Buderus Logano G201 Operating Instructions Manual

Operating Instructions

Solid fuel boiler

DANGER!

If these instructions are not followed exactly, a fire

or explosion may be caused with serious property

damage or loss of life and serious injury.

– Do not store or use gasoline or any other flammable liquids or vapors in the vicinity of this system

or any other heating system.

– The heating system must only be installed and

serviced by a qualified service company or qualified

service provider.

Logano G201

6 720 618 152 - 08/2008 US

For the operator

Please read carefully before

use.

Dear Customer,

heat is our element – and it has been for more than 275

years. From the very beginning, we have invested all of our

energy and passion in order to develop individual solutions to make your climate comfortable.

Regardless of whether heat, hot water or ventilation – with

a Buderus product you will have highly-efficient heating

technology in the proven Buderus quality, which will make

you comfortable reliably for a long time.

We manufacture using the latest technologies and take

care that our products are efficiently attuned to one

another. Operating efficiency and environmental friendliness are always our focus.

Thank you for purchasing our product – and thus also for

efficient energy usage that provides great comfort. So

that things remain this way, please read these operating

instructions carefully. If you have problems, please contact your installer. He will be glad to help you.

What if your installer cannot be reached? Then our customer service is there for you!

We wish you great enjoyment with your new Buderus

product!

Your Buderus Team

2

Logano G201 - Subject to technical modifications.

Contents

1 Safety instructions and symbol key . . . . . . . . . . . . . 4

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . 4

1.2 General safety instructions . . . . . . . . . . . . . . . . . . 4

2 Information about the appliance . . . . . . . . . . . . . . . . 5

2.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Standards, regulations and directives . . . . . . . . . 5

2.3 Operating tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Product description . . . . . . . . . . . . . . . . . . . . . . . . 7

3 General instructions about the fuels wood

and coal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Wood firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Coal firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Condensate and tar formation . . . . . . . . . . . . . . . 8

3.4 Storing fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.1 Storing wood correctly . . . . . . . . . . . . . . . . . . . . . 9

3.4.2 Storing coal correctly . . . . . . . . . . . . . . . . . . . . . . 9

Contents

4 Start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Before operating the appliance . . . . . . . . . . . . . 10

4.2 Check operating pressure, fill up the heating

water, and bleed the heating system . . . . . . . . . 10

4.2.1 Checking the operating pressure . . . . . . . . . . . . 11

4.2.2 Topping up the heating water and bleeding

the heating system . . . . . . . . . . . . . . . . . . . . . . . .11

4.3 Setting the firing controller . . . . . . . . . . . . . . . . . 12

4.4 Heating up the boiler . . . . . . . . . . . . . . . . . . . . . . 13

4.5 Energy absorption . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 Re-filling fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 Constant heating mode (fire continues burning

overnight) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.8 Shutting down the boiler . . . . . . . . . . . . . . . . . . . 16

4.9 Shutting down the boiler temporarily . . . . . . . . . 16

4.10 Shutting down the boiler for a long period . . . . 16

4.11 Action in an emergency . . . . . . . . . . . . . . . . . . . . 16

5 Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . 17

5.1 Cleaning the boiler . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Frequent cleaning . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.2 Monthly cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Logano G201 - Subject to technical modifications.

3

1

Safety instructions and symbol key

1 Safety instructions and symbol key

1.1 Explanation of symbols

Safety instructions in the text are marked

with a warning triangle and printed on a gray

background.

Signal words are used to indicate the level of risk if countermeasures are not taken.

– Caution indicates that minor damage to property may

occur.

– Warning indicates that minor personal injury or severe

damage to property may occur.

– Danger means that severe personal injury may occur.

Very serious cases may result in death.

Notes are identified in the text by this symbol. They are separated by horizontal lines

above and below the text.

Notes contain important information in cases where there

is no risk to the user or the appliance.

1.2 General safety instructions

Risk of poisoning

V Insufficient air supply may cause dangerous combus-

tion gas leaks.

V Never close off or reduce the size of air inlet or outlet

vents.

V The boiler must not be operated until the obstruction

has been removed.

Maintenance and servicing

V Recommendation: sign a maintenance and inspection

contract with an approved heating contractor and have

the appliance serviced annually.

