ISO 9001 Registered Company

ISOMET 2000 Precision Saw

MA112480-20 03/06/00

Declaration of Conformity

Manufacturer: BUEHLER, Ltd.

Of: 41 Waukegan Road

Lake Bluff, Illinois 60044

Declares the following product: ISOMET 2000

To be in accordance with EC Directive(s);

Safety of Machinery: EMC Directive:

89/392/EEC and 91/368/EEC and 93/44/EEC

according to the following standards:

EN 292 PART 1 1991

EN 292 PART 2 1991

EN 60204 PART 1 1993

Position: Engineering Manager

Name: Chuck Motley

Signature:

Chuck Motley

89/336/EEC and 92/231/EEC according to the

following standards:

EN 50081-1: 1992

EN 50082-1: 1992

Date:

11/28/95

This Manual is a custom generated document. It includes all revisions

relative to this specific Buehler item as of the date shown below.

MA112480-20 03/06/00

Table of Contents

Warranty ...................................................................................................................................... 2

Unpacking.................................................................................................................................... 2

Assembly ..................................................................................................................................... 2

Installation.................................................................................................................................... 2

Location .......................................................................................................................... 3

Electrical ......................................................................................................................... 3

Blade Installation ............................................................................................................3

Cooling and Lubrication..................................................................................................4

Operation ..................................................................................................................................... 5

Energizing the Unit .........................................................................................................5

Specimen Loading..........................................................................................................5

Positioning the Sample...................................................................................................6

Setting the Load.............................................................................................................. 7

Checking and Adjusting Load......................................................................................... 8

Cutting the Specimen ..................................................................................................... 8

Blade Dressing ...............................................................................................................10

Pre-Dressing...................................................................................................................10

Dressing During the Cycle..............................................................................................10

Maintenance ................................................................................................................................ 11

General Specification: .................................................................................................... 11

Internal Coolant/Lubricant Recirculating System ........................................................... 11

Cleaning the Unit ............................................................................................................ 11

ISOMET™ 2000 Precision Saw Application Guide........................................................33

OPERATION AND MAINTENANCE INSTRUCTIONS

BUEHLER

ISOMET 2000 PRECISION SAW

MA112480-20 03/06/00

1

Warranty

Unpacking

Assembly

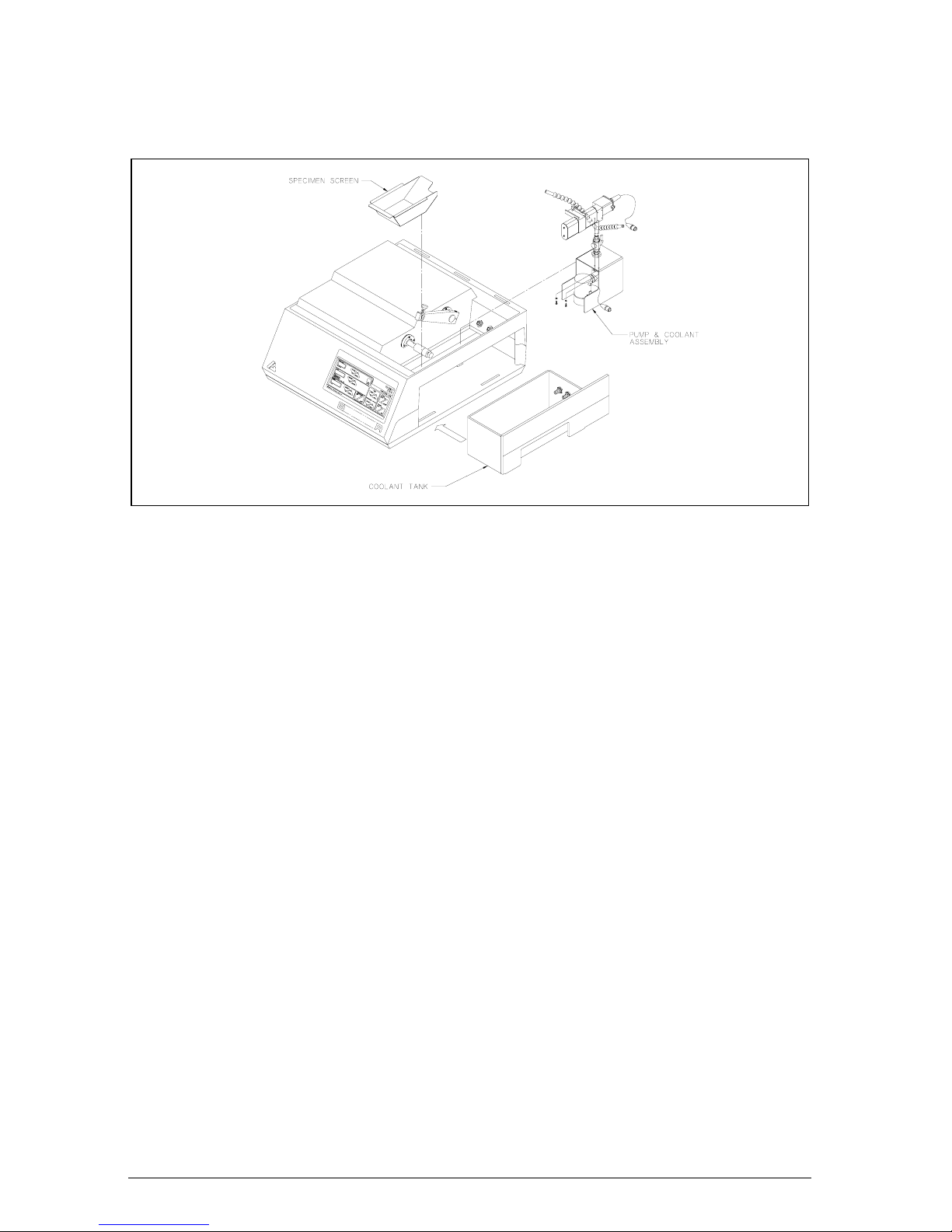

Figure 1 ISOMET™ 2000 Precision Saw

This unit is guaranteed against defective material and workmanship for

a period of two (2) years from date of receipt by customer. Warranty is

void if inspection shows evidence of abuse, misuse or unauthorized

repair. Warranty covers only replacement of defective materials.

If for any reason, this unit must be returned to our plant for warranty

service, please apply for prior authorization with shipping instructions,

and include the following information: Customer Purchase Order

Number, Buehler Invoice Number, Date, Serial Number, and reason for

return.

Carefully unpack and check contents. If any components are missing

or damaged, save the packing list and material and advise the carrier

and BUEHLER of the discrepancy.

The ISOMET™ 2000 Precision Saw is shipped fully assembled. A

Dressing Stick, three Specimen Chucks, two Flanges, one Diamond

Wafering Blade, one bottle of ISOCUT

and an accessory wrench are included. (Accessories available for use

with this unit.)

Installation

MA112480-20 03/06/00

2

®

Plus Cutting Fluid Concentrate,

Location

The ISOMET™ 2000 Precision Saw is intended for bench-top

placement. Select a location with convenient access to electrical and

water services.

Electrical

All units operate with a universal requirement range from 85-264V

50/60 Hz AC Input. Appropriate cord for country of use is supplied.

