Buderus Logano G125 BE US/CA, Logano G125/21-BE, Logano G125/28-BE, Logano G125/34-BE Installation And Service Instructions Manual

Page 1

Installation and Service

Instructions

Low Emissions and

High Efficiency Oil

Boiler

C

Logano G125 BE US/CA

For trained and certified

installers

Read carefully prior to

installation, maintenance

and service.

6 720 804 880 (2012/10) EN-US

Page 2

Table of Contents

1 Safety Considerations and Symbol Descriptions . . . . . . . . . . . . . . . . . . . 4

1.1 Regarding this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Guideline of Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Observe the following Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Boiler Room Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Tools, Materials and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Product Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Technical Data less Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 General Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Packaging and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Moving the Boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Reducing Boiler Weight for Transportation. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Lifting and Carrying the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Moving the Boiler with the Boiler Cart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Placing the Boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Reversing the Burner Door Swing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.3 Installation of boiler Feet (Components of B-Kit) . . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Placement of the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Boiler Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Installation of Venting Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1.1 Vertical Venting Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1.2 Horizontal Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Installation of Combustion Air Supply System. . . . . . . . . . . . . . . . . . . . . . . . . 28

7.3 Installation of Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3.1 B-Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3.2 Installation of Boiler Drain (B-Kit Component) . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3.3 Installation of System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.4 Filling and Checking for Water Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5 Installation of Oil Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.6.1 Installation of Aquasmart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.6.2 Control System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.6.5 Strain Relief Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.6.6 Top Rear Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

Logano G125 BE - Specifications subject to change without notice.

Page 3

Table of Contents

8 Placing the Boiler in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.1 Setting the Initial System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.2 Checking the Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Check Position of Flue Baffles (Room Air Operation). . . . . . . . . . . . . . . . . . . . . 40

8.4 Check Position of Flue baffle Plates (Outside Air Operation) . . . . . . . . . . . . . . . . 41

8.5 Prepare System for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.6 Start-up of Control and Burner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.7 Guidelines for Burner Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.8 Adjusting Stack Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.8.1 Adjusting/Removing Flue Baffles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.8.2 Removing Flue Blocking Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.9 Testing of the Manual Reset High Limit (STB) of Logamatic controls . . . . . . . . . . . 44

8.10 Installation of Front Burner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.11 Detailed Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9 Taking the Boiler Out of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.1 Normal Boiler Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2 Emergency Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Boiler Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 Why do maintenance?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2 Prepare Boiler for Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.3 Boiler Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.3.1Cleaning the Boiler with Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.3.2Wet Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.3.3Inspecting the combustion air hose (sealed combustion only) . . . . . . . . . . . . . . . . . . 50

10.4 Testing System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.5 Testing Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.6 Inspection and Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11 Restoring System Lock-outs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

12 Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

14 Burner Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

15 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Logano G125 BE - Specifications subject to change without notice.

3

Page 4

1

Î

Safety Considerations and Symbol Descriptions

1 Safety Considerations and Symbol Descriptions

1.1 Regarding this Manual

This document contains important information regarding

safe and proper installation, operation and maintenance

of the boiler.

The high tech G125 BE boiler is designated as a hot water heating boiler.

The Installation and Maintenance Instructions are directed to the installing contractor who has professional

knowledge regarding boiler installation and maintenance.

1.2 Guideline of Notices

Two levels of danger are identified by the following

warning labels:

DANGER

Denotes a possible severely dangerous

WARNING!

CAUTION!

situation where, without proper caution,

bodily injury or loss of life may result.

DANGER OF INJURY/SYSTEM

DAMAGE

Denotes a possible dangerous situation

that can lead to mild to moderate bodily injury or physical damage.

1.3 Observe the following Symbols

The local and state codes and regulations must be observed during the installation of the boiler:

– The local building code requirements regarding

placement, combustion air and venting and chimney

system must be followed.

– Follow applicable electrical code requirements.

– Follow the local code and standards regarding safe

boiler operation.

NOTICE

Use only original Buderus spare parts.

Buderus can not be held liable for damage caused by non-Buderus parts.

NOTICE

The boiler installation must be performed

by a qualified installer in accordance with

regulations put forth in NFPA-31 Installation of Oil-Burning Equipment. The installation must comply with all local and

national codes, regulations and authorities having jurisdiction regarding the installation of oil fired boilers.

For Canada refer to the guidelines of

CSA/CGA-B149.1 and 2 Installation

Codes.

NOTICE

Application comment for optimum use of

equipment and adjustment as well as

useful information.

Cross reference

Designated by means of an arrow Î , refers to a notice

in another document.

4

Logano G125 BE - Specification s subject to change without notice.

Page 5

Safety Considerations and Symbol Descriptions

1

1.3.1 Installation Guidelines

DANGER TO LIFE

from electric shock

CAUTION!

z Do not work on electrical components

unless you have the required qualification and applicable certification.

z Do not work on electrical components

unless you have the required qualification and applicable certification.

z Prior to opening the control: shut

down the power supply and prevent

from accidental reactivation.

z Observe all applicable installation

guidelines.

1.3.2 Boiler Room Guidelines

DANGER TO LIFE

from poisoning.

CAUTION!

Insufficient combustion air can result in

dangerous operation if combustion air is

taken from indoors.

1.4 Tools, Materials and Accessories

For the installation and maintenance of the boiler you

will need typical tools used in .

In addition, the following components are useful:

– Boiler cart with rope or Buderus boiler cart.

– Wood blocking.

– Cleaning brushes and/or chemical cleaning agents

for wet cleaning.

1.5 Disposal

z Please dispose of any trash in an environmentaly

friendly fashion.

z Please discard properly of any heating system relat-

ed components.

CAUTION!

z Please observe that combustion air

openings are not reduced in size or

closed.

z Make sure that no mechanical air

openings or devices remove combustion air from the boiler room such as

central vacuum systems, dryers and

air conditioning appliances.

z Make sure that the boiler is connected

to a chimney or horizontal venting system that is capable of handling the

slight positive breeching pressure.

z If any of these problems have not been

corrected, one cannot operate the boiler.

z Make the end-user aware of these

guidelines and their potential danger.

FIRE DANGER

due to flammable or liquid materials.

z Make sure that flammable and liquid

materials are not in the close vicinity of

the boiler.

Logano G125 BE - Specifications subject to change without notice.

5

Page 6

2

Product Description

2 Product Description

2.1 Product Applications

The boiler is designated for use as a hot water heating

boiler for space heating applications and to heat domestic hot water by means of an indirect fired tank for single

and multi-family homes and small commercial heating

applications.

Please observe the technical data on the rating label

and technical information (Î Chapter 3, page 7), to ensure proper application of this product.

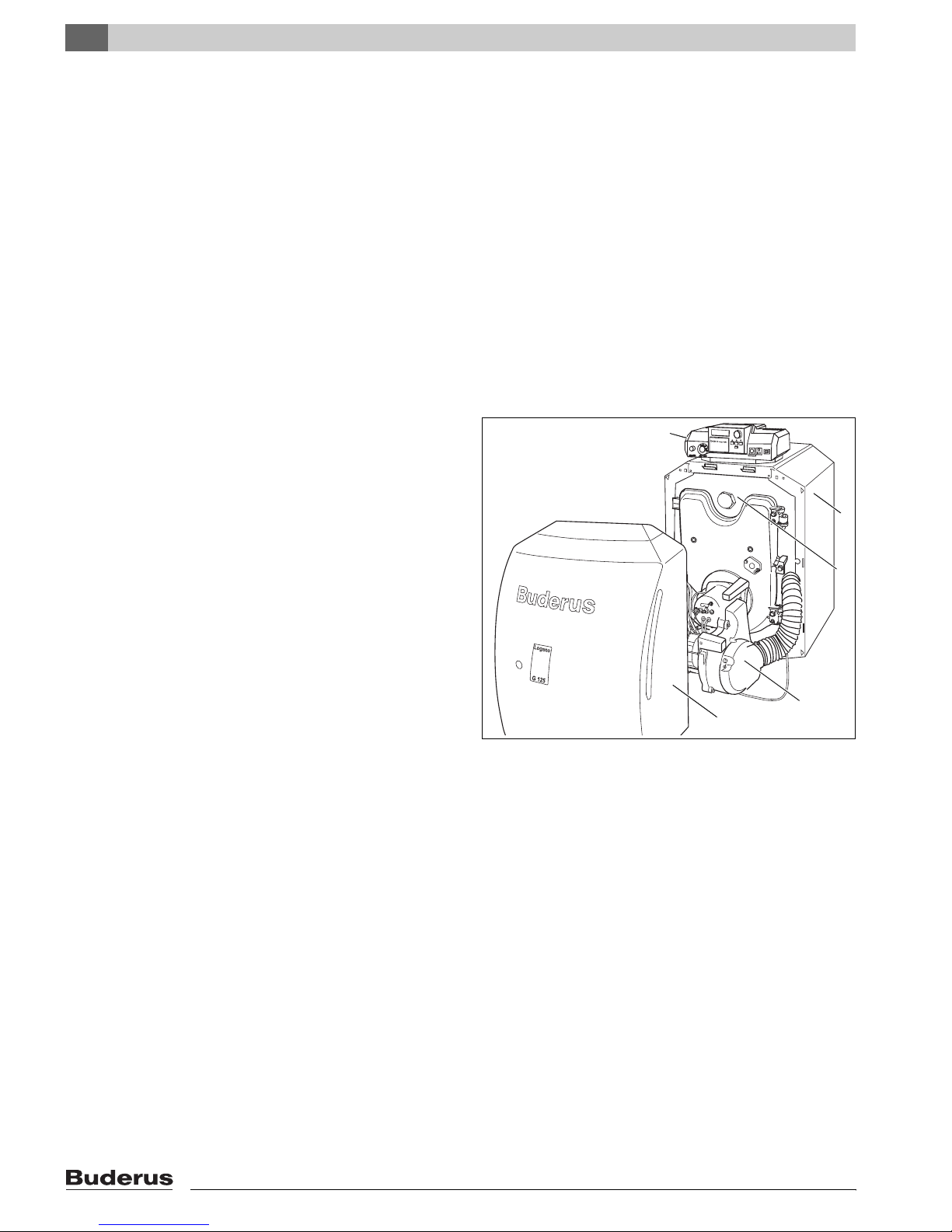

2.2 Product Description

The G125 BE is a oil fired low temperature boiler with

boiler water temperature regulation.

The boiler consists of:

– Optional Logamatic control

– Boiler jacket

– Boiler block with insulation

– Burner

The optional Logamatic control manages most control

functions in a heating system.

As an alternative, a Aquasmart control can be used for

boiler control.

The boiler jacket serves to reduce energy loss and as a

noise reducing agent.

The boiler block transfers the heat generated by the

burner to the boiler water. The insulation reduces the

stand-by losses.

1

Fig. 1 Boiler G125 BE US/CA

1 Control panel

2 Boiler jacket

3 Boiler block with insulation

4 Burner door cover

5 Burner

2

3

5

4

7 747 010 678-01.1RS

6

Logano G125 BE - Specification subject to change without notice.

Page 7

3 Technical Information

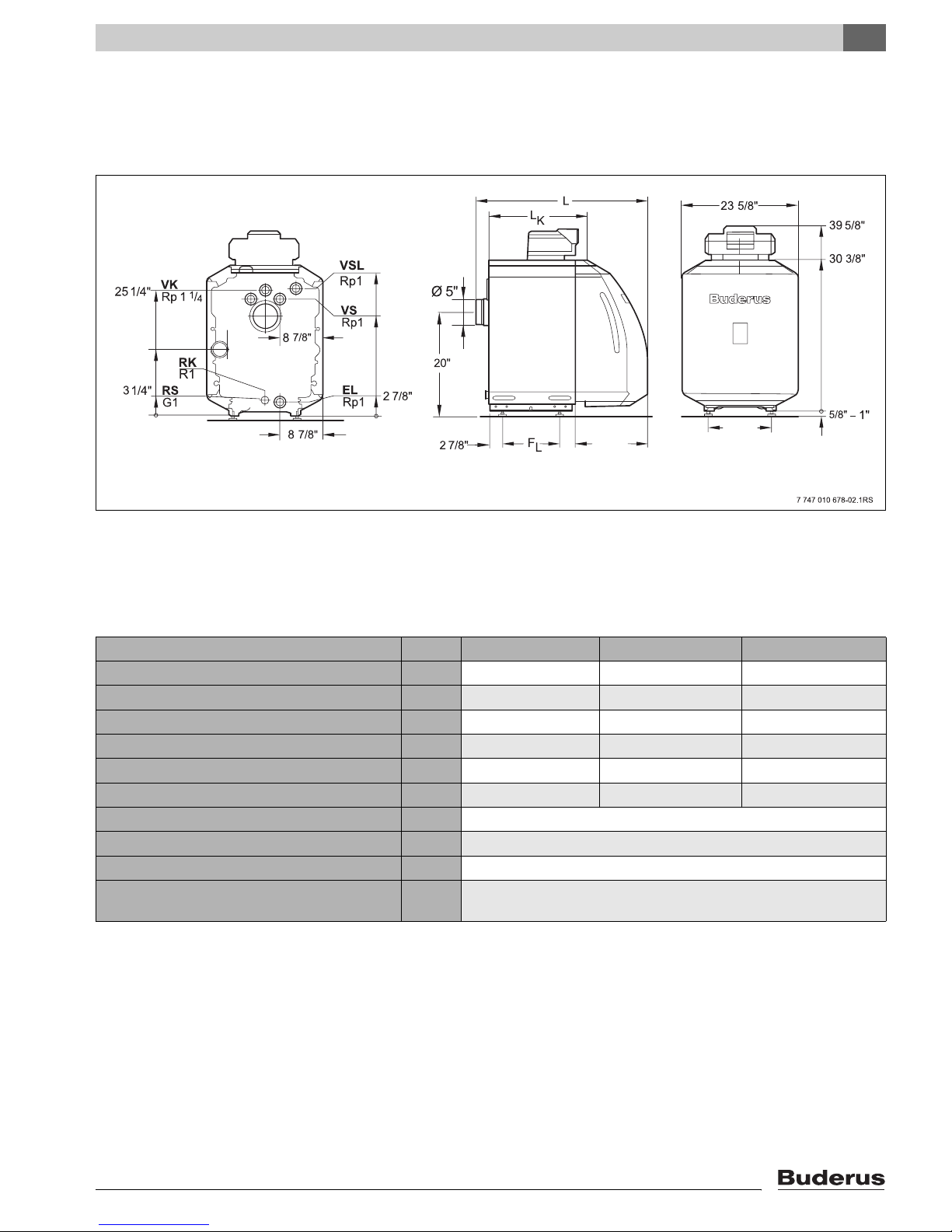

3.1 Technical Data less Burner

25 1/2"

23 1/2"

14 1/2"

Technical Information

12 1/4"

3

Fig. 2 Dimensions and connections (measurements in inches)

