Page 1

Panel Radiators

Design Manual

For Buderus Panel Radiator models:

- Model 21

- Model 22

- Towel Warmers

Page 2

Panel Radiator

Design Manual

2 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 3

Applications manual

Panel Radiator

Design Manual

Table of Contents

1 General Info 5

2 Safety 6

3 Product Description 7

4 Mounting Guidelines 15

5 Radiator Output Ratings 17

6 Radiator Selection Procedure 21

7 Piping Arrangements 22

8 Buderus NB Style Towel Racks 32

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 3

Page 4

Panel Radiator

Design Manual

4 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 5

Applications manual

1. General information

Panel Radiator

Design Manual

1.1. This manual

This application manual is intended for engineers,

architects, contractors, and installers. It provides

specication on panel radiator and towel rack models,

sizing information, and system layout assistance for

hydronic heating systems with panel radiators.

This manual describes the basic operation of the Buderus

panel radiators and towel racks, thermostatic controls and

piping accessories. It also provides rough in dimensions

and installation procedures.

Radiator heating capacities are listed by model, height and

length and are based on different supply water

temperatures.

For added savings Buderus recommends running panel

radiator systems at reduced temperatures. When using a

condensing boiler, the system should be designed so that

the return water temperature makes the boiler condense

except on the coldest days of the year.

Dew point ue gases:

• Natural Gas: 130°F (55°C)

• #2 Fuel Oil: 118°F (48°C)

1.2. Standards, regulations and directives

It is the responsibility of the installer to ensure that the

system corresponds to all current regulations and rules.

General guide lines are discussed with respect to sizing

and radiator selection. The design and radiator selection

process for one and two pipe heat distribution systems are

provided including examples. Quick and easy “rules of

thumb” for trouble free installation and operation are

presented.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 5

Page 6

2. Safety

Panel Radiator

Design Manual

2.1. Layout of the instructions

Two levels of danger are identied and signied by the

following terms:

WARNING! RISK OF FATAL INJURY

Identies possible dangers emanating from

a product, which might cause serious injury

or death if appropriate care is not taken.

WARNING! RISK OF INJURY/SYSTEM

DAMAGE

Indicates a potentially dangerous situation

that could cause minor or moderately

serious injuries and damage to property.

Additional symbols for identication of dangers and user

instructions:

USER NOTE

User tips for optimal use of equipment and

adjustment as well as other useful information.

2.4. Disposal

● Dispose of the packaging in an environmentally

responsible manner.

— Dispose of defunct components through an

authorized agent in an environmentally

responsible manner.

2.2. Please follow these instructions

Only use original Buderus spare parts.

Damage caused by the use of parts not

supplied by Buderus is excluded from the

Buderus warranty.

2.3. Tools, materials and accessories

For the installation of panel radiators and towel racks,

you will need standard tools used for central heating,

boiler and DHW water systems.

6 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 7

Applications manual

Panel Radiator

Design Manual

3. Product Description

With the line of panel radiators Buderus offers a real

alternative to conventional baseboard heating. For

decades Europeans have enjoyed the unsurpassed

comfort and versatility of radiant heat that is more exible,

efcient, and a cleaner alternative to baseboard heating.

Unlike conventional baseboard heat that provides only

convection heat, the high performance hydronic steel

panel radiators provide the perfect combination of both

convective and radiant heat while offering signicant

savings from lower water temperatures.

Radiant Heat vs. Convection Heat:

Forced hot air or baseboard systems with n tubes

produce heat that warms the air by convection, which

requires high water temperatures to effectively output

BTU. This results in large temperature differentials in the

room, can cause drafty conditions, and in many cases

results in hot air collecting at the ceiling and cooler air at

oor level.

Radiant heat, like the sun, warms objects rather than just

the air, creating a greater sense of warmth while requiring

lower room temperatures. The added radiant component

from panel radiators may permit return water

temperatures below 130°F (55°C) for natural gas and

118°F (48°C) for oil red appliances, allowing a

condensing boiler to condense and take advantage of its

added efciency.

Because Buderus radiators don’t turn “on and off”

randomly in the way traditional baseboards do, they are

virtually silent — eliminating the noise associated with

other heating systems.

The exibility of Buderus panel radiators offers builders,

designers, and homeowners a variety of sizes for any

heating and design requirement. These space-saving

panel radiators require between a third to a quarter of the

space of baseboard heating and are a perfect solution

where design exibility is important. The radiator’s unique

wall-mounted and optional oor-mounted styling also

minimizes areas where dust and dirt can collect and

allows for greater exibility in furniture placement.

Panel radiators from Buderus are stocked in several

heights and lengths, and in two widths.

Each panel radiator includes side panels, front and back

grill covers, and a owsetter valve. This feature enables

the system installer to quickly and easily regulate the

water ow through the radiator room by room. The result

is a consistent, even heat throughout all panel units in the

house — no more feeling warm in one room and chilly in

another.

Buderus Panel Radiators

Buderus “solidoux N” panel radiators are manufactured

from 18 Gauge (0.049”/0.125mm) steel panels. They

consist of water lled welded steel panels with convector

channels mounted on the back. These layers are

combined and arranged into two basic models:

model # 21 (width 2.5"), model # 22 (width 4.0").

Standard equipment with each radiator include wall

mounting brackets, bottom piping connections, built in

manual air vents, a drain plug and a ow setter valve with

a protective cover over it.

All stocking models have the ow setter (control) valve

and piping on the same side, and can be mounted facing

left or right.

Available Models

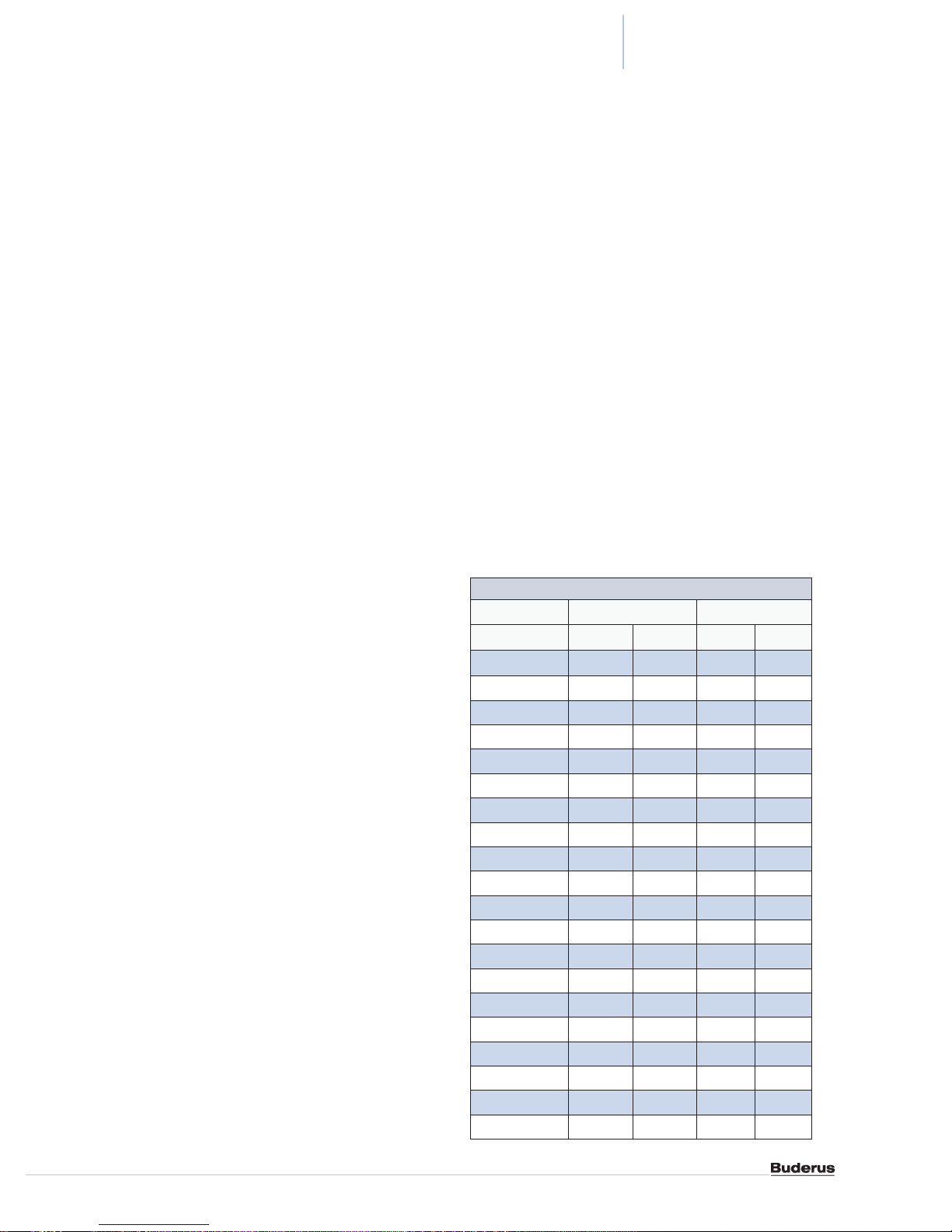

Model 21 Table 1

Dimensions Dry weight Water volume

H x L x W lbs kg gal liters

12"x24"x2"

12"x36"x2"

12"x48"x2"

12"x59"x2" 50 23 1.6 6.3

12"x63"x2" 54 24 1.8 6.7

12"x71"x2" 60 27 2.0 7.6

20"x24"x2" 35 16 1.0 3.8

20"x36"x2" 52 24 1.5 5.8

20"x48"x2" 69 31 2.0 7.7

20"x59"x2" 85 39 2.5 9.4

20"x63"x2" 91 41 2.6 10.1

20"x71"x2" 102 47 3.0 11.4

20 9 0.7 2.6

31 14 1.0 3.8

41 19 1.3 5.1

Special order sizes, up to 3‘ high and 10‘ long, are

available with a 4 to 6 week lead-time.