Blade Installation

Flanges support the Wafering and Abrasive Blades. Failure to provide

adequate flange support may result in curved cuts and damaged

blades. Always select the maximum flange diameter commensurate

with the size of the specimen to be cut. (See Accessories and

Supplies.)

1. Remove Thumb Screw and End Cap Bushing from Drive Shaft.

2. Install the Inner Flange on the Drive Shaft.

3. Install the blade against the inner Flange.

4. Slip on the Outer Flange and End Cap Bushing, then hand

tighten Thumb Screw to complete installation.

NOTE Before installation of a Wafering or Abrasive Blade, the End Cap

Bushing, Screw and Flanges should be cleaned in a mild detergent

solution to remove adherent particles from prior cutting. This will

prevent misalignment and damage to the Blade.

Figure 2 Blade Installation

Blade Dressing

New wafering blades, including the original equipment blade, must be

dressed before making sample cuts. Dressing removes the normal

smeared matrix metal and exposes the abrasive grain to assure free

cutting. New wafering blades should be dressed several times and

MA112480-20 03/06/00

3

older blades dressed as required based on the properties of the

sample material being cut. (See Maintenance: Blade Dressing.)

Cooling and Lubrication

Two different methods of applying coolant/lubricant are provided with

the ISOMET™ 2000 Saw. For most applications the self contained

recirculating system will provide adequate coolant flow. For optimum

cooling at extremely high cutting speeds with hard materials, the

ISOMET™ 2000 Saw can be connected to an external water supply

and drain. A water overflow protects the cutter in the event that the

drain becomes clogged or inadvertently closed. (See Accessories)

NOTE The unit's motor and recirculating system operate only when the cover

is closed. These machines have a water spray deflector built into the

hood, but if the cooling discharge water valve is opened too far, the

directional nozzles may force water between the hood and the top of

the cabinet. This water may well over the lip of the cabinet and run

down the sides of the machine.

Internal Coolant/Lubricant Recirculating System

When using the internal coolant system, fill the coolant tank with the

correct mixture of ISOCUT

®

PLUS Cutting Fluid Concentrate and

water. The fluid level should be approximately 5.0 cm (2″) deep or 4

liters.

ISOCUT

®

PLUS Cutting Fluid has been formulated for optimum cooling

and lubrication in medium and high speed cutting applications. It is a

water soluble concentrate which enhances the cooling properties of

water with effective lubrication and anti-corrosive properties.

ISOCUT

®

PLUS Cutting Fluid promotes clean cutting with diamond

blades or abrasive wheels for faster, superior quality cuts. A flow

control valve is provided at the base of the coolant tubes to prevent

excessive coolant from over-flowing at the hood, etc. (See Accessories

and Supplies for part numbers.)

Internal Pump

The Plumbing Assembly contained in this unit is only used with the

internal coolant/lubricant system. (See Figure 3). When external

coolant is used, the plumbing will be modified. Instructions are supplied

with the Accessory kit.

Check and change the cutting fluid as required.

NOTE When using abrasive cut-off wheels with the ISOMET™ 2000 Saw, the

coolant tank should be cleaned frequently, not exceeding the life of 3

wheels. (See Maintenance Section.)

MA112480-20 03/06/00

4

Figure 3 Internal Lubrication System

Operation

Energizing the Unit

1. Attach the blade and flanges as described in blade installation

section. Refer to Application Guide for proper blade selection.

2. Plug the unit into an appropriate power source.

NOTE Some types of GFI protection circuitry on the market are very sensitive

and may trip prematurely during machine start-up. If this happens, the

BUEHLER Service Department should be contacted to recommend a

solution.

3. Check the circuit breaker on the rear of the unit. It should be in

the (I) On position. Press the POWER ON Button. The green

LED control light should energize as well as all the LED

displays. The unit is now ready for specimen loading.

Specimen Loading

Several chucks are available to hold specimens of many different sizes

and shapes. (See Accessories and Supplies.) Select the proper chuck

for the particular application and attach to the support arm.

1. Open the hood and press the RAISE Button in the Arm section

2. Attach the Chuck to the Support Arm with the Thumb Screw.

3. Clamp specimen into the Chuck.

MA112480-20 03/06/00

on the Control Panel. See Figure 5. Raise the Support Arm all

the way up.

See Figure 4.

5

CAUTION Make sure the specimen is secured into chuck and the chuck to

the arm so that the specimen will not slip or rotate during cutting.

Improper clamping or chuck selection may cause blade damage.

Positioning the Sample

To position the specimen for cutting, the Position section of the Control

Panel in Figure 5 is used.

1. Press the RETRACT Button on the control panel until the

Support Arm and sample are clear of the Blade.

NOTE If the sample will not clear the blade, temporarily replace

the sample with a dummy of similar cross-section that can

clear the blade until after step 3 in this section.

2. Press LOWER Button on the control panel until the Support Arm

and sample are in the position shown in Figure 6A. If the

movement of the sample stops prior to reaching the position

shown, loosen the screw at the rear of the support arm and

adjust the arm as shown. Check to be sure there is enough

clearance so specimen can travel .25 (6 mm) past completion of

the cut to allow for overtravel during the automatic stop cycle.

NO EXTERNAL

FORCES APPLIED

3. Raise the Support Arm to a level approximately 1 cm above the

CAUTION Do not allow the Specimen to contact the Blade while adjusting

the position of the arm. Blade damage may result. Also do not

apply any external force (pushing with fingers) to arm. This will

cause damage to the electronics.

4. Press the ADVANCE Button on the Control Panel moving the

5. Adjust the Position until the desired cut specimen thickness is

MA112480-20 03/06/00

Figure 6A Support Arm Adjustment

blade.

Support Arm until the Specimen is even with the outer surface

of the blade. Press the ZERO DISPLAY Button on the Control

Panel, Figure 3. The MILLIMETER LED Display should now

read zero.

measured on the MILLIMETER LED Display. The position has a

25.4mm range and is graduated in 0.005mm increments.

6

NOTE The Support Arm can be raised/lowered and advanced/retracted with

the cover open or closed.

Figure 4 Specimen Chuck Adjustment

Setting the Load

To set the amount of force to be applied to the sample during the

cutting cycle, the Load section of the Control Panel is used. Refer to

Application Guide for proper load selection.

1. Preset the amount of load to be applied to the blade during the

cutting cycle. This is accomplished by pressing the LOAD

INCREASE or DECREASE Button until the desired load is

indicated on the Load LED Display.

NOTE The Display automatically sets to 100g when the unit is powered up.

The Load can be preset between 100g and 1000g in 10g increments.

NOTE The specimen must be loaded while the arm is in the raised position.

The ISOMET™ 2000 automatically tares the sample weight before a

cycle begins. The taring is done when the arm is in the raised position.

This features allows the saw to accurately apply the force displayed on

the front panel.

MA112480-20 03/06/00

7

Figure 5 Front Panel

Checking and Adjusting Load

During the cutting cycle, the ISOMET™ 2000 Saw will monitor the load

being applied to the blade. If an overload condition occurs, the system

will automatically decrease the load to maintain optimum cutting

conditions. A Bar Graph on the Control Panel indicates the % of set

load at which the unit is operating. Optimum cutting is attained when

the bar graph reads near or at 100% during the cycle.

