK CAN KILL! To reduce

the risk of death or serious injury from shock,

read, understand, and follow the following

safety instructions. In addition, make certain

that anyone else who uses this welding

equipment, or who is a bystander in the

welding area understands and follows these

safety instructions as well.

• IMPORTANT! TO REDUCE THE RISK

OF DEATH, INJURY, OR PROPERTY

DAMAGE, DO NOT ATTEMPT OPERATION of this welding equipment until you

have read and understand the following

safety summary.

• Do not, in any manner, come into physical

contact with any part of the welding current circuit. The welding current circuit

includes:

a. the work piece or any conductive

material in contact with it,

b. the ground clamp,

c. the electrode or welding wire,

d. any metal parts on the electrode

holder, or wire feed torch.

• Do not weld in a damp area or come in

contact with a moist or wet surface.

• Do not attempt to weld if any part of clothing or body is wet.

• Do not allow the welding equipment

to come in contact with water or moisture.

• Do not drag welding cables, wire feed

torch, or welder power cord through or

allow them to come into contact with

water or moisture.

• Do not touch welder, attempt to turn

welder on or off if any part of the body or

clothing is moist or if you are in physical

contact with water or moisture.

• Do not attempt to plug the welder into the

power source if any part of body or clothing is moist, or if you are in physical contact with water or moisture.

• Do not connect welder work piece clamp

to or weld on electrical conduit.

• Do not alter power cord or power cord

plug in any way.

• Do not attempt to plug the welder

into the power source if the ground prong

on power cord plug is bent over, broken

off, or missing.

• Do not allow the welder to be connected

to the power source or attempt to weld if

the welder, welding cables, welding site,

or welder power cord are exposed to any

form of atmospheric precipitation, or salt

water spray.

• Do not carry coiled welding cables around

shoulders, or any other part of the body,

when they are plugged into the welder.

• Do not modify any wiring, ground

connections, switches, or fuses in this

welding equipment.

• Wear welding gloves to help insulate

hands from welding circuit.

• Keep all liquid containers far enough

away from the welder and work area so

that if spilled, the liquid can not possibly

come in contact with any part of the

welder or electrical welding circuit.

• Replace any cracked or damaged parts

that are insulated or act as insulators

such as welding cables, power cord, or

electrode holder IMMEDIATELY.

FLASH HAZARDS

WARNING

ARC RAYS CAN INJURE EYES AND BURN

SKIN! To reduce the risk of injury from arc

rays, read, understand, and follow the following safety instructions. In addition, make certain that anyone else that uses this welding

equipment, or is a bystander in the welding

area understands and follows these safety

instructions as well. Headshields and filter

should conform to ANSI Z87.1 standards.

• Do not look at an electric arc without

proper protection. A welding arc is

extremely bright and intense and, with

inadequate or no eye protection, the retina can be burned, leaving a permanent

dark spot in the field of vision. A shield or

helmet with a number 10 shade filter lens

(minimum) must be used.

• Do not strike a welding arc until all

bystanders and you (the welder) have

welding shields and/or helmets in place.

4

Page 5

• Do not wear a cracked or broken helmet

and replace any cracked or broken filter

lenses IMMEDIATELY.

• Do not allow the uninsulated portion of the

wire feed torch to touch the ground clamp

or grounded work to prevent an arc flash

from being created on contact.

• Provide bystanders with shields or helmets fitted with a #10 shade filter lens.

• Wear protective clothing. The intense light

of the welding arc can burn the skin in

much the same way as the sun, even

through light-weight clothing. Wear dark

clothing of heavy material. The shirt worn

should be long sleeved and the collar kept

buttoned to protect chest and neck.

• Protect against REFLECTED ARC RAYS.

Arc rays can be reflected off shiny surfaces such as a glossy painted surface,

aluminum, stainless steel, and glass. It is

possible for your eyes to be injured by

reflected arc rays even when wearing a

protective helmet or shield. If welding with

a reflective surface behind you, arc rays

can bounce off the surface, then off the filter lens on the inside of your helmet

or shield, then into your eyes. If a reflective background exists in your welding

area, either remove it or cover it with

something non-flammable and non-reflective. Reflective arc rays can also cause

skin burn in addition to eye injury.

FIRE HAZARDS

WARNING

FIRE OR EXPLOSION CAN CAUSE

DEATH, INJURY, AND PROPERTY DAMAGE! To reduce the risk of death, injury, or

property damage from fire or explosion, read,

understand, and follow the following safety

instructions. In addition, make certain that

anyone else that uses this welding equipment, or is a bystander in the welding area,

understands and follows these safety instructions as well. REMEMBER! Arc welding by

nature produces sparks, hot spatter, molten

metal drops, hot slag, and hot metal parts

that can start fires, burn skin, and damage

eyes.

• Do not wear gloves or other clothing that

contains oil, grease, or other flammable

substances.

• Do not wear flammable hair preparations.

• Do not weld in an area until it is checked

and cleared of combustible and/or flammable materials. BE AWARE that sparks

and slag can fly 35 feet and can pass

through small cracks and openings. If

work and combustibles cannot be separated by a minimum of 35 feet, protect

against ignition with suitable, snug-fitting,

fire resistant, covers or shields.

• Do not weld on walls until checking for

and removing combustibles touching the

other side of the walls.

• Do not weld, cut, or perform other such

work on used barrels, drums, tanks, or

other containers that had contained a

flammable or toxic substance. The techniques for removing flammable substance

and vapors, to make a used container

safe for welding or cutting, are quite complex and require special education and

training.

• Do not strike an arc on a compressed

gas or air cylinder or other pressure vessel. Doing so will create a brittle area that

can result in a violent rupture immediately

or at a later time as a result of rough

handling.

• Do not weld or cut in an area where the

air may contain flammable dust (such as

grain dust), gas, or liquid vapors (such as

gasoline).

• Do not handle hot metal, such as the work

piece or electrode stubs, with bare hands.

• Wear leather gloves, heavy long sleeve

shirt, cuffless trousers, high-topped

shoes, helmet, and cap. As necessary,

use additional protective clothing such as

leather jacket or sleeves, fire resistant

leggings, or apron. Hot sparks or metal

can lodge in rolled up sleeves, trouser

cuffs, or pockets. Sleeves and collars

should be kept buttoned and pockets

eliminated from the shirt front.

• Have fire extinguisher equipment handy

for immediate use! A portable chemical

fire extinguisher, type ABC, is recommended.

• Wear ear plugs when welding overhead

to prevent spatter or slag from falling into

ear.

5

Page 6

• Make sure welding area has a good,

solid, safe floor, preferably concrete or

masonry, not tiled, carpeted, or made of

any other flammable material.

• Protect flammable walls, ceilings, and

floors with heat resistant covers or

shields.