Connections (For Measurements see following tables):

VK = Boiler supply VS = Connection (plugged)

RK = Boiler return RS = Connection (plugged)

EL = Boiler drain (Connection for drain valve) VSL = Connection (plugged)

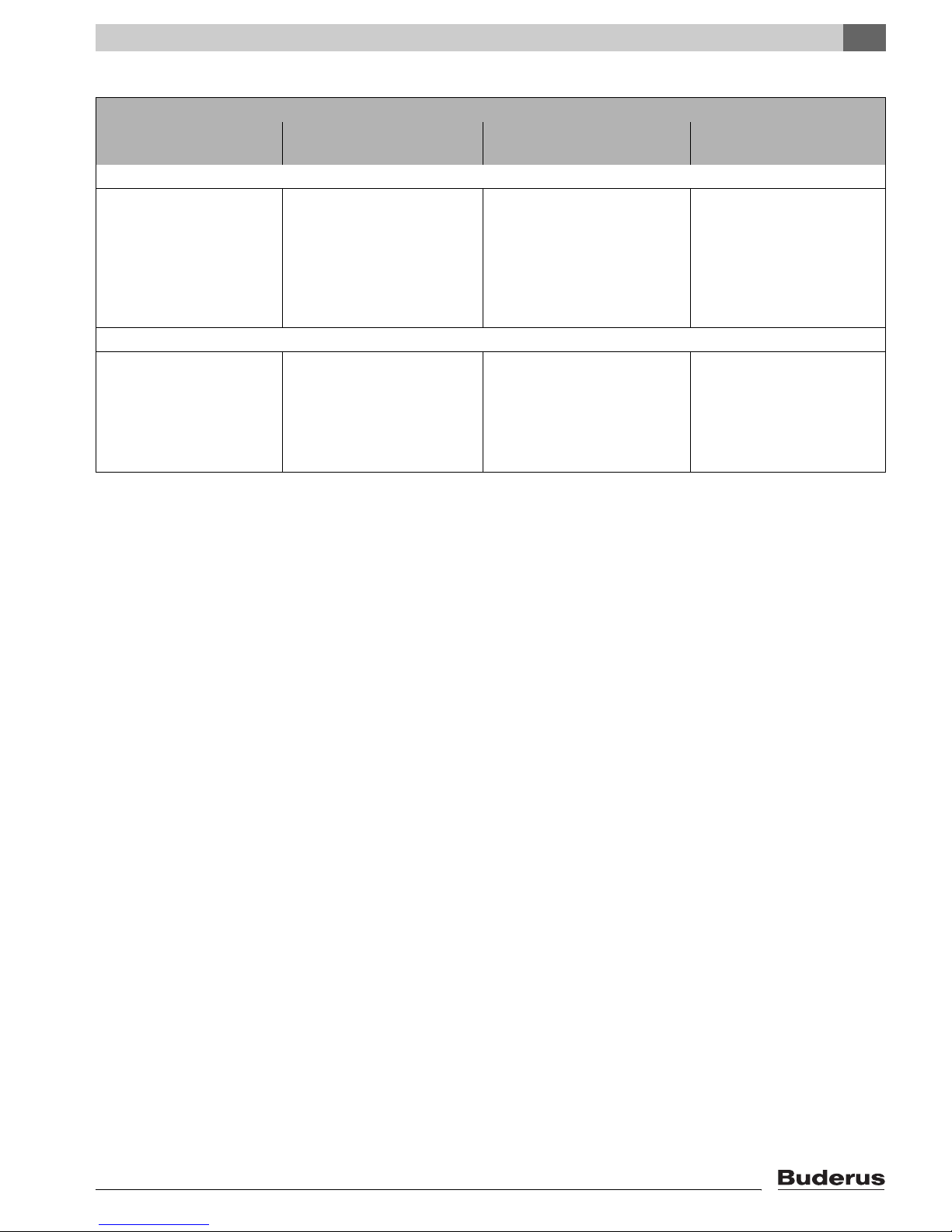

Boiler Model G125/21-BE G125/28-BE G125/34-BE

Number of boiler blocks 34 5

Heating Capacity (Gross Output) MBtu/hr 72 96 116

Net IBR MBtu/hr 63 83 101

Boiler water content Gal 8.7 10.8 12.9

Fireside volume cu.ft. 1.20 1.75 2.21

Oil firing rate GPH .60 .80 1.0

Fireside pressure drop psi 0.00058 – 0.00145

Permissible max. supply temperature

1

°F 230

Allowable operating pressure psi 58

Maximum Reset High Limit for temperature

s 40

sensor and overheat thermostat (STB)

Table 1 Technical Data for G125 BE less burner

1

High limit (overheat thermostat STB)

Permissible maximum supply temperature = High limit (STB) – 32 °F

e.g.: High limit (STB) = 212 °F, maximum permissible supply temperature = 212 – 32 = 180 °F

Select your high limit (STB setting) according to your local codes and requirements.

Logano G125 BE - Specifications subject to change without notice.

7

Page 8

3

Technical Information

Boiler Model G125/21-BE G125/28-BE G125/34-BE

Total boiler length (L) 34 5/8” 39 3/8” 44”

Boiler block length (LK) 21 1/8” 25 3/4” 30 1/2”

Combustion chanber length 16” 20 1/2” 25 1/4”

Firebox diameter 10 5/8”

Burner door thickness 3 1/2”

Distance between boiler feet (FL) 11 3/8” 16 1/8” 20 7/8”

Dry weight

Table 2 Dimensions, Weight and other Data for G125 BE less burner

1

Weight incl. packaging material approx 6 – 8% more.

1

386lbs 459lbs 513lbs

3.2 Operating Conditions

Maintain the operating requirements listed on the following page for long and trouble free operation of the boiler.

Proper and timely maintenance procedures must be followed.

SYSTEM DAMAGE

CAUTION!

If these operating requirements are not

followed, it can lead to premature failure

can result and cause permanent damage

to the boiler.

z Follow the instructions on the rating la-

bel and those in the manual.

8

Logano G125 BE - Specifications subject to change without notice.

Page 9

Technical Information

3.2.1 General Operating Requirements

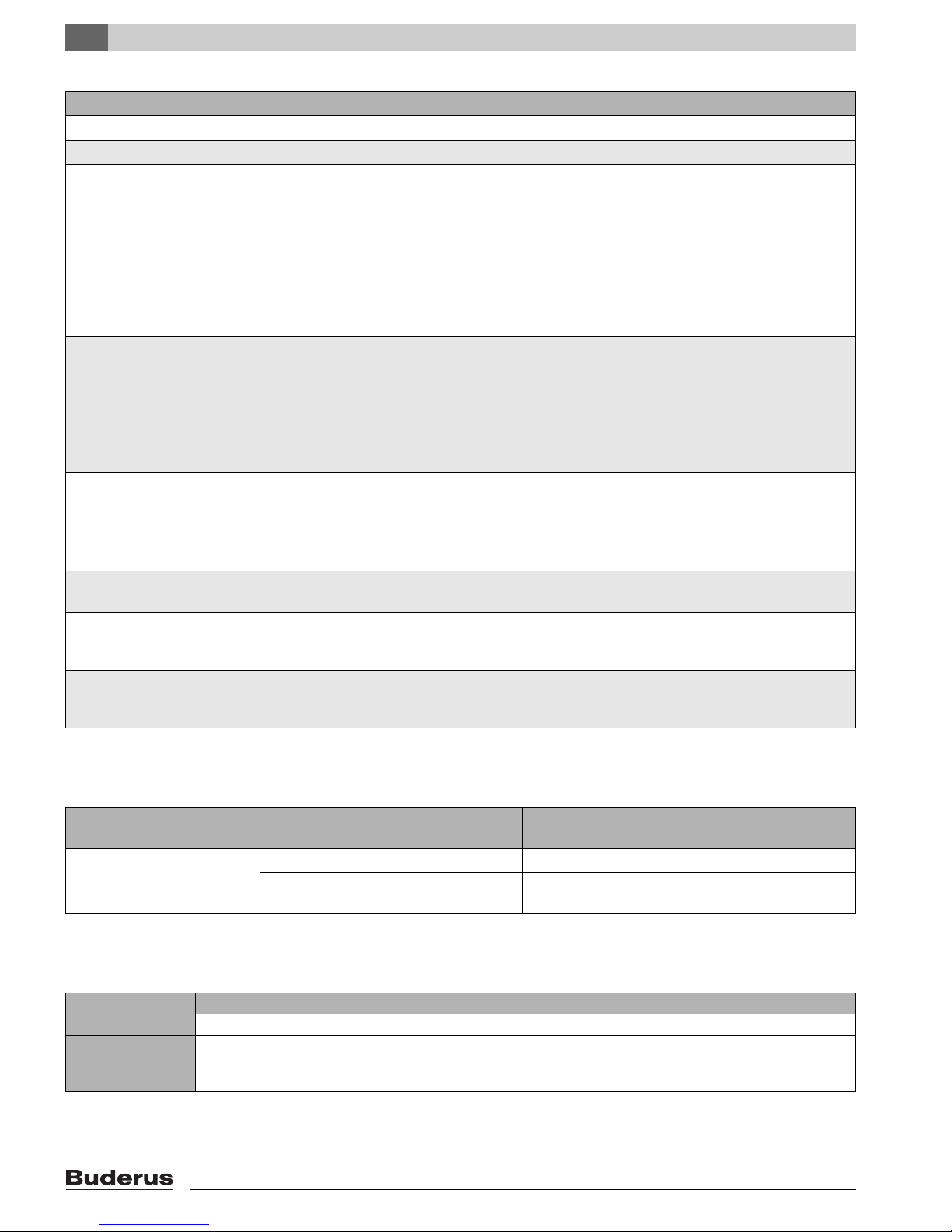

Operating Conditions

Minimum Boiler tempera-

ture

Systems controlled by R2107 controls for outdoor reset operation

No requirements

Operating conditions are met

with R2107 control

150 °F

2

3

Table 3 General Operating Requirements

1

A heating circuit equipped with a motorized mixing valve improves the controllability of that sub-system and is specifically recommended when

requiring different water temperatures.

2

In case the control system has no influence over the flow in a heating circuit (for instance using the Pumplogic feature of the R2107), then one

should achieve a minimum supply temperature of 122 °F within 10 minutes after burner start-up by means of reducing (or interrupting) the water

flow through the boiler.

3

Minimum setting on the adjustable high limit or Aquasmart: During burner operation one should achieve the minimum boiler temperature within

10 minutes after burner start-up by means of flow reduction and one should maintain this temperature.

Boiler Shutdown Boiler Shutdown/

Mixed temperature

Automatic with Logamatic

R2107

No requirement, yet beneficial

with low temperature boiler with

130/113 °F system design

Necessary with:

– Radiant floor applications

– Systems with large water con-

tent > 115 gal/100,000 Btu/hr

Systems controlled by Aquasmart or R2109

Possible, provided the boiler op-

erates after total shut-down for

at least 3 hours.

1

Minimum return temperature

No requirement

Necessary Necessary for:

– Systems with large water

content > 115 gal/100,000

Btu/hr: 130 °F

– Firing with modulating burn-

ers: 130 °F

3

Logano G125 BE - Specifications subject to change without notice.

9

Page 10

3

Technical Information

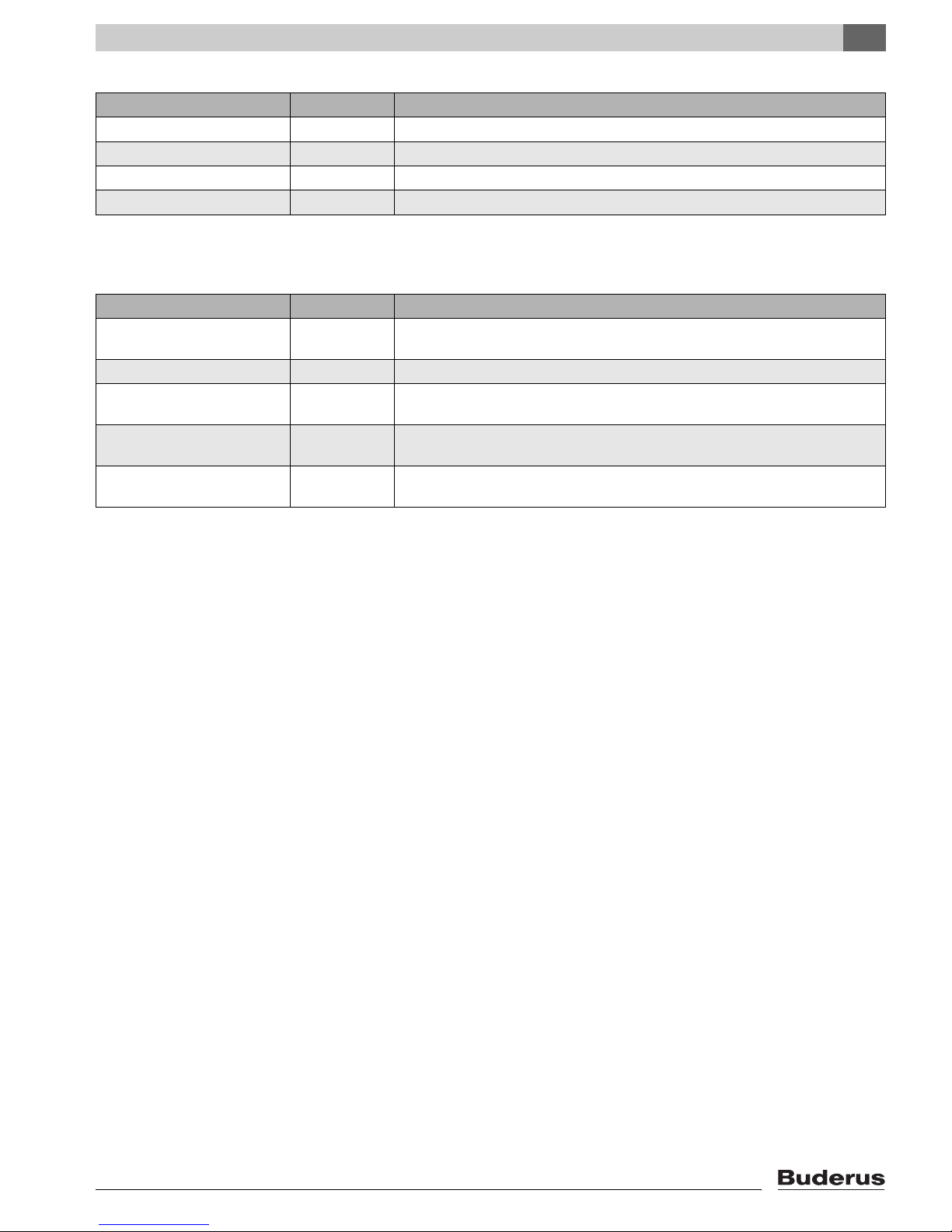

3.2.2 Requirements for Boiler Room and Surroundings

Operating Conditions Comments – Detailed Information

Boiler room temperature +40 to +104 °F

Relative humidity max. 90 % No condensate or dampness in boiler room.