Buderus panel radiators come in a multi-layered, powder

coat enamel white nish that is durable, easy to clean

and ideal for most existing color schemes. They can also

easily be custom painted to any desired color.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

24"x24"x2" 41 19 1.2 4.5

24"x36"x2" 62 28 1.7 6.7

24"x48"x2" 83 38 2.3 8.9

24"x59"x2" 102 46 2.9 10.9

24"x63"x2" 108 49 3.1 11.7

24"x71"x2" 122 56 3.4 13.2

| 7

Page 8

Panel Radiator

Design Manual

Buderus Towel Warmers

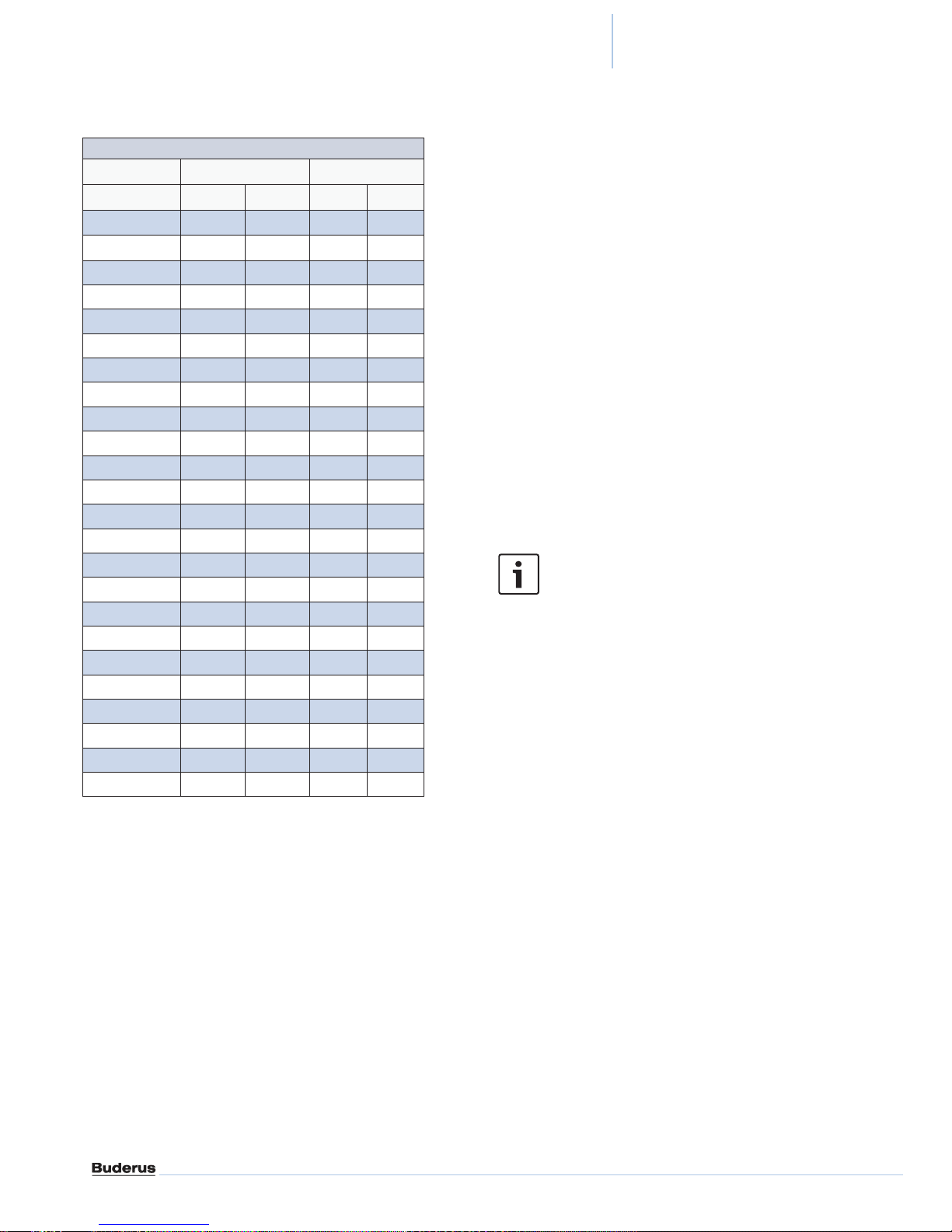

Model 22 Table 2

Dimensions Dry weight Water volume

H x L x W lbs kg gal liters

12"x16"x4"

12"x24"x4"

12"x36"x4"

12"x48"x4" 48 22 1.3 5.1

12"x63"x4" 63 28 1.8 6.7

12"x71"x4" 71 32 2.0 7.6

20"x16"x4" 27 12 0.7 2.6

20"x24"x4" 41 19 1.0 3.8

20"x36"x4" 62 28 1.5 5.8

20"x48"x4" 82 37 2.0 7.7

20"x59"x4" 101 46 2.5 9.4

20"x63"x4" 108 49 2.6 10.1

20"x71"x4" 121 121 3.0 11.4

24"x16"x4" 33 15 0.8 3.0

24"x24"x4" 49 22 1.2 4.5

24"x36"x4" 74 34 1.7 6.7

24"x48"x4" 98 45 2.3 8.9

24"x59"x4" 121 55 2.9 10.9

24"x63"x4" 129 59 3.1 11.7

24"x71"x4" 146 66 3.4 13.2

16 7 0.4 1.7

24 11 0.7 2.6

36 16 1.0 3.8

Nothing is more comforting than a warm towel after a

bath or shower. European towel warmers from Buderus

are the perfect combination of contemporary styling and

economical luxury. Towel warmers are also an excellent

way to add heat and remove humidity and dampness

from any bathroom.

Available in three sizes, the NB style towel warmers are

nished in a high quality white enamel for use in damp

environments like bathrooms. They should not be

installed in showers or areas where they are exposed to

direct water spraying.

The NB style is perfect for minimal space requirements

with a total depth of 5“ and a width of 24“. It is available in

heights of 32“, 48“ and 72“. These ready-to install towel

warmers offer outputs from 2,000 BTU/Hr to 4,500 BTU/

Hr at an average water temperature of 176ºF (80ºC).

All Buderus towel warmers have the water connections

on the bottom and a manual air vent at the top. Mounting

hardware is included. Piping accessories, valves and

thermostatic heads are available as accessories.

Buderus towel warmers must not be used with

potable water or open loop systems.

Chapter 5 has detailed radiator output ratings in table and

graphical form.

36"x16"x4" 48 22 1.1 4.2

8 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 9

Applications manual

Panel Radiator

Design Manual

Radiator Accessories

Buderus offers a variety of accessories for installation

and control of the radiators for different piping

arrangements.

Mounting Brackets

Buderus panel radiators include wall mounting brackets.

Floor mounting brackets are available as an accessory.

Rough in instructions and mounting guidelines are

presented in chapter 5.

Piping Connections

Each stocking radiator has 20 mm (approx. 3/4) metric

male tappings on the bottom on one side. The radiator

can be mounted with these connections facing left or

right. Figure 9 shows supply and return connections

which cannot be reversed. Buderus supplies the following

compression ttings for most applications.

Compression ttings are available from Buderus in sets

of two (see Table 3). These ttings are normally secured

to the piping connection on the radiator. When diverter or

shutoff valves are used, the compression ttings mount

on the valve.