To change the set load during operation, press the LOAD DECREASE

or INCREASE Button.

Cutting the Specimen

To cut the Specimen, the Load, Speed, Lubricant and Cycle portions on

the Control Panel are used.

1. Press the Lower Button on the Arm Section of the Panel until

the Specimen is approximately 1 cm above the Blade.

2. Close the cover.

WARNING The ISOMET™ 2000 Saw is designed to operate only with the cover

closed. This prevents manual feeding of sample materials or

dressing sticks into the rotating blade, which could result in

personal injury and/or blade damage. Efforts to defeat safety

interlock could result in personal injury.

3. Set the Blade speed by pressing the SPEED INCREASE or

4. Press the LUBRICANT ON Button if the cooling/lubricant system is

MA112480-20 03/06/00

DECREASE Buttons until the desired RPM is indicated on the

Speed LED Display. The speed can be set between 200 and 5000

RPM in 100 RPM increments. Refer to Application Guide on Page

29 for proper speed selection.

being used.

8

5. Press the CYCLE RUN Button. The Support Arm will begin to lower

and the Blade will rotate at the selected speed. The preset load will

not be applied for approximately 7 seconds. During this interval, the

sample will approach the blade and a 100g load will be applied in

order to establish a "kerf" cut. The unit will then apply the set load.

The ISOMET™ 2000 Saw is supplied with a 6″ dia. Wafering Blade

as standard equipment and the Support Arm is set at the factory to

accommodate this condition. In normal operation, the Arm automatically advances the specimen into the Wafering Blade until the

cut is completed or until the lower position limit switch within the

cutter is activated, whichever comes first. If the specimen does not

contact the Wafering Blade within seven seconds, the Arm will

automatically return to the start position without cutting the sample.

This could occur if a much smaller Wafering Blade is used or if the

sample is very small and the Specimen Arm is not repositioned.

Figure 6 shows the factory set Arm position (when the arm is

raised to it’s maximum) relative to the various size Wafering

Blades that may be used with the ISOMET™ 2000 Saw. It is

easy to see that there is a considerable distance for the Support

Arm to travel before making contact with a four inch diameter

blade. The support arm should be lowered with the LOWER

button until the specimen is about 1 cm. from the blade before

starting the cut cycle.

If necessary to allow for a variety of operational conditions, the

Support Arm may be repositioned. This is accomplished by

loosening the Mounting Screw that secures the Support Arm to

the shaft. Be careful to prevent the Support Arm from striking

the Wafering Blade. Reposition the Support Arm as described in

Positioning The Sample section on page 6.

NOTE Do not move the specimen arm laterally along the shaft. The arm has

25.4 cm of stroke. Any loss in stroke by repositioning the arm may

result in the arm stalling against the cabinet resulting in loss of

micrometer accuracy.

Figure 6 Support Arm Adjustment

6. During operation, observe the Load Bar Graph. Due to

differences in sample thickness and density/consistency, or as

MA112480-20 03/06/00

9

the blade surface "loads up" when cutting soft materials, the %

set load may vary as the system adjusts for optimum load

conditions. (See Checking and Adjusting Load.)

NOTE If the bar graph does attain 100%, the removal rate may be too high for

the material being cut. (Example: thin wall tubing. The arm may retract

as if "end of cut". To correct for this type of material, the load or speed

should be reduced.

When the Support Arm reaches the end of the cut, it will return to its

upright position and the blade will stop.

NOTE If, at any time during the cutting mode, the operator lifts the cover or

presses the CYCLE STOP Button, the Support Arm will return to its

upright position and the blade will stop immediately.

7. At the end of operation, press the POWER OFF Button.

The ISOMET™ 2000 Saw will retain the last set of parameters

that were used even when the Power Off Button is pressed or if

the unit is disconnected from the power source.

Blade Dressing

Position the Dressing Stick in the Dressing Chuck shown in Figure 7.

Dressing should always be performed with coolant/lubricant.

WARNING The ISOMET™ 2000 Saw is designed to operate only with the

hood closed. Overriding this safety feature could result in serious

injury or equipment damage.

Pre-Dressing

To Pre-Dress the blade, close the hood and press the dressing

CHUCK RETRACT Button on the Control Panel. Hold this button until

the dressing chuck body retracts clear of the blade. Insert the dressing

stone in the clamp placing the edge of the stone approximately 1/16″

behind the blade. Secure the stone by tightening the thumbscrew.

Close the hood. Press the LUBRICANT ON Button to activate the

coolant. Press and hold the DRESSING CHUCK ADVANCE Button

until the stone begins to advance. As the stone advances toward the

blade the saw blade will automatically turn at 500 rpm for optimum

dressing. Continue advancing the stone until it touches the blade. Now

push the button intermittently advancing the stone slowly into the

blade. Press the DRESSING CHUCK RETRACT Button to return the

chuck back to the starting Pre-Dress position. Repeat as required.

NOTE To terminate the dressing cycle at any time simply stop pressing the

DRESSING CHUCK ADVANCE/RETRACT Buttons for a minimum of

three seconds.

NOTE When using 7″ diameter blades use supplied spacer (111198) to lock

dressing stick into vertical position.

Dressing During the Cycle

The blade can also be dressed during the Cycle-Run by simply

advancing the stone until it touches the blade and intermittently

advance the stone into the blade as required.

MA112480-20 03/06/00

10

Figure 7 Dressing Chuck and Blade Dressing

Maintenance

General Specification:

1. Sound level is 77dBA maximum.

Internal Coolant/Lubricant Recirculating System

When Coolant/Lubricant is contaminated with abrasive residue or swarf, it

should be discarded and replaced.

1. To drain coolant; turn off unit, lift the hood, remove the blade and

flanges.

NOTE Retract arm to the far left position.

2. DISCONNECT THE POWER CORDS FROM THE CABINET.

3. Remove the Dressing Chuck Bracket and Coolant Assembly, and

Screen.

4. Lift the Coolant Tank at the handle and pull so that the tank slides

horizontally.

5. Thoroughly clean the Coolant Pump, Specimen Screen, Dressing

Chuck and Coolant Tank.

6. Slide the Coolant Tank back into the cabinet.

7. Place the components back into the tank as shown in Figure 8.

Cleaning the Unit

The ISOMET™ 2000 Precision Saw should be cleaned periodically to

prevent build-up of cutting residue and cutting fluids. Exterior painted

surfaces including the cutting chamber may be cleaned with non-abrasive

household cleaners.

MA112480-20 03/06/00

Connect the power cords into the correct connectors.

11

The protective hood and touch pad control panel should be cleaned using

mild soap and water applied with a soft cloth.