V The flue gas system of the boiler must be in accor-

dance with local approvals for solid fuel boilers.

V Have the entire flue system cleaned once a year by a

qualified chimney sweep.

V The operator is responsible for the general and environ-

mental safety of the system.

V Read and follow the safety instructions in the "Cleaning

and maintenance" chapter.

V Use only genuine spare parts.

Combustion/room air

V Keep combustion/room air free of aggressive materials

(e.g. ones that contain halogenated hydrocarbons,

chlorine or fluorine compounds). This will help you prevent corrosion.

V Prevent heavy accumulation of dust.

Explosive or easily flammable materials

V Do not store flammable materials or liquids near the

boiler.

V Abide by minimum distances to combustible materials.

Installation, operation

V Only have the appliance installed by an approved heat-

ing contractor.

V Do not modify any parts that carry flue gas.

V Do not operate the appliance without water.

V Always keep system openings (doors, maintenance

cover, fill openings) closed during operation.

V Only use approved fuels.

V Do not cover or reduce the size of ventilation openings

in doors, windows and walls.

4

Logano G201 - Subject to technical modifications.

2 Information about the appliance

Information about the appliance

2

These instructions contain important information for the

system operator for the safe operation of the boiler.

2.1 Designated use

The Logano G201 solid fuel boiler is a heating boiler for

coal and wood firing (split log firing) in single and multifamily houses. In order to ensure proper use, please

observe the details on the rating plate and the specifications to ensure proper use of this appliance.

2.2 Standards, regulations and directives

Observe all local codes and standards during

operation!

2.3 Operating tips

When operating the heating system observe the following:

V The boiler may only be operated by adults who are

familiar with the instructions and boiler operation.

V Make sure that children are not allowed in the vicinity of

the boiler unsupervised when it is in operation.

V Do not use any fluids for lighting or boosting the boiler.

V Ashes should be placed in a steel container with a tight

fitting lid, and moved outdoors. Other waste must not

be placed in this container.

V Do not place or store any flammable objects near the

filling or combustion chamber or at a safety distance of

24 to 48 inches around the boiler.

V Do not place any flammable objects on the boiler.

V Only clean the surface of the boiler with non-flammable

cleaners.

V Do not store any flammable materials in the boiler room

(e.g. petroleum, oil).

V Do not use any flammable liquids for heating.

V While the boiler is operating, do not exceed the rated

output of the boiler (overheating).

V Operate the boiler at a maximum temperature of 194 °F

and check it regularly during operation.

V Operate the boiler with a minimum return temperature

of 131 °F. Ensure that this temperature limit is adhered

to with a suitable set-up.

V The minimum boiler water temperature must be above

131 °F, because with a lower temperature, steam can

condense. This has negative consequences for the

proper operation of the boiler and its life span.

V The boiler operator must follow the operating instruc-

tions.

V The boiler operator may only start up the boiler, take the

boiler out of operation, and clean it. All other work must

be performed by an authorized service company.

V The service technician is obligated to inform the boiler

operator about the operation and the correct, safe

operation of the boiler.

V In case of danger of explosion, fire, escaping combus-

tible gases or vapors (e.g. vapors that arise when gluing linoleum, PVC, etc.), do not operate the boiler.

V Heed the flammability of building materials

(Æ installation and maintenance instructions).

2.4 Air supply

DANGER: Risk of fatal injury from lack of

oxygen in the boiler room!

V Make sure there is adequate fresh-air ven-

tilation by providing air vents to the outside.

V Point out to the system operator that

those air vents must remain open.

WARNING: System damage and risk of

injury in case of incorrect start-up!

Lack of adequate air for combustion can lead

to creosote formation.

V Make sure there is adequate fresh-air ven-

tilation by providing air vents to the outside.

V Point out to the system operator that

those air vents must remain open.

WARNING: Risk of system damage due to

aggressive materials in the ventilation!

During combustion, halogenated hydrocarbons that contain chlorine or fluorine compounds cause increased corrosion in the

boiler.

V Keep ventilation free of aggressive materi-

als.

The boiler draws in the required combustion

air from the environment. The boiler may only

be set up and operated in rooms that are permanently well-ventilated!

Logano G201 - Subject to technical modifications.