Dust – No excess amounts of dust should be present in the boiler room, e.g.:

– No sheet rock or construction dust.

The available combustion air can not contain dust or other particles/ use of an air

filter might be needed, e.g.:

– Combustion air from nearby roads with high dust levels.

– Combustion air from nearby production facilities such as chemical plants &

shops.

– Airborne particulates.

Halogenated Hydrocarbons

contamination

Fans, removing air from boiler

room

Animals – The boiler room and especially the air inlet openings for combustion air must be

Fire Protection – Maintain proper clearances to combustible materials as required per local code.

Flood Zone Conditions – Separate the fuel supply and electrical power supply from the boiler during flood

– Combustion air must be free of halogenated hydrocarbons components.

– Eliminate any chemical compound such as paints, lacquers, thinners, clean-

ing agents. If not possible, provide fresh outside air for combustion.

Please observe the following:

– Product information of Buderus catalog.

– Also observe guidelines in K3 chapter of Buderus catalog.

– Avoid forced air removal by mechanical means during boiler operation such as:

– Bathroom exhaust fans

– Dryer

– Air-conditioning equipment

kept free from animals entering by means of grills.

Maintain a minimum distance of 16”. Do not store flammable materials near the

boiler.

conditions. Replace the boiler components such as insulation, electrical and control components afterwards.

Table 4 Boiler room and surroundings

3.2.3 Combustion Air Requirements

Operating Conditions Boiler capacity (combine total boiler ca-

pacity for multiple units)

Two air inlet openings from outside: one top, one near bottom

Table 5 Observe local codes and regulations for combustion air requirements

< 170,000 Btu/hr At least 43 square inch

> 170,000 Btu/hr At least 43 square inch plus 2.5 square inch per 10,000

Btu/hr, if the output is higher than 170,000 Btu/hr.

3.2.4 Fuel Conditions

Country All Countries

Fuel #2 Fuel Oil ASTM D396-05 Type 2

Comments No other fuel may be used with this burner.

Burner requires annual service and cleaning. Verify each time that the complete heating system is in working

order. Defects must be remedied immediately.

Table 6 Permitted fuel types

Cross area required

10

Logano G125 BE - Specifications subject to change without notice.

Page 11

Technical Information

3

3.2.5 Requirements for Power Supply

Operating Conditions Comments – Detailed Information

Main power supply 120 V Provide proper grounding for equipment and personal protection.

High amp protection 10 A

Frequency 60 Hz

Protection – Group all equipment per local code

Table 7 Power supply

3.2.6 Conditions Pertaining to Piping and Water Quality

Operating Conditions Comments – Detailed Information

Operating pressure (over pressure)

Allowable test pressure 45 – 75 psi

Adjustable temperature limit TR122 – 194 °F

Manual reset high limit 210 °F In combination with Beckett AquaSmart the limit value (210 °F) may not be excee-

Water quality – Initial fill water and make-up water should be potable water type quality. A pH

12 – 58 psi Maximum pressure is 30 psi based on supplied relief valve

ded.

range of 8.2 to 9.5 is desired.

Table 8 Piping and water quality

Logano G125 BE - Specifications subject to change without notice.

11

Page 12

4

Packaging and Components

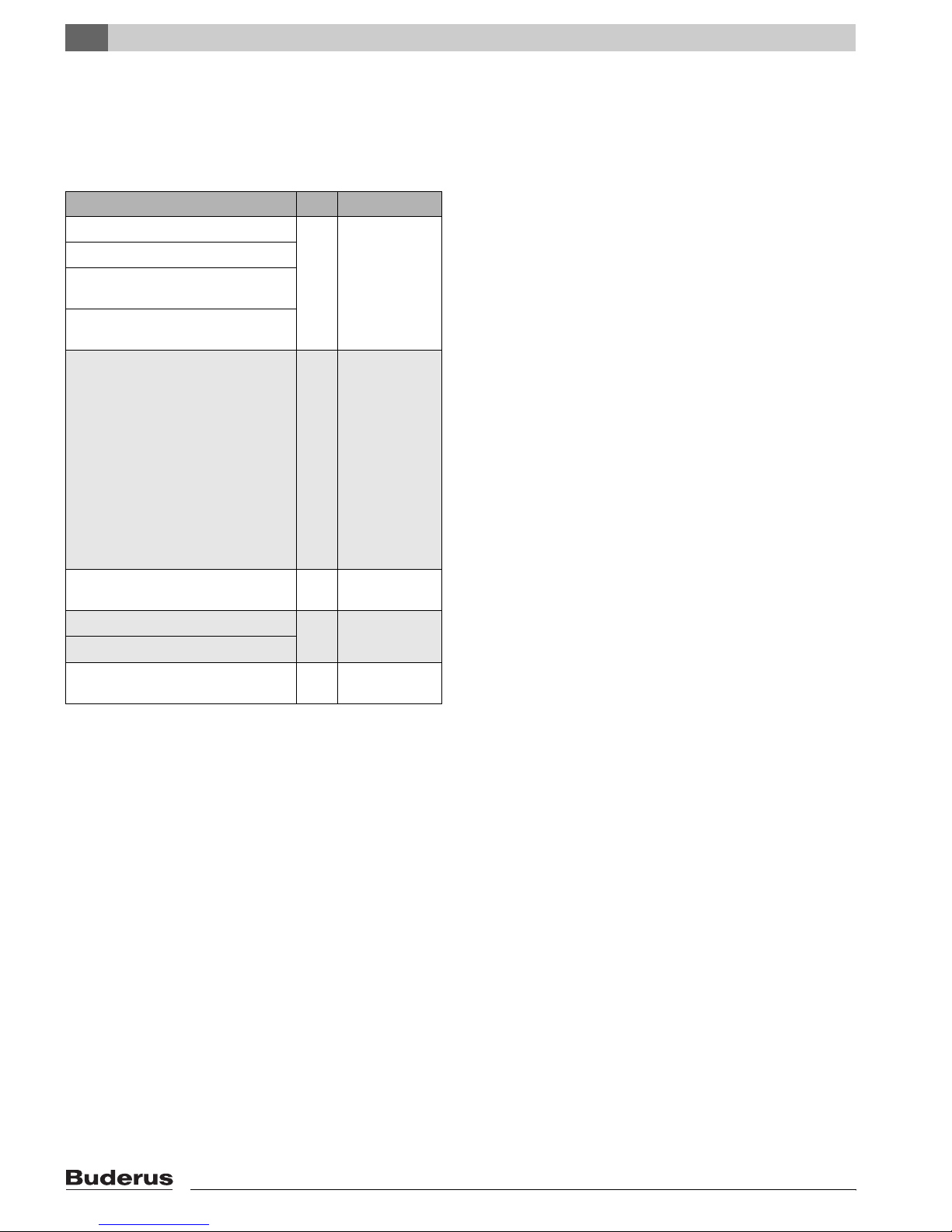

4 Packaging and Components

z Check the packaging for concealed damage.

z Check the packaging for completeness. Contact your

wholesaler in case of missing parts.

Component Qty Packaging

Boiler block 1 Pallet

Boiler jacket, installed on boiler

Burner door and burner door cover

installed on boiler block

Buderus oil burner mounted on customized burner door

B-Kit-Components:

Supply manifold (1¼" NPT)

30 psi relief valve

(¾") boiler drain

Pressure/temperature gauge

(1¼" NPT × R1¼) conversion nipple

(parallel to NPT)

90°-elbow (1¼" NPT)

90°-elbow (¾" NPT)

Burner mounting studs and washers

Screw in feet

14Plastic pack-

aging with boiler

Control panel, alternative Aquasmart control (ordered separately)

Tigerloop oil filter 1 included with

Taco 007 circulator pump w/flanges

Technical documents 1 Plastic pack-

Table 9 Packaging and components

Cardboard

box

boiler package

aging w/boiler

12

Logano G125 BE - Specifications subject to change without notice.

Page 13

5 Moving the Boiler

This chapter describes how to move the boiler.

SYSTEM DAMAGE

due to bumps.

CAUTION!

z Protect the boiler from bumps and

rough treatment.

NOTICE

z Protect the boiler from connections

from damage and dirt, when the boiler

is not installed immediately.

NOTICE

Please dispose of the packaging in an environmentally friendly fashion.

Moving the Boiler

5

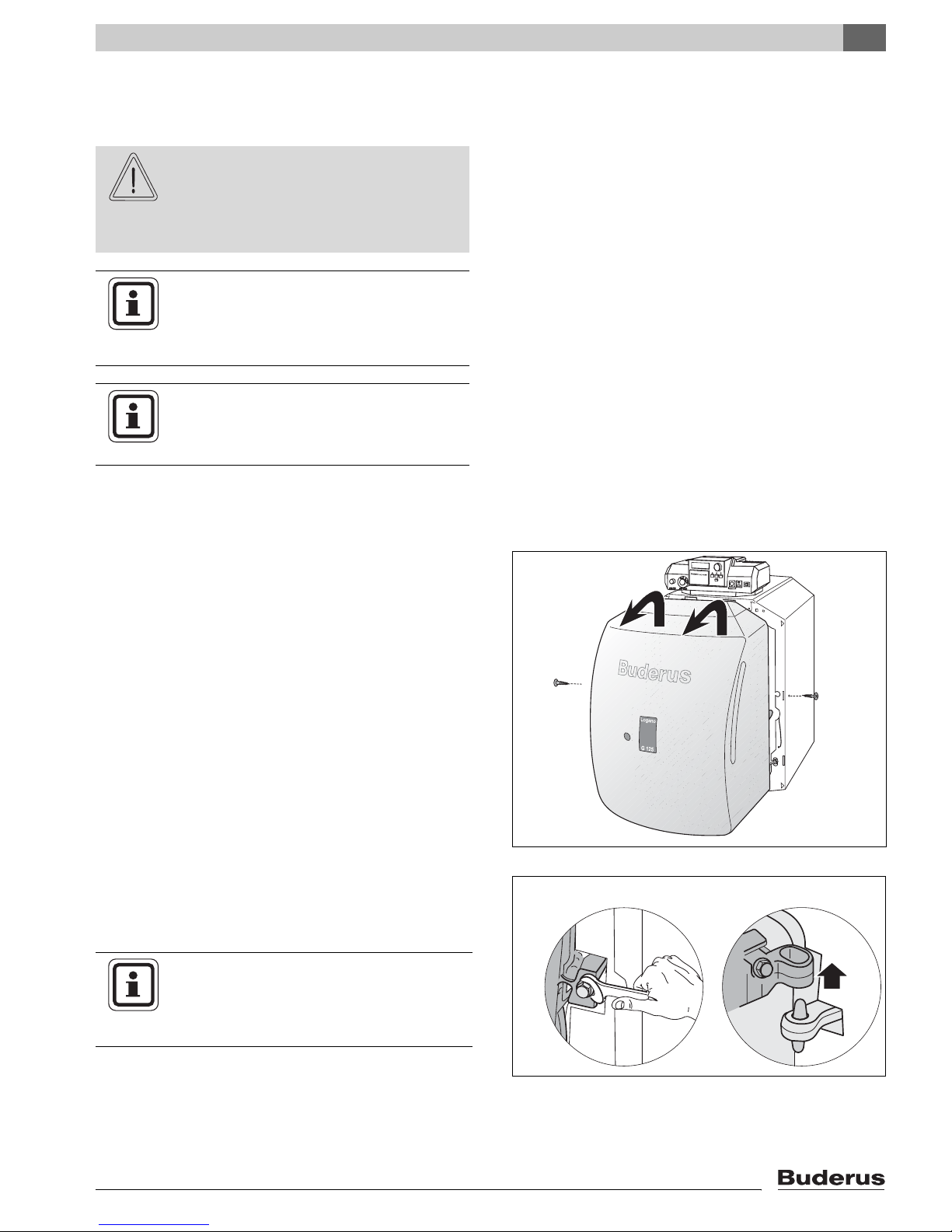

5.1 Reducing Boiler Weight for Transportation

One can reduce boiler weight by removing the front cover and burner door itself.

z Remove the screws holding the front cover in place.

z Lift up the front cover slightly and remove.

z Disconnect burner cable from burner control before

removing the burner door.

z Open burner door by removing the two burner door

bolts.

z Lift burner door from hinges.

NOTICE

Fig. 3 Removing the front cover

z Protect the burner door and the burner

tube from damage and dirt when the

burner door is removed from the boiler.

Logano G125 BE - Specifications subject to change without notice.

Fig. 4 Removal of burner door

13

Page 14

5

Moving the Boiler

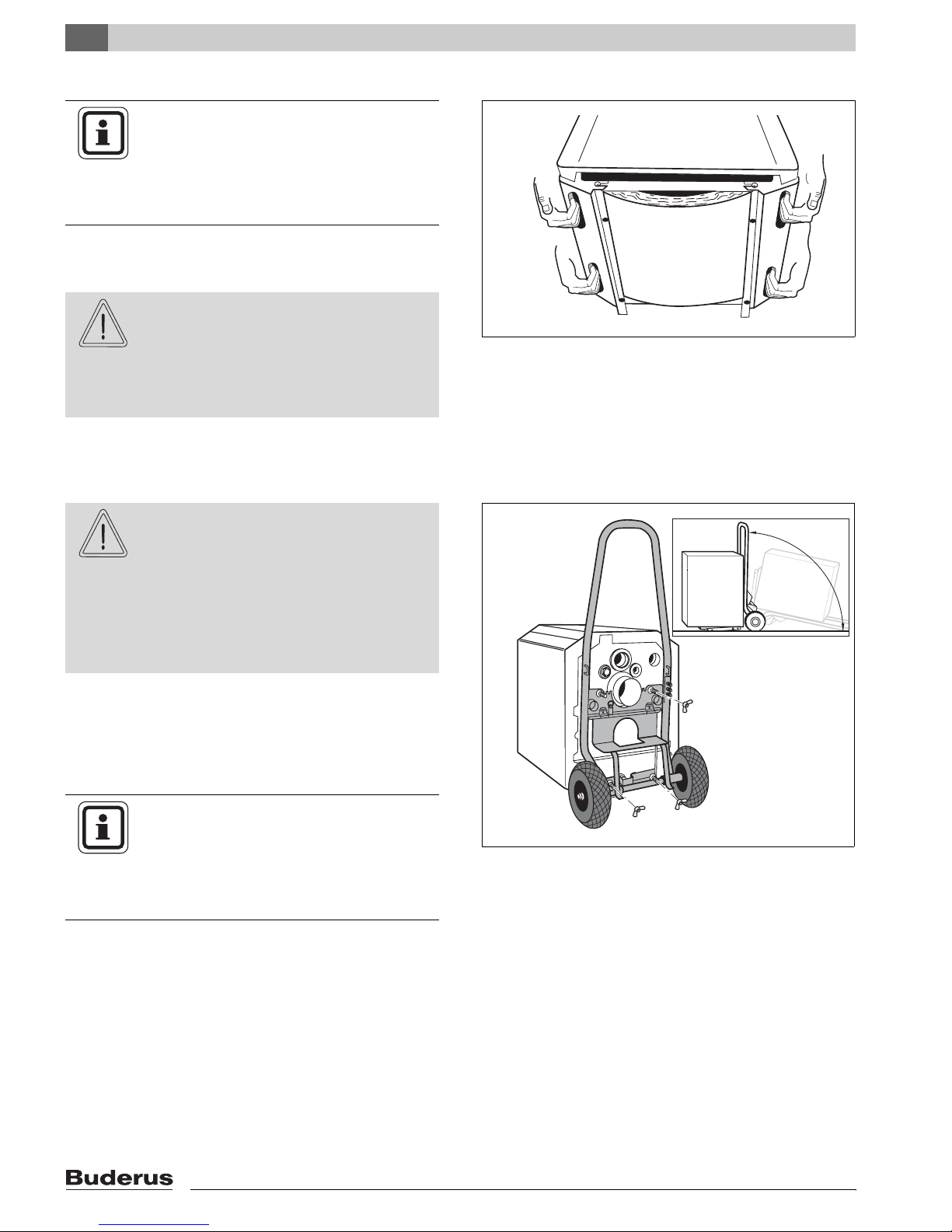

5.2 Lifting and Carrying the Boiler

NOTICE

The boiler is secured to the pallet with two

bolts.

z Remove the bolts from pallet before

lifting the boiler.