Figure 8 Tank Removal and Cleaning

MA112480-20 03/06/00

12

Figure 9 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

13

Figure 10 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

14

Figure 11 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

15

Figure 12 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

16

Figure 13 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

17

Figure 14 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

18

Figure 15 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

19

Figure 16 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

20

Figure 17 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

21

Figure 18 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

22

Figure 19 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

23

POWER SUPPLY

R10095

L2

AC INPUT

85-264V

50/60HZ

L1

GND

N

L

G

STRAIN

GAUGE

TM1+

DC

OUT

TM2-

AC

IN

IEC

CONNECTOR

LINE

FILTER

R9838 (115V)

R9839 (220V)

ARM MOTOR

DRESSER MOTOR

RS232 PORT

2480S142

X1400

5

2

3

4

2480S204

20

21

+S

N/C

-S

N/C

FG

H

N

2480S236

15

16

17

1

1

3

N/C

2

N/C

4

5

N/C

2480S235

R88142480S231 2480S231

1

CIRCUIT

BREAKER

34

+-

A

2480S086

43

J10910

6 PIN

J10101

X1202

J11213

1 2 3 4

2480S228

SAW MOTOR

TACHOMETER

2

G/Y

B

W

18

B

19

W

G/Y

24

2480S139

CPU / ANALOG INTERFACE PCB

4

6

5

1

2

3

342 1

++

2480S217

X1103

AC HI VOLTAGE

X3100

2480S087

MICROMETER MOTOR

1234

J10304

2480S141

X3301

J3103

MICROMETER

X4201

TACHOMETER

1 2 3 4 5

1 2 4 8

J11112

J11011

J10614

J10910

6 PIN

12

N/C

--AA

X1304

R9856

2480S138

OPERATORS CONTROL PANEL

2480S232

2480S231

3

2

1

9

10

11

RED

GRN

BLK

MALE HOUSING 1180S133

MALE PINS R7042

FEMALE

HOUSING R7046

2480S147

3 N/C

7

6

5

2

1

1

23N/C

5

6

LIMIT SWITCHES

7

8

5

6

+

FAN

A

2480S148

-

+

PUMP MOTOR

A

2480S051

-

R8988

J4307

SAW BLADE MOTOR

X4105

2480S005

PART OF

MEMBRANE

2480S147

2480S147

2480S097

X5104

ARM UP

POSITION

ARM DOWN

POSITION

MICROMETER HOME

LID

OPEN

OPERATORS CONTROL

MEMBRANE PANEL

ISOMET 2000

PRECISION SAW

(2480900K.DSN)