• Check welding area to make sure it is

free of sparks, glowing metal or slag, and

flames before leaving the welding area.

FUME HAZARDS

WARNING

FUMES, GASSES, AND VAPORS CAN

CAUSE DISCOMFORT, ILLNESS, AND

DEATH! To reduce the risk of discomfort, ill-

ness, or death, read, understand, and follow

the following safety instructions. In addition,

make certain that anyone else that uses this

welding equipment or is a bystander in the

welding area, understands and follows these

safety instructions as well.

• Do not weld in an area until it is checked

for adequate ventilation as described in

ANSI standard #Z49.1. If ventilation is not

adequate to exchange all fumes and

gasses generated during the welding

process with fresh air, do not weld unless

you (the welder) and all bystanders are

wearing air-supplied respirators.

• Do not heat metals coated with, or that

contain, materials that produce toxic

fumes (such as galvanized steel), unless

the coating is removed. Make certain the

area is well ventilated, and the operator

and all bystanders are wearing air-supplied respirators.

• Do not weld, cut, or heat lead, zinc, cadmium, mercury, beryllium, or similar metals without seeking professional advice

and inspection of the ventilation of the

welding area. These metals produce

EXTREMELY TOXIC fumes which can

cause discomfort, illness, and death.

• Do not weld or cut in areas that are near

chlorinated solvents. Vapors from chlorinated hydrocarbons, such as trichloroethylene and perchloroethylene, can be

decomposed by the heat of an electric

arc or its ultraviolet radiation. These

actions can cause PHOSGENE, a HIGHLY TOXIC gas to form, along with other

lung and eye-irritating gasses. Do not

weld or cut where these solvent vapors

can be drawn into the work area or where

the ultraviolet radiation can penetrate to

areas containing even very small

amounts of these vapors.

• Do not weld in a confined area unless it

is being ventilated or the operator (and

anyone else in the area) is wearing an

air-supplied respirator.

• Stop welding if you develop momentary

eye, nose, or throat irritation as this indicates inadequate ventilation. Stop work

and take necessary steps to improve

ventilation in the welding area. Do not

resume welding if physical discomfort

persists.

6

Page 7

SERVICE

Tool service must be performed only by qualified repair personnel. Service or maintenance by unqualified

personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts and follow instructions in the manual. Use

of unauthorized parts or failure to follow Maintenance Instructions may create a risk of shock or injury.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

This manual contains important information regarding safety, operation, maintenance and storage of this product.

Before use, read carefully and understand all warnings, cautions, instructions and labels. Failure to do so could result

in serious personal injury, property damage or even death.

IMPORTANT SAFETY INSTRUCTIONS

Before using this tool, you need to become familiar with its operation. If you are unsure about the

operation of the tool, or have any questions about its proper use, call the Customer Service Department at

1-888-287-6981. Follow these instructions for safe handling of the tool:

? Be sure your w ork area is clean and secure. Be sure the area is free from all foreign material, nails,

staples, or any other material.

? Always use the appropriate safety gear when operating. Including but not limited to, goggles, dust

mask or respirator.