The boiler can be picked up at the hand grips located

along the lower jacket panels.

BODILY DANGER

due to carrying of heavy loads.

CAUTION!

z Lift and carry the boiler with at least

two people at the designated hand

grip positions.

5.3 Moving the Boiler with the Boiler Cart

BODILY DANGER

if the product is not properly secured to

CAUTION!

z Lift up the boiler from the rear side by using moving

equipment (e.g. Buderus card or other dolly).

z Secure the boiler to the cart.

z Move the boiler to the job location.

the cart.

z Use proper moving equipment such as

the Buderus cart or other dolly.

z Secure the boiler to the cart and move

the boiler to the job location.

Fig. 5 Lifting and carrying the boiler

NOTICE

By tipping the cart you can install the boiler feet (Î Chapter 6.3, page 17).

You can order a Buderus cart from your

local wholesaler.

14

Fig. 6 Moving the boiler with a Buderus cart

Logano G125 BE - Specifications subject to change without notice.

Page 15

6 Placing the Boiler

This chapter discusses how to place the boiler in the

boiler room.

SYSTEM DAMAGE

due to freezing temperatures

CAUTION!

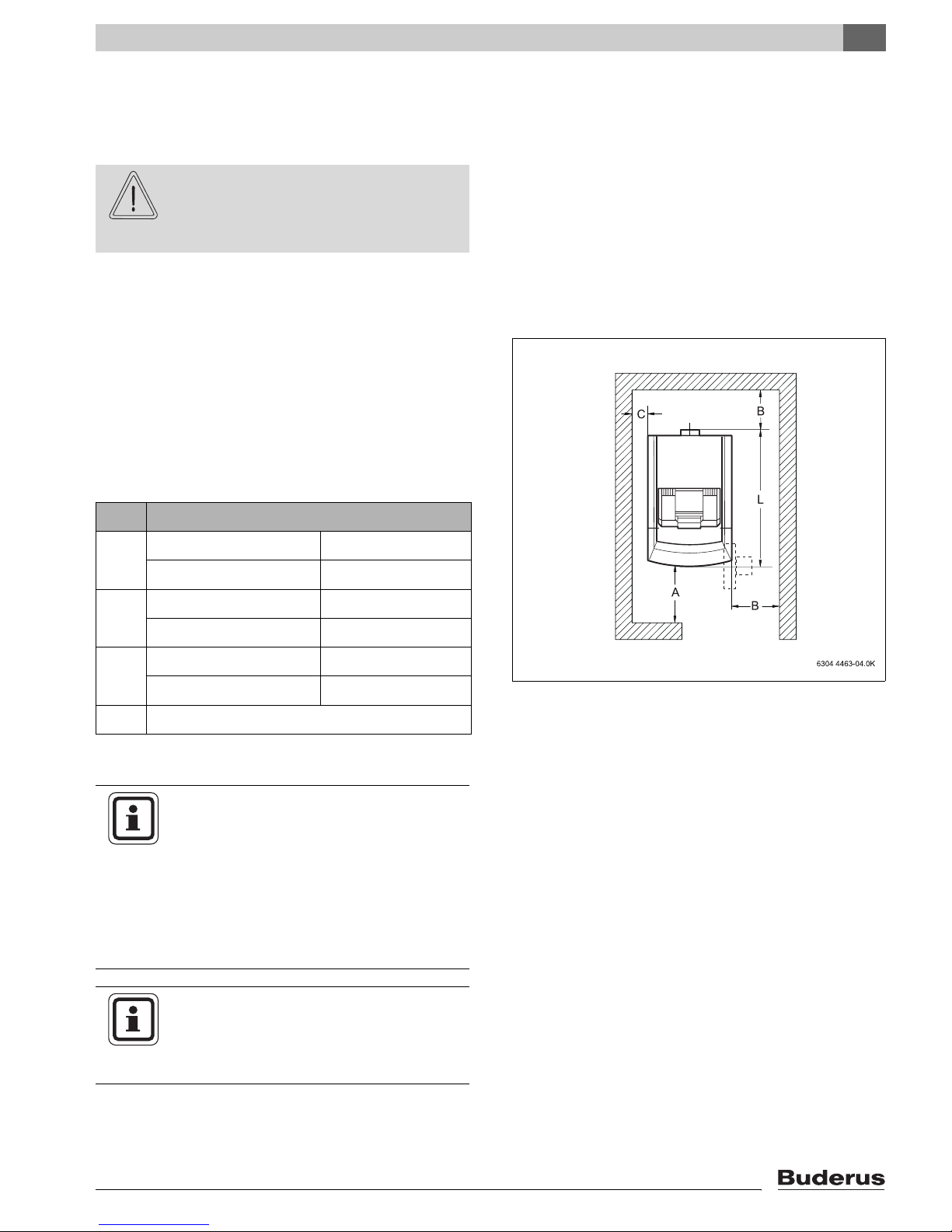

6.1 Clearances

Position the boiler while observing the clearances in

(Î Fig. 7). Access to the boiler is reduced when reducing these clearances.

The boiler foundation must be level and sufficiently

strong.

The burner door is factory installed right swinging. Youcan reverse the door swing in the field.

z Place the boiler in a frost free room.

Placing the Boiler

6

Distance

A Recommended 51 1/8"

minimum 39 3/8"

B Recommended 27 1/2"

minimum 15 3/4"

C Recommended 15 3/4"

minimum 3 7/8"

L see Chapter 3 „Technical Information“

Table 10 Recommended and minimum clearances

(Measurement in Inches)

NOTICE

Smaller clearances must abide with state

and local code. The boiler is approved for

6" side clearances. A minimum distance

of 18" to combustible materials must be

maintained per NFPA 31.

Floor material must comply with

NFPA 31.

Fig. 7 Clearance dimensions for G125 boilers

NOTICE

Observe required distances to other components such as water piping, venting

and other components.

Logano G125 BE - Specifications subject to change without notice.

15

Page 16

6

Placing the Boiler

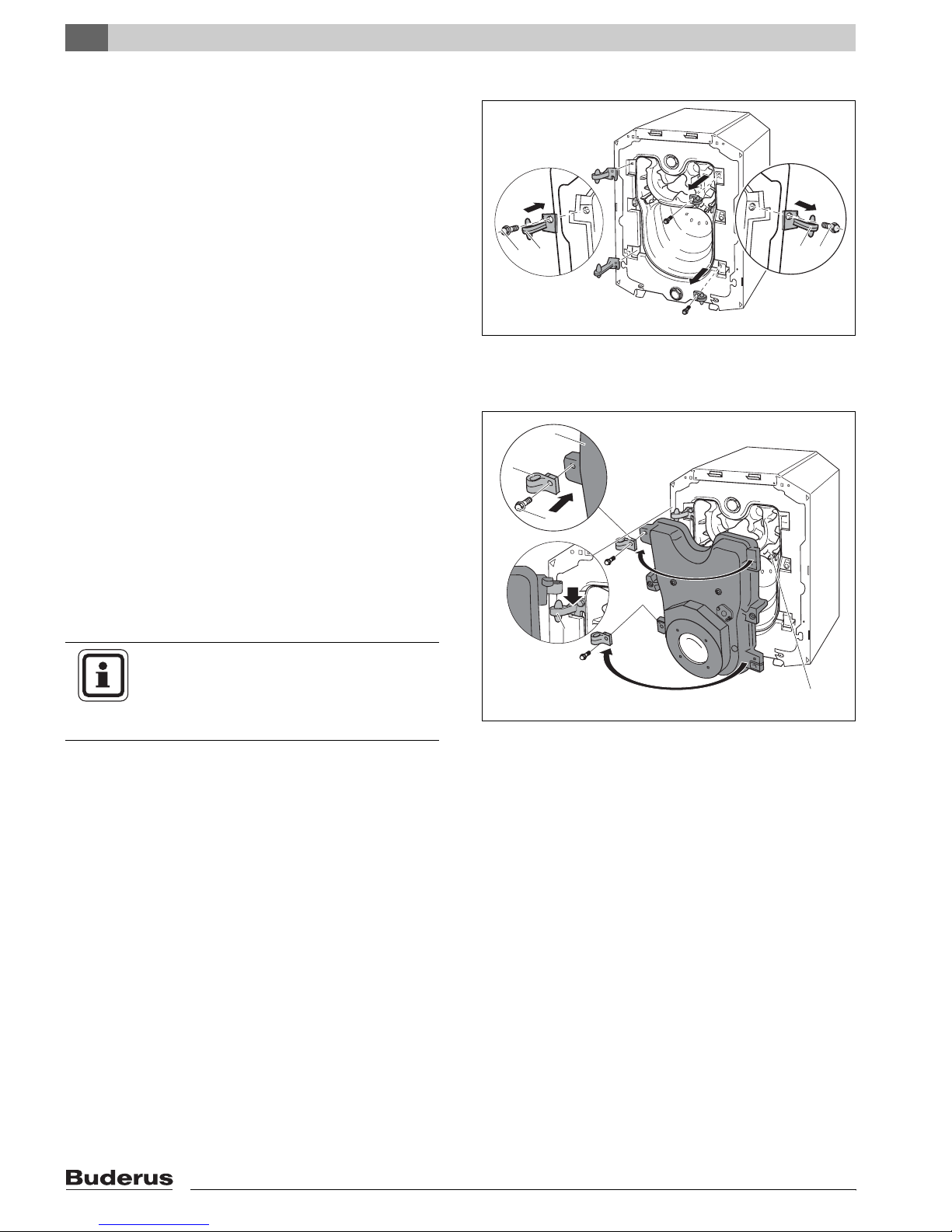

6.2 Reversing the Burner Door Swing

The burner door hinges are factory installed on the right

handside the burner door swings to the right. You can

adjust the hinges so that the burner door swings to the

left in the field.

Note: the front panel must first be removed.

(Î Chapter 5.1, page 13).

z Remove burner door (Î Chapter 5.1, page 13).

z Remove hex head bolts of burner door hinges and re-

move hinges.

z Install the hinges on the left side of the boiler with the

hex head bolts.

z Remove the eyelets from the burner door by remov-

ing the hex head bolts.

z Locate and secure with hex head bolts these eyelets

to the left side of the burner door.

z Hang the burner door on the hinges.

z Check to make sure that the flue baffle plates are

horizontally in the boiler (Î Chapter 8.3, page 40).

z Secure the burner door with the burner door bolts.

Make sure to tighten the burner door bolts evenly

with about 7.5 ft-lbs torque.

NOTICE

When reversing the swing of the burner

door, make sure to remove the burner cable and oil line from the burner first.

2

1

Fig. 8 Reversing burner door (boiler block)

1 Hex head bolts for hinges

2 Door hinges

3

2

1

4

Fig. 9 Reversing burner door (on burner door)

1 Hex head bolts for door eyelets

2 Door eyelet

3 Burner door

4 Door hinges

5 Flue baffles

1

2

5

16

Logano G125 BE - Specifications subject to change without notice.

Page 17

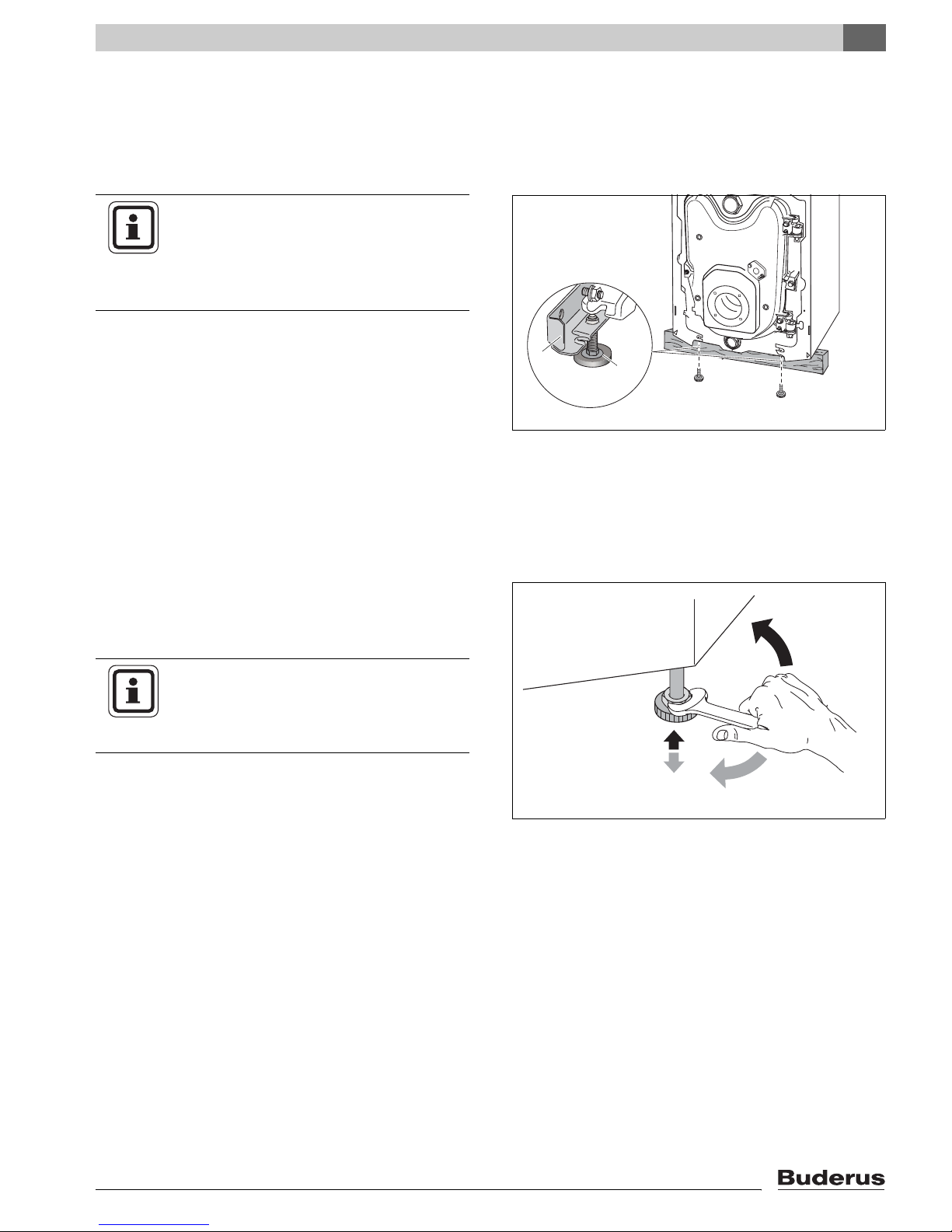

6.3 Installation of boiler Feet (Components of B-Kit)

You can level the boiler using the screw-in boiler feet, so

that air can not collect in the boiler.