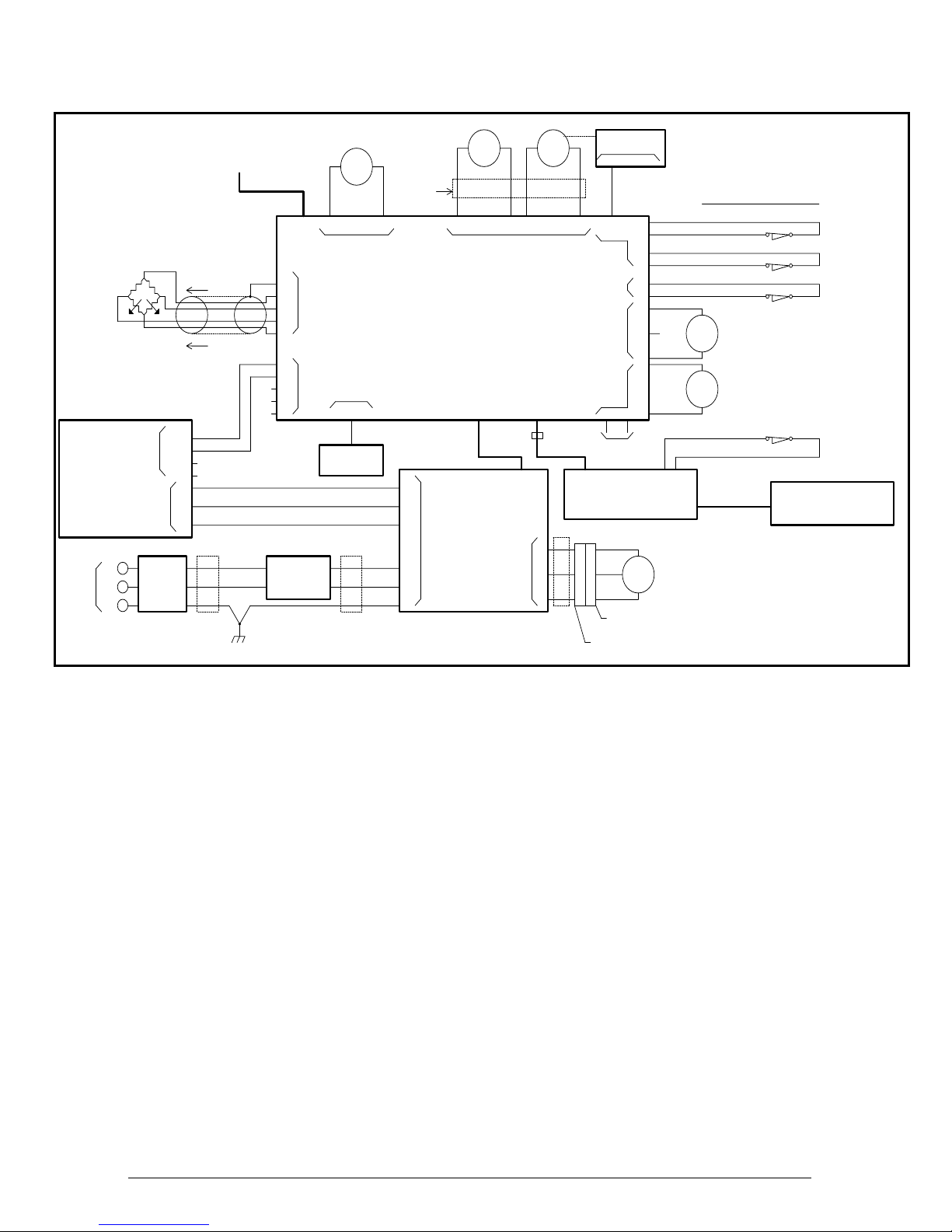

Figure 20 ISOMET™ 2000 Connection Diagram

MA112480-20 03/06/00

24

Figure 21 Parts Diagram for ISOMET™ 2000 Precision Saw

MA112480-20 03/06/00

25

ISOMET™ 2000 Precision Saw Parts List

PART

NUMBER DESCRIPTION QTY U/M

MA112480 MANUAL, INSTRUCT-ISOMET 2000 1.00 EA

MA112483 INSTR SHT, ISOMET PLUS CHUCK 1.00 EA

MA114207 SHEET,INSTRUCTION-7"C/O WHEELS 1.00 EA

R0585 TIE STRAP .10X4IN 8.00 EA

R0603 NUT 4-40 HEX SS 2.00 EA

R0603LW LOCK WASHER #4 STAINLESS STEEL 2.00 EA

R0603W WSHR,FLAT .125X.312X 04 STNSTL 4.00 EA

R0605LWE WSHR, EXT # 6 STN STL 4.00 EA

R0606LW LOCK WASHER #6 SS 2.00 EA

R0612LW LOCK WASHER #10 SS 12.00 EA

R0612W WASHER #10 SS 8.00 EA

R0615LW LOCK WASHER 1/4IN SS 8.00 EA

R0615W WASHER 1/4IN SS 1.00 EA

R0693 SCREW 8-32 1/2IN SKT HD SS 2.00 EA

R0962 SCREW 10-32 3/8IN SKT HD SS 2.00 EA

R0963 SCREW 10-32 1/2IN SKT HD SS 11.00 EA

R0965 SCREW 10-32 3/4IN SKT HD SS 4.00 EA

R0967 SCREW 10-32 1 IN SKT HD SS 1.00 EA

R0969 SCREW 10-32 1-1/4IN SKT HD SS 1.00 EA

R0984 SCREW 1/4-20 5/8IN SKT HD SS 2.00 EA

R0987 SCREW SKT HD 1/4-20 1 IN SS 3.00 EA

R10095 POWER SUPPLY, 12V DC 110W 1.00 EA

R10311 SCREW, 5/16-18 X 2-1/2 4.00 EA

R1185 SCREW SET 10-32 3/8IN 2.00 EA

R1273 SCREW SET 6-32 1/4IN SS 2.00 EA

R1281 SCREW SET 8-32 1/8IN SS 2.00 EA

R1293F SCREW SET 1/4-28 5/16IN SS NLC 1.00 EA

R1625 SCREW 6-32 3/8IN SLT RD HD SS 2.00 EA

R1652 SCREW 8-32 1-1/4IN SLT RDHD SS 4.00 EA

R2004 SCREW 4-40 1/2IN SLT OV HD SS 2.00 EA

R2408 SCREW 1/4-20 1-3/4IN HEX HD SS 4.00 EA

R2858 SPEC PLATE, BLANK - NON-C.S.A. 1.00 EA

R6106 CARTON, 4X3X3 200# OYS WHT 1.00 EA

R6159 16 OZ PVC CYL 1.00 EA

R6190 WHITE POLYPROP RIB CAP 1.00 EA

R6743 CARTON, BOOKFOLD 1.00 EA

R6744 PAD 2.00 EA

R6826 CARTON-ISOMET 2000 1.00 EA

R6826A BASE, PLYWOOD-ISOMET 2000 1.00 EA

R6827A PAD,HOLD DOWN 29.62X24.12X20.5 1.00 EA

R6827B PAD, TOP-ISOMET 2000 1.00 EA

R7042 PIN, MALE MOLEX 3.00 EA

R7079 LOCKNUT HEX - NYLON 21.00 EA

R7318 RETAINING RING EXT .25 SS 2.00 EA

R7414 SCREW, 10-32 X 5/8 IN CR PAN HD 1.00 EA

R7572 SCREW 6 x 7/16 CR PNHD NICKEL 2.00 EA

R7630 SCREW 6-32 3/4IN CR FLT HD SS 2.00 EA

R7654 SCREW 4-40 5/8IN CR RD HD SS 4.00 EA

R7745 CABLE TIE-MEDIUM 5.6 LG 4.00 EA

R7748 ADHESIVE CABLE MOUNT 2.00 EA

R7821 MAGNET-REEDSWITCH 1.00 EA

R7848 SCREW 6-32 3/4IN CR PAN HD SS 9.00 EA

R7855 NUT 1/4-28 HEX JAM SS 2.00 EA

MA112480-20 03/06/00

26

ISOMET™ 2000 Precision Saw Parts List

PART

NUMBER DESCRIPTION QTY U/M

R7861 ROLL PIN 1/16 X 7/16 1.00 EA

R7886 BUMPER RUBBER 5.00 EA

R7908 NUT 10-32 KEPS 6.00 EA

R7969 SCREW SKT HD 1/4-20 3/4 IN SS 4.00 EA

R7978 DOWEL PIN 1/8 X 1IN LONG 1.00 EA

R7979 WASHER .265 ID SS 2.00 EA

R8003 SCREW SET 10-32 5/8IN HFDG 2.00 EA

R8072 SCREW 1/4-20 7/8IN SKT HD SS 4.00 EA

R8086 SCREW 4-40 1/2IN CR PAN HD SS 4.00 EA

R8277 PLUG-HOLE .68 ID 3.00 EA

R8331 WSHR, FLAT .150X.32X.03 NYLON 2.00 EA

R8344 MOUNT-VIBRATION .31 ID 4.00 EA

R8370 MOUNT CABLE TIE 3.00 EA

R8512 SCREW 10-32 X 7/8 SKT HD CAP 4.00 EA

R8530 VALVE-BALL 1/4" FRAME 1.00 EA

R8579 TAPE PCB TRACK MOUNTING 14.00 IN

R8616 SCREW,HEX HD CAP 1/4-20X2-1/4 4.00 EA

R8681 WASHER, 1/4" INTERNAL-EXTERNAL 4.00 EA

R8744 NUT, HEX 1/4-20 HVY NYLON BLK 10.00 EA

R8814 CIRCUIT BREAKER, 10A 250V 1.00 EA

R8898 SCR,MA 4-40X1/4 SOC ST BO 4.00 EA

R8899 SCR,MA 0-80X1/4 SOC ST BO 5.00 EA

R8900 PIN, DOWEL-1/4 DIA X 1 ST NP 4.00 EA

R8902 CONNECTOR, AC POWER 1.00 EA

R8905 SCR,MA 0-80 X 3/8 SOC ST BO 2.00 EA

R8943 SCR, SS 4-40 X 1/8 SS 2.00 EA

R8944 SCR, SS 4-40 X 1/4 SS 4.00 EA

R8945 SCR, MA M2.5 X 16 SOC SS 3.00 EA

R8946 SCR, MA 4-40 X 3/8 SS 16.00 EA

R8972 ADAPTER, 3/4" FGHT X 1/4" MNPT 1.00 EA

R8975 CONN, SNAP-LOC M/HOSE-M/PIPE 1.00 EA

R8976 TUBING, VINYL 3/4" ID X 1" OD 2.00 IN

R8978 TEE, 1/4"FNPT 1.00 EA

R8979 CLAMP, 1" NYLON HOSE 2.00 EA

R8980 ADAPTER, 3/4" X 3/4" MGHT 1.00 EA

R8982 NUT, HEX 3/4-16 JAM SS 1.00 EA

R8983 HOSE, SNAP-LOC 1/4" SYSTEM 1.00 FT

R8985 NOZZLE, SNAP-LOC 1/4" 2.00 EA

R8986 FITTING, SNAP-LOC1/4" NPT 1.00 EA

R8987 PLUG, 1/4" NYLON SQ HD 1.00 EA

R8988 SWITCH, MAGNETIC REED 1.00 EA

R8995 TERMINAL, CRIMP .156 CENTER 8.00 EA

R8996 HOUSING,MOLEX 6 PIN.156 CENTER 1.00 EA

R8997 HOUSING,MOLEX 2 PIN.156 CENTER 1.00 EA

R9001 BUSHING, CORD .090-.265DIA BLK 1.00 EA