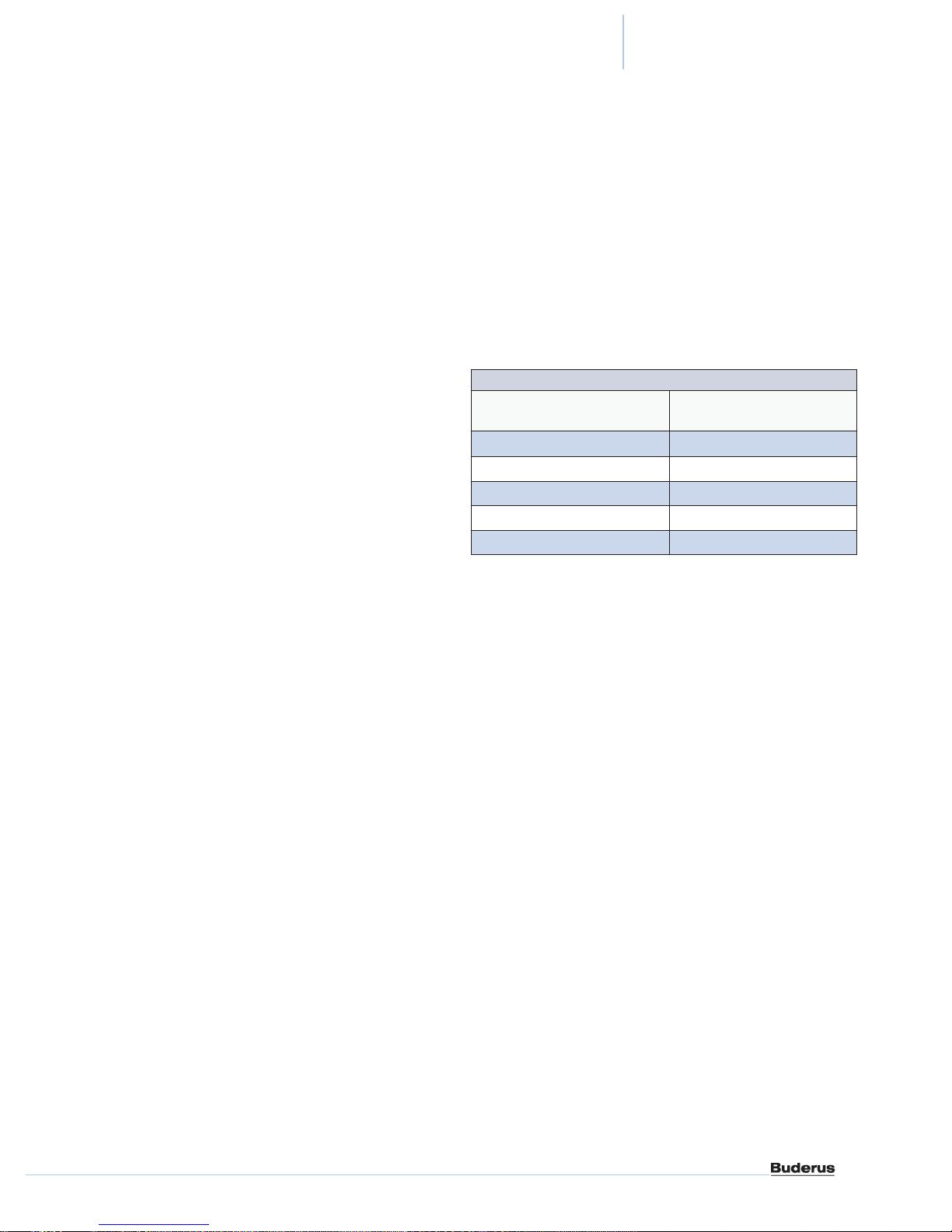

Compression ttings for panel radiators Table 3

Pipe size and style Part #

½" copper

12 x 2 mm (⅜" PEX)

16 x 2 mm (½" PEX)