Requirement: remove front panel from boiler

(Î Chapter 5.1, page 13).

NOTICE

When installing a G125 BE boiler on top

of a horizontal Buderus DHW indirect

tank, do not use the boiler feet on the boiler, but rather use the feet to level the tank.

z Tip the boiler slightly using the boiler cart

(Î Chapter 5.3, page 14) or put a piece of wood under one side.

z Screw in the boiler feet 1/4" – 3/8".

1

Placing the Boiler

6

2

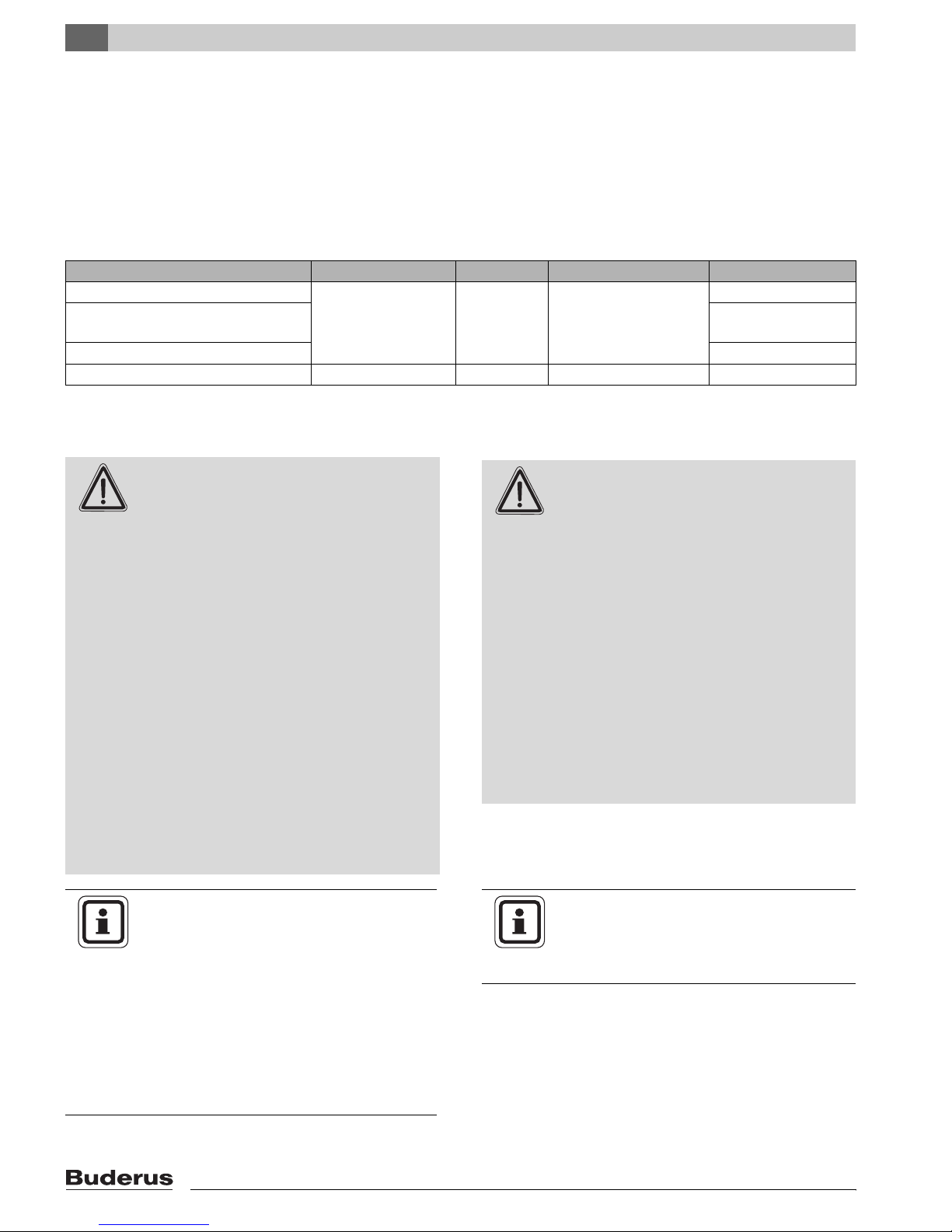

z Level the boiler.

6.4 Placement of the Boiler

z Bring the boiler to its final location.

z Put a level on the boiler and adjust boiler feet to level

the boiler.

NOTICE

z Protect the boiler connections from

dust and debris, if the boiler will not be

connected right away.

Fig. 10 Installation of boiler feet

1 Boiler rail

2 Boiler feet

Fig. 11 Leveling the boiler

Logano G125 BE - Specifications subject to change without notice.

17

Page 18

7

Boiler Installation

7 Boiler Installation

7.1 Installation of Venting Systems

This chapter describes the installation of the venting

system and the combustion air supply system for the

G125 BE boiler.

Following venting options are available:

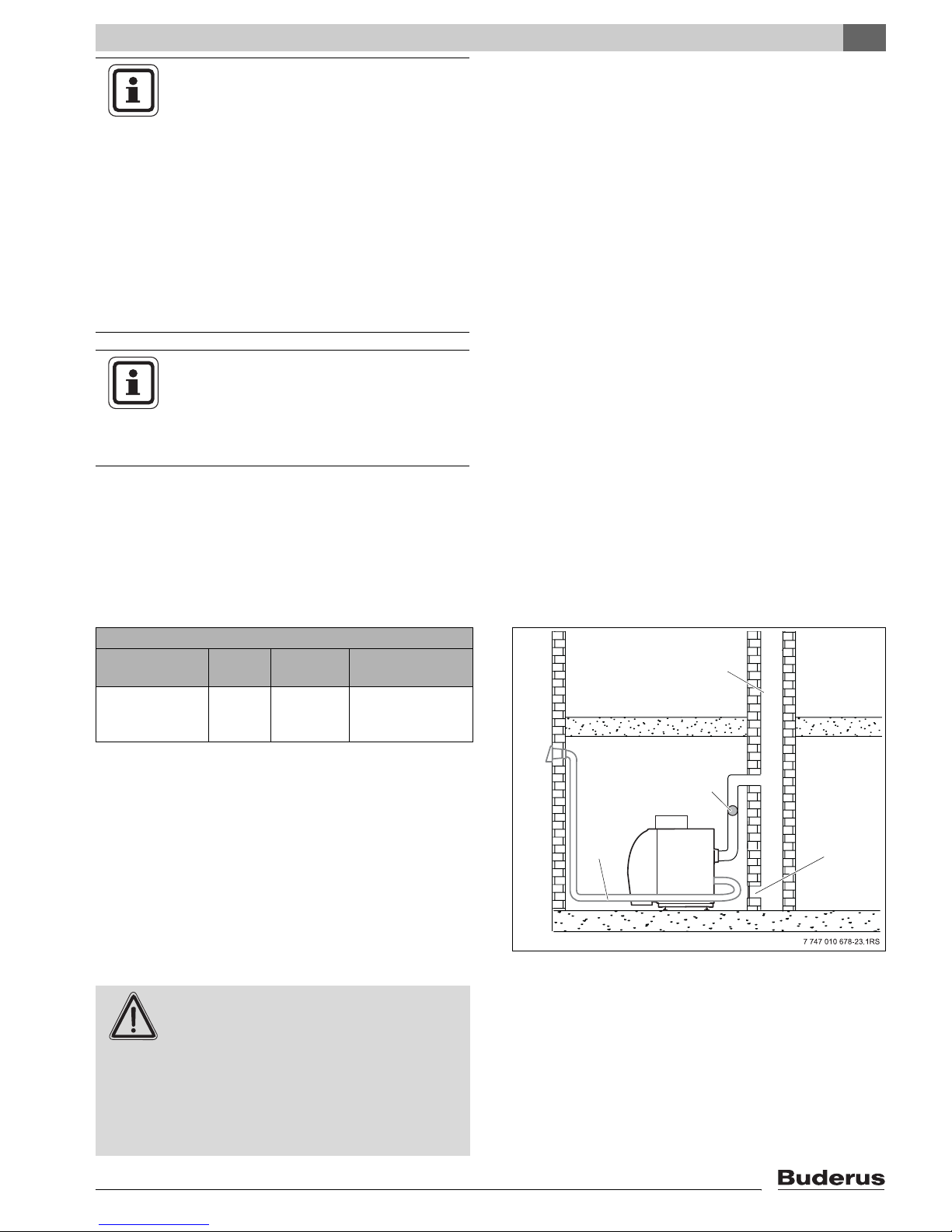

Venting system Comment Draft Combustion air Chapter

Masonry chimney (no liner) Barometric

Masonry chimney

w/ 5" liner

Vertical vent 5" 7.1.1.3, Page 21

Side wall Sealed vent Positive Outside air only 7.1.2, Page 22

Table. 11Venting options

damper

required

Negative Outside air or room air 7.1.1.1, Page 19

7.1.1.2, Page 20

WARNING!

DANGER TO LIFE

from toxic flue gases.

z Never connect more than one appli-

ance to a venting system - regardless of

vertical or horizontal venting.

z Common venting of appliances can

cause property damage and put life at

risk.

z Chimney liners must be a single contin-

uous piece inside an existing chimney

and can not have any connections inside the chimney chase.

z The venting system shall not be routed

into, through, or within any other vent,

such as an existing masonry or factorybuilt chimney that is used to vent any

other appliance.

z Always follow vent manufacturer’s in-

structions.

NOTICE

WARNING!

FIRE DANGER

from insufficient clearance between vent

system components and combustible surfaces.

z Maintain 18" clearance to combustible

surfaces when using galvanized or

stainless pipe in vertical or horizontal

venting.

z Maintain 1" clearance to combustible

surfaces when using flexible oil vent for

horizontal venting.

z Both the Aerocowl (AT-4) exhaust ter-

mination and Fields (FT-4) concentric

exhaust/intake terminations are approved with zero clearance to combustible surfaces.

NOTICE

The boiler installation must be performed

by a qualified installer in accordance with

regulations put forth in NFPA-31 Installation of Oil-Burning Equipment. The installation must comply with all local and

national codes, regulations and authorities

having jurisdiction regarding the installation of oil fired boilers.

For Canada refer to the guidelines of

CSA/B139 Installation Codes.

18

z Avoid excessively long venting sys-

tems and keep the number of elbows to

a minimum.

Logano G125 BE - Specifications subject to change without notice.

Page 19

NOTICE

Due to tight construction of modern

homes, Buderus recommends drawing

combustion air from outdoors. The boiler is

factory prepared for connecting 4" rigid

pipe ducted directly to the increaser at the

rear of the boiler. For further directions

Î Chapter 7.2, page 28.

Except for direct venting, and provided

ample combustion air is available in the

boiler room, combustion air can also be

drawn from the room (Î Chapter 7.2,

page 28 for details).

NOTICE

For Canada the G125 BE is approved

without a Blocked Vent Switch.

Should local authorities require a Blocked

Vent Switch Î Chapter Fig. 63, page 68.

Boiler Installation

7

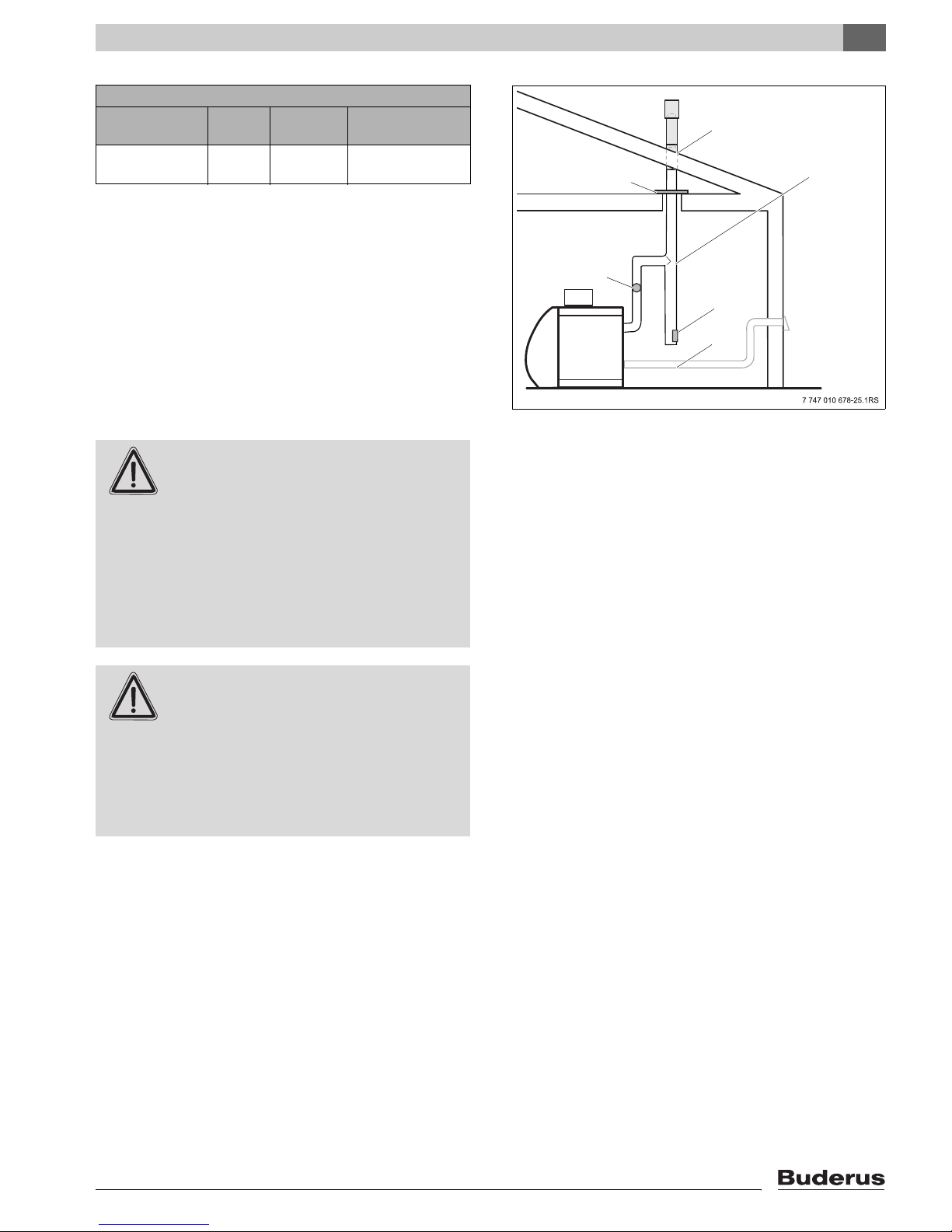

7.1.1 Vertical Venting Systems

The G125 BE boiler can be vented vertically using an

existing masonry chimney or a factory built All-Fuel or Lvent chimney.