R9004 O-RING, 1/16" NOM. DIA. 7.00 EA

R9008A CORD, IEC POWER - U.S 0.00 EA

R9008B CORD, IEC POWER - EUROPE 0.00 EA

R9008C CORD, IEC POWER - U.K 0.00 EA

R9008D CORD, IEC POWER - JAPAN 0.00 EA

R9017 SCR, MA 6-32 X .50 SOC SS 3.00 EA

R9019 SPACER, .15IDX.25ODX.38LG CPVC 14.00 EA

R9022 SCR, MA 4-40 X .75 BH NY 3.00 EA

MA112480-20 03/06/00

27

ISOMET™ 2000 Precision Saw Parts List

PART

NUMBER DESCRIPTION QTY U/M

R9031 WASHER, EXT 1/4X.50X.03 SS 7.00 EA

R9032 SCR, MA 1/4-20X1 RD NL-BLK 6.00 EA

R9033 SCR, MA 1/4-20X3/4 RD NL-BLK 4.00 EA

R9052 NIPPLE, 1/4" NPT X 2" LONG SS 1.00 EA

R9054 SCR, MA 4-40X3/8 PN NL-BLK 4.00 EA

R9055 SCR, MA ¼ -20X ½ RD NL-BLK 4.00 EA

R9064 NIPPLE, CLOSE ¼ NPT NYLON BL 1.00 EA

R9069 WSHR, FLAT .25X.50X.125 NY BLK 4.00 EA

R9088 CONNECTOR, PLUG-IN 3 PIN 1.00 EA

R9089 CONNECTOR, PLUG-IN 6 PIN 1.00 EA

R9184 BEARING, .25 ID X .25 NYLON 1.00 EA

R9200 WASHER, .26ID X .38OD X .031 2.00 EA

R9311 SCR, MA 10-32X2.0 PN ST ZN 4.00 EA

R9327 PLASTIC, CASTING CASTOLITE-AP 1.00 OZ

R9532 SPRING, .36 OD x 1.75 LONG 1.00 EA

R9536 SCR, 6-32 X ¼ SOC STN STL 4.00 EA

R9561 SCR, MA 6-32 X 2 PN CR SS 2.00 EA

R9760 WRENCH, OPEN END 1/2 - 5/8 IN 1.00 EA

R9776 CABLE, BRAIDED SHIELDING 1.25 FT

R9810 TAPE, EMI/RFI SHIELDING 1.5 WIDE 9.00 IN

R9838 FILTER, LINE 10 AMP W/IEC SOCKET 1.00 EA

R9839 FILTER, LINE 6 AMP W/IEC SOCKET 1.00 EA

R9856 SUPPRESSOR, 34-40 RIBBON CABLE 1.00 EA

AK#207 ACCESSORY KIT F/112280/112480 1.00 EA

1180S72 NUT 6-32 KEPS 7.00 EA

1180S97 5/32 INCH HEX WR.CD.PL 1.00 EA

1180S133 MOLEX, 3 PIN MALE PLUG 1.00 EA

1186S001 GLUE CHUCK 1.00 EA

1751P076 CIRCUIT BREAKER, SPEED SENSOR 1.00 EA

1790S062 PLATE, BILINGUAL CAUTION 2.00 EA

1950S054 SWITCH, LIMIT-TOP 1.00 EA

1950S056 SWITCH, LIMIT-BOTTOM 1.00 EA

2280S031A PULLEY, .312 BORE 1.00 EA

2280S031B PULLEY, .500 BORE 1.00 EA

2280S057 FLANGE 4 INCH 2.00 EA

2280S110 BUSHING-SHAFT END ANODIZED 1.00 EA

2280S120 SCREW THUMB 10-32 X .31 1.00 EA

2280S123 LABEL-DRAIN ISOMET + 2.00 EA

2280S124 LABEL-OVERFLOW ISOMET+ 2.00 EA

2280S125 LABEL-EXT FLUID ISOMET+ 2.00 EA

2280S169 HINGE, ISOMET 2000 1.00 EA

2480S005 MOTOR, .4 HP 90 VDC 1.00 EA

2480S013 BASEPLATE,ISOMET 2000 1.00 EA

2480S029 COVER, MIC-ADJUSTMENT 1.00 EA

2480S033 BRACKET, MAIN 1.00 EA

2480S034 BOOT, MIC-MOTOR 1.00 EA

2480S036 BRACKET, MIC LIMIT 1.00 EA

2480S037 HUB AND SLINGER 1.00 EA

2480S038 SPACER 1.00 EA

2480S039 SLINGER, ARM 1.00 EA

2480S040 COVER, MIC-MOTOR 1.00 EA

2480S041 BELT, TIMING 1.00 EA

2480S042 ENCODER, ROTARY H.P. HEDS-5500 1.00 EA

MA112480-20 03/06/00

28

ISOMET™ 2000 Precision Saw Parts List

PART

NUMBER DESCRIPTION QTY U/M

2480S043 MOTOR, D.C. 1 RPM 40 IN.LB. T 1.00 EA

2480S044 MOTOR, D.C. 120 RPM 1 IN.LB. T 1.00 EA

2480S045 HOOD, ISOMET 2000 1.00 EA

2480S046 BRACKET, DRESSING CHUCK 1.00 EA

2480S047 COUPLING, TANK BULK-HEAD 3.00 EA

2480S050 LABEL, DRESS CHUCK-ISOMET 2000 1.00 EA

2480S051 PUMP ASSEMBLY 1.00 EA

2480S053 PUMP, COOLANT 12 VDC 1.00 EA

2480S054 PUMP AND COOLANT ASSEMBLY 1.00 EA

2480S055 GUIDE, DRESSING CHUCK 2.00 EA

2480S057 CLAMP, DRESSING CHUCK 1.00 EA

2480S059 COVER, FRONT 1.00 EA

2480S060 COVER, MIDDLE 1.00 EA

2480S061 LABEL, PUMP-ISOMET 2000 1.00 EA

2480S062 LABEL, POWER-ISOMET 2000 1.00 EA

2480S065 GUARD, SLINGER 1.00 EA

2480S066 CONNECTOR, TANK-PUMP 1.00 EA

2480S070 TANK, REMOVABLE 1.00 EA

2480S072 SAW HOUSING ASSEMBLY 1.00 EA

2480S074 CONNECTOR, CABINET-PUMP 1.00 EA

2480S078 GEAR, MITER-MACHINED 1.00 EA

2480S081 CABINET, UPPER - ISOMET 2000 1.00 EA

2480S082 CABINET, LOWER - ISOMET 2000 1.00 EA

2480S083 SPECIMEN ARM ASSEMBLY 1.00 EA

2480S084 THUMB SCREW ASSEMBLY 1.00 EA

2480S085 MOTOR, DRESSING CHUCK 1.00 EA

2480S086 DRESSING CHUCK ASSEMBLY 1.00 EA

2480S087 PCB, HIGH VOLTAGE 1.00 EA

2480S096 THUMB SCREW ASSEMBLY 1.00 EA

2480S097 MIC-SWITCH ASSEMBLY 1.00 EA

2480S114 CLAMP, SINGLE SADDLE 0.00 EA

2480S115 CHUCK, SINGLE SADDLE 0.00 EA

2480S135 CONNECTOR, SPIGOT 1.00 EA

2480S138 CABLE, OPER CONTROL/CPU ANALOG 1.00 EA

2480S139 HARNESS, CPU ANALOG/MOTORS 1.00 EA

2480S141 CABLE, CPU ANALOG/HIGH VOLTAGE 1.00 EA

2480S142 CABLE, RS232/CPU ANALOG 1.00 EA

2480S147 HARNESS, CPU ANALOG/ENCODER 1.00 EA

2480S148 FAN ASSEMBLY 1.00 EA

2480S149 CONNECTOR, CABINET-DRESSER 1.00 EA

2480S150 CONNECTOR, TANK-DRESSER 1.00 EA