5

2

Information about the appliance

2.5 Disposal

V Packing materials made of wood and paper can be

burned in the boiler.

V Dispose of packaging in an environmentally responsi-

ble manner.

V Dispose of old devices in an environmentally responsi-

ble manner at an authorized disposal site.

6

Logano G201 - Subject to technical modifications.

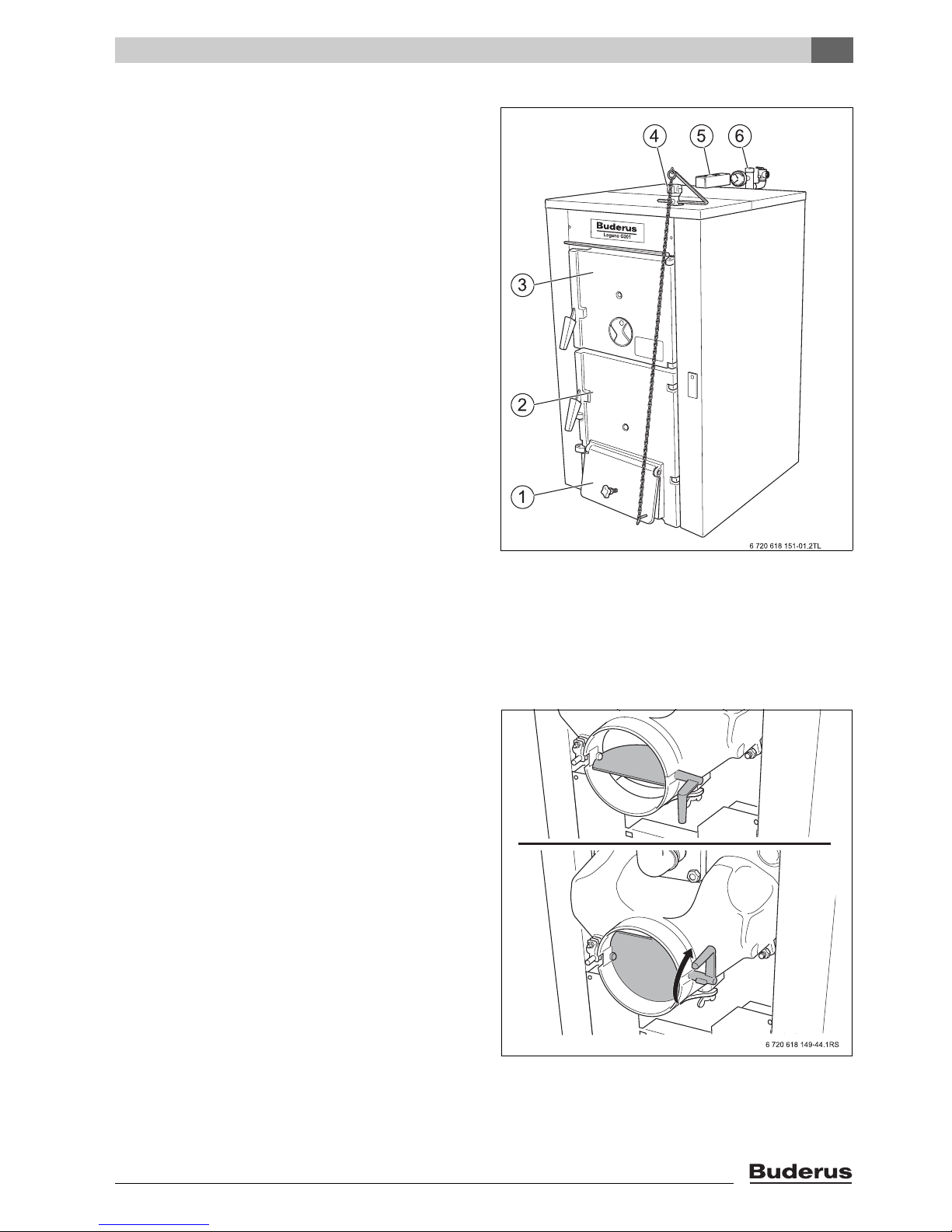

2.6 Product description

The Logano G201 is a solid fuel boiler and approved for

fueling with coal and wood chunks.