MMIG125 MIG / Fluxcore Welder Instructions

7

Page 8

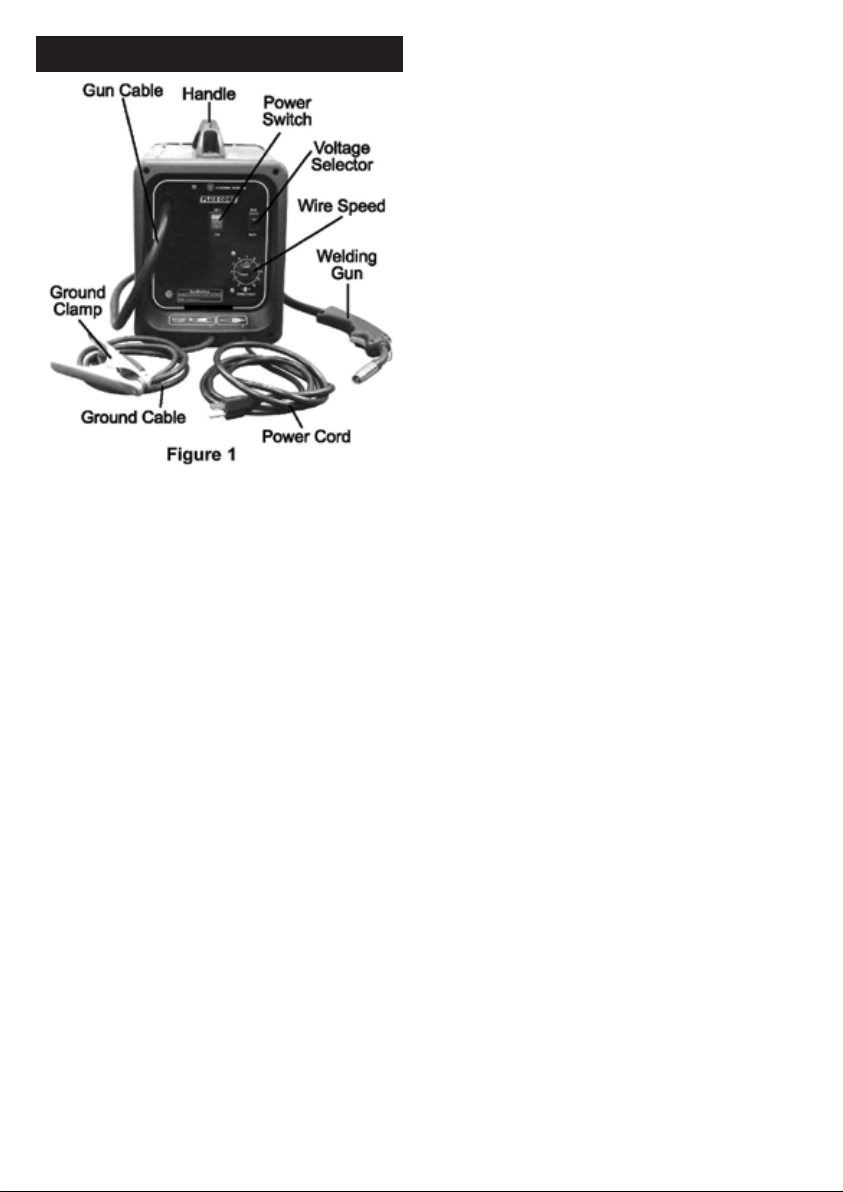

Page 9

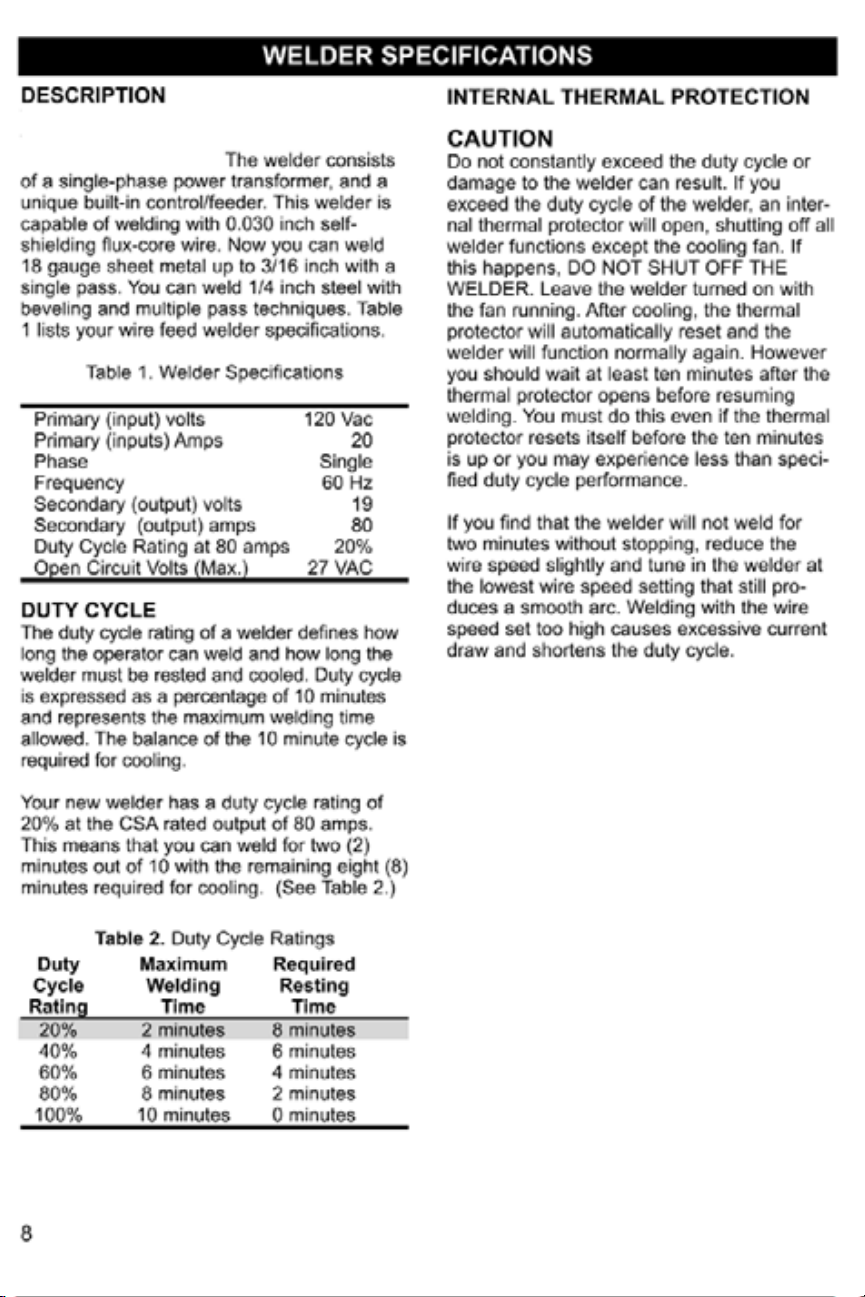

KNOW YOUR WELDER

Figure 1. Model WE6482 Welder

Handle – Rugged, top mounted handle

allows for easy transport of your welder.

Wire Speed Control – Use this dial to adjust

the speed at which the welder feeds wire to

the torch. 1 is the slowest wire feed speed, 10

is the highest. You will need to adjust or “tunein” your wire speed for different welding conditions (thickness of metals, metal type, wire

size, etc.). When the wire speed is properly

“tuned-in” the welding wire will melt into the

material you are welding as quickly as it is fed

through the welding torch.

Voltage Selector – This two position switch

adjusts the voltage or “heat” of your welder.

Select MIN setting for lower voltage and

MAX setting for higher voltage. Different

materials and material thickness will require

different voltage settings. You will need to

adjust your voltage accordingly for different

welding conditions. By properly adjusting

your voltage settings and wire feed speed,

you will enable clean, precision welds.

Power Switch – This switch turns the welder

ON and OFF. (Make sure the power switch is

in the OFF position before performing any

maintenance on the welder.)

Power Cord – This is a standard, grounded

120 volt power cord. (Make sure you are

using a properly grounded 120 Vac, 60Hz,

single phase, 20 amp power source.)

Ground Clamp – Attaching the ground

clamp to your work piece “completes” the

welding current circuit. You must attach the

ground clamp to the metal you are welding. If

the ground clamp is not connected to the

metal work piece you intend to weld, the

welder will not have a completed circuit and

you will be unable to weld. A poor connection

at the ground clamp will waste power and

heat. Scrape away dirt, rust, scale, oil or

paint before attaching the ground clamp.

Ground Cable – The ground cable connects

the ground clamp to the internal workings of

the w elder.

Welding Torch and Cable – The welding

torch controls the delivery of the welding wire

to the material to be welded. The welding

wire is fed through the welding cable and

welding torch when the welding torch trigger

is pulled. You will need to install a contact tip

and welding nozzle to the end of the welding

torch, as described later in this manual, prior

to welding.

Circuit Breaker – This unit is equipped with

a circuit breaker switch which protects the

welder’s power supply from line voltage

surges. If circuit breaker is tripped, reset by

pressing the button located inside the access

panel on the dividing wall of the welder.

Welding Terms -Now that you are familiar

with the main parts of the welder, make note

of the following terms. You will see them

used throughout this manual.

weld puddle: The localized volume

of molten metal in a weld prior to its

solidification.

weld angle: The angle of the welding wire,

as it extends from the welding torch, in relation to the item being welded.

slag: The protective coating that forms on

the surface of molten metal.

arc: A sustained luminous discharge of electricity across a gap in a circuit.

welding bead: The extended build up of a

weld, made by pushing or pulling the weld

puddle.

9

Page 10

WELDER INSTALLATION

POWER SOURCE CONNECTION

POWER REQUIREMENTS

This welder is designed to operate on a

properly grounded 120 volt, 60Hz, singlephase alternating current (ac) power source

fused with a 20 amp time delayed fuse or circuit breaker. It is recommended that a qualified electrician verify the ACTUAL VOLTAGE

at the receptacle into which the welder will

be plugged and confirm that the receptacle is

properly fused and grounded. The use of the

proper circuit size can eliminate nuisance circuit breaker tripping when welding.

DO NOT OPERATE THIS WELDER if the

ACTUAL power source voltage is less than

105 volts ac or greater than 132 volts ac.