2480S153 SCREEN, SPECIMEN 1.00 EA

2480S154 GASKET, DRESSING CHUCK 3.00 EA

2480S155 GASKET, ARM SLINGER 1.00 EA

2480S156 GASKET, GUARD SLINGER 1.00 EA

2480S157 HOOD ASSEMBLY 1.00 EA

2480S158 SPACER, HINGE 3.00 EA

2480S164 WIRE, JUMPER-2" 20 GAUGE BLK 1.00 EA

2480S166 STOP,HOOD 3.00 EA

2480S172 STIFFENER, HOOD 1.00 EA

2480S175 HINGE, ISOMET 2000 3.00 EA

2480S176 BLOCK, DRESSING 1.00 EA

2480S179 KIT, ACCESS-WRENCH 1.00 EA

MA112480-20 03/06/00

29

ISOMET™ 2000 Precision Saw Parts List

PART

NUMBER DESCRIPTION QTY U/M

2480S180 FILM, MYLAR 1.00 EA

2480S181 WASHER, 1.0IDX1.5ODX.19TH FELT 1.00 EA

2480S185 SHIELD, HOOD 1.00 EA

2480S186 SCREW, LH DRESSING CHUCK 1.00 EA

2480S187 COUPLER, SCREW DRESSING CHUCK 1.00 EA

2480S190 LABEL, CAUTION ARM 1.00 EA

2480S191 BODY, DRESSING CHUCK 1.00 EA

2480S192 ELBOW, SPEC 1.0 TUBE x 1/2 TUBE 1.00 EA

2480S193 NIPPLE, 1/2 NPT x 3.0 PVC 1.00 EA

2480S197 PLATE, LIMIT SWITCH 1.00 EA

2480S198 SHAFT, ARM 1.00 EA

2480S203 SCREW, MIC ADJUSTMENT 1.00 EA

2480S204 GAUGE, STRAIN ISOMET 2000 1.00 EA

2480S205 ARM HOUSING ASSEMBLY 1.00 EA

2480S206 MOTOR, D.C. 1RPM 40 IN/LBS T 1.00 EA

2480S207 BRACKET, ANGLE STRAIN GAUGE 1.00 EA

2480S208 PUMP & COOLANT ASSEMBLY 1.00 EA

2480S209 PLATE, STRAIN GAUGE MOUNT 1.00 EA

2480S210 BRACKET, DRESSING CHUCK 1.00 EA

2480S211 LEVER, GEAR MOTOR 1.00 EA

2480S213 ROD, 1/4-28 x 2.0 LG SS THREADED 1.00 EA

2480S217 PCB, CPU/ANALOG INTERFACE 1.00 EA

2480S219 SCREW, THUMB 1.00 EA

2480S221 SCREEN, .125 HOLES POLYPROP 1.00 EA

2480S222 SPACER, HINGE 3.00 EA

2480S226 BRACKET, SPD SENSOR 1.00 EA

2480S227 PLATE, SPEC ISOMET 2000 EC 1.00 EA

2480S228 SENSOR ASSEMBLY, SPEED 1.00 EA

2480S229 CABINET, UPPER-ISOMET 2000 EC 1.00 EA

2480S230 CABINET, LOWER ISOMET 2000 EC 1.00 EA

2480S231 HARNESS, CIRC BKR/EMI FILTER 1.00 EA

2480S232 PCB, OPERATORS CONTROL 1.00 EA

2480S233 NAMEPLATE,ISOMET 2000 MEMBRANE 1.00 EA

2480S235 CABLE, CPU ANALOG/POWER SUPPLY 1.00 EA

2480S236 HARNESS, HV BOARD/POWER SUPPLY 1.00 EA

2480S237 BRACKET, L SHAPE 1.00 EA

111186 CHUCK-WAFERS 1.00 EA

111198 DRESSING BLOCK SPACER KIT 1.00 EA

112282 FLANGE SET 3" SET OF 2 1.00 EA

112293 ISOCUT PLUS FLUID BULK 0.13 GL

112487 SINGLE SADDLE CHUCK 1.00 EA

112491 SMALL DOVETAIL CHUCK ASSEMBLY 1.00 EA

114276 WAFERING BLADE 6X.020X1/2 15LC 1.00 EA

112293016 ISOCUT PLUS FLUID - PINT 1.00 EA

114207001 CUT-OFF WHEEL 7X0.030 X 1/2 10.00 EA

114207010 CUT-OFF WHEELS 7X.030X1/2 0.20 EA

114217001 CUT-OFF WHEEL 7X0.030 X 1/2 10.00 EA

114217010 CUT-OFF WHEELS 7X.030X1/2 0.20 EA

MA112480-20 03/06/00

30

ISOMET™ 2000 Accessories and Supplies

Blades

ISOMET™ 2000 Wafering Blades

Blade Type 4″ dia.

Series 20 HC

Diamond,

high concentration

Series 15 HC

Diamond,

high concentration

Series 20 LC

Diamond,

low concentration

Series 15 LC

Diamond,

low concentration

Series 10 LC

Diamond,

low concentration

Series 5 LC

Diamond,

low concentration

Thickness 5″ dia.

(10.2 cm)

11-4215 .020″

11-4244 .012″

(0.3 mm)

11-4225 .020″

11-4254 .012″

(0.3 mm)

11-4285 .015″

11-4295 .015″

(12.7 cm)

11-4245 .015″

11-4255 .015″

Thickness 6″ dia.

(0.5 mm)

(0.4 mm)

(0.5 mm)

(0.4 mm)

(0.4 mm)

(0.4 mm)

Thickness 7″ dia.

(15.2 cm)

11-4237 .025″

11-4246 .020″

(0.5 mm)

11-4227 .025″

11-4276 .020″

(0.5 mm)

11-4287 .020″

(18.8 cm)

11-4247 .025″

11-4277 .025″

Thickness

(0.64 mm)

(0.63 mm)

(0.64 mm)

(0.64 mm)

(0.5 mm)

ISOCUT® Wafering Blades

Low concentration 11-4264 .012″

(0.3 mm)

11-4265 .015″

(0.4 mm)

11-4266 .020″

Abrasive Cut-off Wheels

For ferrous

materials

For tough non-

ferrous materials

* Use 1/2″ x 1/2″ x 3″ (13mm x 13mm x 76mm) Dressing Stick, Part Number 11-1190

for coarse series 20 & 15, or 11-1195 for fine series 10 & 5 Blades.

(0.5 mm)

11-4267 .025″

(0.6 mm)

11-4207-010

11-4207-010

.030″

(0.8 mm)

.030″

(0.8 mm)

MA112480-20 03/06/00

31

ISOMET™ 2000 Accessories and Supplies

Accessories

Part No. Description

11-1191

11-1197 FLANGES, 2.5” (64mm) DIA. set of two for use with larger diameter blades where greater depth of cut is

11-2282

11-2283

11-2284

11-2481 GONIOMETER, for precision sectioning of samples along specific planes, each axis provides monument in

11-2482

11-2483

11-2484

11-2485 IRREGULAR SPECIMEN CHUCK, for irregularly shaped samples.