20 x 2 mm (¾" PEX) 1016879

⅝" copper

6198924

1016870

1016874

1646851

Additional accessories are available that help with the

installation of the panel radiator as well as the application

in which it is installed.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 9

Page 10

Panel Radiator

Design Manual

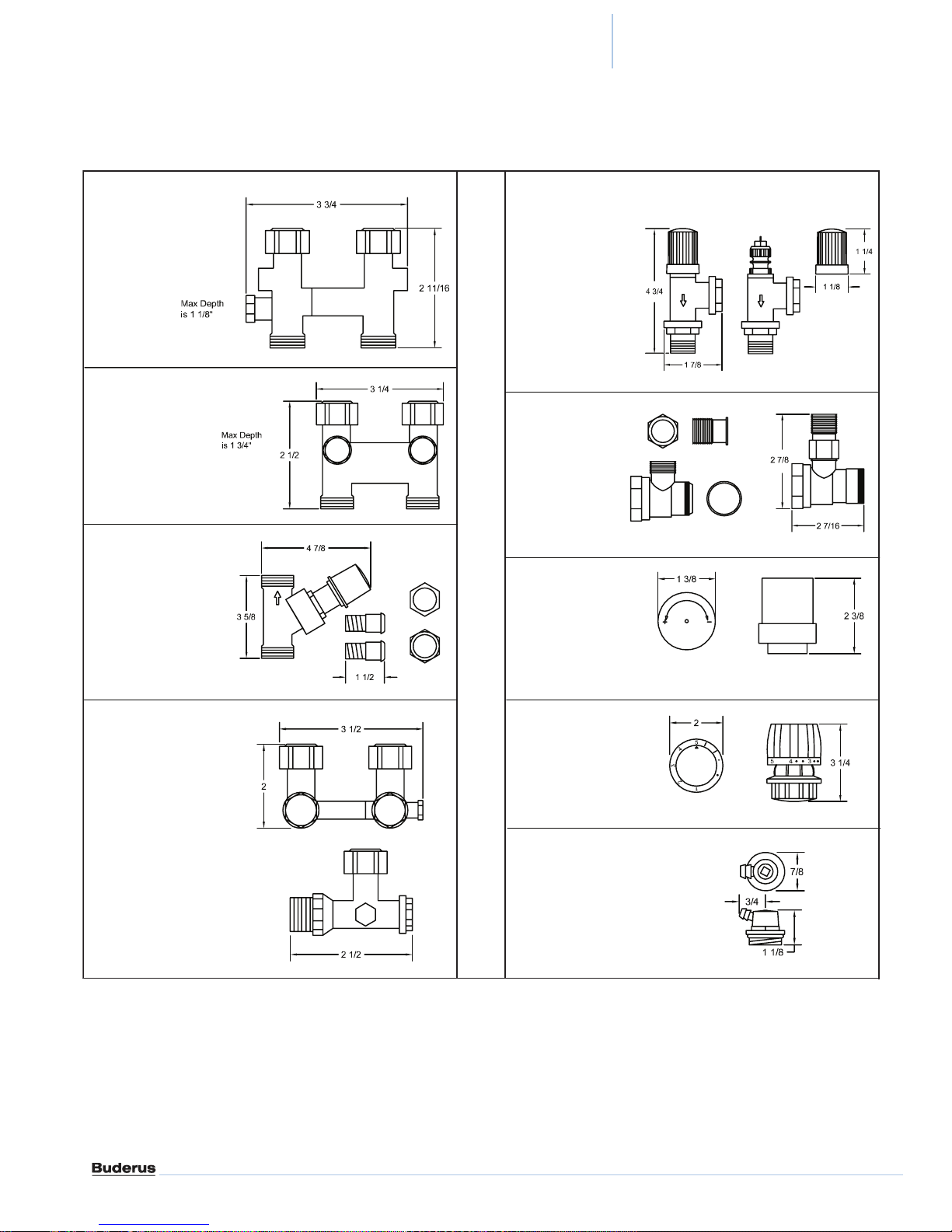

Part no. 1016311

Straight Diverter Valve

w/ isolation valves for

panel radiators

Part no. 1016362

Straight Crossover

Valve w/ isolation

valves for panel

radiators

Part no. 3L602502

Pressure Bypass

Valve 3/4" male

thread for panel

radiators and towel

racks

Part no. 013G81013

Single Valve, angled

with adjustment

facing down for towel

racks; Head can be

replaced with

thermostatic head

#013G8250 or

Part no. 3L0143

Angled Return

Elbow with

isolation valve for

towel racks

Part no. 013G5002

Manual Adjuster

for panel padiators

and towel racks

Part no. 1016312

Angled Diverter

Valve w/ adjustable

bypass and isolation

valves for panel

radiators

Fig. 1 Valve/accessory dimensions in inches

1 0 |

Technical specications are subject to change without prior notice

Part no. 013G8250

Danfoss

Thermostatic Head

for panel radiators

Part no. 82911060

Drain Valve w/

hose bib for panel

radiators

Panel Radiator Design Manual | 12.2009

Page 11

Applications manual

Panel Radiator

Design Manual

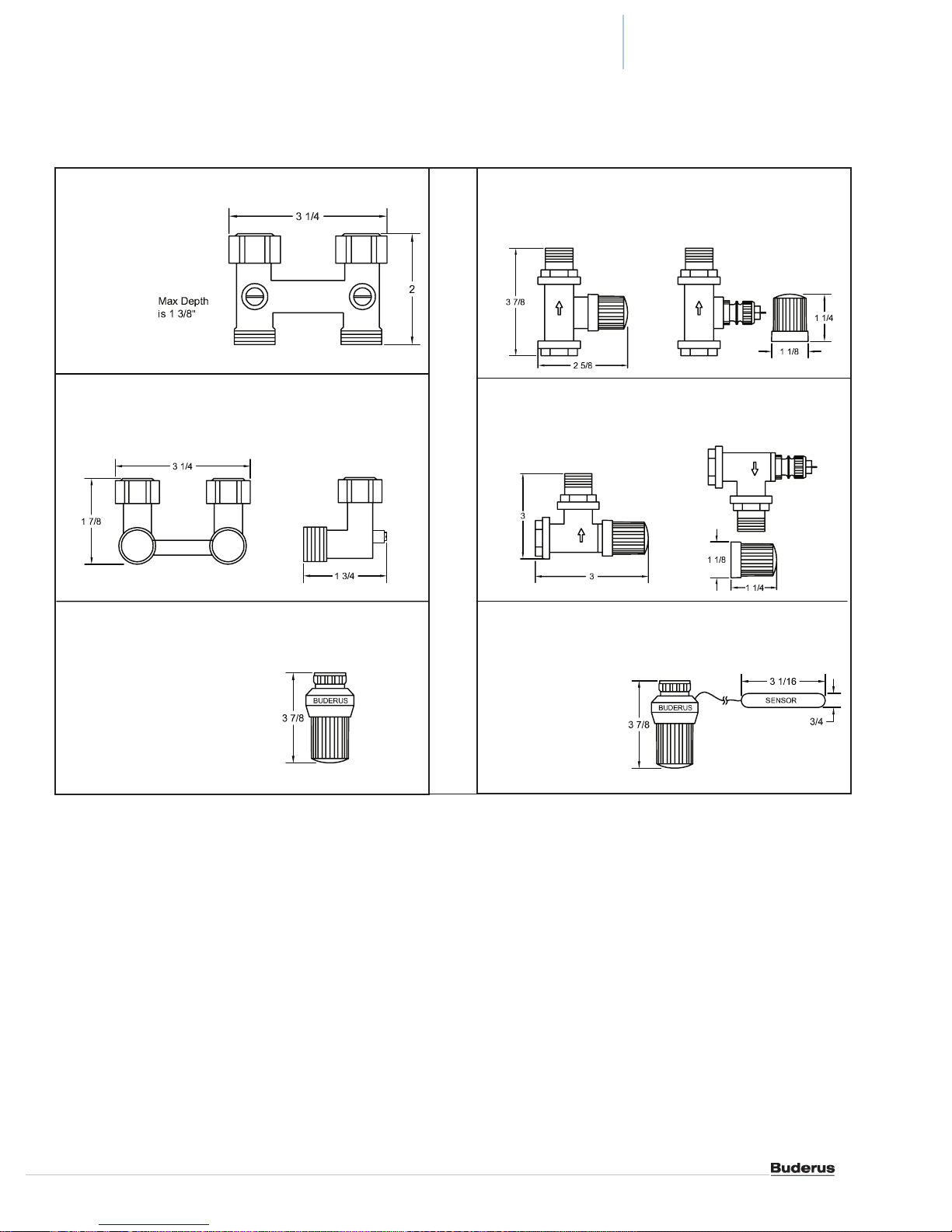

Part no. 80262170

Straight Valve

w/ isolation valves

for panel radiators

Part no. 80262172

Angled Valve w/

isolation valves for

panel radiators

Part no. 82721124

Buderus Thermostatic

Head for panel

radiators and towel

racks

Part no. 013G8015

Single Valve, straight with adjustment at front for towel racks;

Head can be replaced with thermostatic head #013G8250

or #82721124

Part no. 013G8014

Single Valve, angled with adjustment at the front for towel

racks; Head can be replaced with thermostatic head

#013G8250 or #82721124

Part no. 82721180

Buderus Thermostatic

Head w/ remote

sensor for panel

radiators and towel

racks - capillary 79"

(2000 mm)

Fig. 2 Valve/accessory dimensions in inches continued

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 11

Page 12

Floor Brackets for panel radiators Table 4

Floor Brackets Part Number

Model numbers: 22 817-BUD

Model numbers: 21 817-BUD-1

Optional covers for brackets 81606400

Flow Setter Valve:

Each radiator is equipped with a ow setter valve

mounted on the same side as the water connections of

the panel radiator. This valve consists of two part integral

components for temperature control and ow balancing.

Flow Balancing:

Panel Radiator

Design Manual

Fig. 3 Flow setter valve adjustment

Flow balancing is done by adjustment of the ring marked

1-7 and N on the ow setter valve, lining the desired

setting up with the dimple in the rst ring. Turning of the

ring adjusts the diameter available for water ow. The N

marking indicates a fully open setting; the 1 marking

indicates nearly full restriction. The diagram on page 13

shows the pressure drop across the radiator as a function

of the ow rate and setting of the ow setter.

Air Vent and Drain Plug

Each radiator is equipped with a manual air vent (1/2”)

and removable drain plug (3/4”) for draining the radiator.

A at head screw driver is needed to open the air vent.

1 2 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 13

Applications manual

Panel Radiator

Design Manual

Diverter Valves:

Straight (part number 1016311) and angled (part number

1016312) diverter valves are available from Buderus for

use in a one-pipe system (g. 4). Shut offs are located on

the supply and return branches to the radiator, allowing to

isolate the radiator from the piping system so it can be

drained and removed without decommissioning the

complete heating system.

Each diverter valve is factory set for 35 % ow through

the radiator and 65% through the bypass. Other ow

percentages are easily set according to the diagram (g.

5). To adjust the bypass, turn the spindle clockwise to the

fully closed position. Then open the bypass spindle the

desired number of turns from the fully closed position.

Refer to the chart that is on page 30, explaining the

pressure drop for a one-pipe system with diverter valves.

You will need to add up the pressure drop of radiator and

diverter valve when sizing the circulator.

Straight Valve

50

ADJUSTABLE

BYPASS

TO RADIATOR

TO RADIATOR

FROM RADIATOR

ISOLATION

VALVES

FROM RADIATOR

45

40

35

30

Radiator percentage of flow

50

45

40

35

30

Radiator percentage of flow

¾

Fig. 5 Setting for Straight and Angled diverter valves

1

Number of turns

Angle Valve

1¼ 1½ 1¾

1

Number of turns

2 3

Factory setting

Factory setting

ADJUSTABLE

BYPASS

ISOLATION

VALVES

Fig. 4 Straight and Angled Diverter Valves

Installation considerations:

1. The valve mounts directly to the supply and return

of the radiator. The compression ttings now

connect to the diverter valve.

2. Allow 5” oor clearance below the radiator for the

straight; 4” for the angled diverter valve.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 13

Page 14

Thermostatic Sensor head:

Adding a Buderus Thermostatic Head enables room-byroom zone control for optimum comfort and efciency. It

is easily installed on the ow setter valve.

A thermostatic head with remote sensor is available for

locations where the valve head would be covered behind

a curtain or otherwise blocked from sensing the actual

room temperature. Length of the capillary: 79“ (2000

mm).

Panel Radiator

Design Manual

4

3

Buderus

2

Buderus

Temperature Control:

Thermostatic control head is mounted on the ow setter

valve of panel radiators and towel racks, and through its

capillary expansion controls the ow rate and therefore

the heat output of the panel. When using the thermostatic

head the ow setter valve needs to be in the N position. A

moveable, spring-loaded seat assembly inside the ow

setter valve regulates the water ow through thermostatic

action of the control head. This thermostatic head is

required for individual temperature control at each

radiator. The asterics provides frost protection of the

panel itself provided the heating system is operational.

The sensor indicator numbers correspond to the following

approximate temperatures:

Thermostatic Sensor Head Setting Table 5

Dial * 1 2 3 4 5

Room Temperature °F 40 57 63 68 73 79

Room Temperature °C 5 14 17 20 23 26

1

Fig. 6 Thermostatic Sensor Head

1 4 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 15

Applications manual

4. Mounting Guidelines

Panel Radiator

Design Manual

Panel Radiator Installation

Both model 21 and 22 radiators can be wall or oor

mounted. All wall brackets must be secured to studs or

other supports of sufcient strength for panel radiator

weight. Radiators with a length of 71" or less require 2

brackets (1 set); lengths 79” or larger require 2 sets.