Contact a qualified electrician if this problem

exists. Improper performance and/or damage

to the welder will result if operated on inadequate or excessive power.

CONNECT TO POWER SOURCE

WARNING

High voltage danger from power source!

Consult a qualified electrician for proper

installation of receptacle at the power source.

This welder must be grounded while in use to

protect the operator from electrical shock. If

you are not sure if your outlet is properly

grounded, have it checked by a qualified electrician. Do not cut off the grounding prong or

alter the plug in any way and do not use any

adapters between the welder’s power cord

and the power source receptacle. Make sure

the POWER switch is OFF then connect your

welder’s power cord to a properly grounded

120 Vac, 60 Hz, single phase, 20 amp power

source.

Select a properly grounded extension cord

that will mate directly with the power source

receptacle and the welder power cord without the use of adapters. Make certain that

the extension cord is properly wired and in

good electrical condition. Extension cords

must be a #12 gauge cord at the smallest.

Do not use an extension cord over 25 ft. in

length.

ASSEMBLING THE WELDER

The following procedures describe the

process required to assemble, install, maintain, and prepare to weld with your new wire

feed welder.

UNPACKING THE WELDER

1. Remove any cartons or bags containing

parts/accessories. (Most parts are

shipped inside the welder door.)

2. Open the cartons or bags packed with

your welder and inspect their contents for

damage.

3. Layout the parts and compare them to

the the packing list in Table 1 to familiarize yourself with the parts and what they

are called. This will help you when reading the manual.

PACKING LIST

Table 3 contains a list of the items you will

find packed in the carton.

Table 3. Packing List

ITEM QTY.

Welder 1

Face Shield 1

Face Shield Handle 1

Handle Screws 2

Shaded Lens 1

Welder Handle 1

Wire Brush/Hammer 1

Parts Bag 1

Contact Tip 0.030 1

Contact Tip 0.035 1

Nozzle 1

.030 Fluxcore sample

Manual, Instruction 1

EXTENSION CORDS

For optimum welder performance, an extension cord should not be used unless

absolutely necessary. If necessary, care must

be taken in selecting an extension cord

appropriate for use with your specific welder.

10

ASSEMBLE THE FACE SHIELD

1. Insert the upper tongue (1) of the handle

(B) into the upper slot (2) on the face

shield (A).

2. Align the second tab on the handle with

the second slot in the face shield by

pushing the bottom of the handle in

Page 11

towards the face mask (4), while at the

same time pushing upwards (5).

(Alignment of the second tab is made

easier by applying pressure to the point

(3) shown below.)

Figure 2.

Face Shield

Assembly

3. Install the

dark glass

(D) by

sliding it

into place

behind the

glass

retaining tabs (E).

4. Once protective dark glass has been

installed into face shield, secure it in

place with the retaining clips (F). Align the

holes on each of the retaining clips with

the pins on the retaining tabs and firmly

press into place.

INSTALLING THE HANDLE

1. Line up the holes in the handles with the

holes on the top of the welder.

2. Place a lock washer then a washer onto

the welder handle screws.

3. Insert the screws with the washers

through the holes on the welder handle

and into the top of the welder and tighten.

(see Figure 3)

ALIGN AND SET THE DRIVE ROLLER

Before installing any welding wire into the

unit, the proper sized groove must be placed

into position on the wire drive mechanism.

Figure 4. Feed Motor

Adjust the drive roller according to the

following steps:

1. Open the door to the welder drive compartment.

2. Remove the drive tension by loosening

the tension adjusting knob and lifting the

Drive Tension Adjustor away from the

Drive Tension Arm. Pull the drive tension

arm away from the drive roller.

3. If there is wire already installed in the

welder, roll it back onto the wire spool by

hand-turning the spool counterclockwise.

Be careful not to allow the wire to come

out of the rear end of the inlet guide tube

without holding onto it or it will unspool

itself. Put the end of the wire into the hole

on the outside edge of the wire spool and

bend it over to hold the wire in place.

Remove the spool of wire from the drive

compartment of the welder.

4. Rotate the Drive Roller Cap counterclockwise and remove it from the Drive Roller.

5. Pull the Drive Roller off of the Drive

Roller Shaft.

Figure 3. Handle Installation

Figure 5. Drive Roller Adjustments

11

Page 12

Note: The drive roller has two wire size

grooves built into it. When installing the drive

roller, the number stamped on the drive roller

for the wire size you are using should be facing you. Use only the proper size drive roller

when using your welder.

Table 4 indicates which drive roller groove

should be used with each wire diameter size.

Wire Diameter Drive Roller Groove:

.030 inch 0.8

.035 inch 0.9

Table 4. Drive Roller Sizing

so will cause burn through (blowing holes)

in the metal you are intending to we

• If a spool has developed heavy oxidation,

the only solution to the problem is to discard the spool of wire.

If you have an oxidized spool of wire, do not

discard it until you have unspooled a few

turns of wire to see if the wire further down

on the spool is in usable condition, if not, –

discard the spool.

ld.

INSTALL THE WELDING WIRE

WARNING

4. Find the side of the drive roller that is

stamped with the same wire diameter as

that of the wire being installed (see

Figure 6). Push the drive roller onto the

drive roller shaft, with the side stamped

with the desired wire diameter facing you.

Figure 6. Drive Roller

5. Reinstall the Drive Roller Cap and lock in

place by turning it clockwise.

6. Close the door to the welder drive compartment.

SELECTING THE WELDING WIRE

This welder uses both four inch or eight inch

spools of 0.030 inch (0.8mm) or 0.035 inch

(0.9mm) self shielding flux-core wire. Steel

from 18 gauge up to 3/16 inch thick can be

welded with this wire.

NOTE:

• Metal thinner than 18 gauge cannot be

welded with this machine. Attempting to do

Electric shock can kill! Always turn the

POWER switch OFF and unplug the power

cord from the ac power source before

installing wire.

Tech Tip: Before installing welding wire,

make sure that you have removed any old

wire from the Torch Assembly. This will help

to prevent the possibility of the wire jamming

inside the Torch Liner.

Be very careful when removing the welding

nozzle. The contact tip on this welder is electrically hot whenever the torch trigger is

pulled. Make certain POWER is turned OFF.

1. Remove the nozzle and contact tip from

the end of the torch assembly.

2. Make sure the proper groove on the drive

roller is in place for the wire being

installed. If the proper groove is not in

place, change the drive roller as

described above.

3. Unwrap the spool of wire and then find

the leading end of the wire (it goes

through a hole in the oute

spool and is bent over the spool edge to

prevent the wire from unspooling), BUT

DO NOT UNHOOK IT YET.