7.1.1.1 Masonry Chimney

Venting system: Masonry Chimney

Comment Draft Combus-

tion air

Barometric

damper

required

Negative Outside air

or room air

Max. vent length

60 ft.

Refer to NFPA 31 for requirements on chimney venting.

Old, cold or over-sized chimneys require the use of an

approved 5" chimney liner (Î Page 20).

The maximum vent length of a masonry chimney is 60 ft.

A masonry chimney is operated under slight negative

pressure, and requires a barometric damper.

z Follow damper manufacturer’s instructions as to

placement.

z Adjust draft for negative 0.02 – 0.04" W.C.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Verify that all vent pipe connections

have been installed properly.

1

2

4

Fig. 12 Masonry chimney installation

1 Chimney

2 Barometric damper

3 Clean-out

4 Horizontal air connection for combustion air

(optional, see 7.2)

3

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

Logano G125 BE - Specifications subject to change without notice.

19

Page 20

7

Boiler Installation

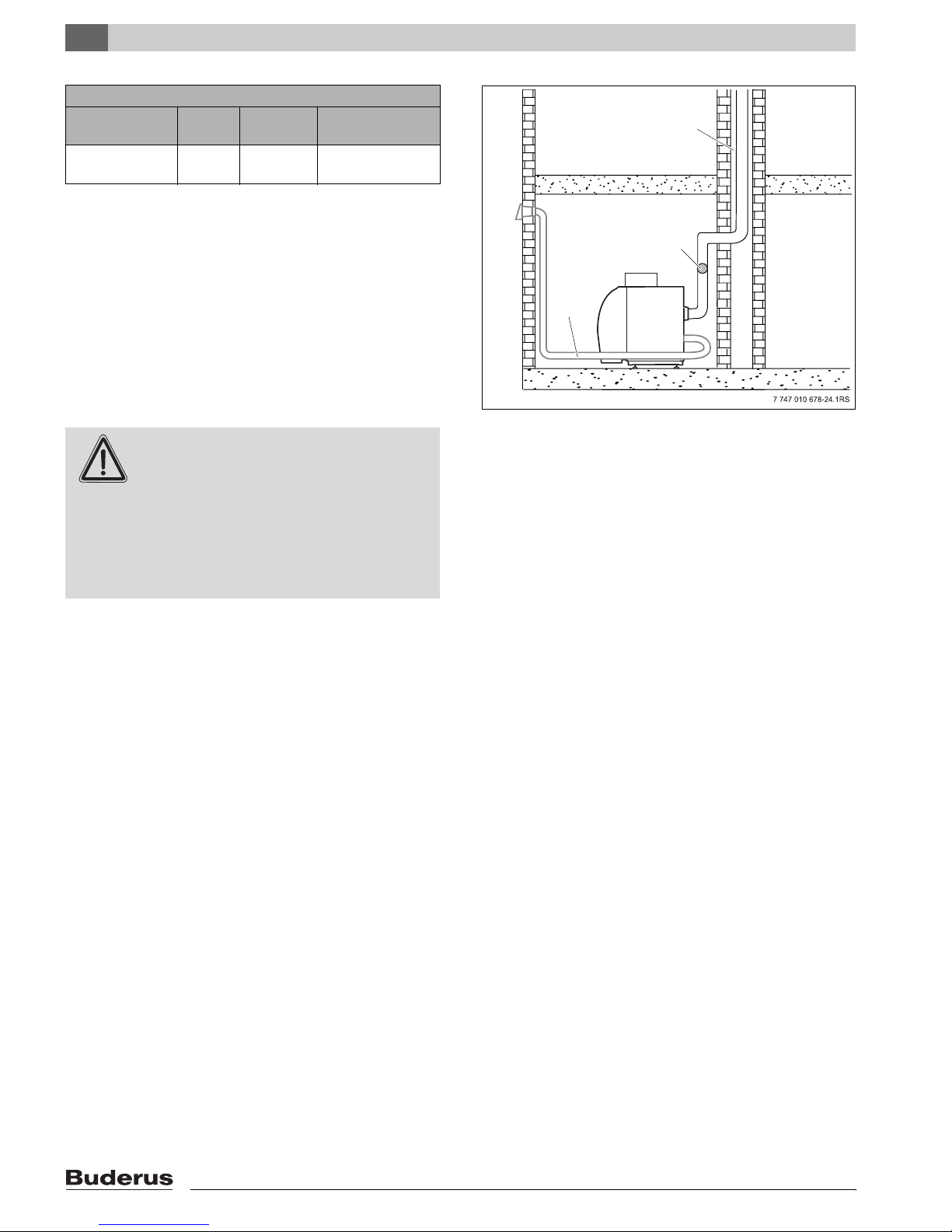

7.1.1.2 Chimney with 5" Liner

Venting system: Chimney with 5" Liner

Comment Draft Combus-

tion air

Barometric

damper required

Negative Outside air

or room air

Max. Vent length

60 ft.

Install liner according to manufacturer’s instructions.

Follow all applicable local and national codes and regulations.

The maximum vent length of 5" liner in a masonry chimney is 60 ft.

The 5" liner in a chimney is operated under slight negative pressure, which requires a barometric damper.

z Follow damper manufacturer’s instructions as to

placement.

1

2

3

z Adjust draft for negative 0.02 – 0.04" W.C.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Verify that all vent pipe connections

have been installed properly.

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

Fig. 13 5" Chimney liner installation

1 5" Chimney liner

2 Barometric damper

3 Horizontal air connection for combustion air

(optional, see 7.2)

20

Logano G125 BE - Specifications subject to change without notice.

Page 21

7.1.1.3 Vertical Vent

Venting system: 5" Vertical Vent

Comment Draft Combus-

tion air

Barometric

damper required

Negative Outside air

or room air

Max. Vent length

60 ft.

Extend the vertical vent pipe sufficiently far above the

roof per NFPA 31. Follow all applicable local and national codes and regulations.

Boiler Installation

7

1

2

3

The maximum length of the vertical 5" venting system is

60 ft.

The 5" vertical venting system operates under a slight

negative pressure, which requires a barometric damper.

z Follow damper manufacturer’s instructions as to

placement.

z Adjust draft for negative 0.02 – 0.04" W.C.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Vertical vent pipe must have an ap-

proved fire stop at each ceiling penetration and the stack must be properly

supported at its base.

z Each venting section must be support-

ed at each elbow and at least every 48"

of straight pipe.

DANGER TO LIFE

from toxic flue gases.

WARNING!

z Verify that all vent pipe connections

have been installed properly.

4

5

6

Fig. 14 Vertical venting system installation (supports are not

shown for clarity)

1 Roof Penetration

2 Fire stop

3 All-Fuel or L vent flue pipe

4 Barometric Damper

5 Clean-out

6 Horizontal air connection for combustion air

(optional, see 7.2)

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

Logano G125 BE - Specifications subject to change without notice.

21

Page 22

7

Boiler Installation

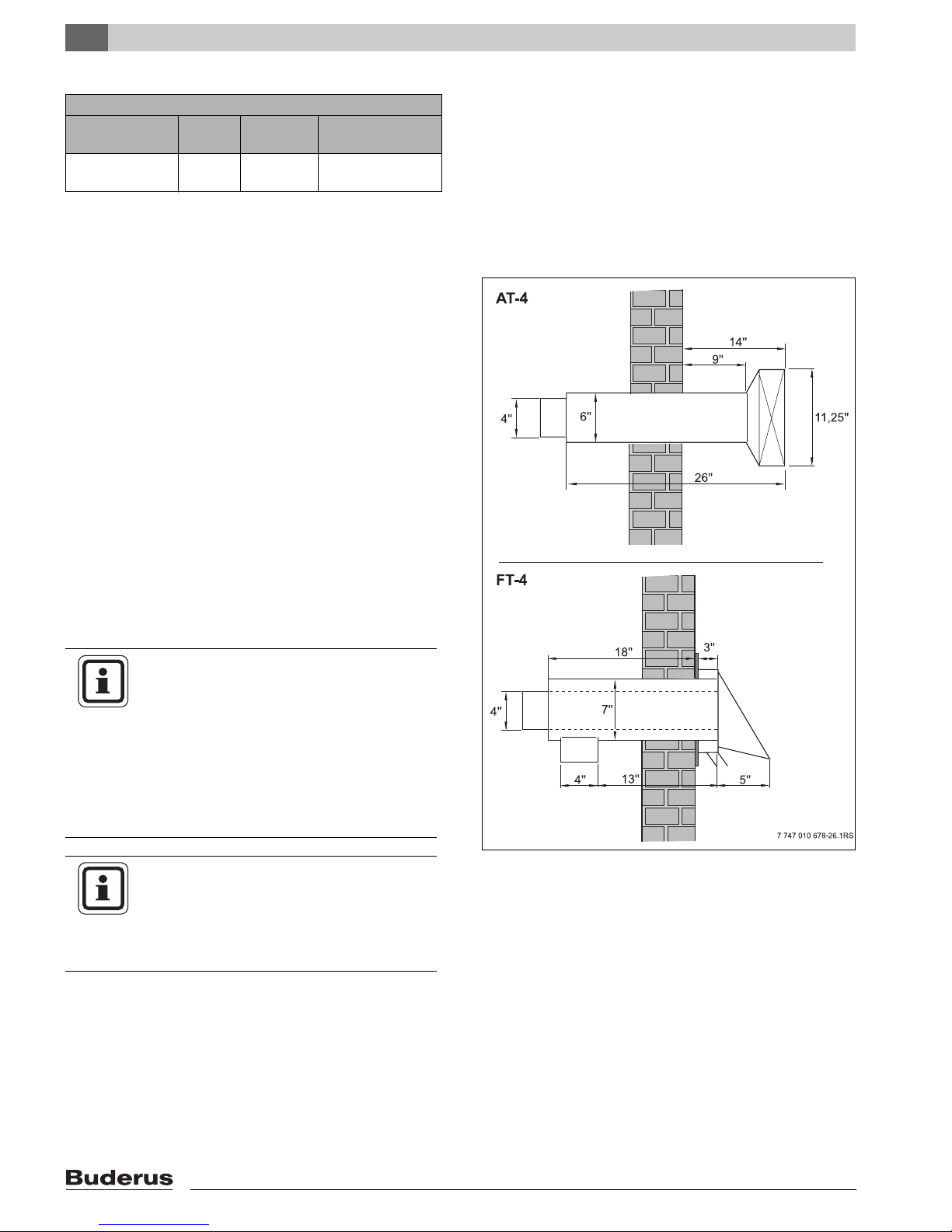

7.1.2 Horizontal Venting

Venting system: Side wall

Comment Draft Combus-

tion air

Sealed vent Positive Outside air

only

Max. Vent length

20 ft.

The maximum length of the direct vent system is 20 ft. of

linear pipe including 3 x 90° elbows. With 4 elbows the

maximum pipe length is 10 ft.

The following two direct vent terminations are approved

with the G125 BE, and are available for purchase from

your Buderus supplier.

Both exhaust terminations are approved for use with two

different exhaust vent pipe options.

– Option 1:

Flexible, insulated 4" stainless steel oil vent. The insulated oil vent is rated for 1" clearance to combustibles. Wrap the adapters with 3" of ceramic wool

covered with foil tape or sheet metal to maintain 1"

clearance. For installation instructions Î Chapter

„7.1.2.6 Installation of Insulated Flexible Oil Vent“,

page 26.

– Option 2:

Standard, 26 gauge galvanized 4" vent pipe. Maintain 18" clearance to combustibles with galvanized

vent pipe (Î Chapter „7.1.2.7 Installation of Galvanized Vent Pipe“, page 27).

NOTICE

Horizontal vent systems operate under

positive pressure, which requires all

seams to be sealed. Use high temperature

silicone (500°F rated, G.E. 106 or equivalent) to seal any joints, screw penetrations,

or combustion test holes, and seal at each

pipe connection and all joints on adjustable elbows. Refer to 7.1.2.2 for details.

NOTICE

Installations in Canada less than 7 ft.

above ground are required to have a

cage/screen over the termination to prevent injury from touching hot surfaces.

Fig. 15 Aerocowl (AT-4) and Concentric (FT-4) termination

22

Logano G125 BE - Specifications subject to change without notice.

Page 23

7.1.2.1 Location of Exhaust Wall Termination

3'

1,5'

Boiler exhaust

Boiler Installation

Boiler exhaust

7

Forced air

at least 1 ft. above grade

Fig. 16 Minimum clearance for termination

Exhaust terminal

must be at least 3 ft. above

any forced air inlet within 10 ft.

The location of the wall termination is one of the

most important aspects of a direct-vent installation.

In addition to the minimum clearances of terminations shown in Fig. 16, observe the following rules:

1. Both the intake and exhaust terminations must

be located on the same outside wall in order to

balance wind pressure effects.

2. Wall terminations shall not be facing the direction of prevailing winds.

3. The exhaust terminal must be located such that

flue gases will be freely dispersed without reentering the building.

4. Exhaust terminal shall be at least 2 ft. from

adjacent buildings, and flue gases shall not be able

to enter adjacent buildings.

5. The exhaust terminal shall be at least 7 ft. above

grade when above public walkways. Ensure that

freezing condensate does not lead to hazardous

conditions on walkways.