11-2486 THIN SECTIONS AND WAFER CHUCK, for wafers, single crystals and thin sections.

11-2487

11-2488

11-2489

11-2491

11-2492

11-2493 EXTERNAL RECIRCULATING KIT.

11-2494 BONE CHUCK, for gripping bones and other irregularly shaped specimens.

11-1189

FLANGES, 1-3/4″ (44 mm) dia., recessed, set of two for use with larger specimens where greater depth of

cut is required.

required.

FLANGES, 3″ (76 mm) dia., set of two for use with larger diameter blades where greater depth of cut is

required.

FLANGES, 4″ (102mm) dia., set of two for use with larger diameter blades when higher cutting speed and

additional blade support is required.

FLANGES, 5″ (127 mm) dia., set of two for use with larger diameter blades where maximum cutting speed

and blade support is required.

2″ increments.

FASTENER CHUCK, 1-1/8″ - 2-1/8″ (29mm - 54mm) length capacity, for longitudinal sectioning of

fasteners, tubes and solid cylinders.

DOUBLE SADDLE CHUCK, 1-3/8″ (35mm) dia. capacity, prevents possible damage to specimen by

holding sectioned portion firmly after cutting is completed.

GLASS SLIDE CHUCK, 1-1/8″ W x 1-7/8″ L (29mm x 46 mm) capacity, for thin sectioning of specimens

mounted to a glass slide.

SINGLE SADDLE CHUCK, 1-1/4″ (32 mm) diameter capacity, for bar and tube stock.

GLASS SLIDE CHUCK, 2″ W x 3″ L (51 mm x 76 mm) capacity, for thin sectioning of specimens mounted

to a glass slide.

MOUNTED SPECIMEN CHUCK, 1-1/2″ (38 mm) diameter capacity for mounted samples.

DOVETAIL CHUCK, 1-1/4″ (32 mm) for rigid mounting of solid stock.

DOVETAIL CHUCK, 1-1/2″ (38 mm) diameter capacity for rigid mounting of solid bar stock.

MOUNTED SPECIMEN CHUCK, 1″ (25 mm) or 1-1/4″ (32 mm) diameter capacity for mounted samples.

Supplies

Part No. Description

11-2293-016 ISOCUT® PLUS FLUID, pint, combination lubricant/coolant concentrate for use with ISOMET™ 2000

11-2490

11-2495

11-2496 ISOMET™ 2000 Chuck Padding, PSA backed.

Precision Saw.

DRESSING STICK for ISOMET™ 2000, 1″ x 1/2″ x 3″ (25 mm x 13 mm x 76 mm) For Series 20 and 15

Diamond Wafering Blades.

DRESSING STICK for ISOMET™ 2000, 1″ x 1/2″ x 3″ (25 mm x 13 mm x 76 mm) For Series 10 and 15

Diamond Wafering Blades.

MA112480-20 03/06/00

32

ISOMET™ 2000 Accessories and Supplies

ISOMET™ 2000 Precision Saw Application Guide

Specimen Material Blade Type Speed Applied Load

Turbine blades - ferrous 11-4207 Abrasive wheel 3500 rpm 300-500 grams

Turbine blades - non-ferrous 11-4217 Abrasive wheel 3500 rpm 200-500 grams

Thermal Spray Coatings:

Ceramics 11-4207 or Series 15 HC diamond

Metallic - ferrous 11-4207 Abrasive wheel

Metallic - non-ferrous 11-4217 Abrasive wheel

Abradable 11-4207 Abrasive wheel

Titanium (bar stock, 1″ dia.)

Aluminum (bar stock, 1″ dia.)

Mild Steel (bar stock, 1″ dia.)

Printed circuit boards 11-4207 or Series 15 HC diamond 2000 rpm 200 grams

Tungsten carbide (1/2″ triangle x 1/4″ thick)

Hot pressed silicon nitride, Si3N4 Series 15 LC diamond 4000 rpm 800 grams

Boron carbide, B4C Series 20 LC diamond 3500 rpm 700 grams

Sapphire, Al2O3 Series 15 LC diamond 1500 rpm 300 grams

Chromium doped sapphire, Al2O3 Series 15 LC diamond 2500 rpm 500 grams

Partially stabilized zirconia, ZrO2 Series 15 LC diamond 2500 rpm 500 grams

Silicon carbide, SiC Series 15 LC diamond 2500 rpm 500 grams

Tungsten carbide 6% cobalt binder, WC Series 15 HC diamond 4000 rpm 800 grams

Tungsten carbide 25% cobalt binder, WC Series 15 HC diamond 4500 rpm 900 grams

High purity fused silica, SiO2 Series 10 LC diamond 1500 rpm 300 grams

Extruded alumina, Al2O3 Series 10 LC diamond 2500 rpm 500 grams

Aluminum nitride, AlN Series 10 LC diamond 3000 rpm 600 grams

Nickel zinc ferrite, Mo. Fe2O3 Series 10 LC diamond 1500 rpm 300 grams

Manganese zinc ferrite, Mo. Fe2O3 Series 10 LC diamond 1500 rpm 300 grams

Yttria alumina garnet, "YAG" Series 10 LC diamond 2500 rpm 500 grams

Chrysocolla (copper ore), hydrous copper

silicate

Gray Cast Iron 11-4207 Abrasive wheel 2500 rpm 800 grams

Zinc 11-4217 Abrasive wheel 3500 rpm 800 grams

Hastelloy 11-4207 Abrasive wheel 3500 rpm 800 grams

White Cast Iron ISOCUT(R) Wafering blade 2500 rpm 700 grams

Stainless Steels 11-4207 Abrasive wheel 4000 rpm 350 grams

Magnesium 11-4217 Abrasive wheel 2500 rpm 800 grams

PC Boards 11-4217 Abrasive wheel 2500 rpm 500 grams

Titanium 11-4217 Abrasive wheel 2500 rpm 800 grams

Plastics 11-4217 Abrasive wheel 2500 rpm 500 grams

Aluminum 11-4217 Abrasive wheel 2500 rpm 600 grams

Brass 11-4217 Abrasive wheel 2500 rpm 600 grams

Thermal Spray Coatings 15 HC Diamond blade 3000 rpm

11-4207 Abrasive wheel

Turbine Blades 15 HC Diamond blade 2500 rpm 600 grams

11-4207 Abrasive wheel 2500 rpm 600 grams

11-4217 Abrasive wheel 3500 rpm 650 grams

11-4217 Abrasive wheel 2500 rpm 500 grams

11-4207 Abrasive wheel 4000 rpm 600 grams

Series 15 HC diamond 3500 rpm 400-600 grams

Series 10 LC diamond 3000 rpm 600 grams

3000 rpm 200 grams

3000 rpm 200 grams

2500 rpm 200 grams

2500 rpm 200 grams

2500 rpm 700 grams

MA112480-20 03/06/00

33

NOTES

MA112480-20 03/06/00

34

Loading...

Loading...