Note: Do not attempt to mount radiators soley to sheet

rock or similar material.

Radiator Clearance Requirements:

Clearance for right hand radiators Table 6

Clearance

dimensions

Floor 2" (51mm)

Minimum

clearance

4" (102mm)

5" (127mm)

5" (127mm)

Reason

- No diverter valves

- Angled diverters

- Straight diverters

- Cross-over valves

Model 21 and 22: Wall Mounting

Each bracket is supplied with a slotted plastic locating

clip. Position brackets evenly along the radiator and at

least 4" in from either side for aesthetic reasons. The

bottom of the radiator rests 5/8" above the bottom edge

of the bracket. The radiator wall clearance can be set at

1-9/16" or 2-1/16" depending on the orientation of the

plastic locating clips. Piping connections are located at

1-3/16" return and 3-3/16” (supply) in from the valve side

of the radiator. The piping wall offset is 3-9/16" or 4-1/16"

for both Model 21 and 22 radiators. For left hand

radiators, measure these dimensions from the left side.

See Fig. 8 and 9 for details.

Mount the brackets to studs or other wall supports

capable of carrying the load of the full radiator (see

Tables 1 & 2). Use at least 2 screws per bracket. Pull the

T-shaped plastic securing plate forward and slide the top

holder upward.

Insert the radiator with the bottom edge into the locating

clip at the bottom of the bracket. Now slide the top

bracket down to secure the radiator in place. Refer to the

installation instructions included with the brackets for

details.

Side of

owsetter

valve

Side opposing

the owsetter

valve

Top 2" - 4"

2" - 4"

(51-102mm)

(51-102mm)

5" (127mm) Thermostatic Sensor Head

Access to manual air

bleeder

Access to the top of wall

bracket

Model 21 and 22: Floor Mounting

Floor brackets permit placement of Model 21 and 22

radiators in front of tall windows or where wall mounting

is not an option. These brackets include a oor pedestal

mount, radiator support, channel section and tightening

assembly. The top grille of the radiator must be removed

to install the channel section and tightening assembly.

Radiators are adjustable in height from 4” to 8” bottom

clearance.

Fig. 7 Floor mounting bracket

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 15

Page 16

Panel Radiator

Design Manual

Finished wall

2½"

Minimum of

4"

Bracket

1⁹/₁₆"

or

2¹/₁₆"

Panel Radiator

Bracket

TOP VIEW

Fig. 8 Model 21 Panel Radiator Rough in Dimensions in inches for wall mounting

Finished wall

Supply

Stud

Minimum of

4"

Return

2" 1³/16"

Stud

2⅝" from

finished

wall to

center of

tapings

1 2

Minimum of

4"

Bracket

4"

1⁹/₁₆"

or

2¹/₁₆"

Panel Radiator

Bracket

TOP VIEW

Fig. 9 Model 22 Panel Radiator Rough in Dimensions in inches for wall mounting

Supply

Minimum

of 4"

Return

2"

1³/

3⅜" from

finished

wall to

center of

tapings

1 2

16"

1 6 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 17

Applications manual

5. Radiator Output Ratings

Outputs depend on panel radiator size, average water

temperature, and room temperature.

Four examples are presented below to illustrate a range

of options. If none of them applies, use Figure 10 and

Table 9 to determine output based on individual

requirements.

Tables 7 and 8 show the outputs of Model 21 and 22

in-stock radiators at four different water temperatures.

Use the high temperature column if restricted in wall

space. To maximize efciency in condensing boiler

applications, ensure the return water temperature drops

below the ue gas’ dew point of 131°F (55°C) for

signicant periods of the heating season.

2½

Radiator outputs in BTU/Hr:

Panel Radiator

Design Manual

Model 21: 2½" (63.5mm) deep Table 7

Output BTU/hr

Supply 194°F (90°C) 176°F (80°C) 158°F (70°C) 140°F (60°C) Part Number

Delta T 36°F (20°C) 36°F (20°C) 18°F (10°C) 18°F (10°C)

12"x24"x2½"

12"x36"x2½"

12"x48"x2½"

12"x59"x2½" 4700 3700 3200 2300 3-41259

12"x71"x2½" 5700 4500 4000 2900 3-41271

20"x24"x2½" 2800 2200 1900 1400 3-42024

20"x36"x2½" 4200 3300 2900 2100 3-42036

20"x48"x2½" 5600 4400 3900 2800 3-42048

20"x59"x2½" 7000 5500 4800 3500 3-42059

20"x71"x2½" 8400 6600 5800 4200 3-42071

24"x24"x2½" 3200 2500 2200 1600 3-42424

24"x36"x2½" 4900 3800 3400 2400 3-42436

24"x48"x2½" 6500 5100 4500 3200 3-42448

24"x59"x2½" 8100 6300 5600 4000 3-42459

24"x63"x2½" 8700 6800 6000 4300

24"x71"x2½" 9700 7600 6700 4800 3-42471

1900 1500 1300 1000 3-41224

2900 2300 2000 1400 3-41236

3800 3000 2600 1900 3-41248

All values based on 68°F (20°C) room temperature.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 17

Page 18

Panel Radiator

Design Manual

Model 22: 4" (100mm) deep Table 8

Output BTU/hr

Supply 194°F (90°C) 176°F (80°C) 158°F (70°C) 140°F (60°C) Part Number

Delta T 36°F (20°C) 36°F (20°C) 18°F (10°C) 18°F (10°C)

12"x16"x4"

12"x24"x4"

12"x36"x4"

12"x48"x4" 4900 3800 3400 2400 3-21248

12"x63"x4" 6500 5100 4500 3300 3-21263

12"x71"x4" 7300 5800 5100 3700 3-21271

20"x16"x4" 2500 2000 1700 1200 3-22016

20"x24"x4" 3700 2900 2600 1900 3-22024

20"x36"x4" 5600 4400 3900 2800 3-22036

20"x48"x4" 7500 5900 5200 3700 3-22048

20"x59"x4" 9300 7300 6400 4600 3-22059

20"x71"x4" 11200 8800 7800 5600 3-22071

24"x16"x4" 2900 2300 2000 1400 3-22416

24"x24"x4" 4300 3400 3000 2200 3-22424

24"x36"x4" 6500 5100 4500 3200 3-22436

24"x48"x4" 8700 6800 6000 4300 3-22448

24"x59"x4" 10800 8400 7400 5300 3-22459

24"x71"x4" 13000 10200 9000 6500 3-22471

36"x16"x4" 3500 2700 2400 1700 3-23616

1600 1300 1100 800 3-21216

2400 1900 1700 1200 3-21224

3700 2900 2500 1800 3-21236

All values based on 68°F (20°C) room temperature.

1 8 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 19

Applications manual

If tables 7 and 8 do not match a system‘s requirements,

the following guidelines provide means to calculate the

effects of ambient room temperature, supply water

temperature and temperature drop through the radiator

on the radiator output.

Ambient room temperature effect: The (adjusted)

output of a radiator at any room temperature (∆T room)

can be computed from the output listed at a room

temperature of 68°F (20°C) as:

Adjusted Output = Listed Output x [1+α x (68-Troom)]

(Troom in °F) where α is a correction factor computed as:

α = 1.385 / (ΔT supply - 75) with ΔT supply in °F.

Note: The listed radiator output depends on the supply

temperature.

Example: Select the proper radiator to heat a porch

which is to be kept at 55°F (13°C) during the winter.

Maximum heat loss is 8,750 Btu/hr. Assume supply

temperature equal to 194°F (90°C).

Panel Radiator

Design Manual

Solution: The larger temperature difference between the

radiator and the porch increases the radiator output. To

nd the proper size radiator, we must compute the listed

output at 68°F (20°C).

Adjusted Output = 8,750 Btu/hr at 194°F (90°C) and 55°F

(13°C). (∆T room).

Compute correction factor α as:

α = 1.385 / (194 - 75) = 0.0116

Listed Output = 8,750 / [1 + (0.0116 x (68 - 55)] =

7,560 Btu/hr

From Table 8: Use Model 22 20” x 48” x 4“ instead of

Model 22 24” x 48” x 4“ (listed output = 7,500 Btu/hr).

This ambient room temperature effect is generally small

and need only be considered in system design if desired

room temperatures are well beyond the typical 68 - 72°F

(20 - 22°C) range.

Supply water temperature effect: The effect of different

supply temperatures on the output of panel radiators is

computed using the conversion factors of Table 9 or read

directly from the Performance Curves in Figure 10.