4. Place the spool on the spindle in such a

manner that when the wire comes off the

spool, it will look like the top illustration in

Figure 7. The welding wire should always

come off the top of the spool into the

drive mechanism.

r edge of the

12

Page 13

Figure 7. Wire Installation

5. If you are installing a four-inch spool of

wire, install the drive brake hardware on

the top of the spool of wire according to

figure 8A. If you are installing an eight-inch

spool, install the spindle adapter and drive

brake hardware as shown in Figure 8B.

The purpose of the drive brake is to cause

the spool of wire to stop turning at nearly

the same moment that wire feeding stops.

Note: If TOO MUCH tension is applied to the

wire spool, the wire will slip on the drive roller

or will not be able to feed at all. If TOO LITTLE tension is applied, the spool of wire will

want to unspool itself. Readjust the drive

brake tension as necessary to correct for

either problem.

7. After checking to make sure that your

welder is disconnected from the ac power

source, free the leading end of the wire

from the spool, but do not let go of it until

told to do so, or the wire will unspool itself.

8. Using a wire cutter, cut the bent end off

the leading end of the wire so that only a

straight leading end remains.

9. Loosen the tension adjusting knob holding

the drive tension arm in place and lift the

tension arm up off the drive roller.

10. Insert the leading end of the wire into the

inlet guide tube. Then push it across the

drive roller and into the torch assembly

about six inches.

CAUTION

Make certain that the welding wire is actually

going into the torch liner. Be very sure it has

not somehow been accidentally been routed

alongside the liner or even in some other

direction. If this should happen, the wire

could feed inside the cable casing or take a

right angle and follow the wires and gas hose

inside the welder. It could also feed back on

itself jamming up the mechanism.

Figure 8A. Drive

Brake Hardware

Installation

6. Once the drive brake hardware is installed,

set the spool tension.

a) With one hand, turn the wire spool and

continue turning it while adjusting the

tension on the spool.

b) With your free hand, tighten (turn clock-

wise) the drive tension adjustment knob.

c) Stop tightening when drag is felt on the

wire spool that you are turning, then stop

hand-turning the wire spool.

Figure 8B. Spindle

Adapter and Drive

Brake Installation

11. Line the wire up in groove of the drive

roller, then allow the drive tension arm to

drop onto the drive roller.

12. Flip the quick release drive tensioner back

up into position on the drive tensioner arm.

13. Tighten (turn clockwise) the drive tension

adjusting knob until the tension roller is

applying enough force on the wire to prevent it from slipping out of the drive

assembly.

14. Let go of the wire.

15. Connect the welder power cord to the ac

power source. Turn the welder ON. Set

the VOLTAGE switch to the voltage (heat)

setting recommended for the gauge metal

that is to be welded. Refer to the label

mounted on the cover, inside the drive

compartment, for recommended voltage

(heat) settings for your welding job. The

VOLTAGE selector controls the weld

13

Page 14

heat. There are two voltage heat selections (labeled MIN and MAX) available on

this welder. Position MIN provides the

lowest voltage (heat) and position MAX

the highest voltage (heat).

16. Set the WIRE SPEED control to the middle of the wire speed range.

17. Straighten the torch cable and pull the

trigger on the welding torch to feed the

wire through the torch assembly.

18. When at least an inch of wire sticks out

past the end of the torch, release the

trigger.

19. Turn the Power Switch to the OFF position.

20. Select a contact tip stamped with the

same diameter as the wire being used. If

stamped in metric see Table 4 on p. 12 of

this manual.

SET THE WIRE DRIVE TENSION

WARNING

Arc flash can injure eyes! To reduce the

risk of arc flash, make certain that the wire

coming out of the end of the torch does not

come in contact with work piece, ground

clamp or any grounded material during the

drive tension setting process or arcing will

occur.

1. Pull the trigger on the torch.

2. Turn the drive tension adjustment knob

clockwise, increasing the drive tension

until the wire seems to feed smoothly

without slipping.

Note: Due to inherent variances in flux-cored

welding wire, it may be necessary to use a

contact tip one size larger than your flux core

wire if wire jams occur.

21. Slide the contact tip over the wire (protruding from the end of the torch). Thread

the contact tip into the end of the torch

and hand-tighten securely.

22. Install the nozzle on the torch assembly.

For best results, coat the inside of the

nozzle with anti-stick spray or gel.

23. Cut off the excess wire that extends past

the end of the nozzle.

24. Turn the welder ON.

When set correctly, there should be no slippage between the wire and the drive roller

under normal conditions. If an obstruction

occurs along the wire feed path, the wire

should then slip on the drive roller.

After the tension is properly adjusted, the

quick release drive tensioner may unlocked

and relocked and no readjustment of the

drive tension adjustment knob will be necessary (unless the diameter or type of wire is

changed).

14

Page 15

OPERATION

Operation of this welder consists of selecting

and adjusting operating controls for optimum

voltage (welding heat) and wire speed

settings.

TUNING IN THE WIRE SPEED

This is one of the most important parts of

MIG welder operation and must be done

before starting each welding job or whenever

any of the following variables are changed:

heat setting, wire diameter, or wire type.

CONTROLS AND INDICATORS

WARNING

Electric shock can kill! Whenever the Torch

Trigger switch is in the ON position, the welding circuit is activated. Under this condition,

an arc will occur if the welding wire or any

part of the welding circuit comes in contact

with welding ground.

POWER SWITCH - The power switch supplies electrical current to the welder.

Whenever the power switch is in the ON

position, the welding circuit is activated.

ALWAYS turn the power switch to the OFF

position and unplug the welder before performing any maintenance.

VOLTAGE SELECTOR - The voltage selector controls the welding heat. The voltage

selector is labeled "MIN" and "MAX". MIN is

the lowest heat and MAX is the highest.

Refer to the label inside the welder side door

(or on page 29 of this manual) for recommended voltage selector settings for your

welding job. Switch position “MAX” produces

the rated output of 80 amps.

WIRE SPEED CONTROL - The wire speed

control adjusts the speed at which the wire is

fed out of the welding torch. The wire speed

needs to be closely matched (tuned-in) to the

rate at which it is being melted off. Some

things that affect wire speed selection are the

type and diameter of the wire being used, the

heat setting selected, and the welding position

to be used.

Note: The wire will feed faster without an

arc. When an arc is being drawn, the wire

speed will slow down.

1. Connect the Ground Clamp to a scrap

piece of the same type of material which

you will be welding. It should be equal to

or greater than the thickness of the actual

work piece, and free of oil, paint, rust,

etc.

2. Select a heat setting.

3. Hold the torch in one hand, allowing the

nozzle to rest on the edge of the workpiece farthest away from you, and at an

angle similar to that which will be used

when welding. (See HOLDING THE

TORCH on page 15 if you are uncertain

of the angle at which you will be welding)

4. With your free hand, turn the Wire Speed

Dial to maximum and continue to hold

onto the knob.