6. The exhaust terminal shall never be located underneath porches or crawl spaces, alcoves, or other

building features that prevent dispersing flue

gases.

Gravity air inlet

inlet

less than 2 ft. from outside corners.

8. The exhaust terminal shall be located at least 3 ft.

above any forced air inlet within 10 ft. horizontally.

9. The exhaust terminal shall never be less than 4 ft.

below, 1 ft. above, or 4 ft. horizontally from any

door, window, or gravity air inlet into the building.

10. The exhaust terminal shall be at least 1 ft. above

grade and snow line, and where it is not susceptible to blockage from debris, leaves or falling snow

or ice.

11. A ½" wire-mesh screen at the exhaust terminal

must be maintained in good working order.

12. The exhaust terminal shall terminate at least 3 ft.

from any other building opening, oil tank vent or oil

tank fill inlet, and 6 ft. from any gas service regulator vent outlet.

13. Select the point of wall penetration maintaining a

minimum slope of ¼" per foot toward the termination on the last horizontal pipe section. The wall termination assembly must also slope ¼" per foot

toward the outside to drain possible condensate

from the venting system.

7. The exhaust terminal shall never be located less

than 3 ft. from inside building corners, and never

Logano G125 BE - Specifications subject to change without notice.

23

Page 24

7

Boiler Installation

7.1.2.2 Installation of Aerocowl exhaust termination

(Part No. AT-4)

z Follow guidelines in section 7.1.2.1 regarding the rel-

ative position of the exhaust and terminal.

z Follow manufacturer’s installation guidelines of the

AT-4.

This system consists of a 4" air intake hood, a 5" x 4" reducer and a 26½" long, insulated Aerocowl exhaust termination. This termination has a zero clearance rating to

combustibles. Do not install the vacuum relief damper

(“not needed”).

z Cut a 6" round opening in the outside wall at the se-

lected location. Apply silicone caulking to the backside of the outer face plate and secure it to the

outside wall.

z Insert the Aerocowl termination from the outside up

to the outer wall stop. Ensure slope of ¼" per foot to

outside.

z Slide inner plate on the termination up to the inside

wall, tighten the gear clamp and secure the inner

plate to the wall.

z For Aerocowl AT-4 installations in Canada less than

7 ft. above ground, install a cage/screen over the ter-

Fig. 17 Aerocowl exhaust termination (Part No. AT-4) and

mination to prevent injury from touching hot surfaces.

7.1.2.3 Installation of the concentric Fields termination (FT-4)

z Follow manufacturer’s installation guidelines of the

FT-4.

This system consists of a 5" x 4" reducer and a zero

clearance concentric combination intake/exhaust termination with a 4" provision for fresh air intake piping. Do

not install the vacuum relief damper (“not needed”).

z Cut a round 7" diameter opening in the outside wall

at the selected location.

z Remove the 4" air intake collar from the termination

assembly.

z Apply silicone caulking to the back side of the wall

face plate. Insert the concentric termination from the

outside.

z Ensure slope of ¼" per foot to outside. Secure the

face plate to the outside wall.

separate air intake hood

z Reinstall the 4" collar.

24

Fig. 18 Combination air intake/exhaust termination (Part No.

FT-4)

Logano G125 BE - Specifications subject to change without notice.

Page 25

7.1.2.4 Sealing of the Vent Pipe

Boiler Installation

7

DANGER TO LIFE

from toxic flue gases.

WARNING!

The discharge side of the direct vent combustion system operates under positive

pressure.

z It is of vital importance to seal all joints

and screw penetrations using high temperature silicone (rated for 500°F, G.E.

106 or equivalent) to prevent leakage of

flue gases into the building.

z The venting system shall never be

pierced under any circumstances after

initial installation. Combustion measurements shall be taken at the exhaust

termination and/or overfire. The

breeching can be pierced for testing as

long as the hole is sealed airtight with a

bolt, washers and high temperature silicone.

7.1.2.3 General Guidelines for Vent Pipe Installation

CAUTION!

DANGER OF FIRE

from combustible material or liquid.

z Establish a safe clearance between

the vent termination and the combustible material per NFPA 31.

The minimum clearance are:

– galvanized vent pipe 18",

– insulated oil vent pipe 1"

The minimum clearances compared to the

boilerÎ Chapter 6.1, page 15.

Maintain a minimum slope of ¼" per foot toward the termination on the last horizontal vent pipe section.

z The wall termination assembly must also slope ¼"

per foot toward the outside to drain possible condensate from the venting system.

z Slope all other horizontal pipe runs ¼" per foot to-

ward the boiler.

z Avoid any dips in the piping, particularly when using

the flexible insulated stainless steel oil vent.

DANGER OF LIFE

from toxic flue gases.

WARNING!

z Never install a barometric damper into

the horizontal direct vent exhaust piping.

z Verify that after system installation, all

vent pipe connections have been installed properly.

z Check all seams and joints for gas

leaks. Correct as necessary.

z Have the entire venting system cleaned

and verified annually by a qualified service company.

Logano G125 BE - Specifications subject to change without notice.

25

Page 26

7

Boiler Installation

7.1.2.6 Installation of Insulated Flexible Oil Vent

z Apply a ¼" wide bead of high temperature silicone all

around the boiler vent connection 1" from the end.

z Install 5" to 4" reducer on boiler vent connection. Se-

cure properly with a clamp.

z Carefully measure the required length of vent pipe.

Cut to length with a hacksaw allowing for the two end

adapters in your measurement.

z Apply a small bead of high temperature silicone to

the outside of the oil vent ends.

z Twist end adapters to each end of the oil vent. Turn

adapters counter clockwise. Engage the outer cover

of the adapter evenly over the exterior of the vent

pipe. Turn the adapter until the vent pipe interior

seats evenly against the expanded teflon gasket of

the end connector.

z Secure adapters to the vent pipe with the provided

clamps.

z Apply a ¼" wide bead of high temperature silicone all

around at the 5" x 4" boiler reducer and wall termination connection.

z Slide adapters on to reducer and wall termination

pipe all the way. Tighten with clamps.

z Support the flexible vent pipe at regular intervals with

brackets or hangers.

z Maintain a 1/2" rise per foot on horizontal runs sloped

to outside.

NOTICE

With the installation:

– Avoid any sag in the pipe.

– Do not bend pipe excessively. Slope

termination to outside.

– Wrap 3" ceramic insulation around

adapter near termination and secure

with sheet metal or foil tape and hose

clamps to maintain 1" clearance.

Fig. 19 Boiler exhaust pipe

26

Logano G125 BE - Specifications subject to change without notice.

Page 27

7.1.2.7 Installation of Galvanized Vent Pipe

Boiler Installation

7

z Apply a ¼" wide bead of high temperature silicone

(500°F rated silicone, G.E. 106 or equivalent) all

around the boiler vent connection (breech) 1" from

the end (Î Fig. 19, page 26).

z Install 5" to 4" reducer on boiler vent connection. Se-

cure properly with a clamp.

z The maximum length of the direct vent system is 20

ft. of linear pipe plus a maximum of 3 x 90º elbows.

With 4 elbows the maximum pipe length is 10 ft. Use

high temperature silicone to seal any joints, screw

penetrations, or combustion test holes, as well as

seal at each pipe connection and all joints on adjustable 90º elbows.

NOTICE

Once the entire venting system is installed, make sure all joints are secure

(Î as well as Chapter „7.1.2.4 Sealing of

the Vent Pipe“, page 25).

NOTICE

Installations in Canada less than 7 ft.

above ground are required to have a

cage/screen over the termination to prevent injury from touching hot surfaces.

WARNING!

HEALTH DANGER

z When using galvanized vent pipe a

proper protection (e.g. screen) at the

wall termination has to be installed. Follow also local codes.

WARNING!

CAUTION!

DANGER TO LIFE

from toxic flue gases.

z All seams and joints of the exhaust

venting must be inspected for flue gas

leaks.

z Have the entire venting system cleaned

and inspected annually by a qualified

service company.

BOILER DAMAGE

from condensation.

When using galvanized vent pipe the flue

gas temperature at the boiler breech must

exceed 300°F in order to avoid condensation. If less than 300°F are measured, the

flue gas temperature will have to be raised

by removal of 2 or more baffles

(Î Chapter 8.8, page 42).

This notice is not applicable if stainless

steel vent pipe is being used instead of galvanized pipe.

Logano G125 BE - Specifications subject to change without notice.

27

Page 28

7

Boiler Installation

7.2 Installation of Combustion Air Supply System

BOILER DAMAGE AND SYSTEM

PROBLEMS

CAUTION!

Due to missing or insufficient openings for

combustion air.

Sufficient openings for combustion air and

ambient air are required.

Insufficient air flow in the boiler room can

lead to temperature rise, with a potential

for consequential property damage.

Insufficient combustion air can result in

poor burner performance and lead to service calls.

z Ensure that primary and secondary air

openings are of sufficient size, and are

not closed off or reduced in size.

z The boiler can not be placed in opera-

tion if such deficiencies have not been

corrected.

z Make the equipment owner aware of

the situation.

To ensure adequate combustion air supply for the boiler

system, follow the guidelines of the NFPA 31, and observe all local and national codes and regulations.

CAUTION!

WARNING!

BOILER DAMAGE

from contaminated combustion air.

z Never place chlorine containing clean-

ing agents, and hydrocarbon based

chemicals near the boiler (e.g. spray

cans, solvents, cleaning agents, paint,

glue).

z Avoid generation and accumulation of

large amounts of dust.

NOTICE

When contamination of combustion air is

expected (such as installations near swimming pools, dry cleaning operations or hair

salons), Buderus strongly recommends

using fresh air ducted directly from the outside to the boiler.

DANGER OF FIRE

from flammable material and liquids.

z Do not store flammables or other liq-

uids in the vicinity of the boiler.

For Canada refer to the guidelines of CSA/CGA-B149.1

and 2 Installation Codes.

28

Logano G125 BE - Specifications subject to change without notice.

Page 29

7.2.1 All air drawn from inside the building

The G125 BE boiler has been approved for operation

drawing all combustion air from the room, provided the

installation meets the requirements of NFPA 31, and the

boiler is NOT vented horizontally.

7.2.2 All air drawn from outdoors

The boiler has been approved for operation drawing all

combustion air from the outside, provided the combustion air intake system meets the following requirements.

The combustion air shall be directly delivered to the rear

of the boiler via 4" ducting.

z Make an opening in the outside wall for wall termina-

tion.

z Use 4" rigid galvanized pipe or 4" flexible metal pipe.

z The maximum length of the fresh air piping must nev-

er exceed 100 ft. Reduce by 10 ft. for every 90° elbow, 5 ft. for every 45° elbow.

z Install a fresh air intake hood with 1/2" screen to

avoid debris and objects from entering the pipe. Install from the outside and secure.

Boiler Installation

7

1

2

3

z Secure reducer to rear of boiler with 2 screws.

z Connect fresh air ducting to reducer.

NOTICE

Use only 4" diameter air intake piping or

flexible metal hose. Outside components,

and not be susceptible to blockage from

debris, leaves or falling snow or ice.

Maximum fresh air intake piping must not

exceed 100 ft.

Fig. 20 Combustion air supply system

1 Wall termination

2 Fresh air intake piping

3 Reducer with sensing port

Logano G125 BE - Specifications subject to change without notice.

29

Page 30

7

Boiler Installation

7.2.3 Guidelines for the location of the air intake terminal

In addition to the minimum clearances of terminations

(Î Chapter „7.1.2.1 Location of Exhaust Wall Termination“, page 23), observe the following rules:

– Both the intake and exhaust terminations must be lo-

cated on the same outside wall in order to balance

wind pressure effects.

– Wall terminations shall not be facing the direction of

prevailing winds.

– The exhaust terminal shall be at least 1 ft. above

grade and snow line, and where it is not susceptible

to blockage from debris, leaves or falling snow or ice.

– An outside air intake riser is permitted, provided it ter-

minates in 2 x 90° elbows facing down (Î Fig. 21).

– The intake and exhaust terminals must be at least

4 ft. apart when using the Aerocowl (AT-4) exhaust

termination. This minimum distance can be reduced

to 2 ft. when the intake terminal is at least 1 ft. below

the exhaust terminal.

– A ½" wire-mesh screen at the exhaust terminal must

be maintained in good working order.

2

1

3

Fig. 21 Outside air intake riser

1 Maximum snow level

2 Air intake riser terminating in 2 x 90° elbows

3 Vent pipe

30

Logano G125 BE - Specifications subject to change without notice.

Page 31

7.3 Installation of Water Connections

SYSTEM DAMAGE

due to leaking connections.

CAUTION!

7.3.1 B-Kit Installation

z Install the piping connections to the

boiler without having undue stress on

the near boiler piping.

Boiler Installation

7

The relief valve and pressure/temperature gauge are installed into the supply manifold as described below:

z Use the 1-1/4" BSP x NPT conversion nipple and in-

stall the unmarked end into the supply (VK) connection of the boiler. This side also has longer thread

length and the thread is straight (BSP).

z The conversion nipple is marked on the 1-1/4" NPT

side with pink color and a NPT stamping in the pipe.

z Install 90° elbow 1-1/4" on conversion nipple.

z Install supply manifold into elbow and orient in de-

sired direction (Fig. 23).

z Install 90° elbow, relief valve and pressure/tempera-

ture gauge.

NOTICE

The pressure relief valve can only be installed after the hydrostatic test

(Î Chapter 7.4, page 33)

Use the supplied ¾" 90° elbow to ensure

that the relief valve discharge is installed

horizontally.

VK

(Europe)

1/4"

R1

NPT

NPT(USA)

1/4"

1

Fig. 22 Measuring thread length on 1-1/4" conversion nipple

5

6

4

3

2

1

NOTICE

We recommend, especially in older, large

volume systems, to install a dirt filter in the

return connection to the boiler to reduce

waterside debris build-up.

Logano G125 BE - Specifications subject to change without notice.

Fig. 23 B-Kit Installation

1 90 degree 1 ¼" NPT elbow

2 (Conversion) nipple

3 Supply manifold

4 Pressure/temperature gauge

5 Relief valve

6 90 degree ¾" NPT street elbow

31

Page 32

7

Boiler Installation

7.3.2 Installation of Boiler Drain (B-Kit Component)

z Install the ¾" boiler drain (B-kit component) into the

EL tapping.

NOTICE

Install a fill connection in the supply piping

to the boiler.

7.3.3 Installation of System Components

Use the adjacent diagram as an aid during the installation of near boiler components.

Additional installation samples are found in

Î Chapter 12, page 57.

RK

Fig. 24 Boiler Drain installation

EL

3

10

2

3

4

1

3

7

5

8

63

9

3

Flow

VK

Water fillpoint

drain

Fig. 25 Installation Diagram

1 Relief valve

2 Pressure/temperature gauge

3 Ball valve

4 Air eliminator

5 System pump

6 Backflow preventer

7 Expansion tank

8 Automatic feet valve

9 Flow check

10 Purge station

Return

RK

32

Logano G125 BE - Specifications subject to change without notice.