Table 9 contains conversion factors needed to compute

the adjusted radiator output from the listed ratings. The

∆T factor is computed as the difference between the

average water temperature and room temperature.

Fig. 10 Performance Curves Model 22 Radiators

Conversion Factors Table 9

∆ T in ºF (°C) Conversion Factor

10 (6) 0.045

20 (11) 0.112

30 (17) 0.198

40 (22) 0.275

50 (28) 0.367

60 (33) 0.466

70 (39) 0.569

80 (44) 0.677

90 (50) 0.789

100 (56) 0.905

108 (60) 1.000

110 (61) 1.024

120 (67) 1.147

130 (72) 1.272

140 (78) 1.401

150 (83) 1.535

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 19

Page 20

Example: Compute the output of a Model 21 20” x 59”

radiator with an average water temperature of 140°F

(60°C) in the radiator and a room temperature of 70°F

(21°C).

Solution: Listed output = 7,000 Btu/hr (See Table 9)

∆T = 140 - 70 = 70°F: Conversion Factor = 0.569 (See

Table 9) Adjusted output = 0.569 x 7,000 = 3,983 Btu/hr.

Comment: The effect of the ambient room temperature is

already accounted for in the conversion factors listed in

Table 9. Figure 10 contains the performance curves for

Model 22 radiators showing the output per linear foot of

radiation for the different heights as a function of supply

temperature.

Different curves are shown based on a 18°F (10°C) and

36°F (20°C) temperature drop through the radiator and a

68°F (20°C) room temperature.

Example: A room requires 12,000 Btu/hr with 6 ft of

available space. Maximum supply temperature is 170°F

(77°C). What model(s) can be used for this application?

Panel Radiator

Design Manual

Solution: Required heat output per foot = 12,000/6 =

2,000 Btu/hr per linear foot. Check Figure 10 at 170°F

(77°C) supply temperature and 2,000 Btu/hr Output:

Model 22: Use 24” high with about 18°F (10°C) ∆T drop.

2 0 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 21

Applications manual

6. Radiator Selection Procedure

Several factors must be considered in the selection of a

panel radiator. These are:

• Heat loss of the room.

• Location of the radiator(s) and available oor to

window height.

• Desired piping arrangement.

• Room usage.

• Type of room control used.

All factors are discussed below and must be given

consideration prior to nal radiator size and model

selection.

1. The panel radiator(s) must have at least the required

capacity to match the heat loss. Oversizing is not a

problem provided thermostatic sensor heads or other

temperature sensitive controls are used to cycle the heat

off once the desired room temperature is reached.

Panel Radiator

Design Manual

2. Radiators are frequently selected based on the

intended location. A 3’ radiator ts nicely under a 36”

window, whereas a 24” radiator may only be needed

based on the heat loss. Window size and number of

windows as well as overall room size affect the selection

process. Once a room exceeds 12’ x 12’, it is advisable to

install 2 smaller radiators on outside walls for more

comfort.

3. The selected piping arrangement affects the radiator

sizing on monoow or one-pipe diverter valve based

systems, because the supply temperature reduces with

distance from the boiler. Minor oversizing of the last

radiators in the one-pipe system may be necessary.

4. For rooms that are used occasionally where a rapid

heat-up is required, it is advisable to install some extra

radiation. This becomes important on heating systems

operating with outdoor reset control. There is no need for

over sizing radiation in main living areas as they are

generally maintained at uniform temperatures.

5. Radiators equipped with thermostatic sensor heads on

a constant circulation system maintain a more uniform

room temperature and respond faster to temperature

disturbances such as open doors or windows, solar or

internal heat gain from appliances, lights, etc. compared

to a centrally located thermostat system.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 21

Page 22

Panel Radiator

Design Manual

7. Piping Arrangements

The design of a panel radiator based heating system

involves selection of a piping system, pipe sizes, overall

design temperature drop, required ow rates and desired

type of system control. For trouble-free system operation,

do not exceed the ow rates in Table 10.

Maximum ow rates & heat carrying capacities Table 10

Pipe size* Max

½" copper

or PEX

⅝" PEX 2.0 20,000 30,000 40,000

¾" copper 4.0 40,000 60,000 80,000

1" copper 8.0 80,000 120,000 160,000

1¼" copper 14.0 140,000 210,000 280,000

Diverter

valve

Radiator

Flow

ow

(gpm)

1.5 15,000 22,500 30,000

2.0 20,000 30,000 40,000

2.5 25,000 37,500 50,000

Note: Q (∆T = 20°F (11°C)) denotes the maximum heat

load carrying capacity based on a 20°F (11°C)

temperature drop.

*Pipe size used for main supply/return piping in multiple

one-pipe diverter valve based systems or for one-pipe

systems using monoow tees. This information is useful

for pipe sizing in two-pipe distribution systems.

This chapter discusses several piping arrangements,

guidelines for system design, pipe size, pump selection

and ne-tuning of individual components. Heat loss (Q),

water ow rate (GPM) and temperature drop (∆T) through

a hydronic heating system are related to each other as:

Q = 500 x GPM x ∆T

This equation is used extensively for accurate sizing of

radiators.

Q

(∆T=20ºF)Q(∆T=30ºF)Q(∆T=40ºF)

One-Pipe System Options

Figure 11 presents three different one-pipe

arrangements. In any one-pipe system, a single pipe

connects all radiators together. Fewer materials are

needed in a one-pipe system where a perimeter loop

supplies water to all radiators. Since water may ow

through all radiators and cools off along the way, it is

necessary to oversize the last radiator(s) in the loop. A

sizing procedure is outlined.

Table 10 shows maximum Btu load on a one-pipe system

based on pipe size and overall temperature drop.

Series loop system

All water ows through all radiators.

A thermostatic head cannot be used on any radiator as it

will shut off all ow. A central thermostat is required for

temperature control. Do not exceed heat loads as listed

in Table 10.

Option 1: one-pipe system with monoow tees

(Fig 11).

Monoow tees are used to divert some water from the

main loop into each radiator. Use one monoow tee on

the return if the radiator(s) are located above the main

loop; use two monoow tees if the radiators are installed

below the main loop. Place the tees in the main loop to

each radiator at least 12” apart. Thermostatic heads on

each radiator provide very easy means for individual

temperature control. The system can be operated off a

central thermostat or with constant circulation using an

outdoor reset system. Size the main loop based on the

selected temperature drop (20°F, 30°F, or 40°F (11°C,

17°C, 22°C)) and heat load. Make sure to oversize the

last radiators properly, especially when using an overall

temperature drop of 30°F (17°C) or 40°F (22°C). It is

important to size the main supply and return pipes for the

total heat load and volume to avoid ow restriction or

noise.

Option 2: one-pipe system with diverter valves

(Fig 12).

This arrangement is similar to using monoow tees

except that now each radiator is equipped with a diverter

valve. Secondly, the total loop ow can NOT exceed 2

GPM because of possible noise at greater ow rates. The

bypass adjustment in the diverter valve can be used to

throttle down the ow through the rst radiators and

increase ow through the last radiators in the loop to

make up for the drop in loop temperature. Thermostatic

heads on each radiator provide an easy means for

individual temperature control. The system

can operate off a central thermostat or with constant

circulation using an outdoor reset system. Follow Table

10 for pipe sizing. It is important to size the main supply

and return pipes for the total heat load and volume to

avoid ow restriction or noise.

2 2 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 23

Applications manual

Option 3: Multiple one-pipe systems.

Options 2 and 3 above can be installed in a multiple loop

fashion where several one-pipe systems are connected

between a common supply and return manifold. Assure

adequate ow in all piping systems when using monoow

loops and/or diverter valve loops. Isolation and balancing

valves are recommended on each loop for service and

ow control.

A properly sized pump operating on constant circulation

can supply water to all loops. A single Grundfos UP15-42

or equivalent can handle up to 3 diverter valve loops; use

a Grundfos UP26-64 or equivalent for 4 to 6 loops. Size

the main piping for the combined ow in all branches,

Option 1: One-Pipe System with Venturi Tees or Monoflow Tees.

1 2

Panel Radiator

Design Manual

following the guidelines in Table 10. Refer to the Pressure

Drop Curves (Fig. 14 & 15) on pages 30 & 31 for

estimating the pressure drop through each radiator when

using monoow tees. Use the Pressure Drop Diagram on

page 30 for a one-pipe system with diverter valves. Use

the approximate ow rate through the radiator and ow

setter valve setting to read off the pressure drop. Size the

circulator based on total ow and overall system pressure

drop. Thermostatic heads are required in this

arrangement for individual temperature control.

Ensure all supply and return piping is sized properly to

avoid restriction and noise.

1 2

1 2

Option 2: One-Pipe System with Diverter Valves.