WARNING

EXPOSURE TO A WELDING ARC IS

EXTREMELY HARMFUL TO THE EYES

AND SKIN! Prolonged exposure to the

welding arc can cause blindness and burns.

Never strike an arc or begin welding until you

are adequately protected. Wear flameproof

welding gloves, a heavy long sleeved shirt,

cuffless trousers, high topped shoes, and a

welding helmet.

5. Lower your welding helmet and pull the

trigger on the torch to start an arc, then

begin to drag the torch toward you while

simultaneously turning the Wire Speed

Dial counter-clockwise.

6. LISTEN! As you decrease the wire speed,

the sound that the arc makes will change

from a sputtering to a high-pitched

buzzing sound and then will begin sputtering again if you decrease the wire

speed too much. The point on the wire

speed adjustment where the high-pitched

buzzing sound is achieved is the correct

setting.

15

Page 16

You can use the wire speed control to slightly

increase or decrease the heat and penetration for a given heat setting by selecting

higher or lower wire speed settings. Repeat

this tune-in procedure if you select a new

heat setting, a different diameter wire, or a

different type of welding wire.

LEARNING TO WELD

MIG (Metal Inert Gas) welding is the process

of uniting metallic parts by heating and allowing the metals to flow together through the

use of an electrical arc. The electrical arc is

created between a continuous consumable

wire electrode (the welding wire) and the

work piece. An inert shielding gas is used to

protect the weld puddle from contamination

and enhance the welding capabilities of the

electrical arc.

Whether you have welded before or not, it is

important that you become familiar with your

new welder, its controls, and the results

achieved at different settings. We strongly recommend that you practice with your new

welder on scrap metal trying different heat

settings, base metal thicknesses, and welding

positions for each type and size of wire you

will be using. By doing this you will gain a feel

for how changes in these welding variables

affect the weld.

Of course, if you have not welded before,

you will need to develop welding skills and

techniques as well.

tions until you find the one that seems to

work best for you. Refer to WELDING

POSITIONS - p.17)

Position the Torch to the Work Piece

There are two angles of the torch nozzle in

relation to the work piece that must be considered when welding.

1. Angle A (Figure 9) can be varied, but in

most cases the optimum angle will be 60

degrees, the point at which the torch handle is parallel to the work piece. If angle A

is increased, penetration will increase. If

angle A is decreased, penetration will

decrease also.

Angle A

Figure 9. Torch Position, Angle A

2. Angle B (Figure 10) can be varied for two

reasons: to improve the ability to see the

arc in relation to the weld puddle and to

direct the force of the arc.

The self-taught welder learns through a

process of trial and error. The best way to

teach yourself how to weld is with short periods of practice at regular intervals. All practice welds should be done on scrap metal

that can be discarded. Do not attempt to

make any repairs on valuable equipment

until you have satisfied yourself that your

practice welds are of good appearance and

free of slag or gas inclusions. What you fail

to learn through practice will be learned

through mistakes and re-welds later on.

HOLDING THE TORCH

The best way to hold the welding torch is the

way that feels most comfortable to you.

While practicing to use your new welder,

experiment holding the torch in different posi-

16

Angle B

Figure 10. Torch Position, Angle B

The force of the welding arc follows a

straight line out of the end of the nozzle.

If angle B is changed, so will the direction of

arc force and the point at which penetration

will be concentrated.

On a butt weld joint, the only reason to vary

angle B from perpendicular (straight up) to

the work piece would be to improve visibility

of the weld puddle. In this case, angle B can

be varied anywhere from zero to 45 degrees

with 30 degrees working about the best.

Page 17

On a fillet weld joint, the nozzle is generally

positioned in such a manner so as to split the

angle between the horizontal and vertical

members of the weld joint. In most cases, a

fillet weld will be 45 degrees.

Distance from the Work Piece

The end of the welding torch is designed with

the contact tip recessed from the end of the

nozzle and the nozzle electrically insulated

from the rest of the torch. This permits the

operator to actually rest the nozzle on the

work piece and drag it along while welding.

This can be very helpful to beginning welders

to steady the torch, allowing the welder to

concentrate on welding technique. If the nozzle is held off the work piece, the distance

between the nozzle and the work piece

should be kept constant and should not

exceed 1/4 inch or the arc may begin

sputtering, signaling a loss in welding

performance.

the weld joint. Moving the torch too fast, too

slow, or erratically will prevent proper fusion

or create a lumpy, uneven bead.

1. TRAVEL DIRECTION is the direction the

torch is moved along the weld joint in

relation to the weld puddle. The torch is

either PUSHED (see Figure 11) into the

weld puddle or PULLED away from the

weld puddle.

Figure 11. Travel Direction

For most welding jobs you will pull the

torch along the weld joint to take advantage of the greater weld puddle visibility.

WELDING TECHNIQUES

WARNING

EXPOSURE TO A WELDING ARC IS

EXTREMELY HARMFUL TO THE EYES

AND SKIN! Prolonged exposure to the weld-

ing arc can cause blindness and burns.

Never strike an arc or begin welding until you

are adequately protected. Wear flameproof

welding gloves, a heavy long sleeved shirt,

cuffless trousers, high topped shoes and a

welding helmet.

WARNING

ELECTRIC SHOCK CAN KILL! To prevent

ELECTRIC SHOCK, do not perform any

welding while standing, kneeling, or lying

directly on the grounded work.

MOVING THE TORCH

Torch travel refers to the movement of the

torch along the weld joint and is broken into

two elements: Direction and Speed. A solid

weld bead requires that the welding torch be

moved steadily and at the right speed along

2. TRAVEL SPEED is the rate at which the

torch is being pushed or pulled along the

weld joint. For a fixed heat setting, the

faster the travel speed, the lower the penetration and the lower and narrower the

finished weld bead. Likewise, the slower

the travel speed, the deeper the penetration and the higher and wider the finished

weld bead.

TYPES OF WELD BEADS

The following paragraphs discuss the most

commonly used welding beads.

Once you have the torch in position with the

wire lined up on the weld joint, lower your

helmet, pull the trigger and the arc will start.

In a second or two you will notice a weld

puddle form and the base of the bead beginning to build. It is now time to begin to move

with the torch. If you are just learning to

weld, simply move the torch in a straight line

and at a steady speed along the weld joint.

Try to achieve a weld with the desired penetration and a bead that is fairly flat and consistent in width.

As you become more familiar with your new

welder and better at laying some simple weld

beads, you can begin to try some different

weld bead types.

17

Page 18

There are two basic types of weld beads, the

stringer bead and the weave bead.