The boiler consists of:

–Air vent [1]

– Ash pan door [2]

– Fuel filler door [3]

– Firing controller [4] with rod and chain

– Aquastat [5]

– Manifold [6] with safety valve and thermometer/

manometer.

Using the firing controller [4], the desired boiler water

temperature is set and limited to this maximum value.

The firing controller [4] is connected to the air vent [1] via

a chain (in the ash pan door) and regulates the airflow of

the boiler. The warmer the boiler becomes, the more the

air vent is closed so that the set boiler water temperature

is not exceeded.

The fuel filler door [3] allows you to fill the ignition chamber with fuel.

The ignition chamber transmits the heat generated to the

heating water.

The ash container is behind the ash pan door [2].

The thermometer/manometer on the manifold [6] displays

the temperature in the boiler and the water pressure.

The jacket is lined with insulation materials and thus prevents radiation loss and stand-by heat losses.

Information about the appliance

Fig. 1 Logano G201

1 Air vent

2 Ash pan door

3 Fuel filler door

4 Firing controller

5 Aquastat

6 Manifold

2

Exhaust flap

The exhaust flap is opened to heat up a cold boiler or in

case of poor flue draft (Æ Fig. 2 above). This allows hot

flue gas to escape more quickly into the chimney and the

chimney "draws" better.

When the boiler is operating normally and when there is

sufficient flue draft, the exhaust flap is closed (Æ Fig. 2

below). This way, less heat is lost through the chimney.

Fig. 2 Exhaust flap (top: open; bottom: closed)

Logano G201 - Subject to technical modifications.

7

3

General instructions about the fuels wood and coal

3 General instructions about the fuels wood and coal

Wood and coal can be used as fuels.

DANGER: Danger of fatal accident due to

escaping carbon monoxide (CO)!

In case of firing with brown coal, the boiler

can silt up and CO can escape.

V Do not use brown coal for firing.

WARNING: Health and/or system damage

due to the use of unsuitable fuels!

The use of unsuitable fuels can create materials that endanger health and/or the heating

system.

V Do not use plastics, household waste,

chemically-treated wood, old paper, chips,

bark or chipboard waste for firing.

The flue gas temperatures are generally 212 – 392 °F.

Depending on local conditions, fuels used (wood or coal),

and how clean the boiler is, these values can be

exceeded.

3.1 Wood firing

Prescribed is split and dried wood with a diameter of

6 inches and a maximum wood humidity of 20 %.