1 2

Option 3: Multiple One-Pipe System (Home Run).

1 2

1 2

1 2

1 2

1 2

Drawing not to scale

Fig. 11 One-Pipe System Options

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 23

Page 24

Panel Radiator

Design Manual

Design procedure for One-Pipe System with

monoow tees or diverter valves

1. Select radiator hook-up sequence.

2. Determine individual heat loads.

3. Determine linear footage of wall space available for

each radiator.

4. Compute the required heat load per foot for each

room.

5. Select system temperature drop ∆T = 20, 30 or 40°F

(11°C, 17°C, 22°C) and maximum supply temperature.

6. Compute the total heat load (Q) in the loop by adding

the individual heat loads.

7. Determine loop ow rate from total heat load (Q) and

selected ∆T as: GPM (loop) = Q / 500 / ∆T

8. Compute the supply temperature for each room based

on the supply temperature and heat load of the

previous room and the total loop ow rate (GPM) as:

New Supply Temp = Previous Supply Temp - (Q room)

/ 500 / GPM

With the supply temperature computed in Step 8 and the

linear heat load in Step 4, refer to Figure 10 to nd the

required radiator size, or tables 9 and 10 for the total

individual radiator output if the any of the four examples

applies. Use the same ∆T value in reading from the

curves in Figure 10 as the selected value in Step 5. In

case more than one radiator is to be installed in a room,

size all radiators based on the above procedure.

Table 11

1 Select

room

sequence

2 Heat load

per room

3 (BTU/hr)

4 Available

wall space

(ft)

5 Minimum

Required

Heat Load

per linear

ft (BTU/ft)

6 Total

heat load

(BTU/ft)

7 Total loop

GPM GPM(loop) = Q / 500 / ΔT = ____ GPM

8 Supply

temp per

room

9 List

possible

radiator

Models

and sizes

Room 1 Room 2 Room 3 Room 4

ΔT =___ºF Supply temp(room1)

=max supply temp

= _______ ºF

Q = __________BTU/Hr

____ºF ____ºF ____ºF ____ºF

2 4 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 25

Applications manual

Panel Radiator

Design Manual

Example: One-Pipe System Layout

Design a one-pipe system for a second oor with

individual room temperature control:

Table 12

Description Heat Load Window

Size

Bathroom 3,000 1x3 ft wide rst

Master Bedroom 9,000 2x4 ft wide second

Bedroom 2 6,000 1x3 ft wide third

Bedroom 3 4,000 1x3 ft wide fourth

Hook-up

Sequence

Solution:

Step 1. Complete the Radiator Sizing Sheet to nd

minimum size radiator.

Step 2. Select control strategy and size piping and pump

using Table 7.

Step 3-4: See Table 13.

Step 5: Assume temperature drop (∆T) = 30°F (17°C),

maximum supply temperature = 180°F (82°C).

Results: Output/ft Radiator Models

Bedroom Supply Temp = 180°F (82°C) 1500 Btu/ft

#22 20”

M. Bedroom Supply Temp = 176°F (80°C) 1125 Btu/ft

#22 x 12

Bedroom #2 Supply Temp = 164°F (70°C) 2000 Btu/ft

#22 24”

Bedroom #3 Supply Temp = 156°F (60°C) 1333 Btu/ft

#22 24”

Use 5/8 ” PEX and diverter valves (or: 3/4” copper main

line with 3/4” x 3/4” x 1/2” monoow tees) with

thermostatic heads on all radiators for individual room

control. Place a thermostat in the bathroom or master

bedroom or run constant circulation. Use a Grundfos

UP15-42, a Taco 007, or equivalent pump with a

balancing valve to throttle the ow. Noise may otherwise

develop in the diverter valves.

Table 13

1 Select

room

sequence

2 Heat load

per room

Bathroom Master

Bedroom

3000 9000 6000 4000

Bedroom 2Bedroom

3

Step 6: Add all heat loads from row 2 and enter in Step 6.

Step 7: Compute ow rate in the one-pipe system in

GPM.

The ow rate can not exceed 2 GPM when

using diverter valves. Using a larger ∆T lowers

the GPM.

Step 8: Here we must compute the supply temperature

for each room. Start with the rst room and

compute each supply temperature step by step

as shown here.

Supply Temp (1) = 180°F (82°C)

Supply Temp (2) = 180 - 3000 / (500 x 1.47) = 176°F

(80°C)

Supply Temp (3) = 176 - 9000 / (500 x 1.47) = 164°F

(70°C)

Supply Temp (4) = 164 - 6000 / (500 x 1.47) = 156°F

(60°C)

Step 9: Now with each value computed in steps 4 and 8,

locate those values in Fig. 10. The output curve

located directly above that point identies the

minimum size radiator required. Use the 18°F

(10°C) ∆T curves if designing for a 20 to 30°F (11

to 17°C) temperature drop, use the 36°F (20°C)

∆T curves if designing for a 40°F (22°C) drop.

3 Available

wall space

(ft)

4 Minimum

required

heat

load per

linear foot

(BTU/ft)

5 Minimum

Required

Heat Load

per linear

ft (BTU/ft)

6 Total

heat load

(BTU/ft)

7 Total loop

GPM GPM = Q / 500 / ΔT = 22000 / 500 / 30 = 1.5 GPM

8 Supply

temp per

room

9 Possible

radiator

Models

and sizes

2 8 3 3

1500 1125 2000 1333

ΔT = 30ºF

Supply temperature (room1)

=max supply temperature

= 180 ºF

Q = 3000 + 9000 + 6000 + 4000 = 22000 BTU/Hr

ΔT = Q / 500 / GPM

180 176 164 156

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 25

Page 26

Two-Pipe System Options

Figure 12 illustrates two common two-pipe congurations.

Option 4: Two-Pipe Direct Return System

1 2

Option 5: Two-Pipe Reverse Return System

1 2

Panel Radiator

Design Manual

1 2

1 2

1 2

1 2

Pressure Bypass Valve

Drawing not to scale

Fig. 12 Two-pipe System Options

Benets of Two-Pipe Systems:

1. Each radiator is supplied with the same

temperature water maximizing radiator output.

2. No limit to the number of radiators on a two pipe

system loop; the supply and return mains must be sized

for maximum ow. Follow the guidelines in Table 10 for

sizing the supply and return runs. Use 1/2” copper or

PEX tubing to connect radiators to main runs.

3. Individual radiator control is easily done using

thermostatic sensor heads. Use constant circulation with

outdoor reset control for optimum system performance. A

central thermostat can be used for on/off control;

however, thermostat location governs overall system

control and may override individual room control.

Requirements for Two-Pipe System:

• Two main distribution pipes are needed; one for

the supply to the radiators and a second pipe for the

return to the boiler.

• A pressure actuated bypass valve (Part No.

3L602502 for a 3/4” Danfoss valve) connected between

supply and return mains is necessary on constant

circulation systems with thermostatically controlled

radiators to prevent dead-heading the pump. This bypass

valve is not needed on thermostat controlled systems if

the radiators are not equipped with thermostatic sensor

heads.

2 6 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 27

Applications manual

Design Procedure for Two-Pipe System

1. Determine individual heat loads.

2. Select desired overall temperature drop of systems

(∆T); i.e. 20°F (11°C), 30°F (17°C) or 40°F (22°C).

3. Compute loop ow rate GPM from:

GPM = Q / 500 / ∆T

4. Use Figure 10 or the Conversion Factors in Table 9 to

determine output of radiator models in case of lower

supply temperatures.

5. Use the Pressure Drop Chart on pages 30-31 as a

guide to set the ow setter valve for each radiator to

ensure proper ow through each radiator. Adjust ow

setter valves as needed based on system

performance. Close down the ow setter on “hot”

radiators by dialing in a lower setting on the adjustment

ring, or adjust the ow setter to a higher setting for

“cool” radiators.

6. Size piping based on system ow rate; size circulator

based on ow rate and overall system pressure drop.

Panel Radiator

Design Manual

Table 14

1 Select

room

sequence

2 Heat load

per room

3 (BTU/hr)

4 Available

wall space

(ft)

5 Minimum

Required

Heat Load

per linear

ft (BTU/ft)

6 Total

heat load

(BTU/ft)

7 Total loop

GPM GPM(loop) = Q / (500xΔT) = ______ GPM

Room 1 Room 2 Room 3 Room 4

ΔT =___ºF Supply temp(room1) =max supply

temp= _______ ºF

Q = __________BTU/Hr

8 Supply

temp per

room

9 List

possible

radiator

Models

and sizes

____ºF ____ºF ____ºF ____ºF

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 27

Page 28

Panel Radiator

Design Manual

Example 2: Two-pipe System Lay-out

Design and select a two pipe panel radiator system with

the following requirements:

Table 15

Description Heat Load Window

Size

Walk-in closet 2,000 none

Bathroom 5,000 1x2 ft wide 2,500

Bedroom 1 8,000 2x3 ft wide 1,333

Bedroom 2 10,000 2x4 ft wide 1,250

Master Bedroom 12,000 2x4 ft wide 1,500

Required

BTU/ft

Total Load: 37,000 Btu/hr

System Parameters:

Maximum Supply Temperature: 194°F (90°C)

Thermostat in master bedroom for ON/OFF control.