Page 33

7.4 Filling and Checking for Water Leaks

The boiler must be tested hydrostatically for leaks.

Check the entire system for leaks prior to placing the

system in operation to prevent leaks during operation.

SYSTEM DAMAGE

Be careful not to expose the system to ex-

CAUTION!

CAUTION!

cessive test pressures during the hydrostatic test as it can damage pressure,

control and safety components.

z Make sure that all pressure, control and

safety components are NOT installed

during the hydrostatic test.

SYSTEM DAMAGE

due to excessive temperatures.

When a hot system is filled with cold water,

large temperatures stresses can occur.

The boiler can develop a leak under these

circumstances.

Boiler Installation

Fig. 26 Pressure and temperature gauge

7

z Fill the system only when the boiler is

cold (The fill water temperature can not

exceed 100 °F).

z Water quality must comply with quality

guidelines and fill water conditions

must be recorded.

Perform the hydrostatic test at 1.5 times the expected

operating pressure and in accordance with local code

requirements:

Maximum operating pressure Maximum test pressure

30 psi (based on supplied

45 psi

relief valve)

58 psi (based on 50 psi re-

75 psi

lief valve)

z Plug relief valve connection (Î Fig. 23, page 31)

and all boiler openings with plugs. (Not supplied).

z Close the ball valve to the expansion tank.

z Open automatic feed valve.

z Fill the boiler slowly with the feed valve.

Logano G125 BE - Specifications subject to change without notice.

33

Page 34

7

Boiler Installation

HEALTH DANGER

due to contamination of drinking water.

CAUTION!

z Please observe local and state require-

ments regarding avoidance of contamination of drinking water (e.g. due to

water from closed loop heating systems).

z Open the automatic air vent to allow air to escape.

z Slowly fill the heating system. Monitor the pressure

gauge.

z Check all water connections for leaks.

z Vent the heating system by opening and bleeding ra-

diators. Open purge valve slowly and allow air to escape.

z When water pressure drops during the fill, open up

the fill valve more.

z When no leaks are found, remove plug, drain water

and install relief valve (Î Fig. 23, page 31).

7.5 Installation of Oil Line

z Install the oil line per local code.

The furnished Tigerloop oil filter must be installed on the

outside of the boiler using the supplied mounting bracket.

z Inspect the existing oil line and replace if necessary.

Check swing direction on burner door and reverse

door swing if desired.

z Drill 4 holes into the side panel of the jacket panel

conforming to the Tigerloop mounting bracket.

z Secure mounting bracket to boiler side panel.

z For a 3/8" oil line, install a 3/8" flare x 3/8" NPT adapt-

er in the inlet and a 1/4" x 3/8" NPT adapter in the outlet of the Firomatic valve.

z Install the Firomatic in Tigerloop.

z Connect the return oil line from the burner using the

G3/8" x ¼" NPT adapter back to the oil filter.

z Install the vacuum gauge in its adapter and screw

into the oil line feeding the burner.

z Secure oil filter assembly to the mounting bracket.

z Attach oil lines.

z Check entire oil line assembly for leaks.

6

5

4

Fig. 27 Field installation of Tigerloop oil filter

1 NPT adapter (3/8" flare x 3/8" NPT)

2 Firomatic valve

3 Tigerloop oilfilter

4 NPT adapter (3/8" x ¼")

5 Vacuum gauge

6 Mounting plate

7 adapter 3/8" x 1/4" NPT

3

1

2

7

34

Logano G125 BE - Specifications subject to change without notice.

Page 35

7.6 Electrical Connections

This section only applies to G125 BE boilers equipped

with a Buderus Logamatic or Aquasmart control.

HEALTH DANGER

from electric shock.

WARNING!

7.6.1 Installation of Aquasmart

An Aquasmart controls the boiler water supply temperature when not using a Buderus Logamatic control.

z If a Beckett AquaSmart is being installed the factory-fit-

ted immersion well must be replaced by the immersion

well supplied with the control.

z All electrical work must be performed

by a qualified electrician.

z Before opening the control: Shut off

electrical supply and prevent from accidental reactivation.

z Observe all installation instructions.

Boiler Installation

7

z Install the Aquasmart according to manufacturers’ in-

structions.

z Install Aquasmart as per wiring diagram (Fig. 62,

page 67).

Fig. 28 Top rear cover removal

Logano G125 BE - Specifications subject to change without notice.

35

Page 36

7

Boiler Installation

7.6.2 Control System Installation

z To remove rear top cover first unscrew two rear sheet

metal screws.

z Carefully route the burner cable on the outside of the

insulation from the front of the boiler to the controls

location at the top of the boiler.

Fig. 29 Removal of rear top cover and top cover plate

z Slide plastic front tabs of control panel into the oval

shaped openings.

z Slide the control panel forward.

z Push forward on plastic snap tabs in rear of control to

engage them into the top panes square knock-outs.

z Remove top cover of control panel. Remove cover

screws.

z Secure control to top cover using small sheet metal

screws.

1

2

3

4

Fig. 30 Installation of control

1 Plastic snap tabs

2 Plastic font tabs

3 Oval knock-outs

4 Square knock-outs

1

36

2

Fig. 31 Removal of top cover

1 Top cover screws

2 Sheet metal screws

Logano G125 BE - Specifications subject to change without notice.

Page 37

7.6.3 Installation of Temperature Sensor and

Burner Cables

Boiler Installation

7

NOTICE

When installing a Logamatic control, you

must replace the installed brass well with

the chrome well supplied with the Logamatic control.

z Remove factory installed sensor well.

z Apply sealant to Logamatic well and screw into tap-

ping.

z Remove plug.

SYSTEM DAMAGE

Be careful not to kink or have the capillary

CAUTION!

tubes come in contact with sharp surfaces.

z Route the capillary tubing carefully and

avoid kinking. Route capillaries and

sensor wiring to the immersion well.

z Strap excess tubing and wiring together and place on

top of insulation.

1

2

Fig. 32 Changing out the well

1 Logamatic well

2 Supplied well

1

2

3

z Plug the burner cable into the designated location of

the Logamatic control (Fig. 63, page 68).

z Burner wiring can be routed down towards the front

of the boiler. If burner is supplied with a wiring harness, route harness between jacket panels and boiler insulation.

z Connect end of burner cable into green plug to Log-

amatic control panel.

z Bring the sensor bundle to the installed chrome well

and slide bundle into the well. The plastic holding clip

will slide back.

z Insert all sensing elements fully into the well and se-

cure tubing with furnished metal holding clip.

NOTICE

Ensure all sensing elements are all fully inserted into the well and make good contact

with well inner surface. Use the tension

clip in the middle of sensing elements.

Fig. 33 Routing and connecting of capillary, sensor and

electrical wiring

1 Capillary and sensor wiring

2 Well location

3 Burner cable/wiring

3

2

1

4

1

Fig. 34 Routing and connecting of capillary, sensor and

electrical wiring

1 Cable raceway opening in top front cover

2 Capillary tubing and sensor wiring

3 Well location

4 Burner cable/wiring

Logano G125 BE - Specifications subject to change without notice.

37

Page 38

7

Boiler Installation

7.6.4 Electrical Connections

Install a power supply point near the boiler in accordance with local and state code.

DANGER OF FIRE

Electrical wiring can be damaged by hot

WARNUNG!

boiler parts.

z Make sure that all tubing and wiring

components are all placed on top of the

boiler insulation.

z Ensure that the unit is properly ground-

ed.

z Route all electrical wiring through the top cover race

way and install wiring per electrical schematics in

Logamatic manuals (Î Chapter 14, page 67).

7.6.5 Strain Relief Installation

Secure all electrical wiring near the Logamatic using the

furnished plastic cable ties.

z Install cable clips with the tab facing up into the rear

of the Logamatic (step 1).

z Slide cable clips down and lock them in (step 2).

z Push cable clips in (step 3).

z Push hinging tab down to secure cable (step 4).

7.6.6 Top Rear Panel Installation

z Put control top cover back and secure.

z Install rear top panel on boiler.

Fig. 35 Secure wiring with cable clips

1

2

38

Fig. 36 Installation of rear top cover

1 Control top cover

2 Rear top panel

Logano G125 BE - Specifications subject to change without notice.

Page 39

8 Placing the Boiler in Operation

This chapter describes the initial start-up procedure for

the G125 BE boiler irrespective of the employed control

system.

z Please fill out the start-up protocol during this pro-

cess (Î Chapter 8.11, page 46).

Further information regarding boiler room lay-out and

clearances, combustion air requirements and venting

system as well as boiler operational requirements, referback to Î Chapter 3.2, page 8.

BOILER DAMAGE

from excessive dust and air contamination.

CAUTION!

z Do not operate the boiler under high

dust conditions, such as sheet rock

dust and construction dust. Make sure

to provide clean combustion air if the

boiler needs to operate under such conditions.

Placing the Boiler in Operation

8

z Install an air filter, or other means to en-

sure clean combustion air. Dust can

originate from within during construction, but also from outside when the installation is in close vicinity of chemical

plants, shop or dusty outside conditions.

8.1 Setting the Initial System Pressure

Set the system for regular operation during the initial

start-up procedure.

SYSTEM DAMAGE

from material stresses as a result of tem-

CAUTION!

z Add additional make-up water until the desired pres-

sure is achieved; at least 12 - 15 psi, but no more

than 30 psi. (Actual settings are dependent on the

pressure rating of the relief valve).

perature differences.

z Use cold water for the initial fill (Limit

the fill water temperature to 100 °F

maximum).

Fig.38 Pressure and temperature gauge

Logano G125 BE - Specifications subject to change without notice.

39

Page 40

8

Placing the Boiler in Operation

HEALTH DANGER

due to contamination of drinking water.

CAUTION!

z Please observe local and state re-

quirements regarding avoidance of

contamination of drinking water (e.g.

due water from closed loop heating

systems).

z Vent the system during the initial fill.

8.2 Checking the Relief Valve

z Make sure nobody is near the discharge of the relief

valve.

z Lift up on the relief valve.

The relief valve has to open and relief water and pressure. Replace the relief valve immediately if it does not

discharge. A defective relief valve can cause damage to

the system.

8.3 Check Position of Flue Baffles (Room Air Operation)

Check to make sure that the flue baffle plates are in horizontal position before the initial start-up process:

z Remove burner cable from burner at disconnect

point.

z Open the burner door by removing the two burner

door bolts.

z Pull the baffle plates slightly out of the boiler.

z Bring the baffles in a fully horizontal position and

push back into the boiler.

z Close the burner door and torque door bolts evenly

with 90 lbs-inch torque using hex-head bolts.

z Reconnect burner cable back at burner.

1

Fig.39 Opening the burner door

1 Flue baffles in secondary passages

40

Logano G125 BE - Specifications subject to change without notice.

Page 41

Placing the Boiler in Operation

8.4 Check Position of Flue baffle Plates (Outside Air Operation)

8

NOTICE

In case of outside air operation, you must

check the position of 8 flue baffles.

The check is identical as described in Î Chapter 8.3.

z In addition, make sure to fully close the burner door

and tighten the burner door bolts.

8.5 Prepare System for Operation

z Open fuel shut-off valve.

z Install burner cover on boiler.

4

3

2

1

Fig.40 Blue baffle plates for fresh air operation

1 Flue baffle plates Nr. 1

2 Flue baffle plates Nr. 2

3 Flue baffle plates Nr. 3

4 Flue baffle plates Nr. 4

4

3

2

1

z Turn on main system disconnect switch or turn on

breaker in main breaker box.

8.6 Start-up of Control and Burner

Follow the burner start-up procedure per burner manufacturer's recommendations. Follow the Î instructions

furnished with the burner.

Turn on the main switch of the Logamatic control to activate the heating system. The burner comes on when

the control is switched to a heat demand occurs or manual mode. Follow the instructions in the Î Service Manual of the control.

z Select "manual" operation.

z Set the desired adjustable limit temperature on the

control.

z Turn control on (Position "I").

8.7 Guidelines for Burner Start-up

Allow the burner to operate for 15 to 20 minutes prior to

performing combustion test. Earlier combustion tests

can lead to erroneous readings due to burning off of the

sealing rope. We recommend to check the burner after

a few weeks of operation.

0

I

2

1

Fig.41 Switching control panel (Logamatic 2000 series

controls)

1 Adjustable high limit dial

2 Main control switch

Logano G125 BE - Specifications subject to change without notice.

41

Page 42

8

Placing the Boiler in Operation

NOTICE

Improper burner adjustments can lead to

improper combustion and sooting of the

boiler. Burner lock-outs can also occur as

a result.

z Always check the combustion with the

following instruments.

z Never check and/or adjust burner op-

eration by eye sight.

Necessary instruments

– CO

measuring equipment

2

– Draft measuring equipment

– Oil pressure gauge

– Stack thermometer

– Smoke tester

z Measure the over fire pressure at the measuring port

on the burner door.

z Measure the breeching draft in the vent connector

two vent pipe diameters away from the vent connections (Only on chimney vent models: refer to Direct

Vent Manual for proper test location).

1

Fig.42 Pressure test port on burner door

1 Pressure test port

8.8 Adjusting Stack Temperatures

BURNER DAMAGE

due to excessively high air inlet tempera-

CAUTION!

42

tures.

z You are only allowed to raise the stack

temperature of the boiler in case of a

dual pipe venting system. In case of

complete concentric venting systems,

one is not allowed to raise the stack

temperature as it may lead to high inlet

air temperatures.

Logano G125 BE - Specifications subject to change without notice.

Page 43

When you determine that the stack temperature is too

low, and condensate formation might take place in the

chimney, the stack temperature can be increased by the

following steps:

– Adjust the flue baffles

– Remove the flue baffles

– Remove flue blocking plates

z Shut-off the boiler (Î Chapter 9, page 47).

DANGER TO LIFE

from electric shock.

WARNING!

z Prior to opening the burner: Shut off

power supply and prevent from accidental reactivation.

z Remove burner cover from boiler (Î Chapter 5.1,

page 13).

BURNING DANGER

Placing the Boiler in Operation

8

due to touching of hot surfaces.

CAUTION!

z Wear thermal protective gloves or use

a set of pliers.

8.8.1 Adjusting/Removing Flue Baffles

Adjust or remove the flue baffles always in pairs.

z Remove burner cable from burner connector.

z For sealed combustion operation, remove hose from

burner intake connection.

z Open burner door by removing the two hex head

bolts.

z Close burner door and secure with burner door bolts

(ca. 90 Lbs/inch). Tighten bolts evenly.

Logano G125 BE - Specifications subject to change without notice.

Fig.43 Adjusting the flue baffles

43

Page 44

8