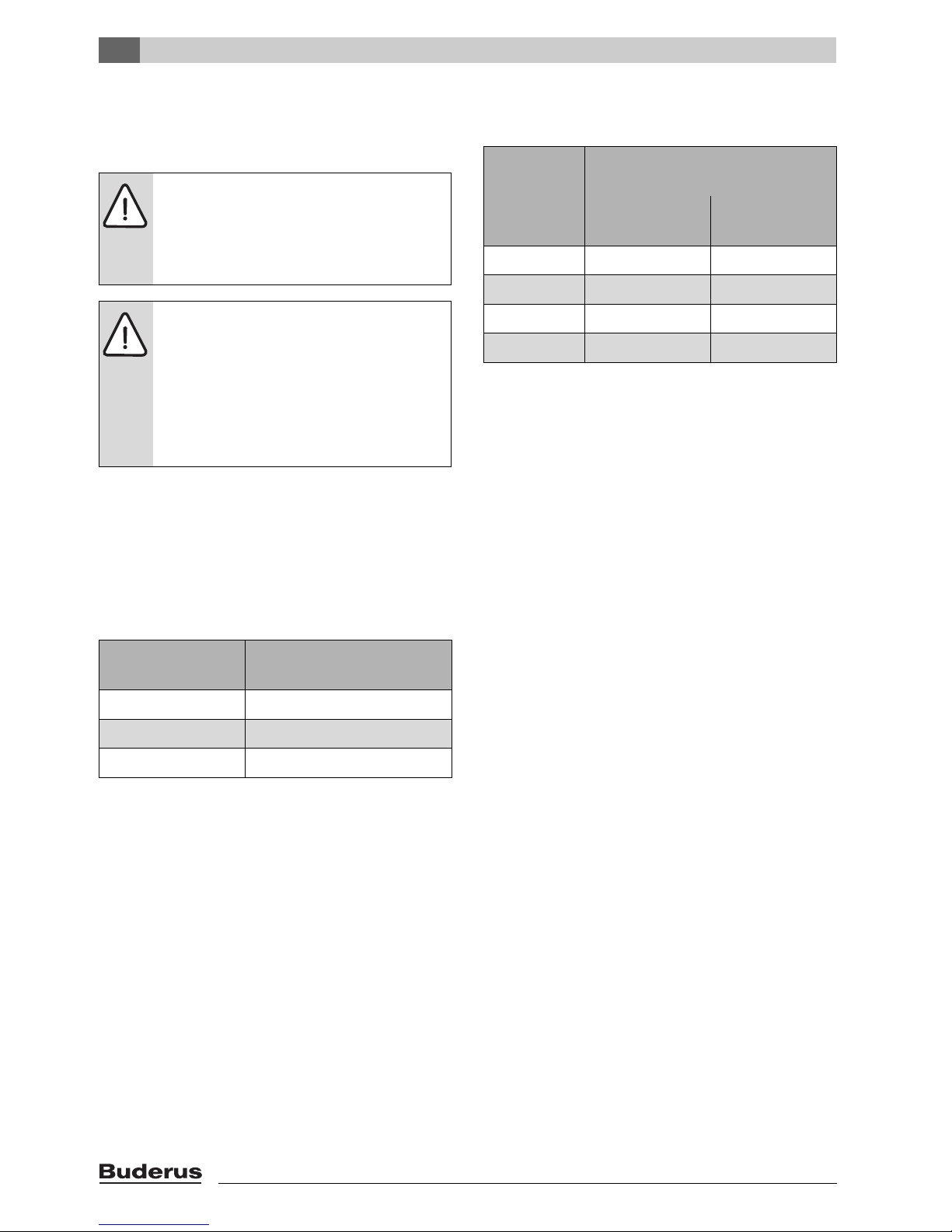

Heating value

(with wood humidity of 20 %)

Type of

wood

Beech 3000 24,000,000

Oak 3250 26,000,000

Pine 1800 17,000,000

Spruce 2100 18,000,000

Tab. 2 Energy value of various types of wood

As substitute fuels, the following are permissible (reduced

output and shorter maintenance intervals): wood briquets

and wood chips.

Weight per

cord LBs

BTUs per cord

air-dried wood

3.2 Coal firing

Best suited are anthracite coal and coke – any kind of

lump 1 (0.8 – 1.6 inches). The burning times for coal are

significantly longer than the burning times for wood.

As substitute fuels, the following are permissible (reduced

output and shorter maintenance intervals): anthracite coal

and coke type lump 2 (0.4 – 0.8 inches) or fragments

(1.6 – 4.0 inches) and pressed fuels.

Maximum length of split

Boiler type

27 15 ¼ inches

35 19 ¼ inches

40 27 ¼ inches

Tab. 1 Maximum length of split or chipped wood

Only use dry, natural, chunky wood. With a wood humidity

of more than 20 %, the boiler output is reduced. In addition, there can be increased tar formation, which reduces

the life span of the boiler. The specified output values and

the unfettered function of the boiler can only be guaranteed with a maximum wood humidity of up to 20 %.

or chipped wood

3.3 Condensate and tar formation

Improper operation of the boiler causes excessive condensate and tar formation. This way, damage to the boiler

and the flue gas system can occur.

When heating up the cold boiler, water condenses in the

boiler, which runs down on the interior walls. This way,

you might think that the boiler is draining off. This "sweating" of the boiler ends as soon as the ashes accumulate

on the interior walls of the boiler.

In case of operation at low boiler temperature (return temp

less than 131 °F) and fuel with too high a humidity content, condensation can also form on the heating surfaces.

Here too, the condensation runs downwards.

Heating with too low a boiler temperature causes tar formation and can cause premature damage to the flue gas

system due to sooting.

V Follow the operating instructions for the boiler.

V Operate the boiler at the recommended operating tem-

peratures.

V Only heat the boiler with the recommended fuels

(Æ Chapter 3.1 and 3.2).

V Remove tar accumulations with the cleaning scraper

when the boiler is warm.

8

Logano G201 - Subject to technical modifications.

Loading...

Loading...