Solution: Two-Pipe System Lay-out

1. If sufcient space is available for radiators, select

radiators based on required heat output and desired

style. Select radiators from Tables 9 & 10 since the

system temperature is similar to those listed.

Table 16: Radiator Option Determination Chart: Two-Pipe

System

Table 16

Description

Walk-in

closet

Bathroom 5000 2,500 1x #22

Bedroom 18000 1,333 2x #22

Bedroom 210000 1,250 2x #22

Master

Bedroom

Heat

Load

2000 1 3-4

12000 1,500 2x #22

BTU/ftSelected

Models

20"x36"

12"x36"

12"x48"

20"x48"

No. and

length of

radiators

1x 3ft 6-7

2x 3ft 5-6

2x 4ft 6-7

2x 4ft 7-N

Flowsetter

valve

If the radiators must be sized for the available window

space, determine the minimum needed model radiator

based on the required Btu/ft for each room from Figure

10 with a 194°F (90°C) supply temperature. Use the

same supply temperature for each radiator in a two-pipe

system.

2. Select an overall temperature drop of 20°F (11°C).

3. Compute system ow rate as: GPM = Q / 500 / ∆T =

37000 / 500 / 20 = 3.7 GPM

4. Combine all information in tabular form as shown in

Table 2.

2 8 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 29

Applications manual

Panel Radiator

Design Manual

Balancing the system

Initial settings of ow setter valves will help to

ensure proper ow through all radiators.

Keep in mind that this is only a starting point

and that the system may require further

adjustment based on the heating

characteristics of the structure.

Procedure for setting the ow-setter valves.

1. Identify the largest radiator. In the above example it

would be the master bedroom radiator. The setting for

this radiator should be “N”. This radiator will have the

highest pressure drop and requires that the ow-setter

valve be fully open.

2.Using the Pressure Drop Chart on page 30-31, nd the

output for this radiator (at selected ∆T) at the bottom of

the chart. Based on 6,000 btu/hr at a 20°F ∆T the ow

rate for this radiator is 0.6 GPM. Follow the 0.6 GPM

line vertically until you intersect the N setting. Reading

across to the left you will see that the pressure drop for

this radiator is approximately 12 in. W.C. or 1ft/hd.

3. Draw a horizontal line across the diagram at 12 in.

W.C.

Piping Lay-out Suggestions:

1. For small systems, use one-pipe system with

monoow tees or diverter valves.

Btu’s per loop:

15,000 - 20,000 Btu/hr with 1/2 “ copper

20,000 - 30,000 Btu/hr with 5/8 “ PEX.

Increasing the overall temperature drop in the system

from 20°F (11°C) to 30°F (17°C) or 40°F (22°C)

permits more radiation per loop. (See Table 14).

Oversize radiators by 20 - 30% at the end of a onepipe loop. Always install a balancing valve in each

loop to regulate the ow rate to eliminate possible ow

noise.

Maximum ow rate for diverter valves: 2 GPM

Maximum ow rate per radiator: 2.5 GPM.

2. For larger systems, use two-pipe reverse return or

multiple one-pipe systems with common supply and

return manifolds. Refer to Table 10 for pipe sizing.

Pump Selection:

1-3 loops: Grundfos UP15-42, Taco 007 or equivalent

3-6 loops: Grundfos 26-64 or equivalent

Use pressure bypass valve on two-pipe systems to

prevent deadheading the pump.

4. Select the next radiator. Identify its btu/hr output, locate

this gure at the bottom of the chart as you did for the

rst radiator. At the corresponding ow-rate, move

vertically on chart until you intersect the horizontal line

that you drew indicating 12” W.C. Find the appropriate

ow setting. If the value is between two settings, say 3

and 4, then simply set the valve between 3 and 4.

5. Repeat step 4 for remaining radiators.

6. Use guidelines in Table 10 to size main piping. In this

case, use 3/4” copper mains with 1/2” copper (or PEX)

to/from each radiator. Install a thermostat in master

bedroom. Size circulator based on total ow rate and

install balancing valve for ow control.

Radiator Selection & System Start-up Suggestions:

1. Size radiators based on heat load, location, available

space, desired style and system operating

temperatures.

2. Use of thermostatic sensor heads increases comfort,

eliminates problems with over sizing the radiation and

provides individual room control.

3. Balance the system to ensure proper heat output from

each radiator using the ow setter valve on each

radiator. Shut off thermostatic heads one at a time and

monitor system response. Make necessary

adjustments.

4. Retighten compression ttings slightly after initial

start-up.

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 29

Page 30

Pressure drop curves:

Panel Radiator

Design Manual

Settings on flowsetter

200

1 2 3 4 5 6 7 N

100

90

80

70

60

50

²

40

30

20

Pressure Drop in Inches H 0

10

9

8

7

6

5

4

0.05 0.08 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.9 1 2 3

BTU/Hr

500 1,000 2,000 5,000 10,000

BTU/Hr

750 1,500 3,000 7,500 15,000

BTU/Hr

1,000 2,000 4,000 10,000 20,000

Fig. 13

3 0 |

Technical specications are subject to change without prior notice

GPM

∆T = 20°F (10°C)

∆T = 30°F (15°C)

∆T = 40°F (20°C)

Panel Radiator Design Manual | 12.2009

Page 31

Applications manual

% Radiator Flow

3

2

45

Panel Radiator

Design Manual

35

30

4050

Fig. 14

1

∆p Head in Feet

0.50 0.75 1.0 1.5 2.0 2.5 3.0 4.0

Circuit Flow - GPM

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 31

Page 32

8. Buderus NB Style Towel Racks

Panel Radiator

Design Manual

The Noblesse style towel racks are attractively designed

with a vertical frame of two 2-3/4" round pipes connected

horizontally with 1” curved round steel tubing precision

welded in the interior. Two ½” NPT female tapings are

available on the bottom of the towel rack for the supply

and return. An air vent is already installed on the top right

of the NB towel rack. The NB has an adjustable offset of

3” and 4” from the wall.

All towel racks come in a multi-layered, powder coat

enamel white nish that is durable, easy to clean and

ideal for most existing color schemes. Supply and return

pipes are reversible. Openings in the towel rack are

provided to hang towels. Complete wall mounting

hardware and a manual air vent is supplied with each

towel rack.

For piping accessories available through Buderus for a

clean, nish installation see Figures 1 and 2.

NB Style towel rack stock sizes Table 17

Model # Dimensions

NB towel

rack

NB towel

rack

NB towel

rack

(height x

width)

24" x 32" 2,000 17 lbs. * NB2432

24" x 48" 3,000 25 lbs. * NB2448

24" x 71" 4,500 35 lbs. NB2471

BTU @

180º F

Approx.

Ship Wt.

Part NO.

* Item can be shipped via UPS

3 2 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 33

Applications manual

Panel Radiator

Design Manual

Width - 24"

(installed)

Recommended Bracket

locations

16"

Bleeder

Finished

Wall

2"

Recommended bracket

spacing

32" Towel Rack - 25"

47" Towel Rack - 41"

72" Towel Rack - 65"

Adjustable

from

3" to 4"

½"

Taping

Recommended Bracket

location

21½"

center to center

½"

Taping

Top view

Recommended minimum

floor clearance 6"

Fig. 15 Buderus NB Style Towel Warmers

- Supply and Return tapings are interchangeable.

| 33

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

Page 34

Panel Radiator

Design Manual

3 4 |

Technical specications are subject to change without prior notice

Panel Radiator Design Manual | 12.2009

Page 35

Applications manual

Panel Radiator

Design Manual

Panel Radiator Design Manual | 12.2009 Technical specications are subject to change without prior notice

| 35

Page 36

Bosch Thermotechnology Corporation

50 Wentworth Avenue

Londonderry, NH 03053

Tel.: 603-552-1100

Fax: 603-584-1681

www.buderus.net

Products manufactured by:

Bosch Thermotechnik GmbH

Sophienstrasse 30-32

D-35576 Wetzlar

www.buderus.de

Bosch Thermotechnology Corporation reserves the right to

make changes without notice due to continuing engineering

and technological advances.

BTC 451001101 A | 12.2009

Loading...

Loading...