1. The STRINGER BEAD (Figure 12) is

formed by traveling with the torch in a

straight line while keeping the wire and nozzle centered over the weld joint. This is the

easiest type of bead to make.

Figure 12. Stringer Bead

2. The WEAVE BEAD (Figure 13) is used

when you want to deposit metal over a wider

space than would be possible with a stringer

bead. It is made by weaving from side to side

while moving with the torch. It is best to hesitate momentarily at each side before weaving back the other way.

Figure 13. Weave Bead

WELDING POSITIONS

There are four basic welding positions: flat,

horizontal, vertical, and overhead.

1. The FLAT POSITION (Figure 14) is the

easiest of the welding positions and is most

commonly used. It is best if you can weld in

the flat position if at all possible as

good results are easier

to achieve.

2. The HORIZONTAL POSITION (Figure 15)

is next in difficulty level. It is performed very

much the same as the flat weld except that

angle B (see HOLDING THE TORCH - p.15)

is such that the wire, and therefore the arc

force, is directed more toward the metal

above the weld joint. This is to help prevent

the weld puddle from running downward

while still allowing slow enough travel speed

to achieve good penetration. A good starting

point for angle B is about 30 degrees DOWN

from being perpendicular to the work piece.

Figure 15. Horizontal Position

3. The VERTICAL POSITION (Figure 16) is

the next most difficult position. Pulling the

torch from top to bottom may be easier for

many people, but in some instances it can be

difficult to prevent the puddle from running

downward. Pushing the torch from bottom to

top may provide better puddle control and

allow slower rates of travel speed to achieve

deeper penetration. When vertical welding,

angle B (see HOLDING THE TORCH - p.15)

is usually always kept at zero, but angle A

will generally range from 45 to 60 degrees to

provide better puddle control.

18

Figure 14. Flat Position

Figure 16. Vertical Position

Page 19

WARNING

Hot slag can cause fires and serious injury

from burns! Be sure to wear protective clothing, eye, and ear gear when using the

Overhead Position.

4. The OVERHEAD POSITION (Figure 17) is

the most difficult welding position because

gravity is pulling at the weld puddle trying to

make it drip off the work piece. Angle A (see

HOLDING THE TORCH - p.15) should be

maintained at 60 degrees, the same as in the

flat position. Maintaining this angle will

reduce the chances of molten metal falling

into the nozzle should it drip from the weld

puddle. Angle B should be held at zero

degrees so that the wire is aiming directly

into the weld joint. If you experience excessive dripping of the weld puddle, select a

lower heat setting. Also, the weave bead

tends to work better than the stringer bead

when welding overhead.

The illustrations in Figure 18 show the

sequence for laying multiple pass beads into

a single V butt joint.

NOTE: WHEN USING SELF-SHIELDING

FLUX-CORE WIRE it is very important to

thoroughly chip and brush the slag off each

completed weld bead before making another

pass or the next pass will be of poor quality.

Figure 18. Butt Joints

Fillet Weld Joints. Most fillet weld joints, on

metals of moderate to heavy thickness, will

require multiple pass welds to produce a

strong joint. The illustrations in Figure 19

show the sequence of laying multiple pass

beads into a T fillet joint and a lap fillet joint.

Figure 17. Overhead Position

MULTIPLE PASS WELDING

Butt Weld Joints. When butt welding thicker

materials, you will need to prepare the edges

of the material to be joined by grinding a

bevel on the edge of one or both pieces of

the metal being joined. When this is done, a

V is created between the two pieces of

metal, that will have to be welded closed. In

most cases more than one pass or bead will

need to be laid into the joint to close the V.

Laying more than one bead into the same

weld joint is known as a multiple-pass weld.

Figure 19. Fillet Weld Joints

19

Page 20

SPECIAL WELDING METHODS

SPOT WELDING

The purpose of a spot weld is to join pieces

of metal together with a spot of weld instead

of a continuous weld bead. There are three

methods of spot welding: Burn-Through,

Punch and Fill, and Lap (see Figure 20).

Each has advantages and disadvantages

depending on the specific application as well

as personal preference.

allowed to fill up the hole leaving a spot

weld that is smooth and flush with the

surface of the top piece.

Select the wire diameter, heat setting,

and tune in the wire speed as if you were

welding the same thickness material with

a continuous bead.

3. The LAP SPOT METHOD directs the

welding arc to penetrate the bottom and

top pieces, at the same time, right along

each side of the lap joint seam.

Select the wire diameter, heat setting,

and tune in the wire speed as if you were

welding the same thickness material with

a continuous bead.

Figure 20. Spot Welding

1. The BURN-THROUGH METHOD welds

two overlapped pieces of metal together

by burning through the top piece and into

the bottom piece.

With the burn-through method, larger wire

diameters tend to work better than smaller diameters because they have greater

current carrying capabilities allowing the

arc to burn through very quickly while

leaving a minimal amount of filler metal

build up. Wire diameters that tend to work

best, with the burn-through method are

0.035 inch self-shielding flux-core wire.

Do not use 0.030 inch self-shielding fluxcore wires when using the burn-through

method unless the metal is VERY thin or

excessive filler metal build-up and minimal penetration is acceptable.

Always select the HIGH heat setting with

the burn-through method and tune in the

wire speed prior to making a spot weld.

2. The PUNCH AND FILL METHOD produces a weld with the most finished

appearance of the three spot weld methods. In this method, a hole is punched or

drilled into the top piece of metal and the

arc is directed through the hole to penetrate into the bottom piece. The puddle is

SPOT WELDING INSTRUCTIONS

1. Select the wire diameter and heat setting

recommended above for the method of

spot welding you intend to use.

2. Tune in the wire speed as if you were

going to make a continuous weld.

3. Hold the nozzle piece completely perpendicular to and about 1/4 inch off the work

piece.

4. Pull the trigger on the torch and release it

when it appears that the desired penetration has been achieved.

5. Make practice spot welds on scrap metal,

varying the length of time you hold the

trigger, until a desired spot weld is made.

6. Make spot welds on the actual work

piece at desired locations.

20

Page 21

MAINTENANCE

GENERAL

This welder has been engineered to give

many years of trouble-free service providing

that a few very simple steps are taken to

properly maintain it.

1. Keep the wire drive compartment lid

closed at all times unless the wire needs

to be changed or the drive tension needs

adjusting.

2. Keep all consumables (contact tips, nozzles, and torch liner) clean and replace

when necessary. See CONSUMABLE

MAINTENANCE and TROUBLESHOOTING later in this section for detailed

information.

3. Replace power cord, ground cable,

ground clamp, or torch assembly when

damaged or worn.

4. Periodically clean dust, dirt, grease, etc.

from your welder. Every six months, or as

necessary, remove the side panels from

the welder and air-blow any dust and dirt

that may have accumulated inside the

welder.

WARNING

Electric shock can kill! To reduce the risk of

electric shock, always unplug the welder

from its ac power source before removing

side panels.

CONSUMABLE MAINTENANCE

IT IS VERY IMPORTANT TO MAINTAIN THE

CONSUMABLES TO AVOID THE NEED

FOR PREMATURE REPLACEMENT OF

THE TORCH ASSEMBLY.

The TORCH LINER is intended to provide an

unrestricted path for the welding wire to flow

through the torch assembly. Over time the

liner will accumulate dust, dirt, and other

debris. Replacement is necessary when

these accumulations begin to restrict the free

flow of wire through the torch assembly.

MAINTAINING THE CONTACT TIP

The purpose of the CONTACT TIP is to

transfer welding current to the welding wire

while allowing the wire to pass through it

smoothly.

Always use a contact tip stamped with the

same diameter as the wire it will be used with.

Note: Due to inherent variances in flux-cored

welding wire, it may be necessary to use a

contact tip one size larger than your flux core

wire if wire jams occur.

1. If the wire burns back into the tip, remove

the tip from the torch and clean the hole

running through it with an oxygen-acetylene torch tip cleaner or tip drill.

2. Over time, the hole in the contact tip will

become worn by the wire passing through

it. The more worn this hole becomes, the

less efficient is the transfer of welding

current to the wire and eventually arc

breakage and difficult arc starting will

result. Replace contact tips when signs of

wear become apparent.

MAINTAINING THE NOZZLE

The nozzle directs the shielding gas to the

weld puddle, determines the size of the

shielding area, and prevents the electrically

hot contact tip from contacting the work

piece.

CAUTION

KEEP THE NOZZLE CLEAN! During the

welding process, spatter and slag will build

up inside the nozzle and must be cleaned

out periodically. Failure to clean and/or

replace the nozzle in a timely fashion WILL

CAUSE DAMAGE TO THE FRONT-END OF

THE TORCH ASSEMBLY.

For best results, coat the inside of a new, or

freshly cleaned nozzle with anti stick spray

or gel.

1. Stop welding and clean any accumulated

slag or spatter from the nozzle every 5 to

10 minutes of welding time.

2. When welding overhead, if any molten

metal drips from the weld puddle and

falls into the nozzle, STOP WELDING

IMMEDIATELY and clean the nozzle.

3. If the slag cannot be thoroughly

cleaned from the nozzle, REPLACE THE

NOZZLE!

Failure to keep the nozzle adequately

cleaned can result in the following problems:

21

Page 22

A SHORTED nozzle results when spatter

buildup bridges the insulation in the nozzle,

allowing welding current to flow through it as

well as the contact tip. When shorted, a nozzle will steal welding current from the wire

whenever it contacts the grounded work

piece. This causes erratic welds and reduced

penetration. In addition, a shorted nozzle

overheats the end of the torch, which can

DAMAGE the front-end of the torch.

A RESTRICTED nozzle is created when

enough slag builds up in the nozzle to affect

the direction, concentration, and/or rate of

the shielding gas flow. This problem can

cause porous, brittle welds and reduce

penetration.

TESTING FOR A SHORTED NOZZLE

Arcing between the nozzle and the work

piece ALWAYS means the nozzle is shorted,

but this can be hard to detect through the

lens of a welding helmet. The following testing method is another way to tell if a nozzle

is shorted.

With the welder unplugged from the ac

power source, touch the probes of an ohmmeter or continuity tester to the end of the

contact tip and the outside of the nozzle. If

there is any continuity at all, the nozzle IS

shorted. Clean or replace as needed.

REPLACE A TORCH LINER

When installing a new torch liner, care must

be taken not to kink or otherwise damage the

torch liner. See Figure 21 for the drive

assembly and Figure 22 for the torch

assembly.

1. Turn OFF welder POWER SWITCH and

unplug welder from power supply.

2. Open the welder side panel.

3. Loosen the tension arm and lift it up off

the drive roller.

4. Turn the wire spool counter-clockwise (be

sure to hold onto the wire itself while turning the spool or the wire will unspool itself

when it becomes free of the torch liner),

and remove wire from the welder.

5. Lay torch cable and torch handle straight

out in front of unit.

6. Remove torch Strain Relief Clamp by

removing the four screws.

7. Take torch handle halves apart by

removing four phillips head screws.

8. Remove the hanging hook from the two

case halves by carefully pulling it apart

until it is free from the torch.

9. Remove liner from gas block by pulling it

from the bottom of the gas block, being

careful not to separate gas block halves.

10. Remove liner from outer torch sleeve by

pulling from torch end.

11. Install new liner, starting from torch end

and feeding towards unit.

12. Push the new liner back through gas

block and into the neck of the torch until it

is fully seated then push into the groove

at the rear or base of the block.

13. Return all components to the handle

casing and realign them as they were

originally.

Tech Tip: Be sure all o-ring’s have been

returned to their original positions.

14. Fit liner for length at feeder end by cutting

liner with wire cutters.

15. Reinstall liner holding clamp at feeder.

16. With both halves of the handle case in

place, tighten the four phillips head

screws.

17. Replace hanging hook.

18. Reinstall the welding wire according to

specifications in INSTALL THE WELDING

WIRE section.

19. Close side panel.

20. Plug welder into power supply and turn

POWER SWITCH to ON position.

PREVENTIVE MAINTENANCE

Except for internal and external cleaning,

cleaning the nozzle, and occasionally retightening screws, there is no periodic maintenance recommended for your welder.

TROUBLESHOOTING

The following TROUBLESHOOTING information is provided as a guide to help resolve

some of the more common problems that

could be encountered. Table 5 is a troubleshooting table provided to help you determine a possible remedy when you are having

a problem with your welder. This table does

not provide all possible solutions, only those

possibilities considered to likely be common

faults. The table consists of a TROUBLE or

symptom, a POSSIBLE CAUSE for the

symptom, and a POSSIBLE REMEDY for

that symptom.

22

Page 23

Page 24

TABLE 5 – TROUBLESHOOTING

24

Page 25

MMIG125 WIRING DIAGRAM

25

Page 26

Page 27

1-888-287-6981

27

Page 28

G20T

201108

Gear 20T

Part Number:

Gear 21T

for Drive Roller

G21T

Part Number:

36Tx12T

Reduction Gear

Diagram of Gear Box for 125 Amp MIG/Fluxcore Welder

MMIG125

RG36x12T

Part Number:

with Steel Square Shank

38Tx12T

Reduction Gear

RG38x12T

Part Number:

46Tx10T

Reduction Gear

RG46x10T

Part Number:

G12T

Part Number:

Brass Motor Gear 12T

Loading...

Loading...